Knoll Pixel KBXL36DG, Pixel KBXC36DG, Pixel KBXW36DG, Pixel KBXB36DG, Pixel KBXL3030G Installation Instructions Manual

...Page 1

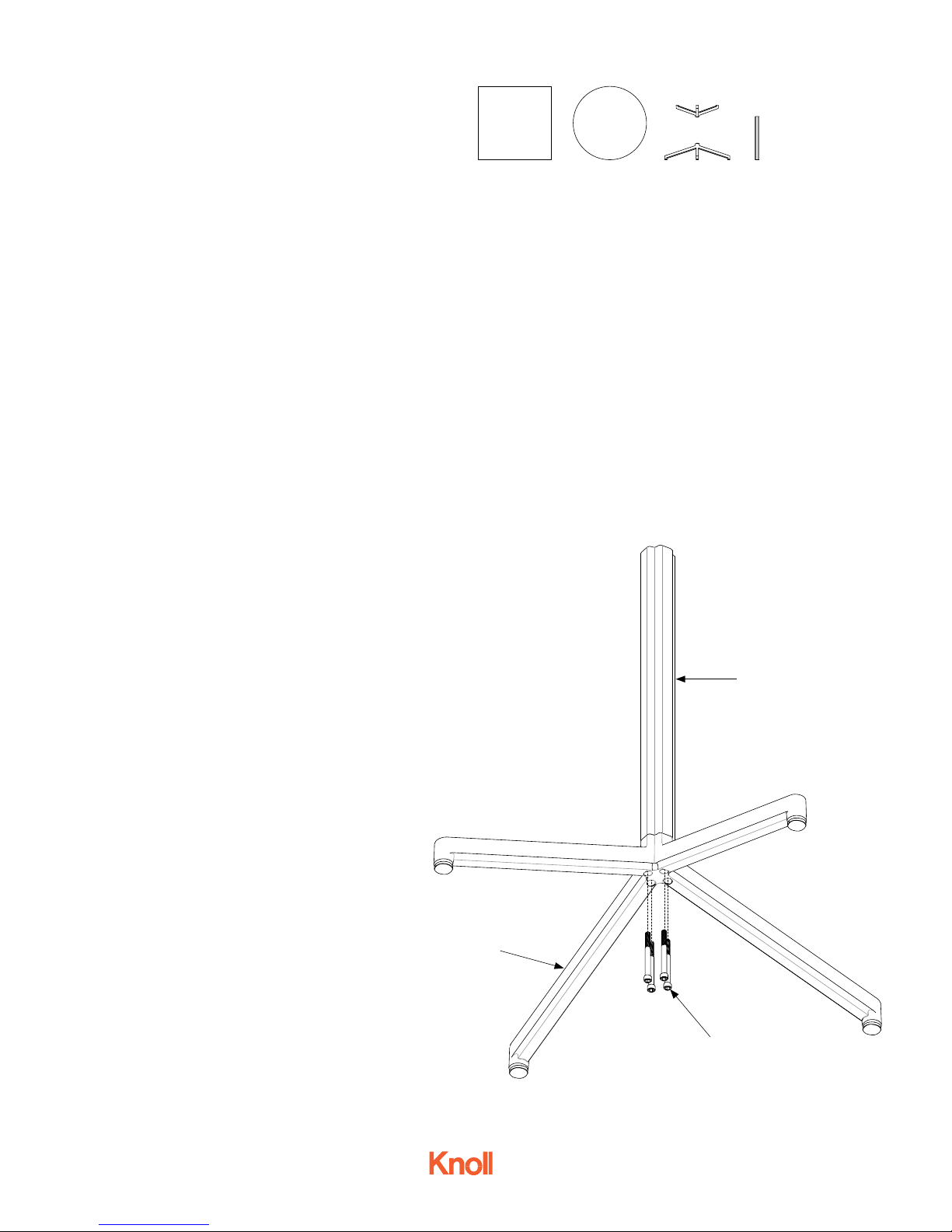

PIXEL™ Installation Instructions

Column Leg Tables

Glides only

Round tables:

KBXL36DG

KBXW36DG

KBXC36DG

KBXB36DG

Square tables:

KBXL3030G

KBXW3030G

KBXC3030G

KBXB3030G

Please pay close attention to torque requirements.

Step 1.

Attach the column extrusion (A) to the base (B)

using 4

socket cap head 5/16-18 x 3.00 screws

(C), torque: 200 in/lb.

Parts list:

1 Table top

1 Column extrusion

1 Top support

1 Base (with glides)

Tools needed:

Allen wrench

Torque wrench

Hardware:

8 Socket cap head 5/16-18 x 3.00 screws

(base/support to extrusion)

4 Socket cap head 5/16-18 x 2.00 screws

(base to top)

2 Vertical wire management clips

(clear plastic)

A

4AU6005 - Oct 2015

Page 1 of 3

B

C

Fig. 1

Page 2

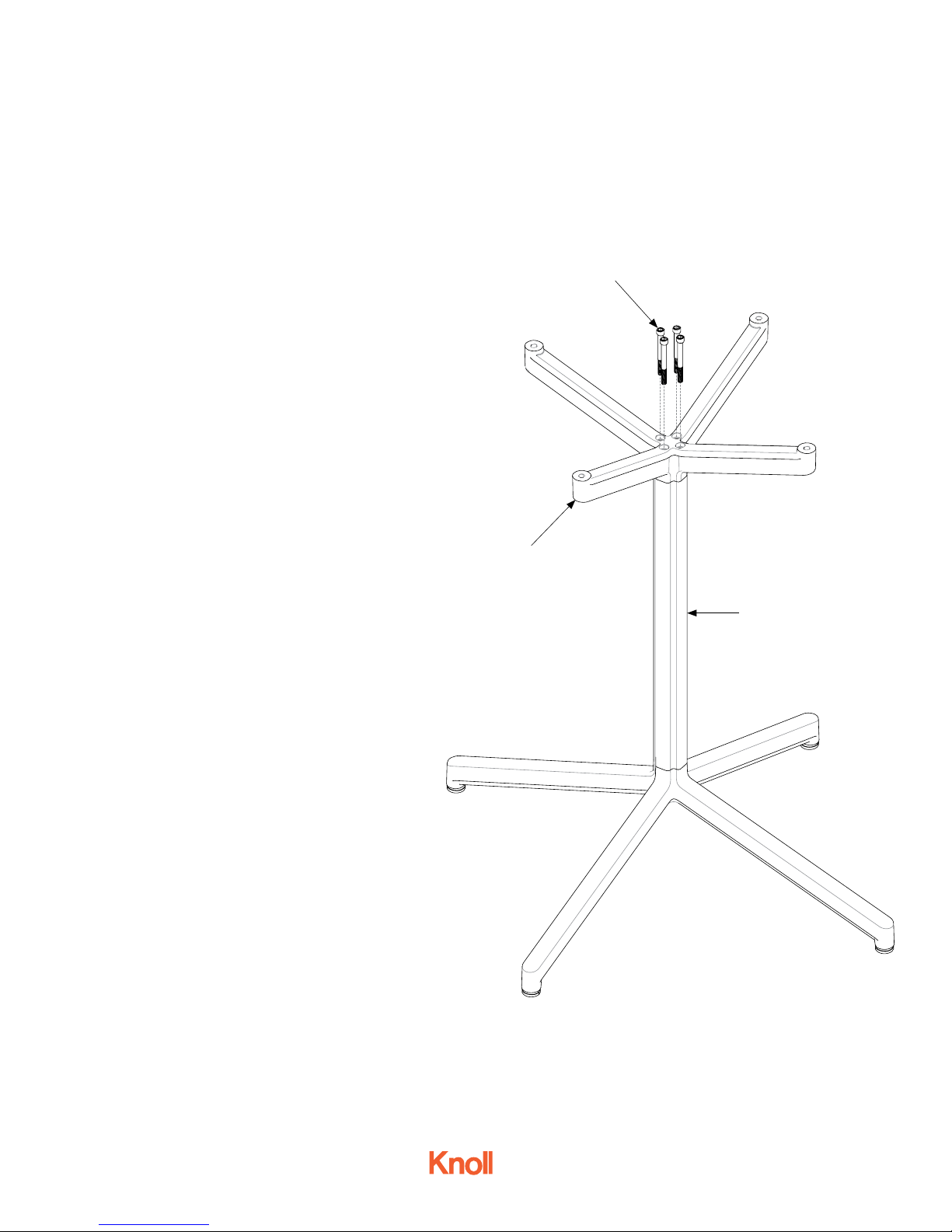

PIXEL™ Installation Instructions

Column Leg Tables

Step 2.

Attach the column extrusion and base (D) to the top

support (E) using 4 socket cap head 5/16-18 x 3.00

screws (F), torque: 200 in/lb.

F

E

D

4AU6005 - Oct 2015

Page 2 of 3

Fig. 2

Page 3

PIXEL™ Installation Instructions

Column Leg Tables

Step 3.

Lay the inverted table top on the floor.

Step 4.

Attach the base assembly (D) to the top using

4 socket cap head 5/16-18 x 2.00 screws (E),

torque: 130 in/lb.

D

Step 5.

Turn the assembled table into the upright

position.

All tables come with 2 vertical wire management clips for use with optional electrical

modules. See separate electrical installation

instructions for details.

E

4AU6005 - Oct 2015

Page 3 of 3

Fig. 3

Loading...

Loading...