Page 1

SP66 IN-W ALL SPEAKER

OWNERS MANUAL

Congratulations and thank you for choosing Knöll inwall speakers! To

assure correct installation and to realize the full potential of these new

speakers, please read and follow these instructions carefully. If you

have questions or comments, please don't hesitate to call or write your

authorized Knöll dealer. Your dealer has the experience needed to

pinpoint any problems that may exist and has easy access to technical

information from the Knöll factory.

Speaker Placement

Knöll SP66 speakers are designed to work within almost any interior

decorating scheme where inwall or flush mounting is possible. Ideally

SP66 speakers are ceiling mounted 2-3 meters (6'-10') apart, away from

corners directly over the listening area. This ideal placement gives the

best stereo imaging. Position SP66 speakers as symmetrically as

possible. SP66 speakers can be ceiling or wall mounted.

Installation T ips

1. Follow all electrical and building code requirements in your area.

2. A minimum mounting depth of 3-1/4" (8.25cm) measured from the

face of the wall or ceiling is needed in order to fit properly. SP66

speakers can be placed right next to studs or other wall interior items

but avoid near proximity to pipes, machinery and high amperage

wiring.

3. The mount brackets provided with SP66 speakers can accommodate

sheet rock or wall board thicknesses of 1/2" to 1-3/8". Spacers or

longer screws can be used on thinner and thicker surfaces.

4. Avoid mounting speakers closer than 0.5m (20") from a video

monitor or TV screen. If any video or TV screen distortion is detected,

the video monitor or TV should be moved farther away from the

speaker.

5. It is not necessary to install SP66 speakers in a special box unless

required to do so by local electrical or fire regulations.

6. Adding insulation such as 10cm (4") rock wool behind the SP66

generally improves sound quality.

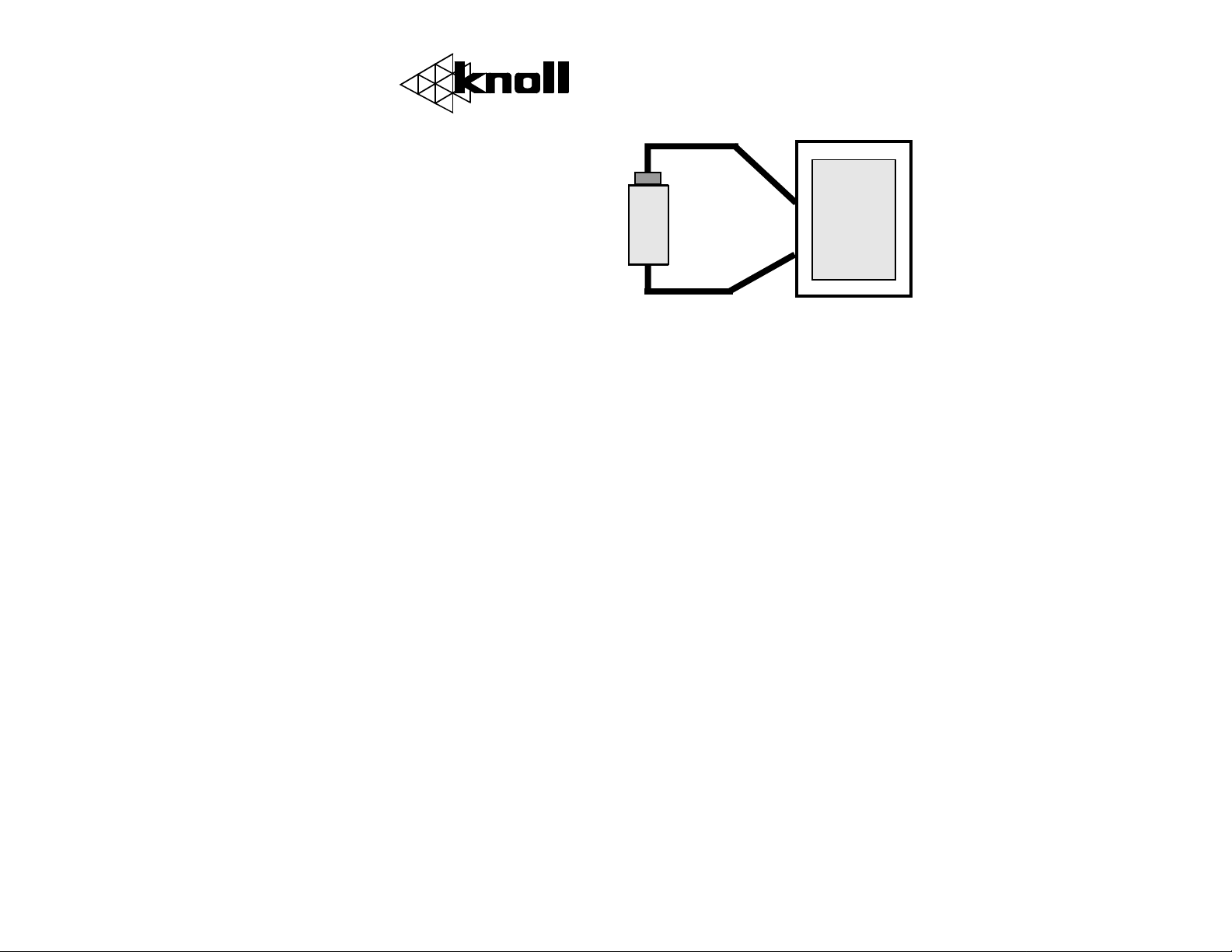

Fig 1: SPEAKER POLARITY VERIFICATION

7. Speaker wire should be

+

1.5VDC

BATTERY

+

SP66

-

-

correct amplifier loading. Avoid series wiring SP66 speakers with any

other speaker type.

9. Always take care to connect the speaker wire runs in phase. An easy

method verify polarity follows. Connect a 1.5V battery across the speaker

wire at the amplifier location (see fig 1) Have someone observe if the

SP65 cone moves in or out. If the cone goes out (toward the observer) the

+ wire is now connected to the + terminal of the battery and that wire

should be connected to the + terminal of the amplifier. Other speaker(s)

should be tested and connected in a similar manner.

minimum 16 gauge (ideally

fire code rated, low oxygen

wire. Runs longer than 10m

(30') should be 14 or 12

gauge.

8. Parallel or series wiring is

generally acceptable for

SP66 speakers to obtain

Installation: Existing Construction

1. Use a stud locator device or other means to determine suitable sized

cavity in the wall or ceiling for the SP66.

2. When ceiling mounting try to make the locations as symmetrical as

possible. When wall mounting carefully measure the distance from the

floor to the speaker center so both speakers are exactly the same distance

from the floor. Draw a rectangular hole 7-1/2"x11" at the correct

location. Cut the hole out using a sheet rock saw, keyhole saw or other

suitable device. Place the SP66 mount bracket in the hole to verify correct

flush mount fit.

3. Run speaker wires from the amplifier to the room volume control

location (optional) then to the left and right speakers. Allow an extra 1m

(3') of wire at the speaker cutout location to make installation easier. Strip

and twist about 1/2" of insulation off wires. The wire runs should be

hidden as well as possible (ask your dealer for tips to conceal wires).

4. Remove the speaker grills.

Page 2

5. Connect the speaker wire to the SP66 speaker carefully observing

correct speaker terminal polarity.

6. Slip the bottom of the speaker down into the opening cut in the wall

or ceiling, slide the whole speaker into the wall cavity and center the

speaker in the hole. Tighten all six screws (just snug, don't over tighten).

This should allow the speaker to line up and clamp the wall board with

the speaker frame.

7. Turn the amplifier on, room volume controls up and test the speakers.

8. Snap the white (paintable) grill into the SP66 speaker bracket.

Installation: New Construction

1. Run two wires from the amplifier location to the room volume control

(optional) then to the intended speaker location. Loop an extra 1m (3')

of wire out from the ceiling or wall. ID tag the wires.

2. After wall board or sheet rock is installed, make sure the 7-3/4" x11"

speaker hole is cut out correctly then follow steps 4-8 in "Existing

Construction".

Amplifier or Receiver Operation

The amplifer or receiver should provide more power than will be

needed. Always reduce sound levels immediately if sound distortion is

present. Any amplifier, especially low powered amplifiers can damage

speakers when distorted sound (usually you will hear a harsh or unclear

sound) is being reproduced. Speaker damage caused by sound distortion

or gross overpowering is easily evident and is not covered by the

warranty.

SP66 Limited Warranty

Knöll Systems warrants SP66 speakers to be free from defects in

materials and workmanship. This warranty extends for one full year from

the date of purchase by the consumer. Any products returned freight

prepaid to Knöll Systems and found to be defective by Knöll systems

within the warranty period will be repaired or replaced at Knöll Systems

option, at no charge. Knöll Systems will not be responsible for the actual

cost of installation or removal of the product, nor for any consequential

or incidental damages. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This warranty gives you specific legal

rights. You may have additional rights which vary from state to state.

Specifications

Speaker Type: 2-way

Woofer: 6-1/2" filled mica

Tweeter: 1" (25mm) Soft dome

Peak Power RMS: 80 watts

Power Rating RMS: 60 watts

Amplifier Power : 5-100 watts/channel

Nominal Impedance: 8 ohms

Sensitivity: 90 dB/W/m

Frequency Range: 50Hz-21kHz

Mount Depth Required: 3-1/4" (90mm)

Dimensions: 12-1/8 8-3/4"

Cut Out Dimensions: 11 x 7-1/2"

Color: Paintable white

Trim Ring Painting

The SP66 speaker baffle and grill can be painted to match any interior

decorating scheme. Ideally paints with nitrocellulose lacquer are used.

Most cold paint types are suitable as well. Primer can be used when

darker colors are required. We do not suggest painting the inner black

cavity or drivers.

Knöll Systems

tel (604) 272-4555

fax (604) 272-5595

Knoll Systems, Richmond, BC Canada

C

COPYRIGHT 1999, Knöll Systems,

In Canada:

11791 Machrina Way

Richmond, B.C. V7A 4V3

SP66

All Rights Reserved

In America:

145 Tyee Drive

Point Roberts, WA 98281

Loading...

Loading...