Page 1

Installation and

Operating Instructions

for use by engineers and heating contractors

KPT 390 to KPT 1250 Series

Wood-fired Boiler

Max. output: 390 to 1250 kW (1331 to 4266 MBH)

Min. output: 98 to 370 kW (334 to 1263 MBH)

Pyrotec

r

IMPORTANT

Please ensure that these instructions are

read and understood before commencing

installation and start-up. Failure to comply

with these Installation Instructions will

render all warranties null and void.

Working on the equipment

The installation, adjustment, service and

maintenance of this product must be

performed by a licensed professional heating

contractor, who is qualified and

experienced in the installation, service

and maintenance of hot water heating

boilers. There are no user serviceable

parts on the boiler or control.

Ensure main power supply to equipment,

the heating system and all external

controls has been deactivated.

Take precautions in all instances to avoid

accidental activation of power during

service work.

Improper installation, service or

maintenance can cause product/property

damage, severe personal injury, and/or

loss of life.

H

5603 882 - 01 07/2014

Product may not be exactly as shown

IMPORTANT

Read and save these instructions

for future reference

.

Please file in Service Binder

Page 2

Introduction

Pyrotec Installation & Operating

Safety, Installation and Warranty Requirements

Please ensure that these instructions are read and understood before commencing installation and service. Failure

to comply with the instructions listed below and details printed in this manual can cause product/property damage,

severe personal injury, and/or loss of life. Ensure all requirements below are understood and fulfilled (including detailed

information found in manual subsections).

Product documentation

Read all applicable documentation before commencing

installation. Store documentation near boiler in a

readily accessible location for reference in the future

by service personnel.

For a listing of applicable literature,

please see section entitled “Important

Regulatory and Safety Requirements”.

Warranty

Information contained in this and

related product documentation must

be read and followed. Failure to do

so renders the warranty null and void.

Licensed professional heating contractor

The installation, adjustment, service and maintenance

of this equipment must be performed by a licensed

professional heating contractor.

Please see section entitled

“Important Regulatory and Installation

Requirements”.

Contaminated air

Air contaminated by chemicals can cause by-products

in the combustion process, which are poisonous to

inhabitants and destructive to Viessmann equipment.

For a listing of chemicals which

cannot be stored in or near the

boiler room, please see subsection

entitled “Mechanical Room”.

Carbon monoxide

Improper installation, adjustment, service and/or

maintenance can cause flue products to flow into

living space. Flue products contain poisonous carbon

monoxide gas.

For information pertaining to the proper

installation, adjustment, service and

maintenance of this equipment to avoid

formation of carbon monoxide, refer

to the “Safety” section.

Fresh air

This equipment requires fresh air for

safe operation and must be installed

ensuring provisions for adequate

combustion and ventilation air exist.

For information pertaining to the

fresh air requirements of this product,

refer to the “Combustion Air Supply”

section.

Equipment venting

Never operate boiler without an installed venting

system. An improper venting system can cause

carbon monoxide poisoning.

For information pertaining to

venting and chimney requirements,

refer to the “Safety” section. All

products of combustion must be

safely vented to the outdoors.

Advice to owner

Once the installation work is complete, the heating

contractor must familiarize the system operator/

ultimate owner with all equipment, as well as safety

precautions/requirements, shutdown procedure, and

the need for professional service. Refer to the Service

and Maintenance Instructions for details.

2

WARNING

Installers must follow local regulations with respect

to installation of carbon monoxide detectors. Follow

manufacturer’s maintenance schedule of the boiler

contained in the ”Service and Maintenance Instructions”.

5603 882 - 01

Page 3

Pyrotec Installation & Operating

About These Instructions

Take note of all symbols and notations intended to draw attention to potential hazards or important

product information. These include ”WARNING”, ”CAUTION”, and ”IMPORTANT”. See below.

Indicates an imminently hazardous situation which,

WARNING

Warnings draw your attention to the presence of potential

hazards or important product information.

CAUTION

Cautions draw your attention to the presence of potential

hazards or important product information.

IMPORTANT

if not avoided, could result in death, serious injury or

substantial product/property damage.

Indicates an imminently hazardous situation which,

if not avoided, may result in minor injury or product /

property damage.

Helpful hints for installation, operation or maintenance

which pertain to the product.

Introduction

Note: Viessmann Manufacturing Company Inc. reserves

the right to make product changes or updates

without notice and will not be held liable for

typographical errors or omissions in the product

literature.

This symbol indicates to note additional information

This symbol indicates that other instructions must be

referenced.

5603 882 - 01

3

Page 4

Table of Contents

Pyrotec Installation & Operating

Page

Introduction

General Information

Safety

Mechanical

Safety, Installation and Warranty Requirements..............2

About These Instructions..............................................3

Important Regulatory and Installation Requirements ........6

Codes...................................................................6

Mechanical room...................................................6

Working on the equipment......................................6

Technical literature................................................6

Product Information.....................................................7

Boiler Description........................................................8

Transport and Installation.............................................9

Lifting...................................................................9

Delivery Condition.....................................................10

Standard delivery condition....................................10

Wood Fuel Requirements...........................................11

Allowed fuels......................................................11

Non-wood fuels....................................................12

Maximum water content.......................................12

Limitation super fines and dust............................12

Suitable fuel types for Pyrotec systems..................12

Content limits for non-combustable substances.......13

Other information.................................................13

Carbon Monoxide......................................................14

Hazardous Materials..................................................15

Fiberglass wool and ceramic fiber materials.............15

First aid measures...............................................15

Power Failure Provision..............................................16

Venting Requirements................................................16

Mechanical Room.....................................................17

Mechanical room conditions...............................18

Sources of combustion and ventilation

contaminants......................................................18

Combustion Air Supply..............................................19

Codes................................................................19

General..............................................................19

Confined spaces..................................................19

Unconfined spaces...............................................19

Louvers and grilles...............................................19

4

Technical Data.........................................................20

Boiler Dimensions......................................................21

Boiler Components....................................................22

Flue Gas Cyclone......................................................23

Recirculation System.................................................24

Safety Devices

Fire extinguishing water tank.................................26

Expansion...........................................................26

The boiler system with 3-way mixing valve.............26

Drain inspection port............................................26

Piping and Installation of Safety Devices......................28

Fire Protection..........................................................30

Power failure provision..........................................30

Protection against back-burn for the boiler plant.......30

Back-burn safeguard for the fuel supply system.......31

Automatic triggering system for fuel supply system.....31

Slide valve..........................................................31

Rotary valve........................................................31

Double rotary valve pressure compensation system...31

Down pipe..........................................................31

Fire protection for fuel storage space......................31

.........................................................26

5603 882 - 01

Page 5

Pyrotec Installation & Operating

Mechanical (continued)

Table of Contents

Page

Fire Extinguishing System.........................................32

Assembly of the Fire Extinguishing System...................33

Negative Pressure Monitoring Assembly........................34

Electrical

Operation

Control Panel...........................................................35

Mounting of control panel....................................35

Electrical connection............................................35

General safety instructions...................................35

Vitocontrol-C Pyrocontrol KPT..............................36

Electrical Components...............................................38

Fuel Transport and Extraction Systems........................40

Rotary valve........................................................40

In-feed auger.......................................................41

Pipe/trough conveyor auger...................................41

Pellet extraction auger..........................................42

Spring extraction system.......................................42

Horizontal extraction system..................................43

Walking floor auger...............................................44

Hydraulic unit......................................................44

Thermal Storage Tank...............................................45

Boiler Wiring.............................................................46

Commissioning......................................................47

Initial startup...................................................47

Filling the heating system..................................47

Fuel for the commissioning................................47

Commissioning and hand over............................47

Filling the Fuel Storage Unit....................................48

Horizontal extraction system and

spring extraction system....................................48

Pellet extraction auger.......................................48

By dumping.........................................................48

By blowing in......................................................48

Fixing malfunctions in the feed systems..................48

Excess Conditions.....................................................49

Excess temperature/power failure..........................49

Low water/excess water pressure.........................49

Pyrocontrol Control System........................................50

Export of operational data via Mod-bus Pyrocontrol..50

Touch screen, Screen 1-8....................................51

Screen 1, Object Indicator Light............................52

Screen 2, Alarm list.............................................53

Screen 3, Managing the user status.......................54

Screen 4, Adjusting settings and parameters...........55

Screen 7, Overview wood powered boiler...............56

Screen 8, Additional boilers...................................57

Pyrotec control system parameters ........................58

Pyrotec controller parameter reference

guide for the technician.........................................59

Operating Modes.......................................................62

Full load operation................................................63

Output control.....................................................63

Sustain...............................................................63

“Cycle for underfeed auger sustain” too high.........63

“Cycle for underfeed auger sustain” too low..........63

Standby..............................................................63

Transition in output..............................................63

Switching off......................................................63

Emergency operation.............................................63

Measurement operation.........................................63

Heating Up Manually.................................................64

5603 882 - 01

5

Page 6

General Information

Pyrotec Installation & Operating

Important Regulatory and Installation Requirements

Take note of all symbols and notations intended to draw attention to potential hazards or important

product information. These include ”WARNING”, ”CAUTION”, and ”IMPORTANT”.

Codes

The installation of this unit shall be in accordance with

local codes. In the absence of local codes, use: B 365-01,

Installation Code for Solid-Fuel Burning Appliances and

Equipment.

All electrical wiring is to be done in accordance with the

latest edition of CSA C22.1 Part 1 and/or local codes. In

the U.S. use the National Electrical Code ANSI/NFPA 70

where required by the authority having jurisdiction.

Mechanical room

Ensure the mechanical room complies with the requirements

listed in this manual. See section entitled Mechanical Room.

Working on the equipment

The installation, adjustment, service, and maintenance

of this boiler must be done by a licensed professional

heating contractor who is qualified and experienced in

the installation, service, and maintenance of hot water

boilers. There are no user serviceable parts on the boiler,

or control.

Ensure main power supply to equipment, the heating

system, and all external controls have been deactivated.

Take precautions to avoid accidental activation of power

during service work.

Please carefully read this manual prior to attempting

installation. Any warranty is null and void if these

instructions are not followed.

For information regarding other Viessmann

System Technology componentry, please reference

documentation of the respective product.

We offer frequent installation and service seminars

to familiarize our partners with our products. Please

inquire.

The completeness and functionality of field supplied

electrical controls and components must be verified

by the heating contractor. These include low-water

cut-offs, flow switches (if used), staging controls,

pumps, motorized valves, air vents, thermostats, etc.

Technical literature

Literature applicable to all aspects of the Pyrotec woodfired boiler:

- Installation and Operating Instructions

- Service and Maintenance Instructions

- Field Wiring Diagram

Leave all literature at the installation site and advise

the system operator/ultimate owner where the

literature can be found. Contact Viessmann for

additional copies.

This product comes with several safety instruction

labels attached.

Do not remove!

Contact Viessmann immediately if replacement labels

are required.

6

5603 882 - 01

Page 7

Pyrotec Installation & Operating

Product Information

General Information

Viessmann solid-fuel boiler may only be installed and

serviced by trained personnel.

Steel wood-fired hot water heating boiler.

For operation primarily with modulating boiler water

temperatures in closed loop forced circulation hot water

heating systems. Under certain conditions, open loop

systems may also be considered. Contact Viessmann

for details.

Maximum allowable working pressure (water)...30 or 60 psi

Maximum water temperature…..250° F (120° C) (closed loop)

Maximum boiler temperature………210° F (99° C) (open loop)

This boiler does not require a flow switch.

WARNING

Exposing the boiler to pressures and temperatures in

excess of those listed will result in damages and will

render the warranty null and void.

Note: “Pyrotec“ is an alternate / interchangeable trade

name with “Pyrtec”.

Codes

CSA B366.1-M91

Solid Fuel Fired Central Heating Appliances

CSA C.22.2#3-M88 (R2004)

Electrical Features of Fuel Burning Equipment

UL2523

Solid Fuel-Fired Hydronic Heating Appliances, Water

Heaters and Boilers

CSA B365-10

Installation Code for Solid Fuel Burning Appliances

and Equipment

5603 882 - 01

7

Page 8

General Information

Boiler Description

Pyrotec Installation & Operating

Description

The PYROTEC Grate Firing System (patent no: EP 0 905

442 B1) was developed for automatic combustion of all dry

to moist wood fuels (remnant wood, pellets and forest wood

chips to max. W50, (see section “Wood Fuel Requirements”)

and combines the benefits of underfeed firing with the

benefits of grate firing.

The PYROTEC Grate Firing System is characterized by

highest efficiencies and perfect combustion in all load

stages. The PYROTEC Boiler Plant has been built to

ASME Sec. IV and has CRN for Canada. It is tested and

approved to the applicable CSA / UL safety standards.

Function:

- The solid, powerful and heat-resistant in-feed auger

moves the fuel over the burner trough into the

descending and moving grate zone. An electrical and

mechanical temperature sensor to operate the

thermal extinguishing valve are located on the in-feed

auger. Above the auger is the metering container with

a light barrier for setting the level of the fuel insulating

layer.

- The fuel is either ignited manually or automatically with

an automatic igniter (optional). The boiler features

a reliable burner trough, a descending grate and

a moving burn-out grate made from highly-refractory

cast steel [approx. b in. (12 mm)]. These items allow

to achieve excellent performance control and highest

safety against back-burn in conjunction with an automatic

de-ashing assembly with ash container (optional)

for the combustion chamber.

The solid, horizontally positioned and large-volume

combustion chamber door has been optimized in terms

of combustion, consists of a high-quality refractory

brick lining and has multiple layers of insulation for the

lowest possible surface temperatures. A variable speed

primary air blower provides preheated air to the

combustion grates in the combustion chamber door.

- In the upper part of the combustion chamber door, the

secondary air is blown into the gas space of the firing

system by variable speed blower via an encircling ring

with individually adjustable nozzles to achieve high

turbulence. This mixes the fuel gases with fresh

secondary air to achieve perfect combustion and very

low emissions. The combustion chamber door is

solidly constructed, air-cooled and very well insulated.

The combustion chamber door is equipped with solid

double-jointed hinges for easy maintenance. The heat

is transferred to the water in the horizontal heat

exchanger. The boiler is well insulated and highly

accessible through the heat exchanger door on the

front. A pneumatic cleaning system (optional) can be

installed at the insulated heat exchanger door.

- The flue gas exhaust blower has been specially

designed for wood burning boilers and quiet operation.

The spring-suspended motor has a solid, heat-resistant

design with a heat dissipation hub. The blower housing

on the intake can be mounted radial by 360° and has a

variable rotation speed and a round blow-out nozzle. It

is mounted directly on the boiler or on the flue gas

cyclone (optional).

8

Supplied with:

- Boiler with combustion chamber and pressure vessel/

heat exchanger including supply and return

temperature sensors and over pressure monitor

- Combustion chamber with burner trough, descending

grate, moving burn-out grate and light barriers for

ember monitoring

- In-feed auger including insulating layer, safety end

switch for maintenance lid, back-burn temperature

sensor, thermostatic valve for extinguishing assembly,

extinguisher water container with mounting bracket

- Flue gas exhaust blower including flue gas temperature

sensor and oxygen sensor

- Boiler cleaning tools for the combustion chamber

and heat exchanger

- Installation fittings including pressure relief valve, drain

valve, low water cut off, safety temperature limiter,

temperature and pressure gauges

- Control cabinet with integrated Pyrocontrol control

system

Customer supplied:

- Counter flanges for the boiler supply and return

- Piping to the 3-way mixing valve, boiler pump and

thermal storage tank

- Piping for the safety heat exchanger

- Wiring to the control panel

- Insulation for the flue gas re-circulation line, the flue

gas recirculation system is optional

Accessories for PYROTEC Grate Firing System:

- Flue gas cyclone 63 USG (240 L)

- Flue gas cyclone 211 USG (800 L)

- Automatic de-ashing assembly with ash container,

63 USG (240 L)

- Automatic de-ashing assembly with ash container,

211 USG (800 L)

- Pneumatic cleaning system

- Automatic igniter

- Set of displacement rods (for Pyrotec 720, 950 and

1250 only)

- Operating pressure 30 or 60 psi

- Two-stage in-feed auger

- Flue gas recirculation system

- Thermal safety flush valve

- Slide valve / Rotary valve

- Boiler pump and boiler mixing valve

- Pyrocontrol control system options:

- 5 sensor thermal storage tank management system

- External control module for field supplied extraction

system

- Output module / Input module

- Input module 0-10V

- ModBus

- BacNet gateway

- Visualization

5603 882 - 01

Page 9

Pyrotec Installation & Operating

Transport and Installation

IMPORTANT

Precautions must be taken to avoid accidents and injury

during the transportation of the boiler.

Only hoist the boiler when it is entirely empty of water,

fuel and ash.

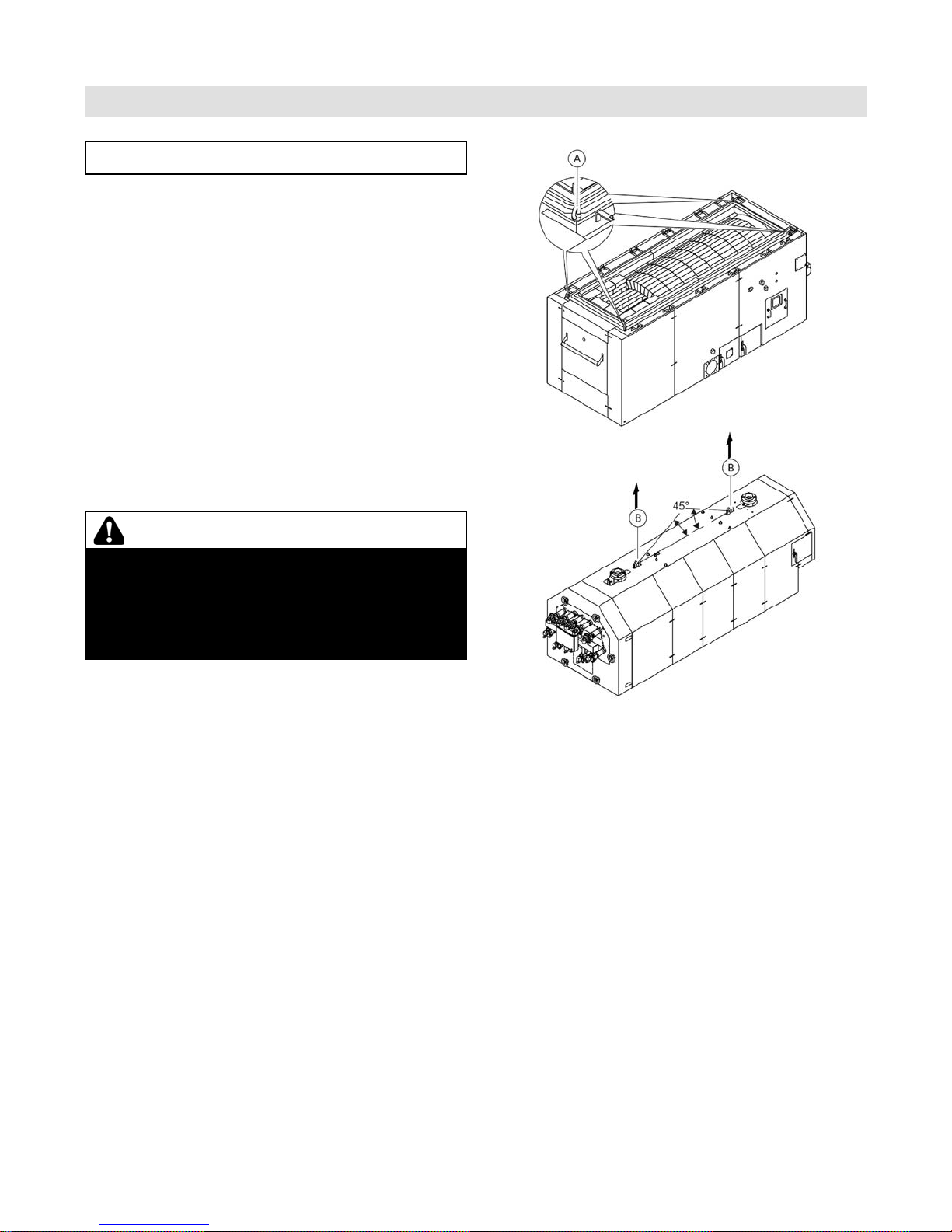

Lifting

The combustion chamber has four lifting lugs that must

be screwed in before lifting. Lifting gear can be attached to

these lifting lugs.

The pressure vessel of the PYROTEC has two lifting lugs

to which lifting gear may be attached.

A special crane (provided by the customer on site) is

required to lift the combustion chamber and the pressure

vessel.

Recommended minimum clearances to walls for

installation and maintenance work must be observed.

An anti-vibration boiler support should be provided if

anti-vibration measures are required.

General Information

WARNING

Follow instructions for proper installation.

For wood-fired installations:

This wood-fired boiler must be installed in accordance

with local codes if any; if not, follow B365-10,

Installation Code for Solid-Fuel Burning Appliances

and Equipment.

A Lifting lugs (screw in before lifting)

B Lifting lugs (pressure vessel)

5603 882 - 01

9

Page 10

General Information

Pyrotec Installation & Operating

Delivery Condition

Standard delivery condition

The standard delivery condition of the Pyrotec boiler includes pre-assembled components as well as components

that need to be assembled by the contractor in the field.

Components that are attached to the boiler at time of delivery:

- Heat exchanger door is mounted to the heat exchanger

- Combustion chamber door is mounted to the combustion chamber

- Flue gas collector is attached to the heat exchanger

- Pneumatic cleaning system (optional) is attached to the heat exchanger door

Components that are not attached or installed to the boiler at time of delivery (scope of the contractor):

- The pressure vessel is not mounted to the combustion chamber

- Brickwork to connect the combustion chamber and the heat exchanger, bricks and mortar are included

- Electrical components which include temperature sensors, oxygen sensor, light barriers for the combustion chamber,

igniter, low water cut off, fixed high limit, negative pressure monitoring assembly and light barriers for

the complete extraction system

- All wiring to the control cabinet

- Installation fittings which include pressure relief valve, drain valve, temperature and pressure gauges

- Drive for the combustion chamber grate is detached

- De-ashing assembly with ash container (optional) and drive for the de-ashing system

- Air compressor (optional) and connection to the pneumatic cleaning system (optional)

- The flue gas exhaust blower is not attached to the flue gas collector

- Primary air blowers are not attached to the combustion chamber

- Secondary air blowers are not attached to the combustion chamber

- Re-circulation system (optional)

- Flue gas cyclone (optional) comes in two pieces

- The in-feed auger is detached from the combustion chamber

- Fire extinguishing system for the in-feed auger

- Slide valve (optional) or rotary valve (optional)

- All components of the extraction system (optional), welding for flanges and support legs required

- Glass fiber insulation between any auger connections

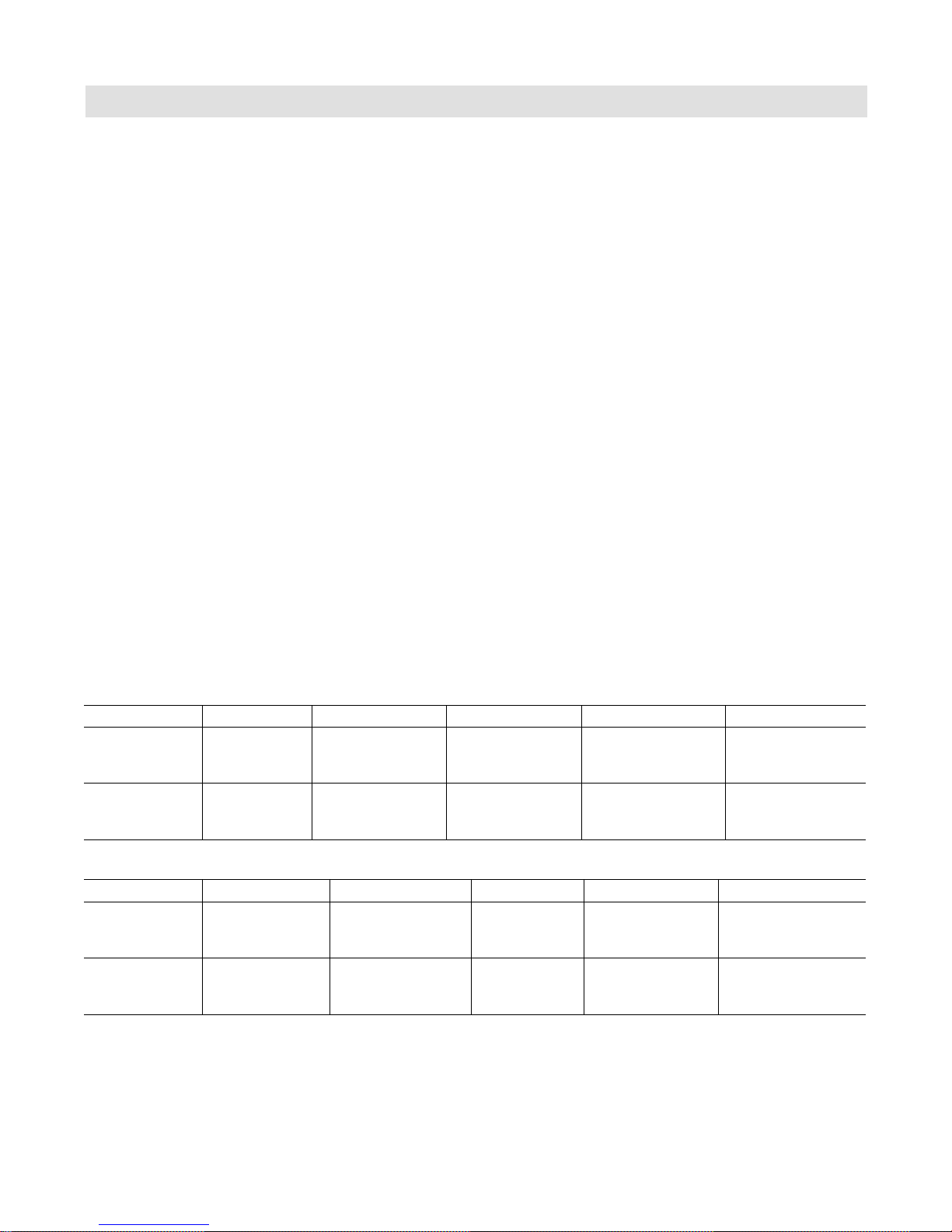

Measurements for the combustion chamber as standard delivery condition

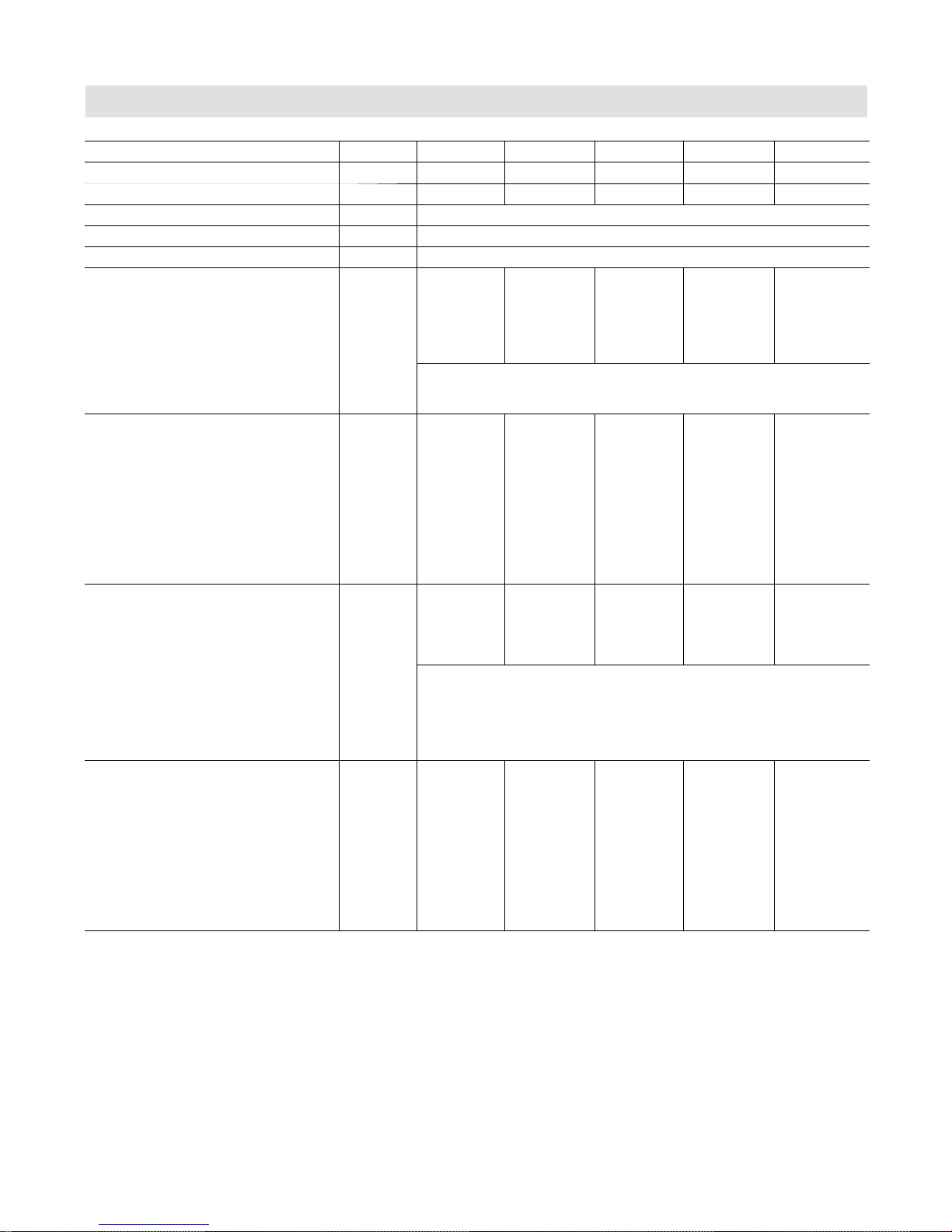

Boiler model KPT390 KPT530 KPT720 KPT950 KPT1250

Minimum size

door (W x H)

Minimum ceiling

opening (W x H)

Measurements for the pressure vessel as standard delivery condition

Boiler model KPT390 KPT530 KPT720 KPT950 KPT1250

Minimum size

door (W x H)

Minimum ceiling

opening (W x H)

59 in. x 59 in.

(1500 mm x

1500 mm)

59 in. x 149 in.

(1500 mm x

3800 mm)

59 in. x 59 in.

(1500 mm x

1500 mm)

59 in. x 112a in.

(1500 mm x

2850 mm)

63 in. x 69 in.

(1600 mm x

1750 mm)

63 in. x 157b in.

(1600 mm x

4000 mm)

63 in. x 69 in.

(1600 mm x 1750

mm)

63 in. x 112a in.

(1600 mm x

2850 mm)

63 in. x 69 in.

(1600 mm x

1750 mm)

63 in. x 196c in.

(1600 mm x

5000 mm)

63 in. x 69 in.

(1600 mm x

1750 mm)

63 in. x 126 in.

(1600 mm x

3200 mm)

74c in. x 73c in.

(1900 mm x

1850 mm)

74c in. x 196c in.

(1900 mm x

5000 mm)

74c in. x 73c in.

(1900 mm x

1850 mm)

74c in. x 130 in.

(1900 mm x

3300 mm)

74c in. x 78c in.

(1900 mm x

2000 mm)

74c in. x 216b in.

(1900 mm x

5500 mm)

74c in. x 78c in.

(1900 mm x

2000 mm)

74c in. x 137c in.

(1900 mm x

3500 mm)

10

5603 882 - 01

Page 11

Pyrotec Installation & Operating

Wood Fuel Requirements

General Information

The Pyrotec is only suitable for burning fuels listed in this

section. A prerequisite for approval is of a fuel by

Viessmann is the approval for the fuel by the responsible

public authorities.

Warranty claims for Viessmann Biomass boilers are

excluded if the following fuel conditions are not met.

IMPORTANT

If different fuels are used, Viessmann will not assume any

liability for the functioning or service life of the boiler plant.

Refer to the “Warranty” section in the General Terms and

Conditions of Delivery.

- Burn wood only

- Do not use chemicals or fluids to start fire.

- Do not burn garbage, gasoline, naphtha, engine oil,

or other inappropriate materials.

Allowed fuels

- Forest wood and plantation wood (complete untreated trees and trunk wood):

Mature wood from trunks and branches, untreated, chopped to chips

- Compressed wood, pellets conforming to standards, as per CAN/CSA-B366.1-M91, size P1, P2, P4.

Untreated wood with limited bark content, compressed by machine and calibrated

Fuel Minimal Diameter Maximal Diameter

P1 - Pellets Small --P2 - Pellets Medium

P4 - Briquettes (Pellets Large)

e in. (10 mm) c in. (20 mm)

c in. (20 mm) 2b in. (60 mm)

e in. (10 mm)

- Wood with an increased proportion of bark, tree cuttings from roadside trees (untreated):

Wood remnants from the forestry and sawmill industries or from landscape conservation (likelihood of elevated ash content).

- Remnants from derived timber products:

Usually a mixture of untreated and treated wood in the form of shavings from processing machinery and chips from

choppers.

- Used wood:

This is untreated wood that has been used prior to its energetic utilization (e.g. pallets). It is reduced in size by

shredders for thermal utilization. The metal parts have to be removed by magnetic separators.

Size of Wood Chips as per CAN/CSA-B366.1-M91, Grade C7

Total mass 100% G 30 Fine G 50 Medium

Coarse percentage max. 20% Max. cross-section in.

Max. length in. (cm)

Coarse sieve nominal mesh width in. (mm)

Main percentage 60 to 100% Medium sieve nominal mesh width in. (mm)

Percentage of fines

Fine sieve nominal mesh width in. (mm)

2

(cm2)

b (3) c (5)

3g (8.5) 4c (12)

f (16) 1a (31.5)

d (2.8) a (5.6)

1

/

(1)

25

1

/

25

(incl. ultrafine content) max. 20%

CAUTION

Chips have to pass through a 1 in. (25 mm) sieve,

additionally, a fraction of max. 5% of the fuel with a

cross-section of max. c in.² (500 mm²) up to a length

of max. 6a in. (160 mm) can be tolerated.

Size of briquettes:

2

- Fraction of one-offs. max. 5% with cross-section of max. c in.

- Frayed surface by chopping tools (shredders) or slow-running choppers.

- Briquettes, diameter max. 2e in. (60 mm).

Consequences of overstepping particle size:

- Increased maintenance because of a substantially higher risk of malfunction

- Shortened service life of the conveyor augers and drives

(500 mm2) up to a length of max. 6a in. (160 mm).

(1)

5603 882 - 01

11

Page 12

General Information

Pyrotec Installation & Operating

Wood Fuel Requirements (continued)

Maximum water content

The maximum allowable water content of the fuel for Pyrotec systems is limited to 50%.

The water content impacts the maximum boiler output.

Non-wood fuels

Non-wood fuels even if consisting of biomass, such as needles, foliage, grain, straw, fruit pits, etc, are unsuited

as fuel for boiler operation and may not be used.

Limitation super fines and dust [wood particles smaller than

Max. 10.0% of the total mass; if fuel does not comply with this limit the following process may occur:

- Temperature peaks

- Slag formation

- Even higher temperature

- This process leads to damage by overheating and can affect refractory materials.

Elevated values are especially critical for remnant wood in combination with elevated values of Chlorine and Sulphur.

Suitable fuel types for Pyrotec systems

3

- Bulk density S in kg/m³ [lb/ft

Note: Fuel for Pyrotec systems allow for a max. of 50% water content (W).

Saw dust

Fuel code Bulk Density kg/m³ [lb/ft³] Water content % Fuel Size Description

a S130 [8.1]

b1 S200 [12.5] W20 to W35 C1 Sawdust, untreated (sawmill)

c2 S250 [15.6] W35 to W50 C1 Sawdust, untreated (sawmill)

Wood chips

Fuel code Bulk Density kg/m³ [lb/ft³] Water content % Fuel Size Description

b2 S200 [12.5]

c1 S250 [15.6]

d1 S300 [18.7]

d2 S300 [18.7]

e1 S350 [21.8]

e2 S350 [21.8]

f1 S400 [24.9]

], water content (W) in %, size C1, C7, P1, P2, P4 as per CAN/CSA-B366.1-M91.

W10 to W20 C1 Sawdust, untreated (planing shop)

W20 C7 Forest wood chips, soft, untreated

W20 to W35 C7 Forest wood chips, soft, untreated

W20 to W35 C7 Forest wood chips, soft/hard, untreated

W35 to W50 C7 Forest wood chips, soft, untreated

W20 to W35 C7 Forest wood chips, hard, untreated

W35 to W50 C7 Forest wood chips, soft/hard, untreated

W35 to W50 C7 Forest wood chips, hard, untreated

1

/32 in. (1.0 mm)]

Shavings and chips

Fuel code Bulk Density kg/m³ [lb/ft³] Water content % Fuel Size Description

g S130 [8.1] Less than W15 C7

h S200 [12.5] Less than W15 C7

i S250 [15.6] Less than W15 C7

Pellets and briquettes

Fuel code Bulk Density kg/m³ [lb/ft³] Water content % Fuel Size Description

j S350 [21.8] Less than W15 P4

k1 S650 [40.6] Less than W10 P1

k2 S650 [40.6] Less than W10 P2

Note: For size of wood chips, see page 11.

12

Shavings & chips from wood remnants,

dry, mixed

Shavings & chips from wood remnants,

dry, mixed

Shavings & chips from wood remnants,

dry, mixed

Briquettes from wood remnants c in. (20

mm) to max. 2 in. (60 mm)

untreated up to e in. (10 mm)

untreated e in. to c in. (11 mm to 20 mm)

5603 882 - 01

Page 13

Pyrotec Installation & Operating

General Information

Wood Fuel Requirements (continued)

Content limits for non-combustible substances

- No wood fuels may contain any foreign bodies, such as pieces of metal, stones, masonry remnants or plastics.

The following limits (per lb/kg of dry fuel) of contained non-combustible substances apply [ash analyzed at a

temperature of 1500° F (815° C)]:

Substance Limit Comparative value untreated forest wood

Chlorine (Cl) max. 300 ppm (300 mg/kg) 10 ppm (10 mg/kg)

Sulphur (S) max. 1000 ppm (1000 mg/kg) 120 ppm (120 mg/kg)

Total Cl, S max. 1000 ppm (1000 mg/kg) 130 ppm (130 mg/kg)

Ash content, total max. 0.25 oz/lb (15.0 g/kg) 0.08 oz/lb (5.0 g/kg)

Alkali oxides in the ash (K2O and Na2O) max. 0.016 oz/lb (1.0 g/kg) 0.006 oz/lb (0.35 g/kg)

Sintering point of the ash min. 1800° F (1000° C) approx. 2200° F (1200° C)

If fuel does not comply with these limits, there is a risk of corrosion within the heat exchanger and early sintering and

melting of the ash which leads to:

- Shortened life of the heat exchanger

- Increased maintenance costs (firing, combustion chamber door)

The maintenance instructions need to be complied with in order to avoid a process, which will increasingly cause

damage to the boiler.

If maintenance instructions are not complied with the following process may occur:

- Cinders change the airflow

- Temperature peaks

- More slag is produced

- More cinder builds up and changes the airflow more

This process leads to damage by overheating and may affect refractory materials.

Additives in remnant and used wood have to be free of heavy metals and halogen compounds.

Other information

- Ash and cleaning:

Untreated wood without bark produces less than 0.5% ash of the fuel mass supplied. All the specifications

regarding cleaning are based on untreated wood with bark attached with an ash amount of 0.8% of the fuel mass.

If the ash content is higher and/or the ash melting point is lower, increased maintenance and/or cleaning are required.

- Changing fuels:

A substantial change in fuel quality, such as bulk density, water content, dust proportion or ash content might require

a manual correction of the firing parameters (see Operating section).

5603 882 - 01

13

Page 14

Safety

Carbon Monoxide

Pyrotec Installation & Operating

The U.S. Consumer Product Safety Commission strongly

recommends the installation of carbon monoxide detectors

in buildings in which wood-burning equipment is installed.

Carbon monoxide (CO) is a colorless, odorless gas, which

may be produced during incomplete combustion of fuel

and/or when the flame does not receive an adequate

supply of combustion air. Carbon monoxide can cause

severe personal injury or loss of life.

Therefore, carbon monoxide detectors that are in

compliance with a nationally recognized standard

(e.g. ANSI/UL 2034-2002, CSA 6.19-01) should be

installed and maintained in buildings that contain woodburning equipment.

Note: Viessmann does not test any detectors and makes

no representation regarding any brand or type of

detector.

For safe operation

We recommend that you frequently:

- Check for debris which could obstruct the flow of

flue gases. The vent or chimney must not be blocked.

A blocked or partially blocked vent or chimney can

cause flue gases to leak into the structure. Flue gases

leaking into the house can cause injury or death.

Blocked or partially blocked chimneys must have the

blockage removed by a qualified heating contractor.

- Check the pressure gauge for correct system (water)

pressure. Check for water on the floor from the

discharge pipe of the pressure relief valve or any

other pipe, pipe joint, valve or air vent.

- Check for moisture, water, or appearance of rust

on the flue gas pipes, their joints as well as vent

dampers, or side wall vent terminals (if so equipped).

- Ensure that nothing is obstructing the flow of

combustion and ventilation air and no chemicals,

garbage, gasoline, combustible materials, flammable

vapors and liquids are stored (not even temporarily)

in the vicinity of the boiler.

- DO NOT allow unsupervised children near the boiler.

Service/inspection of the boiler and the system must be

performed on a regular basis. Maintenance, service and

cleaning are specified in the “Service and Maintenance

Instructions”.

Before the heating season begins, it is recommended that

the boiler be serviced by a qualified heating contractor.

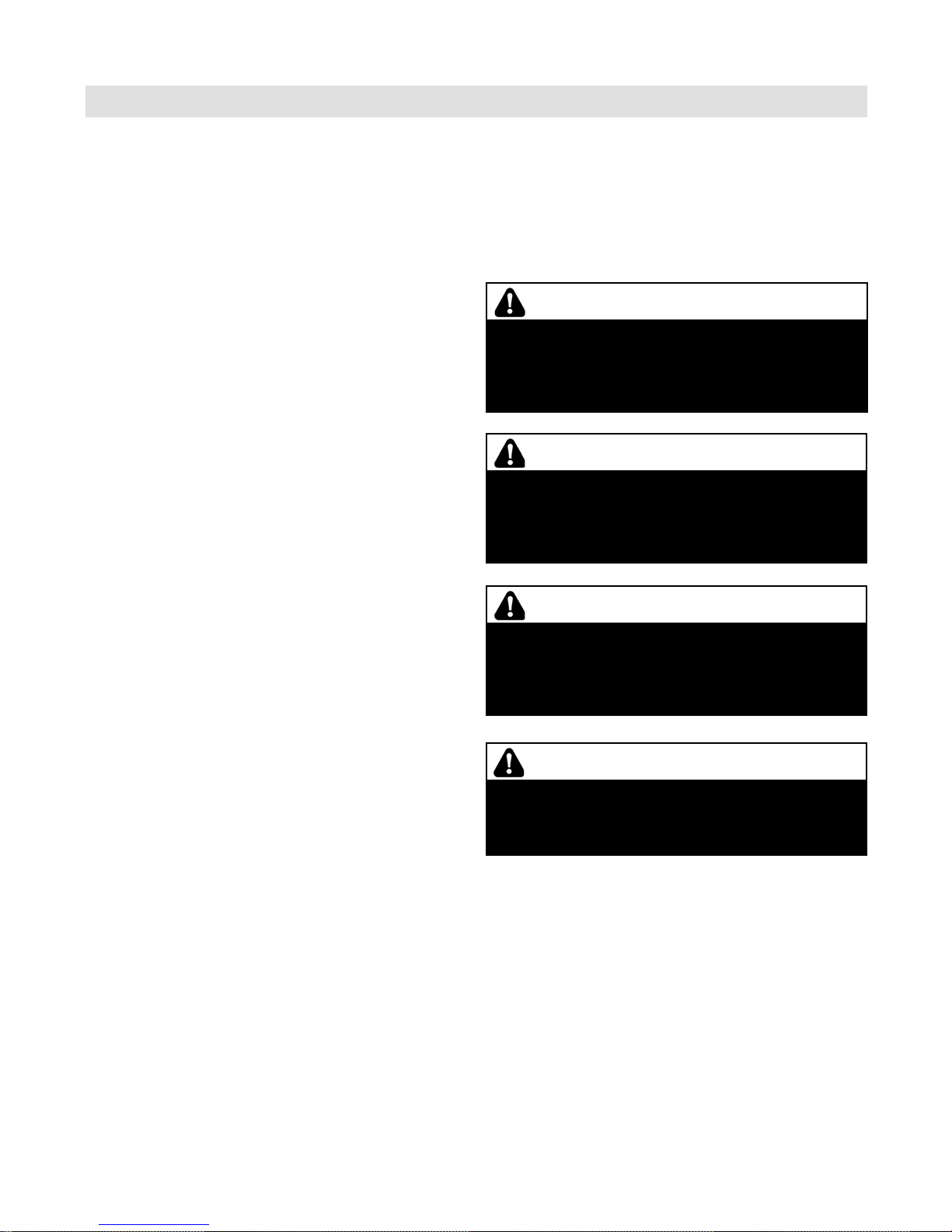

WARNING

As there are no user-serviceable parts on the boiler,

or control, the end-user must not perform service

activities of any kind on system components. Failure

to heed this warning can cause property damage,

severe personal injury, or loss of life.

WARNING

Improper installation, adjustment, service, or maintenance

can cause flue products to flow into living space. Flue

products contain poisonous carbon monoxide gas, which

can cause nausea or asphyxiation resulting in severe

personal injury or loss of life.

WARNING

The operator/ultimate owner is required to have the

heating boiler and controls checked, as a minimum

once per year, by the original installer or by a competent

heating contractor familiar with the equipment. Defects

must be corrected immediately.

CAUTION

Do not use this boiler if any part has been under water.

Immediately call a qualified heating contractor to inspect

the boiler and to replace any part of the control system

which has been under water.

14

5603 882 - 01

Page 15

Pyrotec Installation & Operating

Hazardous Materials

Safety

Fiberglass wool and ceramic fiber materials

WARNING

Inhaling of fiberglass wool and/or ceramic fiber

materials is a possible cancer hazard. These materials

can also cause respiratory, skin and eye irritation.

The state of California has listed the airborne fibers of

these materials as a possible cancer hazard through

inhalation. When handling these materials, special care

must be applied.

WARNING

Appliance materials of construction, products of

combustion and the fuel contain alumina, silica, heavy

metals, carbon monoxide, nitrogen oxides, aldehydes

and/or other toxic or harmful substances which can

cause serious injury or loss of life and which are known

to the State of California to cause cancer, birth defects

and other reproductive harm. Always use proper safety

clothing, respirators and equipment when servicing or

working nearby the appliance.

First aid measures

- If eye contact occurs, flush eyes with water to

remove dust. If symptoms persist, seek medical

attention.

- If skin contact occurs, wash affected areas gently

with soap and warm water after handling.

Suppliers of ceramic fiber products recommend the

following first aid measures

- Respiratory tract (nose and throat) irritation:

If respiratory tract irritation develops, move the

person to a dust free location.

- Eye irritation:

If eyes become irritated, flush immediately with

large amounts of lukewarm water for at least 15

minutes. Eyelids should be held away from the

eyeball to ensure thorough rinsing. Do not rub eyes.

- Skin irritation:

If skin becomes irritated, remove soiled clothing.

Do not rub or scratch exposed skin. Wash area of

contact thoroughly with soap and water. Using a

skin cream or lotion after washing may be helpful.

- Gastrointestinal irritation:

If gastrointestinal tract irritation develops, move

the person to a dust free environment.

Suppliers of fiberglass wool products recommend the

following precautions be taken when handling these

materials

- Avoid breathing fiberglass dust and contact with

skin and eyes.

- Use NIOSH approved dust/mist respirator.

- Wear long-sleeved, loose fitting clothing, gloves

and eye protection.

- Wash work clothes separately from other clothing.

Rinse washer thoroughly.

- Operations such as sawing, blowing, tear-out and

spraying may generate airborne fiber concentration

requiring additional protection.

5603 882 - 01

15

Page 16

Safety

Power Failure Provision

Power Failure Provision

Venting Requirements

Pyrotec Installation & Operating

Customers must ensure that there is a supply of water

independent of the electrical supply. This design ensures

that in case of a power failure, the boiler will be reliably

cooled by the thermal safety flush valve.

The PYROTEC Grate Firing System is equipped with

a flue gas exhaust blower.

This boiler must be properly vented. Use a vent material

certified for use with solid-fuel fired equipment.

This boiler shall be connected to:

a) a masonry chimney conforming to local regulations

or, in the absence of such regulations, to the

requirements of the National Building Code

b) a certified factory-built chimney (refer to the NFPA

211 standard).

A flue pipe serving this boiler shall be constructed of

steel or other suitable material with a melting point of

not less than 2000° F (1100° C).

IMPORTANT

Do not use galvanized steel

For installations in Canada:

The boiler venting system must be tested and listed by

a Nationally Recognized Testing Lab such as ULC/CSA

for solid fuel burning appliances.

The PYROTEC Grate Firing System is output-controlled

within a range from 30%-100% of the rated boiler output.

This produces flue gas temperatures from min. 212° F

(100° C) to max. 482° F (250° C).

An insulated chimney should be provided to prevent sooting.

The distance from the flue gas exhaust blower to the

chimney should be as short as possible. 90° elbows

should be avoided if possible. Flue gas pipes of more than

3 ft. (1 m) in length must be insulated.

The connection to the chimney should be made such that

it rises at an angle of 30°- 45° (to prevent excess ash

accumulating in the lateral section of the vent pipe).

The flue gas line, including the lead-in into the chimney,

must be gas-tight.

16

5603 882 - 01

Page 17

Pyrotec Installation & Operating

Mechanical Room

Safety

Ensure the mechanical room complies with the requirements

in these instructions and local codes.

Viessmann recommends the installation of an additional

electrical disconnect switch and a fuel shut-off valve (if

possible) outside the mechanical room or enclosed area

of installation.

A separate, dry heating room must always be provided

for the PYROTEC Grate Firing System. No combustible

materials may be stored in the heating room. The heating

boiler may only be set up on a fire and temperatureresistant floor.

No temperature-sensitive pipes or lines may be installed

in the floor beneath the heating boiler.

The temperature in the heating room must not exceed

104° F (40° C) while the system is in operation

(in the area approx. 3 ft. (1 m) away from the boiler).

The temperature in the heating room must not fall below

50° F (10° C) while the system is in operation (measured

at the inner side of exterior walls).

The load-bearing capacity of the heating room floor must

be designed for the weight of the system plus filling with

water and fuel. The load-bearing capacity of the floor in

the area of the boiler bearing surface must be 512 lb/ft²

(2500 kg/m²).

IMPORTANT

Always follow the most up-to-date local, municipal and

building regulations and codes.

The minimum distance to the walls and ceiling required

according to the table of dimensions for proper cleaning

and maintenance of the boiler must be complied with.

A sufficient supply of fresh air must be provided directly

from outdoors into the heating room. Induced ventilation is

necessary for heating rooms that are confined or enclosed.

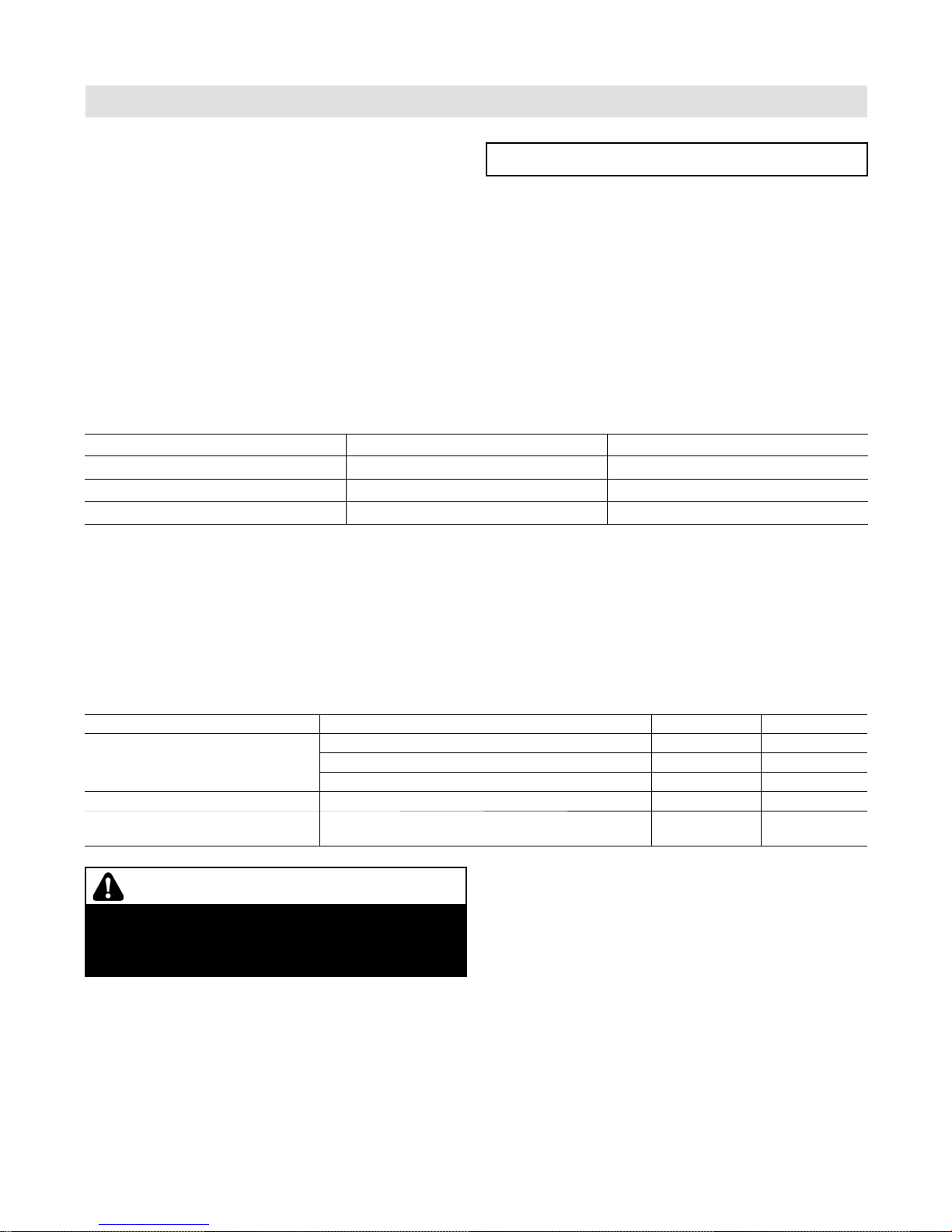

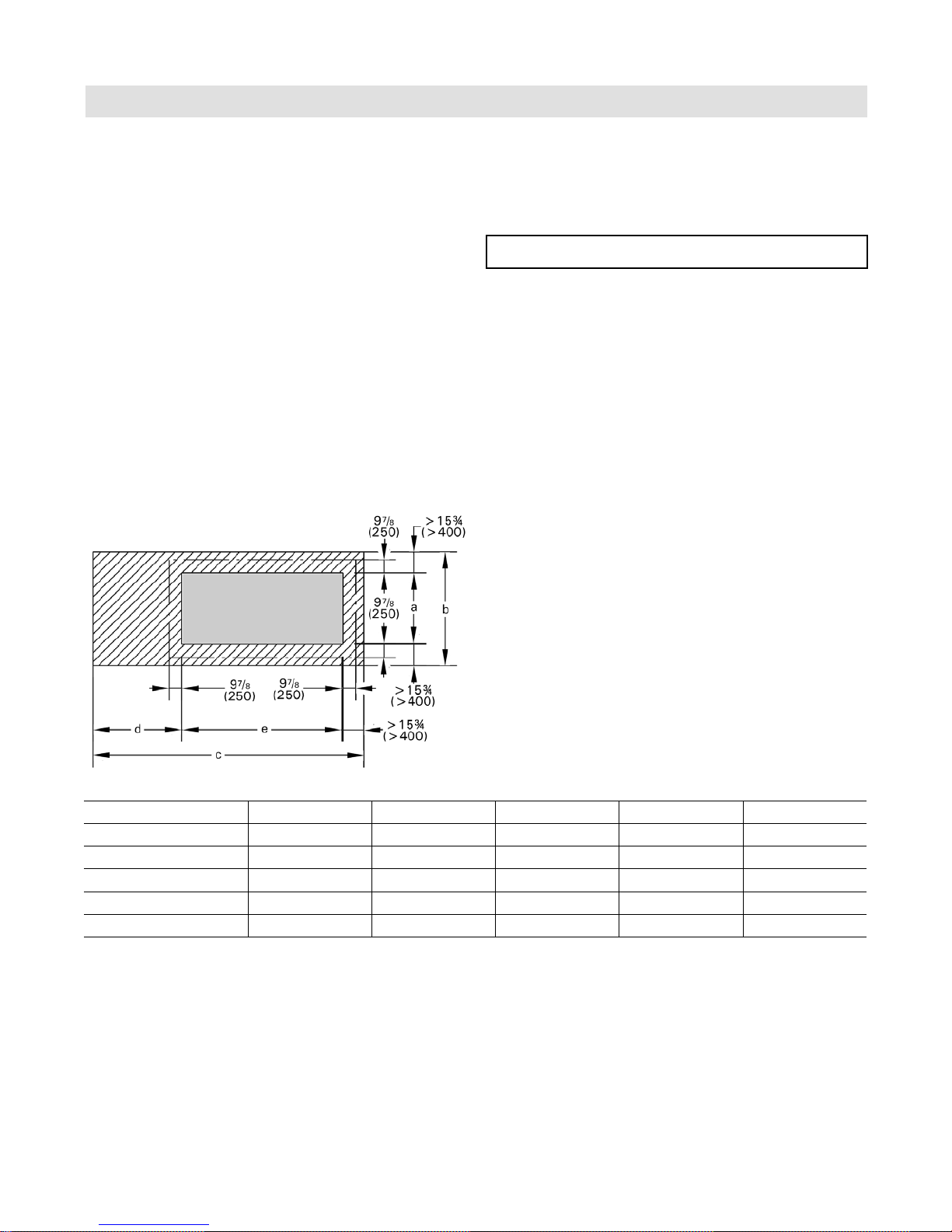

Dimensions shown in. (mm)

Hatched surface Heat-resistant floor

Medium grey surface Boiler supporting surface

Foundation dimensions

Boiler Model KPT- 390 530 720 950 1250

a in. (mm)

b in. (mm) 71

c in. (mm)

d in. (mm)

e in. (mm) 100

40e (1026) 40e (1026) 43c (1112) 53b

7

/8 (1826)

7

/8 (1826) 75a (1912)

71

(1360) 53b (1360)

85 (2160) 85 (2160)

166d (4221) 166d (4721) 193e (4912) 200f (5096)

1

/8 (1400) 641/8 (6030)

49f (1260) 49f (1260)

7

/8 (2561)

120b (3061) 122b (3112) 120c (3066) 142d (3611)

55

1

222

/8 (5641)

64d (1630)

5603 882 - 01

17

Page 18

Safety

Mechanical Room (continued)

Pyrotec Installation & Operating

WARNING

Incorrect ambient conditions can lead to damage to

the heating system and put safe operation at risk.

Mechanical room conditions

Prevent the air from becoming contaminated by homogenate

hydrocarbons (e.g. as contained in paints solvents or

cleaning fluids) and excessive dust (e.g. through grinding

or polishing work). Combustion air for the heating

process, and ventilation of the boiler room must be free of

corrosive contaminants. To that end, any boiler must be

installed in an area that has no chemical exposure.

For the main, currently known sources refer to “Sources

of combustion and ventilation air contaminants”.

Avoid continuously high levels of humidity (e.g. through

frequent drying of laundry).

Never close existing ventilation openings.

WARNING

The boiler must not be located in areas or rooms where

chemicals are stored, or aggressive vapors (i.e. bleach,

hair spray, methyl chloride, carbon tetrachloride or

perchloroethylene) or high dust levels or humidity levels

are present. Heat exchanger corrosion might occur and

reduce the lifetime of the boiler significantly. If above

criteria are not properly observed and boiler damage

results, any warranty on the complete boiler and related

components will be null and void.

IMPORTANT

Components which are not tested with the heating

system may damage the heating system or affect its

functions. Installation or replacement may only be carried

out be a qualified heating contractor.

Sources of combustion and ventilation air contaminants

Areas likely to contain contaminants:

- New building construction

- Swimming pools

- Remodeling areas, hobby rooms

- Garages with workshops

- Furniture refinishing areas

- Dry cleaning/laundry areas and establishments

- Auto body shops

- Refrigeration repair shops

- Metal fabrication plants

- Plastic manufacturing plants

- Photo processing plants

- Beauty salons

Products containing contaminants:

- Chlorine-type bleaches, detergents and cleaning

solvents found in household laundry rooms

- Paint and varnish removers

- Hydrochloric acid, muriatic acid

- Chlorine-based swimming pool chemicals

- Spray cans containing chlorofluorocarbons

- Chlorinated waxes and cleaners

- Cements and glues

- Refrigerant leaks

- Calcium chloride used for thawing

- Sodium chloride used for water softening salt

- Permanent wave solutions

- Adhesives used to fasten building products and other

similar items

- Antistatic fabric softeners used in clothes dryers

18

5603 882 - 01

Page 19

Pyrotec Installation & Operating

Combustion Air Supply

Safety

Codes

Provision for combustion and ventilation air must be made

in accordance with applicable local codes.

In the absence of local codes, use:

CSA B365-10, Installation Code for Solid Fuel Burning

Appliances and Equipment.

Always use latest edition codes.

WARNING

Failure to provide an adequate supply of fresh combustion

air can cause poisonous flue gases to enter living space.

Flue gases entering living space can cause carbon

monoxide poisoning which can result in severe personal

injury or loss of life.

WARNING

Never cover the boiler or store debris or other materials

near the boiler, or in any way block the flow of adequate

fresh air to the boiler. Never cover the combustion air

opening. Advise system operator / ultimate owner

accordingly.

General

This equipment requires fresh air for safe operation

and must be installed ensuring provisions for adequate

combustion and ventilation air exist.

Whenever possible, install boiler near an outside wall so

that it is easy to duct fresh air directly to the boiler area.

The boiler location must never be under negative pressure.

Flue gas exhaust blowers, attic blowers, or dryer blowers

may cause air to be exhausted at a rate higher than air

can enter the structure for safe combustion.

The heating contractor shall ensure all of the following

requirements are met:

- An adequate supply of combustion air must be

available to ensure proper combustion.

- Ambient air temperatures must be maintained within

safe operating limits.

- When a damper is provided in any opening intended

to admit combustion air into the room within which

the appliance is installed, the damper shall be

interlocked to prevent any burner from starting

before the damper is fully open.

- Each duct used to convey air from the outdoors shall

have:

1. a cross-sectional area throughout its length at

least equal to the free area of the inlet and outlet

openings which it connects,

2. making a provision for outside combustion air,

the intake shall not be less than 1 ft. (0.3 m)

above the anticipated snow level for the location.

- The heating contractor must check with local

authorities (municipal building department) for

combustion air requirements particular to the area.

5603 882 - 01

Confined spaces

When a furnace or boiler is enclosed in a space that has

a volume less than 20% of that to be heated by the

appliance, the space shall:

a. have a permanent opening or openings for natural air

circulation with a minimum net free area of 1.5 in² /

1000 Btu/h (3300 mm² / kW) input, and

b. connect to another space or spaces such that the total

volume of air available for natural air circulation is

at least 30% of the total volume to be heated by the

appliance.

The minimum dimension of any opening specified in item

(a) shall be no less than 1 in. (25 mm) The lower edge of

at least one opening shall be located within 1.5 ft. (0.5 m)

of the floor of the enclosed space, and the upper edge of

at least one opening shall be located within 1.5 ft. (0.5 m)

of the ceiling of the enclosed space.

Note: The intent of this Clause is to allow either one

long vertical opening or two shorter horizontal

openings, one high and the other low, to allow

for air circulation to prevent overheating of the

appliance.

Unconfined spaces

Where the boiler is located in an unconfined space in

a building having insufficient infiltration, additional air

for combustion and ventilation shall be obtained from

outdoors or from spaces freely communicating with the

outdoors. Under these conditions, permanent opening(s)

shall be provided so that the total air received through

these openings will be at least as much as would be

admitted by openings having a total free area of 1 in² /

5,000 Btu/h or (450 mm² / kWh) of the total input rating

of all wood-fired appliances.

Louvers and grilles

In calculating free area as specified, consideration shall

be given to the blocking effect of louvers, grilles, or

screens that protect openings. Screens shall be no

smaller than ¼ in. (6 mm) mesh and shall be readily

accessible for cleaning. If the free area through a design

of louver or grilles is known, it shall be used in calculating

the size of opening required to provide the free area

specified. If the design and free area are not known, it

shall be assumed that wood louvers have 20 - 25% free

area and metal louvers and grilles have 60 - 75% free

area.

19

Page 20

Mechanical

Pyrotec Installation & Operating

Technical Data

Boiler model KPT- 390 530 720 950 1250

Maximum output MBH (kW) 1331 (390) 1808 (530) 2457 (720) 3242 (950) 4265 (1250)

Minimum output

Efficiency

Fuel Moisture content

Size of wood chips

Flue gas figures

Connection flue gas pipe

Mass flow rate; W5; O2 6%

Volume flow; W5; O2 6%; 302°F (150ºC)

Mass flow rate; W35; O2 8%;

Volume flow;W35; O2 8%; 302°F (150ºC)

Average flue gas temperature at full load

Average flue gas temperature at partial load

Chimney draft required

Electrical connections

Electrical connections, total

Ignition device

Flue gas exhaust blower

In-feed auger

Primary air blower

Primary air blower

Secondary air blower

Grate drive unit

Electric power consumption at full load

Electric power consumption at partial load

Heating

Water side resistance (diff. 27° F / 15 K)

Boiler water volume

Heating surface

Volume on heating gas side

Volume of ash container for grate ash

Volume of ash container for flue gas cyclone

Test pressure

Maximum allowable working pressure (water)

Maximum water temperature

Minimum return temperature

Weight

Weight of combustion chamber

Weight of pressure vessel (30 psi)

Weight of pressure vessel (60 psi)

Weight of displacement rods

Weight of flue gas exhaust blower

Weight of in-feed auger

Total weight without water (30psi)

Total weight without water (60psi)

Total weight with water (30psi) 7

Total weight with water (60psi)

1

Minimum load: Operation with modulated control (Infinitely variable power control)

1

2

3

4

7 A

5

5

1

2

6

7

7

7

Low load with ON Qmin / OFF (Stop-and-go mode)

2

Moist fuels: Efficiency: Specification with displacement rods and flue gas recirculation system

or dry fuels (W5 to W20) without flue gas recirculation system-reduced values

3

Wet fuels: >W35 further limitations regarding output, degree of efficiency and control behavior

4

Specification: See Section Wood Fuel Requirements

5

Flue gas temperature: An increase is possible by removing the displacement rods [Full load 86° F (30° C);

Partial load 50° F (10° C)]

6

Pressure: Per ASME Sec. IV

7

Overall weight: Includes displacement rods

Other influences: Fuel, water content, ash content, pneumatic cleaning system yes/no; track time (number of

operating hours without cleaning). Specifications for the start of the track time [toward the end

of the track time there is an increase in the flue gas temperature by approx. 59° F (15° C)

20

MBH (kW) 334 (98) 450 (132) 614 (180) 812 (238) 1065 (312)

85%

% W 50

G 30 / G 50 as per CAN/CSA-B366. 1-M91

ft³/s (m³/s)

ft³/s (m³/s)

“wc (mbar)

6

in. mm

lb/s (g/s)

lb/s (g/s)

°F (°C)

°F (°C)

USG (L)

ft² (m²)

USG (L)

USG (L)

USG (L)

psi (bar)

psi (bar)

°F (°C)

°F (°C)

lb (kg)

lb (kg)

lb (kg)

lb (kg)

lb (kg)

lb (kg)

lb (kg)

lb (kg)

lb (kg)

lb (kg)

Pa

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

13b (350)

0.48 (219)

9.18 (0.26)

0.67 (303)

13 (0.37)

6.42

1.6

1.5

1.1

0.14

1.0

.9

0.12

3.36

2.75

5.12 (13)

303 (1150)

291.8 (27.1)

407 (1540)

6570 (2970)

4993 (2265)

4993 (2265)

644 (292)

132 (60)

337 (153)

12820(5815)

12820(5815)

15355(6965)

15355(6965)

13c (350)

0.65 (297)

12.71 (0.36)

0.91 (412)

17.5 (0.50)

8.28

1.6

2.2

1.5

0.3

1.0

1.5

0.12

4.68

3.83

9.23 (23)

383 (1450)

457.5 (42.5)

602 (2280)

9343 (4238)

7094 (3218)

7094 (3218)

721 (327)

172 (78)

337 (153)

17780(8065)

17780(8065)

20964(9509)

20964(9509)

13c (350)

0.89 (404)

17 (0.48)

1.23 (560)

23.6 (0.67)

320 (160)

248 (120)

±0

8.28

1.6

2.2

1.5

0.3

1.0

1.5

0.12

4.68

3.83

17.26 (43)

488 (1850)

597.4 (55.5)

774 (2830)

63 (221) - 240 (800)

63 (221) - 240 (800)

113 (7.8)

30 or 60 (2 or 4)

250 (120)

149 (65)

10919 (4953)

9275 (4207)

9936 (4507)

869 (394)

178 (78)

3.37 (153)

21572(9785)

22234(10085)

25675(11646)

26336(11946)

805.2 (74.8)

1070 (4050)

12740(5779)

12965 (5881)

13627 (6181)

27492(12470)

28153(12770)

31775(14413)

32437(14713)

15c (400)

1.17 (532)

22 (0.63)

1.62 (736)

31 (0.88)

9.51

1.6

2.2

2.2

0.48

1.0

1.85

0.12

5.29

4.28

10.5 (26)

515 (1950)

1186 (538)

181 (82)

419 (190)

17c (450)

1.54 (700)

29 (0.83)

2.13 (968)

40.6 (1.15)

11.31

1.6

4.0

2.2

0.48

1.0

1.85

0.12

6.91

5.6

18 (45)

660 (2500)

979.6 (91.0)

1367 (5210)

14374(6520)

14643 (6642)

15525 (7042)

1186 (538)

236 (107)

419 (190)

30858(13997)

31740(14397)

36330(16479)

37212(16879)

5603 882 - 01

Page 21

Pyrotec Installation & Operating

Specifications

Boiler Dimensions

Mechanical

BR

BS

BR Boiler Return

BS Boiler Supply

Dimensions

Boiler Model KPT- 390 530 720 950 1250

a in. (mm)

b in. (mm)

c in. (mm)

d in. (mm)

e in. (mm)

f in. (mm)

g in. (mm)

h in. (mm)

k in. (mm)

l in. (mm)

m in. (mm)

n in. (mm)

o in. (mm)

p in. (mm)

5603 882 - 01

5

/

93

(2378) 99

8

5

/

91

8 (2328) 97

172 (4370) 191¾ (4870) 207 (5257) 214½ (5447) 235

1

/

87

8 (2060) 100¾ (2560) 100

22¾ (577) 22¾ (577) 22¾ (577) 25

47¼ (1200) 47¼ (1200) 47¼ (1200) 50¼ (1275) 50¼ (1275)

94¾ (2405) 114

42¾ (1086) 42¾ (1086) 54

5

/

31

8 (803) 31

7

/

17

8 (453) 17

81¾ (2077) 91¾ (2331) 98

1

/

12

8 (308) 12

1

/

50

8 (1274) 50

49¾ (1263) 55¾ (1417) 55

7

/

(2536) 111

8

7

/

8 (2486) 109

3

/

8 (2905) 117

5

/

8 (803) 31

7

/

8 (453) 17

1

/

8 (308) 12

1

/

8 (1274) 54

5

/

(2834) 119½ (3035) 127

8

5

/

8 (2784) 117

7

/

8 (2562) 100

7

/

8 (2993) 112

3

/

8 (1380) 63½ (1612) 63½ (1612)

5

/

8 (803) 36

7

/

8 (453) 18

1

/

8 (2491) 96¼ (2444) 103

1

/

8 (308) 17

3

/

8 (1380) 63½ (1612) 63½ (1612)

5

/

8 (1413) 51

3

/

8 (2981) 125 (3176)

7

/

8 (2562) 122

7

/

8 (657) 25

5

/

8 (2861) 134

5

/

8 (929) 36

7

/

8 (479) 18

3

/

8 (440) 17

7

/

8 (1317) 61

5

1

/

(3230)

8

7

/

8

(5992)

3

/

8 (3107)

7

/

8 (657)

1

/

8 (3406)

5

/

8 (929)

7

/

8 (479)

7

/

8 (2639)

3

/

8 (440)

/

8 (1566)

21

Page 22

Mechanical

Pyrotec Installation & Operating

Boiler Dimensions (continued)

a

Legend

A Boiler return

B Motor for de-ashing assembly with ash container

(optional)

C Primary air blower 1

D Boiler supply

Dimensions

Boiler Model KPT- 390 530 720 950 1250

3

/

129

a in. (mm)

b in. (mm)

16 (3282) 149 (3782) 152

5

/

149

8 (3800) 169

5

/

16 (4300) 174

b

E Secondary air blower

F In-feed auger

5

/

8 (3877) 151 (3835) 172

9

/

16 (4434) 173 (4392) 194

1

/

2 (4380)

3

/

8 (4937)

Boiler Components

Legend

BS Boiler supply

BR Boiler return

A De-ashing assembly with ash container

B Cleaning cover, heat exchanger

C Combustion chamber temperature sensor

D Negative overpressure monitoring assembly

E Light barrier, combustion chamber

F Igniter (optional)

G Cleaning cover trough

H Cleaning cover, external grate

K Light barrier de-ashing system

L Heat exchanger door

M Pneumatic cleaning system

N Combustion chamber door

O Limit switch, combustion chamber door

P Primary air blower 2

Q Drive, in-feed grate

R Temperature sensor in-feed auger

S Limit switch, maintenance cover

T Light barrier, in-feed auger

U Extinguishing water connection

V Boiler drain and fill valve

22

5603 882 - 01

Page 23

Pyrotec Installation & Operating

Flue Gas Cyclone

Mechanical

The flue gas cyclone minimizes dust emissions and is

designed as a multi cyclone with axial function. The

cyclone is fully insulated and has three covers for cleaning.

The crude gas chamber is cleaned via the side cleaning

cover. The clean gas chamber is cleaned via the upper

or back cleaning cover (unused blower connection).

The ash box has a carriage and is connected to the cyclone

with quick-action fasteners. It can easily be pulled out for

emptying. The flue gas exhaust blower can be installed

either on the side or the top.

to the

from the

furnace

chimney

D

E

F

G

Supplied with:

- 1 flue gas cyclone

- 1 ash container 63 USG (240L) or 211 USG (800L)

CAUTION

The effects of heat can create dangerous conditions.

Legend

A Flue gas exhaust blower (with variable rotation)

- Either top or side

- Unused connection as cleaning cover

- Alternate mounting of the flue gas exhaust blower

(shown in dark grey)

B Flue gas temperature sensor

C Oxygen sensor

D Flue gas exhaust blower - choice of top or side -

unused connection as cleaning lid, variable rotation,

clean gas chamber

E Cleaning lid crude gas chamber

F Cyclone (axial cyclone)

G Ash bin support frame 63 USG (240 L) or 211 USG (800 L)

G

to the

from the

furnace

chimney

Ash bin support frame: positioning is possible in 4 x 90

(extraction, ash container) Drawn with extraction to the right

Top

Top

Top

Boiler Model KPT- 390 530 720 950 1250

11

A in. (mm) 13¾ (350) 13¾ (350) 13¾ (350) 15¾ (400) 17

7

a in. (mm) 81

c in. (mm) 92

/

(2080) 92

8

7

/

(2359) 92

8

j in. (mm) 125½ (3186) 125½ (3186) 133 (3378) 135

3

/

k in. (mm) 52

(1330) 52

8

l in. (mm) 49½ (1256) 49½ (1256) 49½ (1256) 51

5

m in. (mm) 23

n in. (mm) 17

q in. (mm) 49

/

(600) 23

8

5

/

(447) 17

8

5

/

(1260) 49

8

7

/

(2359) 98

8

7

/

(2359) 98

8

3

/

(1330) 57

8

5

/

(600) 26 (660) 27

8

5

/

(447) 18

8

5

/

(1260) 49

8

1

/

(2491) 96¼ (2444) 103

16

1

/

(2491) 96¼ (2444) 103

16

9

/

(1462) 57

16

1

/

(461) 22

8

5

/

(1260) 40

8

7

/

(3452) 146

8

9

/

(1462) 65¼ (1657)

16

3

/

(1300) 51

16

1

/

(690) 30 (760)

8

7

/

(579) 22

8

1

/

(1020) 40

8

/

7

/

7

/

3

/

3

/

16

7

/

1

/

8

r in. (mm) 24½ (620) 24½ (620) 24½ (620) 37½ (950) 37½ (950)

t in. (mm) 65¾ (1670) 65¾ (1670) 68 (1730) 82 (2083) 84¾ (2153)

5603 882 - 01

º

(450)

16

(2639)

8

(2639)

8

(3717)

8

(1300)

(579)

8

(1020)

23

Page 24

Mechanical

Recirculation System

Pyrotec Installation & Operating

24

5603 882 - 01

Page 25

Pyrotec Installation & Operating

Mechanical

Recirculation System (continued)

Item Boiler Model KPT- 390 530 720 950 1250

no. Description Quantity Quantity Quantity Quantity Quantity

1 Pipe adaptor primary air 1 11111

2 Pipe adaptor primary air 2 11111

3 Elbow 130 x 0.9/90°

with PD

4 Flue damper blade

D=5d in. (130 mm)

5 Pipe 130 x 0.6

7

/

8 in. (250 mm)

L=9

6 Pipe 130 x 0.6

L=19f in. (500 mm)

7 Pipe 130 x 0.6

L=39d in. (1000 mm)

8 Clamping band 130

with gasket

9 Distributor 11111

10 Fan DMVL 11111

11 Intake cone 11111

12 Recirculation bracket 11111

13 Threaded rod M12

L=7b in. (190 mm)

14 Threaded rod M12

7

/

8 in. (250 mm)

L=9

15 Pipe clamp 125-130 M12 22222

16 Fan bracket 11111

17 Mesh 8 x 8 11111

18 Pipe insulation

L=39e in (1000 mm)

19 Bolt M12 x 1 in. (25 mm) 44444

20 Nut M12 44444

21 Lock washer M12 88888

22 Bolt M8 x 1 in. (25 mm) 66666

23

Bolt M8 x c in. (20 mm)

24 Nut M8 66666

25 Lock washer M8 14 14 14 14 14

26

Bolt M5 x c in. (20 mm)

27 Lock washer M5 44888

x Distance between the

27e in. (695 mm) 27e in. (695 mm)

recirculation fan and the

supply flange.

y Height of the horizontal

41b in. (1055 mm) 51a in.(1303 mm) 49b in.(1258 mm) 51d in. (1299 mm)

recirculation section.

Note: Items 6 and 7 need to be lengthened by the customer.

55555

44444

2 -- 1 -- --

1[1x L=8

(225 mm)]

7

/

8 in.

3[1x L=8

7

/

(225 mm)]

8 in.

1[1x L=9 in.

(228 mm)]

3[1x L=12d in.

(308 mm)],

1[1x L=12d in.

(308 mm)]

1[1x L=16d in.

(409 mm)]

3[1x L=31c in.

(805 mm)],

1[1x L=36 in.

(914 mm)]

3[1x L=31c in.

(805 mm)],

1[1x L=32f in.

(830 mm)],

1[1x L=36 in.

(915 mm)]

5[1x L=18d in.

(460 mm)],

1[1x L=28e in.

(720 mm)],

1[1x L=33a in.

(845 mm)]

4[1x L=36 in.

(915 mm)]

5[1x L=36 in.

(915 mm)]

18 18 18 19 20

21222

--1------

45566

88888

44888

7

/

8 in. (735 mm)

28

33a in. (845 mm) 33a in. (845 mm)

7

/

71

8 in.(1825 mm)

5603 882 - 01

25

Page 26

Mechanical

Safety Devices

Pyrotec Installation & Operating

1. Install the pressure relief valve, discharge pipe, air

vent and pressure gauge as illustrated in section piping

and installation of safety devices.

A 30 or 60 psi pressure relief valve is supplied with

the boiler (standard equipment).

The KPT 1250, 30 psi will have 2 PRVs.

2. Install a discharge pipe on the pressure relief valve.

The end of the pipe must not be threaded. The pressure

relief discharge pipe should extend to a floor drain and

end approximately 6 in. (150 mm) above the drain.

IMPORTANT

DO NOT install a shut-off valve in the discharge pipe.

DO NOT reduce the discharge pipe diameter.

DO NOT pipe the discharge to outdoors!

IMPORTANT

Install an approved factory supplied pressure relief valve.

Air vent(s) in the system supply must be installed to

purge the air from the system. To ensure the boiler can

be purged of all air, ensure supply / return water lines do

not contain restrictive piping where air could be trapped.

WARNING

Expansion

With closed expansion, the supply pressure to the

expansion tank should be equal to the max. amount

of the system pressure plus 3 psi (0.2 bar).

The boiler system with 3-way mixing valve

To reliably prevent boiler corrosion through condensation

of the flue gases, the boiler return flow temperature must

never be below 149° F (65° C).

The stepless control of the PYROTEC Grate Firing System

output requires a constant flow through the boiler of the

water to be heated. The boiler circuit, the boiler pump and

boiler-mixing valve must therefore be installed according

to section piping and installation of safety devices.

The boiler circuit should be designed that the temperature

difference between the boiler supply and the boiler return

temperature is equal to or less than 27° F (15° C).

The activation of the boiler pump and boiler mixing valve

is integrated in the custom control panel.

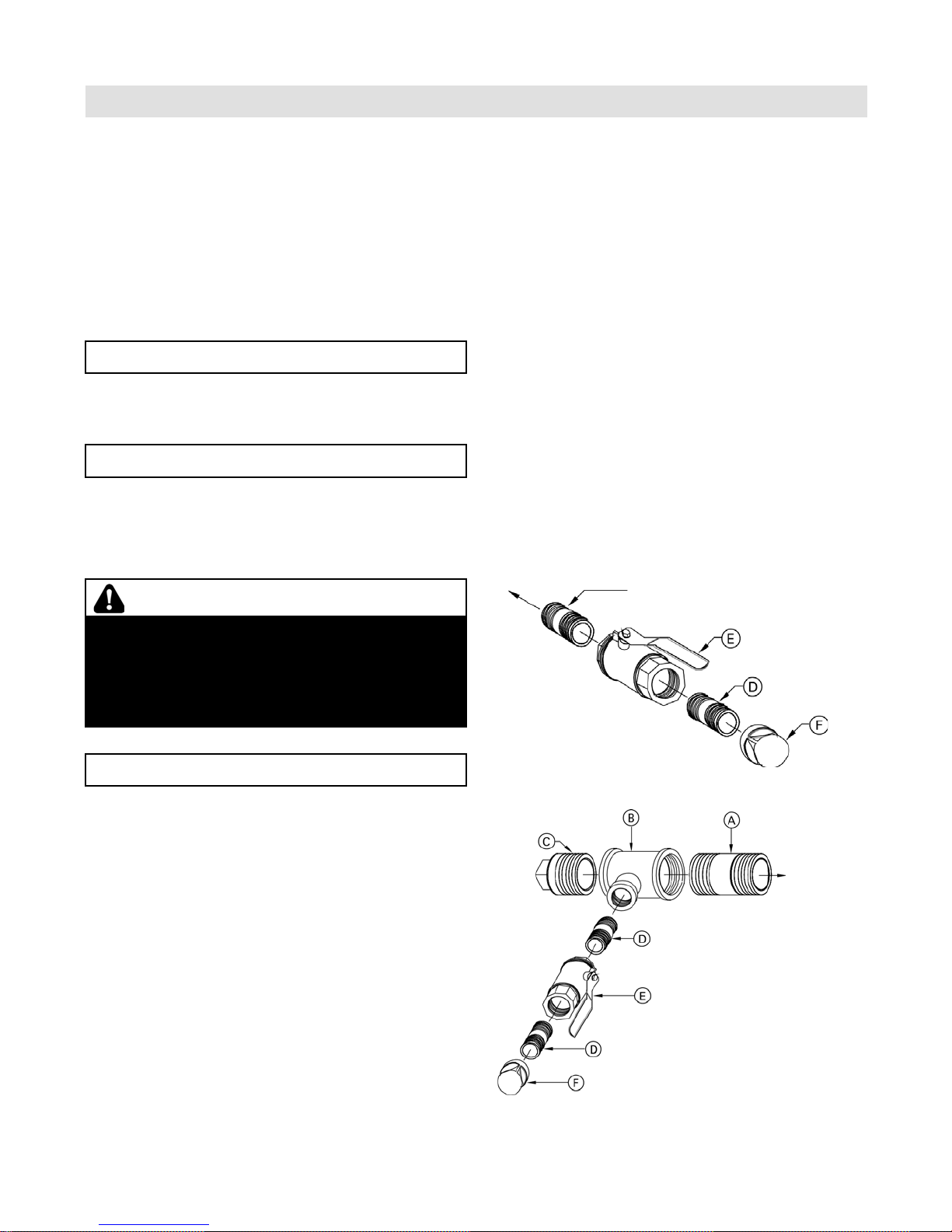

Drain inspection port

KPT 390 - 720

G

Do not install an isolation valve between the boiler and

the pressure relief valve. The discharge pipe for the

pressure relief valve must be oriented to prevent scalding

of attendants. Pipe the pressure relief valve discharge

pipe close to floor drain. Never pipe the discharge pipe to

the outdoors.

IMPORTANT

This boiler does not require a flow switch.

A low water cut-off may be required by local codes.

If the boiler is installed above radiation level, a low water

cut-off device of approved type must be installed in all

instances. Do not install an isolation valve between boiler

and low water cut-off.

Fire extinguishing water tank

The self-activating extinguishing device must be installed

next to the boiler feed system. Refer to section fire

extinguishing systems for the assembly.

The fire suppression is performed by means of an

extinguishing valve, which is not dependent on an electric

current. A float-type switch monitors the water level and

should be electrically connected (see field wiring diagram).

KPT 950 - 1250

Legend

A 3 in. x 5 in. Nipple

B 3 in. x 3 in. x 1b in.

Reducing Tee

C 3 in. Plug

D 1b in. x 2 in. Nipple

E 1b in. Ball Valve

F 1b in. Cap

G 1b in. x 5 in. Nipple

26

5603 882 - 01

Page 27

Pyrotec Installation & Operating

Mechanical

Safety Devices (continued)

The safety equipment for the heating installation must be installed by a heating contractor authorized to do so.

Legend

A Nipple, c in. x 1b in.

B Reducing coupling, c in. x b in.

C Boiler water temperature gauge

D Bushing c in. x a in.

E Nipple a in. x 2b in.

F Ball valve a in.

G Pressure gauge

H Sensor well - fixed high limit (sensor supplied)

I Safety heat exchanger connections, NPTM b in.

J PRV Pressure Relief Valve connection cap

2

K Reducing bushing

L Nipple