Page 1

Spec Sheet

Burner System Loader System

PYROMAT-DYN

1

Köb Holzheizsysteme GmbH, Flotzbachstr. 33, A-6922 Wolfurt, Tel. +43/5574/6770-0, Fax 65707, E-Mail: office@kob.cc

Subject to technical changes

3010-1

2009-03-01_GB

Description:

The PYROMAT-DYN is a boiler with patented double combustion chamber. Which means that the burner system enables

optimized operation with automatic loading (shavings, chippings from waste wood, wood chippings, max. W35; G50) and

may also be used with logs. A large loading shaft with loading lid and separate grid has been fitted in front of the main

combustion chamber to make loading wood easy. In automatic operation, the burner system is suitable for all dry to moist

wood fuels (max. W35). The control is integrated into the burner system with connector-ready cabling to the sensors and

motors. Which permits simple and rapid installation. The PYROMAT-DYN has been tested and approved in accordance

with the latest quality criteria in compliance with EN 303-5 heating boilers for solid fuels,

CE certification as per European Machinery Directive and continuous quality assurance by TÜV.

Max. flow temperature: 100°C

Max. operating pressure: 3.0 bar

Electric connection: 3 x 400V

Safety heat exchanger: Built into the boiler

Function:

- In manual operation, chopped wood and waste wood are degassed on the incineration grate situated before the

main combustion chamber. Simultaneous operation with automatic loading is not possible.

- In automatic operation the feed auger conveys the material to be burned into the main combustion chamber for

degasification.

The fasteners for the burn-back sensor and the thermally operated extinguisher valve are situated on the conveyor

pipe. Above the auger, there is a metering container with a light barrier to ascertain the level of the fuel isolating layer

required according to TRD 414.

- In automatic operation the material to be incinerated is ignited automatically by an electric hot air blower.

The combustion gases are entirely burned out in the afterburn chamber together with secondary airflow.

- The ash is mechanically removed from the main combustion chamber.

- In the upright pipe heat exchanger, the thermal energy from the combustion gases is transferred to

the boiler water. The vertical surfaces of the heat exchanger are regularly cleaned by motor-driven,

moving coil springs.

- The speed-controlled exhaust blower was specially designed for operation in wood heating systems and is very quiet.

- The negative pressure created by it produces a high degree of safety against burn-back in automatic operation and a

convenient feed function in manual operation.

- An integrated heat management system (accumulator-temperature-guided with return circuit valve) enables the best

possible controlled operation.

Scope of delivery:

- Boiler with double combustion chamber, ash pan, kindling and cleaning utensils, coil springs for the heat exchanger

cleaning system, mechanical drive with position sensor for removing the ash from the main combustion chamber.

- Exhaust blower, plug-and-play

- Integrated ECOTRONIC control system (decentralised microprocessor system via CAN-bus), consisting of:

Boiler control panel, control module for mounting preferably on a wall, bus cable for the drive motors wired to

output plug

- Feed auger with isolating layer, incl. Starttec drive via CAN-bus (including data transmission line) for gentle start-up,

automatic reversing and overload safeguard, light barriers for combustion chamber and metering container

- Automatic ignition system

- Burner group ready-installed on connecting flange, consisting of burner pump, two blockage units

Burner control valve, forward and return flow sensors incl. fittings.

- Three KTY heat accumulator sensors, incl. dipping shell (1/2" x 280 mm long) wired together to plug

- Four-pin master switch, uninstalled (for installation near the control module)

ACCESSORIES for PYROMAT-DYN (Article KPM-…) at extra charge:

Name Article Text Sizes Use

Reduction exhaust connection KPM-… 3110 3110 existing chimney 180 mm dia.

Exhaust blower-intake port 90° KPM-… 3110 3110 special exhaust gas conveyance

Exhaust gas deduster KPM-… 3110 3110 optional

De-ashing into the container 20 L KPM-DYN-AS 3200 3200 optional

ECO function for PYROMAT-DYN LSR-DYN 3200 - for use with logs; incl. storage

Error report 230 V ECO-ZA 3200 - optional

External requirements ECO-ANF 3200 - optional

Discharge systems ADE/ADF 3300 3300 material transport silo to boiler

Heater control, module extensions ECO-… 4000ff - optional

Data cable for operating module ECO-… 4020 - required

Boiler safety devices K-… 4500 - optional

Extinguishing equipment K-… 4550 4550 optional

Page 2

Spec Sheet

Burner System Loader System

PYROMAT-DYN

1

Köb Holzheizsysteme GmbH, Flotzbachstr. 33, A-6922 Wolfurt, Tel. +43/5574/6770-0, Fax 65707, E-Mail: office@kob.cc

Subject to technical changes

3010-2

2009-03-01_GB

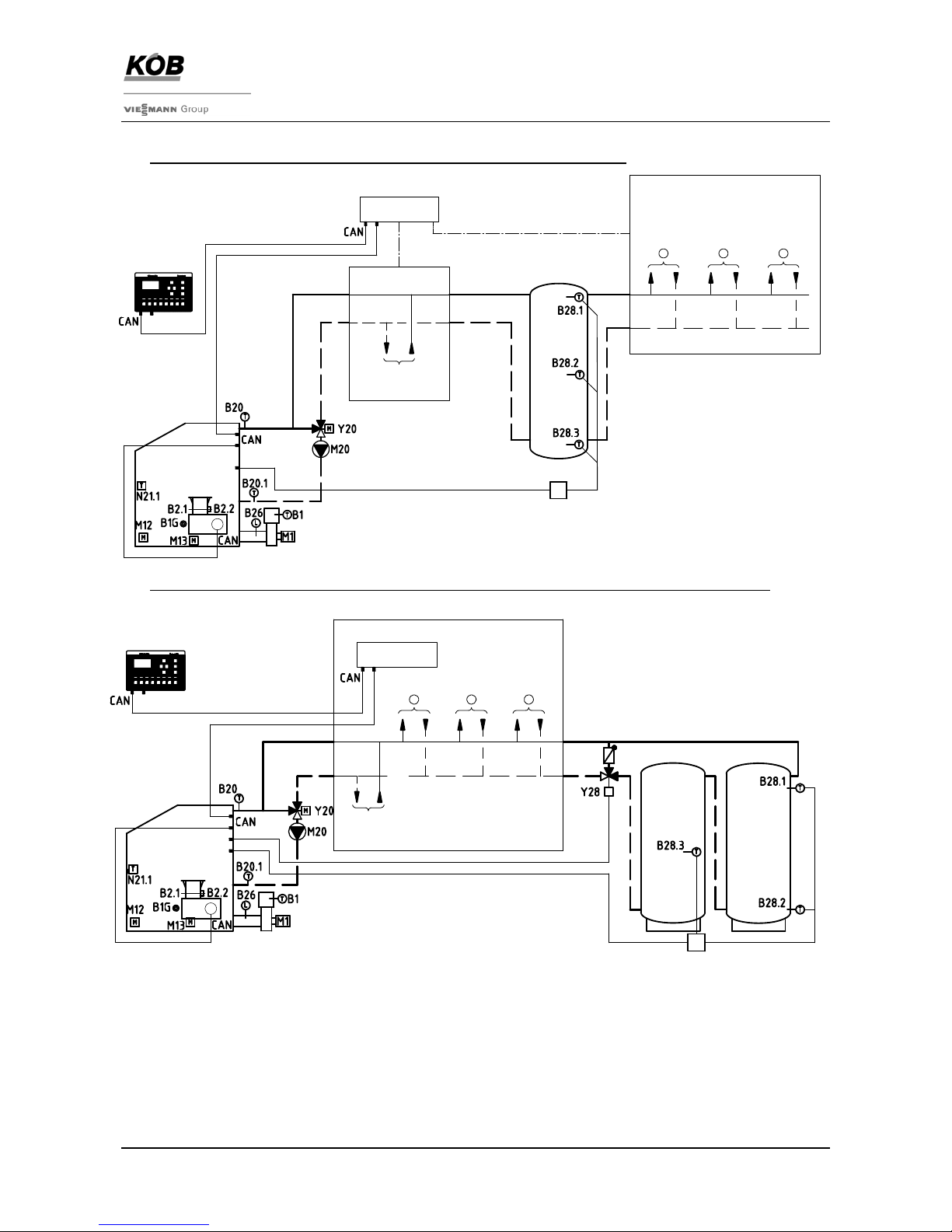

Schematic diagram with ECOTRONIC

a) DYN with reduced log operation (standard with accumulator as hydraulic switcher)

b) DYN with full ECO-function in log operation (accumulator volume as per EN 303-5 – see Spec Sheet 3950)

With this variation, the heat accumulator is incorporated by a storage control valve [Art. No. LSR-DYN-]

ECOTRONIC with heating control unit

The ECOTRONIC can be expanded by a great number of heating control units (heat consumers, auxiliary heat

generators) (refer to spec sheets, Category 4). The operation of the heating control units is all carried out in the control

module for the burner system. Each controller is operated by a separate pushbutton.

For ECOTRONIC expansion possibilities, refer to spec sheets, Category 4

PYROMAT-DYN with integrated heat distributor

One heat distributor with two or three consumer groups can be integrated with the PYROMAT-DYN boiler.

In this design with the manifold attached, the boiler forms a compact overall system (refer to Spec Sheets 4600).

+

F8

OK

-

F7

>

KÖB

F6F5

>

<

F3 F4F1 F2

>

accumulator as

hydraulic switcher

accumulator

additional

heat generator

3

21

heat consumer

control

module

control system module

ECO-RM-00

Pyromat-DYN

control

module

heat consumer

additional

heat generator

1 2 3

control system module

ECO-RM-00

accumulator2accumulator

1

Pyromat-DYN

+

F8

OK

-

F7

>

KÖB

F6F5

>

<

F3

F4F1 F2

>

Page 3

Spec Sheet

Burner System Loader System

PYROMAT-DYN

1

Köb Holzheizsysteme GmbH, Flotzbachstr. 33, A-6922 Wolfurt, Tel. +43/5574/6770-0, Fax 65707, E-Mail: office@kob.cc

Subject to technical changes

3010-3

2009-03-01_GB

Technical data:

Trade name

Boiler PYROMAT-DYN..

45 65 85

Art. No.:

KPM-DYN-45

7387408

KPM-DYN-65

7387860

KPM-DYN-85

7388033

Performance data operation with logs

Nominal heat output [kW] 49 75 100

Max. log length [m] 0.5 0.5 0.5

Firebox volume [l] 185 255 255

Burner efficiency rate [%] 91.7 91.5 91.3

Average exhaust gas temperature [°C] 146 145 144

Performance data automatic operation (chippings)

Maximum nominal heat output [kW] 35 52 70

Minimum nominal heat output [kW] 10 15 20

Burner efficiency rate at nominal load [%] 92.4 92.3 92.3

Electrical connections, total [kW] 1.91 1.91 1.91

Electrical power, ignition device [kW] 1.6 1.6 1.6

Electrical power, exhaust fan [kW] 0.08 0.08 0.15

Electrical power, feed auger [kW] 3 x 400V 0.12 0.12 0.12

Electrical power, de-ashing and cleaning [kW] 0.07 0.07 0.07

Electrical power consumption at max. nominal load [kW] 0.1 0.2 0.3

Electrical power consumption at min. nominal load [kW] 0.04 0.05 0.06

Exhaust gas mass flow, nominal heat output [g/s] 35 56 68

Average exhaust gas temperature at maximum nominal load, °C 138 136 134

Average exhaust gas temperature at minimum nominal load, °C 79 78 77

Maximum water content, forest wood chips [W %]

1)

W35 W35 W35

Maximum chip size G50 G50 G50

Heating-relevant specs

Volume on heating gas side [litres] 170 180 190

Volume of ash pan (logs/automatic) [litres] 14 / 34 18 / 43 18 / 43

Max. flue draught, wood [Pa]

2)

25 25 25

Chimney draught required [Pa] 3) +-0 +-0 +-0

Water-bearing resistance (Diff. 10 K) [mbar] 8 16 25

Boiler water volume [l] 130 170 210

Boiler weight without water [kg] 760 935 1065

Test pressure [bar] 5 5 5

Maximum operating pressure [bar] 3 3 3

Maximum boiler temperature [°C] 100 100 100

Minimum return temperature [°C] 70 70 70

Thermic safety outlet: min. flow rate at 2.5 bar [kg/h] 2000 2800 3500

Burner group

Burner pump, Grundfos model RS 30/6 TOP-S 30/7 TOP-S 30/7

Electrical power for pump [W] 49-93 85-195 85-195

Pump output m³/h at mWS 2.5 at 6.5 7.5 at 7.0 7.5 at 7.0

Burner control valve, Siemens model VXG 48.32 VXG 48.32 VXG 48.40

Drive for burner control valve, Siemens SQS 35.00 SQS 35.00 SQS 35.00

Weight of burner group [kg] 14 16 20

1)

For function, from W 25 reduction of burner output

2)

Maximum overpressure during the start-up phase (chimney cold) in the exhaust pipe after the exhaust blower

3)

Do not install a chimney draught controller!

Page 4

Spec Sheet

Burner System Loader System

PYROMAT-DYN

1

Köb Holzheizsysteme GmbH, Flotzbachstr. 33, A-6922 Wolfurt, Tel. +43/5574/6770-0, Fax 65707, E-Mail: office@kob.cc

Subject to technical changes

3010-4

2009-03-01_GB

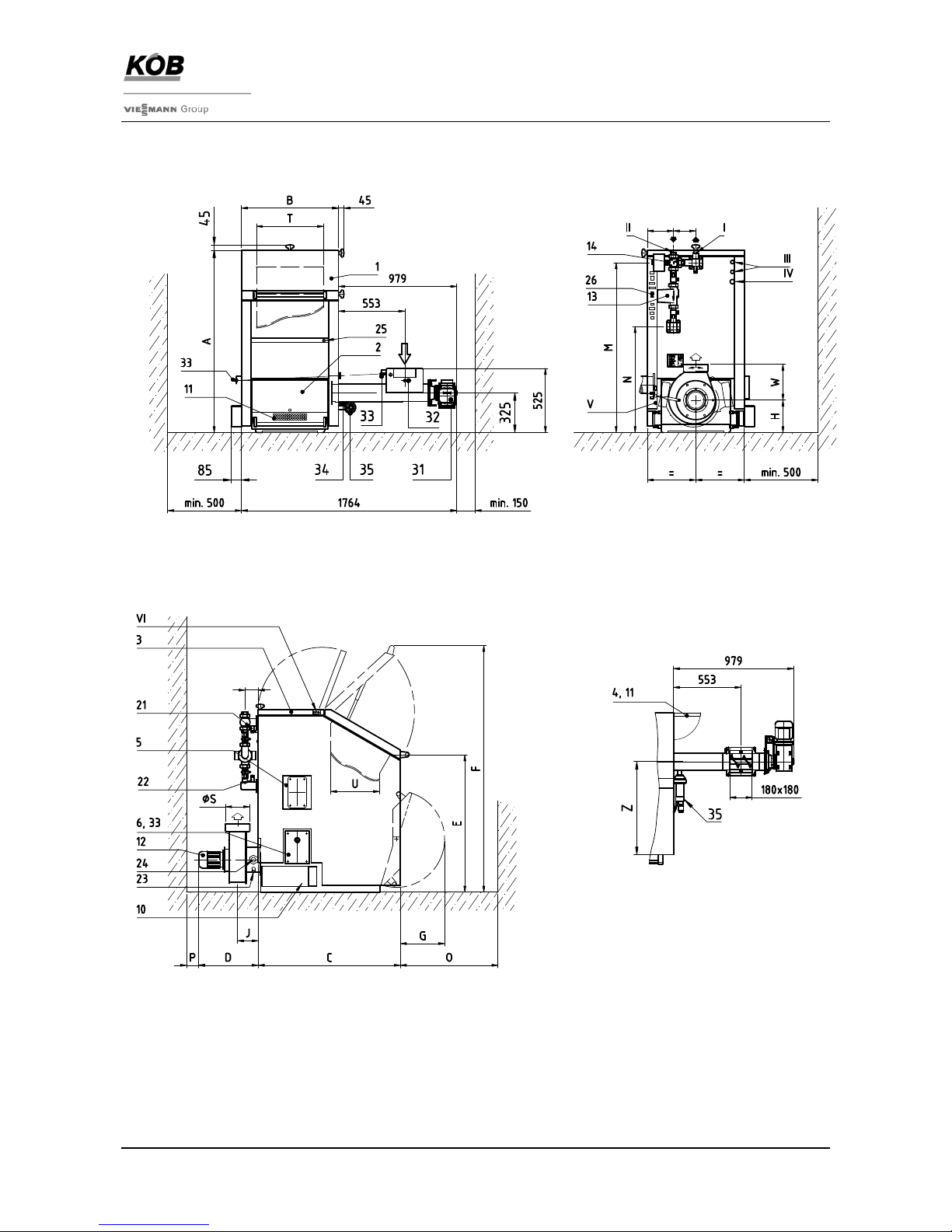

Dimensional drawing:

Feed auger available either left or right turning.

Right design shown

side view (opposite slide-in module)

front view rear view

a

b c

top view

Page 5

Spec Sheet

Burner System Loader System

PYROMAT-DYN

1

Köb Holzheizsysteme GmbH, Flotzbachstr. 33, A-6922 Wolfurt, Tel. +43/5574/6770-0, Fax 65707, E-Mail: office@kob.cc

Subject to technical changes

3010-5

2009-03-01_GB

Table of dimensions:

Pyromat-DYN [Art. No.]

KPM-DYN-45

7387408

KPM-DYN-65

7387860

KPM-DYN-85

7388033

I Forward flow, connection Bsp R 1¼" R 1¼" R 1½“

II Return flow, connection Bsp R 1¼" R 1¼" R 1½“

III Safety valve Bsp connection R ½“ R ½“ R ½“

IV Sensor for run-off safety valve connection Bsp R ½“ R ½“ R ½“

V Drain valve R ½“ R ½“ R ½“

VI Sight glass (transport hook) connection Bsp R 1“ R 1“ R 1“

A Height of casing 1430 1490 1490

B Width of casing (dismantled) 795 (686) 795 (686) 795 (686)

C Length of casing 958 1163 1313

D Length of exhaust blower 500 500 630

E Filling height 1134 1134 1134

F Height of lid, open 1892 2012 2012

G Radius of ash door 365 365 365

H Outlet, boiler 265 265 265

J Outlet, exhaust blower 175 175 300

M Flange, forward flow, boiler 1331 1389 1386

N Flange, return flow, boiler 811 869 693

O Space for operation 800 800 800

P Min. distance to wall 100 100 100

S Connection for exhaust blower 1) 200 200 200

T Width of firebox 550 550 550

U Depth of firebox 300 400 400

W Outlet, exhaust blower 293 293 293

Z Slide-in module flange 650 765 800

a Connection, boiler 108 108 108

b Connection, boiler 214 214 214

c Connection, boiler 183 183 183

Operation and maintenance

1 Firebox door

2 Ash pan door

3 Cleaning door, top

4 Cleaning door, bottom (slide-in module side)

5 Maintenance cover to radiation chamber

6 Maintenance cover to combustion chamber, automatic (opposite slide-in module)

Electric drives, burner [Art. No. KPM-DYN-..]

10 Drive, de-ashing / Cleaning (opposite slide-in module)

11 Motor-driven air vent (primary and secondary)

12 Motor for exhaust blower

13 Boiler pump

14 Burner control valve with actuating drive

Electric connections and sensors, burner

21 Burner sensor

22 Return circuit sensor

23 Exhaust gas sensor

24 Lambda sensor

25 Burner control panel with temperature-limiting safety switch (TLSS)

26 Sockets for electrical connection

Electric drives and sensors, slide-in module

31 Drive for feed auger

32 Light barrier dosing container

33 Light barrier for combustion chamber

34 Temperature sensor for feed auger

35 Ignition device

1

) Reduction up to KPM-DYN-65 is possible (160 mm or 180 mm)

Loading...

Loading...