Page 1

Wood heating systems from 35 to 170 kW

Page 2

Page 3

2/3

Why heat with wood?

Sustainable

When wood is "harvested" from sustainable

forestry, it is a renewable and environmentally

friendly source of energy and an important

part of sustainable resource management.

CO

2

neutral

When wood is burned, only as much CO2 is

released as the trees have absorbed during

the course of their life. That's why heating

with wood is CO2 neutral.

Economical

Wood, as an indigenous fuel, is also very

aordable and not subject to wide price

fluctuations.

The rising costs of fossil fuel and increasing environmental awareness have resulted in an

ever-rising demand for renewable forms of energy. Advanced wood heating systems are

an environmentally responsible and economical alternative (or addition) to conventional

fossil fuel heating systems.

Top technology and reliability

Advanced biomass systems operate fully

automatically and are equipped with control

and safety devices for a reliable, ecient and

safe operation.

Home-grown and independent

Wood is a home-grown product, harvested

using a minimum amount of energy and it

contributes to regional economies.

Page 4

Wood storage

Not only is the combustion of moist wood

uneconomical, it can also lead to high

emissions plus tar deposits inside the

chimney stack on account of low combustion

temperatures. Wood oers its highest

calorific value after being dried for several

years under an open cover.

Here are a few tips:

n Split round logs with a diameter of 10 cm

or more

n Stack logs in a ventilated and preferably

sunny spot underneath a canopy

n If possible, stack logs with generous air

gaps to enable flowing air to absorb the

dissipating moisture

n Stack logs on a support timber so moist air

can escape downwards

n Never store freshly cut wood in a cellar,

as air and sunshine are required for drying

However, dry wood can be stored in

ventilated cellars.

Important facts

regarding wood and

pellets

What you should know

Köb wood heating systems are oered for diverse forms of wood fuel.

See below for information about their storage and purchase.

Pellet properties

100 % natural waste wood is used to produce

pellets compliant with DIN-Plus or ÖNorm.

This raw material is waste matter created

by the wood processing industry in large

volumes through planing or sawing.

Fine grained waste wood is compressed

under high pressure and formed into pellets,

i.e. pressed into a cylindrical shape. The fuel

is stored and transported in perfectly dry

conditions. Absolutely dry storage conditions

must also be ensured by the system user.

Perfect and eective combustion can only

be ensured under these conditions.

Pellets are oered in packs or loose in bulk.

In their loose form, pellets are transported by

silo tanker and pumped into the storage room

via a hose system.

If an oil heating system is to be completely

replaced by a new pellet heating system, the

room in the cellar that was previously used to

store fuel oil is ideally suited for this purpose.

Page 5

4/5

Questions regarding wood boilers

Köb Holzheizsysteme is aware of its responsibility for the sustained protection of the

environment. Its company philosophy and products focus on this.

Can anyone heat with a wood boiler?

The advanced wood boilers from Köb are

so convenient to use that they can supply

practically any detached house and apartment

building with heat. One important requirement

is a dry storage room, as the residual moisture

in the wood is one of the crucial factors

influencing combustion quality. Conversions,

for example, of the chimney stack, are

generally not required. Wood heating systems

from Köb are also a perfect companion for

oil and gas heating systems. You can then

determine for yourself when to use which

fuel.

What is better – heating with logs or

pellets?

Logs are an ideal choice for those who can

acquire the fuel themselves, e.g. from local

forestry operations. The wood needs to be

dried correctly, in other words stored until

it has the lowest possible residual moisture

content. In addition, a heating water buer

cylinder is required to ensure a continuous

heat supply.

Pellets are created under pressure from

sawdust and oer a high calorific value

because of their low residual moisture

content. Pellets are also easy to deliver and

store. Dispensing and supply to the wood

heating system is automatic and convenient.

Where can I obtain wood fuel?

Wood fuel, primarily pellets, are today

a standard fuel for most fuel merchants.

As with fuel oil, they are "pumped" into the

storage room. This is accomplished quickly

and without major eort. Many sawmills

and wood processing enterprises also oer

pellets. You can obtain logs at favourable

prices from forestry operators or farmers with

forestry enterprises attached.

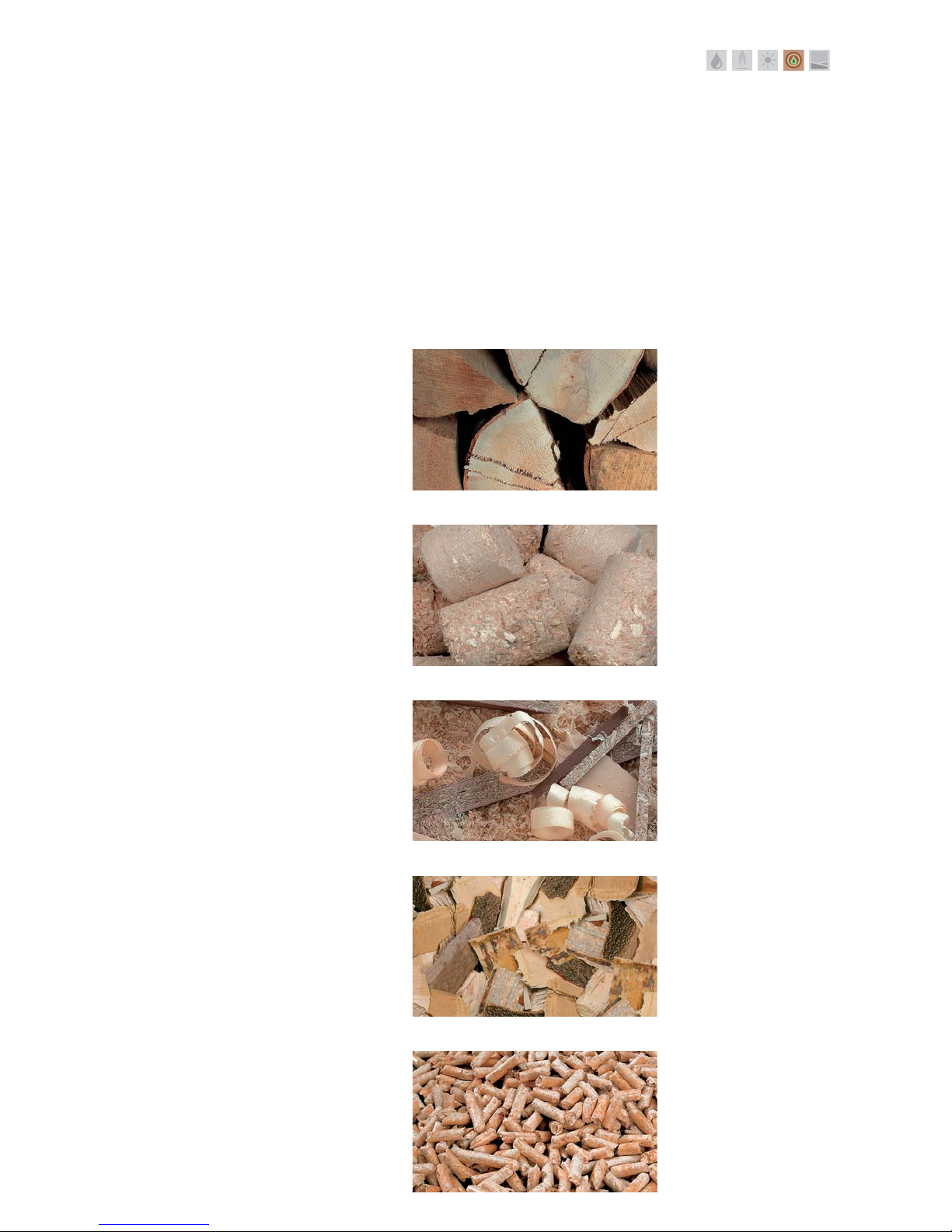

Wood bri quet tes

Wood briquettes are made from

waste wood, compressed to reduce

the proportion of fine particles.

The size and density of the wood

briquettes should be matched to

the form of charging employed.

Logs

Logs are pieces of wood (hard and

soft wood) from forestr y operations

and landscape gardening.

Waste woo d

Waste wood is the most diverse

in both consistency and size of

individual pieces; it is comprised

of both hard and soft wood.

Woodchips

Woodchips are pieces of chipped

natural wo od, with and without

bark.

Pellets

Pellets are the most compact form

of wood energy and oer a high

calorific value. Ensure that the

pellets conform to stand ard branded

quality (e.g. DIN -Plus or ÖNORM).

Page 6

Page 7

6/7

Wood heating systems from 35 to 170 kW

PYROMAT ECO

PYROMAT DYN

Wood boilers for logs, wood briquettes, waste wood, woodchips and pellets.

Pyromat ECO

Log boiler for manual

charging with logs, wood

briquettes and waste wood,

either loose or in pieces.

Hopper width: 550 mm

40 to 95 kW

Page 8

Pyromat DYN

Wood boiler for manual

charging with logs and

pieces of waste wood, or

automatic charging with

pellets, woodchips, wood

briquettes or loose waste

wood.

35 to 100 kW

Page 10

The Pyromat ECO oers the greatest

operating convenience when heating

with logs thanks to its large charging chute.

Eciency of up to 92 % and regulated

utilisation of residual heat enable low fuel

consumption. Ten models oer the right

solution for any application: The rated output

of the Pyromat ECO covers from 40 to

170 kW. From a rated output of 85 kW and

higher, this log boiler is also available as a

boiler for 1 m long logs.

The Pyromat DYN can convert many forms

of wood fuel into heating energy. It is suitable

for manual charging with logs and pieces of

waste wood, or for automatic charging with

pellets, woodchips, wood briquettes and

loose waste wood.

Pyromat ECO

Log boiler for manual

charging with logs, wood

briquettes and waste wood,

either loose or in pieces.

Hopper width: 1080 mm

85 to 170 kW

Page 8

Page 8

1

3

2

4

6

5

9

10

7

8

11

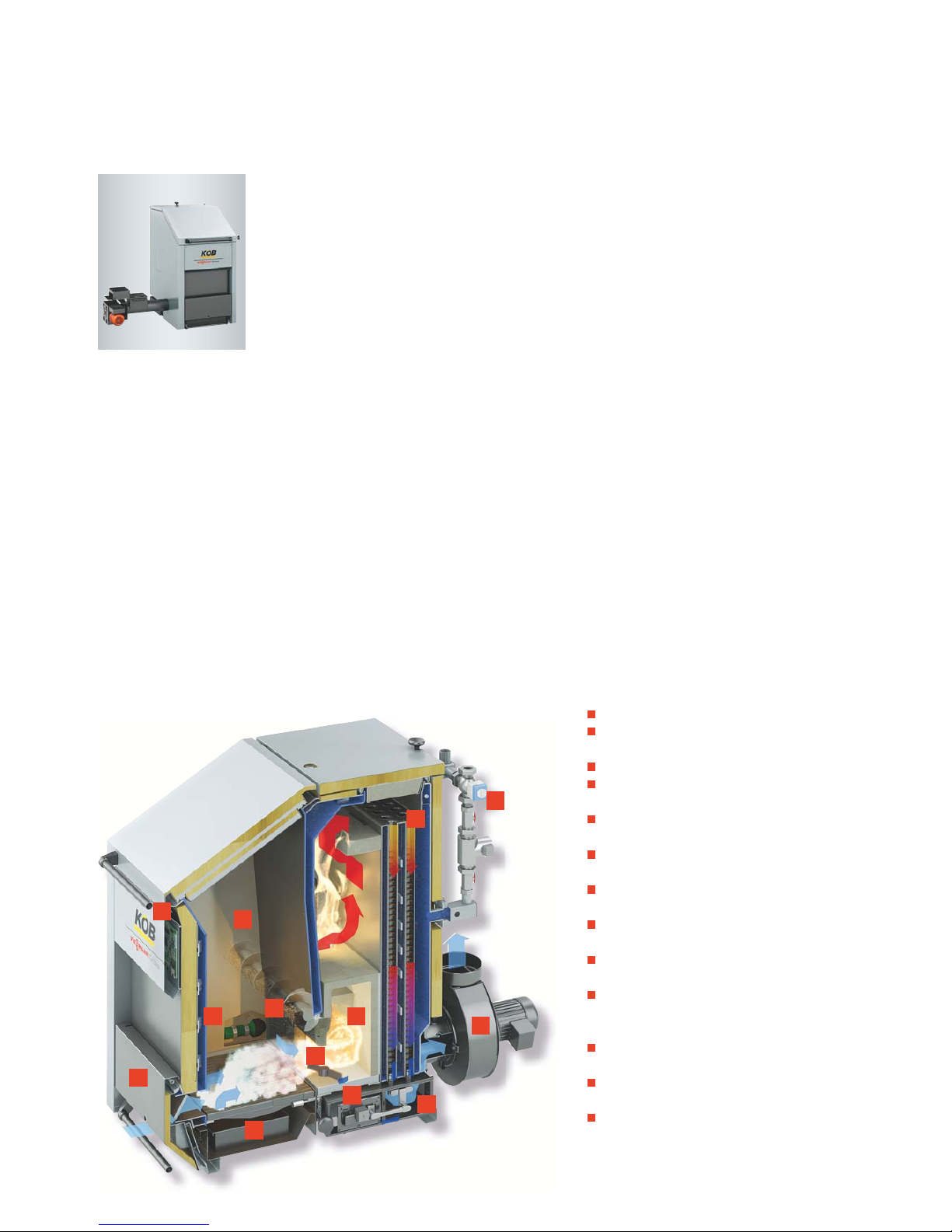

Log boiler Pyromat ECO

The Pyromat ECO log boiler has already been

proven in thousands of applications. Charging

from the top oers easy handling; control via

the Lambda probe guarantees low emissions,

and the integral heat management system

ensures maximum convenience.

Clean and ecient combustion

The microprocessor-controlled Ecotronic

captures all details relevant for the operation

and regulates the amount of heat and its

demand. As a result, the boiler system is

monitored constantly in all operating phases,

from heat-up, operation under load, and

from recharging right up to burnout, and it is

held – via its motorised air dampers – within

its optimum operating range. This safeguards

clean and ecient combustion.

The Pyromat ECO was developed specifically for the combustion of logs and represents

state of the ar t combustion technology.

PYROMAT ECO

Large hopper for combustion lasting

several days

The Pyromat ECO oers the greatest

operating convenience when heating with

logs thanks to its large charging chute. Log

boilers in the output range 40 to 95 kW can

operate with logs of 0.5 m length; in the

range 85 to 170 kW the hopper width

increases to 1080 mm, ensuring convenient

charging, even with logs of 1 m length.

With oil burner connection

The Pyromat ECO is approved as an oil boiler

compliant with EN standard; the necessary

connections have already been prepared.

Fitting an oil burner may, for example, help

to bridge holiday times when manual charging

with logs is not feasible.

The Pyromat ECO is particularly suitable for

the combustion of logs, wood briquettes and

waste wood, either loose or in pieces.

Pyromat ECO

1

Easily accessible charge door for charging

the wood boiler from above

2

Ecotronic control unit

3

Hopper tapering downwards

4

Degasification zone with cast grate and

fireclay bed

5

Large, easily accessible ash box for the

grate ash

6

Combustion chamber made from high

temperature-resistant refractory concrete

7

Ash container below the heat exchanger

8

Induced draught fan with Lambda probe

and temperature sensor

9

Vertical tubular heat exchanger

10

Upper cleaning cover

11

Boiler assembly as part of the standard

delivery (return temperature raising) with

boiler circuit pump, boiler control valve,

flow and return temperature sensor

Pyromat ECO log boiler

Page 9

8/9

Take advantage of these benefits:

n Log boiler for logs of 0.5 and 1 m length with high operating convenience

through charging from the top

n For the following fuels: logs, wood briquettes and waste wood, either loose or

in pieces

n Large hopper capacity (185 to 500 litres) for combustion lasting several days

n Fully wired

n Proven induced draught fan for quiet operation and a long service life

n No draught controller or limiter required

n Constantly regulating air damper with heat-up and burnout optimisation

n Accurate temperature stratification of a DHW cylinder by means of a cylinder

heating control valve – no possible irritation of the cylinder stratification through

the return (option)

n Boiler assembly (return temperature raising facility) fully fitted

n Not sensitive to foreign bodies (nails, screws, etc.)

n Integral buer heating management

n Lambda probe control

Specification

n Rated output range: 40 to 170 kW

Log boiler (0.5 m logs) (hopper width: 550 mm), 6 types from 40 to 95 kW

Log boiler (1 m logs) (hopper width: 1080 mm), 4 types from 85 to 170 kW

n Eciency up to 92 %

n Permissible flow temperature up to 100 °C

n Permissible operating pressure 3 bar

n CE designation according to current Directive

For specification see page 18

Pyromat ECO log boiler – manual

charging from the top

Page 10

1

4

3

7

10

8

6

2

5

12

9

11

13

Wood boiler Pyromat DYN

The Pyromat DYN is suitable for manual charging with logs and pieces of waste wood, or

for automatic charging with pellets, woodchips, wood briquettes or loose waste wood.

PYROMAT DYN

The high eciency of the Pyromat DYN is

the result of a long burnout path, the optimum

heat transfer through self-cleaning boiler

passes and the utilisation of residual heat

in the ash. In standard operation, the ash

is automatically removed from the main

combustion chamber into the front

combustion chamber, where it remains

until all incandescence has ceased.

Large hopper for combustion lasting

several days

Large hopper above the combustion chamber

for a convenient operation with logs lasting

several days. A simple push of a button is

enough to change over to log combustion

(patented air damper function).

Pyromat DYN

1

Ecotronic control unit

2

Front combustion chamber charged from

the top

3

Automatic ignition fan

4

Charge screw and degasification grate with

primary air

5

Combustion chamber door with primary air

damper

6

Large ash chamber with utilisation of

residual heat

7

Combustion chamber made from heat-

resistant refractory concrete

8

Automatic ash removal from the

combustion chamber

9

Drive for automatic ash removal and

cleaning

10

Secondary combustion chamber

(secondary air via combustion chamber

door)

11

Variable speed flue gas fan with Lambda

probe and temperature sensor

12

Tubular heat exchanger with automatic

cleaning

13

Boiler assembly as part of the standard

delivery (return temperature raising facility)

with boiler circuit pump, boiler control

valve, flow and return temperature sensor

Pyrom at DYN

35 to 100 kW

The Pyromat DYN can convert many forms of

wood fuel into heating energy. An ignition fan

system automatically ignites the charge when

the wood boiler is equipped with automatic

charging. Combined with a DHW cylinder,

this permits a perfect low load control (DHW

mode in summer).

Self cleaning heat exchanger surfaces

The vertical heat exchanger surfaces are

permanently cleaned through motorised coil

springs. The drive mechanism sits below

inside the protected cool gas flow. The

springs can be removed easily for the annual

cleaning by the flue gas inspector/chimney

sweep.

Page 11

10/11

Take advantage of these benefits

n Wood boiler, suitable for manual charging with logs and pieces of waste wood,

or automatic charging with pellets, woodchips, wood briquettes or loose waste

wood

n Boiler assembly (return temperature raising facility) fully fitted

n Fully wired

n Proven flue gas fan for quiet operation and a long service life

n Constantly regulating air dampers with heat-up and burnout optimisation

n Accurate temperature stratification of a DHW cylinder by means of a cylinder

heating control valve – no possible irritation of the cylinder stratification through

the return (option)

n Automatic ignition through a hot air fan (with automatic charging)

n Automatic heat exchanger cleaning via coil springs

n Automatic ash removal into an ash box with 20 litre capacity (option)

Specification

n Rated output range: 35 to 100 kW

n Eciency up to 92 %

n Permissible flow temperature up to 100 °C

n Permissible operating pressure 3 bar

n CE designation according to current Directive

For specification see page 18

Pyromat DYN with automatic charging

Page 12

System components

The complete system from a single source. That makes perfect sense, since all

Köb system components are perfectly matched to each other and consequently

form a complete heating system.

The operator is therefore assured of an absolutely reliable operation and a quality

service for the entire system from a single source.

System technology

The boiler system incorporating the boiler

assembly (boiler pump, boiler control valve) as

well as the variable speed induced draught fan

are fully wired.

Automatic ash removal (20 litre capacity)

(only with the Pyromat DYN)

The clean combustion leaves only the

minerals stored in the wood behind as ashes.

A grate with moving grate elements extracts

the ashes from the combustion chamber and

guides them into the ash container. As soon

as they have cooled down, the ash removal

conveyor guides the ashes into a large-volume

external ash container.

Solid room discharge for woodchips

(only with the Pyromat DYN)

With dierent discharge radii and screw

lengths, the system is matched perfectly to

the physical site conditions.

Feed screw for pellets

(only with the Pyromat DYN)

The feed screw is an extremely adaptable,

easy to install and quiet pellet charging

solution with low power consumption.

Boiler feed with dispensing hopper

The boiler feed with dispensing hopper can be

fitted either on the left or right side of the log

boiler. This sophisticated system oers the

highest protection against fires.

Fully assembled heat manifold

The fully assembled heat manifold is available

for installation on the boiler or as a wall

mounted version.

Heating water buer cylinder or

DHW cylinder

An extensive range of high quality products

(integrated or supplied separately) including all

accessories are available.

Test mark s

All components are thoroughly tried,

tested and ap proved by dierent

bodies

TÜV-tested to EN 303-5

Test report EMPY approval VKF

VHe type-tested

Automatic ash removal (2 0 litre capacity)

Solid room discharge for woodchips

Feed screw for pellets

Boiler feed with dispensing hopper

Page 13

12/13

The Ecotronic system control unit is a decentralised microprocessor system (CAN BUS)

with dierent modules that are easily connected by means of a data cable.

Comprehensive energy management

Ecotronic as boiler controller

Central heating

Weather-compensated heating circuit control

with digital time switch for individual day and

7-day programs

n On request with room device

n ECO control and frost protection function

n Easy setting of individual heating curve

DHW cylinder

n DHW cylinder is automatically reheated

by the boiler or the heating water buer

cylinder

n Volume control with minimum return

temperature for precise cylinder

stratification

n The heating water buer cylinder supplies

DHW for up to 14 days (summer mode)

Air heater

n Air volume control with minimum return

temperature for precise cylinder

stratification

Solar control unit

n Solar energy is stored in the DHW cylinder

or in the heating water buer cylinder

n The Ecotronic enables the maximum heat

transfer from the solar collectors to the

heating system

n May be extended up to 12 groups with the

distribution module on the heat manifold.

Ecotronic as boiler controller

Combustion controller

The combustion controller is integrated into

the log boiler and regulates the motorised air

dampers via the integral Lambda probe. The

appliance is fully wired internally. This results

in perfect combustion, optimised for lowest

emissions.

Charging controller

The CAN BUS control is a new feature. It

enables charging motors to be controlled via

an integral BUS cable directly from the boiler

module to the Starttec controller. The threephase power is routed to the motors, ready to

plug in. In this case too, the connection at the

boiler is simple, making extensive installation

unnecessary. The control is free of wear, even

with high switching frequency. An integral

motor protection (overload and temperature

relays) ensures a reliable operation.

Boiler assembly controller

The return temperature raising facility ensures

a long service life for the log boiler. Best

possible protection against overheating is

ensured by heat transfer to the DHW cylinder,

shutting down the induced draught fan and

closing the air dampers. The boiler assembly

(pump and control valve) is fully wired and

fitted to the log boiler.

Ecotronic control unit

Page 14

Group

1

2 2

3

4

5

6

7

8

9

10

11

11

11

12

13

14

Hydraulics

Pyromat ECO

The right heat concept ensures the reliable and safe operation of a log boiler.

Hydraulic connection of a Pyromat ECO

Heating water buer cylinder

n Perfect wood combustion requires an

adequately sized heating water buer

cylinder (specified by EN 303-5 since

2000). A precise layering of heat is a

must for the optimum utilisation of the

available heat.

n The Ecotronic control unit with the reliable

cylinder control valve ensures this function

in an excellent fashion.

n The utilisation of solar energy can therefore

be combined perfectly with log combustion.

Heat management (ECO function)

n During the combustion phase, boiler heat

not required for heating purposes is routed

into the heating water buer cylinder with

precision layering.

n After burnout, the residual boiler heat is

fully utilised. The utilisation of residual heat

as practiced by Köb received an award

as part of the Swiss ENERGIE 2000

campaign. In trials, an increased yield of

9 % per burnout was achieved.

n Only then is heat supplied by the heating

water buer cylinder. The clever control

modules for heating convenience discharge

the heating water buer cylinder with

precision according to the stratified

temperature layers.

n This delivers heat from the heating water

buer cylinder over the longest possible

time.

Hydraulic scheme for a log boiler

providing cylinder heating

Key to sym bols

1

Pyromat ECO log boiler

2

Heating water buer cylinder

3

DHW cylinder

4

Expansion vessel

5

Central heating

6

Boiler assembly

7

Heating assembly

8

Cylinder assembly

9

Buer cylinder control valve

10

Flow temperature sensor

11

Heating water buer cylinder sensor

12

DHW cylinder sensor

13

Cylinder return temperature sensor

14

Ecotronic control unit

Page 15

14/15

Storage and

supply systems

Pyromat DYN

The adjustable feed screw is easy to install and can be tailored to the specific physical

site conditions.

Patented pellet discharge.

Storage and supply systems for the Pyromat DYN

Boiler feed with dispensing hopper with

fire protection

The solidly constructed feed screw made

from heat resistant chrome-nickel steel

charges the fuel – irrespective of whether

pellets or woodchips – into the combustion

chamber in accurately dispensed volumes.

A dispensing hopper with light guard that

determines the level of the separating fuel

layer, is located above the screw. This fuel

barrier prevents an exchange of gases and

consequently a back burning of the fuel.

A second back burning protection takes

the form of the tested shut-o slider. This

spring-loaded slider opens during the heating

phase and closes automatically afterwards or

in case of a power failure.

For woodchips

Solid room discharge

A bottom agitator with two leaf spring arms

fills a screw channel let into the floor. Agitator

and feed screw are designed for robust

operation and high torque. This safeguards

a trouble-free and reliable fuel discharge

of the most diverse woodchips. The stable

torque support protects the gearbox against

overloads and ensures a consistently smooth

and quiet operation.

For pellets

Very quiet feed screw with low power

consumption

The feed screw is made from hardened steel

(chrome-nickel steel) and is characterised by

its high torsional strength, spring loading and

the lowest friction losses. Outside the store

room, the feed pipe is made from natural

chrome-nickel steel.

Fuel silo for pellets with quiet

plastic feed screw with low power

consumption

Fuel silo for woodchips with solid

room discharge

Page 16

Specification

Rated output kW 40 50 60 75 80 95

Hopper

Width

Capacity

mm

litres

550

185

550

185

550

255

550

255

550

255

550

255

Dimensions

Length

Width

Height

mm

mm

mm

958

795

1433

958

795

1433

116 3

795

1490

116 3

795

1490

1313

795

1490

1313

795

1490

Weight kg 750 760 920 935 1040 1065

Flue outlet ø mm 200 200 200 200 200 200

Pyromat ECO

Log boiler for logs up to 0.5 m long

Rated output kW 85 100 120 170

Hopper

Width

Capacity

mm

litres

1080

375

1080

375

1080

500

1080

500

Dimensions

Length

Width

Height

mm

mm

mm

1018

1324

1433

1018

1324

1433

1353

1324

1490

1353

1324

1490

Weight kg 1300 1320 1680 1720

Flue outlet ø mm 200 200 250 250

Pyromat ECO

Log boiler for logs up to 1 m long

Page 17

16/17

Rated output

Operation with logs kW 49 75 100

Rated output

Operation with woodchips kW 35 52 70

Hopper

Width

Capacity

mm

litres

550

185

550

255

550

255

Dimensions

Length

Width

Height

mm

mm

mm

958

795

1430

116 3

795

1490

1313

795

1490

Weight kg 760 935 1065

Flue outlet ø mm 200 200 200

Pyromat DYN

Log boiler

Page 18

Vitosol fl at-plate and tube collectors

Wood heating systems

Wood boilers are ideal for integrating with

one or more sources of energy, such as

fossil fuels or solar thermal energy. Our

comprehensive product range oers

heating systems for all forms of energy that

are considerably more than just individual

heating components. Whether it is an oil/

gas boiler or a solar thermal system, all parts

fit together perfectly and form a reliable and

economical system.

High performance solar thermal systems

Our high performance solar thermal systems

with flat-plate or vacuum tube collectors

are ideal for the DHW heating and as central

heating backup for your biomass system.

By incorporating solar energy, you can reduce

the costs for generating domestic hot water

by up to 65 % (depending on the size of

the solar thermal system) and you can also

increase your contribution to the environment.

Perfectly matched to suit your system

With Viessmann system technology, you can easily expand your wood heating systems

and enjoy all the benefits in an integrated system working with renewables.

Viessmann system technology

Page 19

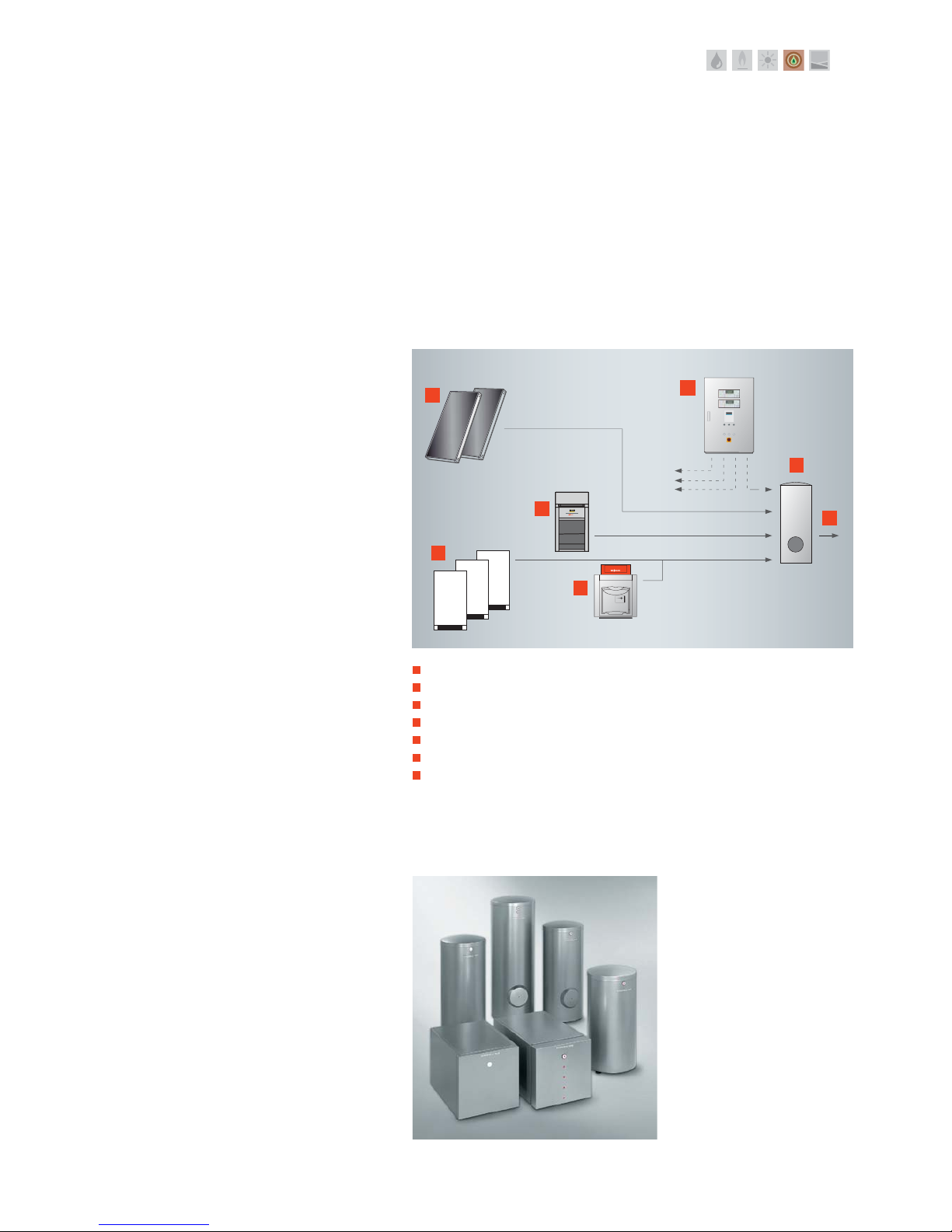

18/19

2

6

3

4

5

1

7

Vitocell DHW cylinders

High performance DHW cylinders

The Vitocell DHW cylinders for indirect

heating enable a quick, plentiful and reliable

supply of DHW at all times. For applications

requiring large amounts of DHW, the

vertical and horizontal DHW cylinders can

be combined to create cylinder banks. By

integrating the DHW supply into your wood

heating system, you can save up to 50 % of

the running costs compared to directly heated

DHW.

Proven boilers

In an integrated system working with

renewables, wood heating is often connected

to a conventional oil/gas boiler that covers

peak loads or backs up the biomass boiler.

Depending on the type and temperature

demand of your system, Viessmann oers

highly ecient condensing boilers as well as

low temperature boilers.

1

Viessmann bespoke control panel

2

Solar thermal system

3

Wood boiler

4

Condensing boilers

5

Low temperature boiler

6

DHW cylinder

7

System distribution

Page 20

References

Köb wood heating systems

Köb has been installing commercial

wood heating systems for more than

30 years. During that time it has achieved

significant recognition for its innovative

and environmentally responsible products.

Köb is part of the Viessmann Group, which

supplies innovative high performance heating

systems and systems for renewables.

Wood heating systems in operation

More than 1500 installations around the world operate with wood heating systems from Köb.

Alpine guest house Hörmoos –

a Pyromat DYN 65 heats the guest

house and the holiday guest rooms

Pyromat DYN with spring core

discharge

Storage room

Page 21

20/21

Pyromat ECO log boiler for manual

charging with a hopper width of

1080 mm

Pyromat ECO log boiler with

adjacent Vitoplex 300 low

temperature oil boiler

Pyromat ECO log boiler heats a

two-family home in Niederbipp

(Switzerland)

Page 22

The comprehensive range of products and services

from Viessmann

Individual solutions with ecient systems

The comprehensive range of products and

services from Viessmann

The comprehensive range of products and

services from Viessmann oers individual

solutions with ecient systems for all

applications and all energy sources. As

environmental pioneers, the company has,

for decades, been supplying particularly

ecient and clean heating systems for oil

and gas, as well as solar thermal systems

along with heat generators for sustainable

fuels and heat pumps.

The comprehensive range of products

and services from Viessmann oers top

technology and sets new benchmarks.

With its high energy eciency, this range

helps to save heating costs and is always the

right choice where ecology is concerned.

Individual and ecient

Viessmann oers the right heating system for

any demand – wall mounted or floorstanding,

in individual combinations – all are futureproof

and economical. And whether for detached

houses or two-family homes, large residential

buildings, commercial/industrial use or for

local heating networks; for modernising

existing properties or new build – they are

always the right choice.

Detached houses

Apartment buildings

Commerce / Industry

Local h eating

networks

Solar th ermal and

photovoltaics

Oil low tem perature a nd

condensing technology

13 – 20,0 00 kW

Gas low t emperatur e and

condensing technology

4 – 20,0 00 kW

Page 23

22/23

The comprehensive range of produc ts and services from

Viessmann: Individual solutions with ecient systems for all

energy sources and applications

Viessmann is extremely highly specialised in

all these market segments, yet at the same

time the company has a crucial advantage over

specialist suppliers: Viessmann understands

heating technology as a systematic whole and

oers unbiased advice on technology and fuel

type. This guarantees the best solution for

every application.

Key performers

The Viessmann Group sets the technological

pace for the heating industry. This is what the

Viessmann name represents, and also what

the names of the subsidiaries in the Group

represent, as they are founded on the same

pioneering spirit and power of innovation.

The company oers the following:

n Condensing technology for oil and gas

n Solar thermal systems

n Heat pumps

n Wood combustion systems

n CHP modules

n Biogas plants

n Services

Air conditioning technology System components

Heat pu mps for

brine, w ater and air

1.5 – 200 0 kW

Wood combustion technology,

CHP and biogas production

4 – 13,00 0 kW

Page 24

The comprehensive range of products and services

from Viessmann

The co mprehensiv e range of pro ducts and ser vices fro m Viessmann :

Indivi dual solution s with ecien t systems fo r all energy sou rces and applic ations

Detac hed houses Apar tment buildin gs Comme rce / Industr y Local h eating net works

HafenCity Hamburg,

Germany

City o f Tomorr ow, Malmö,

Sweden

The Pal m Jumeirah,

Dubai

Heliotr op Freiburg ,

Germany

Solar th ermal and

photovoltaics

Residential development Zi Wei

Garden Xi‘an, China

Ameco A380 Hangar Beijing,

China

European Parliament, Strasbourg,

France

Archi tect‘s own h ome, Bad Füssi ng,

Germany

Oil low tem perature a nd

condensing technology

13 – 20,0 00 kW

„Wohnoase“ residential park in

Regensburg, Germany

Porsche Leipzig,

Germany

European Parliament, Brussels,

Belgium

Detached house, Kevelaer,

Germany

Gas low t emperatur e and

condensing technology

4 – 20,0 00 kW

Hotel L agorai Cav alese,

Italy

Congressional Centre, Brunstad,

Norway

Monas tery St. O ttilien,

Germany

Detached house, Wie sloch,

Germany

Wood combustion

techn ology,

CHP and b iogas

production

4 – 13,00 0 kW

Studio flats, Brandenburg,

Germany

University library, Bamberg,

Germany

Residential estate, Pfäkon,

Switzerland

Lof tcube Region al Garden Sho w,

Neu-U lm, Germany

Heat pu mps for

brine, w ater and air

1.5 – 2,00 0 kW

Page 25

24/25

City of Tomorrow, Malmö, Sweden

Futureproof heating technology for

all requirements

Energy consumption worldwide has doubled

since 1970 and will triple by 2030. The

result: The fossil fuels, oil and gas, are

dwindling, energy prices are on the rise and

excessive CO

2

emissions continue to aect

our environment. Energy eciency is a must if

we want our future to be secure.

In almost every industrial nation, supplying

heat to residential and commercial buildings

accounts for the largest share of energy

consumption – consequently it also oers the

greatest savings potential. Advanced ecient

heating systems from Viessmann are in use

around the world, not only in many private

households, but also in numerous major

international projects, where they make a

sizeable contribution to the ecient use of

energy resources.

In these projects, Viessmann again and

again faces up to the most varied challenges

to supply ecient heating technology by

oering innovative solutions – in historical

listed buildings as well as in modern industrial

complexes or in the large-scale residential and

industrial arena.

Page 26

The company

Page 27

26/27

Viessmann Werke GmbH & Co. KG

Viessmann – climate of innovation

Viessmann won the German

Sustainability Award 2009 for its

commitment to climate protection

and ecient use of resources.

For the particularly ecient

utilisation of energy through the

innovative heat recovery centre

at the company‘s main site in

Allendorf/Eder, Viessmann was

rewarded with the Energy Eciency

Award 2010.

The Viessmann brand promise concisely

expresses all that we hope to achieve. It is

our key brand message and, together with

our brand label, is an identifying feature

throughout the world. “Climate of innovation“

is a promise on three levels: It is a commitment

to a culture of innovation. It is a promise of

high product utilisation and, at the same time,

an obligation to protect the environment.

Comprehensive range of products and

services for all fuel types

Viessmann is one of the leading international

manufacturers of heating systems and, with

its comprehensive range of products and

services, oers individual solutions in the

shape of ecient systems for all applications

and types of fuel. As an environmental

pioneer, the company has been supplying

particularly ecient and clean heating

systems.

Acting in a sustainable manner

For Viessmann, to take responsibility, means

a commitment to act in a sustainable way.

This means bringing ecology, economy and

social responsibility into harmony with each

other, ensuring that current needs are

satisfied without limiting the basis for life

for the generations to come.

Eciency Plus

With the sustainability project “Eciency

Plus“ Viessmann shows at its Allendorf site,

that the political goals set for 2020 with

regard to climate and energy can already be

achieved today with commercially available

technology.

This project demonstrates:

n Environmental protection

n Eciency with resources

n Securing manufacturing sites for the future

As a result, fossil fuels have been cut by

40 percent and CO

2

emissions reduced by

a third.

Performance spectrum

n Condensing technology for oil and gas

n Solar thermal systems

n Heat pumps

n Wood combustion systems

n CHP modules

n Biogas plants

n Services

Company details

n Established in: 1917

n Employees: 9000

n Group turnover: €1.7 billion

n Export share: 50 percent

n 16 factories in Germany, France, Canada,

Poland, Hungary, Austria, Switzerland

and China

n Sales organisation in 37 countries

n 120 sales oces worldwide

n 3 service providers

Page 28

Köb Holzheizsysteme GmbH

Flotzbachstraße 33

A-6922 Wolfurt

Telephone +43 5574 6770-0

Fax +43 5574 65707

www.kob.cc

The Viessmann Group

D-35107 Allendorf (Eder)

Telephone +49 6452 70-0

Fax +49 6452 70 -2780

www.viessmann.com

Your heating contractor:

9443 309 - 1 GB 02/2011

Copyright Viessmann.

Duplication and alter native use onl y with prior written consent.

Subject to technical modifications.

Loading...

Loading...