Page 1

PYROT

Wood boiler 100 to 540 kW

PYROT ROTATION COMBUSTION

SYSTEM

Fully automatic wood boiler

for the combustion of dry woodchips and pellets

5822 516 GB 05/2010

Technical guide

Page 2

Index

1. Principles of wood combustion 1. 1 Principles of pellet combustion for generating heat .................................................... 6

■ What are wood pellets? .......................................................................................... 6

■ Fuel requirements ................................................................................................... 6

■ Forms of delivery .................................................................................................... 6

1. 2 Principles of woodchip combustion for generating heat ............................................. 6

■ What are woodchips? ............................................................................................. 6

■ Fuel requirements ................................................................................................... 6

1. 3 Minimum wood fuel requirements ............................................................................... 7

■ Content ................................................................................................................... 7

■ Non-wood biomass fuels ......................................................................................... 7

■ Wood fuel regulations and standards ..................................................................... 7

2. PYROT rotation combustion 2. 1 Product description ..................................................................................................... 8

■ Benefits at a glance ................................................................................................ 8

■ Delivered condition ................................................................................................. 8

2. 2 Specification ............................................................................................................... 9

■ Specification ............................................................................................................ 9

3. Control unit 3. 1 Specification for ECOTRONIC .................................................................................... 14

■ Structure and function ............................................................................................. 14

3. 2 Accessories for Ecotronic ........................................................................................... 15

■ Modules and data cables ........................................................................................ 15

■ Optional combinations ............................................................................................ 15

■ Overview: Possible Ecotronic controllers ................................................................ 15

■ Controller, central heating ....................................................................................... 16

■ Controller, adjacent building ................................................................................... 16

■ Room controller QAA 35 ......................................................................................... 16

■ Safety thermostat RAK-TW.1000B ......................................................................... 17

■ Controller, long-distance line .................................................................................. 17

■ Controller, space heater .......................................................................................... 18

■ Controller, DHW cylinder B1 ................................................................................... 18

■ Controller, DHW cylinder B2 ................................................................................... 19

■ Controller, DHW circulation ..................................................................................... 19

■ Controller, solar DHW cylinder ................................................................................ 20

■ Controller, solar/DHW and central heating ............................................................. 20

3. 3 Accessories for ECOTRONIC output management .................................................... 22

■ Cylinder management 3 sensors ............................................................................ 22

■ Cylinder management 5 sensors ........................................................................... 22

■ External requirement ON/OFF ................................................................................ 22

■ Operating message potential-free ........................................................................... 22

■ Output signals 0-10 V ............................................................................................. 22

3. 4 Accessories for ECOTRONIC remote transfer ........................................................... 23

■ Fault message device, analogue with battery ......................................................... 23

■ Export of operating data .......................................................................................... 23

■ Visualisation Pyrot - internal ................................................................................... 23

■ Visualisation, additional functions ........................................................................... 23

■ Data cable to visualisation - internal ....................................................................... 23

■ Visualisation, externally via modem (connected with cable) ................................... 24

3. 5 Mastercontrol for two-boiler systems .......................................................................... 25

■ Information on the Mastercontrol ............................................................................ 25

■ Standard delivery .................................................................................................... 25

■ Visualisation with touch-screen ............................................................................... 25

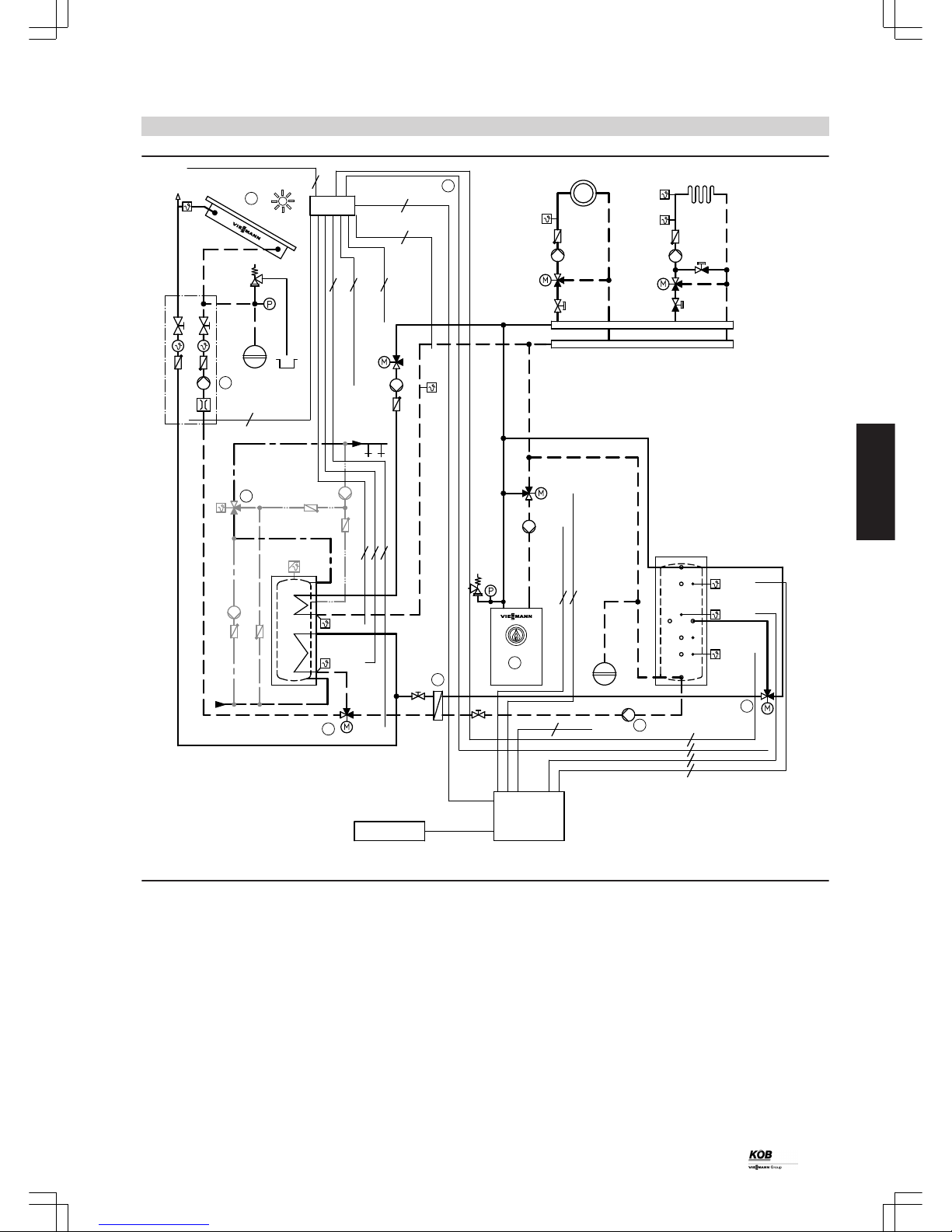

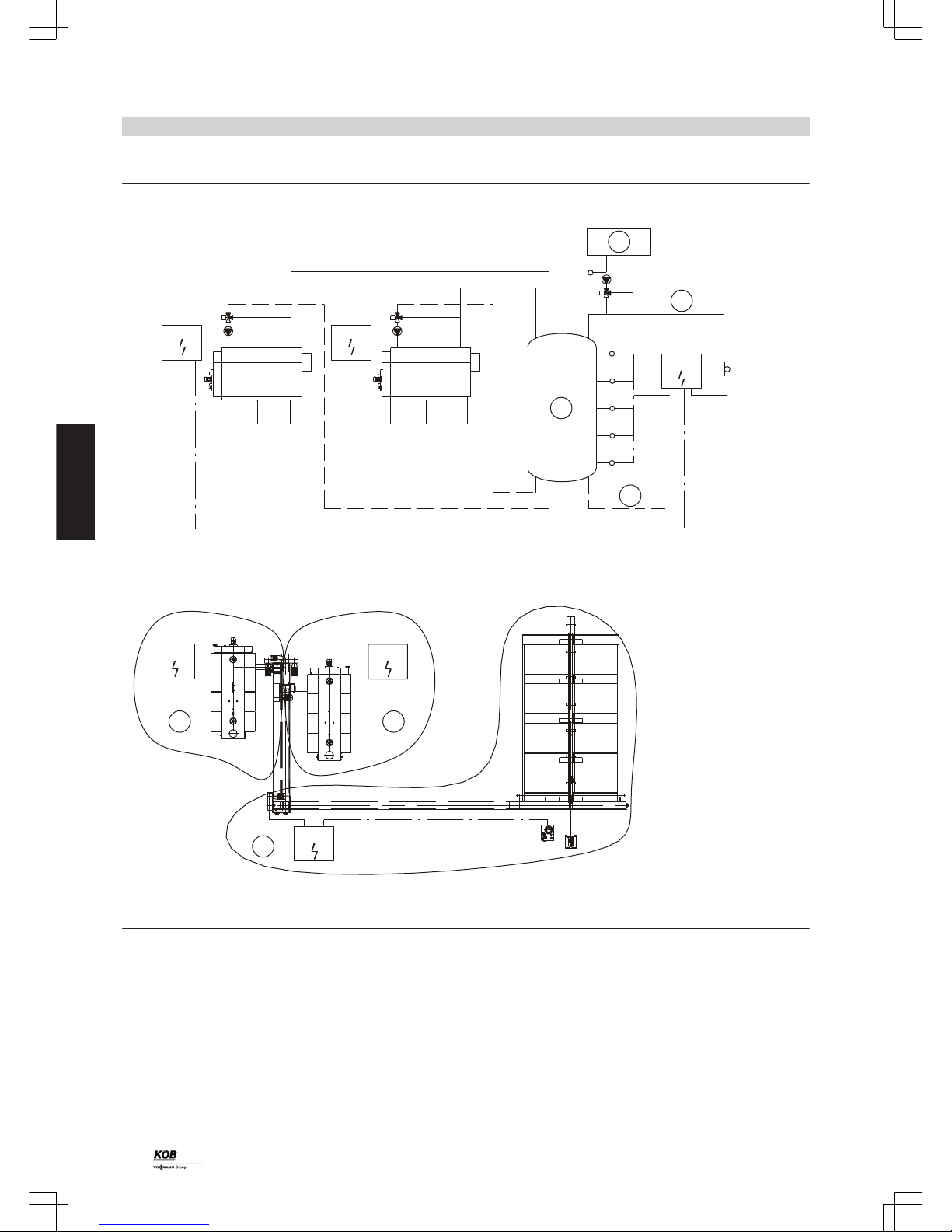

■ Schematic diagram ................................................................................................. 26

3. 6 Accessories for Mastercontrol .................................................................................... 27

■ Heat meter signal .................................................................................................... 27

■ Requirement, additional heat source KP0 .............................................................. 27

■ Requirement, additional heat source KP1 .............................................................. 27

■ Fault message device, analogue with battery ......................................................... 28

■ Export of operating data .......................................................................................... 28

4. Heating water buffer cylinder 4. 1 Specification, buffer cylinder ....................................................................................... 29

■ Buffer cylinder HPM ................................................................................................ 29

■ Buffer cylinder WDW 2000 l .................................................................................... 30

■ Buffer cylinder WDW 2900 l .................................................................................... 31

Index

2

PYROT

5822 516 GB

Page 3

5. Installation accessories 5. 1 Boiler safety equipment .............................................................................................. 32

■ Thermally activated safety valve 100 °C ................................................................. 32

■ Thermally activated extinguishing valve ½”, 50-90 °C ............................................ 32

■ Supply screw conveyor two-level ............................................................................ 32

■ Insulation, flue gas recirculation line ....................................................................... 32

5. 2 Accessories, heat distribution ..................................................................................... 33

■ Motor three-way valve for Pyrot 100 kW ................................................................. 33

■ Motor three-way valve for Pyrot 150-540 kW .......................................................... 33

■ Pumps ..................................................................................................................... 33

5. 3 Accessories, flue system ............................................................................................ 34

■ Flue gas dust extractor ........................................................................................... 34

■ Metal mesh filter ...................................................................................................... 36

■ Cleaning, pneumatic ............................................................................................... 37

■ Price reduction net compressed air on site ............................................................ 38

5. 4 Accessories, ash removal ........................................................................................... 39

■ External container ................................................................................................... 39

■ Ash removal into the base container ....................................................................... 41

6. Design information 6. 1 System design ............................................................................................................ 41

■ Selection of rated output ......................................................................................... 41

■ Flow temperatures .................................................................................................. 41

■ Safety temperatures ................................................................................................ 42

6. 2 Delivery ....................................................................................................................... 42

6. 3 Handling ...................................................................................................................... 42

6. 4 Siting ........................................................................................................................... 42

■ Requirements for boiler room ................................................................................. 42

■ Requirements of the Muster-Feuerungsverordnung [Germany] ............................. 43

■ Combustion air supply ............................................................................................ 43

■ Safety precautions .................................................................................................. 44

■ Minimum clearances ............................................................................................... 44

6. 5 Water connection ........................................................................................................ 45

■ Heating connections ............................................................................................... 45

■ Boiler circuit and shunt pumps ................................................................................ 45

■ Safety equipment to DIN EN 12828 ........................................................................ 45

■ System example ..................................................................................................... 45

6. 6 Electrical installation ................................................................................................... 47

■ Positioning of the programming module and control panel ..................................... 47

6. 7 Safety equipment ........................................................................................................ 47

■ Expansion ............................................................................................................... 47

■ Extinguishing facilities ............................................................................................. 47

■ Extinguishing water container ................................................................................. 48

■ Extinguishing facility with cold water supply ........................................................... 48

■ Prevention of combustion chamber overfilling ........................................................ 49

■ Reignition protection (RZS) ..................................................................................... 49

■ Back burning protection, fuel supply (RSE) ............................................................ 49

■ Shut-off gate valve .................................................................................................. 49

■ Rotary lock valve ..................................................................................................... 49

■ Low water indicator ................................................................................................. 49

■ Maximum pressure limiter ....................................................................................... 49

■ Minimum pressure limiter ........................................................................................ 49

■ Safety valve ............................................................................................................ 49

■ Expansion vessel .................................................................................................... 49

6. 8 Fire protection ............................................................................................................. 50

■ Fire safety, fuel store .............................................................................................. 50

6. 9 Commissioning ........................................................................................................... 50

■ Fuel for commissioning ........................................................................................... 50

■ Filling the heating system ....................................................................................... 50

6.10 Fuels ........................................................................................................................... 50

■ Suitable fuels .......................................................................................................... 50

6.11 Fuel discharge by means of screw conveyor .............................................................. 51

■ Discharge screw conveyor, pellet, D = 120 mm ..................................................... 51

■ Drive, discharge screw conveyor, pellets ................................................................ 52

6.12 Fuel discharge by means of agitators ......................................................................... 53

■ Spring core discharge AF ....................................................................................... 53

■ Discharge screw conveyor AF to spring core discharge ......................................... 55

■ Horizontal discharge AH ......................................................................................... 55

■ Discharge screw conveyor AH for horizontal discharge ......................................... 58

■ Protective panel AH for bunker ............................................................................... 58

■ Cover panel AH for pellets ...................................................................................... 58

Index

(cont.)

PYROT

3

5822 516 GB

Page 4

6.13 Fuel discharge by means of funnel discharge ............................................................ 59

■ Funnel discharge .................................................................................................... 59

■ Additional outlet flange ............................................................................................ 60

■ Funnel, large .......................................................................................................... 60

6.14 Fuel discharge by means of push floor (sizing) .......................................................... 60

■ Number and length of the pushrods with a maximum dumping height ................... 60

■ Specification for the pushrod drives ........................................................................ 61

■ Forces on the building ............................................................................................. 61

■ Slot discharge, for pulling ........................................................................................ 62

■ Centre discharge ..................................................................................................... 63

■ Slot discharge with fill function ................................................................................ 65

6.15 Fuel discharge by means of push floor (accessory) ................................................... 67

■ Pushrod drive, individual ......................................................................................... 67

■ Weld base, pushrod drive, individual ...................................................................... 67

■ Pushrod drive, twin ................................................................................................ 67

■ Weld base, pushrod drive, twin ............................................................................... 67

■ Weld base, bunker .................................................................................................. 67

■ Pushrod ................................................................................................................... 68

■ Hydraulic drive, AS individual ................................................................................. 68

■ Hydraulic drive, AS twin .......................................................................................... 69

■ Push floor screw conveyor D = 190 mm ................................................................. 69

■ Push floor screw conveyor D = 250 mm ................................................................. 69

■ Drive, push floor screw conveyor, standard ............................................................ 70

■ Drive, push floor screw conveyor, higher-power ..................................................... 70

■ Cover, push floor screw conveyor ........................................................................... 70

6.16 Charging the boiler with fuel ....................................................................................... 70

■ Trough screw conveyor ........................................................................................... 70

■ Drive, trough screw conveyor, standard ................................................................. 71

■ Pipe screw conveyor ............................................................................................... 71

■ Drive, pipe screw conveyor, pellet .......................................................................... 73

■ Drive, pipe screw conveyor, standard ..................................................................... 74

■ Drive, pipe screw conveyor, high-power ................................................................. 74

6.17 Fuel storage in on-site pellet store (sizing) ................................................................. 74

■ Sizing the pellet storage room ................................................................................ 74

■ Pellet storage room design and required system components ............................... 75

■ Additional safety instructions for pellet stores ......................................................... 76

■ Protective boards with Z brackets ........................................................................... 76

■ Fill connector and return connector ........................................................................ 76

6.18 Fuel storage in on-site pellet store (accessories) ....................................................... 79

■ Deflector 1.42 x 1.25 m ........................................................................................... 79

■ Fill connector and return connector, straight ........................................................... 79

■ Fill connector and return connector, 45° ................................................................. 79

■ Extension of fill connector and return connector ..................................................... 80

6.19 Fuel storage in on-site bunker (accessories) .............................................................. 80

■ Silo cover, manual FDM 2.9/1.3 m .......................................................................... 80

■ Bunker cover hydraulic FDH ................................................................................... 81

■ Fall protection grille 120 for FDH ........................................................................... 83

■ Fall protection grille 200 for FDH ........................................................................... 83

■ Bunker cover, movable FDB ................................................................................... 83

■ Fall protection grille, 120 for FDB ........................................................................... 85

■ Fall protection grille, 200 for FDB .......................................................................... 85

■ Shaker motor for fall protection grille ...................................................................... 85

■ Hydraulic drive, bunker charging cover, ASH ......................................................... 85

■ Cover drives for hydraulic drive, ASH .................................................................... 86

■ Silo filling screw conveyor FS 300 .......................................................................... 86

■ Drive, silo filling screw conveyor ............................................................................ 86

6.20 Back burning protection .............................................................................................. 87

■ Rotary lock valve ..................................................................................................... 87

■ Shut-off gate valve MA 220 ..................................................................................... 88

■ Downpipe L = 1.0 m ................................................................................................ 88

■ Special adaptor ....................................................................................................... 88

6.21 Connection on the flue gas side ................................................................................. 89

■ Chimney .................................................................................................................. 89

■ Flue pipe (sizing) ..................................................................................................... 89

■ Flue gas routing (accessories) ................................................................................ 89

6.22 Sound insulation ......................................................................................................... 90

■ Braces ..................................................................................................................... 90

7. Appendix 7. 1 Sizing the expansion vessel ....................................................................................... 90

■ Selection example ................................................................................................... 91

Index

(cont.)

4

PYROT

5822 516 GB

Page 5

7. 2 General information regarding low pressure hot water boilers with safety temperatures

of up to 110 ºC ............................................................................................................ 91

7. 3 Pipe connections ........................................................................................................ 91

7. 4 Electrical installation ................................................................................................... 92

7. 5 Operating instructions ................................................................................................. 92

7. 6 Flue system ................................................................................................................ 92

7. 7 Checks as part of the Building Regulations approval process .................................... 92

8. Keyword index .............................................................................................................................................. 93

Index

(cont.)

PYROT

5

5822 516 GB

Page 6

1.1 Principles of pellet combustion for generating heat

What are wood pellets?

Wood pellets are made from 100% natural wood remnants. This raw material is waste matter created by the wood industry in large volumes

through planing or sawing. Wood remnants are compressed under high pressure and formed into pellets, i.e. pressed into a cylindrical shape.

The raw material is stored and transported in completely dry conditions. The system user should also ensure completely dry storage conditions.

Optimum and effective combustion can only be ensured under these conditions.

Fuel requirements

For combustion in the PYROT, use pellets with a diameter of 6 mm, a

length from 5 to 30 mm (20 % up to 45 mm) with a maximum residual

moisture content of 10 %.

The wood pellets used for combustion in the PYROT must correspond

to the requirements of DINplus or ÖNORM M 7135.

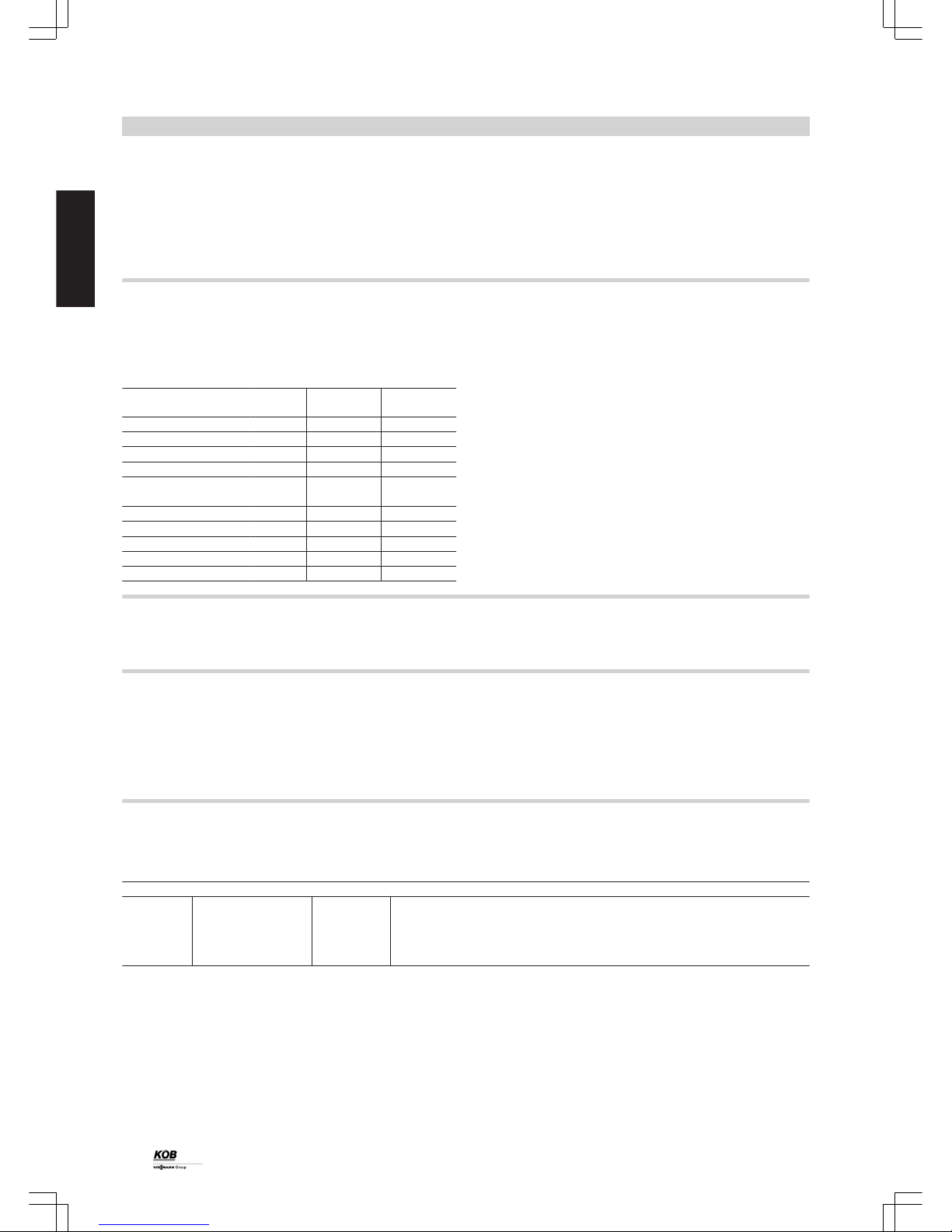

Requirements DINplus ÖNORM

M 7135

Abrasion resistance %

≤ 2.3 ≤ 2.3

Raw density

kg/dm

3

≥ 1.12 ≥ 1.12

Water content %

≤ 10 ≤ 10

Ash content %

≤ 0.5 ≤ 0.5

Net calorific value MJ/kg

≥ 18 ≥ 18

kWh/kg

≥ 5 ≥ 5

Sulphur content %

≤ 0.04 ≤ 0.04

Chlorine content %

≤ 0.02 ≤ 0.02

Nitrogen content %

≤ 0.3 ≤ 0.3

Compression additive %

≤ 2 ≤ 2

Ext. production control yes –

Quality characteristics

High quality pellets:

■ Smooth shiny surface

■ Uniform length

■ Low proportion of dust

■ Sink in water

Low quality pellets:

■ Cracked rough surface

■ Severely varying length

■ High proportion of dust

■ Float in water

Forms of delivery

In their loose form, pellets are transported by silo tanker and pumped

into the storage room via a hose system.

Careful handling of pellets enables a low proportion of dust, troublefree boiler charging and a constant wood boiler output.

1.2 Principles of woodchip combustion for generating heat

What are woodchips?

Woodchips are made from 100 % natural wood from forests and plantations. This raw material comes in the form of trunks or branches. The

wood is then processed with high speed cutting tools in accordance with ÖNORM M 7133.

The raw material is stored and transported in completely dry conditions. The system user should also ensure completely dry storage conditions.

Optimum and effective combustion can only be ensured under these conditions.

Fuel requirements

For combustion in the PYROT, use woodchips with a maximum coarse

percentage of 20 %, a maximum cross-section of 5 cm² and a maximum length of 12 cm (5 % with max. 16 cm).

Bulk density S (kg/m³, water content W (%), size G (mm) as per ÖNORM M 7133

S 200 W20 G30/50 Soft natural woodchips from forests

S 250 W20 to W35 G30/50 Soft natural woodchips from forests

S 300 W20 to W35 G30/50 Soft/hard natural woodchips from forests

S 300 W35 to W50 G30/50 Soft natural woodchips from forests

S 350 W20 to W35 G30/50 Hard natural woodchips from forests

Quality characteristics

High quality woodchips:

■ As per ÖNORM M 7133

■ Size G30 or G50

■ Max. 5 % outliers

■ Smooth surfaces

Low quality woodchips:

■ Frayed surface

■ More than 5 % outliers

■ Coarse percentage higher than 20 %

■ Greater than G30 or G50

Principles of wood combustion

6

PYROT

1

5822 516 GB

Page 7

1.3 Minimum wood fuel requirements

Content

When procuring wood for combustion, it is important to ensure that

foreign matter (e.g. stones, metal parts, brick fragments, plastics, etc.)

is avoided. This changes the composition of the fuel and therefore the

critical parameters of the combustion process.

The values must not exceed or fall below the following limits (per kg of

dry fuel) for the non-combustible content (ash at an analysis temperature of 815 °C):

Limit Comparison with natural wood from forests

Chlorine Cl mg/kg max. 300 10

Sulphur S mg/kg max. 1000 120

Total Cl, S mg/kg max. 1000 130

Ash content total g/kg max. 15.0 5.0

Alkali oxides in the ash (K2O and Na2O) g/kg max. 1.0 0.35

SB start of ash sintering °C min. 1000 approx. 1200

A consequence of exceeding the above limits is a shortened service

life of the combustion chamber and wood boiler. This also means that

maintenance work is increased and service intervals are reduced.

The proportion of dust-like and fine-grain materials should also be

minimised (in accordance with ÖNORM M 7133).

Non-wood biomass fuels

Non-wood biomass fuels, such as needles, leaves, grain, straw, husks,

fruit kernels, etc., are generally unsuitable as a fuel for trouble-free

operation and are therefore not permissible.

In some cases, the fuel properties (essential composition, ash sintering point, etc.) differ considerably from those of wood. Combustion in

a Pyrot may lead to impairment of the combustion characteristics and

to greater stress on the fireclay lining and the heat exchanger surfaces.

Warranty claims can therefore only be asserted when using permissible fuels.

Wood fuel regulations and standards

Germany Revised first version of BImSchV dated 22.03.2010

Austria FAV dated 18.11.1997 "Ordinance for Combustion Systems" § 3.(1) 3. Solid fuels

Switzerland Clean air regulations LRV dated 16.12.1985 (as of 28.03.2000)

ÖNORM M 7133 Woodchips for energy purposes (1998)

EN 303-5 Boilers for solid fuels, table 8 "Test fuels"

CEN/TS 14961 Solid biofuels

Principles of wood combustion

(cont.)

PYROT

7

5822 516 GB

1

Page 8

2.1 Product description

A

Controlled secondary air with rotary fan

B

Rotary combustion chamber

C

Boiler heat exchanger

D

Safety heat exchanger

E

Flue gas fan with Lambda probe and temperature sensor

F

Pneumatic cleaning

G

Flue gas recirculation, controllable

H

Regulated primary air

K

Ignition fan

L

Fully moving grate

M

Ash removal

With its patented rotation combustion, the Pyrot wood boiler represents state of the art wood combustion. A supply screw conveyor continuously guides the wood fuel onto a moving grate on which the fuel

combustion takes place. Continuous gasification takes place under air

starvation. A rotary fan is used to mix rising combustion gases with the

secondary air displaced in a rotary motion. This ensures thorough

mixing with the combustion gases.

Clean and efficient combustion

The proven combustion technology in the Pyrot achieves similar emissions values to those of a modern gas combustion system and keeps

the release of CO, NOx and dust particles to a minimum, subject to

fuel type. The combination of combustion technology and digital modulating output control enables efficiency levels of up to 92 %.

Mobile containerised heating centre

Pyrot wood boilers are available as containerised complete solutions

for uses where there are no boiler houses available or where the onsite building costs have to be reduced to a minimum. This complete

solution incorporates the pre-assembled wood boiler inside a special

container with all ancillary devices. In addition to finished container

solutions, individual versions can be specially matched to your

needs.

Benefits at a glance

■ High efficiency levels (up to 92 %) and low emissions through regulated primary and secondary air supply and low particle combustion

■ Two-pass heat exchanger and modulating output control (4:1 control

range)

■ Automatic ignition prevents having to maintain the incandescent bed

and saves fuel

■ Easy service thanks to fully automatic ash removal, optional pneumatic cleaning system and flue gas dust extractor

■ Highly developed safety devices ensure a safe and reliable operation

■ Individual planning of your system by our team of experts

■ Available as a complete ready-to-use containerised solution

Delivered condition

Pre-assembled steel boiler for wood pellets and woodchips according

to DINplus and ÖNORM M 7135.

Combustion chamber door, ash doors, ash boxes, cleaning device.

1 supply screw conveyor with separating barrier, incl. extinguishing

valve with dirt trap

1 flue gas fan

1 extinguishing water container with holder

1 automatic ignition system

1 set displacer rods

1 recirculation gas device

1 secondary air device (draught stabiliser); for on-site installation in the

flue pipe

Sensors:

■ Infrared light barrier for level monitoring, separating barrier, supply

screw conveyor

■ Safety limit switch on inspection cover of supply screw conveyor

■ Contact sensor Pt100 at the supply screw conveyor

■ Infrared light barriers for level monitoring of the fuel in the combustion chamber

■ Zirconium dioxide probe with measured value transducer

■ Flue gas temperature sensor PT-100

■ Return temperature sensor KTY

■ Boiler water temperature sensor KTY

■ High limit safety cut-out (STB)

■ Temperature sensor, rotary fan

■ Sensor KTY with sensor well

PYROT rotation combustion

8

PYROT

2

5822 516 GB

Page 9

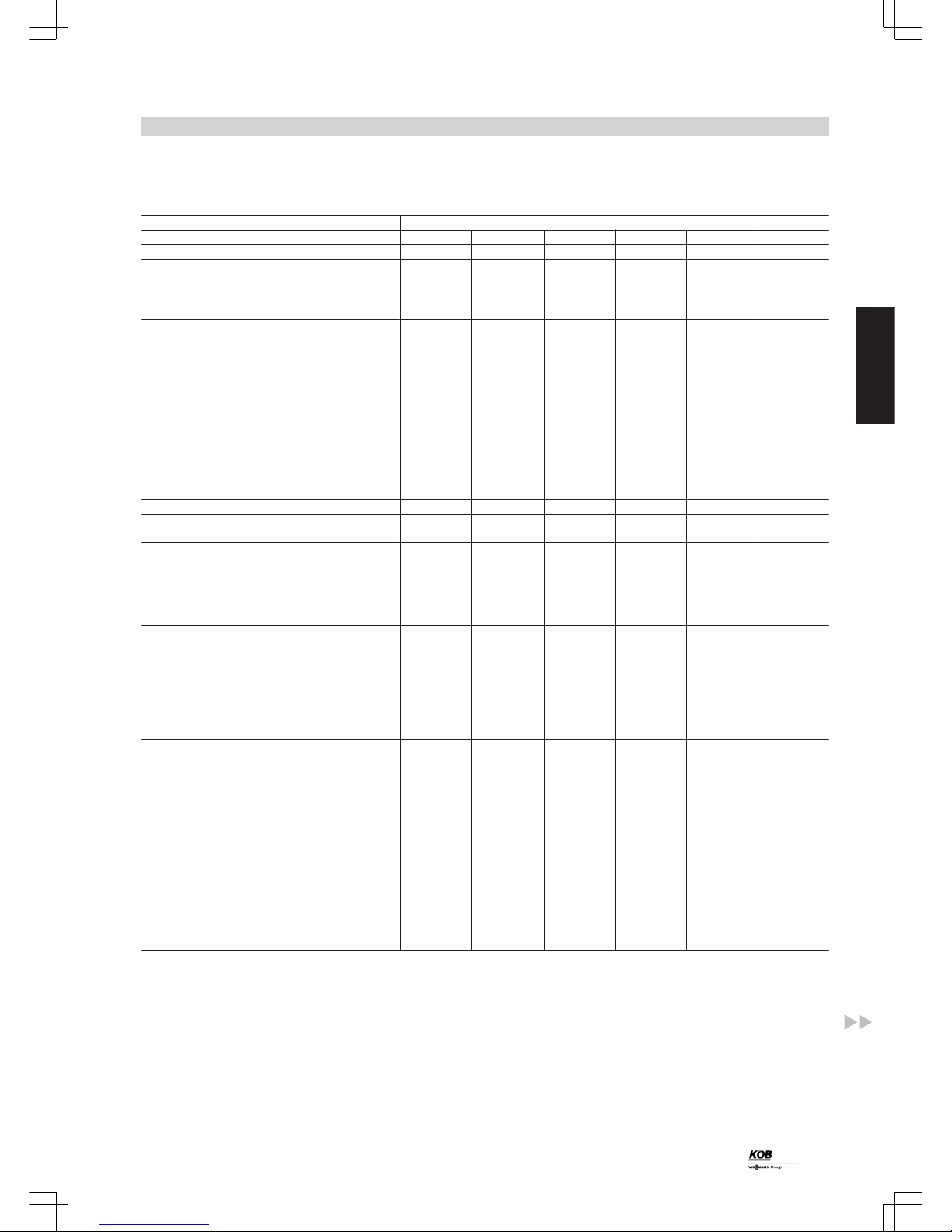

2.2 Specification

Specification

Trade name Pyrot rotation combustion

Rated output kW 100 150 220 300 400 540

Part no.: 7423 656 7423 657 7423 658 7423 659 7423 660 7423 661

Output data

Rated output kW 100 150 220 300 400 540

Continuous output

*1

kW 90 135 200 270 360 480

Minimum output Q

min

*2

kW 30 45 60 80 100 140

Heating data

– Content on hot gas side l 325 374 744 883 1340 1613

– Permissible shutdown temperature of

the high limit safety cut-out.

°C 100 100 100 100 100 100

– Minimum return temperature °C 65 65 65 65 65 65

– Grate ash container capacity l 26 32 45 55 75 91

– Ash container capacity, flue gas dust

extractor

l 90 90 90 90 90 90

Boiler water content l 395 432 794 903 1326 1510

Pressure drop on the DHW side mbar 38 33 76 42 29 56

Permiss. operating pressure

Test pressure bar 5 5 5 5 5 5

Maximum operating pressure bar 3 3 3 3 3 3

Heating surface

m

2

8.28 10.78 16.4 20.72 28.76 39.36

CE designation CE CE CE CE CE CE

Boiler class to DIN EN 303-5 3 3 3 3 3 3

Overall dimensions

Total length (with door open) mm 2870 3120 3424 3780 4004 4232

Total width mm 1050 1050 1330 1330 1570 1570

Total width (with supply screw conveyor) mm 2070 2180 2350 2350 2590 2590

Total height mm 1825 1825 2084 2084 2422 2492

Total height (with induced draught fan) mm 2236 2266 2526 2534 2832 2902

Total weight

–

Boiler

*3

kg 1278 1451 2119 2441 3235 3671

– Combustion block kg 432 477 581 641 778 937

– Displacer rods kg 68 87 141 163 220 289

– Flue gas fan kg 37 40 40 45 62 62

– Supply screw conveyor kg 143 143 143 143 143 149

–

Total dry weight

*4

kg 1958 2198 3024 3433 4438 5108

– Total wet weight kg 2353 2630 3818 4336 5764 6618

Max. power consumption

– During ignition W 1600 1600 1600 1600 1600 1600

– Electrical connections (total) W 2670 2670 2850 3600 3980 3630

– Supply screw conveyor W 370 370 550 1100 1100 750

– Rotary fan W 120 120 120 120 120 120

– Flue gas fan W 550 550 550 750 1100 1100

– Grate drive W 30 30 30 30 60 60

– Electrical power consumption with QNW 850 1032 1108 1521 1868 1753

– Electrical power consumption with Q

min

W 280 355 369 434 480 460

Boiler connections

Boiler flow and return G 2 fem. 2 fem. DN80 PN6 DN80 PN6 DN100 PN6 DN100 PN6

Extinguishing water connection R ¾ ¾ ¾ ¾ ¾ ¾

Boiler drain valve Rp 1 ½ 1 ½ 1 ½ 1 ½ 1 ½ 1 ½

Safety heat exchanger 2x R ½ ½ ½ ½ ½ ½

Sensor well for TS Rp ½ ½ ½ ½ ½ ½

*1

Levelled output as base load boiler in continuous operation with pneumatic cleaning

*2

Q ≥ Q

min

: Output operation modulating control (variable output control)

Q ≤ Q

min

: Low load with ON Q

min

/ OFF (Stop and Go operation)

*3

Incl. door and refractory concrete lining

*4

Incl. displacer rods

PYROT rotation combustion

(cont.)

PYROT

9

5822 516 GB

2

Page 10

Trade name Pyrot rotation combustion

Rated output kW 100 150 220 300 400 540

Part no.: 7423 656 7423 657 7423 658 7423 659 7423 660 7423 661

Flue gas

*5

Average temperature (gross*6)

–

Average flue gas temperature with Q

N

*7

°C 160 160 160 160 160 160

– Average flue gas temperature with Q

min

°C 130 130 130 130 130 130

Mass flow rate

– QN; W5; O2 6 % g/s 53.6 80.4 117.9 160.8 214.4 289.44

– Q

W35

; W35; O2 8 % g/s 71.3 106.9 156.9 213.9 285.2 385.1

Flow rate

– QN; W5; O2 6 %; 150 °C

m3/s

0.06 0.09 0.14 0.19 0.25 0.35

– Q

W35

; W35; O2 8 %; 150 °C

m3/s

0.08 0.12 0.19 0.25 0.34 0.46

CO2 content in the flue gas % 15 15 15 15 15 15

Flue outlet 7 mm 200 250 250 300 350 350

Required draught Pa 0 0 0 0 0 0

Efficiency

– At full load % 90 90 90 90 90 90

– At partial load % 92 92 92 92 92 92

*5

Values for calculating the size of the flue system to DIN EN 13384, based on 12.0 % CO

2

*6

Actual flue gas temperature as average gross value as per EN 304 at 20 °C combustion air temperature

*7

Flue gas temperature: Increase possible by removing the displacer rods (QN+ 30 °C; Q

min

+ 10 °C)

PYROT rotation combustion

(cont.)

10

PYROT

2

5822 516 GB

Page 11

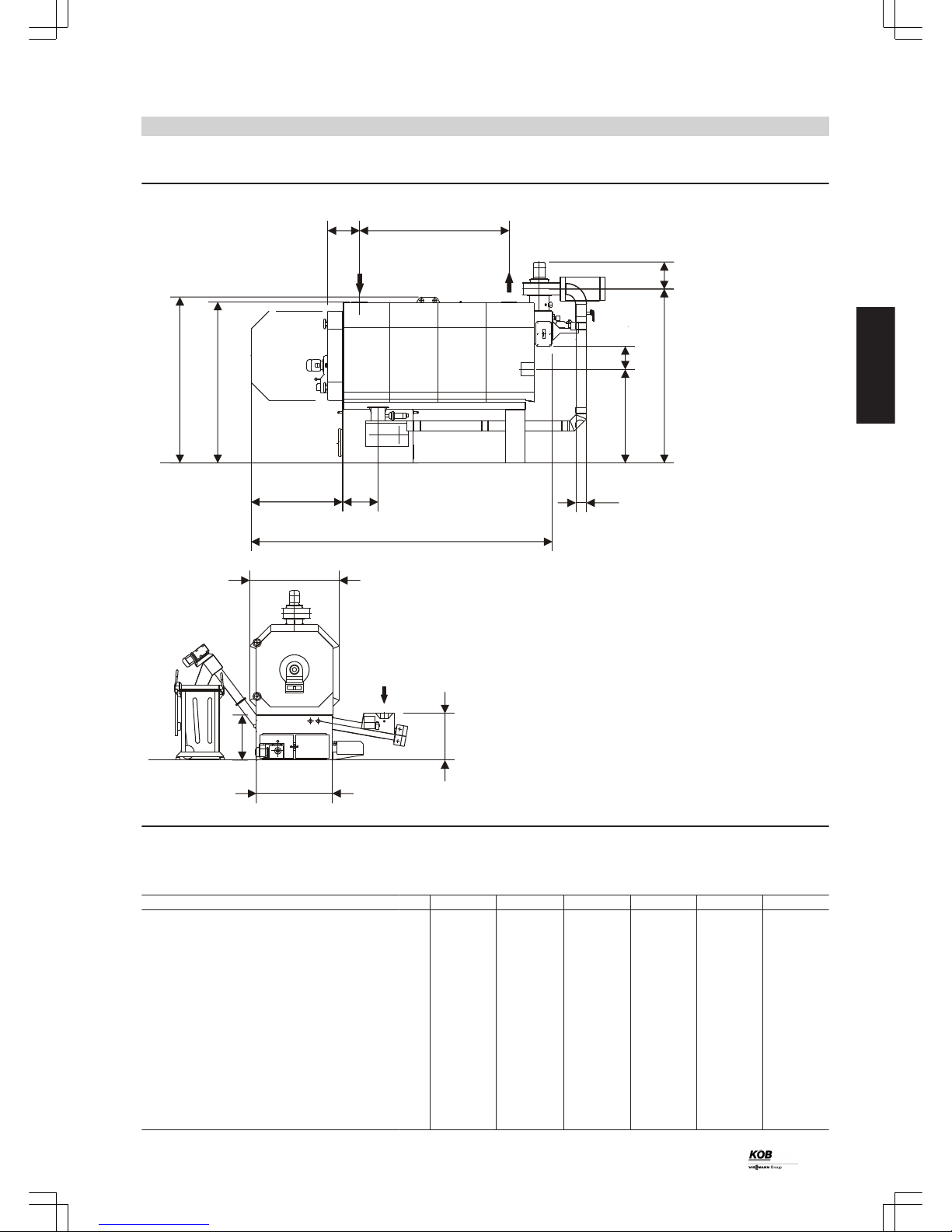

Dimensions

44.84 mm

7.01 mm

9.04 mm23.53 mm

77.57 mm

42.74 mm

24.11 mm5.96 mm

41.51 mm

8.22 mm38.51 mm

h

l k

m

n

a

b

c

d

f

e

KR

KV

2.67 mm

g

23.03 mm

19.57 mm

11.60 mm

r

p

q.

12.05 mm

o

KR Boiler return

KV Boiler flow

Dimensions

Rated output kW 100 150 220 300 400 540

a mm 392 392 406 406 466 466

b mm 1291 1541 1525 1875 1800 2030

c mm 345 358 358 352 375 375

d mm 1891 1908 2168 2182 2457 2527

e mm 303 303 316 316 319 319

f mm 1093 1093 1179 1179 1219 1219

g mm DN 80 DN 80 DN 80 DN 125 DN 125 DN 125

h mm 2870 3120 3424 3780 4004 4232

k mm 320 370 370 440 480 548

l mm 870 870 1150 1150 1390 1390

m mm 1765 1765 2024 2024 2262 2262

n mm 1825 1825 2084 2084 2422 2492

o mm 700 700 700 700 700 742

p mm 870 870 1150 1150 1390 1390

q mm 673 673 673 673 673 750

r mm 1050 1050 1330 1330 1570 1570

PYROT rotation combustion

(cont.)

PYROT

11

5822 516 GB

2

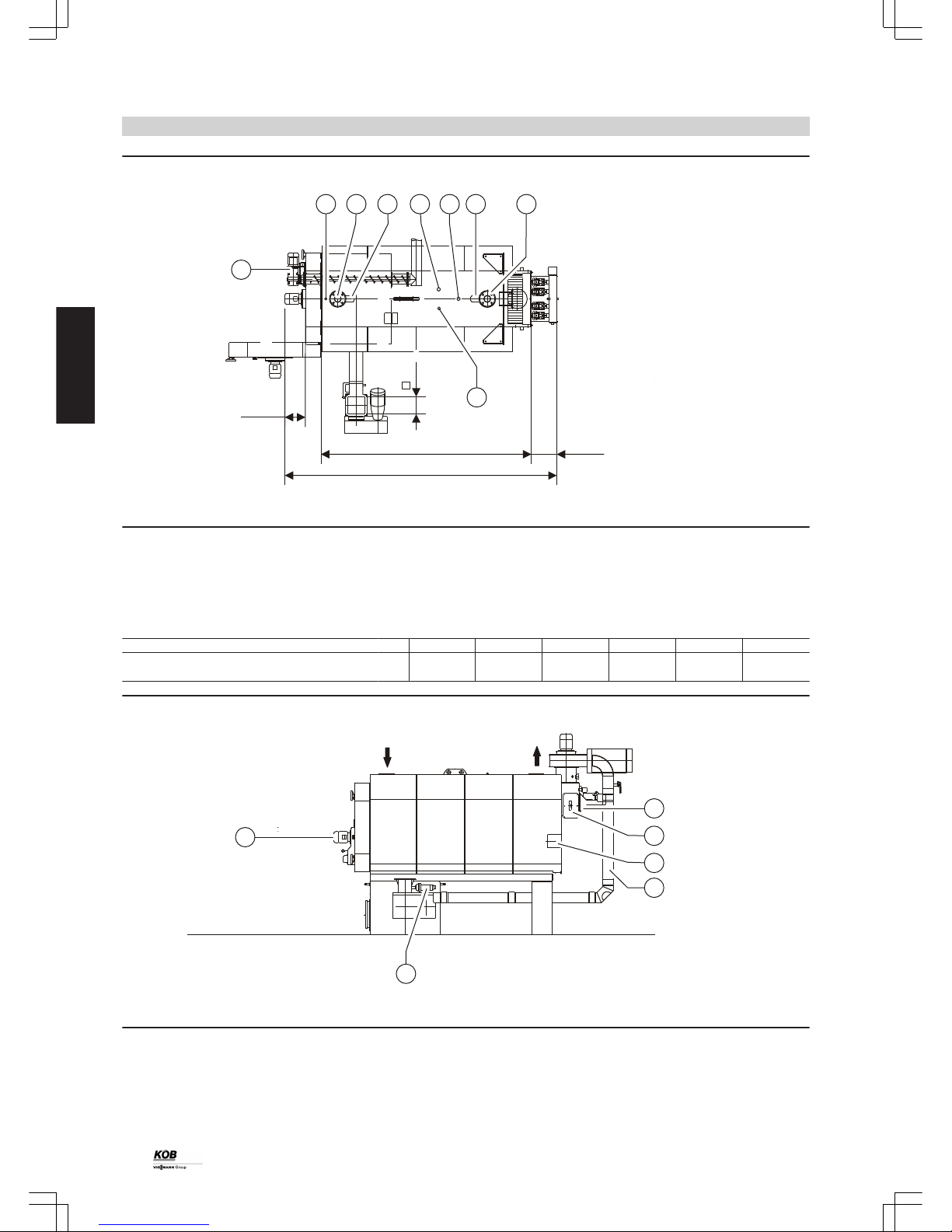

Page 12

54,17 mm6,68 mm

5,30 mm

70,02 mm

4,52 mm

K

A B C E F G

H

263

220

b

a

330

D

A

Sensor well for TS

B

Boiler return

C

Return temperature sensor

D

Safety heat exchanger

E

High limit safety cut-out (STB)

F

Boiler water temperature sensor

G

Boiler flow

H

Safety heat exchanger

K

Ash removal, combustion block

Dimensions

Rated output kW 100 150 220 300 400 540

a mm 2785 3035 3059 3415 3457 3685

b mm 2000 2250 2274 2630 2614 2842

KR

KV

F

A

E

D

C

B

A

Pneumatic cleaning

B

Cleaning cover, flue gas collector

C

Flange for burner trolley; standard version: Cover with sight

glass

D

Recirculation gas line, line routing variable

E

Ignition unit

F

Rotary fan

KV Boiler flow

KR Boiler return

PYROT rotation combustion

(cont.)

12

PYROT

2

5822 516 GB

Page 13

A B

K

FH

E

D

C

G

A

Flue gas fan

B

Boiler door with rotary fan

C

Extinguishing water connection

D

Supply screw conveyor

E

Drive, infeed grate

F

Ash doors of the grate ash container (2 pce)

G

Drive, ash removal

H

Maintenance cover, combustion block

K

Ash removal, rising screw conveyor

PYROT rotation combustion

(cont.)

PYROT

13

5822 516 GB

2

Page 14

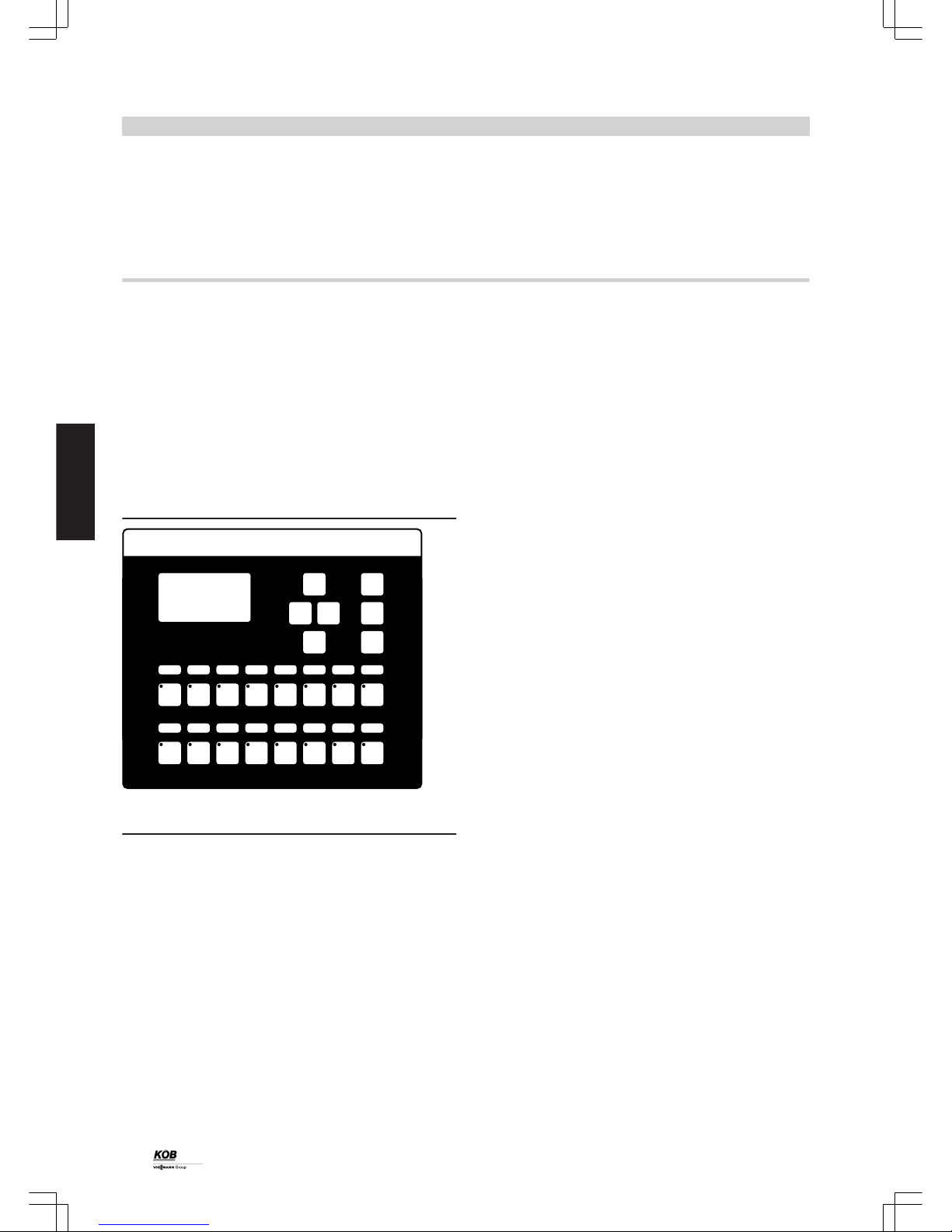

3.1 Specification for ECOTRONIC

The Ecotronic system control unit is a decentralised microprocessor

system (CAN BUS). To control the boiler system, the Ecotronic comprises a module (PCB) integrated into the control panel, and the programming module. Controller modules can be added to the Ecotronic

(modular structure). It is therefore possible to extend operation individually according to customer requirements.

Structure and function

Modular structure

The Ecotronic system control unit is a decentralised microprocessor

system (CAN BUS). To control the boiler system, the Ecotronic comprises a module (PCB) integrated into the boiler, and the programming

module. Three-sensor cylinder management is part of the standard

Ecotronic version. Controller modules can be added to the Ecotronic

(modular structure). It is therefore possible to extend operation individually according to customer requirements.

Programming module

The programming module is included in the standard delivery for the

boiler and is used to operate the heating system. The backlit screen

offers an extensive text display. A data cable connects the programming module with the control panel.

F10F9

F12

F11

F13

F14

F15

F16

>

F2F1

F4

F3

<

>

F5

F6

Wärme aus Holz

KÖB

>

F7

-

OK

F8

+

Ecotronic 800

The programming module

Functions:

■ Automatic ignition

■ Output control circuit with modulating output operation (25-100 %)

– Air-controlled by means of variable speed flue gas fan subject to

flow temperature

– Exact fuel supply via the supply screw conveyor from dosing con-

tainer with separating barrier

– Topping up of the dosing container with level monitoring

– Limitation and distribution of the mass to be burned in the com-

bustion chamber by means of level monitoring in the combustion

chamber and movement of the infeed grate.

■ Emission optimised control circuit: Optimisation of the air supply

through motorised air dampers using Lambda probe measurement

ensures optimum combustion

■ Keeping up the return temperature with the boiler mixer ensures a

long boiler service life

■ Control unit for oil burner on the PYROT

■ Safety functions for:

– Excessive temperature

– Burn-back

– Opening of a charging cover

– Forced heat transfer

■ Potential-free output (fault message)

Operation:

Operation is carried out via a control panel with touch-sensitive keypad

and plain text display. All operating data can be shown on the display.

The set values of all important parameters can be entered easily with

a keyboard. Fault messages are displayed in plain text and output in

the sequence of occurrence.

Standard delivery:

■ Microprocessor control unit (control panel with backlit plain text display), CE-tested, real time clock, battery backed, serial interface RS

232 for PC connection

■ Data cable from the programming module to the control panel; length

10 m

■ Control panel, surface powder-coated in RAL 7035 (grey) texture.

Version, as per ÖVE/VDE directives, fully wired to terminal strips,

feed 3 x 400 V 50 Hz; control voltage 230 V or 24 V;

– Update-compatible software

– Starttec for all charging drives (3 x 400 V) according to separate

price items

– Motor overload relay for boiler pump

– Outputs for stepper motors (air dampers)

– Inverter (EMC operating class 3) for flue gas fan

■ In the control panel door:

– 4-pole main isolator

– Documentation incl. fixed wiring diagram, terminal connection dia-

gram with cable designation, operating and maintenance instructions, installation instructions in plan pocket

■ Sensors and switches installed at the supply screw conveyor:

– Infrared light barrier, level monitoring, separating barrier, supply

screw conveyor

– Safety limit switch on inspection cover of supply screw conveyor

– Contact sensor PT-100 at the supply screw conveyor

■ Sensors and switches at the combustion block, the combustion system and in the flue outlet (installation on site):

– Infrared light barriers, level monitoring, fuel in combustion cham-

ber

– Zirconium dioxide probe with measured value transducer (Lambda

probe)

– Flue gas temperature sensor PT-100

■ Sensors and switches installed at top of boiler:

– Boiler water temperature sensor KTY in connector flow

– Return temperature sensor KTY in connector return

– High limit safety cut-out (STB)

– Temperature sensor, rotary fan

■ Sensor supplied

– 1 sensor KTY with sensor well 1/2 " x 280 mm (B28.1)

Control unit

14

PYROT

3

5822 516 GB

Page 15

3.2 Accessories for Ecotronic

Modules and data cables

The standard Ecotronic version can be customised with additional

controller modules or controllers and data cables. Additional heat

sources, heat consumers or DHW cylinders can be incorporated into

the control system with/without solar heating circuit backup.

Data cables

The data cable connects the individual modules to the overall system

control unit. Data cables can be connected together (max. 2 cables).

The total length of all CAN BUS cables must not exceed 200 m.

Note

Every time the system is extended, it is necessary to check whether a

data cable is required. Each additional controller module requires a

corresponding data cable.

Designation Part no.

Data cable with connector 10.0 m standard 7387 587

Data cable with connector 2.0 m 7387 858

Data cable with connector 5.0 m 7388 000

Data cable with connector 20.0 m 7388 025

Data cable with connector 40.0 m 7387 588

Data cable with connector 80.0 m 7387 972

Data cable with Y-distributor 7387 948

Controller module

The controller module is supplied in a plastic casing (length 325 mm,

height 195 mm, depth 75 mm) incl. outside temperature sensor (QAC

31).

The control keys for the controller module are available at the programming module and are enabled according to the number of controllers.

Either 3 or 5-sensor cylinder management is available. 5-sensor cylinder management requires an additional controller module.

Optional combinations

Additional controller modules for an additional charge

Programming module with

key extension

1 controller module 2 controller modules 3 controller modules

12 controller keys Max.

4 controllers

and

7 sensors possible

Max.

8 controllers

and

14 sensors possible

Max.

12 controllers

and

21 sensors possible

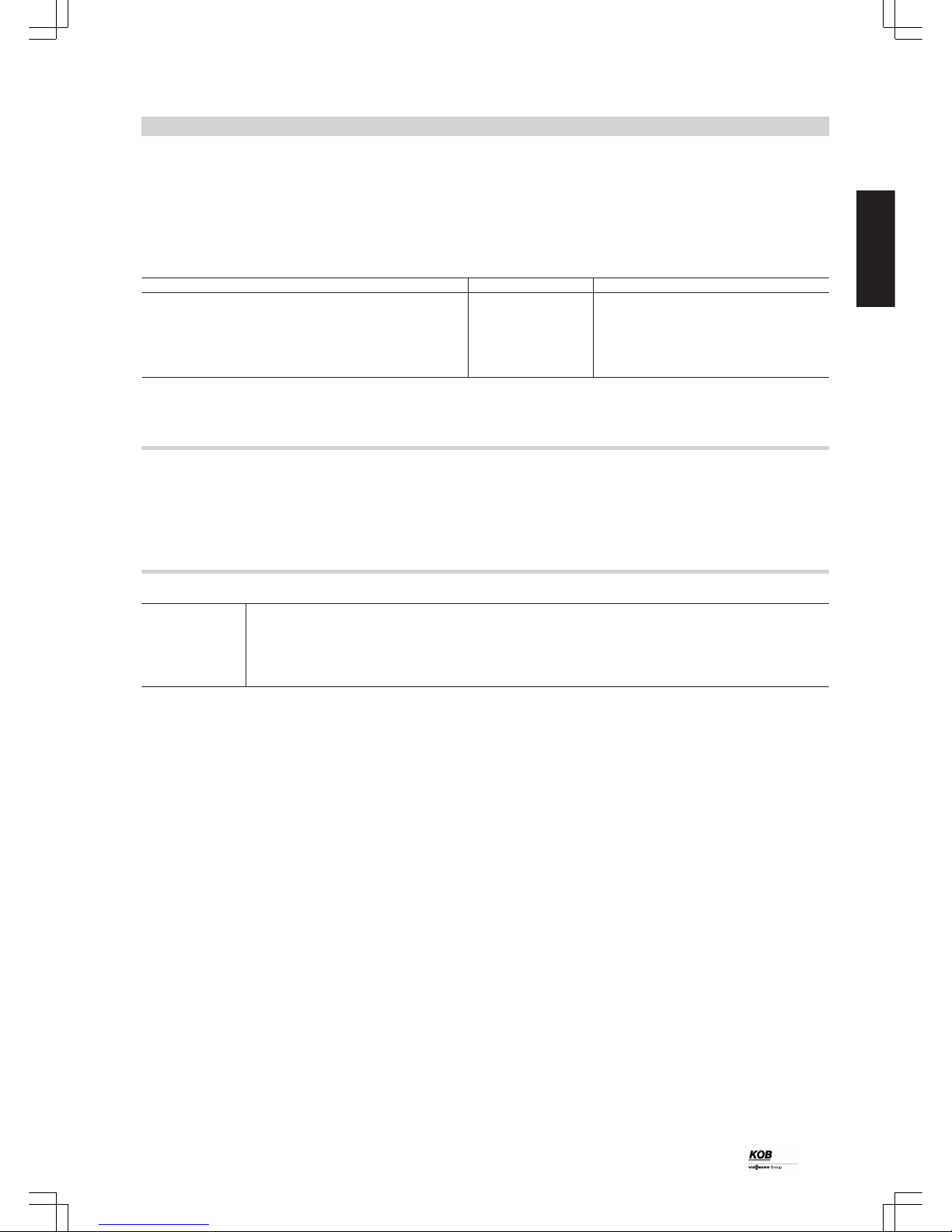

Overview: Possible Ecotronic controllers

Controller Part no. Keys Number of control-

lers

Number of sensors

Controller, additional heat sources

Heat source, parallel 7387 908 1 2 1

Controller, central heating

Central heating (heating circuit with mixer) 7379 402 1 1 1

Adjacent building 7387 865 1 2 2

Long-distance line 7379 401 1 1 1

Space heater group 7387 825 1 1 1

Room controller QAA 35

*8

7379 405 — — 1

Safety thermostat

*9

7387 940 — — —

DHW controller

DHW cylinder B1 (without flow control) 7387 853 1 1 1

DHW cylinder B2 (with flow rate control) 7379 400 1 1 2

DHW circulation 7387 849 1 1 —

Controller, solar

Solar DHW cylinder 7387 818 1 1 2

Solar DHW and central heating 7387 786 1 2 2

Controller, cylinder management

Cylinder management 5 sensors 7387 852 1 1 4

*8

Only in conjunction with controller for central heating or controller for adjacent building

*9

For limiting the heating circuit flow temperature

Control unit

(cont.)

PYROT

15

5822 516 GB

3

Page 16

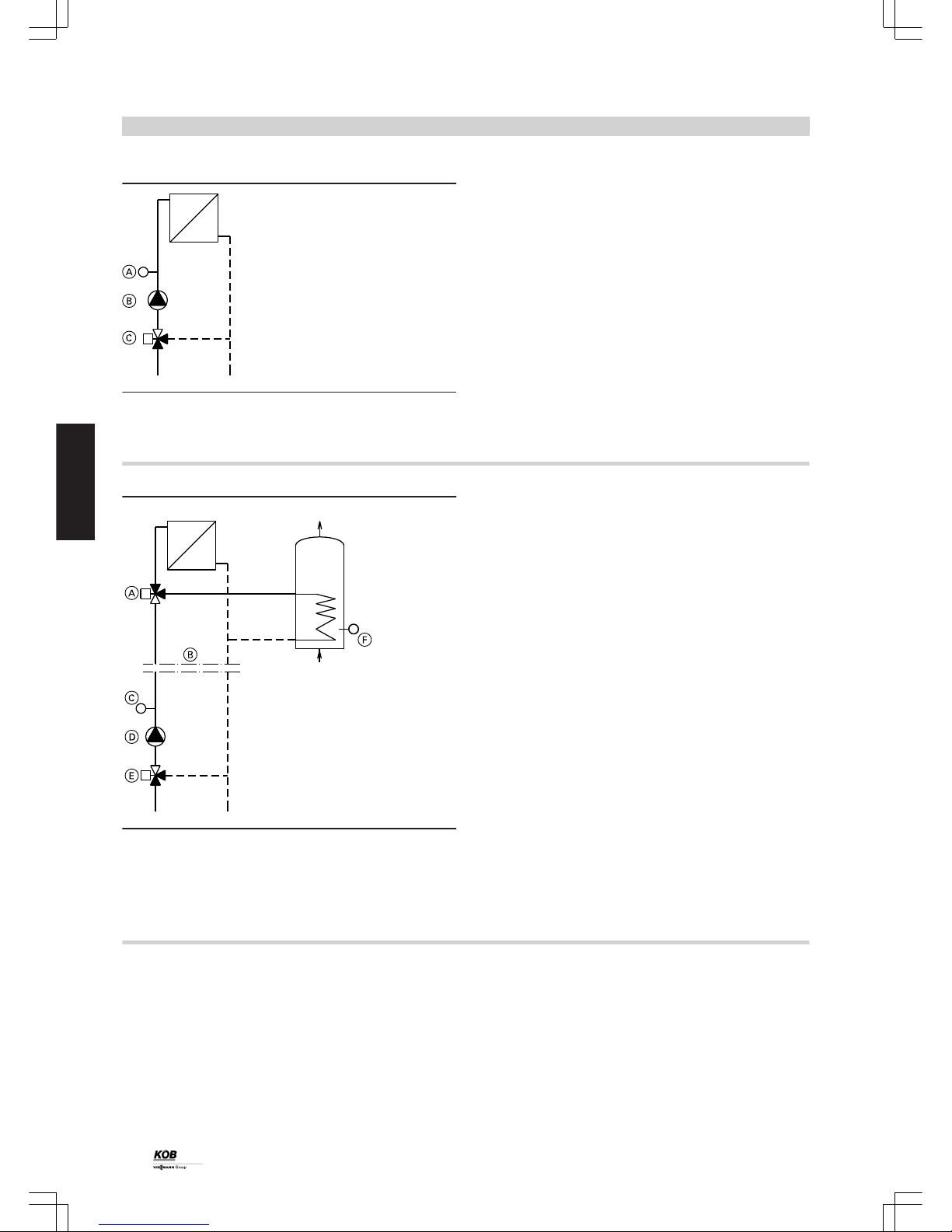

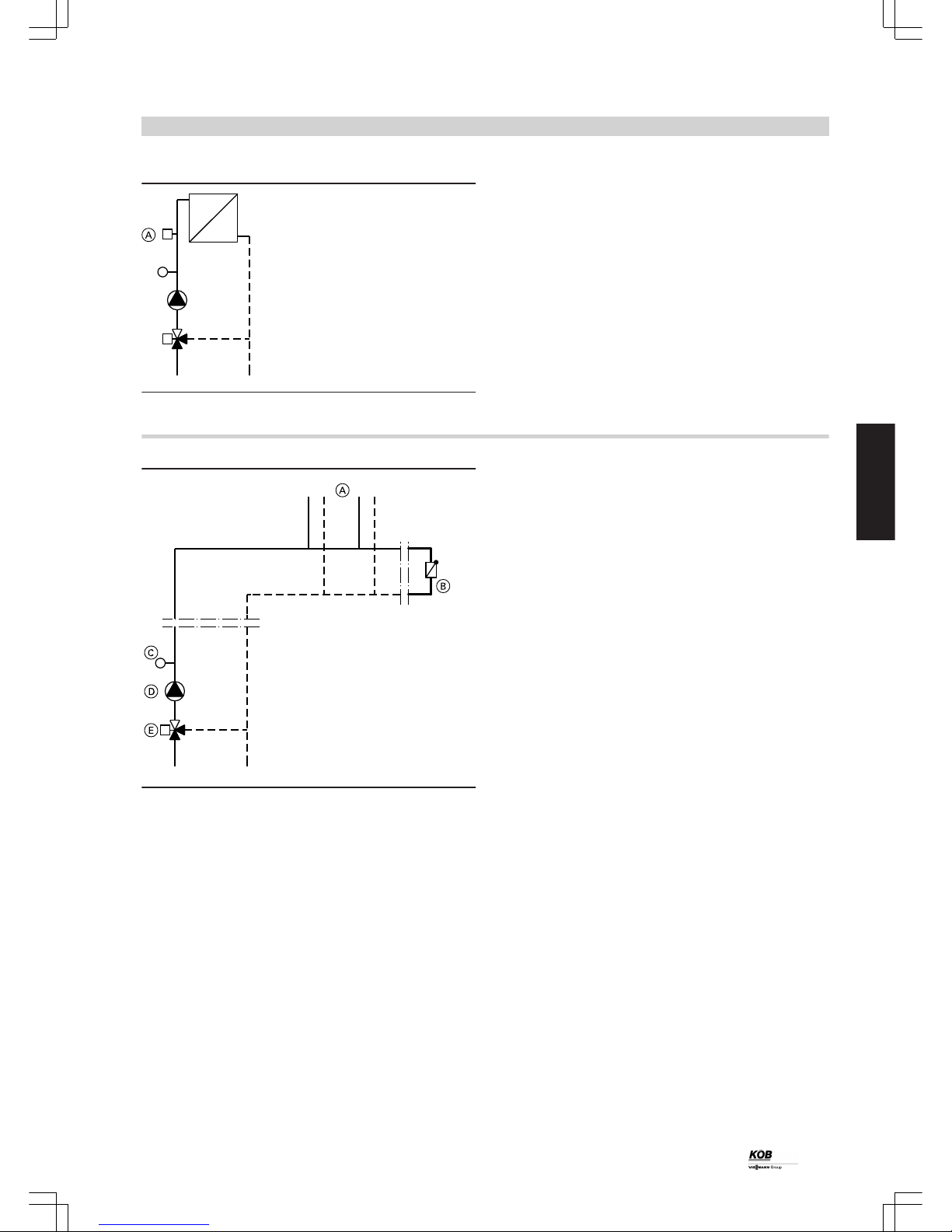

Controller, central heating

A

Contact sensor QAD 21

B

Pump

C

Mixing valve

Part no. 7379 402

Weather-compensated heating control unit with digital time switch for

setback mode according to individual day and seven-day program,

with pump control unit, frost protection function, eco mode and limited

flow temperature.

Standard delivery:

■ Button, central heating

■ Controller output for pump and mixing valve

■ Contact sensor QAD 21

Controller, adjacent building

A

Diverter valve

B

Adjacent building

C

Contact sensor QAD 21

D

Pump

E

Mixing valve

F

Sensor QAZ

Part no. 7387 865

The cable to the adjacent building is controlled with weather compensation via the heating circuit control unit. The DHW cylinder is heated

with the selected maximum flow temperature. For this, the heating

water is diverted to the DHW cylinder via a valve. Via the time switch,

the DHW cylinder is reheated in the downtimes (setback periods).

Standard delivery:

■ Button, adjacent building

■ Controller output for pump, mixing valve and diverter valve

■ Contact sensor QAD 21

■ Sensor QAZ 21.5220 with sensor well ½" x 200 mm

Room controller QAA 35

Part no. 7379 405

Addition to the controller for central heating and controller for adjacent

building. The room controller can be connected as a remote control

and as a room temperature sensor (room temperature compensation).

Standard delivery:

■ Room controller QAA 35

Control unit

(cont.)

16

PYROT

3

5822 516 GB

Page 17

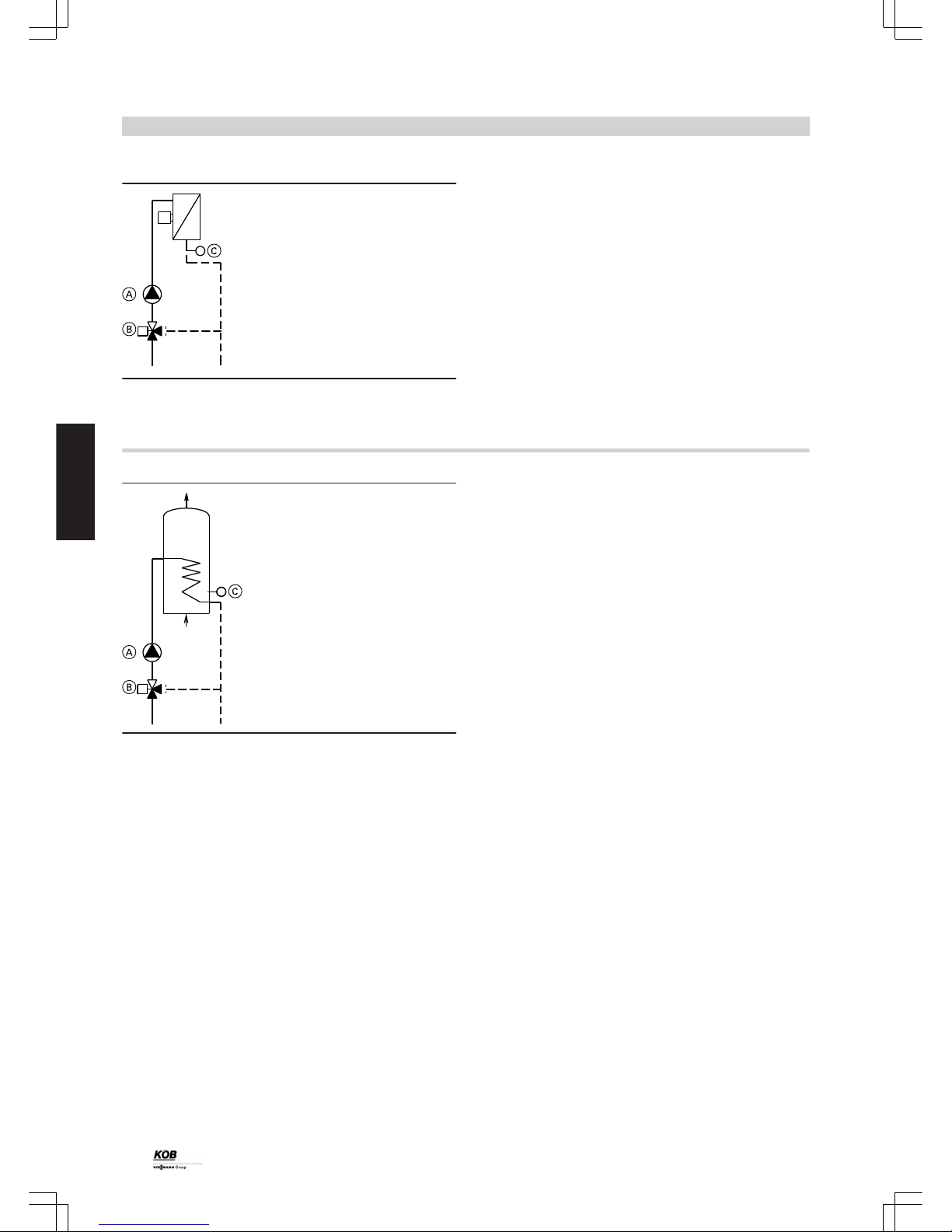

Safety thermostat RAK-TW.1000B

A

Safety thermostat RAK-TW.1000B

Part no. 7387 940

For safe limitation of the flow temperature of a heating circuit.

Standard delivery:

■ Safety thermostat RAK-TW.1000B

Controller, long-distance line

A

Sub-distributor

B

Bypass

C

Contact sensor QAD 21

D

Pump

E

Control valve

Part no. 7379 401

Via a long-distance line, a building is supplied with separate heat distribution. The long-distance line is controlled upstream according to

the demand of the heating circuits. The heating circuits of the separate

heat distribution must be controlled via the Ecotronic.

Standard delivery:

■ Button, long-distance line

■ Controller output for pump and control valve

■ Contact sensor QAD 21

Note

The long-distance line controller module can only be used while Köb

controller modules in the sub-distributor are also being used.

Control unit

(cont.)

PYROT

17

5822 516 GB

3

Page 18

Controller, space heater

A

Pump

B

Mixing valve

C

Contact sensor QAD 21

Part no. 7387 825

The space heaters are supplied with maximum flow temperature by

the boiler cylinder system.

The switching of the fan is carried out by on-site switches or controllers.

The flow rate of the heating water is controlled via the return temperature and matched to the output of the space heater (flow control). This

results in optimum cylinder stratification with sustained high temperature at the cylinder flow. The heating periods (individual day and

seven-day program) can be adjusted via the integrated time switch.

Standard delivery:

■ Button, space heater group

■ Controller output for pump and mixing valve

■ Contact sensor QAD 21

■ Restrictor, bypass

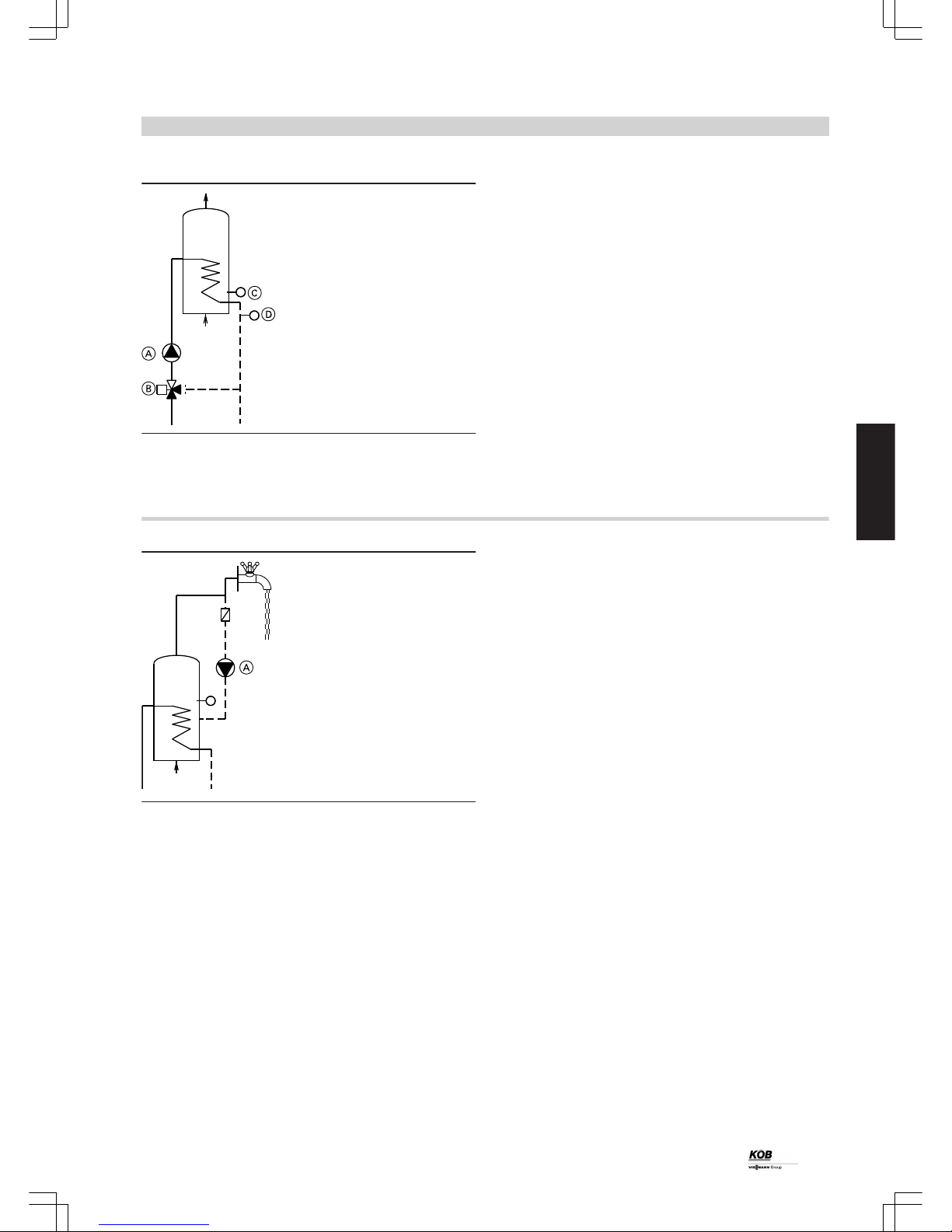

Controller, DHW cylinder B1

A

Pump

B

Two-way valve

C

Sensor QAZ 21.5220

Part no. 7387 853

When its temperature drops, the DHW is reheated via the integral heat

exchanger directly by the boiler or by the buffer cylinder. This is

dependent on a corresponding difference in temperature (either differential temperature or fixed temperature control unit).

The heating periods (individual day and seven-day program) can be

individually adjusted via the integral time switch.

Standard delivery:

■ Button, DHW cylinder

■ Controller output for pump and two-way valve

■ Sensor QAZ 21.5220 with sensor well ½" x 200 mm

Control unit

(cont.)

18

PYROT

3

5822 516 GB

Page 19

Controller, DHW cylinder B2

T

A

Pump

B

Control valve

C

Sensor QAZ 21.5220

D

Contact sensor QAD 21

Part no. 7379 400

When its temperature drops, the DHW is reheated via the integral heat

exchanger directly by the boiler or by the buffer cylinder. This is

dependent on a corresponding difference in temperature (either differential temperature or fixed temperature control unit).

The flow rate of the heating water is controlled via the return temperature (flow control). This results in optimum buffer cylinder stratification

with sustained high temperature at the cylinder flow. The heating periods (individual day and seven-day program) can be adjusted via the

integrated time switch.

Standard delivery:

■ Button, DHW cylinder

■ Controller output for pump and control valve

■ Contact sensor QAD 21

■ Sensor QAZ 21.5220 with sensor well ½" x 200 mm

Controller, DHW circulation

T

A

Pump

Part no. 7387 849

The circulation periods (individual day and seven-day program) can

be adjusted via the integral time switch.

The start-up duration of the DHW circulation pump can be adjusted via

timed cycling.

Standard delivery:

■ Button, DHW circulation

■ Controller output for pump

Control unit

(cont.)

PYROT

19

5822 516 GB

3

Page 20

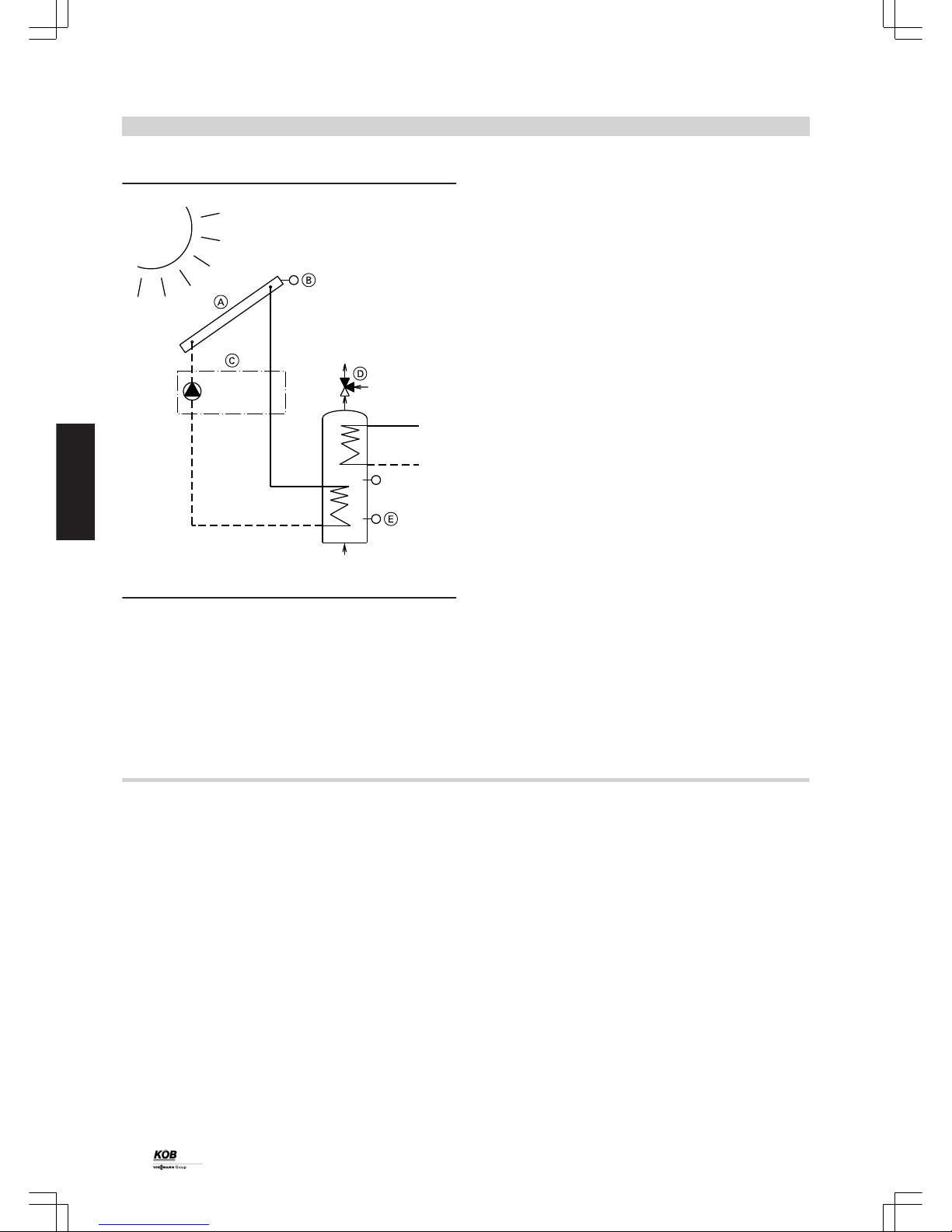

Controller, solar DHW cylinder

T

T

T

KW

WW

KW

HV

HR

RL

VL

HR Heating return

HV Heating flow

KW Cold water

RL Return (solar)

VL Flow (solar)

WW DHW

A

Solar collector

B

Collector temperature sensor

C

Solar station with solar circuit pump

D

Thermostatic water mixer

E

Cylinder temperature sensor QAZ 21.5220

Part no. 7387 818

Use for single solar thermal system as a single circuit control unit for

heating the DHW in the solar DHW cylinder.

If the temperature of the DHW (in the lower section of the DHW cylinder) falls below the collector temperature, the DHW is heated by the

solar collector (adjustable differential temperature: 2 - 20 °C).

Note

The controller for the solar DHW cylinder can only be used in conjunction with a controller for a DHW cylinder (B1 or B2).

Run-on time of the solar circuit pump adjustable from 0 to 120 s (subject to line length).

Maximum DHW temperature adjustable from 20 to 90 °C.

Safety: the solar circuit pump switches off at 140 °C collector temperature; restarts at 120 °C.

Standard delivery:

■ Button, solar

■ Collector temperature sensor PT-1000

■ Cylinder temperature sensor QAZ 21.5220

■ Controller output for the solar circuit pump

Controller, solar/DHW and central heating

Part no. 7387 786

Use for a larger solar thermal system for heating the DHW in the solar

DHW cylinder and for heat supply to the heating cylinder as a threecircuit control unit.

The first circuit is used to heat the DHW, the second heats the heating

cylinder back/bottom and the third heats the heating cylinder front/top.

The heating cylinder is heated with an external plate heat exchanger.

Changing over from the DHW cylinder to the heating cylinder starts the

secondary pump. This then operates with the solar circuit pump. For

optimum functioning, the flow rate in the secondary circuit must be

matched to the primary circuit (e.g. with flow meter in the primary and

secondary circuits).

Differential temperature, collector/DHW 2-20 °C.

The following differential temperatures are freely adjustable:

differential temperature, collector/cylinder back/bottom 2-20 °C.

Note

Controller, solar/DHW and central heating can only be used in conjunction with a controller for a DHW cylinder (B1 or B2).

Run-on time of the solar circuit pump adjustable from 0-120 s (subject

to line length).

Shutdown safety:

■ At 140 °C collector temperature

■ At 95 °C cylinder temperature

Optimised DHW priority (either absolute or no DHW priority).

Cylinder heating with stratification in accordance with the cylinder temperatures via a charging valve for the cylinder front/back.

Standard delivery:

■ Button, solar

■ Collector temperature sensor PT-1000

■ Cylinder temperature sensor QAZ 21.5220

■ Controller output for the solar circuit pump

■ Controller output, charging valve, DHW cylinder

■ Controller output for secondary pump

■ Controller output, charging valve, cylinder back/cylinder front

Control unit

(cont.)

20

PYROT

3

5822 516 GB

Page 21

KW

WW

--M20--

--Y20--

---

--Y6X.1--

--Y6X.2--

--Y6X.1--

--M6X.1--

--B6X.2--

--B6X.1--

--M6X.1--

---

--B6X.1--

--B28.1--

--B28.2--

--B28.3--

CAN

B

--B6X.2--

--M6X.2-2

4

2

2

3

4

3

2

2

4

3

2

4

2 2

4

3

E

Return

Flow

A

D

B

C

G

F

H

KW Cold water

WW DHW

A

Solar collector

B

Solar station with solar circuit pump

C

Thermostatic water mixer

D

Plate heat exchanger

F

Secondary pump

G

Charging valve, buffer cylinder front/back

H

Boiler

Control unit

(cont.)

PYROT

21

5822 516 GB

3

Page 22

3.3 Accessories for ECOTRONIC output management

Cylinder management 3 sensors

Part no. 7387 828

Modulating output operation of the PYROT rotation combustion system is optimised with the use of a buffer cylinder. Short term heat

demand peaks are also covered. The temperature sensors record the

heating of the buffer cylinder. The combustion output is matched to the

charging level of the buffer cylinder.

Standard delivery:

■ 2 additional sensors KTY with sensor well 1/2" x 280 mm

Cylinder management 5 sensors

Part no. 7387 852

Modulating output operation of the PYROT rotation combustion system is optimised with the use of a buffer cylinder. Short term heat

demand peaks are also covered. The temperature sensors record the

heating of the buffer cylinder. The specification of the charging level of

the buffer cylinder is weather-compensated and carried out via the

outside temperature sensor. The combustion output is matched to the

charging level of the cylinder.

Standard delivery:

■ 4 additional sensors KTY with sensor well 1/2" x 280 mm

Note

Part no. 7379 403 controller module and

Part no. 7387 587 data cable required.

External requirement ON/OFF

Part no. 7387 855

Input for automatic switching on/off of the system via external floating

N/O contact.

Operating message potential-free

Part no. 7387 934

If the PYROT boiler is operating on higher control technology, the

operating condition "Load operation" (potential-free output) is issued.

Standard delivery:

■ Potential-free output (operating message)

Output signals 0-10 V

Part no. 7387 800

Issuing of boiler output as voltage signal and a connection to receive

a maximum limit of the boiler output included in standard delivery.

Functions:

■ Issue of the output signals

■ Receipt and processing of an external output restriction

– 0 - 0.5 V... OFF

– 0.6 – 3 V... Standby

– 3.1 – 10 V... 30 % to 100 % output range

Note

Note: The installation of "Output signals 0 – 10 V" downstream of

QM wood heating plants is possible irrespective of additional control

modules used.

Control unit

(cont.)

22

PYROT

3

5822 516 GB

Page 23

3.4 Accessories for ECOTRONIC remote transfer

Fault message device, analogue with battery

Part no. 7387 994

Four different text messages are possible, as the fault message

modem has four independent digital inputs.

Standard delivery:

■ Analogue modem in control panel

■ Battery station (also works in event of a power failure)

To be carried out on customer side:

■ Electrical connection of the phone line to the modem

■ Configuration in accordance with the documentation

Export of operating data

Part no. 7388 038

Issue of relevant operating data and fault messages of the boiler system as ASCII dataset via serial interface to higher control technology

on the customer side. If permitted by the control technology, the higher

control technology can change all adjustable parameters.

Standard delivery:

■ Interface at the control panel

■ Software module

■ MOD-BUS protocol

Note

Additional fault message device, analogue with battery station, part

no. 7387 994, possible

Additional visualisation, wired or wireless, part no. 7388 003, not

possible

Visualisation Pyrot - internal

Part no. 7387 839

With a data cable (max. 30 m), all data can be fed via the serial interface RS 232 from the programming module to the PC. The current

operating data for the boiler system is displayed visually on a function

screen. All options for inputting values and functions and reading out

the operating conditions (exception: "Start boiler)" are shown. All operating data is archived cyclically and can be evaluated graphically in an

extremely simple way.

Note

The PC and data cable are not included in the price.

Standard delivery:

■ CD with visualisation software and installation instructions

Note

Requirements for on-site PC:

Operating system: Windows 98 / 2000 / XP

At least 50 MB free hard disk memory

At least 128 MB RAM

1 free serial interface per boiler

Visualisation, additional functions

Part no. 7387 821

Extension of visualisation [ECO VII] with the functions of additionally

enabled buttons (from F4). Additional functions include each heating

controller (heat source, heat consumer, solar) and automatic charging.

Every button function is shown on a separate function screen with all

options for entering values, reading out the operating conditions and

archiving. Price per piece for additionally enabled button on programming module.

Standard delivery:

■ Extension of the visualisation software CD

Data cable to visualisation - internal

Part no. 7379 404

Data cable comprising:

■ D-SUB connector for connection between programming module and

data cable, soldered

■ 30 m data cable 3-pole (cut to length as required on site)

■ D-SUB connector with threaded fittings, 9-pole for connection to the

PC

Control unit

(cont.)

PYROT

23

5822 516 GB

3

Page 24

Visualisation, externally via modem (connected with cable)

Part no. 7387 792

Package for the transmission of relevant data to an EDP workstation

(internal and/or external) for the visualisation, remote maintenance

and operating data archiving of the PYROT boiler system. Hardware

and software are integrated into the Ecotronic control unit. All adjustable parameters can be changed from the EDP workstation.

Standard delivery:

■ Industrial PC with interfaces for screen, keyboard and PC mouse for

EDP workstation close to boiler room

■ Analogue modem in control panel

■ Windows operating system, remote maintenance software pcAnywhere and visualisation/archiving software installed and tested on

the industrial PC.

Images on the screen:

■ Cross-section image of boiler, 3D with display fields

■ Installation scheme for heat source with display fields

■ Table of parameters (with change option)

To be carried out on customer side:

■ EDP workstation for remote maintenance together with modem,

installation of pcAnywhere and modem is to be set up independently

by the customer

Note

Additional fault message device, analogue with battery station, part no.

7387 994, possible

Additional export of operating data, part no. 7388 038, not possible

Control unit

(cont.)

24

PYROT

3

5822 516 GB

Page 25

3.5 Mastercontrol for two-boiler systems

The Mastercontrol optimises the entire heat generation of two biomass

boilers (PYROT dual system) incl. control of an oil, gas or electric boiler

as a redundancy and/or as a peak load boiler.

Information on the Mastercontrol

Function:

■ Heat management:

Optimum division of the required output between the two biomass

boilers with the main load on the lead boiler and the remaining load

on the lag boiler via a default output value. The default output is

calculated in accordance with QM wood heating stations in line with

the required set temperature in the common low loss header. Automatic switchover of the two boilers between the lead boiler and the

lag boiler is possible. This ensures an even boiler load over a long

operating time (e.g. weekly changeover).

■ Charging:

If fuel for the two biomass boilers is taken from a common fuel store,

charging is controlled up to fuel distribution by the Mastercontrol.

■ Operating data archiving:

Relevant operating data of the past 31 days is stored in a ring buffer

and can easily be displayed in graph form on the Mastercontrol

touch-screen.

Operation:

Operation is carried out via a 10“ touch-screen integrated in the control

panel.

Standard delivery

■ Control panel, loose,

surface powder-coated in RAL 7035 (grey) texture. Version as per

ÖVE/VDE directives fully wired to terminal strips, feed 3 x 400 V 50

Hz; control voltage 230 V or 24 V

■ Freely programmable control unit, CE-tested, program and real time

clock are battery backed

■ Contactor/motor overload relay combinations for all common charging drives (3 x 400 V) according to separate price items

■ Ethernet interface (network connection) on touch panel

■ Potential-free output (fault message)

■ 10“ touch-screen

■ 4-pole main isolator

■ Documentation incl. fixed wiring diagram

■ Terminal connection diagram with cable designation in plan pocket

■ Heater management 5 sensors (QM)

■ 5 sensors PT-1000 with sensor well 1/2" x 280 mm

■ 1 weather sensor PT-1000

■ Default output value for both biomass boilers for processing in the

subordinate boiler control units via CAN BUS

Note

Remote maintenance with PC or network, water-side and electrical

installation on customer side.

Visualisation with touch-screen

■ Operating data archive

■ Display and archiving of the relevant

■ Operating data of both wood boiler systems and the Mastercontrol

■ Easy operation of the wood boiler systems at the touch-screen of the

Mastercontrol

■ Installation scheme for heat source with display fields

■ Table of parameters (with parameter setting options)

■ Fault history

Control unit

(cont.)

PYROT

25

5822 516 GB

3

Page 26

Schematic diagram

M

T

T

T

T

T

M

M

T

1

PYROT 1 PYROT 2

2

ECOTRONIC ECOTRONIC

MASTERCONTROL

A

B

C

D

B28.1

B28.5

B28.4

B28.3

B28.2

ECOTRONIC

1

ECOTRONIC

2

E F

1

2

G

MASTERCONTROL

Schematic diagram of a two-boiler system with Mastercontrol

A

Additional heat source

B

Flow consumers

C

Buffer cylinder as low loss header

D

Return consumers

E

Exclusively charging boiler 1 in control unit boiler 1

F

Exclusively charging boiler 2 in control unit boiler 2

G

Common charging, control unit modules

Control unit

(cont.)

26

PYROT

3

5822 516 GB

Page 27

3.6 Accessories for Mastercontrol

Heat meter signal

Part no. 7387 975

Note

Only for Mastercontrol.

With this analogue input (0-10 V signal), the external heat meter can

be read into the Mastercontrol. The current values can be displayed

on the screen. The heat meter data is archived in the visualisation.

Requirement, additional heat source KP0

Part no. 7387 923

Function:

The additional heat source supplies, individually or jointly with the

boiler, heat to the buffer cylinder. This is designed as a low loss header.

Taking into consideration the inertia of the boiler, the boilers are controlled so that the additional heat source covers the peak load and the

wood boiler covers the base load. In the operating phase of the additional heat source, the boiler pump is operating and the motorised

shut-off device is open.

Standard delivery:

■ Sub-menu on touch-screen

■ Contactor and motor overload relay, boiler circuit pump, additional

heat source

■ Control of motor, shut-off device

■ Floating contact for the control of the burner

■ Sensor PT-1000 incl. sensor well ½” x 280 mm loose (installation in

low loss header-system sensor)

Note

The electrical output data of the on-site boiler pump (kW, ampere, volt)

must be given.

Requirement, additional heat source KP1

Part no. 7387 908

Function:

The additional heat source supplies, individually or jointly with the

boiler, heat to the buffer cylinder. This is designed as a low loss header.

Taking into consideration the inertia of the boiler, control is carried out

so that the additional heat source covers the peak load and the boiler

covers the base load. In the operating phase of the additional heat

source, the boiler pump is operating and the control unit of the boiler

mixer is enabled.

Standard delivery:

■ Sub-menu on touch-screen

■ Contactor and motor overload relay, boiler circuit pump, additional

heat source

■ Control of motor, shut-off device

■ Floating contact for the control of the burner

■ Sensor PT-1000 incl. sensor well ½” x 280 mm loose (installation,

return of additional heat source)

■ Sensor PT-1000 incl. sensor well ½” x 280 mm loose (installation in

low loss header-system sensor)

Note

The electrical output data of the on-site boiler pump (kW, ampere, volt)

must be given.

Pt1000

Control unit

(cont.)

PYROT

27

5822 516 GB

3

Page 28

Fault message device, analogue with battery

Part no. 7387 840

Transmits the boiler system fault messages as a phone message. The

fault message must be acknowledged. Four different text messages

are possible, as the fault modem has four independent digital inputs.

Standard delivery:

■ Analogue modem in control panel

■ Battery station (also works in event of a power failure)

To be carried out on customer side:

■ Electrical connection of the phone line to the modem

■ Configuration in accordance with the documentation

Export of operating data

Part no. 7387 890

Issue of relevant operating data and fault messages of the boiler system via MOD-BUS as ASCII dataset via a serial interface to higher

control technology on the customer side. If the option is available, the

higher control technology can change all adjustable parameters.

Standard delivery:

■ Interface at the control panel

■ Software module

■ MOD-BUS protocol

Note

■ Additional fault message device, analogue with battery station possible (part no. 7387 840)

■ Additional visualisation, wired (part no. 7387 997) or wireless (part

no. 7387 874) possible

Control unit

(cont.)

28

PYROT

3

5822 516 GB

Page 29

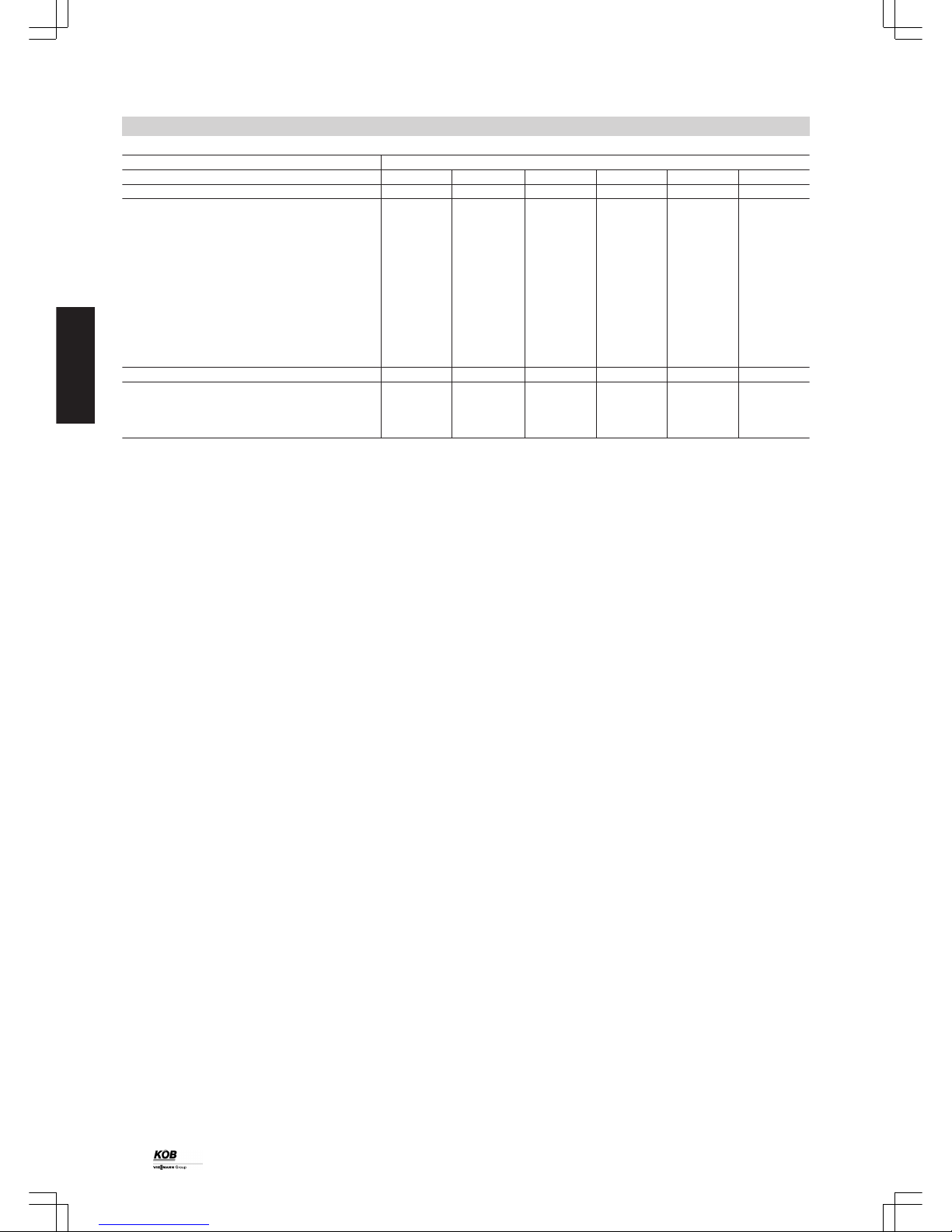

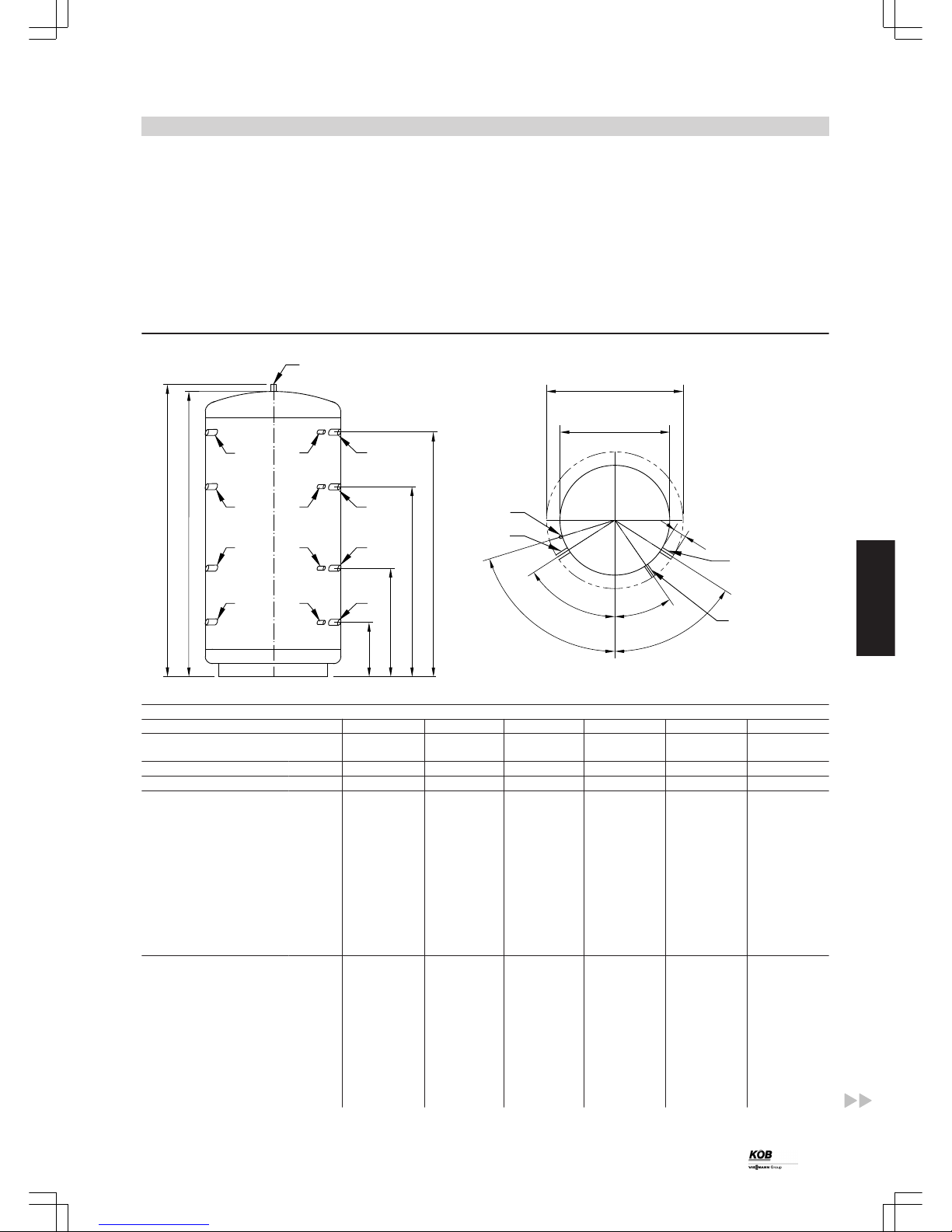

4.1 Specification, buffer cylinder

Buffer cylinder HPM

Buffer cylinder for integration in a wood combustion system with a

maximum boiler output of up to 150 kW.

Version:

■ Steel S 235 JRG2, untreated inside, anti-rust coating outside

■ Operating pressure: max. 3.0 bar; test pressure: 4.5 bar

■ Connections: 8 female connections R 1½, 4 female connections

R ½, 1 sensor pipe 14 x 1.5 mm, 1 female connection top R 1¼

Flexible foam insulation to HPM

The insulation is made from 100 mm thick flexible PUR foam elements

with polystyrene casing.

Fire safety category B3.

Note

Delivery is ex-stock.

Alternative cylinder sizes and insulation types on request.

e

a

b

c

d

03

f

01

01

01

01

01

01

01

01

02

02

02

02

01

02

1

4

o

k

l

m

n

g

h

Part no. buffer cylinder HPM 7424130 7424131 7424132 7424133 7424134 7424135

Part no. flexible foam insulation to

buffer cylinder HPM

7424136 7424137 7424138 7424139 7424140 7424141

Contents l 1000 1250 1500 2000 2500 3000

Weight kg 170 176 185 211 260 300

Dimensions

Height when tilted mm 2080 2070 2200 2410 2375 2780

a mm 310 310 380 320 535 380

b mm 745 745 825 900 975 1020

c mm 1250 1250 1350 1490 1415 1680

d mm 1710 1710 1760 2020 1855 2330

e mm 1993 1948 2098 2308 2217 2655

f Total height mm 2043 1998 2148 2358 2267 2705

g Diameter without

insulation

mm 790 950 1000 1100 1250 1250

h Diameter with insula-

tion

mm 990 1150 1200 1300 1450 1450

Connections

k 50° 50° 50° 50° 50° 50°

l 50° 50° 50° 50° 50° 50°

m 28.2° 31.9° 32.8° 34.3° 36.2° 36.3°

n 70° 70° 70° 70° 70° 70°

o Length of female con-

nections

mm 100 100 100 100 100 100

01 Female connections,