KoçDigital IoT Solution Portfolio

Platform360 Industrial IoT Solutions

using Azure Services

1

Platform360 Industrial IoT Solutions

USING MICROSOFT AZURE

TABLE OF CONTENTS

1 INDUSTRIAL IOT CHALLENGES

2 KOÇDIGITAL INDUSTRIAL IOT SOLUTIONS

3 INDUSTRIAL USE CASES

4 APPENDIX

2

Source: KoçDigital

Digital Transforms Manufacturing Projects

Manufacturing field workforce CIO, CDO, CTODecision

Makers

Variety of vendors for piecemeal

traceability

End-to-end manufacturing transparency

Governance

Automation Firms IoT firms, Digital Transformation firms

Suppliers

Monitor basic KPIs with manual input Connected Digital twin of manufacturing

Technology

Operational Needs Business Value

Incentive

3

WHY DO WE NEED INDUSTRIAL IOT?

Increase

Efficiency

Improve

Quality

Increase

Safety

4

OT

Security

Applications

and analytics

Communication

IoT Solution

IoT backbone/

platform

Connected Things

Services

KoçDigital is

IoT System Integrator

which provides

end-to-end solutions

Iot Solution Stack

Solution Ecosystem

Managed Services

5

Engaging in IIoT based digital manufacturing solutions create

substantial impact

Increase in

equipment uptime

10-20%

Industrial IoT creates business values, increases productivity, and customers gets/stays competitive

Throughput increase with

horizontal product line

optimization

5-10%

Reduction of unplanned

downtime

50-70%

Increase in engagement of

maintenance teams

35-50%

Source: KoçDigital Customer Insight

Reduction of spare

parts usage

15-20%

Decreased Energy

Usage

5-10%

Eliminate process related

production downtimes

100%

Eliminate paper

based processes

100%

6

Platform360 Industrial IoT Solutions

USING MICROSOFT AZURE

TABLE OF CONTENTS

1 INDUSTRIAL IOT CHALLENGES

2 KOÇDIGITAL INDUSTRIAL IOT SOLUTIONS

3 INDUSTRIAL USE CASES

4 APPENDIX

7

KoçDigital’s solution set to digitize existing/new factories

Offerings of KoçDigital

in Industrial IoT

Assembly Management

System

Remote Asset

Management

Quality Monitoring

RTLS (Manufacturing Traceability)

Energy Management

Manufacturing Information

System (MIS)

Predictive Maintenance

Manufacturing Analytics

Manufacturing Execution

System

Industry 4.0 Health Check

Source: KoçDigital

Manufacturing Execution Platform

9

Industrial IoT Platform

(IIoT Platform)

10

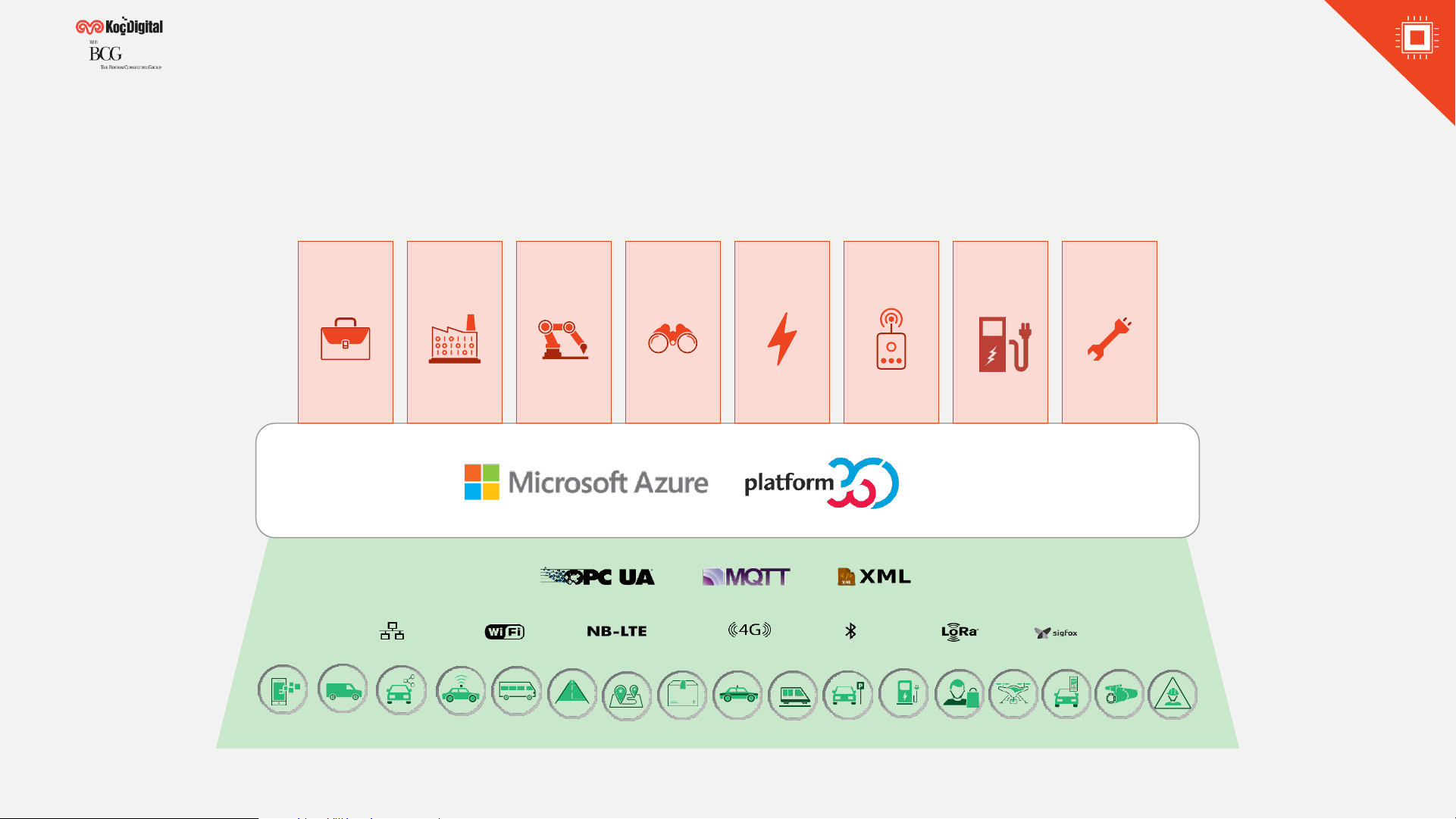

Platform360 is the common service layer, enabling

numerous Industrial IoT Applications & Analytics

Source: KoçDigital

Internet of Things - Platform 360

…

Manufacturing

Information

Systems

Assembly

Management

RTLS –

Manufacturing

Traceability

1

EV Charging

Management

Manufacturing

Execution

System

Industry 4.0

Consulting

Remote Asset

Monitoring

1

Predictive

Maintenance

1

11

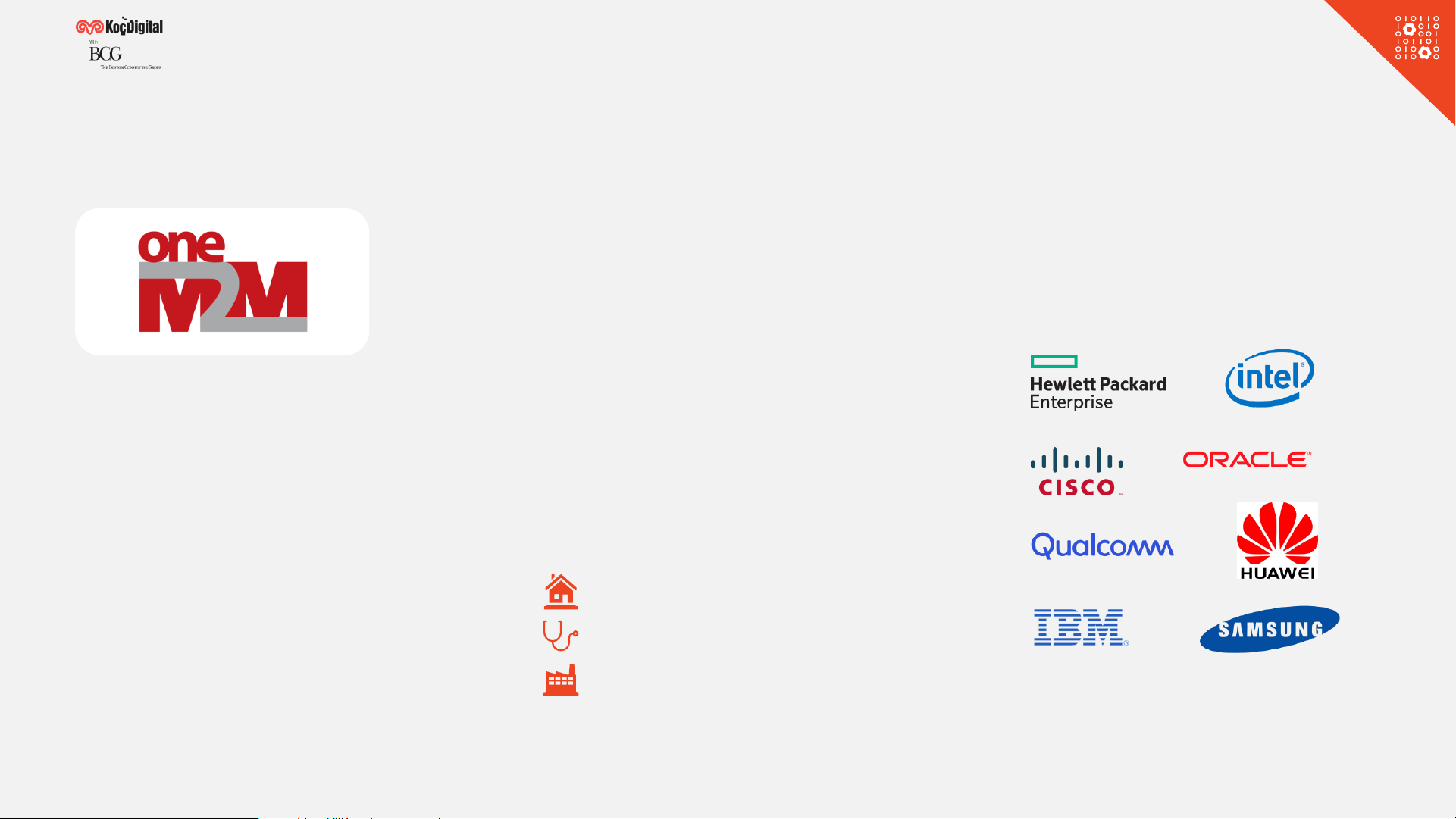

Platform360 is based on OneM2M, the global standards

initiative for Machine-to-Machine and IoT technologies

The purpose of OneM2M is to

specify, promote and maintain a

Common IoT Service Layer

allowing every component to

communicate as one system

It provides a flexible architecture

to accommodate a variety of

device platforms

• Requirements

• Architecture

• API specifications

• Security

• Interoperability

Provides technical support

artifacts …

Over 200 participating partners

and members …

Home automation

eHealth

Industrial automation

Used across industries …

Standardization

12

2

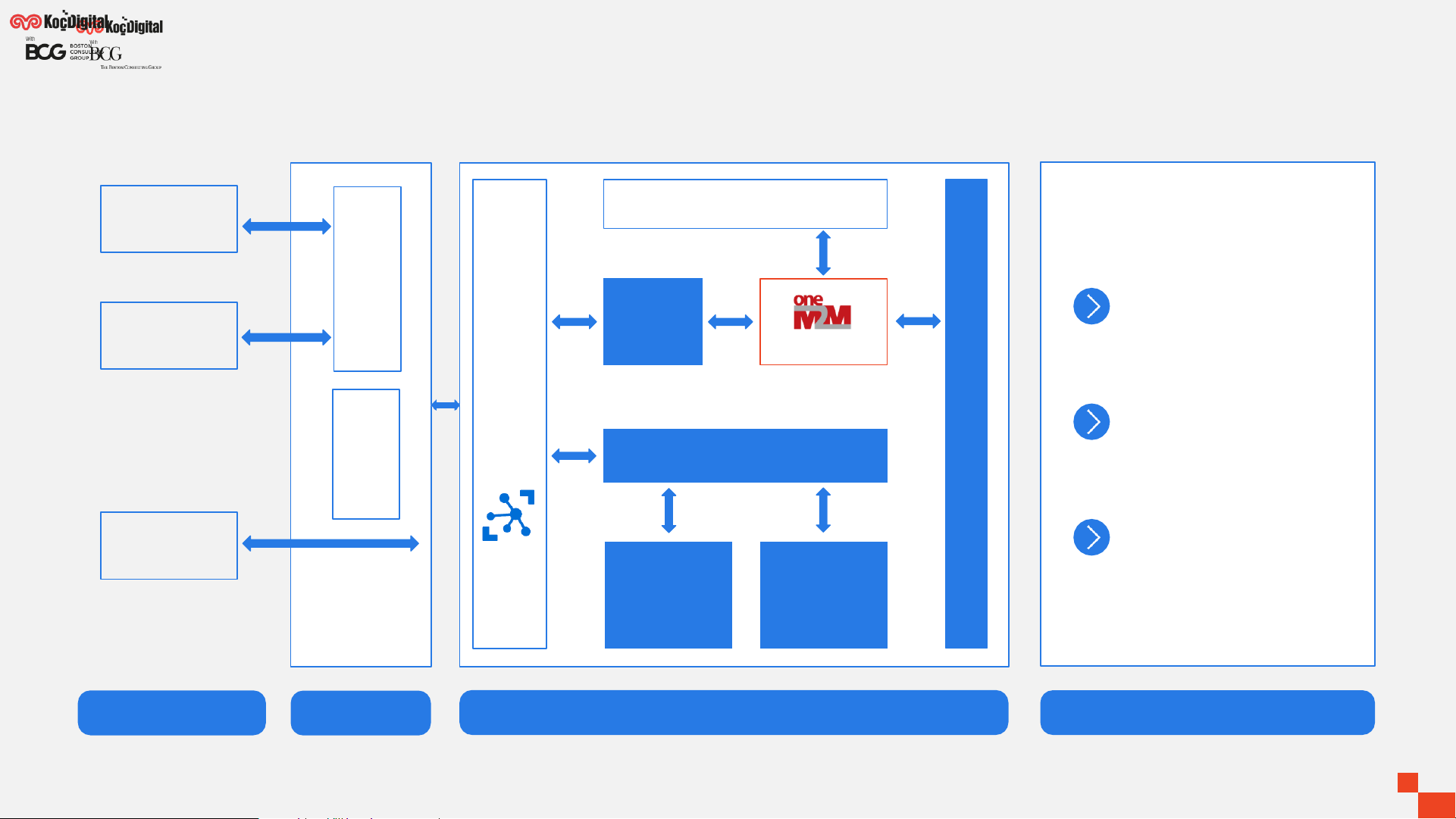

Platform360 on Azure

Data Processing,Analytics Solutions

Azure IoT

Hub

Stream Processor

Big Data

Storage

Analytics &

Machine

Learning

Service

Bus

Modules

Hot Storage

Asset

Management

Low Powered

Devices

Non-OneM2M

Devices

OneM2M

Devices

IoT Gateway

(IPE)

Manufacturing

Execution System

Energy

Monitoring

Connected

Vehicles

Applications

Devices Edge

“OneM2M module” content will be shown on the next page

13

3

OneM2M Modules

Registration Group Management SecurityDiscovery

Data Management&

Repository

Application &Service

Management

DeviceManagement

Subscription &Notification

CommunicationManagement

Service Charging&

Accounting

Location

Network ServiceExposure

Transaction Management Semantics

14

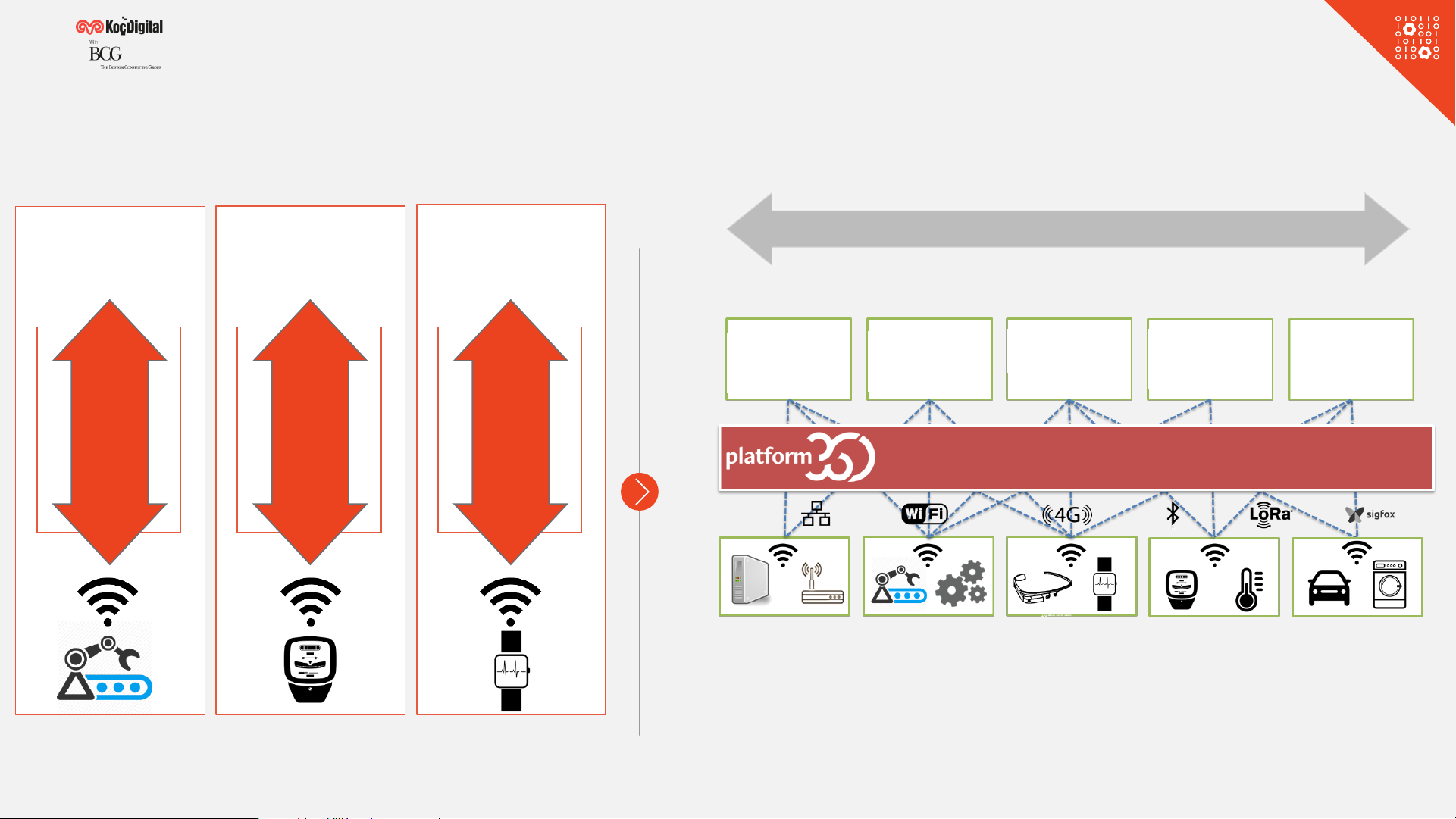

Horizontal IoT Platform

Vertical

Information Flow

Smart

Manufacturing

Platform360 provides horizontal information flow with Azure Services

Smart Energy

Smart Wearable

Horizontal Information Flow

Oth. Vertical

Solutions or 3.

party systems

Manufacturing

Intelligence

Vertical

Information Flow

Vertical

Information Flow

Assembly

Management

Remote Asset

Management

Automated

Meter Reading

Common IoT Service Layer

Competitive

Advantages

15

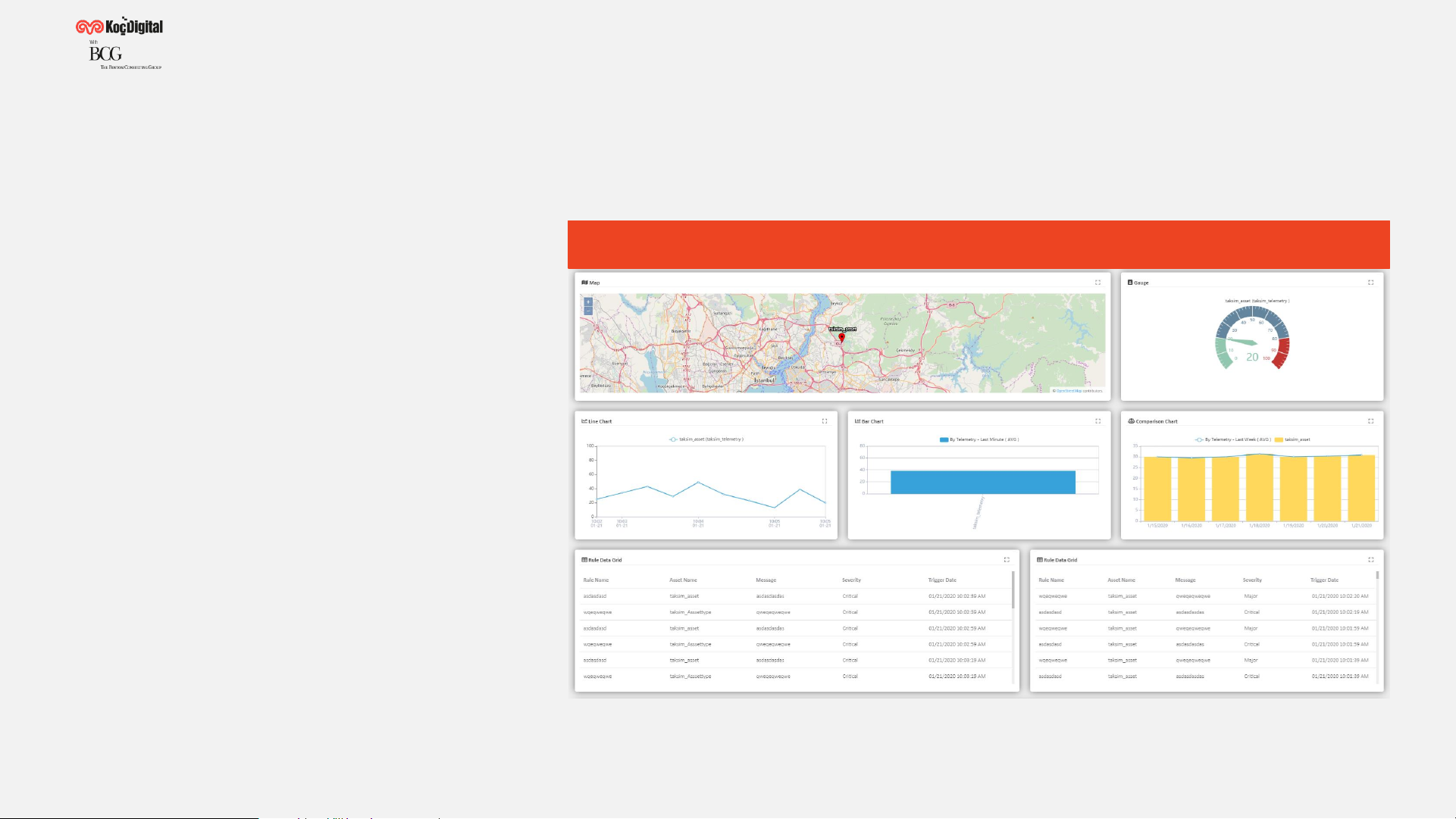

Self Service Dashboard

Self Service :

Widgets allow designing user-

defined dashboard views

Stream Data:

Investigate real-time data

streams/events in real-time

Query Data:

Investigate existing data using

data queries

Map Layer:

Visualize location services and

monitor device positions

User Defined Dashboard Views

Visualization of IoT Daa

16

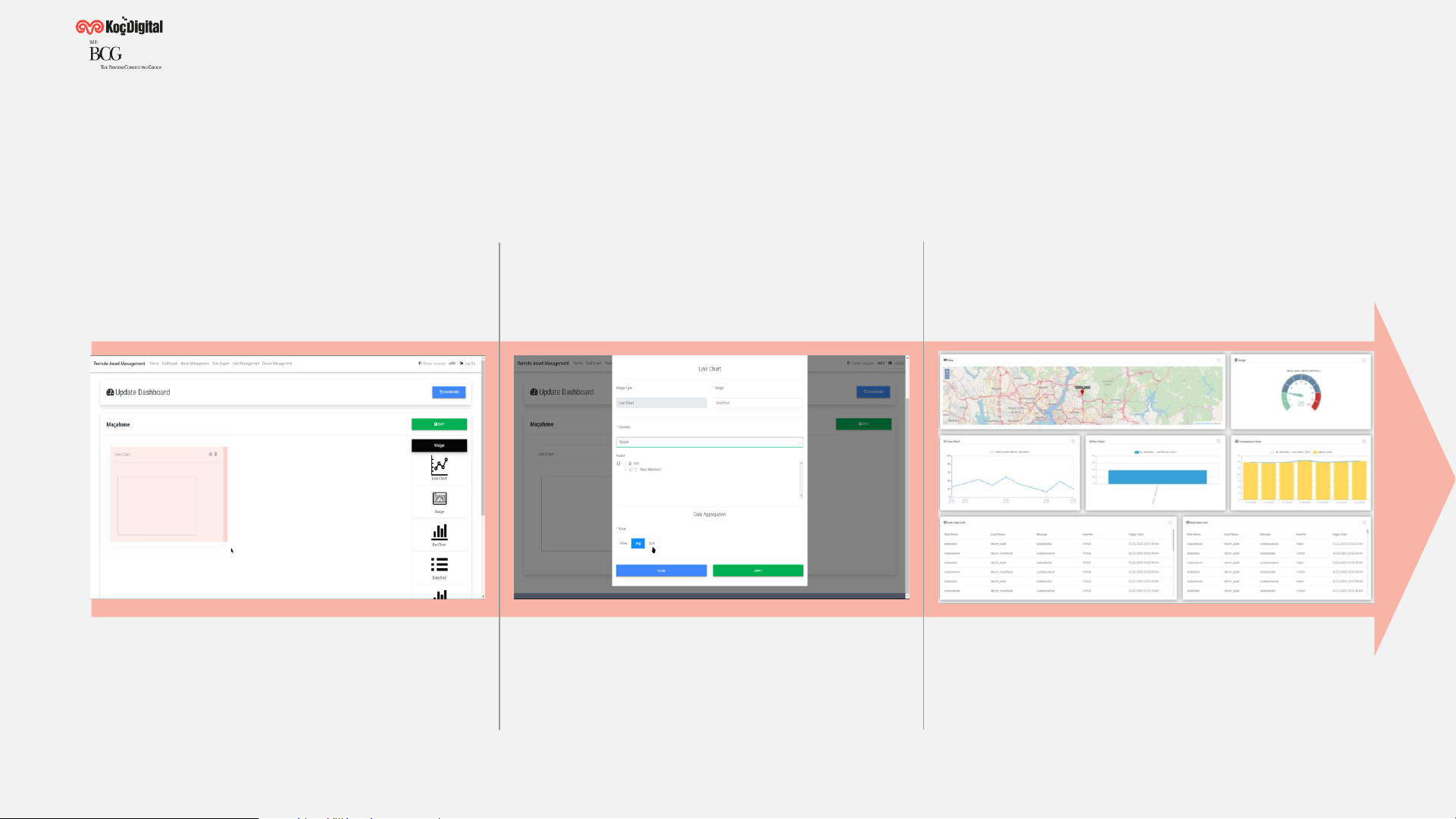

3-Step Approach for Self-Service IoT Dashboards

Define Dashboard and Widgets

Connect to Assets and Data

Deploy Dashboards

17

Platform360 Industrial IoT Solutions

USING MICROSOFT AZURE

TABLE OF CONTENTS

1 INDUSTRIAL IOT CHALLENGES

2 KOÇDIGITAL INDUSTRIAL IOT SOLUTIONS

3 INDUSTRIAL USE CASES

4 APPENDIX

18

Manufacturing Information

System (MIS)

192021

Asset Performance & Job Per Hour

Manufacturing Asset Layout Management

Rule Based Machine Monitoring

Cycle Analysis

Bottleneck Analysis

Asset Downtime & Alarm Management

Root Cause Analysis

MTBF & MTTR Reporting

Anomaly Detection

Productivity KPIs

Bottleneck Analysis

Maintenance Management

Tangible impact in decision making with

actionable insights

22

Manufacturing Information Systems Objectives

Aggregate & process sensor

generated data into a

unified platform

Unification of machine data to

single semantic layer

Create a digital data platform for

advanced manufacturing analytics

Up to % 10

Throughput increase with horizontal

product line optimization

Up to % 50

Increase in employee engagement with

real-time monitoring and predictive

maintenance

23

Platform deployed across the whole factory

Press shop, welding, paint shop & assembly

Large Automotive Manufacturer Customer Case

2200

Stations

250+

PLCs

450k

sensors

20+ TB

of data

annually

Source: KoçDigital

Increased overall output without additional investment

on capacity.

Maintenance employee engagement increased.

Paper-based data collection has been eliminated on KPI

calculation and plant monitoring.

Automated processes have increased employee

productivity.

Project Impact

At the first year of the project, KPIs reached

KoçDigital Client Example

Customer

Case Example

25

Track & Trace

26

Product Traceability

Correct position of products are traced during manufacturing process

Support for variety of technologies

RFID Tags

Photoelectric Sensors

Barcode Scanner

OPC UA PLC Connectivity

SCADA Integration

Position Data

Photoelectric sensors

Physically Wired

HMI1

Vehicle positions

over LAN

Position data

Carrier

RF-TAG

Reflectors

Vehicle

Barcode

Carrier

RF-TAG

Reflectors

Vehicle

Barcode

PLC (Siemens S7-1200)

LAN

Barcode Scanner

OPC Server App

Position Data

HMI(n)

.NET

OPC UA

Client

.NET

OPC UA

Client

Including .NET

Apps For

Operators

Örnek Body Tracking

teknolojilerini gösteren

örnektir

Encoder

Case Example

27

Track & Trace: Palletizing Process Example

Move

packages

into pallets

Move pallet

to forklift

Move Pallet

to the

storage

Packaging

Barcode

Writer

Sensors

Static

Barcode

Reader

Mobile

Barcode

Reader

HMI

Integrates with MES and prints

relevant barcode code on the

package according to the

production plan

1

Checks validity of printed

barcodes

2

Packages are traced and

packaged into pallets in

synchronization with MES system

3

Packages are stacked in pallets,

and pallets are barcoded

4

Palet information is synced with

ERP system

5

Case Example

28

Assembly Management

29

Manufacturing Assembly Management

30

Assembly Management System (ASM) Objectives

Shop-floor integration with

Manufacturing equipment and

Product traceability

Human machine interfaces

for worker guidance

Trace and enforce how and from

which parts each end-product

manufactured

Increased Manufacturing quality

Through monitoring and

enforcing quality guidelines

Zero

Defect

Targeted assembly

process

Objectives

Decrease worker costs for

Adapting to Manufacturing

different product variants

31

Shop Floor Connectivity

Collect Manufacturing Data from Assembly Equipment and Human Machine Intefaces

Different Screen Sizes

Industrial Grade HMIs customized according to

requirements

• Supports asynchronous operations

• Different installation methods according to

shop floor layout

• Edge industrial data collection

• Visual and Audio Alarms

Human Machine Interfaces

Tablets

Commercial or Industrial Tablets

• Shows status of manufacturing quality operations

• Allows digitized entry of defects to system by

quality personnel

Assembly Equipment

32

• Guides worker through assembly

process

• Monitors the procedure and parts of the

assembly

• Can be integrated with assembly and

quality tools such as electric wrench (

Open Protocol support)

• Support with a-sync operation, network

latencies doesn’t effect manufacturing

process

• Can be integrated to customer Product

Lifecycle Management Solution

Worker Guidance for Assembly Operations

Employees are driven to quality with visual guidance

33

Remote Asset Management

(RAM)

34

Energy Status: Ok

Enviromental Factors: Ok

Security: Ok

Remote Asset Monitoring

Status: Healthy

System Room

Cellular

Tower

ATM

Enviroment Infrastructure …

Observe: Status, Operation, Enviromental Factors

Manage: Data and workflows

Optimize: Historical data, asset reliability, utilization,

usage and efficiency

35

Asset Monitoring Dashboard Example

Map with Asset Layout

• Asset data can be overlayed on map

or sketches

• Assets in with different conditions are

color coded. (Critical condition can be

denoted as red etc.)

• Important asset attributes are

accessible on Mouse hover

• Detailed asset information can be

shown on a seperate dashboard

• System events/alarms can be shown in

table format

3

5

Gizlilik Sınıflandırması : HİZMETE ÖZEL

Dashboard layouts are completely configurable using widgets

36

Detailed

Dashboard

Detailed Asset Dashboard Example

Detailed Telemetry Data of Selected

Asset

• Temperature gauges, Battery Pack

Voltage graphs, Currents Grid and

Generator Analyzer Graphs, and all

other telemetries configured, can

be displayed at detailed asset

Dashboard.

• This is a configurable dashboard

that can be expanded by adding

new widgets for each telemetry

that are expected to be seen on

the page.

• All alarms and warnings can also be

displayed here for the pole

selected.

Door-2 isopened

Door-2 isopened

Door-1 isopened

Temperature in

Lower section of

cabinet is in

alarm status

Temperature in

Lower section of

cabinet is in

alarm status

3

6

Gizlilik Sınıflandırması : HİZMETE ÖZEL

37

Telecom Operator – Remote Asset Management

Instantaneous Monitoring of CCTV Poles andAssets

Assuring the stations health by monitoring sensor data collected by P360 RAM platform

• Aims to monitor 1400 CCTV poles setup located in

multiple cities

• Monitoring each pole on a map design to see instant

condition

• Poles assets health by collecting sensor data such as;

• Cameras condition

• DC power supply status

• Air Condition of all cabinet assets

• Security of the cabinet by checking sensors on

• cabinet doors

• User friendly, configurable dashboard and rule

management mechanism for configuration and reporting

1400

CCTV Poles

3

500

Sensors per

pole

Customer

Case Example

38

Manufacturing Analytics

39

40

Advanced analytics

KoçDigital advanced analytics and IOT solutions in core mining

Value chain

Value drivers

Cost

reduction &

margin

improvement

Throughput

increase

Quality

increase

Productivity

Safety

Other

(HR, people, etc.)

HR Analytics

Safety and Security with Intelligent Video Analytics

Predictive Maintenance

Production Forecast

Productivity Optimization

Bottleneck Analysis

ImplementedOngoing

Source: BCG case experience

41

Manufacturing Analytics Customer Case in Mining

Results

Client Situation

•

Large mining company with numerous distributed mining

fields wants to increase operational efficiency using IoT

and analytics

•

Operational IoT and IT systems unified in single datalake

•

Analytical use cases improved business processes

%21

decrease in

downtime

duration

1.2M

annual

operational

efficiency in

just 3 mines

%8

less energy

usage

%17

less usage of

additive

material

Customer

Case Example

42

Planned/ Predictive Maintenance

43

Maintenance Workflows

Maintenance

Types

Planned

Periodical Usage Based

Periodical

and Usage

Based

Unplanned

Prediction

Downtime

44

Platform360 Maintenance Flow

Maintenance

Management

Real-time

Condition

Monitoring

Gather Data

Enrich with

Predictive

Models

Optimize

• Real-time data

collection with IoT

• Integrate with

operational systems

for context

• Asset monitoring

& management

• Evaluate alarm

data using

context

• Planned

Maintenance

management

• Downtime

management

• Use asset sensor data

and work history to

predict asset health

and future failures

• Enrich with user

defined rules

• Continuous model

improvement through

feedback loops

45

50-70%

reduction of

unplanned

downtime

10-20%

increase in

equipment

uptime

10-30%

reduced overall

maintenance

costs

Source: KoçDigital, BCG, Deloitte, Mckinsey

Predictive maintenance reduce surprises and cost

while increasing equipment uptime

46

VISION

• Minimize unplanned downtimes and improve

asset availability

• Doing the most efficient preventive

maintenance

• Minimize mean time between failures (MTBF)

• Autonomous control of equipment condition

• Completely paperless maintenance activities

VALUE SOURCE

• Reduced equipment downtime at core

machinery

• Improve first-time-fix-rate (FTFR) and reduce

mean-time-to-repair

• Reduce cost of maintenance without

sacrificing reliability

Predictive Maintenance Solution

Source: BCG case experience

50

Energy Management

Efficiency Improvement

51

What to Expect from Energy Monitoring?

How much energy do we consume?

• What is my manufacturing area/line or even product based

energy consumption?

• What is my real cost for manufacturing?

• How can I react to energy spending fluctuations?

Trends of Energy Usage

• Is my energy usage better or worse than before?

• What are my trends in energy consumption that reflect

seasonal, weekly, and other operating patterns?

Waste & Problems

• Where are the specific areas of wasted energy?

• Is there anomalies in energy consumption?

• How can I make warning signs visible to maintenance staff?

Analytics

• How much energy will I consume next month?

• How can I correlate this data with other connected factory

data?

Facility

Manager

Manufacturing

Area Manager

Industry 4.0

Transformation

Manager

52

Industry leaders follow a holistic IoT platform based approach

in energy management

• User defined rules to be enforce known business rules

• Analytical models can be deployed on the system to detect advanced data

correlations

• Create user/role specific dashboards and widgets for

customizable usability

• Cross-functional data ingestion

• Clear process & APIs for data dissemination

• Horizontal information flow

• Analytical products for Industry standard gains

• Predictive statistics tailored to specific needs

Real-time data processing

to detect events and alarms

Self service dashboards for

visualization

Common service layer,

enabling numerous IoT

analytics & applications

Advanced analytics to

predict and prescribe

Collect energy information

from variety of systems

1

2

3

4

5

Energy Meter

Energy Analyzer Remote Assets

EV Charging

Station*

53

Manufacturing Execution

System

54

Manufacturing Company Example

Mix of legacy machines and new

machines from various vendors

Variety of sensors communicating in

different protocols

Diverse family of products

manufactured by same manufacturing

assets

More than one manufacturing plant but

no single view of manufacturing

Shop Floor Status Governance

• Increased manufacturing throughput

• Decreased unplanned downtimes

• Traceable and improved manufacturing

quality

• Data driven decision making by

convergence of IT & OT

Targets of Industrial IoT

IT generally not involved in acquisition

of OT systems.

OT software acquisitions were driven by

operational needs

Data connectivity is not an issue to be

considered in new asset acquisitions

OT management software vision was

focused on asset KPIs such as OEE

(Overall Equipment effectiveness)

Decisions are not driven by data

55

Personas in Manufacturing

Manufacturing Manager

What is happening in manufacturing in real-time?

How can I minimize unplanned downtimes?

How does my manufacturing line efficiency change per

product type?

Where are my manufacturing bottlenecks?

How can I increase quality of products?

How to optimize energy spending?

How can I add an IT capabilities in OT systems?

Can I create a backbone for all my industrial systems?

Can I build-up on the system without vendor lock-in?

How can I become a data-driven company?

Can I create a single view for all my manufacturing

areas/plants?

How can I create a secure infrastructure?

IT & Digital Transformation Manager

56

Manufacturing Execution on Internet of Things Modules

IoT Platform

• Manufacturing

Backbone

• Operational

Data Store

• Rule Engine

• Common API

Layer

Data Collection

• Shop Floor

Connectivity

• Energy

Monitoring

• PLC

• SCADA

• MQTT

Tracking

• Track Items

inside

manufacturing

process

• Track workers

• Track

Equipment

• RFID read/Write

• Barcode reader

• Labels printing

Plant KPIs

• OEE

• Job Per Hour

• Bottleneck

analysis

• Cycle Analysis

• Plant

Performance

• Station

Performance

per product

type

Maintenance

• Asset

Downtime,

MTTR, MTBF

monitoring

• Anomaly

Detection

• Root Cause

Analysis

• Predictive

Maintenance

Operational

Intelligence

• Self service

dashboard

• Digital Twin of

the Plant

Quality

Monitoring

• Quality

Inspection

• Video Analytics

based quality

inspection

Procedural

enforcement

•Manufacturing

process steps are

performed;

•in the correct

order

•At the right time

•By the correct

resource

•In conformance

with quality req.

Planning&

Scheduling

•Production

Planning

•Shift Management

•Batch production

execution

•Components

picking list

Manufacturing

Process

Management

•BOM Recipe

•Process Planning

/Work instructions

Resource

Management

•Equipment

•Materials

Dispatching

•Dispatch work

acc. To source

avail. Schedul. nd

capacity

Production

Management

•Process to order

management

Integration

•ERP Integration

•PLM Integration

•Supplier

/Customer system

integration

57

Manufacturing Execution System Customer Case

Source: KoçDigital

MES including operational data store, equipment

tracking and plant performance.

Model & critical part matching process for 12

production points

Station based production, fault, downtime &

anomaly detection reports

31

Stations

4

Production

lines

700

sensors

500+GB*

of data

annually

Project Impact

Eliminate quality errors in manufacturing

Platform360 deployed to an Air Conditioner Plant as

manufacturing execution system

Customer

Case Example

58

Platform360 Industrial IoT Solutions

USING MICROSOFT AZURE

TABLE OF CONTENTS

1 INDUSTRIAL IOT CHALLENGES

2 KOÇDIGITAL INDUSTRIAL IOT SOLUTIONS

3 INDUSTRIAL USE CASES

4 APPENDIX

59

KoçDigital is a Digital Center of Excellence, combining strengths

of BCG and Koç Holding & KoçSistem

KoçDigital

Academy

Advanced

Analytics

Data Platform

Design & Development

IoT

Solutions

World class

capabilities

in analytics

Access to >3,000

digital experts

>3,000

State-of-the-art

enablement

Digital

capabilities and

infrastructure

Very strong

implementation

capabilities

Trusted

Koç brand

Source: KoçDigital

KoçDigital overview

60

KoçDigital

Overview

We already have 100+ staff in KoçDigital, supported

by 850+ Gamma and 1500+ KoçSistem professionals

100+

Data analytics &

IoT professionals

850+

Data scientists and

engineers of BCG

GAMMA

9

1500+

System Integration&

Managed Services&

Business Applications

Loading...

Loading...