Page 1

PORTABLE

AIR COMPRESSOR

DIRECT-DRIVE, OIL FREE

OWNER’S MANUAL

and Parts List

For customer service, contact:

1-800-628-8815 ext. 5000

M-F 8:00 AM - 5:00 PM CST.

Item #37296

Model #F226VWLVP

WARNING!

Read and understand all safety precautions and operating instructions before using portable air compressor.

8/20/2008 Printed in China Part No. E103490

Page 2

TABLE OF CONTENTS

Page

Safety Definitions ..................................................................................................................................... 1

Important Safety Instructions & Guidelines ........................ .......................................................... 1

Specifications ............................................................................................................................................. 2

Glossary ...................................... ................................................................................................................ 2

Duty Cycle ...................................... ............................................................................................................ 2

Parts & Features ........................................................................................................................................ 3

Operating Procedures ................................ ........................................................................................... 4

Maintenance .................................... ......................................................................................................... 6

Storage ..................................... .................................................................................................................. 6

Troubleshooting Guide ............................... .......................................................................................... 7

Exploded Parts Diagram ........................................................................................................................ 8

Parts List....................................................................................................................................................... 9

Limited Warranty ...................................................................................................................................... 10

Français ....................................................................................................................................................... 11

Español ....................................................................................................................................................... 23

DO NOT RETURN THIS

PRODUCT TO THE STORE!

Please call 1-800-628-8815 (ext. 5000)

STOP

for any questions regarding this product.

M-F 8:00 AM - 5:00 PM CST.

Thank You

Page 3

Safety Instructions

The information listed below should be read and understood by the operator. This information is given to protect

the user while operating and storing the air compressor. We utilize the symbols below to allow the reader to recognize

important information about their safety.

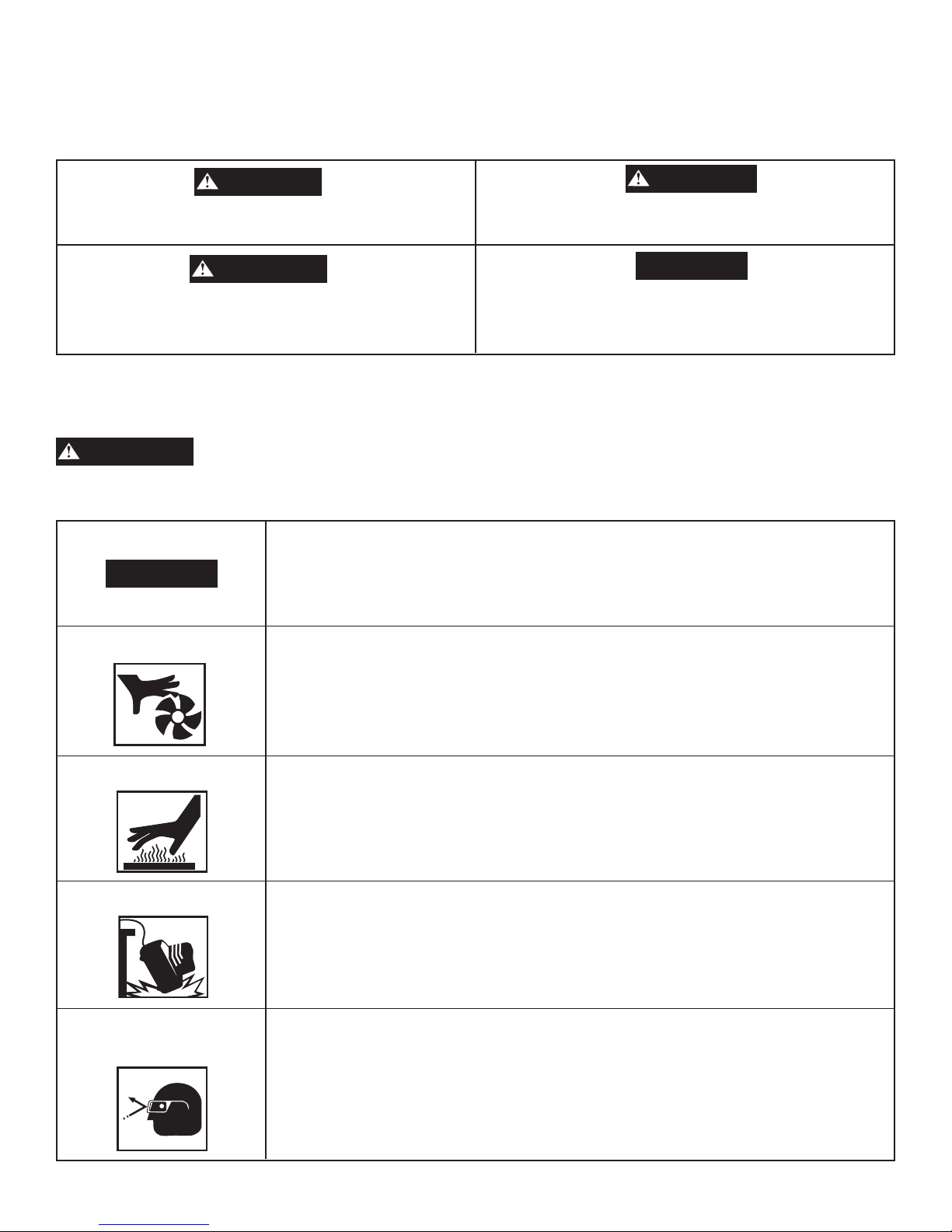

DANGER

Indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

When used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided,

may result in property damage.

CAUTION

CAUTION

Important Safety Instructions and Guidelines

• Save all instructions

WARNING

Improper operation or maintenance of this product could result in serious injury and/or property damage. Read and

understand all of the warnings and safety instructions provided before using this equipment.

The air compressor should be operated on a dedicated 15 amp circuit. If the circuit

does not have 15 free amps available, a larger circuit must be used. Always use

CAUTION

more air hose before utilizing extension cords. All extension cords used must be 12

gauge with a maximum length of 25 ft. The circuit fuse type must be a time delay.

Low voltage could cause damage to the motor.

Risk of Moving Parts

Risk of Burns

Risk of Falling

Risk from

Flying Objects

If the air compressor is in operation, all guards and covers should be attached or

installed correctly. If any guard or cover has been damaged, do not operate the

equipment until the proper personnel has correctly repaired the equipment. The

power cord should be free of any moving parts, twisting and/or crimping while in

use and while in storage.

There are surfaces on your air compressor that while in operation and thereafter

can cause serious burns if touched. The equipment should be allowed time to cool

before any maintenance is attempted. Items such as the compressor pump and the

outlet tube are normally hot during and after operation.

Operation of the air compressor should always be in a position that is stable. Never

use the air compressor on a rooftop or elevated position that could allow the unit to

fall or be tipped over. Use additional air hose for elevated jobs.

Always wear ANSI Z87.1 approved safety glasses with side shields when the air

compressor is in use. Turn off the air compressor and drain the air tank before

performing any type of maintenance or disassembly of the hoses or fittings. Never

point any nozzle or sprayer toward any part of the body or at other people or

animals.

1

Page 4

Important Safety Instructions & Guidelines

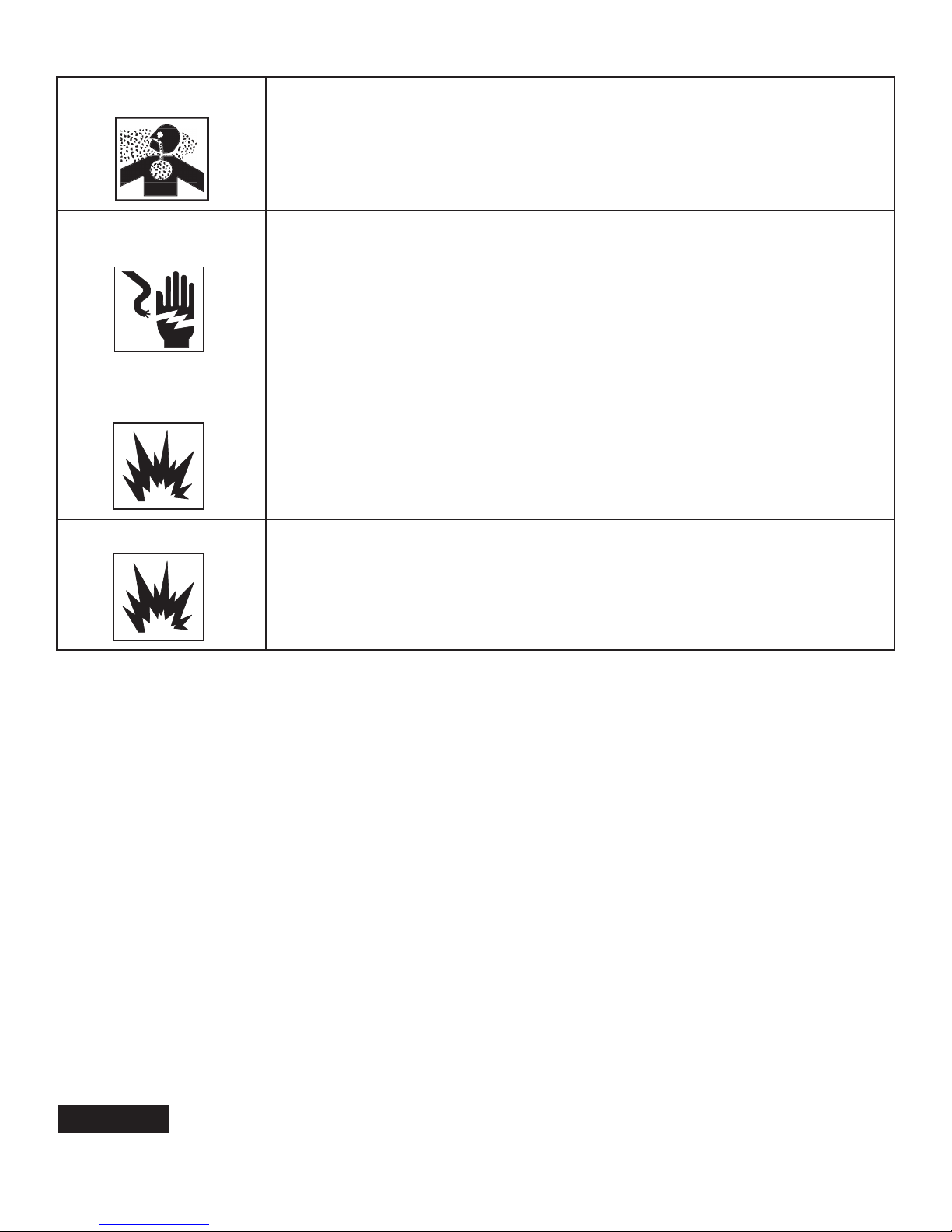

Risk to Breathing

Risk of

Electrical Shock

Risk of

Explosion or Fire

Risk of Bursting

Avoid using the air compressor in confined areas. Always have adequate space

(12 inches) on all sides of the air compressor. Also keep children, pets, and others out of

the area of operation. This air compressor does not provide breathable air for anyone or

any auxiliary breathing device. Spraying material will always need to be in another area

away from the air compressor to not allow intake air to damage the air compressor filter.

Never utilize the air compressor in the rain or wet conditions. Any electrical issues or

repairs should be performed by authorized personnel such as an electrician and should

comply with all national and local electrical codes. The air compressor should also have

the proper three prong grounding plug, correct voltage, and adequate fuse protection.

Never operate the compressor near combustible materials, gasoline or solvent vapors.

If spraying flammable materials, locate the air compressor at least 20 feet away from

the spray area. Never operate the air compressor indoors or in a confined area.

Always drain the air compressor tank daily or after each use. If the tank develops

a leak, then replace the air compressor. Never use the air compressor after a leak

has been found or try to make any modifications to the tank. Never modify the air

compressor’s factory settings which control the tank pressure or any other function.

Specifications

Pump ....................................Oil-free direct drive

Induction Motor.......................................1.5 HP

Bore ................................................. 2.48 in.

Stroke................................................ 0.87 in.

Voltage Single Phase ................................ 120 VAC

Minimum Circuit Requirement ......................15 Amps

Air Tank Capacity ................................. 26 Gallons

Cut-in Pressure .......................................120 PSI

Cut-out Pressure .....................................150 PSI

SCFM @ 40 PSI............................................5.0

SCFM @ 90 PSI............................................4.0

Glossary

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per minute; a unit of measure

for air delivery.

PSIG: Pounds per square inch gauge; a unit of

measure for pressure.

ASME: American Society of Mechanical Engineers.

California Code: Unit may comply with California Code

462 (l) (2)/ (M) (2).

Cut-In Pressure: The air compressor will automatically

start to refill the tank when the pressure drops

below the prescribed minimum.

Cut-Out Pressure: The point at which the motor stops

when the tank has reached maximum air

pressure.

Code Certification: Products that bear one or more of

the following marks: UL, CUL, ETL, CSA, have

been evaluated by OSHA-certified independent

safety laboratories and meet the applicable

Underwriters Laboratories Standards for Safety.

Duty Cycle

CAUTION

This is a 50% duty cycle air compressor. Do not run the air compressor more than 30 minutes of one hour. Doing

so could damage the air compressor.

2

Page 5

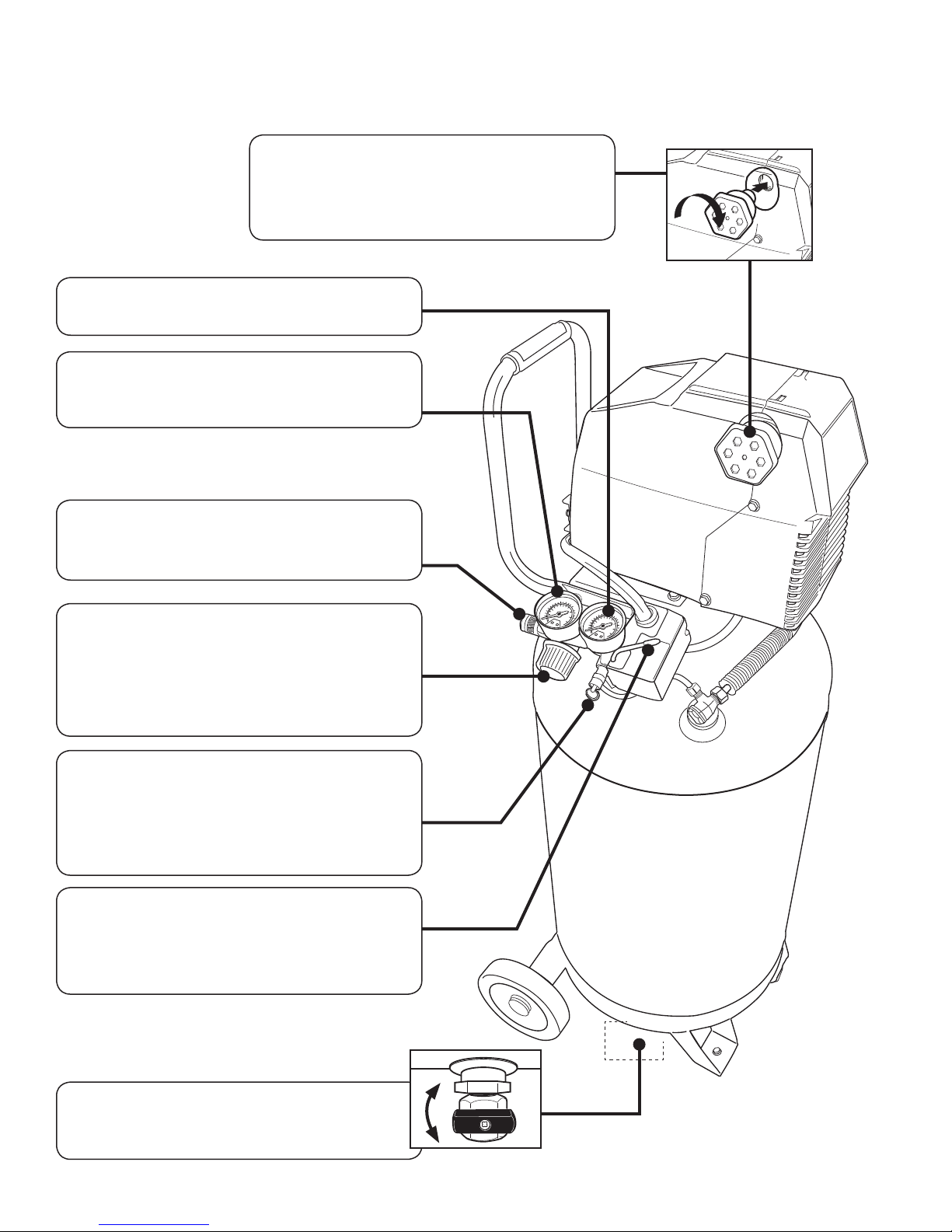

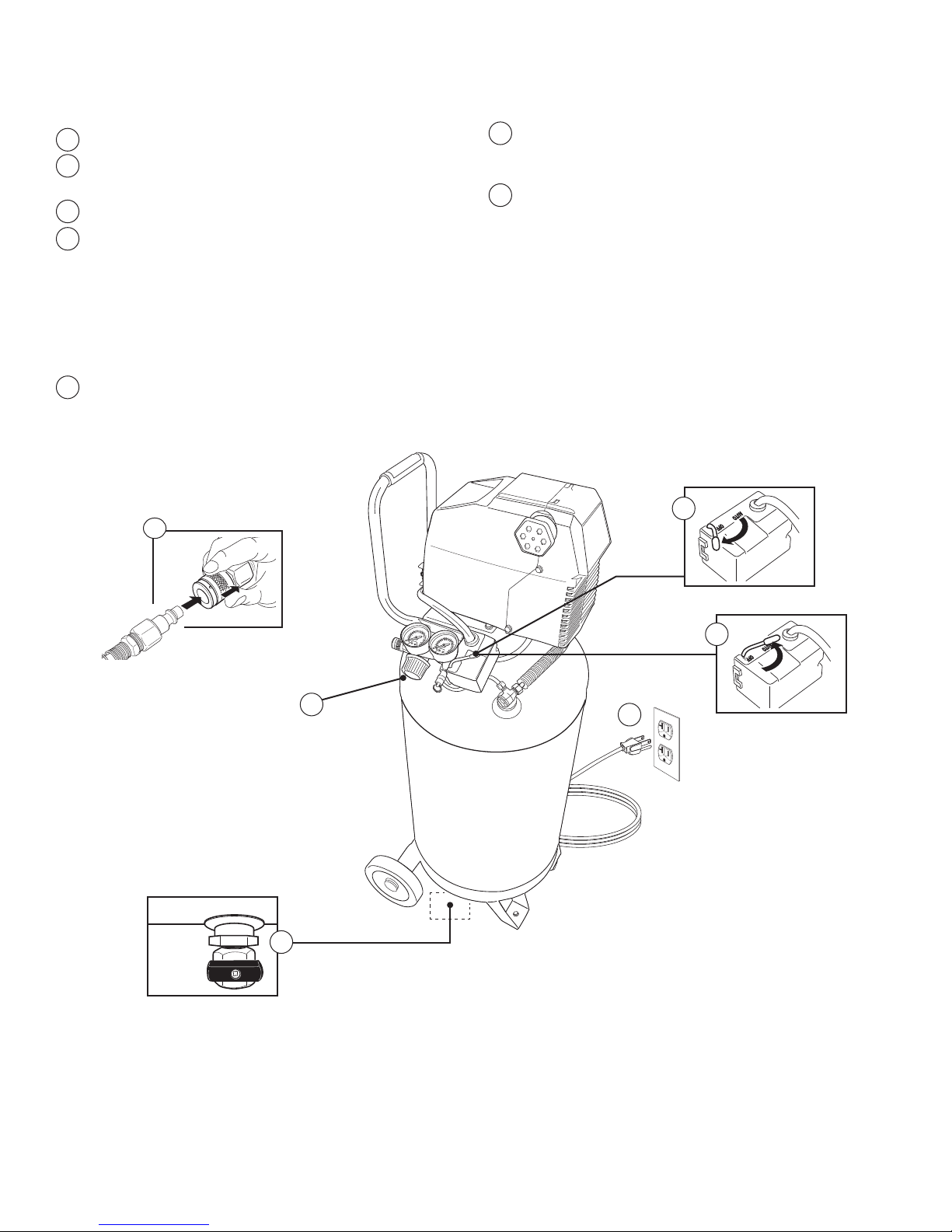

Parts & Features

See figures below for reference.

Air Intake Filter

Provides clean air to the pump and must

always be kept free of debris. Check on a daily

basis or before each use.

Tank Pressure Gauge

Indicates the reserve air pressure in the tank.

Regulator Gauge

Indicates the outgoing air pressure to the

tool and is controlled by the regulator.

Quick Connect

Offers a quick release feature for attaching and

removing the air hose.

Regulator

The air pressure coming from the air tank is

controlled by the regulator. To increase the

pressure turn the knob clockwise and to

decrease the pressure turn the knob

counterclockwise.

Tank Safety Valve

Used to allow excess tank pressure to escape

into the atmosphere. This valve should only

open when the tank pressure is above the

maximum rated pressure.

Power Switch

This controls the power to the cut-in/cut-out

pressure switch. The pressure switch serves as

the Auto-On/Off positions for the motor.

Tank Drain Valve

Used to drain condensation from the air tank.

Located at bottom of tank.

3

Page 6

Operating Procedures

WARNING

The air compressor should be turned off and unplugged

from the power source before any maintenance is

performed as well as the air bled from the tank and the

unit allowed time to cool. Personal injuries could occur

from moving parts, electrical sources, compressed

air or hot surfaces. The regulator assembly must be

attached before use. Failure to assemble correctly could

result in leaks and possible injury. If unsure of assembly

instructions or you experience difficulty in the assembly

please call customer service for further instruction.

Location of the Air Compressor

The air compressor should always be located in a

clean,

dry, and well ventilated environment. The unit should

have

at minimum, 12 inches of space on each side. The air

filter intake should be free of any debris or obstructions.

Check the air filter on a daily basis to be sure it is clean

and in working order.

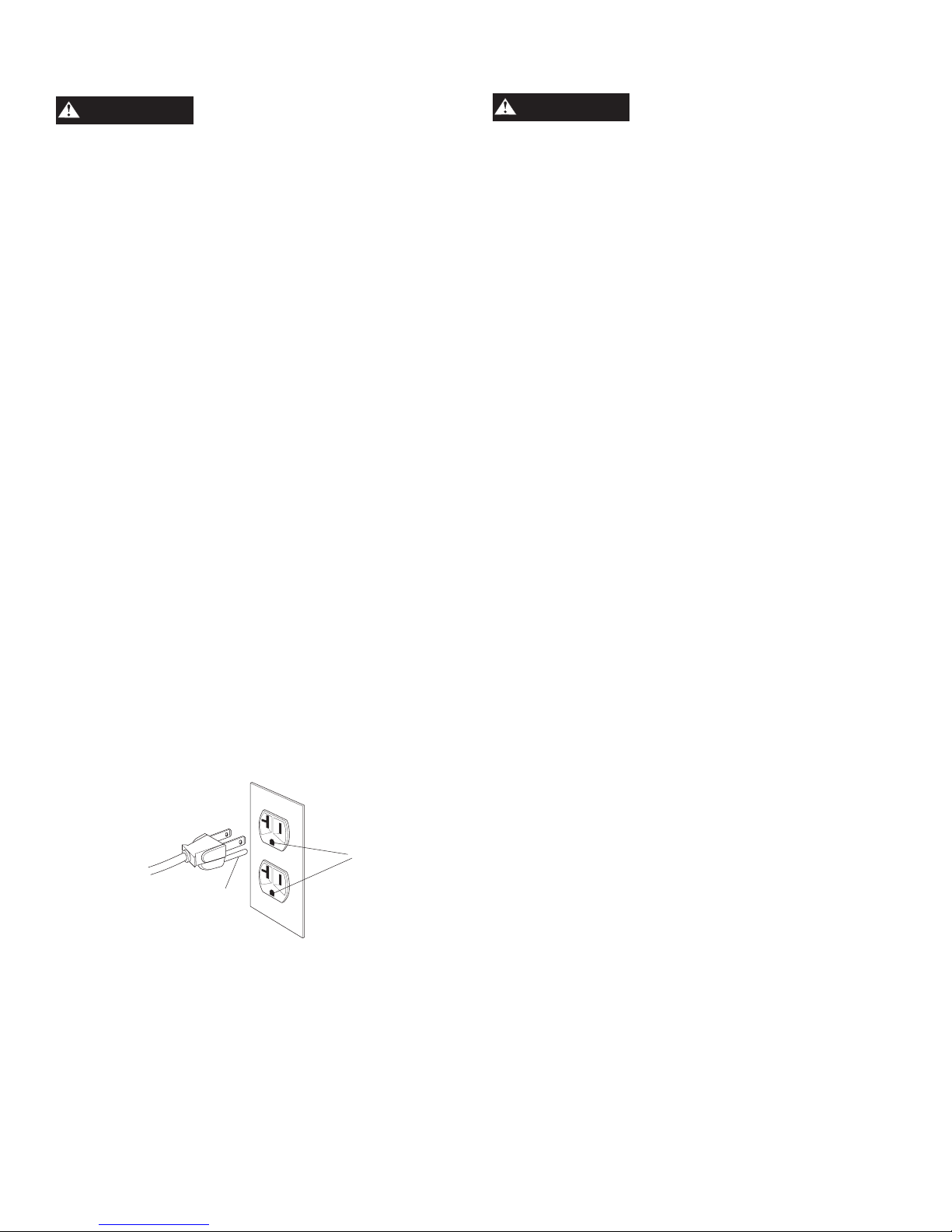

Grounding Instructions

This product should be grounded. In the event of an

electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the

electric current. This product is equipped with a cord

having a grounding wire with an appropriate grounding

plug. (See the figure below.) The plug must be plugged

into an outlet that is properly installed and grounded in

accordance with all local codes and ordinances. Check

with a qualified electrician or service personnel if these

instructions are not completely understood or if in doubt

as to whether the tool is properly grounded.

WARNING

Improper installation of the grounding plug will result in a

risk of electric shock. If repair or replacement of the

cord

or plug is necessary, do not connect the grounding wire

to either flat blade terminal. The wire with insulation

having an outer surface that is green with or without

yellow stripes is the grounding wire. Check with a

qualified electrician or serviceman if the grounding

instructions are not completely understood, or if in doubt

as to whether the product is properly grounded. Do not

modify the plug provided; if it will not fit the outlet, have

the proper outlet installed by a qualified electrician.

This product is for use on a circuit having a nominal

rating of 120 volts and is factory-equipped with a

specific electric cord and plug to permit connection to

a proper electric circuit. Make sure that the product is

connected to an outlet having the same configuration as

the plug. No adapter should be used with this product. If

the product must be reconnected for use on a different

type of electric circuit, qualified service personnel should

make the reconnection.

Extension Cords

Use only a 3-wire extension cord that has a 3-blade

grounding plug, and a 3-slot receptacle that will accept

the plug on the product. Make sure your extension cord

is in good condition. When using an extension cord, be

sure to use one heavy enough to carry the current your

product will draw. Cords must not exceed 25 feet and

No. 12 AWG size must be used. An undersized cord will

cause a drop in line voltage resulting in loss of power

and overheating.

Break-In Procedures

No break-in procedure is required by the user. This

product is factory tested to ensure proper operation and

performance.

Plug

Grounding Pin

Grounded

Outlet

4

Page 7

Daily Start-Up Procedures

1. Set the Power Switch to the Off position.

2. Check the air compressor visually for any damage

or obstruction.

3. Close the drain valve.

4. Connect the air hose to the quick connect socket on

the regulator assembly by inserting the quick connect

plug on the air hose into the quick connect socket.

The quick connect socket collar will snap forward and lock

the plug into place providing an air tight seal

between the socket and plug. To release the air hose

push the collar back on the quick connect socket.

5. Plug the power cord into the proper receptacle.

4

6. Turn the Power Switch to the On-Auto position and the

compressor will start and build air pressure in the tank

to cut-out pressure and then shut off automatically.

7. Adjust the regulator to a PSI setting that is needed for

your application and be sure it is within the safety

standards required to perform the task. If using a

pneumatic tool, the manufacturer should have

recommendations in the manual for that particular

tool on operating PSI settings.

NOTE: Always wear ANSI Z87.1 approved safety glasses

with side shields when the air compressor is in use.

Never point any nozzle or sprayer toward any part of

the body or at other people or animals.

Always wear the proper hearing protection.

1

Close

6

7

5

3

5

Page 8

Operating Procedures

Daily Shut-Down Procedures

1. Set the Power Switch to the Off position.

2. Unplug the power cord from the receptacle.

3. Set the outlet pressure to zero on the regulator.

4. Remove any air tools or accessories. When draining

the tank, always use ear and eye protection. Drain the

tank in a suitable location; condensation will be

present in most cases of draining.

5. Open the drain valve allowing air to bleed from the

tank. After all of the air has bled from the tank, close

the drain valve to prevent debris buildup in the valve.

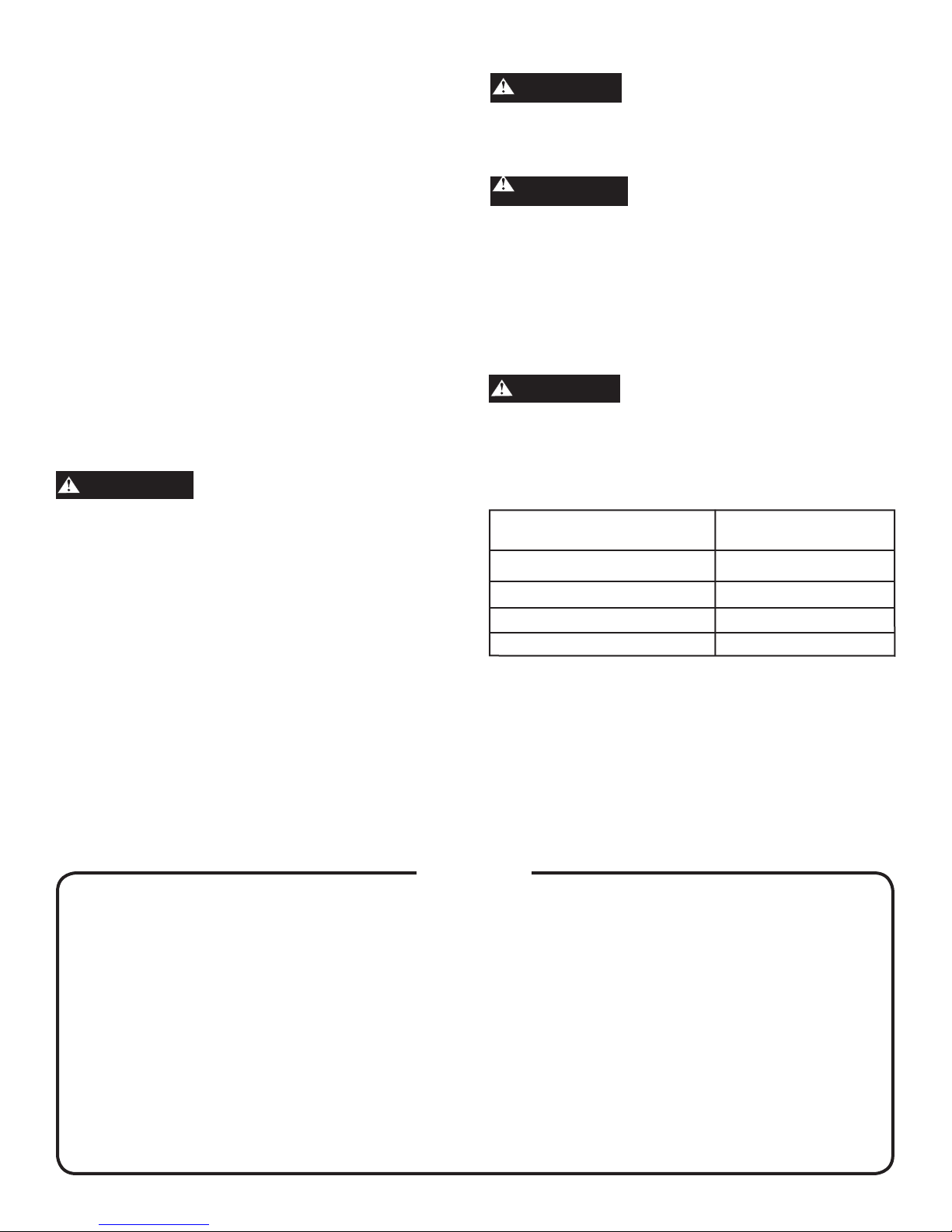

Maintenance

NOTE: Any service procedure not covered in the

maintenance schedule below should be performed by

qualified service personnel.

WARNING

The air compressor should be turned off and unplugged

from the power source before any maintenance is

performed as well as the air bled from the tank and the

unit allowed time to cool. Personal injuries could occur

from moving parts, electrical sources, compressed air or

hot surfaces.

CAUTION

When draining the tank, always use ear and eye protection. Drain the tank in a suitable location; condensation

will be present in most cases of draining.

WARNING

Water that remains in the tank during storage will corrode

and weaken the air tank which could cause the tank to rupture. To avoid serious injury, be sure to drain the tank after

each use or daily.

CAUTION

To ensure efficient operation and longer life of the air

compressor unit, a routine maintenance schedule should

be followed. The following schedule is geared toward a

consumer whose compressor is used in a normal working

environment on a daily basis.

Items to Check/Change

Check Tank Safety Valve X

Overall Unit Visual Check X

Check Air Filter X

Drain Tank X

Before each

use or daily

Storage

For storing the air compressor, be sure to do the following:

1. Turn the unit off and unplug the power cord from the

receptacle.

2. Remove all air hoses, accessories, and air tools from

the air compressor.

3. Open the drain valve to bleed all air from the tank.

NOTES

4. Close the drain valve.

5. Perform the daily maintenance schedule.

6. Store the air compressor in a clean and dry location.

6

Page 9

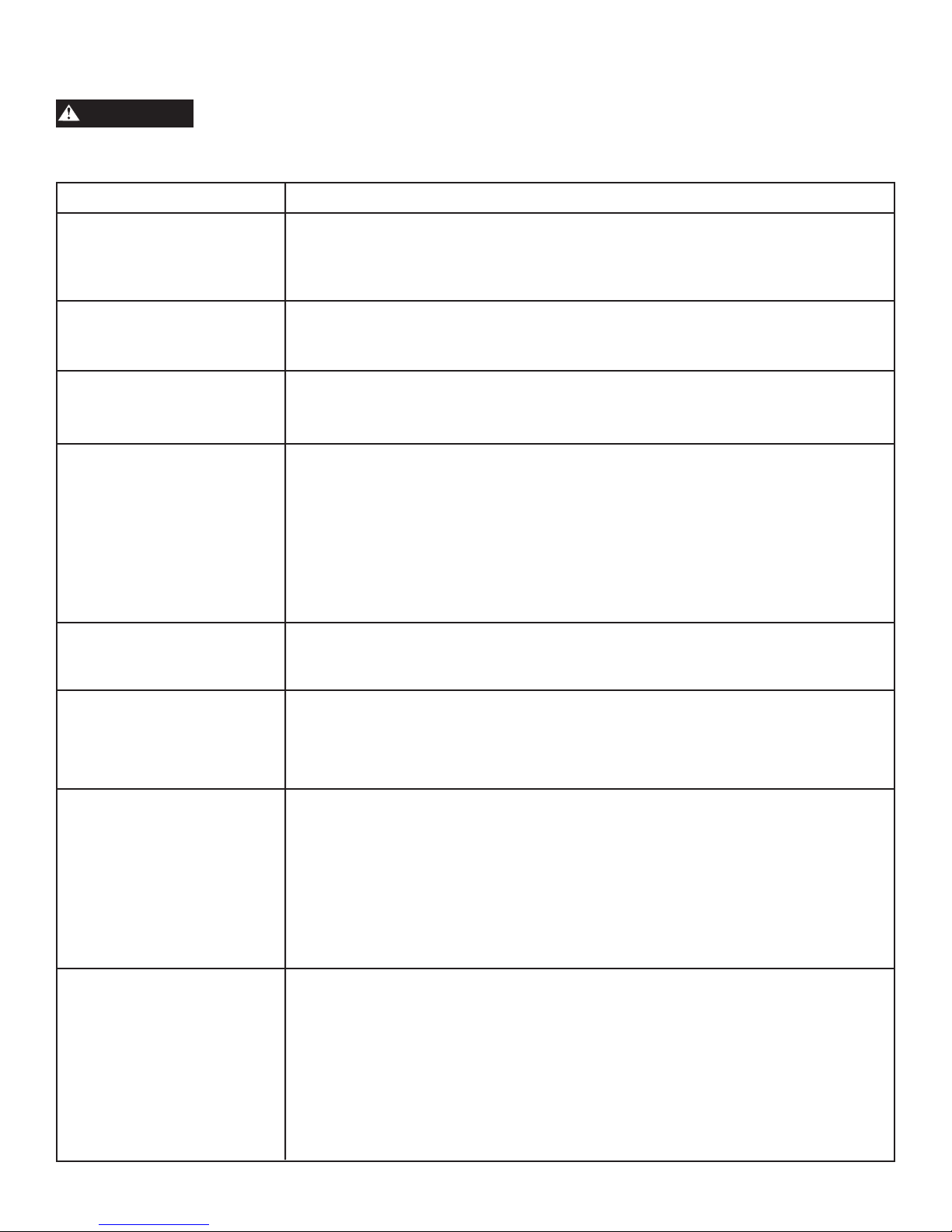

Troubleshooting Guide

WARNING

PROBLEM

Air leaks at the check valve or

at the pressure relief valve.

Air leaks between head and

cylinder.

Air leak from safety valve.

Pressure reading on the

regulated pressure gauge

drops when an accessory is

used.

The air compressor should be turned off and unplugged from the power source before any

maintenance is performed as well as the air bled from the tank and the unit allowed time to

cool. Personal injuries could occur from moving parts, electrical sources, compressed air, or hot

surfaces.

POSSIBLE CORRECTION

A defective check valve results in a constant air leak at the pressure relief valve

when there is pressure in the tank and the compressor is shut off. Drain the tank,

then remove and clean or replace the check valve.

Be sure of proper torque on head bolts. If leak remains, contact customer service

or technician.

Operate the safety valve manually by pulling on the ring. If the valve continues to

leak when in the closed position, it should be replaced.

If there is an excessive amount of pressure drop when the accessory is used,

replace the regulator.

NOTE:

Adjust the regulated pressure under flow conditions (while accessory is being used).

It is normal for the gauge to show minimal pressure loss during initial use of the

tool.

Excessive tank pressure.

Motor will not start.

Excessive moisture in the

discharge air.

Air leaks from the tank body or

tank welds.

Move the Power Switch to the Off position. If the unit doesn’t shut off, unplug it from the

power source and contact customer service or technician.

Make sure power cord is plugged in and the switch is on. Inspect for the proper size fuse in

your circuit box. If the fuse was tripped, reset it and restart the unit. If repeated

tripping occurs, replace the check valve or contact customer service or technician.

NOTE:

To reset the motor overload turn ON/OFF switch OFF and wait 10 minutes

(minimum). Restart unit.

Remove the water in the tank by draining after each use. High humidity

environments will cause excessive condensation. Utilize water filters on your air

line.

NOTE:

Water condensation is not caused by compressor malfunction. Be sure the compressor’s air

output is greater than your tool’s air consumption rate.

Never drill into, weld or otherwise modify the air tank or it will weaken. The tank canrupture

or explode. Compressor cannot be repaired. Discontinue use of the air compressor.

7

Page 10

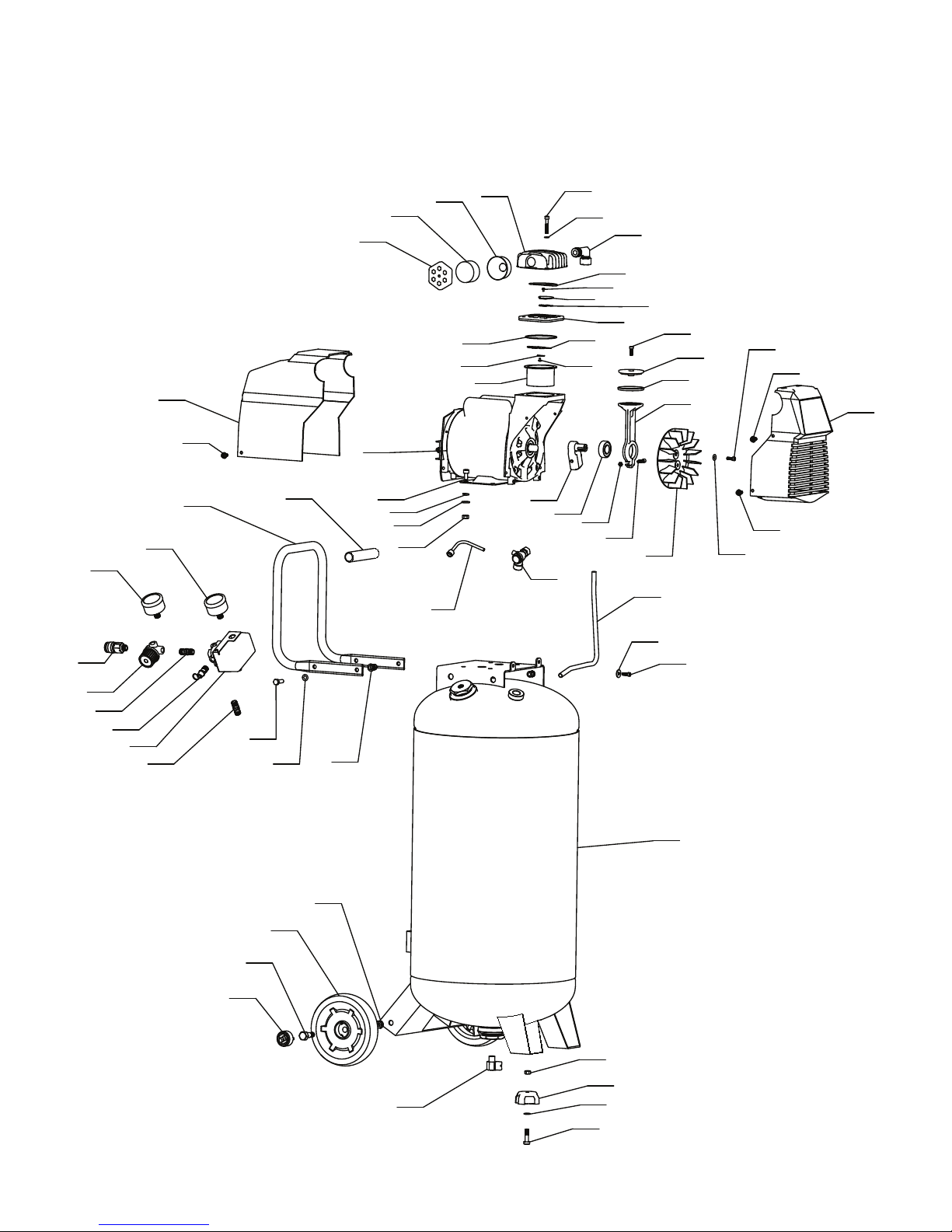

4

5

6

7

8

9

10

11

12

13

14

15

9

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

17

17

37

38

39

40

42

43

43

44

45

46

47

48

46

49

50

51

52

56

55

54

53

58

59

60

61

16

2

3

1

41

57

Air Compressor Item # 37296 / Model # F226VWLVP

Exploded Parts Diagram

8

Page 11

Air Compressor Item # 37296 / Model # F226VWLVP

Parts List

Ref. Kit Part

# # Number

1 1 Cover, Intake Filter 1

2 1 Element, Intake Filter 1

3 1 Housing, Intake Filter 1

4 Head, Cylinder 1

5 Bolt, m6 x 1 x 35mm SHCS 4

6 Washer, Lock 6mm 4

7 Fitting, 90 degree Elbow,

3/8” npt x 3/8 Flare 1

8 4 O-Ring, Head 1

9 4 Bolt, m3 x 4 x 5mm HFHS 2

10 4 Valve, Retainer, Outlet 1

11 4 Valve, Outlet 1

12 4 Valve Plate 1

13 4 O-Ring, Cylinder 1

14 4 Valve, Intake 1

15 4 Valve, Retainer, Intake 1

16 2 Cylinder 1

17 Screw, m6 x 1 x 12mm HFHS 6

18 E103492 Shroud, F2, Full, Rear, Gray 1

19 Pump/Motor 1

20 Bolt, m8 x 1 x 16mm 4

21 Washer, Lock, 8mm 4

22 Washer, Flat, 8mm 4

23 Nut, m8 x 1 x 25mm ZDC 4

24 E103287 Tube, Relief 1

25 E101362 Valve, Check 90 degree, Left 1

26 Eccentric 1

27 Bearing, Piston 1

28 2 Screw, m5 x 0.8 x 16mm SHCS 1

29 2 Piston Cap 1

30 2 Piston Ring 1

31 2 Piston 2

32 2 Nut, m5 x 8mm 1

33 2 Bolt, m5 x 0.8 x 25mm 1

34 E100297 Fan 1

35 Washer, Flat, 6mm 1

36 Bolt, m6 x 1 x 16mm SCHS 1

37 E103491 Shroud, F2, Full, Front, Gray 1

38 E103286 Tube, Outlet 1

Description Quantity

Ref. Kit Part

# # Number

39 Washer, Flat, 6mm 2

40 Bolt, m6 x 1 x 16mm SHCS 2

41 Handle, Grip 1

42 E103485 Handle 1

43 E101733 Gauge, 2”, 150 Redline,

Back Feed, Kobalt 2

44 E100307 Quick Connect, One Hand 1

45 Regulator 1

46 Nipple, 1/4 npt x 35mm 2

47 E102595 Safety Valve, 165 psi 1

48 E100957 Pressure Switch, 150 psi 1

49 Bolt, m8 x 1.25 x 25mm 4

50 Washer, Flat, 8mm 4

51 Nut, Insert m8 4

52 Tank, Asm 1

53 3 Nut, 10mm 2

54 3 Wheel, 7” Kobalt 2

55 3 Bolt, m10 x 1.25 x 20mm 2

56 3 Hubcap, Kobalt 2

57 E101717 Drain Valve, 1/4-Turn 1

58 Nut, m8 x 1 x 25mm ZDC 2

59 E101805 Isolator, Kobalt 2

60 Washer, Flat, m8 2

61 Bolt, m8 x 1 x 20mm 2

NOTE: Any part number field without a number listed is not available.

Descriptions are provided for reference only.

Kit numbers, descriptions, and included components are listed below:

Kit # Part # Kit Name Reference #

1 E101611 Air Filter Kit 1-3

2 E103495 Piston Kit 16, 28-33

3 E103496 Wheel Kit

(One Wheel Asm per Kit) 53-56

4 E103497 Valve Plate Assy Kit 8-15

Description Quantity

For replacement parts, please call 1-800-628-8815 ext. 5000.

9

Page 12

Limited Warranty

This warranty is limited to manufacturing defects in the compressor for a 36-month period, except for manufacturing

defects related to the compressor pump, check values, pressure switch and electric motor for which the warranty on

these “excluded items” shall be for a 12-month period. If at any time during the 36-month period your air compressor

fails due to a manufacturing defect take it to an authorized warranty repair center. If the repair center determines the

product has failed due to its workmanship it will be repaired at no charge. If the failure is due to normal wear and

tear or any malfunction, failure or defect resulting from misuse, abuse, neglect, alterations, modifications or repair by

anyone other than an authorized warranty service center the warranty is void.

LIMITED WARRANTY FOR COMMERCIAL USE

This warranty is limited to manufacturing defects. If at any time from the first 90 days of purchase date your air

compressor fails due to a manufacturing defect take it to an authorized warranty repair center. If the repair center

determines the product has failed due to its workmanship it will be repaired at no charge. If the failure is due to normal

wear and tear or any malfunction, failure or defect resulting from misuse, abuse, neglect, alterations, modifications or

repair by anyone other than an authorized warranty service center the warranty is void.

PROOF OF PURCHASE REQUIRED

NOTE: All warranty is contingent on the customer providing a valid receipt for proof of purchase.

If no receipt is provided, the manufactures date code will be used in place of purchase date.

Limited Warranty applies in the U.S. and Canada only and gives you specific legal rights. You may also have other

rights that vary from State to State or country to country. To find your authorized

warranty service center, please call 1-800-628-8815, ext. 5000.

10

Page 13

Article N°37296

Modèle # F226VWLVP

COMPRESSEUR

D’AIR PORTABLE

TRANSMISSION DIRECTE, SANS HUILE

MODE D’EMPLOI

et liste des pièces

Pour le service à la clientèle,

appelez le : 1-800-628-8815,

poste 5000

L-V 8 h 00 – 17 h 00, heure

centrale.

AVERTISSEMENT !

Veuillez lire et bien comprendre toutes les mesures de sécurité et les

instructions relatives au fonctionnement du compresseur d’air portable

avant de l’utiliser.

8/20/2008 Imprimé en Chine Article No. E103499

Page 14

TABLE DES MATIÈRES

Page

Définitions des termes de sécurité ....................................................................... 13

Importantes consignes et directives de sécurité .................................................. 13

Caractéristiques techniques ................................................................................. 14

Glossaire ............................................................................................................... 14

Cycle d’emploi ...................................................................................................... 14

Pièces et caractéristiques .................................................................................... 15

Installation et assemblage .................................................................................... 4

Consignes d’emploi .. ........................................................................................... 16

Entretien ..... ......................................................................................................... 18

Entreposage ......................................................................................................... 18

Guide de dépannage . .......................................................................................... 19

Diagramme des pièces (vue éclatée) ................................................................... 20

Nomenclature des pièces. .................................................................................... 21

Garantie limitée .................................................................................................... 22

Espagnol ............................................................................................................. 23

NE RETOURNEZ PAS CE PRODUIT

AU MAGASIN !

Veuillez appeler le 1-800-628-8815 (poste

arrêt

5000) pour toute question concernant ce

produit.

L-V 8 h 00 – 17 h 00, heure centrale.

Merci

12

Page 15

Consignes de sécurité

Les indications décrites ci-dessous devraient être lues et comprises par l’utilisateur. Elles ont pour objet de protéger

l’utilisateur durant l’utilisation et l’entreposage du compresseur d’air. Les symboles décrits ci-dessous, permettent au

lecteur d’identifier d’importantes informations concernant sa sécurité.

DANGER

Signale une situation imminente et dangereuse qui, si

elle n’est pas évitée, entraînera la mort ou des blessures graves.

AVERTISSEMENT

Signale une situation potentiellement dangereuse

susceptible, si elle n’est pas évitée, d’entraîner la mort

ou des blessures graves.

Signale une situation potentiellement dangereuse

susceptible, si elle n’est pas évitée, de causer des

blessures de mineures à moyennes.

Utilisé sans le symbole d’alerte de sécurité, signale une

situation potentiellement dangereuse susceptible, si elle

n’est pas évitée, de causer des dégâts matériels.

MISE EN GARDE

MISE EN GARDE

Importantes consignes et directives de sécurité

• Conserver toutes ces directives

AVERTISSEMENT

Une utilisation ou un entretien incorrects de ce produit, peut entraîner de graves blessures et/ou des dégâts matériels.

Veuillez lire et comprendre tous les avertissements et consignes de sécurité suivants, avant d’utiliser cet équipement.

Le compresseur doit être alimenté par un circuit de 15 ampères qui lui est propre. Si

le circuit ne possède pas une disponibilité de 15 ampères, un circuit de plus grande

MISE EN GARDE

Pièces en mouvement

dimension doit être utilisé. Toujours utiliser un boyau d’air plus long, avant d’ajouter

une rallonge électrique. Toute rallonge utilisée doit être de calibre 12 et d’une

longueur maximale de 7,5 m. Le fusible du circuit doit être de type temporisé. Les

basses tensions peuvent endommager le moteur.

Tous les capots et protecteurs du compresseur doivent être correctement fixés

ou installés, lorsque le compresseur d’air est en marche. En cas de dommage de

quelconque des capots ou des protecteurs, ne pas utiliser le matériel avant qu’il

n’ait été correctement réparé par du personnel compétent. Lors de l’utilisation ou de

l’entreposage de l’appareil, s’assurer que le cordon d’alimentation est à l’écart des

pièces en mouvement et qu’il n’est ni vrillé, ni pincé.

Risques de brûlures

Risques de chute

Risques de projection

d’objets

Certaines surfaces du compresseur d’air peuvent causer des brûlures graves, si elles

sont touchées pendant et après le fonctionnement. Laisser au matériel le temps de

refroidir, avant de procéder à toute opération d’entretien. Certaines pièces telles que

la pompe de compression et le tube de sortie, sont habituellement chaudes pendant

et après le fonctionnement.

Le compresseur d’air doit toujours être utilisé et fonctionner dans une position de

stabilité. Ne jamais utiliser le compresseur d’air sur un toit ou dans une position

élevée,de laquelle il pourrait tomber ou basculer. Rallonger le boyau d’air pour les

travaux en hauteur.

Toujours porter des lunettes de sécurité à écrans latéraux, homologuées ANSI Z87.1,

lorsque le compresseur d’air est en marche. Éteindre le compresseur et vidanger

le réservoir d’air avant de procéder à toute opération d’entretien ou de démontage

des boyaux ou raccords. Ne jamais pointer une buse ou un pulvérisateur vers une

quelconque partie du corps, d’autres personnes ou des animaux.

13

Page 16

Importantes consignes et directives de sécurité

Risques pour

la respiration

Risques de choc

électrique

Risques d’explosion

ou d’incendie

Éviter d’utiliser le compresseur d’air dans un espace clos. Toujours prévoir un dégagement suffisant (30 cm) tout autour du compresseur d’air. Veiller également à tenir les

enfants, animaux et autres personnes, hors de la zone de travail. Ce compresseur

d’air n’est pas destiné à fournir de l’air respirable à des personnes ou à l’usage de

dispositifs respiratoires. Afin d’éviter d’endommager le filtre de prise d’air du compresseur d’air, éloigner le compresseur d’air des travaux de pulvérisation et ne jamais

pulvériser en direction du compresseur d’air.

Ne jamais utiliser le compresseur d’air sous la pluie ou dans un milieu détrempé.

Toute intervention ou réparation électrique doit être effectuée par du personnel

autorisé, tel un électricien et être conforme à toutes les réglementations nationales et

locales d’électricité. Le compresseur doit présenter une fiche appropriée avec broche

de mise à la terre, la tension électrique requise et une protection adéquate par fusible.

Ne jamais utiliser le compresseur à proximité de matières combustibles, d’essence

ou de vapeurs de solvants. Pour la pulvérisation de substances inflammables,

placer le compresseur à au moins 6 mètres de l’aire de travail. Ne jamais utiliser le

compresseur d’air à l’intérieur ou dans un espace clos.

Risques d’éclatement

Vidanger le réservoir du compresseur à chaque jour ou après chaque utilisation. En

cas de fuite du réservoir, remplacer le compresseur d’air au complet. Ne jamais utiliser

le compresseur d’air, après avoir détecté une fuite, ni tenter d’apporter une quelconque

modification au réservoir. Ne jamais modifier les réglages d’usine, contrôlant la

pression du réservoir ou toute autre fonction du compresseur d’air.

Caractéristiques techniques

Pompe . . . . . . . . . . . . . . .Transmission directe sans huile

Moteur d’induction ..........................1.5 HP

Alésage..................................2,84 po

Course ..................................0,87 po

Tension monophasée......................120 VAC

Glossaire

CFM: (Cubic Feet per Minute) Pieds cubes par minute

(équivalent à 28,3 l/min).

SCFM: (Standard Cubic Feet per Minute) Pieds cubes par

minute standard; unité de mesure de débit d’air.

PSIG: (Pounds per Square Inch Gauge) Livres par

pouce carré manométrique ; unité de pression.

(équivalent à 6.894 kPa).

ASME: American Society of Mechanical Engineers.

Société américaine d’ingénieurs en mécanique

Code de Californie: L’appareil peut être conforme au

Code 462 (l) (2)/ (M) (2) de la réglementation de

la Californie.

Alimentation électrique minimum ..........15 ampères

Capacité du réservoir d’air ................26 Gallons

Pression d’enclenchement ..................120 PSI

Pression de coupure ...................... 150 PSI

Pi3/mn à 40 psi ..............................5,0

Pi3/mn à 90 psi ..............................4,0

Cut-In Pressure: The air compressor will automatically

start to refill the tank when the pressure drops

below the prescribed minimum.

Cut-Out Pressure: The point at which the motor stops

when the tank has reached maximum air

pressure.

Homologation: Les produits portant l’une ou plusieurs

des marques suivantes : UL, ULc, ETL, CSA, ont

été évalués par des laboratoires de sécurité

indépendants agréés par l’OSHA et

sont conformes aux normes de

sécurité d’Underwriters Laboratories.

Cycle d’emploi

MISE EN GARDE

Ce compresseur d’air possède un cycle d’emploi de 50%. Ne pas faire fonctionner le compresseur d’air pendant plus de

30 minutes à la fois. Une telle procédure pourrait l’endommager.

14

Page 17

Pièces et caractéristiques

Consulter les diagrammes ci-dessous pour référence.

Manomètre de réservoir

Indique la pression de l’air comprimé dans le

réservoir.

Manomètre de réservoir

Indique la pression de l’air comprimé dans le

réservoir.

Manomètre de régulateur

Indique la pression de la sortie d’air vers

l’outil, contrôlée par le régulateur.

Connexion rapide

Équipé d’un mécanisme de déclenchement

rapide pour la fixation et le retrait du tuyau

à air.

Régulateur

Contrôle la pression de l’air à la sortie du

réservoir du compresseur. Tourner le bouton

dans le sens des aiguilles d’une montre pour

augmenter la pression et dans le sens inverse

pour la réduire.

Soupape de sûreté de réservoir

Utilisée pour libérer l’excédent de pression du

réservoir dans l’atmosphère. Cette soupape

ne doit s’ouvrir, que si la pression du réservoir

excède la pression nominale maximale.

Interrupteur d’alimentation

Cet interrupteur contrôle l’alimentation de

l’interrupteur pression (enclenchement/

déclenchement). L’interrupteur pression

comprend les positions de mise en marche/

arrêt automatique pour le moteur.

Soupape de vidange de réservoir

Utilisée pour vidanger la condensation du

réservoir d’air. Située à la partie inférieure

du réservoir.

15

Page 18

Consignes d’emploi

AVERTISSEMENT AVERTISSEMENT

Avant de soumettre le compresseur à tout entretien,

s’assurer de l’éteindre et le débrancher de sa source de

courant, ainsi que de vidanger l’air du réservoir et de

laisser à l’appareil le temps de refroidir. Les pièces en

mouvement, les sources de courant, l’air comprimé et les

surfaces chaudes présentent des risques de blessures.

L’assemblage à raccord rapide doit être fixé en place,

avant d’utiliser le compresseur d’air. Négliger d’effectuer

correctement cette procédure pourrait provoquer des

fuites et des blessures. En cas d’incertitude au sujet des

directives ou de difficulté à procéder à l’assemblage,

veuillez contacter votre département de service local,

pour obtenir des directives supplémentaires.

Emplacement du compresseur d’air

Le compresseur doit toujours être placé dans un endroit,

comportant un environnement propre, sec et bien ventilé.

Prévoir un dégagement de 30 cm minimum, sur chaque

côté de l’unité. La prise du filtre à air doit être exempte

de tout débris ou obstruction. Vérifier quotidiennement la

propreté et le bon état de marche du filtre à air.

Directives de mise à la terre

Ce produit doit être muni d’une connexion de mise à la

terre. Dans l’éventualité d’un court-circuit électrique, la

mise à la terre réduit les risques de choc électrique, en

offrant un fil de décharge du courant électrique.

Ce produit est équipé d’un cordon d’alimentation,

possédant un fil de mise à la terre et muni d’une

fiche appropriée à cet effet. (voir illustration cicontre).

Cette fiche doit être branchée dans une prise

de courant correctement installée et munie d’une

connexion de mise à la terre, conformément à toute la

réglementation locale d’électricité en vigueur. En

cas de problème de compréhension de ces directives

ou de doute, quant à la mise à la terre adéquate de

cet appareil, consulter un électricien ou technicien

d’entretien qualifié.

Une installation inadéquate de la fiche de mise à la

terre présente un risque de choc électrique. S’il est

nécessaire de réparer ou de remplacer le cordon ou la

fiche, ne raccordez jamais le fil de mise à la terre, à l’une

ou l’autre des broches plates de la fiche. Le fil de mise

à la terre est recouvert d’une gaine isolante de couleur

verte, avec ou sans rayures jaunes. En cas de problème

de compréhension de ces directives ou de doute, quant

à la mise à la terre adéquate de cet appareil, consulter

un électricien ou technicien d’entretien qualifié. Ne pas

modifier la fiche fournie; si celle-ci ne convient pas à

la prise de courant, faire installer une prise de courant

adéquate par un électricien qualifié.

L’utilisation de cet appareil est conçue pour un circuit de

tension nominale de 120 V et celui-ci est équipé en usine,

d’un cordon et d’une fiche d’alimentation spécifiquement

prévus pour le raccordement à un circuit électrique

adapté.S’assurer de bien brancher l’appareil sur une prise

de courant, présentant la même configuration que la fiche.

Ne pas utiliser de fiche d’adaptation avec cet appareil. Si

l’appareil doit être recâblé pour permettre son utilisation

sur un circuit électrique de type différent, confier

Rallonges électriques

S’assurer d’utiliser seulement une rallonge à 3 fils, munie

d’une fiche à 3 broches avec mise à la terre et branchezla

dans une prise à 3 fentes, compatible avec la fiche

de ce produit. S’assurer que la rallonge est en bon état

de fonctionnement. Lors de l’utilisation d’une rallonge,

s’assurer que celle-ci est de calibre suffisant pour

l’intensité de courant requise par cet appareil. Utiliser des

rallonges de calibre 12 AWG, d’une longueur maximale

de 7,5 m. Une rallonge de calibre insuffisant produira une

chute de la tension d’alimentation et provoquera une perte

de puissance et une surchauffe.

Rodage

No break-in procedure is required by the user. This

product is factory tested to ensure proper operation and

performance.

Fiche

Broche de mise

à la terre

Prise de

courant

avec mise à la

terre

16

Page 19

Consignes de démarrage quotidien

/ .

/ & &

1. Placez l’interrupteur d’alimentation dans la position

d’arrêt.

2. Vérifiez visuellement que le compresseur d’air n’est

pas endommagé ou obstrué.

3. Fermez la soupape de vidange.

4. Branchez le boyau d’air sur la douille du raccord rapide

de l’assemblage du régulateur, en introduisant l’embout

mâle du boyau dans la douille du raccord rapide. Le

collet de la douille du raccord rapide s’imbriquera vers

l’avant et verrouillera l’embout en place, procurant ainsi

un joint étanche et hermétique à l’air, entre l’embout et

la douille. Pour libérer le boyau d’air, poussez le collet

du raccord rapide vers l’arrière.

5. Branchez le cordon d’alimentation dans une prise de

courant appropriée.

6. Faites tourner l’interrupteur d’alimentation jusqu’à

la position « On-Auto » et le compresseur se mettra

en marche, accumulera de la pression dans le

réservoir jusqu’à atteinte de la pression de

déclenchement, puis il s’arrêtera automatiquement.

7. Réglez le régulateur au niveau de pression (kPa/PSI)

requis, selon l’application souhaitée, en vous assurant

que le niveau de pression est conforme aux normes

de sécurité requises pour effectuer la tâche. En cas

d’utilisation d’un outil pneumatique, reportez-vous aux

réglages de pression de service (kPa/ PSI)

recommandés par le fabricant dans le manuel de l’outil

utilisé.

REMARQUE : Portez toujours des lunettes de sécurité

conformes à ANSI Z87.1 et munies d’écrans latéraux

quand vous utilisez le compresseur d’air. Ne pointez

jamais un gicleur ou un pulvérisateur en direction d’une

partie de votre corps, d’une autre personne ou d’un

animal. Portez toujours un dispositif de protection de

l’ouïe approprié.

4

Close

1

6

7

5

3

17

Page 20

Consignes d’emploi

Consignes d’arrêt quotidien

1. Placez l’interrupteur d’alimentation dans la position

d’arrêt.

2. Débranchez le cordon d’alimentation de la prise de

courant.

3. Réglez la pression de sortie à zéro sur le régulateur.

4. Retirez tous les outils à air ou accessoires. Durant la

procédure de vidange du réservoir, assurez-vous de

toujours porter une protection auditive et

oculaire.Procédez à la vidange du réservoir dans un

endroit approprié; habituellement lors de la vidange,

l’air expulsé contient de la condensation.

5. Ouvrez la soupape de vidange pour libérer l’air présent

et vidanger le réservoir. Après avoir complété la

procédure de vidange du réservoir, fermez la soupape

de vidange, pour prévenir l’accumulation de débris

dans la soupape.

MISE EN GARDE

Durant la procédure de vidange du réservoir, s’assurer de

toujours porter une protection auditive et oculaire. Procéder

à la vidange du réservoir dans un endroit approprié; habituellement lors de la vidange, l’air expulsé contient de la

condensation.

AVERTISSEMENT

En présence d’eau à l’intérieur durant l’entreposage, le

réservoir subira un processus de corrosion qui le fragilisera et pourrait en provoquer l’éclatement. Pour éviter de

sérieuses blessures, s’assurer de vidanger le réservoir à

chaque jour ou après chaque utilisation.

Entretien

MISE EN GARDE

REMARQUE: Toute procédure d’entretien non indiquée

dans le tableau du calendrier d’entretien, doit être confiée

àdu personnel d’entretien qualifié.

AVERTISSEMENT

Avant de réaliser la moindre opération de maintenance,

le compresseur d’air doit être arrêté et débranché de sa

source d’alimentation, l’air doit être purgé du réservoir et

l’appareil doit avoir eu le temps de refroidir. Sans quoi

des dommages corporels pourraient être causés par des

pièces en mouvement, des sources électriques, de l’air

comprimé ou des surfaces chaudes.

Avant de soumettre le compresseur à tout entretien,

s’assurer de l’éteindre et le débrancher de sa source de

courant, ainsi que de vidanger l’air du réservoir et de

laisser à l’appareil le temps de refroidir.

Éléments à

vérifier / remplacer

Vérifier la soupape de sûreté

de réservoir

Vérifier l’aspect visuel global

de l’appareil

Vérifier le filtre à air

Vidanger le réservoir X

Entreposage

Pour entreposer le compresseur d’air, s’assurer de bien suivre les consignes suivantes:

1. Fermez l’appareil et débranchez le cordon

d’alimentation de la prise de courant.

2. Retirez tous les boyaux à air, accessoires et outils

pneumatiques du compresseur d’air.

3. Procédez aux étapes du calendrier d’entretien

quotidien.

4 Ouvrez la soupape de vidange pour libérer l’air

présentet vidanger le réservoir.

5. Fermez la soupape de vidange

6. Entreposez le compresseur d’air dans un endroit pro

pre et sec.

À chaque jour ou

avant chaque usage

X

X

X

Remarques

18

Page 21

Guide de dépannage

AVERTISSEMENT

Avant de soumettre le compresseur d’air à tout entretien, s’assurer de l’éteindre et le débrancher

de sa source d’alimentation électrique, ainsi que de vidanger l’air du réservoir et de laisser à

l’appareil le temps de refroidir. Les pièces en mouvement, les sources d’alimentation électrique, l’air

comprimé et les surfaces chaudes présentent des risques de blessures.

PROBLÈME

Fuites d’air au niveau du

clapet anti-retour ou de la

soupape de surpression.

Fuites d’air entre la culasse

et le cylindre.

Fuite d’air par la soupape

de sûreté.

À l’usage d’un accessoire,

il se produit une chute de

la mesure de pression

sur le manomètre de

régulateur.

Pression excessive du

réservoir.

Le moteur ne démarre pas.

CORRECTION POSSIBLE

Un clapet anti-retour défectueux produit une fuite d’air constante au niveau

de la soupape de surpression, lorsque le réservoir est sous pression et que le

compresseur est fermé. Vidangez le réservoir et par la suite, retirez et nettoyez ou

changez le clapet anti-retour.

Vérifiez qu’une force de torsion appropriée a été appliquée sur les boulons bruts. Si la

fuite persiste, appelez le service à la clientèle ou un technicien.

Actionnez la soupape de sûreté à la main, en tirant sur l’anneau. Si la soupape

continue à fuir en position fermée, elle devrait être remplacée.

En cas de chute de pression excessive à l’usage d’un accessoire, changez le

régulateur.

Remarques:

Ajustez la pression régulée en mode de débit (durant l’utilisation d’un

accessoire). Il est normal que le manomètre affiche une légère chute de pression,

durant l’utilisation initiale d’un outil.

Placez l’interrupteur dans la position d’arrêt. Si l’appareil ne s’éteint pas, débranchez-le de sa source d’alimentation et appelez le service à la clientèle ou un technicien.

Assurez-vous que le cordon d’alimentation est bien branché et que l’interrupteur est

dans la position de marche. Vérifiez que les fusibles dans votre boîte de disjonction

sont de la bonne taille. Si le fusible a disjoncté, réenclenchez-le et remettez l’appareil

en marche. Si plusieurs disjonctions se produisent, remplacez le clapet anti-retour,

ou appelez le service à la clientèle ou un technicien.

REMARQUE :

Pour une remise à l’état initial après une surcharge du moteur, mettez l’interrupteur

de MARCHE/ARRÊT dans la position d’arrêt et attendez 10 minutes (minimum).

Remettez l’appareil en marche.

Présence d’humidité

excessive dans l’air

expulsé.

Fuites d’air dans la

structure ou aux ponts de

soudure du réservoir.

Retirez l’eau du réservoir, en le vidangeant après chaque utilisation. Les

environnements très humides produisent une condensation excessive. Utilisez des

filtres à eau sur la ligne d’air comprimé.

REMARQUE :

La condensation de l’eau n’est pas provoquée par un mauvais fonctionnement du

compresseur. Assurez-vous que le débit d’air du compresseur est supérieur à la

consommation de l’outil pneumatique utilisé.

Ne percez, ni soudez ou modifiez jamais de quelque manière le réservoir, sinon

il se fragiliserait. Le réservoir pourrait se rompre ou exploser. Arrêtez l’usage du

compresseur d’air.

19

Page 22

4

5

6

7

8

9

10

11

12

13

14

15

9

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

17

17

37

38

39

40

42

43

43

44

45

46

47

48

46

49

50

51

52

56

55

54

53

58

59

60

61

16

2

3

1

41

57

Compresseur d’air Article N° 37296 / Modèle #

F226VWLVP

Explosé Sépare le Diagramme

20

Page 23

Compresseur d’air Article N° 37296 / Modèle #

F217HKL

Nomenclature des pièces

No No Numéro de Description Quantité

référence trousse pièce

No No Numéro de Description Quantité

référence trousse pièce

1 1 Couvercle du filtre d’entrée 1

2 1 Élément du filtre d’entrée 1

3 1 Bâti du filtre d’entrée 1

4 Tête de cylindre 1

5 Boulon, m6 x 1 x 35 mm SHCS 4

6 Rondelle d’arrêt de 6 mm 4

7 Coude à 90 degrés, filetage npt

3/8 po x raccord conique 3/8 1

8 4 Joint torique de la tête 1

9 4 Boulon, m3 x 4 x 5 mm HFHS 2

10 4 Clapet de retenue, sortie 1

11 4 Clapet de sortie 1

12 4 Plaque porte-clapet 1

13 4 Joint torique du cylindre 1

14 4 Clapet d’aspiration 1

15 4 Clapet de retenue, entrée 1

16 2 Cylindre 1

17 Vis, m6 x 1 x 12 mm HFHS 6

18 E103492 Protecteur arrière complet, F2, gris 1

19 Pompe/moteur 1

20 Boulon, m8 x 1 x 16 mm 4

21 Rondelle d’arrêt de 8 mm 4

22 Rondelle plate de 8 mm 4

23 Écrou, m8 x 1 x 25 mm ZDC 4

24 E103287 Tuyau de décharge 1

25 E101362 Clapet anti-retour gauche, 90 degrés 1

26 Excentrique 1

27 Palier de piston 1

28 2 Boulon, m5 x 0,8 x 16 mm SHCS 1

29 2 Couvercle de piston 1

30 2 Segment de piston 1

31 2 Piston 2

32 2 Écrou, m5 x 8 mm 1

33 2 Boulon, m5 x 0,8 x 2 5 mm 1

34 E100297 Ventilateur 1

35 Rondelle plate, 6 mm 1

36 Boulon, m6 x 1 x 1 6 mm SCHS 1

37 E103491 Protecteur frontal complet, F2, gris 1

38 E103286 Tube de sortie 1

39 Rondelle plate, 6 mm 2

40 Boulon, m6 x 1 x 16 mm SHCS 2

41 Poignée de préhension 1

42 E103485 Poignée 1

43 E101733 Manomètre Kobalt de 2 po ,

150 Redline, alimentation arrière, 2

44 E100307 Connexion rapide, à une main 1

45 Régulateur 1

46 Mamelon, 1/4 npt x 35 mm 2

47 E102595 Clapet de sécurité, 165 psi 1

48 E100957 Interrupteur pression, 150 psi 1

49 Boulon, m8 x 1,25 x 25 mm 4

50 Rondelle plate, 8 mm 4

51 Écrou d’insertion m8 4

52 Ensemble de réservoir 1

53 3 Écrou, 10 mm 2

54 3 Roue Kobalt de 7 po 2

55 3 Boulon, m10 x 1,25 x 20 mm 2

56 3 Chapeau de moyeu Kobalt 2

57 E101717 Robinet de purge quart de tour 1

58 Écrou, m8 x 1 x 25 mm ZDC 2

59 E101805 Isolateur Kobalt 2

60 Rondelle plate, m8 2

61 Boulon, m8 x 1 x 20 mm 2

Remarque: Tout élément ne comportant pas de numéro de trousse

ou de pièce n’est pas disponible. Leur description est à titre informatif seulement. La colonne de numéros de trousse indique

qu’une pièce est disponible dans une trousse spécifique. Une pièce

de chaque par trousse.

Les numéros de trousses et les pièces incluses sont les suivants :

Numéro Numéro Description de trousse Numéro de

de trousse de pièce référence

1 E101611 Kit de filtre à air 1-3

2 E103495 Kit de piston 16, 28-33

3 E103496 Kit de roue

(un ensemble par kit) 53-56

4 E103497 Kit d’ensemble de plaque

porte-clapet 8-15

Pour les parties de remplacement, s’il vous plaît appeler

1-800-628-8815 ext. 5000.

21

Page 24

GARANTIE LIMITÉE

Cette garantie est limitée à des défauts de fabrication dans le compresseur pour une période de 36 mois, à l’exception

des défauts de fabrication liés à la pompe du compresseur, aux clapets anti-retour, à l’interrupteur pression et au moteur

électrique, (collectivement appelés les « articles exclus »), pour lesquels la garantie s’appliquera pour une période de 12

mois. Si à un moment quelconque durant cette période de 36 mois votre compresseur d’air tombe en panne à cause

d’un défaut de fabrication, apportez-le à un centre agréé pour les réparations couvertes par la garantie. Si le centre de

réparation détermine que le produit est tombé en panne à cause d’un défaut d’exécution il sera réparé gratuitement. Si la

panne est due à une usure normale, ou à un dysfonctionnement, une défaillance ou un défaut quelconques résultant d’un

mésusage, d’un usage abusif, d’une négligence, d’altérations, de modifications ou de réparations effectuées par quiconque

autre qu’un centre agréé pour les réparations couvertes par la garantie, alors la garantie est nulle et non avenue.

GARANTIE LIMITÉE POUR UTILISATION COMMERCIALE

Cette garantie est limitée à des défauts de fabrication. Si à un moment quelconque au cours des premiers 90 jours à

partir de la date d’achat votre compresseur d’air tombe en panne à cause d’un défaut de fabrication, apportez-le à un

centre agréé pour les réparations couvertes par la garantie. Si le centre de réparation détermine que le produit est tombé

en panne à cause d’un défaut d’exécution il sera réparé gratuitement. Si la panne est due à une usure normale, ou

à un dysfonctionnement, une défaillance ou un défaut quelconques résultant d’un mésusage, d’un usage abusif, d’une

négligence, d’altérations, de modifications ou de réparations effectuées par quiconque autre qu’un centre agréé pour les

réparations couvertes par la garantie, alors la garantie est nulle et non avenue.

PREUVE D’ACHAT EXIGÉE

NOTE: REMARQUE : toute garantie dépend de la fourniture par le client d’un reçu valide constituant une preuve

d’achat..

Si aucun reçu n’est fourni, le code de date du fabricant sera utilisé au lieu de la date d’achat.

La Garantie limitée s’applique uniquement aux É-U. et au Canada et elle vous confère des droits spécifiques reconnus

par la loi. Vous pouvez également avoir d’autres droits qui varient d’un État à un autre, d’une province à une autre ou

d’un pays à un autre. Pour trouver votre centre agréé pour les réparations couvertes par la garantie, veuillez appeler le

1-800-628-8815, poste 5000.

22

Page 25

Modelo # F226VWLVP

COMPRESOR DE AIRE

PORTÁTIL

IMPULSIÓN DIRECTA, SIN ACEITE

Manual del propietario

y lista de partes

Para servicio al cliente llame al:

1-800-628-8815 ext. 5000

L-V 08:00 - 17:00 (Hora central)

Artículo # 37296

¡ADVERTENCIA!

Lea y entienda todas las precauciones de seguridad y las instrucciones de

operación, antes de utilizar el compresor de aire portátil.

8/20/2008 Impreso en China Part No. E103490

Page 26

ÍNDICE DE MATERIAS

Página

Instrucciones de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .......................25

Instrucciones y pautas de seguridad importantes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Especificaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Glosario . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Ciclo de trabajo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .......................26

Piezas y características . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .......................27

Instalación y ensamblaje . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....................28

Procedimientos de operación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....................29

Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....................30

Almacenamiento . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....................30

Diagnóstico y corrección de fallas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Diagrama de los componentes . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...................32

Lista de las piezas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Garantía limitada. . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . tapa trasera

¡NO DEVUELVA ESTE PRODUCTO

A LA TIENDA!

Favor llamar al 1-800-628-8815 ext. 5000

PARE

para obtener información con relación

a este producto

L-V 08:00 – 17:00 (Hora central)

Gracias

24

Page 27

Instrucciones de seguridad

El operador debe leer y entender la información descrita a continuación. Esta información se ofrece para proteger al

usuario al operar y almacenar el compresor de aire. Los símbolos siguientes son los que se utilizan para indicar al

lector información que es importante para su seguridad.

PELIGRO

Indica una situación de riesgo inminente que, de no

evitarse, provocará lesiones graves o la muerte.

ADVERTENCIA

Indica una situación potencialmente peligrosa que,

de no evitarse, podría provocar lesiones graves o la

muerte.

Indica una situación potencialmente peligrosa que,

de no evitarse, podría provocar lesiones menores o

moderadas.

Cuando aparezca sin el símbolo de alerta de seguridad, indica que hay una situación potencialmente

peligrosa que, de no evitarse, podría causar daños

materiales.

PRECAUCIÓN

PRECAUCIÓN

Instrucciones y pautas de seguridad importantes

• Conserve todas las instrucciones •

ADVERTENCIA

La operación y el mantenimiento inadecuados de este producto pueden provocar lesiones graves y daños materiales.

Antes de utilizar este equipo, lea y entienda las advertencias e instrucciones de seguridad aquí contenidas.

El compresor de aire se debe operar desde un circuito especial de 15 amperios. Si

el circuito no dispone de una capacidad de 15 amperios, se debe usar un circuito de

PRECAUCIÓN

mayor capacidad. Si es necesario, antes de emplear una extensión eléctrica, añada

una manguera del aire más larga. Todas las extensiones eléctricas utilizadas deben

ser de calibre 12 y tener una longitud máxima de 7,6 m. El fusible del circuito debe

ser de acción retardada. Un voltaje demasiado bajo puede dañar el motor.

Riesgo por causa de

partes en movimiento

Riesgo de quemaduras

Riesgo de caída

Riesgo de lanzamiento

de objetos

Al operar el compresor, todos los protectores y cubiertas deben estar fijados e

instalados correctamente. Si alguno de los protectores o cubiertas está dañado,

no opere el equipo hasta que personal calificado repare el problema. El cable de

corriente debe mantenerse alejado de las partes móviles del equipo y no debe

torcerse ni prensarse durante su empleo, ni al almacenarse.

En su compresor hay superficies que, al ser tocadas durante y después de su

operación, pueden causar quemaduras graves. Antes de darle mantenimiento al

equipo, se debe dejar enfriar. Por lo normal, durante y después de su operación,

ciertas partes como la bomba del compresor y el tubo de salida estarán calientes.

El compresor siempre debe ser operado en una posición estable. Nunca utilice

el compresor sobre un techo o en una posición elevada ya que podría caer o

volcarse.

Al trabajar en posiciones elevadas, utilice una manguera de aire más larga.

Al emplear el compresor, siempre utilice anteojos de seguridad con protectores

laterales que cumplan con la norma ANSI Z87.1. Antes de llevar a cabo cualquier

clase de mantenimiento y antes de desconectar las mangueras y los acopladores,

apague el compresor y drene el tanque de aire. Nunca apunte la boquilla o el

rociador hacia ninguna parte del cuerpo, ni hacia otras personas o animales.

25

Page 28

Instrucciones y pautas de seguridad importantes

Riesgo para la

respiración

Riesgo de

descargas eléctricas

Riesgo de

explosión y fuego

Riesgo de estallido

Evite utilizar el compresor de aire en áreas encerradas. Siempre tenga un espacio

libre adecuado (30 cm.) alrededor del compresor. También mantenga fuera del área

de operación a las mascotas, niños y otras personas. Este compresor de aire no

provee aire que pueda ser respirado ni empleado con un dispositivo respiratorio

auxiliar. El material de rociado siempre deberá estar en otra zona, alejado del

compresor de aire, para evitar que el aire aspirado dañe al filtro del compresor.

Nunca utilice el compresor de aire bajo lluvia o en lugares mojados. Los problemas

eléctricos deben ser reparados por personal autorizado, tal como sería un

electricista, y deben cumplir con las normas eléctricas nacionales y locales. El

compresor también debe tener el enchufe adecuado de tres clavijas con conexión

a tierra y contar con un suministro eléctrico que sea del voltaje correcto y con un

fusible de protección adecuado.

Nunca opere el compresor cerca de materiales combustibles, gasolina, ni vapores

de solventes. Si está rociando materiales inflamables, coloque el compresor a

una distancia de cuando menos 6 metros de la área de rociado. Nunca opere el

compresor de aire en interiores o en lugares cerrados.

Siempre drene el compresor diariamente o después de cada utilización. Si el

tanque tiene una fuga, reemplace el compresor. Nunca utilice el compresor si se ha

detectado una fuga, ni trate de modificar el tanque. Nunca modifique los ajustes

de fábrica del compresor que controlan la presión del tanque o cualquier otra

función.

Especificaciones

Bomba . . . . . . . . . . . . . . . . . . . . De impulsión directa, sin

aceite

Motor por inducción ...................................1,5 HP

Diámetro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,48 pulg.

Carrera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,87 pulg.

Voltaje monofásico . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120 VAC

Capacidad mínima del circuito . . . . . . . . . . . . . . . . . . . . . . . 15 Amp.

Capacidad del tanque de aire . . . . . . . . . . . . . . 17 gal / 64,4 litros

Presión de arranque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 PSI

Presión de parada .....................................150 PSI

Pies cúbicos por minuto (SCFM)@ 40 PSI ...................5,0

Pies cúbicos por minuto (SCFM)@ 90 PSI ...................4,0

Glosario

CFM: Pies cúbicos por minuto.

SCFM: Pies cúbicos estándar por minuto; unidad de

medición de suministro del aire.

PSIG: Libras por pulgada cuadrada sobre la presión

atmosférica; unidad de medición de presión.

ASME: Sociedad estadounidense de ingenieros

mecánicos.

Código de California: La unidad puede cumplir con el

código de California 462 (l) (2)/ (M) (2).

Presión de arranque: El compresor arranca automática-

Presión de parada: El motor se para cuando el tanque

Certificación de código: Los productos que tienen

mente cuando la presión baja a menos del mínimo

prescrito.

alcance la presión máxima de aire.

alguna o varias de las siguientes marcas han

sido evaluados por laboratorios de seguridad independientes certificados por OSHA,

y cumplen con las normas de seguridad de

Underwriters Laboratories: UL, CUL, ETL, CSA.

Ciclo de trabajo

PRECAUCIÓN

Este compresor tiene un ciclo de trabajo de 50%. Nunca opere el compresor de aire por más de 30 minutos cada

hora. Ya que al hacerlo, podría dañar el compresor de aire.

26

Page 29

Piezas y características

Como referencia, vea las figuras abajo.

Filtro del aire

Suministra aire limpio a la bomba. Siempre

debe conservarlo limpio. Revíselo diariamente

o antes de cada uso.

Manómetro de presión del tanque

Indica la presión de la reserva del aire del

tanque.

Manómetro de presión de salida

Indica la presión de salida del aire a la

herramienta, la cual es controlada por el

regulador.

Conector de acoplamiento rápido

Permite conectar y desconectar

rápidamente la manguera del aire.

Regulador

La presión del aire que sale del tanque es

controlada por el regulador. Para aumentar

la presión, gire la perilla en sentido horario;

para disminuirla, gire el botón en dirección

anti-horario.

Válvula de seguridad del tanque

Permite que el exceso de presión en el tanque

escape hacia el medio ambiente. Esta válvula

sólo se abrirá cuando la presión en el tanque

esté por encima de la presión máxima nominal

del modelo.

Interruptor

Controla la potencia del interruptor de presión

de arranque / Presión de parada.

Utilice el conmutador de contactos a presión,

para las posiciones Auto-On/Off del motor.

Válvula de drenaje

Sirve para drenar la condensación acumulada en

el fondo del tanque.

Se encuentra en la parte inferior del tanque.

27

Page 30

Instalación y ensamblaje

ADVERTENCIA

Antes de darle cualquier tipo de mantenimiento al

compresor de aire, se debe apagar y desconectar

de la fuente de alimentación eléctrica, además de

purgar el aire del tanque y darle suficiente tiempo

para enfriarse. Existe el riesgo de que las partes

móviles, las fuentes eléctricas, el aire comprimido y las

superficies calientes provoquen lesiones. El ensamblaje

del regulador debe estar instalado, antes de usar el

compresor. Un ensamblaje inadecuado puede ser causa

de fugas y posiblemente de lesiones. Si no está seguro

de entender las instrucciones de ensamblaje o tiene

dificultad para llevar a cabo el armado, por favor llame

a su departamento local de servicio para obtener más

instrucciones.

Ubicación del compresor del aire

El compresor del aire siempre debe estar en un medio

ambiente limpio, seco y bien ventilado. La unidad debe

tener por lo menos 30 cm de espacio libre en cada lado.

La toma del filtro del aire debe estar limpia y sin ningún

tipo de obstrucción. Por favor revise diariamente el filtro

del aire para comprobar que esté limpio y funcione correctamente.

Instrucciones de conexión a tierra

Este producto se debe conectar a tierra. En el caso de

que haya un cortocircuito, la conexión a tierra reduce

el riesgo de descargas eléctricas al ofrecer una ruta de

escape para la corriente eléctrica. Este producto cuenta

con un cable que tiene un alambre de tierra y un enchufe

con terminal de tierra (vea la figura a continuación). La

clavija debe enchufarse en un tomacorriente instalado y

puesto a tierra según las normas locales. Hable con un

electricista o agente de servicio calificado si no entiende

completamente estas instrucciones, o si tiene dudas

sobre la correcta puesta a tierra de la herramienta.

vicio calificado. No modifique el enchufe que viene con

el equipo; si no puede enchufarlo en el tomacorriente,

llame a un electricista calificado para que le instale el

tomacorriente adecuado.

Este producto está diseñado para trabajar en un circuito

con un voltaje nominal de 120 voltios y está equipado

en la fábrica con un cable y enchufe especificados,

que permiten una conexión a un circuito eléctrico apropiado. Asegúrese de que el producto esté conectado

a un tomacorriente con la misma configuración que el

enchufe. No se debe usar un adaptador con este equipo.

Si debe conectar el equipo con un circuito eléctrico de

diferente tipo, consiga la ayuda de personal calificado

para realizar la reconexión.

Cables de extensión

Sólo utilice un cable de extensión de tres (3) alambres

con un enchufe con extensión a tierra de tres (3) terminales que pueda enchufarse en un tomacorriente de tres

(3) orificios. Asegúrese de que el cable de extensión esté

en buenas condiciones. Si utiliza un cable de extensión,

compruebe que sea de la capacidad de la corriente que

requiere su equipo. Las extensiones no deben ser de

más de 25 pies (7,6 m) de largo y deben tener cable de

calibre 12 AWG. Un cable más delgado provocará una

caída en el voltaje de la línea, lo que ocasionaría una

pérdida de potencia y sobrecalentamiento.

Procedimiento inicial de preparación

No se requiere un procedimiento inicial de preparación.

Este producto ha sido probado en la fábrica para asegurar su operación y rendimiento adecuados.

Clavija

Terminal de tierra

Tomacorriente

con conexión a

ADVERTENCIA

Una conexión a tierra inadecuada puede provocar una

descarga eléctrica. Si necesita reparar o cambiar el

cable o el enchufe, no conecte el alambre de tierra con

ninguna de los terminales planos. El cable de tierra es de

color verde, con o sin franjas amarillas. Si no entiende

completamente las instrucciones de conexión a tierra,

o si tiene dudas sobre la correcta puesta a tierra de la

herramienta, hable con un electricista o agente de ser-

tierra

28

Page 31

Procedimientos de operación

/ .

/ & &

Procedimiento diario de arranque

1 Ponga el interruptor en la posición de apagado (Off).

2 Verifique visualmente que el compresor del aire no

tenga daños ni obstrucción.

3 Cierre la válvula de drenaje.

4 Conecte la manguera del aire al acoplamiento de

conexión rápida del ensamblaje del regulador, inser

tando el enchufe de conexión rápida en la manguera

del aire, dentro del acoplamiento de conexión rápida.

El collarín del acoplamiento de conexión rápida saltará

hacia adelante, sujetando el enchufe en su lugar y pro

porcionará una junta hermética el acoplamiento y el

enchufe. Para desconectar la manguera del aire,

empuje hacia atrás el collarín del acoplamiento de

conexión rápida.

5 Enchufe el cable de corriente en un tomacorriente

apropiado.

6 Gire el interruptor hacia la posición de encendido

(Auto-On); el compresor deberá arrancar, acumulando la

presión del aire en el tanque hasta llegar a la

presión de apagado, momento en el cual se apagará

automáticamente.

7 Ajuste el regulador a la presión de aire recomendada

(PSI) para su aplicación, cerciorándose de que esté

dentro de las normas de seguridad para llevar a cabo

la tarea. Para las herramientas neumáticas, el manual del

fabricante debe tener recomendaciones sobre la

presión de operación (PSI).

NOTA: Ahora el compresor de aire está listo para ser

usado. Los siguientes accesorios de inflado y de

limpieza, los cuales vienen con esta unidad, sólo se

deben operar a una presión máxima de 20-30 PSI:

soplete, boquilla cónica, agujas para inflar, adaptador

de soplete. Espere al menos 5 segundos después de

apagar el motor del compresor, antes de volver a

encenderlo.

NOTA: Al emplear el compresor, siempre utilice anteojos

de seguridad con protectores laterales que cumplan

con la norma ANSI Z87.1. Nunca apunte la boquilla o

el rociador hacia ninguna parte del cuerpo, ni hacia

otras personas o animales.

Siempre lleve una protección apropiada para el oído.

4

Close

1

6

7

5

3

29

Page 32

Procedimientos de operación

Procedimiento diario de apagado

1. Ponga el interruptor en la posición de apagado (Off).

2. Desconecte el cable del tomacorriente.

3. Ponga en cero el regulador de presión de salida.

4. Desconecte las herramientas y los accesorios de aire.

Siempre use protección para los oídos y los ojos al

drenar el tanque. Drene el tanque en un lugar

adecuado; en casi todos los casos habrá presencia de con

densación en el drenaje.

5. Abra la válvula de drenaje permitiendo que escape el aire

del tanque. Cuando haya salido del tanque todo

el aire, cierre la válvula de drenaje para evitar la

acumulación de suciedad en la válvula.

Mantenimiento

NOTA: Cualquier procedimiento de servicio que no

esté cubierto en el programa de mantenimiento que

sigue, deberá ser efectuado por el personal de servicio

calificado.

ADVERTENCIA

Antes de dar mantenimiento al equipo, se debe apagar

y desconectar del tomacorriente, así como purgar el aire

del tanque y permitir que la unidad se enfríe. Las partes

en movimiento, las fuentes eléctricas, el aire comprimido

y las superficies calientes pueden provocar lesiones.

PRECAUCIÓN

A fin de asegurar una operación eficiente y una larga

vida del compresor de aire, se debe seguir un programa

PRECAUCIÓN

Al drenar el tanque utilice protección para los oídos y

los ojos. Drene el tanque en un lugar apropiado; en casi

todos los casos habrá presencia de condensación en el

drenaje.

ADVERTENCIA

Si no drena el tanque al almacenarlo, en su interior

quedará agua que lo corroerá y debilitará, lo cual puede

provocar su ruptura. Para evitar lesiones graves, drene

de mantenimiento de rutina. El siguiente programa

de mantenimiento está enfocado al consumidor cuyo

compresor es usado en un medio ambiente normal y

diariamente.

Puntos para verificar/cambiar

Revisar la válvula de X

seguridad del tanque

Revisar visualmente el aspecto X

general de la unidad