KOB PYROMAT DYN, Pyromat DYN 45, Pyromat DYN 85 Operating And Maintenance Instructions Manual

Page 1

Operating and Maintenance Instructions for the

PYROMAT DYN 45 to 85

ID: 103708-G English

Page 2

© by Köb Holzfeuerungen GmbH

Flotzbachstrasse 33

A-6922 Wolfurt

All rights reserved, including photomechanical reproduction and storage in electronic

media.

Viessmann Group

Page 3

1 General information _____________________________________________________________________ 4

1.1 Foreword ____________________________________________________________________________ 4

1.2 Latest developments in the technology ___________________________________________________ 4

1.3 Intended use _________________________________________________________________________ 4

1.4 Technical specs_______________________________________________________________________ 4

1.5 Documented information _______________________________________________________________ 4

1.6 CE-Symbol___________________________________________________________________________ 4

2 Important information____________________________________________________________________ 5

2.1 Safety information_____________________________________________________________________ 5

2.2 Excess temperature & power failures _____________________________________________________ 5

2.3 Fire hazard___________________________________________________________________________ 6

2.4 Minimum requirements for wood fuels ____________________________________________________ 6

2.5 Filling the fuel storage unit______________________________________________________________ 7

2.5.1 By dumping _________________________________________________________________________ 7

2.5.2 By blowing in ________________________________________________________________________ 7

2.6 Correcting malfunctions of the conveyor equipment ________________________________________ 7

2.7 Correcting malfunctions in the de-ashing system___________________________________________ 7

3 Burner design __________________________________________________________________________ 8

4 Starting up / Operation ___________________________________________________________________ 9

4.1 Initial start-up_________________________________________________________________________ 9

4.2 Automatic operation ___________________________________________________________________ 9

4.2.1 Heating up__________________________________________________________________________ 9

4.2.2 Operation___________________________________________________________________________ 9

4.3 Log operation _______________________________________________________________________ 10

4.3.1 Filling_____________________________________________________________________________ 10

4.3.2 Heating up_________________________________________________________________________ 10

4.3.3 Operation__________________________________________________________________________ 11

4.3.4 Adding fuel ________________________________________________________________________ 11

5 The ECOTRONIC Control System _________________________________________________________ 12

5.1 General information __________________________________________________________________ 12

5.1.1 Battery replacement _________________________________________________________________ 12

5.2 The functions of the buttons ___________________________________________________________ 12

5.3 The burner and its loading F3, F4 _______________________________________________________ 13

5.3.1 F3 button "PYROMAT parameters"______________________________________________________ 13

5.3.2 F4 button "PYROMAT loading" _________________________________________________________ 14

5.4 The F5-F8 extended control systems ____________________________________________________ 15

5.4.1 Room heating unit ___________________________________________________________________ 15

5.4.2 Utility water heater___________________________________________________________________ 17

5.4.3 Air heater__________________________________________________________________________ 18

5.4.4 Neighbouring buildings _______________________________________________________________ 19

5.4.5 Pipeline ___________________________________________________________________________ 20

5.4.6 Additional boilers____________________________________________________________________ 21

5.4.7 Solar _____________________________________________________________________________ 22

6 Cleaning______________________________________________________________________________ 23

6.1 Automatic operation __________________________________________________________________ 23

6.1.1 Cleaning of de-ashing system (optional)__________________________________________________ 24

6.1.2 Cleaning of main combustion chamber___________________________________________________ 24

6.1.3 Cleaning of exhaust gas deduster (optional)_______________________________________________ 24

6.2 Chopped wood operation______________________________________________________________ 25

7 Shutdowns____________________________________________________________________________ 26

8 Waste disposal ________________________________________________________________________ 26

9 Enclosures

- Spec Sheet 1010-1, 2

- Error Reports / Error Correction

Page 4

4

1 General information

1.1 Foreword

Dear System Owner, you have made a good selection in the PYROMAT DYN. It will provide you

with all the advantages of a modern, economically

efficient heating system. Fully developed technology in combination with a sturdy design guarantee

a high degree of operational reliability and long

service life.

These Operating and Maintenance Instructions

contain important information for the intended use,

correct operation and proper maintenance of the

PYROMAT DYN.

Non-compliance with the Operating and Maintenance Instructions will result in loss of the

guarantee.

If you still need any further information after studying the Operating and Maintenance Instructions:

The Assembly and Installation Instructions contain

important information about:

- Standards and regulations,

- Structural surroundings of the burner

- Transport & assembly

- Water installation and electrical installation,

- Fire protection,

- Starting up,

as well as an appendix with diagrams of connections and dimensions as well as the complete technical specifications.

Our sales and services offices will be glad to provide you with any further information. Their addresses can be found on the reverse side of these

Operating and Maintenance Instructions.

1.2 Latest developments in the technology

The Operating and Maintenance Instructions are in

keeping with the PYROMAT DYN at the time it is

delivered. In the interest of our customers, we reserve the right to make, without any notification requirement, the following changes resulting from

further technology developments.

1.3 Intended use

The intended use of the PYROMAT DYN is for incinerating wood fuels.

The intended use of the PYROMAT DYN is stipulated:

- in the regulations of the Assembly and Installation Instructions

- by the limits of the technical specifications

- in Spec Sheet 1010 "Minimum requirements for

wood fuels – instructions",

- by the safety regulations in these Operating and

Maintenance Instructions.

Any other use of the PYROMAT DYN or use of it

going beyond this will be considered as unintended

use unless written approval by the manufacturer

has been obtained.

The following, among other things, will be considered as unintended use:

- Operation of the PYROMAT DYN by unqualified

personnel, without any training or knowledge of

the Operating and Maintenance Instructions.

- Disabling the safety or monitoring devices on the

PYROMAT DYN.

- Removal of any protective covers or cladding on

the PYROMAT DYN by unauthorised individuals.

- Making any conversions or alterations to the PYROMAT DYN without approval by the manufac-

turer.

- Using spare parts or accessories from other

manufacturers without approval by the manufacturer.

The operating organisation will be liable for

any damage or accidents in case of any unintended use.

1.4 Technical specs

The following important limits apply to the PYROMAT DYN heating boiler:

- Max. operating pressure allowed: 3.0 bar

- Max. boiler temperature allowed: 100°C

- Min. return temperature: 70°C

The complete technical specifications listed in the

appendix of the Assembly and Installation Instructions.

1.5 Documented information

The Operating Instructions contain the information

required according to the EC Directive on Machinery 98/37/EEC, Appendix 1, Number 1.7.4.

Issue: 2007-09 _English

Prepared by: KaW/ScM

1.6 CE-Symbol

The PYROMAT DYN is delivered with a CEsymbol on its type plate an EC attestation of conformity in accordance with II A or the EC Directive

on Machinery 98/37/EEC.

If the PYROMAT DYN is altered by equipment

from other manufacturers being added, or the

safety equipment or control system are combined

with a different system and/or integrated into an

overriding system (building control system), then in

the European Union a new attestation of conformity has to be issued before it is put on the market.

Page 5

5

2 Important information

2.1 Safety information

When carrying out work on the heating system,

such as cleaning and maintenance, wear appropriate protective equipping when required.

There is a danger of getting injured through:

burning, knocking against corners and edges,

crushing in moving parts and noise.

Mains supply: 400V

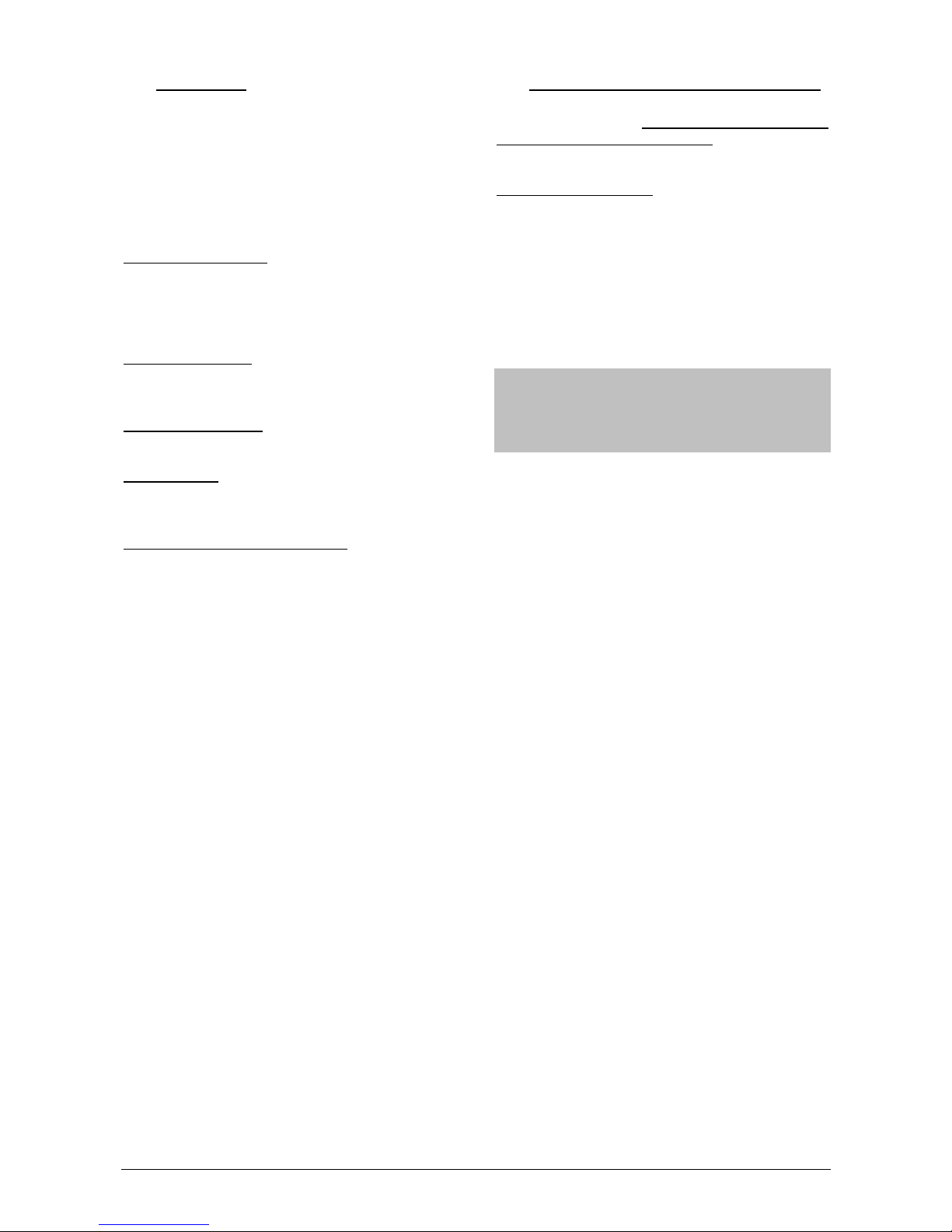

In dangerous situations, the PYROMAT DYN can

be disconnected from the electrical mains system

using the master switch (1) delivered unmounted

along with the system (which the customer should

install next to the control panel),

or by means of the plug connection for the power supply on

the rear side of the burner (2),

disconnecting all the pins.

Doors

When the access door is not opened all the way, it

automatically falls back shut.

The burner must never be operated with the

doors open!

Any burning bits that escape could result in a fire.

Only open the doors in manual operation and then

only during the starting phase or during the burnout phase (for refilling, exhaust gas temperature

less than 130°C). If the doors were opened during

operation, sparks and tongues of fire could leap

out.

Equipment for dissipating excess heat

The functioning of the thermal run-off safety valve

must be inspected every year by a competent specialist.

The safety heat exchanger must not under any circumstances be used as an operational heat exchanger.

Seals

It is important for the functioning and controllability

of the burner that no unwanted air be able to enter

unchecked through leaks.

The doors and lids have to close tightly without

leakage. Any damaged seals must be immediately

replaced. Tighten snugly the fastening bolts and

handles.

Operation, cleaning & maintenance

Bear in mind that only if operated and maintained

properly can even the best of products fulfil their

functions well, for a long time and free of malfunctions.

Compliance with the "Cleaning" section is mandatory!

2.2

Excess temperature & power failures

Do not open the doors or lids on the burner!

• Switch on additional heat consumers.

• The exhaust fan goes out of operation.

• The temperature-limiting safety switch triggers.

• The valve for the thermal run-off safety valve

opens at approx. 95°C. The excess heat is

conducted off into the channel.

If the temperature-limiting safety switch (TLSS)

has triggered, then it has to be manually unlocked.

To reset, unscrew the black cap and press the button.

IMPORTANT

: Only as of a temperature of approx.

70°C is resetting possible.

Possible causes for excess temperature

:

• Incorrect setting on the control module.

• Defective component of the system (pump or

valve).

• Sudden drop in output to zero. The feed auger

still has to be run empty. The heat then produced by this can result in excess temperature.

Activate the "Eliminate Excess Heat" function!

1

2

The TLSS (temperaturelimiting safety switch) is

situated in the front

metal plate beneath the

refill access lid.

Page 6

6

2.3 Fire hazard

With insertion-type firing systems, the conveying

route creates a connection between the silo and

the burning material in the burner. With the PY-

ROMAT DYN insertion-type heating boiler, the

feed auger is also the metering auger, and thus

always filled full with material during operation.

There are various safety devices provided to prevent back burn.

Temperature sensors:

By means of temperature sensors on the feed auger, in case of excess temperature the loading to

the feed auger is interrupted, and the feed auger's

material is inserted into the combustion chamber.

Slide valve (option):

This closes in case of a standstill, danger of back

burn or power failure (spring return motor).

Rotary valve (option):

Instead of a slide valve, in silos with pressurisation.

Drop-off route:

A vertical drop-off route interrupts the connected

line of burning material.

Fire-extinguishing system (option):

This system, which functions independently of the

electrical power, brings about a flooding of the material to be burned that is located in the feed auger.

The activation temperature is approx. 95°C.

2.4 Minimum requirements for wood fuels

The PYROMAT DYN is only suitable for incinerating the fuels listed in Spec Sheet 1010 "Minimum

Requirements for Wood Fuels" (see enclosure)

and here.

Logs for manual loading

:

Untreated, air-dried logs, such as split wood, billet

wood and round wood.

Hardwood: max. ∅ 15 cm

Soft wood: max. ∅ 12 cm

Benchmark figures for storage (in dry storage)

Hardwood: 2 to 2

1

/2 years

Soft wood: 1 to 1

1

/2 years

If different fuels are used, KÖB will not assume

any liability for the functioning or service life of

the burner. Refer to the "Warranty" section in

the General Terms and Conditions of Delivery.

Page 7

7

2.5 Filling the fuel storage unit

2.5.1 By dumping

Rotary sweep extraction and spring-operated

extraction

Heating system in operation:

- If the articulated arms or spring-mounted plates

are still covered by fuel

, refilling can be carried

out immediately.

- If the articulated arms or spring-mounted plates

are no longer covered by fuel

, fill the silo evenly

to approx. 30 cm above the articulated arm or

over the spring-mounted plates. As soon as the

articulated arms or spring-mounted plates have

retracted through a request for material, the refilling can be continued.

Heating out of operation:

- If the articulated arms or spring-mounted plates

are still covered by fuel

, refilling can be carried

out immediately.

- If the articulated arms or spring-mounted plates

are no longer covered by fuel

, fill the silo evenly

to approx. 30 cm above the articulated arm or

over the spring-mounted plates. Then activate

the "SILO FILLING" function. To do so, press

the LOADER SYSTEM key (F4) and then the

LEFT ARROW KEY (<). Then select "YES" and

confirm with "OK". Wait until the articulated

arms or the spring-mounted blades go under

the cup washer, and then finish evenly

filling

the silo. The "SILO FILLING" function brings

about the filling of the fire box.

NOTE: The "SILO FILLING" function cannot be

activated until the heating system has been out

of operation for one hour.

Moving floor conveyor

- Fuel can be refilled automatically.

Funnel extraction system

- It is mandatory that the heating system be in

operation!

2.5.2 By blowing in

The heating system has to be out of operation

(danger of excess pressure or negative pressure caused by the action of blowing-in). Filling

procedure as described in section 2.6.1.

2.6 Correcting malfunctions of the conveyor equipment

The cause of motor malfunctions in conveyor systems is usually clogging by large pieces of wood or

foreign matter

(e.g. pieces of wood or stones).

CAUTION

DANGER OF INJURY:

Always turn off the master switch before carrying out any repair of a malfunction on feed systems and every time before a maintenance lid

is opened or a protective device is removed!

Due to the facility's automatic operation, the point

in time for the conveying means to be switched on

is not foreseeable.

2.7 Correcting malfunctions in the de-ashing

system

The cause of motor malfunctions in the de-ashing

system is usually clogging by large pieces of foreign matter or stones.

Important:

The main switch must be switched off

each time

before correcting a malfunction in the de-ashing

system! The automatic operation of the system

makes it impossible to foresee the time point when

the de-ashing auger will switch on!

Safety instructions:

− Use gloves and protective eyewear.

− Set the boiler control system to "Out of opera-

tion".

− Allow the boiler to cool down.

− The foreign matter will be hot! For this reason,

remove the foreign matter with the kindling utensil or with pliers.

− Never reach into the feed system with your fin-

gers! Use tools!

Procedure:

− Mark the position of installation for the grate

elements.

− Then remove the grate elements.

− Remove the foreign matter with pliers.

− If the foreign matter gets jammed:

Remove the protective lid at the motor de-

ashing unit.

Turn the fan wheel on the motor to make the

auger move slightly. This will loosen the foreign matter.

Remove the foreign matter with pliers.

After the final cleaning of the components taken off

(protective lid, grate elements, etc.) put back on

properly.

Functional test:

When the mechanical cleaning system is operating, the de-ashing system should also be running.

Page 8

8

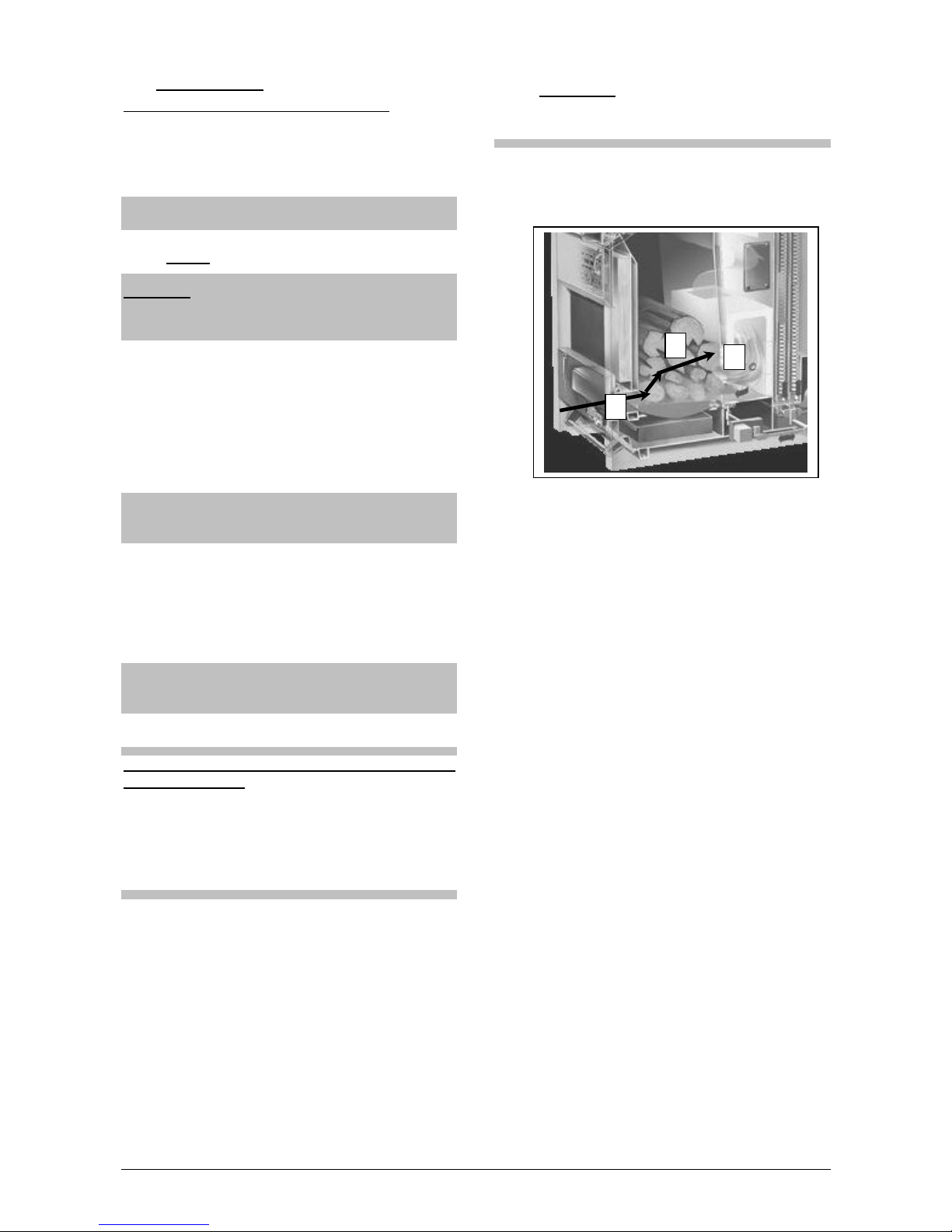

3 Burner design

(Picture: PYROMAT DYN 45)

(1) Electronic burner control panel

(2) Feed auger and degassing grate with primary

airflow

(3) Automatic ignition device

(4) Main combustion chamber made of heat-

resistant refractory concrete

(5) Post-combustion chamber (secondary airflow

via firebox door)

(6) De-ashing system for the combustion chamber

Explanation of illustration: The position of the

sweeper adjusts in the mechanism and has to

support the "flow" of the ash toward the ash

compartment. (Note: the inoperative position for

the sweeper is not shown in the illustration.)

(7) Large ash compartment with utilisation of re-

sidual burning embers

(8) Front combustion chamber with filling on top

(9) Firebox door with air vent control

(10) Pipe-type heat exchanger with automatic

cleaning system

(11) Drive for automatic de-ashing and cleaning

(12) RPM-controlled exhaust fan

(13) Lambda sensor

(14) Safety heat exchanger

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Page 9

9

4 Starting up / Operation

4.1 Initial start-up

The initial start-up is carried out either by Köb

Holzfeuerungen GmbH or another heating specialist.

Be absolutely sure to follow the instructions in

the Assembly and Installation Instructions. No

guarantee may be claimed in cases of initial

start-ups carried out improperly by oneself.

First check:

• Is there enough water in the heating system?

• Has the heating system been bled?

• Are the slide valves open to the heating forward

and reverse flow?

• Can enough fresh air get into the heating

room?

• Are the doors and lids on the burner all closed

leak-tight?

4.2 Automatic operation

CAUTION: Do not start automatic operation

with the filling shaft filled Æ Danger of explosion!

4.2.1 Heating up

• Press the F2 button "PYROMAT Auto". The

loader modules will be switched on in the order

required. When there is enough fuel in the

combustion chamber, the entire loader system

switches off.

• The automatic ignition then takes place. The

ignition process stops as soon as the fire is

started.

4.2.2 Operation

With hydraulically switched heat storage tank

• The material is supplied depending on the light

barriers in the metering container and in the

combustion chamber, allowing for the residual

oxygen.

• The primary and secondary air vents change

their positions depending on the exhaust gas

temperature and residual oxygen.

• Using the setting "Storage Management, Temperature, Storage, Average", it is possible to

keep the facility in continuous high-performance

operation for as long as possible – with fewer

ignitions, better efficiency and lower emissions.

• When the boiler temperature set is reached, the

facility switches to "run auger empty". When

the feed auger has been run empty, and the

exhaust gas temperature is less than 90°C, the

exhaust gas fan switches off and the air vents

close.

• When the "System Temperature Setting" is

fallen short of, the facility is automatically

started back up.

With ECO function (option), heat accumulator

with storage control valve

An additional storage control valve for exact temperature stratification in the accumulator and optimum exploitation of the residual boiler heat.

How to switch off

• Press the F2 button "PYROMAT Auto". As

feedback to this, "Run Auger Empty" will appear

on the control panel.

I M P O R T A N T:

Do NOT use the master button to switch off

Æ DANGER OF BACK BURN !!!

Page 10

10

4.3 Log operation

Check the storage unit temperature! Check

whether the storage unit temperature has dropped

so far that heating up is practical, and whether the

amount of heat to be expected can be accepted or

stored.

Maximum storage unit temperature: 90°C

4.3.1 Filling

CAUTION: Never fill shavings or woodchips di-

rectly from the grate Æ There is a danger such

going up in flames suddenly!

• The slots in the grate have to be free of ash.

Only charcoal (approx. 2 cm) may remain lying

on the grate. Evenly spread out paper on this

(better than cardboard) and easily combustible

wood over the entire width of the burner

(approx. 25 cm high). Position the pieces of

wood crosswise such that a layer permeable to

air is created.

Finer material may only be filled on the layer of

chopped wood.

• Neatly lay the billet wood and logs horizontally

and compactly over the entire width of the firebox.

• When closing the access door, be sure that the

supporting surface for the refill access lid seal

is clean.

Note that even a small ember remaining can

also inadvertently ignite the kindling wood.

With hydraulically switched heat storage tank

Only fill the firebox partially – only reduced log operation is possible!

Load with logs to a maximum of 20 kg to 40 kg per

filling, depending on the thermal acceptance.

With ECO function (option), heat accumulator

with storage control valve

• Full operation with logs.

• Only refill as much wood as energy that the

storage unit can still accommodate until the

maximum storage unit temperature of 90°C is

reached.

4.3.2 Heating up

Kindling

• Is the airway (1) to (3) clear through the entire

area of the grate, through fuel at the bottom and

into the combustion chamber? Is the lower part

of the wood loaded (2) permeable to air?

• Open the ash pan lid. Ignite, ideally doing so

over the entire width of the firebox,

• such that the fire spreads over the entire area

of the grate as quickly as possible.

Aim to keep the heating-up procedure short,

quickly producing a lot of heat and embers.

Rapid heating up of the combustion chamber

rapidly produces perfect incineration.

• Press the F1 button "PYROMAT Manual".

• Leave the ash pan lid approx. 10 cm open until

the material to be burned has started to burn

well.

• When the temperature of the exhaust gas

reaches approx. 110°C, close the ash pan lid.

1

2

3

Page 11

11

4.3.3 Operation

• All the lids and doors have to be closed with no

leakage during the burn-off.

• The temperature of the exhaust gas should rise

to 130°C to 150°C in just a few minutes, and be

between 160°C and 200°C in continuous operation.

• If the temperature of the exhaust gas prematurely drops back down during the burn-off, you

have a hollow fire.

Cause:

Pieces of wood have been poorly

stacked or are irregular.

Remedy:

Carefully open the ash pan lid and

with a poker spread the wood over the entire

bed of embers.

Combustion time for:

• Each loading of wood from deciduous trees:

approx. 4 hours

• Each loading of wood from coniferous trees:

approx. 3 hours

4.3.4 Adding fuel

First check:

• Check the storage unit temperature! Can the

energy to be expected be accepted or stored?

Maximum storage unit temperature: 90°C.

• Is the burner already in the burn-out phase (ex-

haust gas temperature below 130°C)?

• Is the exhaust gas fan already out of operation?

Adding fuel:

• If the exhaust gas fan is already out of opera-

tion:

Press the F1 button "PYROMAT Manual".

• If the exhaust gas fan is still in operation:

Before adding

, press the F1 button "PYROMAT

Manual" (Add Fuel function). This will bring

about fast stabilisation of the operation.

• First only raise the access door slightly,

so that

any accumulation of low-temperature gas present in the upper part of the firebox can be suctioned off.

• Then unlock the safety lock (1) and open the lid

all the way.

• Neatly lay the billet wood and logs horizontally

and compactly over the entire width of the firebox. Only refill as much wood as energy that

the storage unit can still accommodate.

I M P O R T A N T: Do not put any wood shavings or fine chips directly onto the embers Æ

There is a DANGER such GOING UP IN FLAMES SUDDENLY!

• Close access door. Be sure that the supporting

surface for the refill access lid seal is clean.

Afterwards check:

• The surface of the ceramic combustion chamber should remain white.

• The vertical pipe-type heat exchanger must not

have any shining soot or tar deposits.

• The ash content is very low when the wood incinerates in a controlled fashion (approx. 1 percent by weight). The ash should be grey!

1

Page 12

12

5 The ECOTRONIC Control System

5.1 General information

The ECOTRONIC facility control system is a decentralised microprocessor system (CAN-BUS)

developed by KÖB with various modules that are

connected by a data transmission line.

Its function

The ECOTRONIC records all the data relevant to

operation and controls the supply of and demand

for heat.

Thus the burner system is continuously monitored

during all the operating phases and kept within an

optimum range in terms of emissions.

Factory settings (pre-settings)

All the parameters in the ECOTRONIC, including

set point values and switching times, are pre-set

and can be called back up at any time. The figures

for the factory settings are given in brackets for the

various parameters.

5.1.1 Battery replacement

There is a battery built in beneath the removable

lid on the control module (type: Panasonic Lithium

BR2330). It is for buffering the time, date and settings.

- The battery needs replacing every five

years!

- Do not disconnect the mains voltage while

changing the battery (do not turn off master

switch)!

5.2 The functions of the buttons

F1 (PYROMAT Manual)

Switch on manual operation

F2 (PYROMAT Auto)

Switch automatic operation on and off

F3 (PYROMAT parameters)

Set parameters, set point values, time and date.

F4 (PYROMAT loader system)

Setting of cycle switchover switching, advance

flows and post flows

F5 (Group 1)

Setting parameters and set point values

(heat distribution, Group 1)

F6 (Group 2)

Setting parameters and set point values

(heat distribution, Group 2)

F7 (Group 3)

Setting parameters and set point values

(heat distribution, Group 3)

F8 (Group 4)

Setting parameters and set point values

(heat distribution, Group 4)

< Go one page to the left in menu masks

> Go one page to the right in menu masks

∧ Go one line up

(Only possible when the scroll up symbol Ï is

displayed.)

∨ Go one line down

(Only possible when the scroll down symbol

Ð is displayed.)

+ Change numeric values and set point values

- Change numeric values and set point values

OK Adopt (acknowledge) settings and/or changes

The following applies to the F3, F4, F5, F6, F7 &

F8 buttons:

• Pressing once will take you to the respective

menu. As feedback, the relevant LED will blink.

• If a set point value is changed and not confirmed with "OK", then it will not be adopted.

• Pressing the function button again will bring

back the normal display

• When no button is pressed for a period of sixty

seconds, the normal display automatically reappears.

NOTE:

Depending on the execution and setting, some

menus and texts do not appear.

Page 13

13

5.3 The burner and its loading F3, F4

5.3.1 F3 button "PYROMAT parameters"

(mask number ) parameter (factory setting)

(01) Storage unit temperatures ( - ):

Indication of all the storage unit temperatures

(02) Return flow, burner (70°C):

Set point value for burner return circuit valve

(03) Forward flow, burner (80°C):

Set point value for storage unit loading temperature

(04 ) Exha u s t g as , b u r n e r (200°C):

Limit of maximum exhaust gas temperature

(05) Exh aust gas, residual O

2

(7%):

Set point value for residual oxygen for air vent control

(06) O

2

-control (ON):

Switch O

2

-control on and off

(07) Air vents without O

2

-control (30%):

Position of the air vents with O

2

-control switched

off

(08) Carry away excess heat at (95°C):

Limit temperature for carrying away excess heat

(12) System Temperature Set Point Minimum

(50°C):

Minimum forward flow temperature for heat distribution provided by customer (only if System Temperature Set Point Minimum YES Æ Service Menu)

(14) Load storage unit with

automatic operation up to (STORAGE UNIT AT

BOTTOM):

To which heat storage sensor should the storage

unit be heated up

(15) Load storage unit with

automatic operation up to (80°C):

To what storage unit temperature should the storage unit be heated up with automatic operation?

(16) Storage Management, Temperature, Storage, Average (80°C):

Set point value, average temperature, storage unit

Æ Burner output is reduced according to loading of

storage unit.

(17) Start boiler when the system temperature

set point is fallen short of (accumulator at top)

If the system temperature set point is fallen short

of at the accumulator sensor selected, automatic

operation of the PYROMAT DYN starts (if preselected).

(18) Accumulator with integrated utility water

heater; temperature of utility water minimum

(50°C)

Minimum utility water temperature for accumulator

with integrated utility water heater.

Indication only if:

Accumulator with integrated utility water heater −

YES (Pyromat DYN Service).

(20) Automatic start with external request (NO):

Should the burner be switched on and off by an external zero-potential contact?

(21) Material take-back larger with air vent positioning (50%):

Material take-back by means of adjustable air vent

positioning.

(23) Feed auger cycle heat-up set point (5%)

When the filling procedure and ignition procedure

are completed, the feed auger starts with this onperiod.

(24) Feed auger, maximum (60%)

Maximum on-period for the feed auger (set point

value for feed auger with deactivated O2-control).

(28) Automatic operation ( 0 ):

Operating hours/minutes, automatic operation of

the PYROMAT DYN

(29) Manual operation ( 0 ):

Operating hours/minutes, manual operation of the

PYROMAT DYN

(31) Date / Year (current):

Set year

(32) Date / Month (current):

Set month

(33) Date / Day (current):

Set day

(34) Date / Day of week (current):

Set day of week

(35) Date / Hours (current):

Set hours

(36) Date / Minutes (current):

Set minutes

(40) Enter permanent code (-):

(41) Measurement operation (NO):

This activates measurement operation for chimney

sweep measurements. IMPORTANT: The control

of output is then not functioning: provide for sufficient thermal acceptance.

Page 14

14

5.3.2 F4 button "PYROMAT loading"

(Mask number) Parameter (Factory setting)

(01) Cleaning (NO):

This activates the cleaning function. De-ashing in

continuous operation, with exhaust fan at maximum RPM.

(02) Feed-motion grate, pause (400 s):

Cyclical switching system for de-ashing auger (option) and sweeper. The pause time is adjustable.

One impulse always causes one complete rotation

of the sweeper.

(03) Metering container, empty running time

(5s):

When the running time is up that is set for the feed

auger with the light barrier for the feed auger clear,

the prompt for material will be made.

(04) Conveyor Device 1 / Delay (3 s):

Delay before connecting Conveyor Equipment 1

(e.g. rotary valve, conveyor auger, etc.)

(05) Conveyor Device 1, after-running (0 s):

After-running of Conveyor Device 1

(e.g. pneumatic conveyor, etc.)

(06-33) Conveyor Devices 2-15:

Delay before connecting or after-running of Conveyor Devices 2 to 15

(34) Extraction System 1 / Delay (3 s):

Delay before connecting Extraction System 1

(e.g. spring-operated extraction system, inclined

extraction system, etc.)

(35) Extraction System 1 / Impulse (5 s):

Impulse for the cycle switching for Extraction System 1

(e.g. spring-operated extraction system, inclined

extraction system, etc.)

(36) Extraction System 1, Pause (0 s):

Pause in the cycle switching for Extraction System

1

(e.g. spring-operated extraction system, inclined

extraction system, etc.)

(37) Extraction System 2 / Delay (3 s):

Delay before connecting Extraction System 2

(e.g. spring-operated extraction system, inclined

extraction system, etc.)

(38) Extraction System 2 / Impulse (5 s):

Impulse for the cycle switching for Extraction

System 2

(e.g. spring-operated extraction system, inclined

extraction system, etc.)

(39) Extraction System 2, Pause (0 s):

Pause in the cycle switching for Extraction System

2 (e.g. spring-operated extraction system, inclined

extraction system, etc.)

(40) Extraction System 1 / Hydraulics / Delay (5

s):

Delay before connecting hydraulic drive for Extraction System 1

(41) Extraction System 2 / Hydraulics / Delay (5

s):

Delay before connecting hydraulic drive for Extraction System 2

(50) Silo filling (NO)

Should the silo filling function be started (only possible when the boiler has been out of operation for

at least one hour).

Page 15

15

5.4 The F5-F8 extended control systems

The F5 to F8 buttons are assigned customerspecific extended control systems as desired.

Each extended control system is assigned a separate button.

5.4.1 Room heating unit

Function (ECO-H):

Weather-controlled regulation of heating with digital timer for lowerable operation according to a

daily or weekly programme, with pump control,

frost protection function, ECOcircuit and limited

supply temperature.

Operating modes

• Off:

The room heating unit is switched off.

• Day / Night:

Heating operation according to clocked programme. Normal temperature during the day

and reduced temperature at night.

• Day / Off:

Heating operation according to clocked programme. Normal temperature during the day

and switched off at night.

• Day:

Normal temperature continuously.

• Night:

Reduced temperature continuously.

• Manual:

Pump on; valve is not controlled (emergency

operation)

(Mask number) Parameter (Factory setting)

(01) Operating mode (Day / Night)

Selection of operating mode

(02) Number of heating periods (1)

The weekly programme has to be entered in the

form of heating periods. Each weekly programme

consists of the heating day, start and end. A

maximum of seven heating periods is available.

(03) Heating Day 1; Heating days (MON to SUN)

Day or days on which the switching times apply.

Select the heating days with Buttons F1 (for Monday) to F7 (for Sunday). Press the button once Æ

selects the day, pressing the button again Æ drops

the day.

Only with the operating modes Day/Night or

Day/Off

(04) Heating Period 1; Start (6:00)

The switch-over time from lowered temperature (or

Off) to normal temperature

Only with operating modes Day/Night and Day/Off.

(05) Heating Period 1 / End (22:00)

The switch-over time from normal temperature to

lowered temperature (or Off)

Only with the operating modes Day/Night or

Day/Off.

(06-23) Heating Periods 2-7

These depend on the number of heating periods

(see Mask 2), consisting of heating days, start and

end.

(24) Temperature of flow / at +5°C (43°C)

Desired flow temperature at atmospheric temperature of +5°C (see heating curve).

(25) Temperature of flow; at -15°C (64°C)

Desired flow temperature at atmospheric temperature of -15°C (see heating curve).

(26) Temperature Room Day (20°C)

Setting for temperature of room during daytime

operation.

(27) Temperature Room Night (15°C)

Setting for temperature of room during night-time

operation.

(28) Night-time lowering of flow temperature

by (-6°C)

This temperature set is subtracted from the flow

temperature calculated for night-time lowering.

(29) Flow temperature / Maximum (70°C)

Maximum limit of flow temperature.

(30) ECOcircuit (YES)

The ECO automatic savings system makes the

heating switch on and off as required.

(31) Switch off below system temperature (NO)

Should the room heating unit group be switched off

when a minimum system temperature is fallen

short of?

(32) Frost protection function (YES)

With the frost protection function switched on, the

room heating unit is turned on when there is a

danger of frost.

(33) Carry off excess heat (NO)

In case of danger of the PYROMAT DYN

overheating (e.g. through too much fuel added in

manual operation), there is the option of the

excess heat being carried off. The room unit

adjusts to "Flow temperature / Maximum".

Page 16

16

¥Auto

e

The heating curve

The correspondence of the flow temperature to the

outdoor temperature can be set directly and read

directly. The setting is carried out by two points:

Point 1:

Flow temperature at atmospheric temperature of

+5°C (setting range from 20°C to 90°C).

Point 2:

Flow temperature at atmospheric temperature of

-15°C (setting range from 20°C to 90°C).

I M P O R T A N T:

Point 2 always has to be higher than Point 1!

The two points marked indicate the factory setting.

Point 1 is set to 43°C and Point 2 to 64°C. This is

equivalent to a steepness of approx. 1.5.

Room thermostat (option):

The Model QAA 35 Room Thermostat can be used

with or without influence by the room temperature.

Possible switch positions

:

• Position:

Heating operation following clocked programme

according to setting in the ECOTRONIC.

•

Position:

Continuous normal temperature.

(The operating mode set in the ECOTRONIC

will be ignored.)

•

Position:

Continuous reduced temperature.

(The operating mode set in the ECOTRONIC

will be ignored.)

+5°C

Point 1

-15°C

Point 2

(Fig: Heating curve)

Page 17

17

5.4.2 Utility water heater

Function:

• ECO-B1

When the temperature of the utility water drops,

it is reheated by the built-in heat exchanger

from the burner or from the heat accumulator.

The condition for this is a relevant difference in

temperature (choice of preset temperature difference or fixed preset temperature).

The heating periods (daily and weekly programmes) can be set using the integrated

timer.

• ECO-B2

When the temperature of the utility water drops,

it is reheated by the built-in heat exchanger

from the burner or from the heat accumulator.

The condition for this is a relevant difference in

temperature (choice of preset temperature difference or fixed preset temperature).

The flow rate of the heating water is controlled

by the return temperature (quantity control).

This produces optimum storage stratification

with long-lasting high temperature on the storage unit flow pipe.

The heating periods (daily and weekly programmes) can be set using the integrated

timer.

Operating modes:

• Off:

The utility water heating system is switched off.

• Timer:

Utility water heating following clocked

programme. (The boiler is only warmed up

during the heating period.)

• On:

The boiler is heated up on request for heat and

when there is sufficient system temperature.

• Manual:

Pump on; valve is not controlled (emergency

operation)

(Mask number) Parameter (Factory setting)

(01) Operating mode (timer)

Select operating mode

(02) Number of heating periods (1)

The weekly programme has to be entered in the

form of heating periods. Each weekly programme

consists of the heating day, start and end. A maximum of seven heating periods is available.

(03) Heating Period 1 / Heating days (MON to

SUN)

Day or days on which the switching times apply.

Select the heating days with Buttons F1 (for Monday) to F7 (for Sunday). Press the button once Æ

selects the day, pressing the button again Æ drops

the day.

(Only with TIMER operating mode)

(04) Heating Period 1 / Start (6:00)

Start, clearance, utility water heating

(Only with TIMER operating mode)

(05) Heating Period 1 / End (22:00)

End, clearance, utility water heating

(Only with TIMER operating mode)

(06-23) Heating Periods 2-7

These depend on the number of heating periods

(see Mask 2), consisting of heating days, start and

end.

(24) Temperature of utility water (60°C)

Set the desired temperature of the utility water.

Additional parameters for ECO-B2

(Mask number) Parameter (Factory setting)

(25) Temperature of return flow __°C higher

than the temperature of the utility water

Desired set-point temperature of return flow:

actual boiler temperature plus the amount set here.

Page 18

18

5.4.3 Air heater

Function (ECO-L):

The air heaters are supplied with maximum flow

temperature from the burner storage system. The

fans are connected by switches or controllers provided by the customer. The flow rate of the heating water is controlled by the temperature of the return flow and thus adjusted to the air heater's

thermal output (quantity control). This produces

optimum storage stratification with long-lasting

high temperature on the storage unit flow pipe.

The heating periods (daily and weekly programmes) can be set using the integrated timer.

Operating modes:

• Off:

The air heater is switched off

• Day / Off:

Heating operation following clocked

programme. During the day the system is

adjusted to the set point value for return flow,

and at night it is off.

• Day:

Adjusted to the set point value for return flow

(continuous operation)

• Manual:

Pump on; the valve is not controlled (emergency operation)

(Mask number) Parameter (Factory setting)

(01) Operating mode (Day / Off)

Select operating mode

(02) Number of heating periods (1)

The weekly programme has to be entered in the

form of heating periods. Each weekly programme

consists of the heating day, start and end. A maximum of seven heating periods is available.

(03) Heating Period 1 / Heating days (MON to

SUN)

Day or days on which the switching times apply.

Select the heating days with Buttons F1 (for Monday) to F7 (for Sunday). Press the button once Æ

selects the day, pressing the button again Æ drops

the day.

(Only with the operating mode Day/Off)

(04) Heating Period 1 / Start (6:00)

Time to switch on air heater

(Only with the operating mode Day/Off)

(05) Heating Period 1 / End (22:00)

Time to switch off air heater

(Only with the operating mode Day/Off)

(06-23) Heating Periods 2-7

These depend on the number of heating periods

(see Mask 2), consisting of heating days, start and

end.

(24) Temperature of return flow (60°C)

Desired temperature of return flow

(25) ECOcircuit (YES)

The ECO automatic savings system makes the

heating switch on and off as required.

(26) Switch off below system temperature (NO)

Should the air heater group be switched off when a

minimum system temperature is fallen short of?

(27) Frost protection function (YES)

With the frost protection function switched on, the

air heater is turned on when there is a danger of

frost.

(28) Carry off excess heat (NO)

In case of danger of the PYROMAT DYN

overheating (e.g. through too much fuel added in

manual operation), there is the option of the

excess heat being carried off. The air heater adjusts to "Flow temperature / Maximum".

Page 19

19

5.4.4 Neighbouring buildings

Function (ECO-N):

The pipeline is usually supplied with a lowered

temperature required by the weather-guided heating control system. The utility water heater is

loaded with the maximum flow temperature set.

To do so, the heating water is re-channelled by a

valve to the utility water heater. The integrated

timer shifts this to non-productive times, where the

room heating unit is quickly interrupted.

Operating modes for the room heating unit

• Off:

The room unit is switched off.

• Day / Night:

Heating operation following clocked programme. Normal temperature during the day,

and reduced temperature at night.

• Day / Off:

Heating operation following clocked programme. Normal temperature during the day,

and off at night.

• Day:

Normal temperature continuously

• Night:

Reduced temperature continuously

• Manual:

Pump on; the valve is not controlled

(emergency operation)

(Mask number) Parameter (Factory setting)

(01) Operating mode (Day / Night)

Select operating mode

(02) Number of heating periods (1)

The weekly programme has to be entered in the

form of heating periods. Each weekly programme

consists of the heating day, start and end. A maximum of seven heating periods is available.

(03) Heating Period 1; Heating days (MON to

SUN)

Day or days on which the switching times apply.

Select the heating days with Buttons F1 (for Monday) to F7 (for Sunday). Press the button once Æ

selects the day, pressing the button again Æ drops

the day.

Only with the operating modes Day/Night or

Day/Off.

(04) Heating Period 1 / Start (6:00)

Switch-over time from lowered temperature (or Off)

to normal temperature.

Only with the operating modes Day/Night or

Day/Off.

(05) Heating Period 1 / End (22:00)

Switch-over time from normal temperature to

lowered temperature (or Off).

Only with the operating modes Day/Night or

Day/Off.

(06-23) Heating Periods 2-7

These depend on the number of heating periods

(see Mask 2), consisting of heating days, start and

end.

(24) Flow temperature; at +5°C (43°C)

(25) Flow temperature; at -15°C (64°C)

(26) Temperature, Room, Day (20°C)

Set point room temperature, daytime operation

(27) Temperature, Room, Night (15°C)

Set point room temperature, nighttime operation

(28) Nighttime lowering of the flow temperature

by (-6°C)

This temperature set is subtracted from the flow

temperature calculated for nighttime lowering.

(29) Flow temperature; maximum (70°C)

The maximum limit for the flow temperature

(30) ECOcircuit (YES)

The ECO automatic savings system makes the

heating switch on and off as required.

(31) Switch off below system temperature (NO)

Should the room heating unit group be switched off

when a minimum system temperature is fallen

short of?

(32) Frost protection function (YES)

With the frost protection function switched on, the

room heating unit is turned on when there is a

danger of frost.

(33) Carry off excess heat (NO)

In case of danger of the PYROMAT DYN

overheating (e.g. through too much fuel added in

manual operation), there is the option of the

excess heat being carried off. The room unit

adjusts to "Flow temperature / Maximum".

The heating curve

See "Extended control system for room heating

unit"

Room heating unit:

See "Extended control system for room heating

unit"

Page 20

20

Operating modes of the utility water heater:

• Off:

The utility water heating system is switched off.

• Timer:

Utility water is heated following a clocked

programme (the boiler is only heated during the

heating period).

• On:

The boiler is heated on request for heat and

when there is sufficient system temperature.

• Manual:

Pump on; the valve is not controlled

(emergency operation).

Utility water heater (Mask number) Parameter

(Factory setting)

(34) Operating mode (timer)

Select operating mode

(35) Number of heating periods (1)

The weekly programme has to be entered in the

form of heating periods. Each weekly programme

consists of the heating day, start and end. A maximum of seven heating periods is available.

(36) Heating Period 1; Heating days (MON to

SUN)

Day or days on which the switching times apply.

Select the heating days with Buttons F1 (for Monday) to F7 (for Sunday). Press the button once Æ

selects the day, pressing the button again Æ drops

the day.

(Only with TIMER operating mode)

(37) Heating Period 1 / Start (6:00)

Start, clearance, utility water heating

(Only with TIMER operating mode)

(38) Heating Period 1 / End (22:00)

End, clearance, utility water heating

(Only with TIMER operating mode)

(39-56) Heating Periods 2-7

These depend on the number of heating periods

(see Mask 35), consisting of heating days, start

and end.

(57) Temperature of utility water (60°C)

Set the desired temperature of the utility water.

5.4.5 Pipeline

Function (ECO-F):

This is for neighbouring buildings with a separate

heat distribution system, which is supplied with

heat via a pipeline. According to requests by the

heat distribution system, the temperature of the

pipeline is pre-adjusted for the lowest loss in the

line.

Operating modes:

• Off

Pump off; valve closed

• Automatic

Adjustment to the temperature requested

• Manual

Pump on; the valve is not controlled

(emergency operation).

(Mask number) Parameter (Factory setting)

(01) Heating / Operating mode (Automatic)

Select operating mode

(02) Frost protection function (YES)

With the frost protection function switched on, the

pipeline is turned on when there is a danger of

frost.

(03) Flow temperature; minimum (20°C)

Minimum temperature desired

(04) Flow temperature; maximum (60°C)

Maximum temperature desired

Page 21

21

5.4.6 Additional boilers

Function:

• Boiler, single (ECO-KE)

To cover the heat requirement (single operation), an additional boiler is automatically connected after the heat is removed from the storage unit. Loading of the storage unit is only

possible with the PYROMAT DYN. When it is

put into operation, the additional boiler switches

off, and the closed shut-off valve prevents it

from being flowed through.

• Boiler, single, gliding (ECO-KG)

To cover the heat requirement (single operation), an additional boiler is automatically connected after the heat is removed from the storage unit. Loading of the storage unit is only

possible with the PYROMAT DYN. When it is

put into operation, the additional boiler switches

off, and the closed shut-off valve prevents it

from being flowed through. The boiler temperature is adjusted in gliding fashion to the minimum temperature according to the heat requirement.

• Boiler, parallel (ECO-KP)

An additional boiler is automatically connected

when required. This may take place to cover

the heat requirement after the heat is removed

from the storage unit (single operation). Or the

additional boiler serves to cover peaks in heat

requirements (parallel operation to the PYRO-

MAT DYN). For parallel operation, a burner

group is necessary to carry off heat that simultaneously provides for keeping up the return

flow.

Operating modes:

• Off:

The additional boiler is switched off.

• Automatic:

Automatic clearance of the additional boiler

through a request by a heat consumer, or (only

ECO-KP) when an adjustable connecting temperature for the wood-powered boiler is fallen

short of.

• On:

The additional boiler has been cleared.

• Manual:

The additional boiler has been cleared, and

(only ECO-KP) the pump is on; the valve is not

controlled (emergency operation).

(Mask number) Parameter (Factory setting)

(01) Operating mode (automatic)

Select operating mode

(02) Delay before connecting (15 min)

Clearance is given when the time set is up.

(03) Connecting temperature, system set-point

temperature (-15°C)

If the system temperature falls by this amount below the system set-point temperature, the delay

before connecting (Fig 2) begins to lapse.

(04) Switch-off temperature for system setpoint temperature (- 5°C)

Switch-off difference with parallel operation and

loading of storage unit: NO

(05) Forward flow, burner / Maximum (80°C)

(06) Forward flow, burner / Minimum (20°C)

(07) Set-point temperature of return flow (50°C)

The set-point value for the temperature of the return flow

(08) Loading, storage unit (NO)

Should the storage unit be heated up by the additional boiler?

(09) Loading, storage unit up to (storage unit

top)

Up to which heat storage sensor should the storage unit be heated up?

(10) Loading, storage unit up to (70°C)

Up to what temperature at the heat storage sensor

selected should the additional boiler heat up the

storage unit?

(12) Service function of additional boiler

A maintenance function for the specialist

(13) Operating hours counter

Page 22

22

5.4.7 Solar

Function (ECO-S1):

This is used in simple solar systems with a single

control circuit to heat the utility water in the solar

utility water heater (Art No: WSS- __). The ECOS1 controller is an additional component for the

ECO-B1(2) controller for the utility water heater.

When the solar collector is hotter than the utility

water at the bottom, it is heated up by the solar

collector.

Operating modes

• Off:

Pump off; valve shut

• Automatic:

Automatic heating of the solar utility water

heater by means of difference-based control.

• Manual:

Emergency operation: Pump on.

(Mask number) Parameter (Factory setting)

(01) Operating mode (automatic)

Select operating mode

(02) Temperature of utility water / Maximum

(65°C)

The maximum temperature of the utility water with

solar heating

(04) Collector / Utility water;

Set difference (10°C)

The difference between the solar collector and the

utility water heater at the bottom

(10) Operating hours counter

Function (ECO-S3):

This is used in large solar systems to heat the utility water in a solar utility water heater (Art. No:

WSS-___) and for supplying heat to the heat storage tank by means of a triple control circuit. The

first circuit is for heating up the utility water, the

second circuit is for heating up the heat storage

tank at the rear/bottom, and the third circuit is for

heating up the heat storage tank in front/at the top.

The heating storage unit is heated up by an externally situated plate-type heat exchanger. On

switchover from utility water heater to heating storage unit, the secondary pump is switched on,

which is then in operation with the solar pump. For

optimised functioning, the flow rate in the secondary circuit has to be adapted to the primary circuit

(e.g. with flow rate gauges in the primary and secondary circuits).

Operating modes

• Off:

Pump off; valve shut

• Automatic:

Automatic heating of the solar utility water

heater by means of difference-based control.

• Manual:

Emergency operation Æ Solar pump and secondary pump on; valves are not controlled

(emergency operation).

(Mask number) Parameter (Factory setting)

(01) Operating mode (automatic)

Select operating mode

(02) Temperature of utility water; maximum

(65°C)

The maximum temperature of utility water with solar heating.

(03) Priority to utility water (optimised)

- Optimised:

Priority to loading utility water, but if the solar output is not sufficient to finish loading the utility water

heater, there is a switchover to solar heated heating. If the solar output rises (cyclical examination)

so much that heating of utility water is possible,

there is again a switchover to solar heated utility

water.

- Absolutely:

Loading utility water has absolute priority, i.e. solar

heated heating is not allowed until the utility water

heater has been completely loaded.

- No:

Solar heating of utility water / Heating according to

the temperature difference between the collector

and the utility water at the bottom or the collector

and the storage unit at the bottom

(04) Collector / Utility water; set difference

(10°C)

The temperature difference between the collector

and the utility water at the bottom for solar utility

water heating.

(05) Collector / Storage unit; set difference

(15°C)

The temperature difference between the collector

and the storage unit at the bottom for solar heating

system heating.

(10) Operating hours counter

Page 23

23

6 Cleaning

6.1 Automatic operation

Regular cleaning of the facility is the customer's most important job for years of trouble-free operation and to obtain the greatest possible output with the best efficiency.

The cleaning intervals may vary, depending on the fuel, the amount of foreign matter and the operating method.

CAUTION – RISK OF INJURY: Before beginning cleaning work, put the facility out of operation. Be

absolutely sure to wear protective gloves, protective eyewear if required and use the cleaning utensils that come with the facility – danger of blow-ups, burns and getting crushed!

After 900 hours of operation:

Open lid, pull the spiral springs out of the tubes, and

dust off and/or sweep off. Then go through the bundle

of tubes with the cleaning brush that comes with the

system.

After 300 hours of operation:

Open the lid on the slide-in module side

and empty the two drawers under the

heat exchanger and the slide-in module.

After 1800 hours of operation:

Unplug the plug from the exhaust gas

fan, unscrew the thumb screws, pull out

the motor with the running wheel and

clean with broom or wire brush.

IMPORTANT:

DANGER OF GETTING INJURED!

After 300 hours of operation:

Take off the maintenance lid on the side, and clean combustion chamber and grate.

Remark: The sweeper does not have to be taken off for the

cleaning.

If the sweeper is taken off anyway, be sure to put it back on

with the correct positioning later:

The end of the sweeper turned toward the maintenance lid

should point toward the filling shaft when in the nonoperative mode, thus deflecting the flow of ash toward the

large ash compartment.

See also Photo 6.1.3 on the next page.

After 900 hours of operation:

Take off the panelling, undo the

thumb screws, take off the lid

and clean the combustion chamber with a vacuum cleaner.

After 300 hours of operation:

Take off and clean the light barrier inspection glasses on both sides. Remove dust

and ash deposits in the openings.

Clean the ash compartment according to the amount of ash produced (figures experienced are

fuel-dependent). The supply air to the combustion chamber has to be able to flow in unhindered.

The "de-ashing auger" option extends the period until ash is removed up to an ash volume of

20 litres.

Page 24

24

6.1.1 Cleaning of de-ashing system (optional)

6.1.2 Cleaning of main combustion chamber

6.1.3 Cleaning of exhaust gas deduster (op-

tional)

Optionally you have ordered an Exhaust gas deduster. Proceed the following way.

Weekly:

Open lid and check level of ash.

When the level of filling reaches only 10

cm below the top edge, the ash bucket

has to be removed.

Emptying the ash bucket:

Unlatch the clasps on the left and right

and remove the ash bucket out sidewards.

Important

! There is a danger of getting

crushed at the end of the de-ashing auger. Never reach into the feed system

with your fingers!

Afterwards, re-assemble properly: The

ash bucket and lid always have to be

closed ti

g

ht during operation.

After 300 hours of operation:

Take off lid, and check exhaust

gas route to make sure the passageway is clear.

Depending on the amount of

ash produced (figures experienced are fuel-dependent)

Undo the butterfly nuts, remove

lid and take out ash.

Depending on the amount of ash

produced (figures experienced

are fuel-dependent)

Insert the cleaning scraper into the

main combustion chamber (photo)

via the fire box door and the large

ash compartment, in order to clean

the grate there.

Also remove ash deposits in front

of the light barriers with the cleaning scraper (also clean combustion

chamber in front of the maintenance lid).

Check sweeper position (after

dismantling of sweeper):

The end of the sweeper turned toward the maintenance lid should

point toward the filling shaft when

in the non-operative mode, thus

deflecting the flow of ash toward

(direction of arrow) the large ash

compartment.

Page 25

25

6.2 Chopped wood operation

Regular cleaning of the facility is the customer's most important job for years of trouble-free operation and to obtain the greatest possible output with the best efficiency.

The cleaning intervals may vary, depending on the fuel, the amount of fine matter and the operating

method!

CAUTION – RISK OF INJURY: Before beginning cleaning work, put the facility out of operation. Be

absolutely sure to wear protective gloves, protective eyewear if required and use the cleaning utensils that come with the facility – danger of blow-ups, burns and getting crushed!

Monthly :

Open lid, pull the spiral springs out of the tubes, and

dust off and/or sweep off. Then go through the

bundle of tubes with the cleaning brush that comes

with the s

y

stem.

Weekly :

Open the lid on the slide-in module

side and empty the two drawers under

the heat exchanger and the slide-in

module.

Twice per year :

Unplug the plug from the exhaust gas

fan, unscrew the thumb screws, pull out

the motor with the running wheel and

clean with broom or wire brush.

IMPORTANT:

Three times per year

Take off the maintenance lid on the side, and clean

combustion chamber and grate.

Every day:

Open ash pan lid and with a poker move the fine ash through slots in the grate into the

ash pan.

If a lot of paper has been burned, completely remove the ash from the grate.

If only wood has been burned, it is sufficient to evenly distribute the charcoal.

When a lot of paper and cardboard are burned, the inlet into the combustion chamber

might also be clogged. If necessary, clear with a poker.

Check ash pan and empty before it is completely full.

Twice per year :

Take off the panelling, undo the

thumb screws, take off the lid

and clean the combustion

chamber with a vacuum cleaner.

Monthly :

Take off and clean the light barrier inspection glasses on both sides. Remove dust and ash deposits in the openings.

Page 26

26

7 Shutdowns

Heating boiler

• Pipe-type heat exchanger

When the PYROMAT DYN is put out of operation for a long period (such as for summer

breaks), be sure to carefully clean the pipe-type

heat exchanger with a steel brush required.

• Prevent high-temperature corrosion when

chipboards are incinerated:

If the heating room is moist or there is any other

atmosphere that promotes corrosion (e.g. poor

ventilation, residual enamel near the heating

room, etc.), after carrying out the cleaning, also

spray the pipe-type heat exchanger with biodiesel.

• Remove encrustation from the walls of the

firebox and boiler with a trowel or flat scraper.

• If there is a danger of frost, empty the heating

system, following the heating installer's rules, or

have anti-frost agent filled.

Control system

Even when the PYROMAT DYN is put out of operation for long periods, the power supply to the

control system should not be interrupted (do not

turn off master switch).

Why

?

• The "intermittent control system" switches the

consumer pumps on for five seconds every 24

hours. This prevents the pumps from jamming

during long standstills. This saves on expensive repairs.

• Avoid the formation of condensation in the

lambda sensor.

• Extend the service life of the buffer battery.

8 Waste disposal

Shutting down operation

• If necessary, first switch off the PYROMAT

DYN using the F1 or F2 button. When the

burn-out has taken place, and the burner has

cooled off, turn off the master switch.

• Disconnect the mains connection to the control

cabinet.

IMPORTANT: DANGEROUS VOLTAGE!

Only licensed electrical firms are allowed to

disconnect and dismantle the connection to

the electrical network.

• Close the forward flow and return flow slide

valves.

• Open the drain tap on the bottom of the boiler

of the PYROMAT DYN and drain water.

Only heating system installers may drain the

boiler and dismantle the connections to the

heating system.

• Disconnect the forward flow pipe and return

flow pipe from the PYROMAT DYN.

Instructions regarding transport to a different

location

The personnel who carry out transports to different

locations have to know the dangers involved of accidents that might arise in doing so and use suitable measures to prevent such from happening.

Instructions regarding waste disposal

• Comply with customary laws and regulations on

disposing waste.

• Contract a disposal firm to dispose of and recycle waste in an environmentally friendly fashion.

Page 27

Spec Sheet

Wood Fuels

Minimum Requirements / Information

KÖB Holzfeuerungen GmbH, Flotzbachstr. 33, A-6922 Wolfurt, Tel. +43/5574/6770-0, Fax 65707, E-Mail: office@kob.cc

Subject to technical changes

1010/d-1

2007-09-12_E

A prerequisite for approval is the express permission for such by the public authority responsible. For claims to

the warranty according to Section 11 of our General Terms and Conditions of Delivery, wood fuels have to meet

the following conditions. If those conditions are not met, then approval is possible with restrictions (warranty,

maintenance, operational safety) with a written statement by the manufacturer in reference to the facility.

1) Non-combustible substances contained

No wood fuels may contain any foreign bodies, such as pieces of metal, stones, masonry remnants or plastics. Nor

must the following limits (per kg of dry fuel) for non-combustible substances contained (ash analysed at a

temperature of 815°C) be exceeded or fallen short of:

Limit Comparison with untreated forest wood

1.1) Chlorine Cl: max. 300 mg/kg 10 mg/kg

1.2) Sulphur S: max. 1000 mg/kg

120 mg/kg

1.3) Total Cl, S: max. 1000 mg/kg 130 mg/kg

1.4) Ash content, total: max. 15.0 g/kg 5.0 g/kg

1.5) Alkali oxides in the ash (K

2

O and Na2O): max. 1.0 g/kg 0.35 g/kg

1.6) Sintering point of the ash: min. 1000°C approx. 1200°C

Consequence of substantial overstepping of limits (1.1, 1.2, 1.3, 1.5, 1.6):

a) Hot-gas corrosion in the heat exchanger → Special maintenance instructions for heat exchanger

→ Shortened service life of heat exchanger

b) Early sintering and melting of the ash → Special maintenance instructions for firing,

→ Increased maintenance costs (firing, boiler door)

If the maintenance instructions are not followed, a process will be created that builds up in a negative fashion with:

→ Cinders change the airflow → Temperature peaks → more slag → etc, until there is fast destruction of the

refractory materials

1.7) Additives in remnant and used wood: Free of heavy metals and halogen compounds

2) Superfines & dust (wood particles smaller than 1.0 mm as per ÖNORM M 7133)

2.1) Without pre-dryer, max. 10.0% of the total mass; consequence of substantial overstepping of limit:

Temperature peaks → Slag formation → Even higher temperature → etc, to the point of destruction;

→ Special maintenance instructions for firing;

Elevated values are especially critical for remnant wood in combination with elevated values as per 1.1, 1.2

2.2) For forest wood chips with pre-dryer, max 4.0% of the total mass; consequence of substantial overstepping of

limit:

→ Moving the exhaust air lines → Special maintenance instructions for cleaning exhaust air line

3) Origin and treatment

3.1) Forest wood and plantation wood (complete trees and trunk wood untreated)

Mature wood from trunks and branches, untreated, chopped as billet wood or chips

3.2) Compressed wood, pellets (conforming to standards, such as: ÖNORM M 7135)

Untreated wood with limited bark content, compressed by machine and calibrated

3.2) Increased proportion of bark, tree cuttings from roadside trees (untreated)

Remnants from the forestry and sawmill industries or from conservation of the countryside (elevated ash

content).

3.3) Remnants from derived timber products

Usually a mixture of untreated and treated wood in the form of shavings from processing machinery and chips

from choppers that run slowly. In cases of elevated proportions of dust and/or limited storage volumes, these

shavings are compressed into briquettes.

3.4) Used wood

This is essentially untreated wood that has been used prior to its energetic utilisation (e.g. pallets). It is reduced

in size by shredders for thermal utilisation. The metal parts have to be removed afterwards (by magnetic

separators).

4) Particle size: adjustment of the conveyor augers

4.1) G30/G50 chips from untreated wood as per ÖNORM M 7133:

made by fast-running and cutting tools;

max. coarse fraction with cross-section and length

G 30 of 20% max. 3 cm

2

max. 8.5 cm;

G 50 of 20% max. 5 cm

2

max. 12 cm;

Required cross-sections of the loading: depends on the boiler output:

up to 150 kW up to 500 kW from 500 kW

Conveyor auger D min. 12 cm; min. 15 cm; min. 20 cm

Drop cross-section A min. 175 cm2 min. 300 cm2 min. 600 cm

2

Page 28

Spec Sheet

Wood Fuels

Minimum Requirements / Information

KÖB Holzfeuerungen GmbH, Flotzbachstr. 33, A-6922 Wolfurt, Tel. +43/5574/6770-0, Fax 65707, E-Mail: office@kob.cc

Subject to technical changes

1010/d-2

2007-09-12_E

4.2) Chips not from the forest; origin as per 3.2, 3.3, 3.4; briquettes, origin as per 3.3

Size essentially as per ÖNORM M 7133 G50, additionally, however:

- Fraction of one-offs max. 5% with cross-section of max. 5 cm² up to a length of max. 16 cm

- Frayed surface by chopping tools (shredders) or slow-running choppers

- Briquettes, diameter max. D 60 mm (hydraulic compressors, pressure geared to loading system)

Conveyor augers diameter min. 20 cm; drop-off route, rotary valve cross-section min. 600 cm

2

Consequence of overstepping particle size:

- Extra expenditures for correcting malfunctions

- Shortened service life of the conveyor augers and drives

5) Bulk density S (kg/m³), water content W (%), size G (mm) as per ÖNORM M 7133

In automatically loaded boiler plants, the wood fuels that come to be used should be individually listed in offers and

orders as follows:

a) S 130 W10 to W20 G30/50 Sawdust, untreated (planing shop)

b1) S 200 W20 to W35 G30/50 Sawdust, untreated (sawmill)

b2) S 200 W20 G30/50 Forest wood chips, soft, untreated

c1) S 250 W20 to W35 G30/50 Forest wood chips, soft, untreated

c2) S 250 W35 to W50 G30/50 Sawdust, untreated (sawmill)

d1) S 300 W20 to W35 G30/50 Forest wood chips, soft/hard, untreated