Page 1

NEXT GENERATION

OF TOUGH TOOLS

TM

1

Serial Number Purchase Date

Questions, problems, missing parts? Before returning to your retailer, call our

customer service department at 1-888-3KOBALT (1-888-356-2258), 8 a.m - 8 p.m., EST,

Monday - Friday.

ITEM #0394231

MODEL #K10D-06AB

10-AMP

CORDED DRILL

Français p. 14

Español p. 27

ATTACH YOUR RECEIPT HERE

KOBALT® and the K & Design®

are registered trademarks of

LF, LLC. All Rights Reserved.

Page 2

TABLE OF CONTENTS

Product Specications ..............................................................2

Safety Information .................................................................3

Package Contents .................................................................6

Operating Instructions ..............................................................8

Care and Maintenance ............................................................12

Troubleshooting ..................................................................13

5-Year Hassle-free Warranty ........................................................13

PRODUCT SPECIFICATIONS

COMPONENT SPECIFICATION

Motor 120V~60Hz, 10A

Switch VSR (Variable Speed Reversible)

No-load speed 0 - 1,200 RPM

Chuck capacity 1/2 in.

Cord length 12 ft.

Weight 5 lbs. 13 oz.

2

Page 3

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble or operate this product.

If you have any questions regarding the product, please call customer service at 1-888-3KOBALT,

8 a.m. - 8 p.m., EST, Monday - Friday.

WARNING

• Read all safety warnings and all instructions. Failure to follow all warnings and instructions may

result in electric shock, re, and/or serious injury. Save all warnings and instructions for future

reference.

• The operation of any power tool can result in foreign objects being thrown into your eyes, which

can result in severe eye damage. Before beginning power-tool operation, always wear safety

goggles or safety glasses with side shields and a full-face shield, when needed. We recommend

using a wide vision safety mask over eyeglasses or standard safety glasses with shields. Always

use eye protection marked to comply with ANSI Z87.1.

• Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to the state of California to cause cancer, birth defects, or other

reproductive harm. Some examples of these chemicals are:

– Lead from lead-based paints

– Crystalline silica from bricks, cement, and other masonry products

– Arsenic and chromium from chemically-treated lumber

• Your risk from these exposures varies, depending upon how often you do this type of work. To

reduce your exposure to these chemicals:

– Work in a well-ventilated area.

– Work with approved safety equipment, such as dust masks that are specially designed to lter

out microscopic particles.

– Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other

construction activities. Wear protective clothing and wash exposed areas with soap and water.

Allowing dust to get into your mouth or eyes or to lie on the skin may promote absorption of

harmful chemicals.

Know the Tool

To operate this tool, carefully read this manual and all labels afxed to the drill before using it. Keep

this manual available for future reference.

The term “power tool” in the warnings refers to your main operated (corded) power tool or battery

operated (cordless) power tool.

3

Page 4

SAFETY INFORMATION

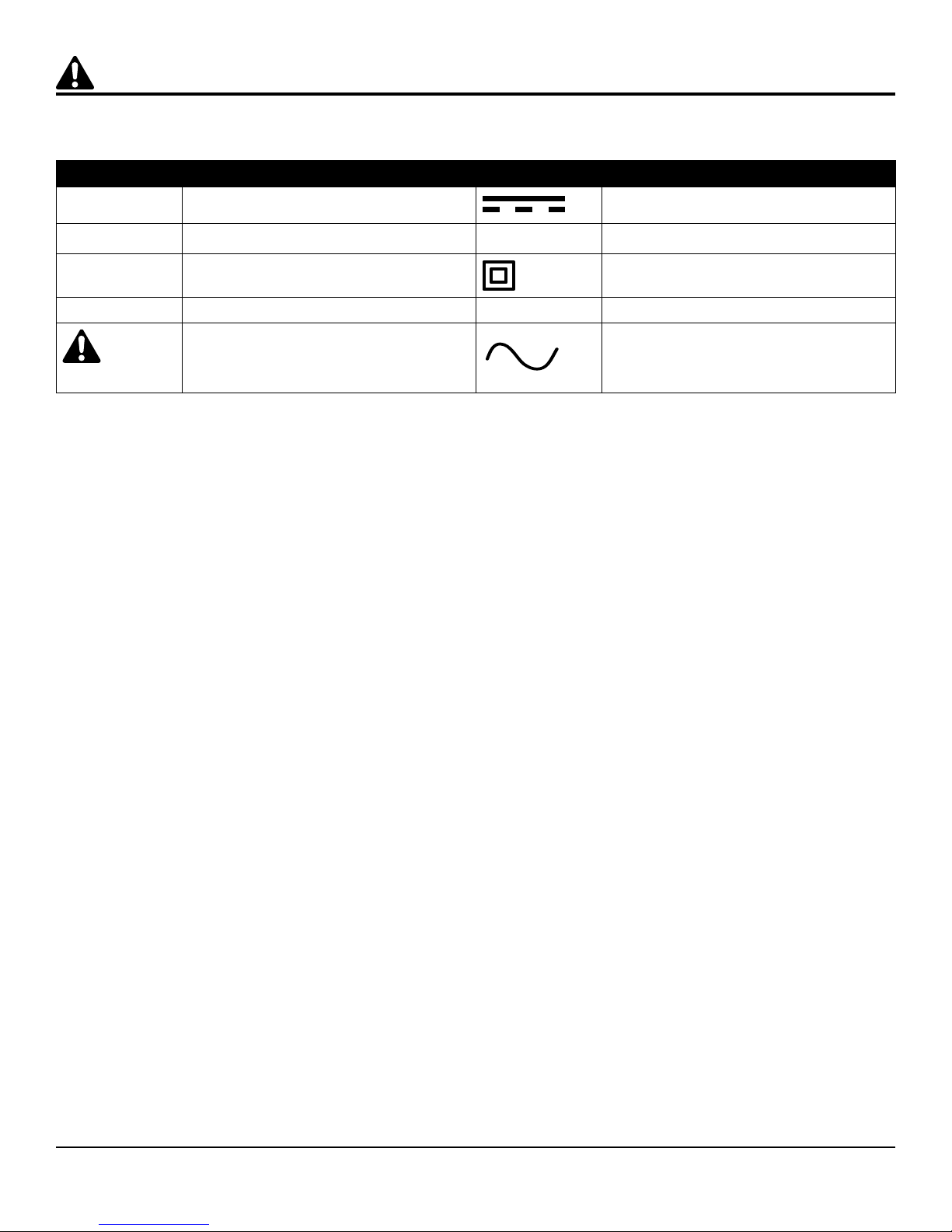

Some of the following symbols may be used on this tool. Please study them and their meaning.

Proper interpretation of these symbols will allow you to operate the tool better and more safely.

SYMBOL DEFINITION SYMBOL DEFINITION

V Volts

Direct Current

A Amps n

Hz Hertz

0

No-load Speed

Class II Construction

W Watts /min Revolutions or Strokes per Minute

A danger, warning, or caution.

Alternating Current

It means ‘Attention! Your safety

is involved.’

IMPORTANT: This tool should only be serviced by a qualied service technician.

Work Area Safety

• Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

• Do not operate power tools in explosive environments, such as in the presence of ammable

liquids, gases, or dust. Power tools create sparks, which may ignite the dust or fumes.

• Keep children and bystanders away while operating a power tool. Distractions can cause you to

lose control.

Electrical Safety

• Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adaptor

plugs with earthed (grounded) power tools. Unmodied plugs and matching outlets will reduce the

risk of electric shock.

• Avoid body contact with earthed (grounded) surfaces such as pipes, radiators, ranges, and

refrigerators. There is an increased risk of electric shock if your body is earthed (grounded).

• Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

• Do not abuse the cord. Never use the cord for carrying, pulling, or unplugging the power tool. Keep

the cord away from heat, oil, sharp edges, or moving parts. Damaged or entangled cords increase

the risk of electric shock.

• When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric shock.

• If operating a power tool in a damp location is unavoidable, use a ground-fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

4

Page 5

SAFETY INFORMATION

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do

not use a power tool while you are tired or under the inuence of drugs, alcohol, or medication. A

moment of inattention while operating power tools may result in serious personal injury.

• Use personal protective equipment. Always wear eye protection. Protective equipment, such

as a dust mask, non-skid safety shoes, a hard hat, or hearing protection, used for appropriate

conditions, will reduce personal injuries.

• Prevent unintentional starting. Ensure that the switch is in the OFF position before connecting to a

power source and/or battery pack, picking up, or carrying the tool. Carrying power tools with your

nger on the switch or energizing power tools that have the switch on invites accidents.

• Remove any adjusting keys or wrenches before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing, and gloves away

from moving parts. Loose clothing, jewelry, or long hair can be caught in moving parts.

• If devices are provided for the connection of dust-extraction and collection facilities, ensure that

these are connected and properly used. Use of these devices can reduce dust-related hazards.

Power Tool Use and Care

• Do not force the power tool. Use the correct power tool for your application. The correct power tool

will do the job better and more safely at the rate for which it was designed.

• Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source and/or the battery pack from the power tool before

making any adjustments, changing accessories, or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool. Power tools are dangerous in the hands

of untrained users.

• Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts, and

any other condition that may affect the power tool’s operation. If damaged, have the power tool

repaired before use. Many accidents are caused by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

• Use the power tool, accessories, tool bits, etc., in accordance with these instructions, taking into

account the working conditions and the work to be performed. Use of the power tool for operations

different from those intended could result in a hazardous situation.

5

Page 6

SAFETY INFORMATION

Service

• Have your power tool serviced by a qualied repair person using only identical replacement parts.

This will ensure that the safety of the power tool is maintained.

• Hold the power tool by the insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire may make exposed

metal parts of the power tool “live” and could give the operator an electric shock.

• Use the auxiliary handles supplied with the tool. Loss of control can cause personal injury.

• Use clamps or other practical means to support the workpiece and secure it to a stable platform.

Holding the workpiece by hand or against your body is unstable and may lead to loss of control.

• Inspect the tool cords periodically and, if damaged, have them repaired by a qualied repair

person. Constantly stay aware of the cord location. Following this rule will reduce the risk of electric

shock or re.

PREPARATION

Before attempting to use the drill, familiarize yourself with all of its operating features and safety

requirements.

WARNING: Do not allow familiarity with the drill to cause carelessness. Remember that one

careless moment is enough to cause severe injury. Before attempting to use any tool, be sure to

become familiar with all of the operating features and safety instructions.

WARNING: Do not attempt to modify this tool or create accessories not recommended for use

with this tool. Any such alteration or modication is misuse and could result in a hazardous condition

leading to possible serious personal injury.

WARNING: Never connect the drill to the power source when you are assembling parts, making

adjustments, installing or removing bits, cleaning, or when it is not in use. Disconnecting the drill will

prevent accidental starting, which could cause serious personal injury.

6

Page 7

PACKAGE CONTENTS

B

C

K

J

A

G

D

E

H

F

I

PART DESRIPTION QUANTITY

A Sleeve 1

B Chuck key hole 1

C Chuck 1

D Direction-of-rotation selector 1

E Trigger switch 1

F Chuck key 1

G Lock-on button 1

H Live wire indicator light 1

I Chuck key strap 1

J Auxiliary handle 1

K Auxiliary handle quick-clamp 1

7

Page 8

OPERATING INSTRUCTIONS

1. Trigger Switch

a. To turn the drill ON, press the trigger switch (E).

b. To turn the drill OFF, release the trigger switch.

NOTE: The trigger switch delivers higher speed with

increased trigger pressure and lower speed with

decreased trigger pressure.

2.

This drill is equipped with a lock-on button (G), which is

convenient for continuous drilling/driving for extended

periods of time.

1

E

2

a. To drill continuously, press and hold the trigger switch

(E) and then press the lock-on button. Release the

trigger switch.

b. To unlock the lock-on button and stop continuous

drilling, press the trigger switch.

3. Direction-of-Rotation Selector

The direction of bit rotation is reversible and is controlled

by a selector located above the trigger switch (E). With

the drill held in the normal operating position, pointing

away from you:

a. Position the direction-of-rotation selector (D) to the

left of the tool for forward rotation.

b. Position the direction-of-rotation selector to the right

of the tool for reverse rotation.

G

E

3

D

Reverse

E

NOTE: To prevent gear damage, always allow the drill to

come to a complete stop before changing the direction of

rotation.

NOTE: The drill will not run unless the direction-ofrotation selector is fully engaged to the left or right.

D

Forward

E

8

Page 9

OPERATING INSTRUCTIONS

4.

This drill is equipped with an auxiliary handle (J). For

ease of operation, you can use the handle with either the

left or right hand. The handle can be rotated 360°.

To adjust the auxiliary handle assembly:

a. Loosen the auxiliary handle quick-clamp (K) by lifting

the clamp lever up.

b. With the clamp lever open, turn the handle

counterclockwise to loosen the assembly.

c. Attach the auxiliary handle over the sleeve (A) to the

desired operating position.

d. Press the auxiliary handle quick-clamp lever to lock

the auxiliary handle.

e. Hand-tighten the handle by turning the handle

clockwise.

WARNING: For safety and ease of operation,

securely tighten the auxiliary handle by turning the handle

clockwise after you press the quick-clamp lever down.

4

K

A

J

5. Live Wire Indicator Light

The live wire indicator light (H) is a blue light located in

the handle where the power cord enters the handle. This

blue light is always on when the drill is plugged into a

power source.

5

H

9

Page 10

OPERATING INSTRUCTIONS

6. Installing Bits (sold separately)

a. Unplug the drill from the power source.

b. Lock the trigger switch by placing the direction-of-

rotation selector (D) in the OFF (center) position.

c. Open the chuck (C) jaws by turning the sleeve (A)

in a counterclockwise direction until the opening is

slightly larger than the bit you intend to use. Raise

the front of the drill slightly to keep the bit from falling

out of the chuck (C) jaws.

d. Insert the drill bit into the chuck.

e. Tighten the sleeve by hand.

f. Place the chuck key (F) in one of the three chuck key

holes (B) and tighten in clockwise direction. Repeat

with the remaining two chuck key holes.

WARNING: It is important to tighten the chuck with

all three key holes to prevent slippage.

6

C

B

A

D

F

C

g. Remove the chuck key.

WARNING: Insert the drill bit straight into the chuck

jaws. Inserting the drill bit into the chuck jaws at an angle

and then tightening the chuck and using the drill could

cause the drill bit to be thrown from the drill, resulting in

possible serious personal injury or damage to the chuck.

7. Removing Bits

a. Unplug the drill from the power source.

b. Lock the trigger switch (E) by placing the direction-of-

rotation selector (D) in the OFF (center) position.

c. Place the chuck key (F) in one of the three chuck key

holes (B) and loosen the chuck (C) by turning in a

counterclockwise direction.

d. Loosen the sleeve (A) by hand.

e. Remove the drill bit.

B

7

A

C

B

D

f. Remove the chuck key.

E

F

10

Page 11

OPERATING INSTRUCTIONS

8. Drilling

a. Secure the material to be drilled in a vise or with

clamps to keep it from turning as the drill bit rotates.

b. Install the correct bit.

c. Verify that the direction-of-rotation selector (D) is at

the correct setting (forward).

d. Hold the drill rmly and place the bit at the point to be

drilled.

e. Press the trigger switch (E) to start the drill.

f. Move the drill bit into the workpiece, applying only

enough pressure to keep the bit cutting. Do not force

the drill or apply side pressure to elongate a hole.

Allow the tool to do the work.

g. When drilling hard, smooth surfaces, use a center

punch to mark the desired location of the hole. This

will prevent the drill bit from slipping off-center as the

hole is started.

h. When drilling metals, use light oil on the drill bit to

keep it from overheating. The oil will prolong the life

of the bit and increase the drilling action.

8

D

E

i. If the bit jams in the workpiece or if the drill stalls,

stop the tool immediately. Reverse the direction of

rotation and gently squeeze the trigger switch to

remove the bit from the workpiece. Investigate and

correct the cause of jamming before you resume

work.

9. Drilling in Wood

For maximum performance, use high-speed steel or brad-point bits for wood drilling.

a. Begin drilling at a very low speed to prevent the bit from slipping off the starting point.

b. Increase the speed as the drill bit enters the material.

c. When drilling holes all the way through the workpiece, place a block of wood behind the

workpiece to prevent ragged or splintered edges on the back side of the hole.

11

Page 12

OPERATING INSTRUCTIONS

10. Drilling in Metal

For maximum performance, use high-speed steel bits for metal or steel drilling.

a. When drilling metals, use light oil on the drill bit to keep it from overheating. The oil will prolong

the life of the bit and increase the drilling action.

b. Begin drilling at a very low speed to prevent the bit from slipping off the starting point.

c. Maintain a speed and pressure that allows cutting without overheating the bit. Applying too much

pressure will:

– Overheat the drill

– Wear the bearings

– Bend or burn the bits

– Produce off-center or irregularly-shaped holes

CARE AND MAINTENANCE

All maintenance should only be carried out by a qualied repair person.

Cleaning

Before cleaning or performing any maintenance, disconnect the tool from the power source. For safe

and proper operation, always keep the tool and its ventilation slots clean. Only use a soft, dry cloth to

clean your drill. Never use any detergent or alcohol.

C

a. Unplug the drill from the power source.

A

b. Open the chuck (C) jaws by turning the sleeve (A) in

a counterclockwise direction.

c. Use a Phillips screwdriver (not included) to remove

the chuck screw by turning it in a clockwise direction.

d. Insert a 5/16 in. or larger hex key (not included)

C

into the chuck and securely tighten the chuck jaws

A

around the hex key.

e. Tap the hex key sharply with a mallet (not included)

in a counterclockwise direction. This will loosen the

chuck for easy removal.

Chuck screw

NOTE: The chuck screw has left-handed threads. Attach

a new chuck to the spindle and tighten the chuck screw.

C

A

12

Page 13

WARNING: Turn the switch to the OFF position and unplug the drill from the power source

before you perform any troubleshooting procedures.

If you have any questions regarding this product, please call customer service at 1-888-3KOBALT,

8 a.m. - 8 p.m., EST, Monday - Friday.

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

The motor does not start. The tool is not connected to a power

source.

The bit cannot be installed. 1. The sleeve is not released.

Connect the tool to a power

source.

1. Release the sleeve.

2. The bit does not t the chuck jaw.

The motor is overheating. Ensure cooling vents are free of dust

and obstacles.

2. Use the appropriate bit.

Clean and clear the vents. Do

not cover the vents with your

hand during operation.

This drill is warranted to the original purchaser from the original purchase date for ve (5) years

subject to the warranty coverage described herein.

This drill is warranted for the original user to be free from defects in material and workmanship.

If you believe that the drill is defective at any time during the specied warranty period, simply return

the drill along with proof of purchase to the place of purchase for a free replacement or refund, or call

1-888-3KOBALT (1-888-356-2258) for warranty service.

This warranty is void if: defects in materials or workmanship or damages result from repairs or

alterations which have been made or attempted by others or the unauthorized use of nonconforming

parts; the damage is due to normal wear, damage is due to abuse (including overloading of the tool

beyond capacity), improper maintenance, neglect or accident; or the damage is due to the use of the

tool after partial failure or use with improper accessories or unauthorized repair or alteration.

This warranty excludes accessories.

This warranty gives you specic legal rights, and you may also have other rights that vary from state

to state.

Printed in China

13

Loading...

Loading...