Page 1

ATTACH YOUR RECEIPT HERE

Serial Number Purchase Date

Questions, problems, missing parts? Before returning to your

retailer, please call our Customer Service Department at

1-888-3KOBALT, 8 a.m. – 8 p.m., EST, Monday – Friday.

ITEM #0840781

MODEL #SGY-AIR185

1/2 IN. COMPACT

IMPACT WRENCH

Français p. 17

Español p. 34

kobalttools.com

AB1752

Kobalt® is a registered trademark of LF, LLC.

All rights reserved.

1

Page 2

kobalttools.com

2

TABLE OF CONTENTS

Safety Information..........................................................................................3

Compressor Requirements.............................................................................2

Package Contents........................................................................................10

Product Specifications....................................................................................3

Preparation...................................................................................................10

Assembly Instructions...................................................................................11

Operating Instructions..................................................................................13

Care and Maintenance.................................................................................14

Troubleshooting............................................................................................15

Warranty.......................................................................................................16

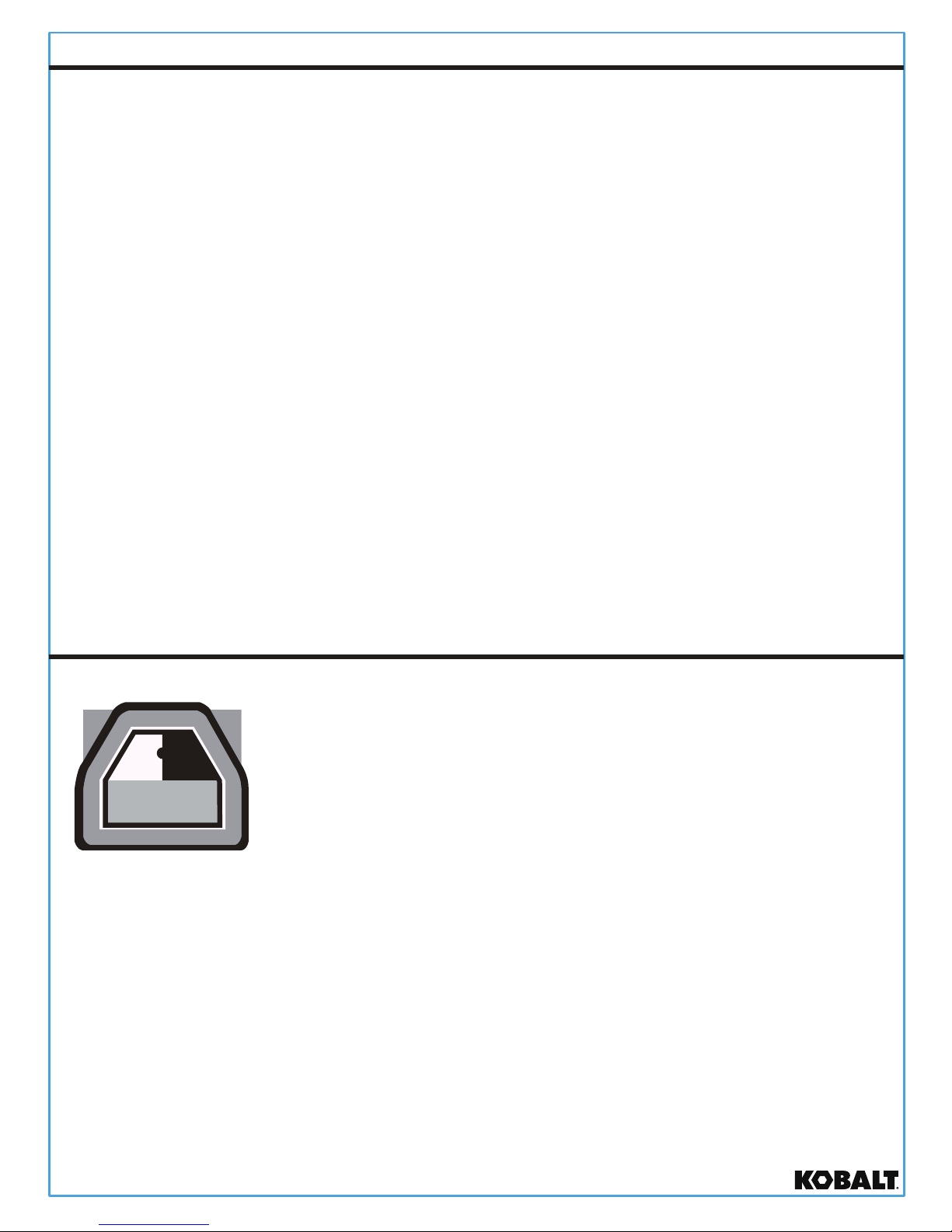

COMPRESSOR REQUIREMENTS

5.3

SCFM90PSI

Tool Requirements

Exigences relatives aux outils

Requisitos de herramientas

@

IMPORTANT: To operate correctly, this tool requires airflow of at least

5.3 Standard Cubic Feet per Minute(SCFM) at 90 Pounds per Square

Inch (PSI).

Air hoses may cause loss in pressure up to 15 PSI, requiring a higher

compressor output to compensate and maintain required pressure at the tool.

Check the specifications of your air compressor to be sure it can support

both the SCFM and PSI required by this specific tool.

Page 3

kobalttools.com

3

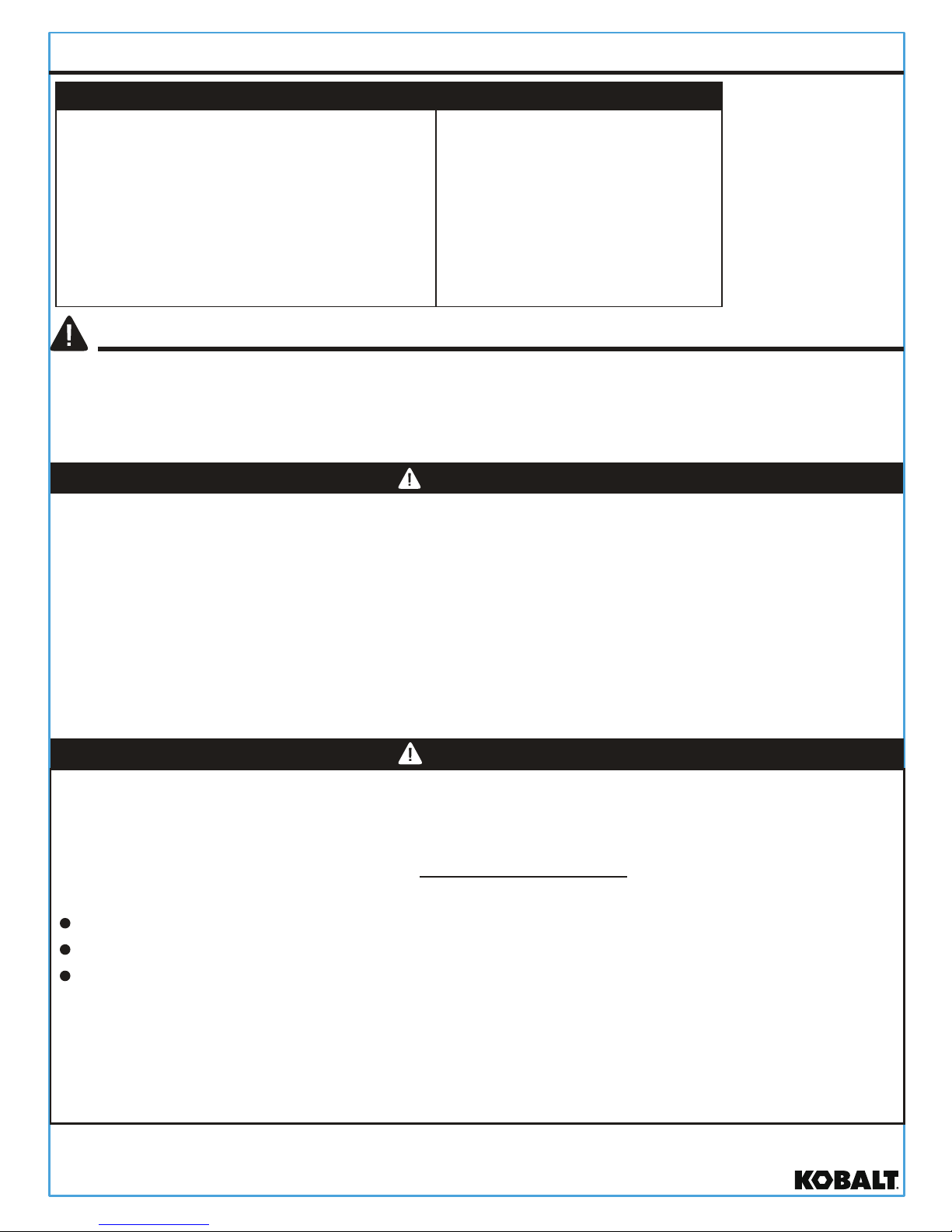

PRODUCT SPECIFICATIONS

SPECIFICATIONS

1/2 IN

10,000 RPM

450 FT-LB

5.3 SCFM

1/4 IN NPT

3/8 IN

90 PSI

COMPONENT

SQUARE DRIVE

SPEED

MAX. TORQUE

AVERAGE AIR CONSUMPTION

AIR INLET

RECOMMEND AIR HOSE

WORKING PRESSURE

SAFETY INFORMATION

Please read and understand this entire manual before attempting to

assemble, operate or maintain this product. If you have any questions,

please call our Customer Service Department at 1-888-3KOBALT,

8 a.m. – 8 p.m., EST, Monday – Friday.

WARNING

WARNING

Improper operation or maintenance of this tool could result in serious injury

and property damage. Read and understand all warnings and operation

instructions before using this tool. When using any tool, basic safety

precautions should always be followed to reduce the risk of personal injury.

Use each tool for its intended function only. Do not use this product in

unsafe work conditions. It is always recommended to keep a fire

extinguisher and first aid kit near work areas.

FAILURE TO OBSERVE AND FOLLOW SAFETY INSTRUCTIONS COULD

RESU IN INJURY OR DEATH.

Some dust created by paint spraying, power sanding, sawing, grinding,

drilling and other related activities is known to the State of California to

cause cancer, birth defects and other reproductive harm. A listing of

chemicals can be obtained from www.oehha.ca.gov under proposition 65.

Some examples of these chemicals are:

Lead from lead based paints

Crystalline silica from bricks, cement and other masonry products

Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals, work in a well

ventilated area and wear appropriate/approved safety equipment such as

respirators or dust masks which are specially designed to filter microscopic

particles.

Page 4

kobalttools.com

4

SAFETY INFORMATION

RISK OF EYE OR HEAD INJURY

WARNING

WARNING

WARNING

WHAT COULD HAPPEN HOW TO PREVENT IT

WHAT COULD HAPPEN HOW TO PREVENT IT

WHAT COULD HAPPEN HOW TO PREVENT IT

This air-powered tool is capable of

propelling materials such as

fasteners, metal chips and other

debris at high speed, which could

result in serious injury.

Always wear ANSI-approved Z87.1

safety glasses with side shields.

Never leave a pressurized tool

unattended.

Disconnect tool from air supply when

tool is not in use or when changing

accessories to prevent accidental

operation.

Compressed air can be hazardous,

propelling objects or particles that

can cause injury into soft tissues

such as eyes and ears.

Never direct air at yourself or

anyone else.

For additional protection, use an

approved face shield in addition to

safety glasses.

Tool attachments can become loose

or break and fly apart, becoming

projectiles or propelling other objects

at the operator or bystanders in the

work area.

Make sure all attachments are

properly assembled and securely

fastened before use.

Always use the tool at a safe

distance from others in the work area.

Maintain awareness of work area

safety at all times.

RISK OF LOSS OF HEARING

RISK OF FIRE OR EXPLOSION

Always wear ANSI S3.19 hearing

protection.

Exposure to noise produced by air

tools can lead to permanent hearing

loss.

This tool is capable of generating

sparks which can result in ignition of

flammable materials.

Work in a clean, well ventilated area

free of combustible materials.

Never operate tools near flammable

substances such as gasoline,

naphtha, cleaning solvents, etc.

This tool is not recommended for

use in explosive atmospheres or

underwater.

Page 5

kobalttools.com

5

SAFETY INFORMATION

RISK OF FIRE OR EXPLOSIN

WARNING

WARNING

WARNING

WHAT COULD HAPPEN HOW TO PREVENT IT

WHAT COULD HAPPEN HOW TO PREVENT IT

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF ENTANGLEMENT

RISK OF CUTS OR BURNS

This tool is capable of generating

sparks, which can result in ignition of

flammable materials.

Never use oxygen, carbon dioxide or

other bottled gasses as a power

source for air tools. Use only clean,

dry air at the specified pressure.

Wiping or cleaning rags and other

flammable waste materials that may

have been used on the tool must be

placed in a tightly closed metal

container, and disposed of in a

proper manner.

Air tools that contain moving

elements or drive other moving parts

(such as impact sockets) can

become entangled in hair, clothing,

jewelry and other loose objects,

resulting in severe injury.

Do not wear loose clothing, jewelry

or anything that may get caught or

tangled in the tool, hose or workpiece.

Always keep hands and body parts

away from moving parts.

Always wear properly fitted clothing

and other properly fitted safety

equipment when using tools.

Whipping hoses can cause serious

injury. Always check for damaged or

loose hose fittings before using tools.

Air tools are capable of causing

serious injury if operated improperly

or in a manner for which the tool is

not intended. Accessories can

become extremely hot through

friction where they contact the

workpiece.

Wear gloves when using tools.

Keep the working part of the tool

away from hands and body.

Do not touch accessories with bare

hands during or immediately after

use.

Page 6

kobalttools.com

6

SAFETY INFORMATION

RISK OF ELECTRIC SHOCK

WARNING

WARNING

WHAT COULD HAPPEN HOW TO PREVENT IT

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF PERSONAL INJURY

This tool is NOT electrically insulated.

Contact with a “live” wire will also

make exposed metal parts of the tool

“live” and can result in electrical

shock, electrocution injury or death.

Never use air tools where they may

come in contact with energized

electrical wiring.

Avoid body contact with grounded

surfaces such as pipes, radiators,

refrigerators and ranges. There is

an increased risk of electrical shock

if your body is grounded.

Whenever possible, it is

recommended that electrically

non-conductive clothing and non-skid

footwear be worn when using tools.

Air tool accessories such as impact

sockets or drills that come into

contact with hidden electrical wiring

could cause electrocution or death.

Thoroughly investigate workpieces

and work areas for possible hidden

wiring before performing work.

An unattended tool could be

activated by unauthorized/untrained

persons, leading to their injury or

injury to others.

Remove air hose when the tool is

not in use and store tool in a secure

location away from reach of children

and untrained users.

Air tools can propel fasteners,

loose/broken accessories or other

objects throughout the work area.

Never run the tool off the workpiece.

Maintain awareness of work area

safety at all times. Always be aware

of other people around the work area

to ensure safety.

Use only parts, fasteners and

accessories recommended by the

manufacturer.

Keep work area clean, free of clutter

and well lit. Do not allow children to

operate any tool, and keep children

away from work areas.

Page 7

kobalttools.com

7

SAFETY INFORMATION

WARNING

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF PERSONAL INJURY

Sockets that are left attached to a

rotating part of the tool may fly off

and increase the risk of personal

injury.

Air tools can become activated by

accident while being handled or

during tool changes, maintenance

or repair.

Always remove and secure the

socket after use.

Disconnect the tool from the air

supply during tool changes,

maintenance or repair.

Never carry the tool by the air hose.

Always carry the tool by the handle.

Avoid unintentional operation.

Never carry the tool with the trigger

depressed or engaged. Do not lock,

tape or wire the trigger for

continuous operation.

Only an authorized service

representative should do repair

servicing.

Air tools can cause the workpiece to

move upon contact, leading to injury.

Always make sure the workpiece is

secure. Use clamps or other devices

to prevent movement.

Loss of control of the tool can lead to

operator injury or injury to others in

the work area.

Always shut off the air supply and

release/drain air pressure from the

hose before changing accessories or

making repairs. When tool is not in

use, disconnect it from the air supply

and store the tool in a safe location.

Never operate tools while using

drugs or alcohol.

Do not overreach or stretch to

operate the tool.

Page 8

kobalttools.com

8

SAFETY INFORMATION

WARNING

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF PERSONAL INJURY

There is a risk of bursting if the tool

is damaged.

Loss of control of the tool can lead to

operator injury or injury to others in

the work area.

Keep proper footing at all times

when handling tools. Slipping,

tripping and/or falling are major

causes of serious injury and or death.

Keep tool handles dry, clean and

free from oil/grease.

Be aware of excess air hose,

electrical power sources and other

obstacles or hazards in the work area.

Stay alert. Watch what you are doing.

Use common sense. Do not operate

tools when you are tired.

Operators must be able to easily

handle the entire weight of the tool in

operation, to maintain full control of

the tool 100% of the time.

Check for misalignment or binding of

moving parts, broken parts and other

conditions that affect safe tool

operation.

Poor quality, improper or damaged

attachments can detach or fly apart

during operation, sending projectiles

through the work area and causing

serious injury.

Never use a tool that has been

dropped, damaged or appears to

malfunction. Never use tools that

are leaking air or have missing parts.

Remove damaged or malfunctioning

tools from the workplace immediately.

Do not use pressure exceeding the

recommended operating pressure of

any of the parts (hoses, fittings, etc.)

in the system.

Use only impact-grade sockets with

air impact tools. Always use

attachments rated for the speed of

the tool. Do not modify tools or

attachments.

Do not apply excessive force to the

tool; let the tool perform the work.

Follow lubrication instructions for

best and safest operation.

Page 9

kobalttools.com

9

SAFETY INFORMATION

WARNING

WHAT COULD HAPPEN HOW TO PREVENT IT

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF PERSONAL INJURY

WARNING

INHALATION HAZARD

Poor quality, improper or damaged

attachments can detach or fly apart

during operation, sending projectiles

through the work area and causing

serious injury.

Always follow assembly, operation,

maintenance and repair instructions.

Improperly maintained tools and

accessories can cause serious

injury.

Maintain the tool and accessories

with care. Do not abuse hoses or

connectors.

Keep hoses away from heat, oil and

sharp edges. Always check air hoses

for weak or worn connections before

each use and make certain that all

connections are secure.

Keep tools clean and properly oiled

for best and safest performance.

Using an accessory not intended for

a specific tool increases the risk of

injury to the operator and everyone

else in the work area.

Always use accessories and

attachments designed for the tool

and the work at hand.

Do not improvise or modify tools or

accessories.

Repetitive motions, awkward

positions and exposure to vibration

can be harmful to hands and arms.

Discontinue use of tool if discomfort,

tingling feeling or pain occurs.

Consult a physician before resuming

use if any of these symptoms occur.

Abrasive tools such as grinders,

sanders and cut-off tools generate

dust and abrasive materials, which

can be harmful to the lungs and

respiratory system. Paint spraying

tools generate paint vapors, which

can be harmful to the lungs and

respiratory system.

Always wear a properly fitting

facemask or respirator rated for the

application when using such tools.

Some materials such as adhesives

and tar give off vapors, which could

cause serious injury with prolonged

exposure.

Always work in a clean, dry,

well-ventilated area. Be aware of

chemicals in the work area and read

all Materials Safety Data Sheets

(MSDS) for the materials and/or

chemicals that may be present.

Page 10

kobalttools.com

10

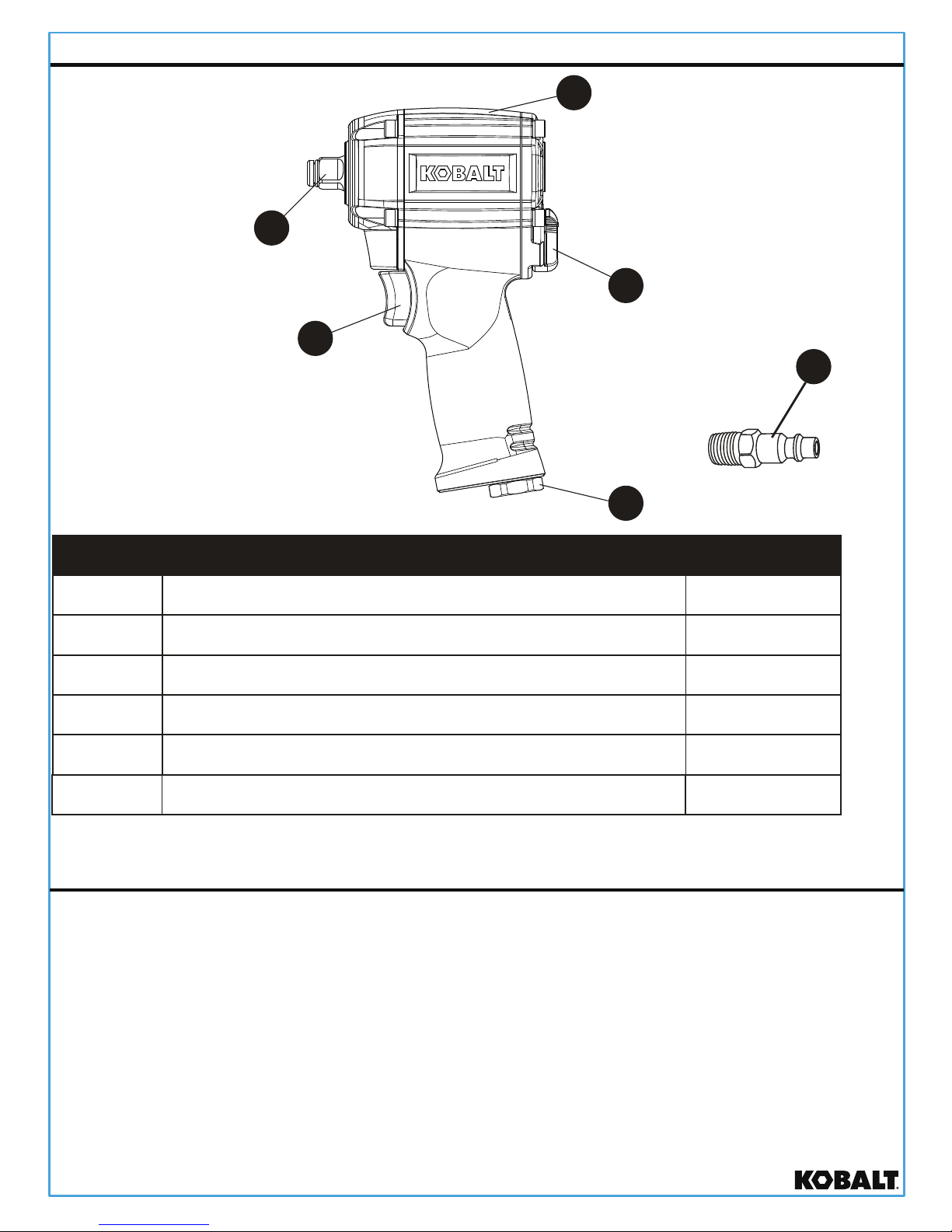

PACKAGE CONTENTS

PREPARATION

DESCRIPTION

Wrench

Anvil (preassembled to Wrench (A))

Trigger (preassembled to Wrench (A))

Switch (preassembled to Wrench (A))

Air Inlet (preassembled to Wrench (A))

QUANTITY

1

1

1

1

1

PART

A

B

C

D

E

1/4 in. male plug

1

F

E

F

A

D

B

C

Before assembling this tool, make sure all parts are present. Compare parts

with package contents list. If any part is missing or damaged, do not attempt

to assemble the tool.

Estimated Assembly Time: 1 – 3 minutes

Tools and Materials Required for Assembly (not included):

• Adjustable wrench or 9/16-in. wrench

• Thread sealant tape

• Air tool oil (NOTE: Air tool oil is NOT compressor oil. Use of compressor oil

in this tool can damage the tool and/or shorten tool life. Use only air tool oil

in this tool).

Page 11

kobalttools.com

11

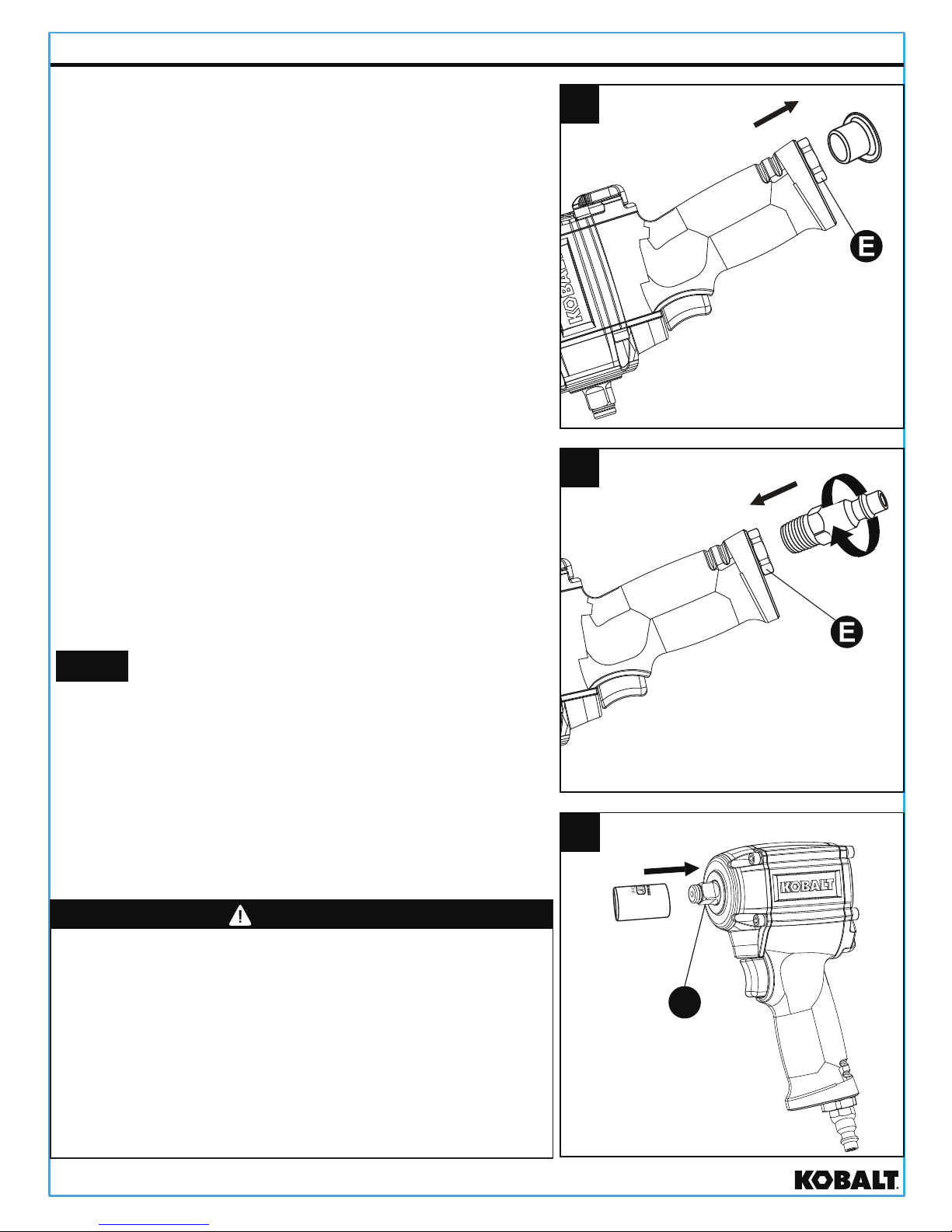

ASSEMBLY INSTRUCTIONS

1. Remove plastic air inlet protective cap

from air inlet (E).

1

2

3

NOTE

2. Prepare a 1/4-in. male plug by applying

sealant tape (not included) to the

threading, wrapping clockwise. Screw

threaded male air plug by hand into air

inlet (E), then tighten with a wrench

(not included) for an airtight connection.

DO NOT OVERTIGHTEN.

Sealant tape must be used on this

connection.

3. Select the correct impact socket

(not included) for the threaded fastener to

be tightened or loosened and mount it onto

the anvil (B) until it clicks into place.

B

Use only adapters and sockets with a torque

rating equal to or greater than the tool itself.

Always make sure adapters and sockets are

properly mounted and secure before using

the tool. Loose attachments can break or fly

off, causing serious injury to the operator or

bystanders in the work area. Always follow

all manufacturers’ specifications for proper

attachment and use.

WARNING

Page 12

kobalttools.com

12

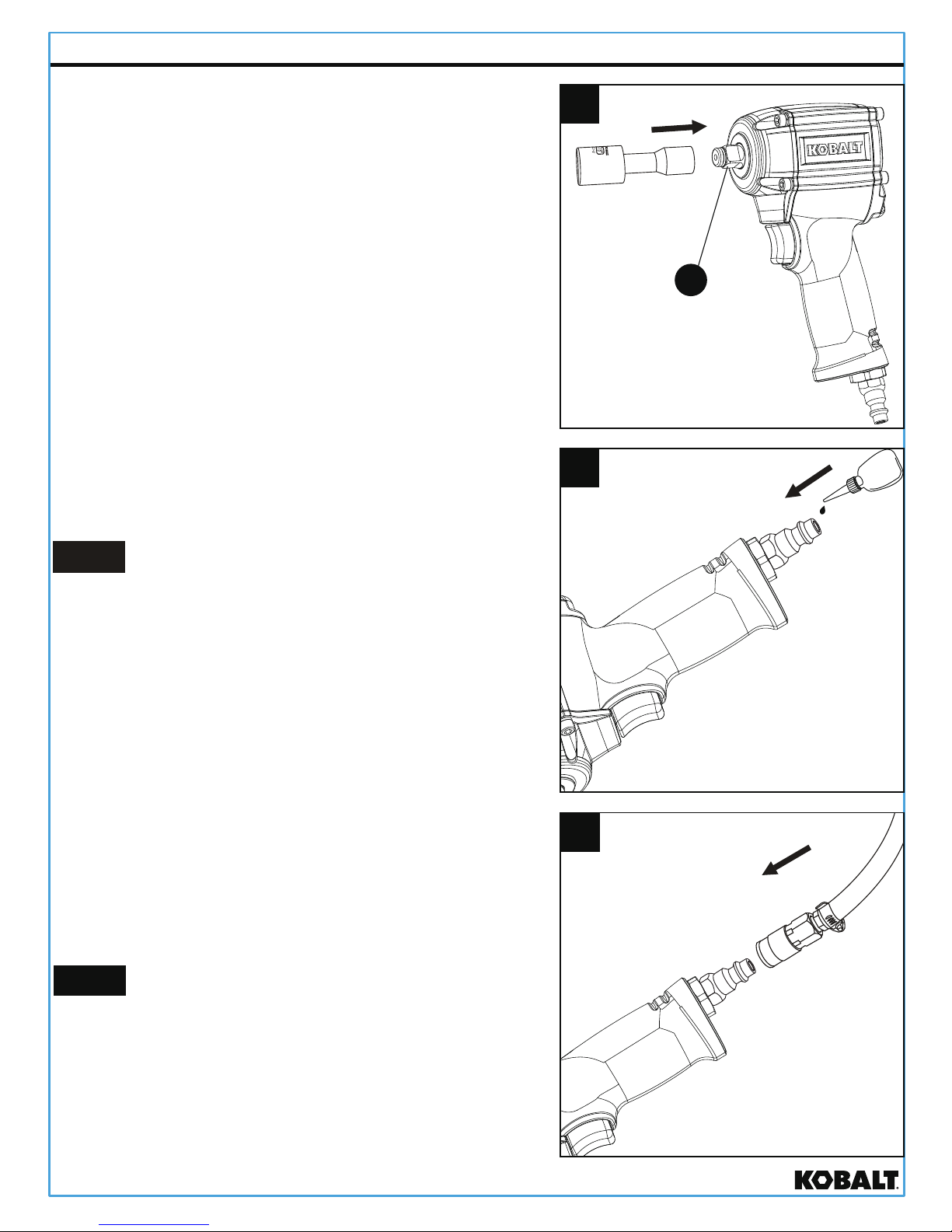

ASSEMBLY INSTRUCTIONS

4

5

6

B

4. If necessary for a longer reach, mount an

extension bar (not included) onto the

anvil (B) until it clicks into place, then

mount the socket on the adapter.

NOTE

5. Place 2 – 3 drops of air tool oil

(not included) into the male air plug before

each use, as shown in Fig. 5.

Proper lubrication is EXTREMELY

important to assure proper tool performance

and avoid tool damage. ALWAYS lubricate

the tool before each use if not using an

in-line oiler.

6. Connect the air supply hose (not included)

to the male air plug, making sure it is

completely seated and secure. Set the

working pressure at 90 PSI for best tool

performance.

NOTE

To operate correctly, this tool requires

airflow of at least 5.3 cubic feet per minute

(SCFM) at 90 pounds per square inch (PSI)

at the tool.

Page 13

kobalttools.com

13

OPERATING INSTRUCTIONS

D

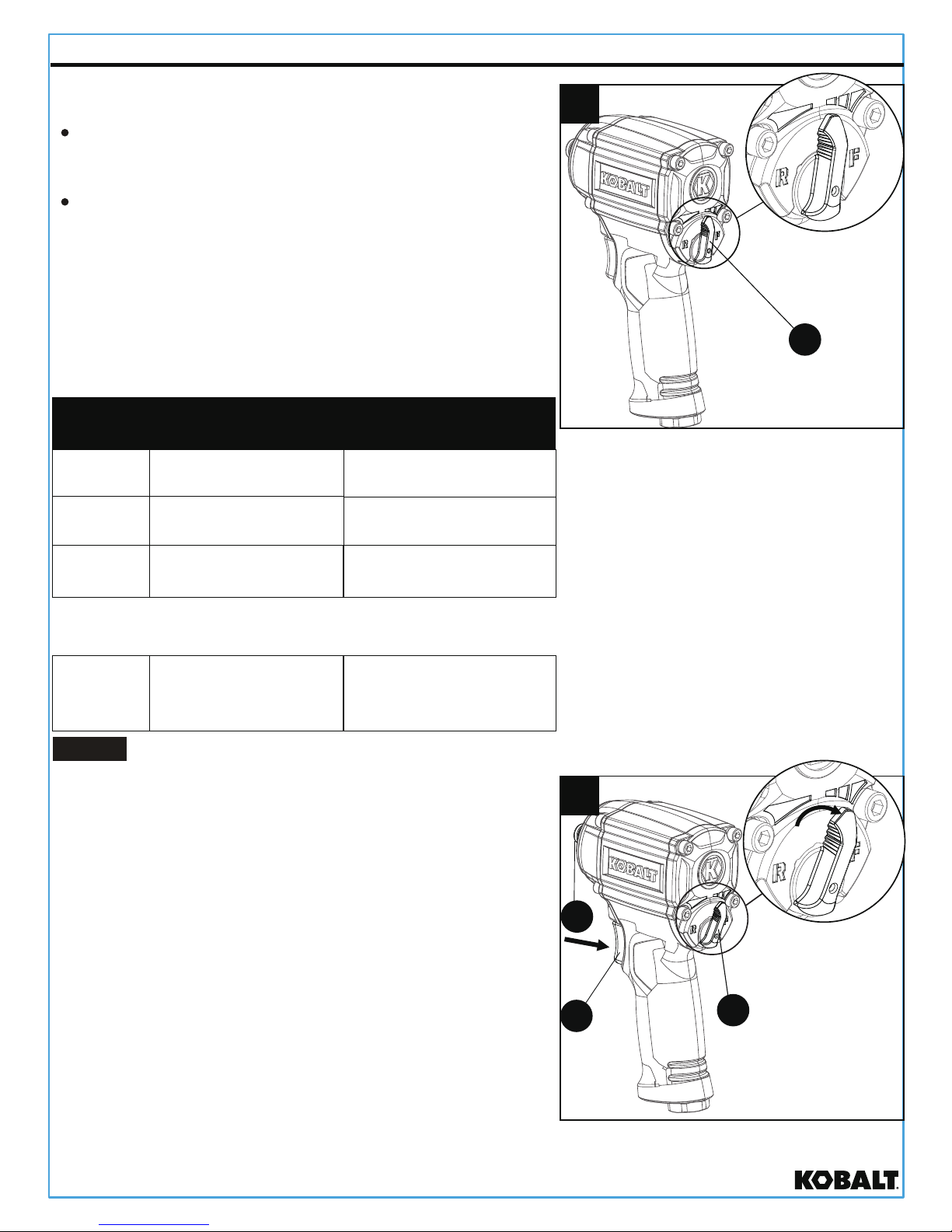

1.This tool features a switch (D) that has

two functions:

Control the direction of spin: Forward (“F”)

to tighten or Reverse (“R”) to loosen the

fastener.

Set the amount of torque applied to the

fastener in the Forward (“F”) position:

Settings Low, Middle or High.

The Forward (“F”) settings Low, Middle and

High provide reference torque as shown

below. Choose the correct torque setting to

mount fasteners properly on the workpiece

as shown in Fig 1.

LOW

Middle

High

150 - 250 ft-lb

250 - 350 ft-lb

350 - 450 ft-lb

The Reverse (“R”) setting ALWAYS operates

at maximum power, as shown below:

R

≥450 ft-lb

Maximum power to

remove fastener from

workpiece.

Setting

Suggested Use

Torque in

Forward (“F”)

Least power to mount

fastener on workpiece

Medium power to

tighten fastener

Highest power to

tighten fastener

NOTE

Impact wrenches are NOT torque

wrenches.

Fasteners requiring a specific

torque must be checked with an appropriate

torque wrench after the fastener has been

tightened.

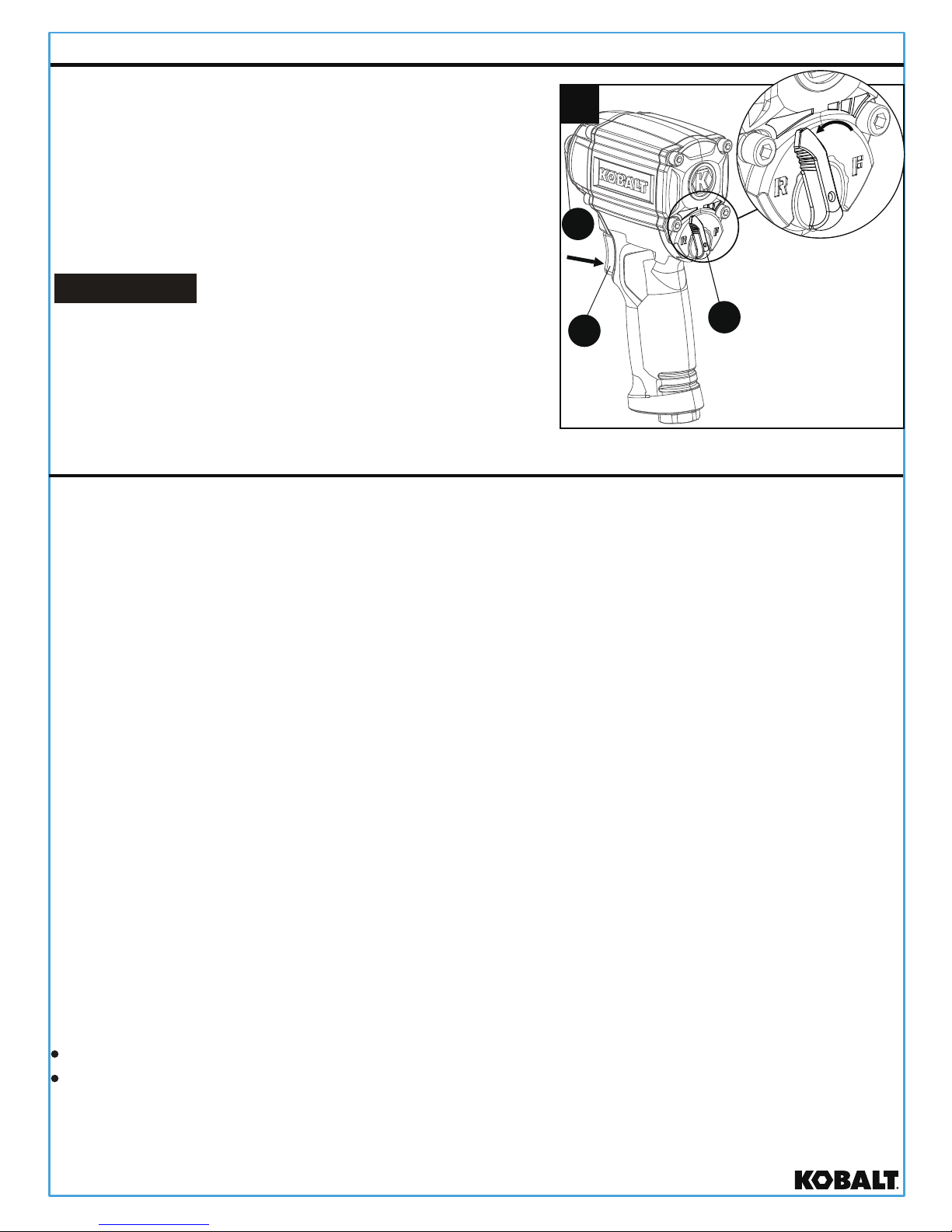

2.To install and tighten a threaded

fastener (not included), turn the switch (D)

to the right, until it clicks into place for the

desired setting.

Place the

socket (not included) over the threaded

fastener on the workpiece, apply

pressure and press the trigger (C).

The anvil (B) will spin clockwise to tighten

the threaded fastener down.

D

C

B

2

1

Page 14

kobalttools.com

14

OPERATING INSTRUCTIONS

CARE AND MAINTENANCE

3

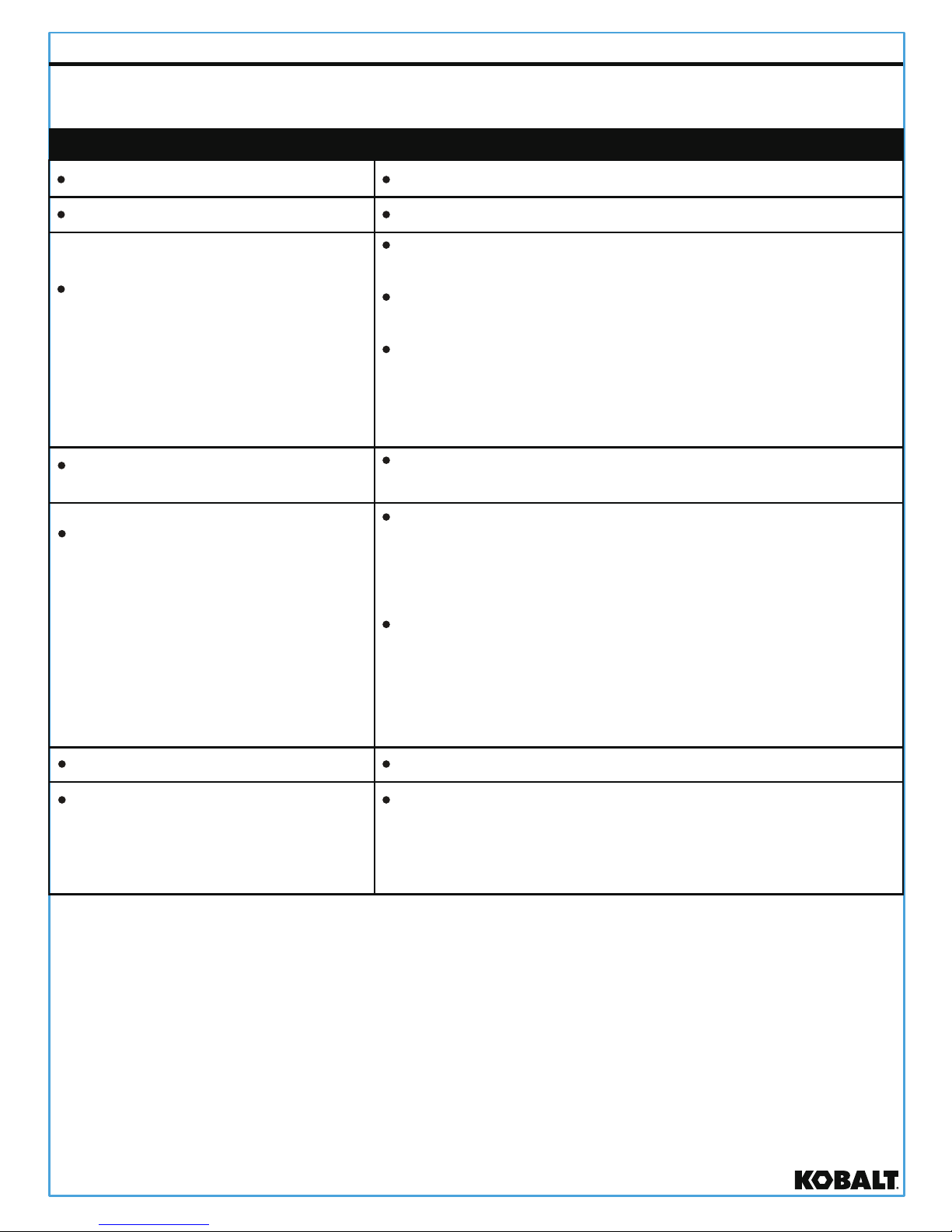

3.To loosen or remove a threaded fastener,

turn the

switch (D) to the left until it clicks

into place.

Place the socket over the

threaded fastener on the workpiece,

apply pressure and press trigger (C).

The anvil (B) will spin counterclockwise to

loosen the threaded fastener up.

D

C

B

WARNING:

Always make sure the

workpiece is secure. Never run the tool off

the workpiece. Do not apply excessive

force to the tool; let the tool perform the

work.

ALWAYS DISCONNECT TOOL FROM THE AIR SUPPLY BEFORE

PERFORMING ANY MAINTENANCE ON THE TOOL.

Always make sure the tool is properly lubricated during operation. Proper

lubrication is shown in this instruction manual.

An in-line oiler (not included) is recommended to help increase tool life and

keep the tool properly lubricated. The in-line oiler should be regularly

checked and filled with air tool oil as needed. Proper adjustment of the in-line

oiler can be performed by placing a sheet of paper next to the tool’s exhaust

ports while holding the throttle completely open for 30 seconds. When a light

stain of oil collects on the paper, the oiler is properly adjusted. Excessive

amounts of oil should be avoided.

Clean the entire tool with a cotton rag after each use. If storing the tool for an

extended period, it should be lubricated and run for approximately 30

seconds to ensure oil has been evenly distributed throughout the tool. Always

store tools in a clean, dry environment away from the reach of children.

Recommended lubricants: air-tool oil or any other high-grade turbine oil

containing moisture absorbent, rust inhibitors, metal wetting agents and an

EP (Extreme Pressure) additive. Consult your local retailer for further

assistance in selecting air tool oil best suited for proper lubrication.

STORAGE:

Tool must be well cleaned and lightly lubricated before storing.

Store tool in a dry, safe place out of the reach of children.

Page 15

kobalttools.com

15

TROUBLESHOOTING

If the tool runs slowly or will not operate, check these possible problems and

take the required corrective action:

POSSIBLE PROBLEM SOLUTION

Grit or gum in tool.

No oil in tool.

Low air pressure.

Flush the tool with air-tool oil or gum solvent.

Lubricate the tool.

Adjust the regulator on the tool to the

maximum setting.

Adjust the compressor regulator to tool

maximum of 90 PSI.

NOTE: Air hoses may cause up to 15 PSI

loss in pressure, so you may need to set a

higher compressor output to maintain the

required pressure at the tool.

Tighten and seal hose fittings with sealing

tape if leaks are found.

Air hose leaks.

Pressure drops.

Be sure the hose is the proper size. Long

hoses or tools using large volumes of air may

require an internal diameter of 1/2 in. I.D. or

larger, depending on total hose length.

Do not use multiple hoses connected together

with quick-connect fittings. This causes

additional loss of pressure and reduces the

tool power. Use single hoses of the proper

length.

Replace rotor blade.Worn rotor blade.

Moisture blowing out of tool

exhaust.

Water in compressor tank; drain tank.

(See air compressor manual.) Oil the tool and

run until no water is evident. Oil the tool again

and run 1 – 2 seconds.

Page 16

kobalttools.com

16

WARRANTY

This tool is warranted by the manufacturer to the original purchaser from the

original purchase date for three (3) years subject to the warranty coverage

described herein. This tool is warranted to the original user to be free from

defect in material and workmanship. If you believe that a tool is defective,

return the tool, with proper proof of purchase to the point of purchase. If it is

determined that the tool is defective and covered by this warranty, the

distributor will replace the tool or refund the purchase price.

This warranty is void if: defects in materials or workmanship or damages

result from repairs or alterations which have been made or attempted by

others or the unauthorized use of nonconforming parts; the damage is due to

normal wear, damage is due to abuse (including overloading of the tool

beyond capacity), improper maintenance, neglect or accident; or the damage

is due to the use of the tool after partial failure or use with improper

accessories or unauthorized repair or alteration.

This warranty gives you specific legal rights, and you may also have other

rights that vary from state to state. For warranty questions, call our Customer

Service Department at 1-888-3KOBALT, 8:00 a.m. – 8:00 p.m., EST,

Monday – Friday.

Printed in China

Kobalt® is a registered trademark of LF, LLC.

All rights reserved.

Page 17

JOIGNEZ VOTRE REÇU ICI

Numéro de série Date d'achat

Des questions, des problèmes, des pièces manquantes? Avant

de retourner l'article au détaillant, communiquez avec notre service

à la clientèle au 1 888 3KOBALT, entre 8 h et 20 h (HNE), du lundi

au vendredi.

ARTICLE #0840781

MODÈLE #SGY-AIR185

1,27 CM CLÉ À

CHOCS COMPACTE

kobalttools.com

17

Kobalt est une marque de commerce

déposée de LF, LLC. Tous droits réservés.

®

Page 18

kobalttools.com

18

TABLE DES MATIÈRES

Consignes de sécurité..................................................................................19

Exigences relatives au compresseur............................................................18

Contenu de l’emballage................................................................................27

Caractéristiques du produit...........................................................................19

Préparation...................................................................................................27

Instructions pour l’assemblage.....................................................................28

Mode d’emploi..............................................................................................30

Entretien.......................................................................................................31

Dépannage...................................................................................................32

Garantie........................................................................................................33

EXIGENCES RELATIVES AU COMPRESSEUR

5.3

SCFM90PSI

Tool Requirements

Exigences relatives aux outils

Requisitos de herramientas

@

IMPORTANT : Cet outil nécessite un débit d'air d'au moins 5.3 pi3 par minute

à une pression de 90 lb/psi

2

.

L’utilisation d’un tuyau à air peut entraîner une chute de pression allant

jusqu’à 15 lb/po

2

. Il faut donc augmenter la pression venant du compresseur

afin de compenser cette chute et de maintenir un niveau adéquat à l’outil.

Vérifiez les spécifications de votre compresseur d’air afin de vous assurer

qu’il satisfait aux exigences (pi

3

/min et lb/po2) de l’outil.

Page 19

kobalttools.com

19

CARACTÉRISTIQUES DU PRODUIT

CARACTÉRISTIQUES

12,7 mm

10 000 tours/minute

62,21 kgf/m

0,15 m

3

/mi

1/4 po NPT

3/8 po

90 lb /po

2

COMPOSANTE

LARGEUR DE L' EMBOUT CARRÉ

VITESSE

COUPLE MAXIMAL

CONSOMMATION D'AIR MOYENNE

ENTRÉE D'AIR

TUYAU À AIR RECOMMANDÉ

PRESSI ON DE SERVICE

CONSIGNES DE SÉCURITÉ

Veuillez vous assurer de lire et de comprendre l’intégralité du présent guide

avant d’assembler, faire fonctionner ou entretenir cet article. Si vous avez

des questions, veuillez téléphoner au service à la clientèle au

1 888 3KOBALT, entre 8 h et 20 h (HNE), du lundi au vendredi.

AVERTISSEMENT

AVERTISSEMENT

Une utilisation ou un entretien inadéquat de ce produit peut causer des

blessures graves ou des dommages matériels. Assurez-vous de lire et de

comprendre tous les avertissements et toutes les instructions concernant ce

produit avant de l’utiliser. Lorsque vous utilisez un outil pneumatique,

observez toujours les mesures de sécurité de base afin de réduire les risques

de blessure. Utilisez uniquement un outil, quel qu’il soit, pour l’usage auquel il

est destiné. N’utilisez pas cet article dans des conditions de travail

dangereuses. Il est toujours recommandé d’avoir un extincteur d’incendie et

une trousse de premiers soins à proximité des aires de travail.

LE NON-RESPECT DES CONSIGNES DE SÉCURITÉ PEUT ENTRAÎNER

DE GRAVES BLESSURES OU LAMORT.

La poussière créée pendant la pulvérisation de peinture, le ponçage, le sciage, le

polissage, le perçage et d’autres activités est reconnue par l’État de la Californie

comme étant la cause de cancers, d’anomalies congénitales et d’autres

problèmes liés aux fonctions reproductrices. Vous pouvez obtenir la liste de ces

produits chimiques au www.oehha.ca.gov conformément à la proposition 65.Voici

des exemples de ces produits chimiques :

•

le plomb contenu dans la peinture au plomb;

•

la silice cristalline provenant de la brique, du ciment ou d’autres matériaux de

maçonnerie;

•

l’arsenic et le chrome provenant du bois d’oeuvre traité avec un produit chimique.

Les risques liés à l’exposition à ces produits varient en fonction de la fréquence à

laquelle vous effectuez ce type de travaux. Afin de limiter votre exposition à ces

produits chimiques, travaillez dans un endroit bien ventilé et utilisez de

l’équipement de sécurité approuvé, tel qu’un appareil respiratoire ou un masque

antipoussière conçus spécialement pour filtrer les particules microscopiques.

Page 20

kobalttools.com

20

CONSIGNES DE SÉCURITÉ

RISQUES DE BLESSURE AUX YEUX OU À LA TÊTE

AVERTISSEMENT

RISQUE

MESURES PRÉVENTIVES

RISQUE

MESURES PRÉVENTIVES

Cet outil pneumatique peut projeter

des fixations, des fragments de

métal et d’autres débris, ce qui peut

causer des blessures graves.

Portez toujours des lunettes de

sécurité conformes à la norme

ANSI Z87.1 et pourvues d’écrans

latéraux.

Ne laissez jamais un outil sous

pression sans surveillance.

Débranchez l’outil de l’alimentation

en air lorsque vous ne l’utilisez pas

ou lorsque vous changez

d’accessoire, afin d’éviter qu’il se

déclenche accidentellement.

RISQUE DE PERTE AUDITIVE

Portez toujours des protecteurs

auditifs conformes à la norme

ANSI S3.19.

L’air comprimé peut être dangereux,

car il est susceptible de projeter des

objets ou des particules pouvant

causer des blessures aux tissus

mous du corps, notamment les yeux

et les oreilles.

Ne pointez jamais le jet d’air vers

vous-même ou une autre personne.

Pour plus de protection, utilisez un

écran facial approuvé et portez des

lunettes de sécurité.

Les accessoires de l’outil peuvent se

desserrer ou se briser et se détacher.

Ils peuvent ainsi se transformer en

projectiles ou percuter d’autres objets

et les projeter vers l’utilisateur ou

d’autres personnes se trouvant dans

la zone de travail.

Assurez-vous que tous les

accessoires sont bien assemblés et

correctement fixés avant d’utiliser

l’article.

Utilisez toujours l’outil à une distance

sécuritaire des autres personnes

présentes dans l’aire de travail.

Assurez-vous que les mesures de

sécurité dans l’aire de travail sont

connues en tout temps.

L’exposition au bruit produit par les

outils pneumatiques peut entraîner

une perte auditive permanente.

AVERTISSEMENT

Page 21

kobalttools.com

21

CONSIGNES DE SÉCURITÉ

RISQUE

MESURES PRÉVENTIVES

RISQUES D’INCENDIE OU D’EXPLOSION

AVERTISSEMENT

RISQUE

MESURES PRÉVENTIVES

RISQUE D’EMMÊLEMENT

AVERTISSEMENT

Cet outil peut produire des étincelles

susceptibles d’enflammer certains

matériaux.

N’utilisez jamais un outil à proximité

d’une substance inflammable

comme de l’essence, du naphta, des

solvants de nettoyage, etc.

Travaillez dans un endroit propre,

bien ventilé et dépourvu de

matériaux combustibles.

Il n’est pas recommandé d’utiliser

cet outil dans un endroit présentant

un risque d’explosion ni sous l’eau.

Ne portez pas de vêtements amples,

de bijoux ni tout autre article qui

pourrait s’accrocher ou s’emmêler dans

l’outil, le tuyau ou la pièce travaillée.

Gardez toujours vos mains et les

autres parties de votre corps à

distance des pièces en mouvement.

Portez toujours un respirateur ou un

écran facial bien ajusté lorsque vous

utilisez ce genre d’outils.

N’utilisez jamais d’oxygène, de

dioxyde de carbone ni d’autre gaz

embouteillé comme source

d’alimentation pour les outils

pneumatiques. Utilisez seulement

une alimentation en air propre et sec

à la pression indiquée.

Les chiffons et autres matériaux

inflammables qui entrent en contact

avec l’outil doivent être jetés de

manière adéquate dans un

contenant en métal bien fermé.

Les outils qui contiennent ou

déplacent des pièces mobiles, par

exemple les douilles à choc, peuvent

s’emmêler dans les cheveux, les

bijoux ou les vêtements amples et

causer des blessures graves.

Le fouettement du tuyau peut causer

des blessures graves. Vérifiez toujours

si le tuyau n’est pas endommagé ou si

ses raccords ne sont pas desserrés

avant d’utiliser l’outil.

Page 22

kobalttools.com

22

CONSIGNES DE SÉCURITÉ

RISQUE DE COUPURE OU DE BRÛLURE

AVERTISSEMENT

RISQUE

MESURES PRÉVENTIVES

Les outils pneumatiques peuvent

causer des blessures graves s’ils

sont utilisés d’une manière

inadéquate ou autre que celle pour

laquelle ils sont conçus. La friction

des accessoires sur les pièces

travaillées peut rendre ces derniers

extrêmement chauds.

Portez des gants lorsque vous

utilisez des outils.

Prenez garde à vos mains lorsque

vous utilisez I’outil.

Ne touchez pas les accessoires à

mains nues pendant l’utilisation ni

immédiatement après.

RISQUE DE CHOC ÉLECTRIQUE

AVERTISSEMENT

RISQUE

MESURES PRÉVENTIVES

Cet outil n’est PAS isolé

électriquement. Lorsque l’outil entre

en contact avec un fil sous tension,

ses parties métalliques exposées

peuvent causer des chocs

électriques, des blessures par

électrocution ou la mort.

N’utilisez jamais d’outils pneumatiques

dans des endroits où ils pourraient entrer

en contact avec des fils sous tension.

Évitez de toucher à des surfaces

mises à la terre, par exemple un tuyau,

un radiateur, une cuisinière ou un

réfrigérateur. Le contact de votre corps

avec une surface mise à la terre

augmente les risques de choc électrique.

Dans la mesure du possible, il est

RISQUE DE BLESSURE

AVERTISSEMENT

RISQUE

MESURES PRÉVENTIVES

Lorsque vous n’utilisez pas l’outil,

rangez-le dans un endroit sécuritaire,

hors de la portée des enfants et

autres personnes inexpérimentées,

et débranchez le tuyau à air.

recommandé de porter des vêtements

non conducteurs et des chaussures

antidérapantes lorsque vous utilisez

des outils.

Avant de commencer à travailler,

vérifiez soigneusement la surface

pour déceler les fils dissimulés.

Le contact d’accessoires comme les

douilles à choc avec des fils électriques

dissimulés peut causer des chocs

électriques potentiellement mortels.

Si vous laissez un outil sans

surveillance, il risque d’être mis en

marche par une personne non

autorisée ou non expérimentée,

laquelle risque de se blesser ou de

blesser d’autres personnes.

Page 23

kobalttools.com

23

CONSIGNES DE SÉCURITÉ

RISQUE DE BLESSURE

AVERTISSEMENT

RISQUE

MESURES PRÉVENTIVES

Les outils pneumatiques peuvent

projeter des pièces de fixation ou

d’autres objets dans l’aire de travail.

Ne jamais faire fonctionner l'outil de

la pièce.

N’utilisez que des pièces, attaches et

accessoires recommandés par le

fabricant.

Maintenir la sensibilisation de la

sécurité de la zone de travail à tout

moment. Toujours être au courant des

autres personnes autour de la zone

de travail pour assurer la sécurité.

Gardez l’aire de travail propre,

dépourvue de débris et bien éclairée.

Ne laissez pas les enfants utiliser

l’outil et gardez les enfants à distance

de l’aire de travail.

Les douilles qui sont restées fixées à

une pièce rotative de l’outil peuvent

être projetées, ce qui augmente les

risques de blessure.

N’utilisez que des accessoires

recommandés par le fabricant pour

l’outil.

Retirez toujours les douilles et

rangez-les après leur utilisation.

Les outils pneumatiques peuvent être

accidentellement mis en marche

lorsque vous les manipulez, que vous

changez d’outil ou que vous effectuez

un entretien ou une réparation.

Débranchez l’outil de l’alimentation

en air avant de changer d’outil ou

d’effectuer un entretien ou une

réparation.

Ne tenez jamais l’outil par le tuyau à air.

Tenez toujours l’outil par la poignée.

Seuls les représentants autorisés

devraient effectuer l’entretien et les

réparations de l’outil.

Afin d’éviter de mettre l’outil en

marche accidentellement, ne le

transportez jamais en maintenant la

gâchette enfoncée. Ne bloquez pas

la gâchette, que ce soit à l’aide de

ruban adhésif, de câble ou autre, pour

obtenir un fonctionnement en continu.

Assurez-vous que la pièce travaillée

est toujours solidement fixée en place.

L’utilisation d’un accessoire qui n’est

pas conçu pour l’outil augmente les

risques de blessure.

Page 24

kobalttools.com

24

CONSIGNES DE SÉCURITÉ

RISQUE DE BLESSURE

AVERTISSEMENT

RISQUE

MESURES PRÉVENTIVES

Il ya un risque d'éclatement si l'outil

est endommagé.

Vérifiez tout désalignement ou

coincement des pièces mobiles, des

pièces cassées et d'autres conditions

qui affectent le fonctionnement de

l'outil en toute sécurité.

Une perte de maîtrise de l’outil peut

causer des blessures à l’utilisateur

ou aux autres personnes présentes

dans l’aire de travail.

Coupez toujours l’alimentation en air

et évacuez toujours la pression d’air

du tuyau avant de changer les

accessoires ou d’effectuer des

réparations. Lorsque vous n’utilisez

pas l’outil, débranchez-le de

l’alimentation en air et rangez-le dans

un endroit sécuritaire.

N’utilisez jamais I’outil sous I’effet de

drogues ou de I’alcool.

Évitez de tendre les bras trop loin ou

de vous étirer pour utiliser l’outil.

Gardez une posture sécuritaire en tout

temps lorsque vous manipulez l’outil.

Les glissades, les pertes d’équilibre ou

les chutes sont des causes importantes

de blessures ou de décès.

Gardez les poignées de l’outil sèches,

propres, et exemptes d’huile et de

graisse.

Faites attention à l’excédent du tuyau

à air. aux prises d’alimentation, ainsi

qu’à tout autre obstacle ou danger

présent dans l’aire de travail.

Soyez vigilant. Prêtez attention à ce

que vous faites. Usez de votre

jugement. N’utilisez pas d’outils si

vous êtes fatigué.

Les utilisateurs doivent être en mesure

de supporter facilement le poids de

l’article au complet lorsque celui-ci

fonctionne et d’en assurer le plein

contrôle en tout temps.

Page 25

kobalttools.com

25

CONSIGNES DE SÉCURITÉ

RISQUE DE BLESSURE

AVERTISSEMENT

RISQUE

MESURES PRÉVENTIVES

Des accessoires de mauvaise

qualité, endommagés ou

inappropriés peuvent se détacher

ou être projetés lors de l’utilisation

et envoyer des débris dans l’aire de

travail, ce qui peut entraîner des

blessures graves.

N’utilisez jamais un outil qui a subi un

impact, qui a été endommagé ou qui

semble mal fonctionner. N’utilisez jamais

d’outils qui présentent des fuites d’air ou

dont des pièces manquent. Retirez

immédiatement les outils endommagés

ou défaillants de l’aire de travail.

N’excédez pas la pression recommandée

pour le fonctionnement des pièces

(p. ex., tuyaux et raccords) de l’outil.

N’utilisez que des douilles à choc avec

les outils pneumatiques à choc. N’utilisez

que des accessoires qui conviennent à la

vitesse de l’outil. Ne modifiez pas les

outils ni les accessoires.

N’exercez pas une pression excessive

sur l’outil; laissez-le accomplir la tâche

lui-même.

Suivez les instructions pour la

lubrification afin d’assurer un

fonctionnement optimal et sécuritaire.

Suivez toujours les instructions pour

l’assemblage, l’utilisation, l’entretien

et les réparations.

Tenez les tuyaux éloignés des sources

de chaleur, de l’huile et des objets

coupants. Vérifiez toujours l’état des

tuyaux à air avant chaque utilisation et

assurez-vous qu’ils sont correctement

raccordés.

Entretenez soigneusement l’outil et les

accessoires.

Ne faites pas un usage

abusif des tuyaux ou des raccords.

Gardez les outils propres et

ad

é

quatement huilés pour un rendement

optimal et s

é

curitaire.

Outils et accessoires mal

entretenus peuvent causer

des blessures graves.

Page 26

kobalttools.com

26

CONSIGNES DE SÉCURITÉ

RISQUE DE BLESSURE

AVERTISSEMENT

RISQUE

MESURES PRÉVENTIVES

RISQUES D’INHALATION

AVERTISSEMENT

RISQUE

MESURES PRÉVENTIVES

L’utilisation d’un accessoire qui

n’est pas conçu pour un outil donné

augmente les risques de blessure

pour l’utilisateur et les personnes

qui se trouvent dans l’aire de travail.

N’utilisez que des accessoires et des

outils de travail conçus pour l’outil et

la tâche à effectuer.

Ne modifiez pas les outils ni les

accessoires, et ne tentez pas d’en créer.

Les mouvements répétitifs, les

positions inconfortables et

l’exposition aux vibrations peuvent

présenter un danger pour les mains

et les bras.

Cessez d’utiliser l’outil si vous

ressentez un inconfort, un picotement

ou une douleur. Consultez un médecin

avant d’utiliser l’outil de nouveau si

vous éprouvez l’un de ces symptômes.

Les outils abrasifs comme les

meuleuses, les ponceuses et les

outils à tronçonner engendrent de la

poussière et des matériaux abrasifs

pouvant causer des dommages aux

poumons et au système respiratoire.

Les pistolets à peinture émettent des

vapeurs pouvant causer des

dommages aux poumons et au

système respiratoire.

Certains matériaux, notamment

les adhésifs et le goudron,

contiennent des produits chimiques

dont les vapeurs peuvent être très

nocives après une exposition

prolongée.

Portez toujours un respirateur ou un

écran facial bien ajusté lorsque vous

utilisez ce genre d’outils.

Travaillez toujours dans un endroit

propre, sec et bien ventilé. Vous

devez savoir quels sont les produits

chimiques présents dans l’aire de

travail et lire toutes les fiches

signalétiques correspondantes.

Page 27

kobalttools.com

27

CONTENU DE L'EMBALLAGE

PRÉPARATION

DESCRIPTION

Clé

Butée (préassemblé à la clé [A])

Gâchette (préassemblé à la clé [A])

Interrupteur (préassemblé à la clé [A])

Entrée d’air (préassemblé à la clé [A])

QUANTITÉ

1

1

1

1

1

1

PIÈCE

A

B

C

D

E

F

E

A

D

B

C

• Clé à molette ou clé de 9/16 po

Avant de commencer l’assemblage de l’outil, assurez-vous d’avoir toutes les

pièces. Comparez le contenu de l’emballage avec la liste des pièces. S’il y a

des pièces manquantes ou endommagées, ne tentez pas d’assembler le

produit.

Temps d’assemblage approximatif : de 1 à 3 minutes.

Outils et matériel nécessaires pour l’assemblage (non inclus) :

Connecteur mâle de 0,25 po

•

Ruban d’étanchéité

• Huile pour outils pneumatiques (REMARQUE : L’huile pour outils

pneumatiques est différente de l’huile pour compresseur. L’utilisation d’huile

pour compresseur dans cet outil pourrait l’endommager et réduire sa durée

de vie. N’utilisez que de l’huile pour outils pneumatiques dans cet outil.)

F

Page 28

kobalttools.com

28

INSTRUCTIONS POUR L’ASSEMBLAGE

1. Retirez le capuchon protecteur en

plastique de l’entrée d’air (E) de l’outil.

1

2

3

REMARQUE

2. Préparez le connecteur mâle de 1/4 po en

enroulant du ruban d’étanchéité

(non inclus) sur son filetage dans le sens

des aiguilles d’une montre. Vissez à la

main le connecteur fileté mâle à l’entrée

d’air (E), puis serrez à l’aide d’une clé

(non incluse) afin que le raccord soit

étanche à l’air.

Évitez de serrer excessivement.

Utilisez du ruban d’étanchéité

pour ce raccordement.

3. Sélectionnez la bonne douille à choc

(non incluse) pour serrer ou desserrer la

pièce de fixation filetée, et enclenchez-la

sur la butée (B).

B

N’utilisez que des adaptateurs et des douilles

prenant en charge un couple nominal

équivalent ou supérieur à celui de l’outil.

Assurez-vous toujours que les adaptateurs

et les douilles sont bien installés et fixés

avant d’utiliser l’outil. Les accessoires

desserrés peuvent se briser et être projetés,

ce qui peut causer de graves blessures à

l’utilisateur ou à d’autres personnes présentes

dans l’aire de travail.Suivez toujours

l’ensemble des instructions du fabricant des

accessoires pour bien fixer et utiliser ces

derniers.

AVERTISSEMENT

Page 29

kobalttools.com

29

INSTRUCTIONS POUR L’ASSEMBLAGE

4

5

6

B

4. Si vous avez besoin d’une plus grande

portée, enclenchez une

rallonge (non incluse) sur la butée (B),

puis fixez la douille à l’adaptateur.

REMARQUE

5. Versez deux ou trois gouttes d’huile à outil

pneumatique (non inclus) dans le

connecteur mâle avant chaque utilisation

(consultez la figure 5).

6. Branchez le tuyau d’alimentation en

air (non inclus) sur le connecteur mâle en

vous assurant qu’il est bien enfoncé et fixé.

Pour un fonctionnement optimal, réglez la

pression de service à 6,32 kg/cm².

Pour fonctionner correctement,

cet outil nécessite un débit d'air d'au moins

5,3 pieds cubes par minute (SCFM) à

90 livres par pouce carré (PSI) à l'outil.

important de bien lubrifier l’outil pour

préserver sa performance et éviter de

l’endommager. Lubrifiez toujours l’outil

avant de l’utiliser si vous n’avez pas

recours à un huileur en ligne.

Il est EXTRÊMEMENT

REMARQUE

Page 30

kobalttools.com

30

MODE D’EMPLOI

D

1. Cet outil est doté d’un bouton de réglage

du couple (D) associé à deux fonctions :

le contrôle du sens de rotation : serrage

(« F ») et desserrage (« R »);

Pour régler le couple appliqué à la pièce

de fixation à la position « F » (serrage) :

Réglages : faible, moyen ou puissant.

Le couple associé aux réglages de serrage

faible, moyen et puissant est indiqué

ci-dessous. Choisissez le couple adéquat pour

installer les pièces de fixation de façon

adéquate sur la pièce travaillée, comme

l’illustre la figure 1.

Faible

Moyen

Puissant

20,73 à 34,56 kgf/m

34,56 à 48,38 kgf/m

48,38 à 62,21 kgf/m

Le desserrage (« R ») s’effectue TOUJOURS

à puissance maximale, c’est-à-dire :

R ≥ 62,21 kgf/m

Puissance maximale pour retirer la

pièce de fixation de la pièce travaillée

Réglage Utilisation suggérée

Couple de

serrage (« F »)

Puissance la plus faible pour installer la

pièce de fixation sur la pièce travaillée

Puissance moyenne pour

serrer la pièce de fixation

Puissance la plus élevée

pour serrer l a pièce de fixation

REMARQUE

Les clés à choc ne sont PAS des

clés dynamométriques. Les pièces de fixation

qui doivent être posées avec un couple

donné doivent faire l’objet d’une vérification à

l’aide d’une clé dynamométrique une fois la

pièce de fixation serrée.

2. Pour installer et serrer une pièce de

fixation filetée (non incluse), tournez

l’interrupteur (D) vers la droite jusqu’à ce

qu’il s’enclenche sur le réglage voulu.

Placez la douille (non incluse) sur la pièce

de fixation filetée se trouvant sur la pièce

à travailler. Appliquez une certaine

pression et appuyez sur la gâchette (C). La

butée (B) tournera dans le sens des

aiguilles d’une montre afin de serrer la

pièce de fixation filetée.

D

C

B

2

1

Page 31

kobalttools.com

31

MODE D’EMPLOI

ENTRETIEN

3

3. Pour desserrer ou retirer une pièce de

fixation filetée, tournez l’interrupteur (D)

vers la gauche jusqu’à ce qu’il

s’enclenche. Placez la douille sur la pièce

de fixation filetée se trouvant sur la pièce

à travailler. Appliquez une certaine

pression et appuyez sur la gâchette (C).

La butée (B) tournera dans le sens

contraire des aiguilles d’une montre afin

de desserrer la pièce de fixation filetée.

D

C

B

AVERTISSEMENT

Assurez-vous que la

pièce travaillée est toujours solidement

fixée en place. Ne faites jamais

fonctionner l’outil sans pièce à travailler. N’exercez pas une pression

excessive sur l’outil; laissez-le accomplir la tâche lui-même.

COUPEZ TOUJOURS L’ALIMENTATION EN AIR AVANT D’EFFECTUER

TOUT ENTRETIEN DE L’OUTIL.

Assurez-vous que l’outil est toujours correctement lubrifié pendant

l’utilisation. Les conditions de lubrification appropriées sont indiquées dans le

présent manuel. Il est recommandé d’employer un huileur en ligne

(non inclus), car celui-ci contribue à prolonger la durée de vie de l’outil tout

en lubrifiant ce dernier. Le graisseur en ligne doit être régulièrement vérifié et

rempli avec de l'huile de l'outil de l'air au besoin. Pour vérifier si l’huileur en

ligne est réglé correctement, vous pouvez placer une feuille de papier à côté

des orifices d’échappement de l’outil et maintenir la soupape complètement

ouverte pendant environ 30 secondes. Si une légère tache d’huile se forme

sur le papier, le réglage de l’huileur est adéquat. Évitez de lubrifier

excessivement l’outil.

Nettoyez l’outil en entier à l’aide d’un linge en coton après chaque utilisation.

Si l’outil est resté rangé pendant une longue période, vous devez bien le

lubrifier et le faire fonctionner pendant environ 30 secondes pour vous

assurer que l’huile a été répartie uniformément dans l’outil. Rangez toujours

l’outil dans un endroit propre et sec, hors de la portée des enfants.

Lubrifiants recommandés : Utilisez de l’huile pour outil pneumatique ou toute

autre huile de qualité pour turbine contenant un absorbant d’humidité, des

antioxydants, des agents mouillant pour le métal et un additif EP(extrême

pression). Veuillez communiquer avec votre détaillant local pour savoir quelle

huile pour outil pneumatique offrira la meilleure lubrification de votre outil.

Nettoyez adéquatement l’outil et lubrifiez-le légèrement avant de le ranger.

Rangez l’outil pneumatique dans un endroit sec et sûr,

hors de la portée des enfants.

RANGEMENT :

Page 32

kobalttools.com

32

PROBLÈME

De la gomme ou des cailloux

se sont logés dans l’outil.

DÉPANNAGE

Si l'outil fonctionne lentement ou ne fonctionne pas, vérifier ces problèmes

possibles et prendre les mesures correctives nécessaires:

MESURE CORRECTIVE

L’outil manque d’huile.

La pression d’air est trop

faible.

Le tuyau à air fuit.

La pression chute.

La pale du rotor est usée.

De l’humidité s’échappe

des orifices de l’outil.

Remplacez la pale du rotor.

Rincez l’outil avec de l’huile pour outil

pneumatique ou du dissolvant de gomme.

Lubrifiez l’outil.

Réglez le régulateur de l’outil à son maximum.

Réglez le régulateur du compresseur de l’outil

à sa pression manométrique maximale, soit

90 lb/po

2

.

REMARQUE: L’utilisation d’un tuyau à air

peut entraîner une chute de pression allant

jusqu’à 1,05 kg/m

2

. Il peut donc s’avérer

nécessaire d’augmenter la pression venant du

compresseur afin de maintenir un niveau

adéquat à l’outil.

Si vous décelez des fuites, serrez les raccords

du tuyau et scellez-le à l’aide de ruban

d’étanchéité.

Assurez-vous que le tuyau est de dimensions

appropriées. Un tuyau long ou des outils

utilisant de grandes quantités d’air peuvent

nécessiter un tuyau de 1/2 po de diamètre

intérieur ou plus, selon la longueur totale des

tuyaux.

N’utilisez pas des tuyaux multiples reliés par

des raccords à branchement rapide;

ceux-ci engendrent des chutes de pression

supplémentaires et diminuent la puissance de

l’outil. Utilisez plutôt un seul tuyau de la bonne

longueur.

De l’eau s’est accumulée dans le réservoir

évacuez-la (consultez le manuel du

compresseur d’air). Lubrifiez l’outil et faites-le

fonctionner jusqu’à ce qu’il n’y ait plus de

trace d’eau. Lubrifiez de nouveau l’outil et

faites-le fonctionner pendant une ou deux

secondes.

Page 33

kobalttools.com

33

GARANTIE

Cet outil est garanti par le fabricant pour une période de trois (3) ans à partir

de la date d’achat, selon les modalités décrites aux présentes.

Cette garantie sera annulée si : les défauts de matériaux ou de fabrication ou

les dommages résultent de réparations ou de modifications non autorisées,

de l’utilisation de pièces non conformes, de l’usure normale, d’un usage

abusif (notamment une surcharge de l’outil), d’un entretien inadéquat, d’une

négligence, d’un accident, d’une utilisation après une défaillance partielle ou

de l’utilisation d’accessoires inappropriés.

Cette garantie vous confère des droits précis. II est possible que vous

disposiez également d’autres droits, qui varient d’un État ou d’une province

à l’autre.

Pour toute question concernant la garantie, communiquez avec le service à

la clientèle au 1 888 3KOBALT, entre 8 h et 20 h (HNE), du lundi au vendredi.

Cet outil est garanti contre les défauts de matériaux et de fabrication. Si vous

croyez qu’il est défectueux, retournez-le, accompagné d’une preuve d’achat

acceptable, au point de vente d’origine. Si l’outil est jugé défectueux et qu’il

est couvert par la présente garantie, le distributeur l’échangera ou vous

remboursera le prix d’achat.

Imprimé en Chine

Kobalt est une marque de commerce déposée

de LF, LLC. Tous droits réservés.

®

Page 34

¿Preguntas, problemas, piezas faltantes? Antes de volver a la

tienda, llame a nuestro Departamento de Servicio al Cliente al

1-888-3KOBALT, de lunes a viernes de 8:00 a.m. a 8:00 p.m., hora

estándar del Este.

ARTÍCULO #0840781

MODELO #SGY-AIR185

LLAVE DE PERCUSIÓN

COMPACTA DE 1/2 PULG

kobalttools.com

34

Kobalt es marcas registradas

de LF, LLC. Todos los derechos reservados.

®

ADJUNTE SU RECIBO AQUÍ

Número de serie

Fecha de compra

Page 35

kobalttools.com

35

ÍNDICE

Información de seguridad ............................................................................36

Requerimientos del compresor ....................................................................35

Contenido del paquete ................................................................................44

Especificaciones del producto .....................................................................36

Preparación .................................................................................................44

Instrucciones de ensamblaje .......................................................................45

Instrucciones de funcionamiento .................................................................47

Cuidado y mantenimiento ............................................................................48

Solución de problemas ................................................................................49

Garant

ía .......................................................................................................50

5.3

SCFM90PSI

Tool Requirements

Exigences relatives aux outils

Requisitos de herramientas

@

REQUERIMIENTOS DEL COMPRESOR

IMPORTANTE: para funcionar de manera correcta, esta herramienta

requiere un flujo de aire de por lo menos 5,3 pies cúbicos por minutos

(SCFM por sus siglas en inglés) para 90 libras por pulgada cuadrada

(PSI, por sus siglas en inglés).

Las mangueras de aire comprimido pueden causar pérdida de presión hasta

de 15 PSI, lo que requiere una potencia más alta del compresor para

compensar y mantener la presión requerida en la herramienta. Revise las

especificaciones de su compresor de aire para asegurarse de que admita

los requisitos de flujo de aire y de PSI de esta herramienta específica.

Page 36

kobalttools.com

36

ESPECIFICACIONES DEL PRODUCTO

1/2 pulg.

INFORMACIÓN DE SEGURIDAD

•

BROCA CUADRADA

VELOCIDAD

FUERZA MÁXIMA DE TORSIÓN

CONSUMO DE AIRE PROMEDIO

ENTRADA DE AIRE

MANGUERA DE AIRE COMPRIMIDO RECOMENDADA

PRESIÓN DE TRABAJO

10.000 RPM

204,11 kgf-m

0,15 M

3

/MIN

NPT de 1/4 pulg

3/8 pulg

90 PSI

Lea y comprenda completamente este manual antes de intentar

ensamblar, operar o darle mantenimiento a este producto. Si tiene alguna

pregunta, IIame al Departamento de Servicio al Cliente al 1-888-3KOBALT,

de lunes a viernes de 8:00 a.m. a 8:00 p.m., hora estándar del Este.

ADVERTENCIA

ADVERTENCIA

ESPECIFICACIONESCOMPONENTE

NO CUMPLIR NI SEGUIR LAS INSTRUCCIONES DE SEGURIDAD

PODRÍA PROVOCAR LESIONES O LA MUERTE.

EI uso o mantenimiento inadecuado de este producto puede ocasionar

lesiones graves y daños a la propiedad. Lea y comprenda todas las

advertencias e instrucciones de funcionamiento ante de usar este equipo.

Cuando utilice herramientas neumáticas, siga siempre las medidas de

precaución básicas para reducir el riesgo de lesiones personales. Use cada

una de las herramientas solo para el fin para el cual fue concebida. No use

este producto en condiciones de trabajo inseguras. Se recomienda tener

siempre un extintor de incendios y un kit de primeros auxilios cerca del área

de trabajo.

Parte del polvo producido por el lijado, el serruchado, la trituración y la

perforación eléctrica y otras actividades relacionadas contiene químicos

reconcidos por el estado de california como causantes de cáncer, defectos

congénitos u otros daños en el aparato reproductivo. Se puede obtener una

lista de las sustancias químicas en www.oehha.ca.gov bajo proposition 65

(propuesta 65). Algunos ejemplos de estas sustancias químicas son:

Plomo de pinturas a base de plomo

•

Arsénico y cromo de madera tratada con químicos

Su riesgo luego de estas exposiciones varía, dependiendo de cuán a

menudo realice este tipo de trabajo. Para reducir su exposición a estas

sustancias químicas, trabaje en un área bien ventilada y utilice un equipo de

seguridad apropiado o aprobado, como barbijos o mascarillas antipolvo que

estén especialmente diseñadas para filtrar partículas microscópicas.

•

Sílice cristalina de ladrillos, cemento y otros productos de

mampostería

Page 37

kobalttools.com

37

INFORMACIÓN DE SEGURIDAD

RIESGO DE LESIONES EN LOS OJOS O LA CABEZA

ADVERTENCIA

LO QUE PODRÍA OCURRIR CÓMO EVITARLO

LO QUE PODRÍA OCURRIR CÓMO EVITARLO

Esta herramienta neumática puede

lanzar materiales como sujetadores,

astillas de metal y otros residuos a

alta velocidad, lo que puede

provocar lesiones.

Use siempre gafas de seguridad con

protecciones laterales aprobadas por

la norma ANSI Z87.1.

Desconecte la herramienta del

suministro de aire cuando no esté en

uso o mientras cambia los

accesorios con el fin de prevenir

cualquier operación accidental.

RIESGO DE PÉRDIDA DE LA AUDICIÓN

El aire comprimido puede ser

peligroso ya que puede lanzar

objetos y partículas que pueden

causar lesiones a zonas de tejido

blando como los ojos y orejas.

Nunca deje una herramienta

presurizada sin supervisión.

Nunca dirija aire a usted mismo ni a

otras personas.

Para una protección adicional, use

una máscara protectora aprobada,

además de las gafas de seguridad.

Los accesorios de las herramientas

pueden soltarse o romperse y

desprenderse transformándose en

proyectiles, o pueden lanzar otros

objetos al usuario y los que estén en

la zona de trabajo.

Asegúrese de que todos los

accesorios estén ajustados

adecuadamente y bien asegurados

antes del uso.

Siempre use la herramienta a una

distancia segura de las demás

personas que se encuentran en el

lugar de trabajo. Manténgase

constantemente alerta con relación a

la seguridad del área de trabajo.

ADVERTENCIA

La exposición al ruido producido por

las herramientas neumáticas puede

producir la pérdida permanente de la

audición.

Use siempre protección para los

oídos aprobada por la norma

ANSI S3.19.

Page 38

kobalttools.com

38

INFORMACIÓN DE SEGURIDAD

LO QUE PODRÍA OCURRIR CÓMO EVITARLO

LO QUE PODRÍA OCURRIR CÓMO EVITARLO

RIESGO DE ENREDOS

RIESGO DE INCENDIO O EXPLOSIÓN

ADVERTENCIA

Nunca utilice oxígeno, dióxido de

carbono u otros gases embotellados

como fuente de alimentación para

las herramientas neumáticas.

Nunca use herramientas cerca de

sustancias inflamables como gasolina,

nafta, solventes de limpieza, etc.

Esta herramienta puede producir

chispas, las cuales podrían causar la

ignición de materiales inflamables.

No se recomienda la utilización de

esta herramienta en atmósferas en

las que exista riesgo de explosión o

bajo el agua

Nunca use oxígeno, dióxido de

carbono u otros gases embotellados

como fuente de energía para las

herramientas de aire. Use solo aire

limpio y seco con la presión indicada.

Los paños de limpieza y otros

residuos inflamables que puedan

haberse usado en la herramienta

deben colocarse en un recipiente

metálico herméticamente cerrado y

desecharse de manera adecuada.

Las herramientas que contienen

elementos móviles o impulsen otras

piezas móviles, tales como dados de

percusión, se pueden enredar en el

pelo, la ropa, joyas y otros objetos

holgados y causar lesiones graves.

Los latigazos de las mangueras

pueden causar lesiones graves.

Siempre compruebe que no haya

mangueras y enchufes dañados o

flojos antes de utilizar las herramientas.

ADVERTENCIA

No use vestimenta suelta, joyas, ni

cualquier elemento que pueda atascarse

o enredarse en la herramienta,

manguera o piezas de trabajo.

Mantenga siempre sus manos y

partes del cuerpo alejadas de las

piezas en movimiento.

Utilice siempre ropa de calce

adecuado y otro equipo de seguridad

cuando use la herramienta.

Page 39

kobalttools.com

39

INFORMACIÓN DE SEGURIDAD

RIESGO DE CORTES O QUEMADURAS

ADVERTENCIA

LO QUE PODRÍA OCURRIR

CÓMO EVITARLO

ADVERTENCIA

RIESGO DE LESIONES PERSONALES

ADVERTENCIA

Cuando la herramienta no esté en

uso, retire la manguera de aire

comprimido y almacene la

herramienta en una ubicación segura

y alejada del alcance de niños y

usuarios no capacitados.

Las herramientas neumáticas son

capaces de causar lesiones graves

si se operan de forma inadecuada o

si se utilizan para una fin para el que

no fueron diseñadas. Los accesorios

pueden alcanzar altas temperaturas

durante la fricción en la que hacen

contacto con las piezas de trabajo.

Mantenga la pieza de trabajo de la

herramienta alejada de las manos y

el cuerpo.

Use guantes cuando utilice las

herramientas.

No toque los accesorios con las

manos descubiertas durante su

utilización o después de utilizarlos.

RIESGO DE DESCARGA ELÉCTRICA

LO QUE PODRÍA OCURRIR CÓMO EVITARLO

LO QUE PODRÍA OCURRIR CÓMO EVITARLO

Esta herramienta NO está aislada

eléctricamente. El contacto con un

cable energizado también hará que

las piezas de metal de la

herramienta estén energizadas y

pueden ocasionar electrocución,

heridas por electrocución o la

muerte.

Nunca utilice herramientas

neumáticas en lugares donde puedan

entrar en contacto con algún

cableado eléctrico energizado.

Siempre que sea posible, se

recomienda usar ropa que no

conduzca electricidad y calzado

antideslizante al utilizar herramientas.

Evite el contacto del cuerpo con

superficies conectadas a tierra, como

tuberías, radiadores, extractores o

refrigeradores. Existe un gran riesgo

de descarga eléctrica si su cuerpo

está en contacto con tierra.

Los accesorios de la herramienta

neumática, tales como los dados de

percusión, que entren en contacto con

un cableado eléctrico oculto pueden

causar electrocución o la muerte.

Inspeccione completamente la pieza

de trabajo en búsqueda de un posible

cableado oculto antes de realizar

trabajos.

Si se deja una herramienta sin

supervisión puede ser activada por

personas no autorizadas o sin

capacitación, por lo que puede sufrir

o provocar lesiones.

Page 40

kobalttools.com

40

INFORMACIÓN DE SEGURIDAD

ADVERTENCIA

Los dados que se dejan conectados

a una pieza giratoria de la

herramienta pueden volar y aumentar

el riesgo de lesiones personales.

Las herramientas neumáticas se

pueden activar accidentalmente

cuando hace cambios en la

herramienta o durante su

manipulación, el mantenimiento o la

reparación.

Siempre retire y asegure el dado

después del uso.

Las herramientas neumáticas pueden

provocar que la pieza de trabajo se

mueva al tener contacto y causar

lesiones.

Asegúrese siempre de que las piezas

de trabajo estén aseguradas. Utilice

abrazaderas u otros dispositivos

para evitar que se mueva.

Desconecte la herramienta del

suministro de aire mientras hace

cambios en la herramienta, durante

el mantenimiento o la reparación.

Nunca transporte la herramienta por

la manguera de aire comprimido.

Siempre transporte la herramienta

por el mango.

Solo un representante de servicio

autorizado debe realizar reparaciones.

Evite los encendidos accidentales.

Nunca transporte la herramienta con

el gatillo apretado o enganchado. No

bloquee ni fije con cinta o cable el

gatillo para obtener un

funcionamiento continuo.

RIESGO DE LESIONES PERSONALES

LO QUE PODRÍA OCURRIR CÓMO EVITARLO

Las herramientas neumáticas pueden

lanzar sujetadores, accesorios

sueltos o rotos, u otros materiales en

el área del trabajo.

Nunca haga funcionar la herramienta

de la pieza de trabajo.

Mantener la conciencia de la seguridad

de la zona de trabajo en todo momento.

Que sea siempre consciente de otras

personas en todo el área de trabajo

para garantizar la seguridad.

Mantenga el área de trabajo limpia,

ordenada y bien iluminada. No

permita que los niños operen la

herramienta y manténgalos alejados

del área de trabajo.

Utilice solo las piezas, sujetadores y

accesorios recomendados por el

fabricante.

Page 41

kobalttools.com

41

INFORMACIÓN DE SEGURIDAD

RIESGO DE LESIONES PERSONALES

ADVERTENCIA

LO QUE PODRÍA OCURRIR

CÓMO EVITARLO

Si la herramienta se daña, existe el

riesgo de que reviente.

Verifique que no haya mala alineación

o reabas en las piezas móviles, piezas

rotas ni cualquier otra condición que

afecte el funcionamiento de la

herramienta.

La pérdida del control de la

herramienta puede provocar

lesiones al operador o a otras

personas en el área de trabajo.

Siempre cierre el paso del suministro

de aire, libere/drene la presión de aire

de la manguera antes de cambiar los

accesorios o realizar reparaciones.

Cuando la herramienta no esté en uso,

desconéctela del suministro de aire y

almacénela en un lugar seguro.

Nunca use la herramienta si está bajo

la influencia del alcohol o drogas.

No se estire ni se extienda demasiado

para operar la herramienta.

Mantenga una posición adecuada en

todo momento al manipular las

herramientas. Los deslizamientos, los

tropezones y las caídas son las

causas principales de lesiones graves

o la muerte.

Mantenga las manijas de la

herramienta seca, limpia y sin aceite

ni grasa.

Tenga cuidado con los excedentes de

las mangueras de aire comprimido,

las fuentes de alimentación eléctrica y

otros obstáculos o peligros en el área

de trabajo.

Manténgase alerta. Preste atención a

lo que está haciendo. Use el sentido

común. No utilice las herramientas si

está cansado.

Los operadores deben poder manejar

fácilmente el peso total de la

herramienta que están ejecutando

para tener un completo control de la

misma el 100% del tiempo.

Page 42

kobalttools.com

42

Realice un mantenimiento adecuado

de la herramienta y los accesorios. No

maltrate las mangueras o los enchufes.

Las herramientas y los accesorios

con mantenimiento inadecuado

pueden causar lesiones graves.

INFORMACIÓN DE SEGURIDAD

ADVERTENCIA

RIESGO DE LESIONES PERSONALES

LO QUE PODRÍA OCURRIR CÓMO EVITARLO

Los accesorios de mala calidad,

inadecuados o dañados pueden

desprenderse durante el uso y

lanzar proyectiles por el área de

trabajo causando lesiones graves.

Nunca use una herramienta que se haya

caído, se haya dañado o parezca

funcionar mal. Nunca use herramientas

que tengan fugas de aire o que le falten

piezas. Quite inmediatamente del área

de trabajo las herramientas que están

dañadas o que no funcionan

adecuadamente.

No use una presión que exceda la

presión de trabajo recomendada de

cualquiera de las piezas (mangueras,

enchufes, etc.) del sistema.

Use solo dados de percusión con

herramientas neumáticas. Utilice siempre

accesorios clasificados para la velocidad

de la herramienta. No modifique las

herramientas ni los accesorios.

No aplique fuerza excesiva a la

herramienta; deje que esta realice el

trabajo.

Siga las instrucciones de lubricación

para un funcionamiento óptimo y seguro.

Siempre respete las instrucciones de

ensamblaje, funcionamiento,

mantenimiento y reparación.

Mantenga las mangueras alejadas del

calor. el aceite y los bordes filosos.

Siempre inspeccione las mangueras

de aire comprimido en busca de

conexiones deterioradas o débiles

antes de cada uso y asegúrese de que

todas las conexiones estén seguras.

Mantenga las herramientas limpias y

bien lubricadas para obtener un

rendimiento óptimo y seguro.

Page 43

kobalttools.com

43

INFORMACIÓN DE SEGURIDAD

RIESGO DE LESIONES PERSONALES

ADVERTENCIA

PELIGRO DE INHALACIÓN

ADVERTENCIA

Las herramientas abrasivas, tales

como amoladoras, lijadoras y

herramientas de corte, generan

polvo y materiales abrasivos, los

cuales pueden ser dañinos para los

pulmones y el sistema respiratorio.

LO QUE PODRÍA OCURRIR CÓMO EVITARLO

LO QUE PODRÍA OCURRIR CÓMO EVITARLO

El uso de accesorios que no estén

diseñados para utilizarse con las

herramientas específicas aumenta

el riesgo de provocar lesiones al

operador y a las personas que

estén en el área de trabajo.

Utilice siempre accesorios diseñados

para la herramienta y el trabajo a

realizar.

No modifique ni improvise con las

herramientas o los accesorios.

Los movimientos repetidos, las

posiciones incómodas y la

exposición a la vibración pueden

ser perjudiciales para las manos

y los brazos.

Deje de utilizar la herramienta si se

siente incómodo, si siente

entumecimiento o dolor. Si se

presentan algunos de estos síntomas,

consulte al médico antes de reanudar

el trabajo.

Las herramientas para pintar por

pulverización generan vapores de

pintura que pueden ser perjudiciales

para los pulmones y el sistema

respiratorio.

Siempre utilice una máscara o un

respirador del tamaño adecuado y

calificado para la aplicación al usar

dichas herramientas.

Algunos materiales, como los

adhesivos y el alquitrán, despiden

vapores que pueden causar

lesiones graves tras la exposición

prolongada.

Tenga cuidado con las sustancias