Knuth KKS 250, KKS 315, KKS 350 Operating Instructions Manual

WERKZEUGMASCHINEN Operating instructions

KKS 250 / 315 / 350 1/29

Operating

Instructions

Circular saw

KKS 250

Part No. 102129

KKS 315

Part No. 102133

KKS 350 Part No. 102135

WERKZEUGMASCHINEN Operating instructions

KKS 250 / 315 / 350 2/29

1 MACHINE DESCRIPTION....................................................................................................................... 3

2 SPECIFICATION.......................................................................................................................................5

3 SECURITY INSTRUCTION..................................................................................................................... 6

4 INSTALLATION ........................................................................................................................................ 9

4.1 CONNECTIONS .................................................................................................................................... 10

4.2 CONTROL HANDGRIP........................................................................................................................... 10

5 USE............................................................................................................................................................. 13

5.1 CONTROL DEVICES.............................................................................................................................. 14

5.2 NORMAL CUTTING / WORKING ............................................................................................................ 15

5.3 CUTTING OF MACHINE STOP................................................................................................................ 16

5.4 MITER CUT.......................................................................................................................................... 16

5.5 VICE UNIT........................................................................................................................................... 16

5.6 HEAD SIDE SHIFTING...........................................................................................................................18

5.7 CLUTCH UNIT ADJUSTMENT ................................................................................................................ 19

5.8 SCREW GEARING ADJUSTMENT ........................................................................................................... 20

5.9 CUTTING BLADE REPLACEMENT.......................................................................................................... 21

6 MAINTENANCE ...................................................................................................................................... 22

6.1 OIL CHANGE IN THE REDUCTION UNIT................................................................................................. 23

6.2 ELECTRIC SYSTEM .............................................................................................................................. 24

6.3 WIRING DIAGRAM............................................................................................................................... 25

7 PARTS........................................................................................................................................................ 27

7.1 HEAD.................................................................................................................................................. 27

7.2 BASE................................................................................................................................................... 28

8 SPARE ARTS............................................................................................................................................ 29

WERKZEUGMASCHINEN Operating instructions

KKS 250 / 315 / 350 3/29

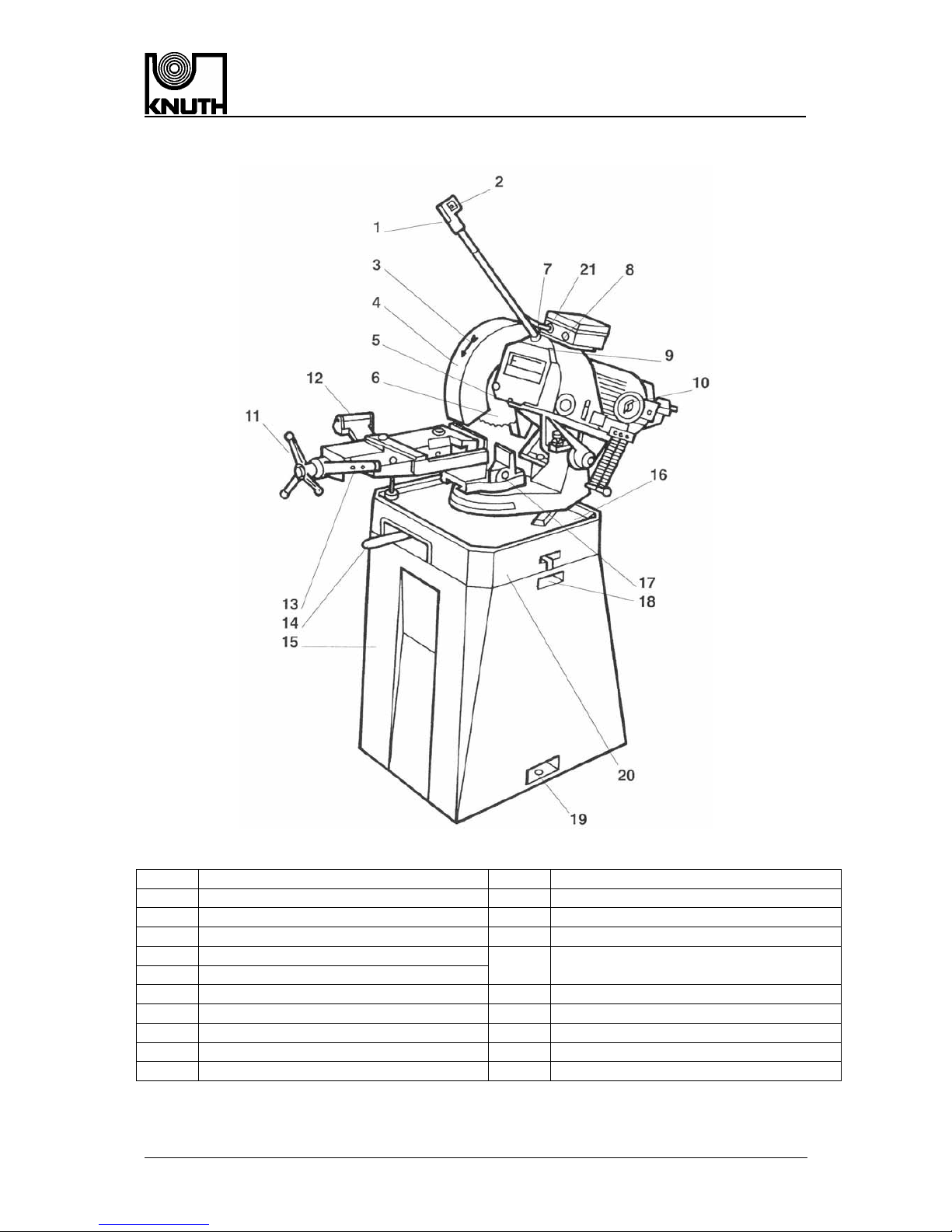

1 Machine description

Fig. 1

1 Control handgrip 12 Bar holding arm

2 Micro switch 13 Quick clamping lever

3 Blade rotation arrow 14 Vice clamping lever

4 Protection guard 15 Machine base (optional)

5 Reduction unit oil drain plug

6 Cutting blade

16

Opening for the introduction of

emulsifiable liquid

7 Hosing for the control handgrip rod 17 Housing for bar stopping rod

8 Start push button 18 Cutting off machine base fastener

9 Oil filing cap in the reduction unit 19 Base floor fastener

10 Control switch 20 Identification plate

11 Vice handwheel 21 Connecting plug to the electric box

WERKZEUGMASCHINEN Operating instructions

KKS 250 / 315 / 350 4/29

The cutting of machine is supplied with:

- Diaphragm cooling pump

- Manual quick clamping vice with anti-burr device

- 45° left / right swivelling head and vice

- Rod with bar stopping

- Set of wrenches for the routine use and maintenance

- Maintenance and operating instructions

WERKZEUGMASCHINEN Operating instructions

KKS 250 / 315 / 350 5/29

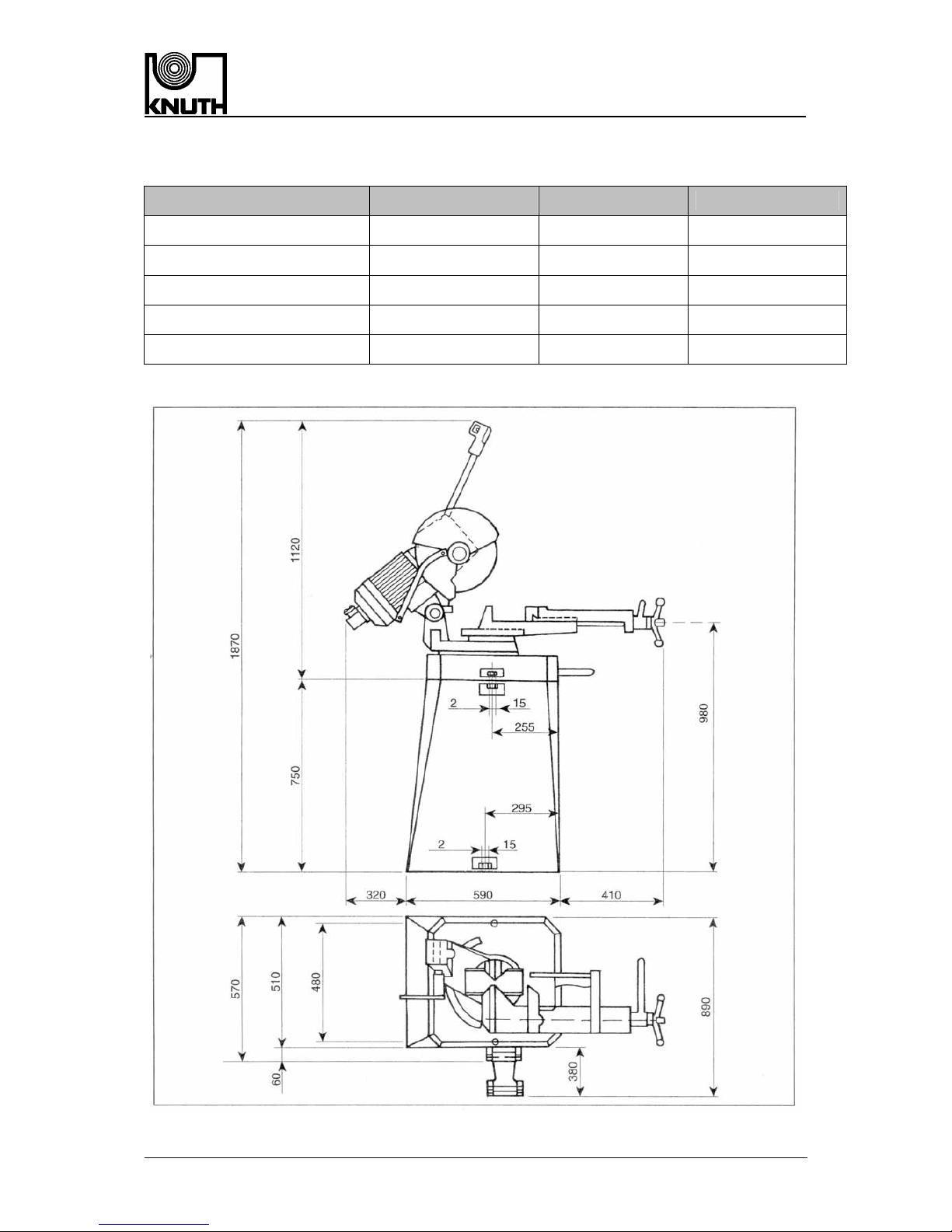

2 Specification

Model KKS 250 KKS 315 KKS 350

max. saw blade dimension 250 mm 315 mm 350 mm

Motor 400V 2-speed 0,73 kW / 0,95 kW 1,3 kW / 1,9 kW 1,5 kW / 2,2 kW

Speed (rotation) 51,102 rpm 44, 88 rpm 40,80 rpm

Width of vice 120 160 mm 160

Weight 80 kg 155 kg 205 kg

Fig.2

WERKZEUGMASCHINEN Operating instructions

KKS 250 / 315 / 350 6/29

3 Security instruction

Operation manual

For your own security read the operation manual before starting the machine. The

operation manual should be kept in a secure place. You should know about how to

handle the machine, its limits and it’s specific dangers.

Keep your working place clean

Disorder on your working place will result in danger. Take care that your working

place is free from chips and dirt. Use only the right tools to clean your machine from

chips. Keep your working place free from obstacles.

Check if there are any damages at the machine

Before you start the machine check the function of the security equipment. Check the

function of all movable parts. All parts have to be mounted correctly. Damaged

security parts should be repaired or exchanged by the after sales service.

Take care about outer conditions

Don’t use the machine in dangerous areas. Take care, that electrical parts don’t get

humid or wet. Work only with a good illumination.

Don’t use electrical parts near flammable fluids or gas.

Protect yourself from electric shock

Don’t remove mechanical or electrical security parts. Check if all security parts are

mounted and adequately functioning.

Wear only suitable clothes

Don’t wear large clothes, wristwatches or jewels. For your own security wear alwaysworking shoes while working. If you have long hair always wear a hairnet. While

working with the machine you have to wear security glasses. If you work under dusty

conditions you have to wear a dust protection-breathing mask.

Keep incompetent persons away from the working area

Take care, that there are no persons in your working area witch could be exposed to

danger. Children and visitors should be kept in a secure distance to the working area.

Keep children away from the machine.

Don’t let other people touch the machine or the cable of the machine.

Make sure that only authorised persons can reach the workshop.

WERKZEUGMASCHINEN Operating instructions

KKS 250 / 315 / 350 7/29

Take care about the Power supply cable

Before connecting the power supply cable to the wall socket ensure that the machine

is switched off. Don’t use the cable to pull the plug out of the socket. Take care, that

there is no tensile force on the cable. Beware the power supply cable from heat, oil

and sharp edges.

Control the plug and the cable regular and in case of damage let it repair by the after

sales service. Please control also the extension cable. Never use the machine

without Protection Earth.

Unplug the machine

If you don’t use and while servicing the machine pull off the power supply plug. This

is necessary because the machine should not run unintentionally and to protect you

from electric shock.

Beware of unintentional run

Confirm that the main power switch is off while you plug in the power supply plug.

Be careful with your tools

Keep your tools sharp and clean to work well and secure. Follow the instructions for

tool exchange and servicing.

Don´ t forget tools inside the machine

Before starting makes sure that there are no tools inside the machine which could be

hurled out of the machine. Make sure, that there are no loosen parts witch could be

dangerous.

Take care about your hands

Make sure, that tools and work pieces are securely fastened. Use only the right tools

to clamp and to fasten tools and work pieces. This is more secure than to fasten the

work piece with the hand, and you have two hands to handle the machine.

Pay attention to your balance

Take care about the position of your feed. Never climb on the machine, because

dangerous injury may result from falling down or contacting moving parts.

Accessories and accessory parts

Only use accessories and the operation manual or the supplier specifies accessory

parts witch. The use of other accessories and accessory parts may result in

dangerous injury and damage the machine. Only use accessories and accessory

parts for the right tasks.

WERKZEUGMASCHINEN Operating instructions

KKS 250 / 315 / 350 8/29

Electrical parts

The electrical parts confirm to the determinations of electrical security.

Electric specialist to prevent accidents for the user may only do mending.

Cleaning solvent

Before you work with cleaning solvent you should read the instruction of the fluid, to

prevent accidents.

Leaving the machine

Never leave the machine while it is running.

Alcohol, medicaments, drugs

Never use the machine under influence of alcohol, medicaments or drugs

Danger of fire

Don’t use highly inflammable fluids.

WERKZEUGMASCHINEN Operating instructions

KKS 250 / 315 / 350 9/29

4 Installation

The machine is supplied ready to be used, without cutting blade and emulsifiable

liquid.

When closing the machine position it is convenient to consider:

- That it is free from any hindrances, in a non-damp area, sheltered from the

bad weather

- That it is provided with a good lighting;

- That ft la close to the main switch;

- That the room temperature is between 0° and 45°C.

To carry out the Installation, keep to the following Instruction:

- Screw an M16 threaded eyebolt (minimum capacity load 400 kg.) into the

control handgrip note (7 fig.1)

- Hook the machine by means of ropes and tie rods of suitable carrying capacity

Lifting and handling operations can be very dangerous, if not carefully carried out:

for this reason outsiders must be kept far from the installation area, which is to be

cleaned, cleared out and delimited; ascertain that the available equipment fits the

requirements and Is free of vices; do not handle suspended loads and keep a safety

distance; the loads, during their handling should not be lifted more than 20 cm from

the ground.

- By means of an especially intended crane or hoist lift the machine and place it

in its pre-determined area. Mark, on the ground, the two holes for the machine

fastening to the floor (19 fig. 1)

- Lift the machine again, and place it close by.

- Making use of a suitable drill carry out the two holes and introduce the relevant

- Position the machine and base in its seat and subsequently fasten the base by

means of the two relevant screws

Should the machine be supplied without base, it must be fastened, through the two

holes (18 fig. 1), on suitable frame, able to support the machine weight and any

possible unbalancing resulting from its use.

The manufacturing company decline any responsibility for possible damages caused

by wrong installations or by the use of unsuitable bases.

Loading...

Loading...