Page 1

Page1of34

Page 2

Page2of34

Page 3

Page3of34

TABLE OF CONTENTS:

4 INTRODUCTION

5 CERTIFICATION CE

5 CONFORMITY ACCORDING TO CE DIRECTIVE

6 DANGER WARNINGS

7 GENERAL WARNINGS

7 LIMITATIONS

8 RISK AWARENESS

10 TECHNICAL SPECIFICATIONS

12 USAGE

29 PRE DIVE PREPARATIONS

33 MAINTENANCE ROUTINE

33 WARRANTY

Page 4

Page4of34

INTRODUCTION

Thank you for purchasing a KNIGHT DIVERS BCD.

Our BCDs are made exclusively with the best European production materials, selected and

tested in order to offer a product of the highest quality.

Development and continuous research allow us to be constantly evolving.

Our BCDs have been designed to meet the requirements of the UNI EN 1809: 2014 + A1:

2016 standard with regard to the requirements for buoyancy compensators.

Design and production are carried out entirely in MALTA. All the materials used are

certified non-toxic and hypoallergenic to contact with the skin, all in compliance with the

protection of the health of the user, workers and the environment. Each BCD is

individually tested to prove the pressure seal, the functionality of the valves and the

connection hose.

It is important to read the recommendations in the following pages very carefully.

KNIGHT DIVERS Ltd is at your disposal for any eventual clarification regarding the use of

the BCD. For any query, please contact us at:

KNIGHT DIVERS Ltd

62,Triq L-Gholjiet

Mellieha MLH 2105

Malta

Phone +356 7903 0676

www.knightdivers.eu

info@knightdivers.eu

Page 5

Page5of34

CE CERTIFICATION

The BCDs described in this manual have undergone a CE type examination, verified and

certified by the RINA laboratory, S.p.A. - Via Corsica, 12 - 16128 Genoa - Italy, Notified

Body No. 0474 in compliance with the EN 1809: 2014 + A1: 2016 standard as a stabilizing

jacket (Class II).

CONFORMITY ACCORDING TO CE DIRECTIVE

The undersigned manufacturer KNIGHT DIVERS Ltd with headquarters in 62, Triq LGholjiet, Mellieha MLH 2105 MALTA declares that the PPE described below: Floating

compensators (balancing jackets) for underwater use models:

GR 13 One size (adjustable from XS to XXL)

GR 13 TEK One size (adjustable from XS to XXL)

GR 15 One size (adjustable from XS to XXL)

GR 15 TEK One size (adjustable from XS to XXL)

GR 19 One size (adjustable from XS to XXL)

GR 19 TEK One size (adjustable from XS to XXL)

GR 19 R One size (adjustable from XS to XXL)

comply with the provisions of Directive 89/686/CEE (implemented in Italy with Legislative

Decree 4/12/92 No. 475 and subsequent amendments and / or additions) and with

national regulations that implement the harmonized standard EN1809: 2014 + A1: 2016 ;

are identical to the PPE subjected to Certification Certificate No. PPE416917CS/001 and

No. PPE416917CS/002 issued by RINA Services S.p.A. via Corsica 12, 16128 Genoa

(Notified body no. 0474).

Page 6

Page6of34

DANGER WARNINGS

This manual contains graphic symbols to inform you about the risks and dangers you may

encounter in the use and maintenance of the BCDs.

These graphic symbols and their associated captions are:

DANGER :

Indicates an imminent hazard which, if not avoided, may result in serious injury

or death.

ATTENTION :

Indicates a potential hazard which, if not avoided, may result in serious injury

or death.

CAUTION :

Indicates a potential hazard which, if not avoided, may result in slight or

moderate injury. May also indicate the unsafe execution of a procedure.

Page 7

Page7of34

GENERAL WARNINGS

Before using the BCD or any other product for scuba diving it is necessary to

follow a course held by qualified instructors and obtain the relevant license.

The use of diving equipment by unqualified persons is dangerous and may

result in serious injuries or death to the diver and his companions.

If you are not experienced in the use of this equipment, we recommend that you

familiarize yourself with its operation during shallow depth test diving and in favorable

conditions; if necessary, it is advisable to contact a qualified instructor for a refresher

course. During the assembly and setting of the BCD, all possible precautions have been

implemented to provide a highly reliable product over time. Such measures can be

rendered inefficient if the user does not use the BCD correctly and does not provide

adequate maintenance. KNIGHT DIVERS Ltd declines all responsibility for any problems

arising from failure to observe the recommendations in this manual.

For any problem you can contact your dealer or contact directly KNIGHT DIVERS Ltd. To

ensure maximum safety, any repair or maintenance must only be carried out by technical

centers authorized by KNIGHT DIVERS Ltd. In case it is necessary to perform routine

maintenance operations or extraordinary maintenance, KNIGHT DIVERS Ltd makes

available its Technical Service Centre to provide all the assistance and the original

spare parts.

These BCDs have been certified according to the EN 1809 standard which provides for a

long series of functional tests up to a maximum depth of 50 meters and at temperatures

between -20 ° C and + 70 ° C.

LIMITATIONS

It is not the purpose of the EN 1809 standard to establish requirements for flotation

devices or life jackets.

The BCD is not intended to ensure a high head position on the surface in case of

unconsciousness or inability of the diver. The instructions that follow must be

integrated with those relating to the other components making up your SCUBA

set (cylinder unit or assembled double tank). Before using your assembled

cylinder or bottle assembly read carefully all the instructions for use given in

the relevant manuals.

KNIGHT DIVERS Ltd declines its responsibility for any errors in the compilation of the Use

and Maintenance Manual and, constantly working for the improvement of all its products,

reserves the right to make changes at any time, without prejudice to the essential

characteristics described herein illustrated.

Page 8

Page8of34

RISK AWARENESS

WARNING :

This booklet is not a dive manual! Read the entire manual before using this

equipment! The user manual must be retained for the entire period of the

product life!

WARNING :

According to the European standards, our BCDs are to be considered certified

only if they are complete with all the components as the original KNIGHT

DIVERS configuration, including the quick release LP hose.

For safety reasons, the BCD must only be used with the original quick release

LP hose supplied by KNIGHT DIVERS. The manufacturer cannot be held

responsible for damage to persons or property deriving from the use of

different hoses.

DANGER :

This BCD is not a life jacket or a rescue device and does not guarantee the

support in surface of an unconscious diver in a position where the face remain

out of the water.

DANGER :

Do not use this BCD until you have acquired the specific license. Use of this BCD

by divers who have not obtained the required license, may result in serious

injuries or death.

This BCD should be used up to the depth of 50 meters.

WARNING :

These BCDs have been designed to be used with normal atmospheric air

conform to requirements for breathable air as established in CEN EN 12021.

The use of this product with oxygen-enriched gas or mixtures (commonly

known as NITROX) requires specific preparation and compliance with laws of

the country where the equipment is used. If this is not done according to

recommendations, it may cause serious or fatal injury due to fires or

explosions, or seriously cause damage to the equipment.

Page 9

Page9of34

WARNING :

A bad or improper use of this BCD could result in a loss of trim, including rapid

and uncontrolled ascents and descents, with the risk of drowning or

decompression sickness.

DANGER :

Diving in an environment that is chemically, biologically, or radiologically

contaminated is extremely dangerous. The BCDs KNIGHT DIVERS must not be

used in contaminated environments.

DANGER :

Diving in ice water (in water at 5°C or less) is extremely dangerous. Do not dive

in ice water unless you have been fully trained and with specially dedicated

equipment.

DANGER :

It is essential to take good note of these hazard and danger symbols to avoid

critical situations that may occur while using the BCDs. Such situations may

result in serious injury or death.

Page 10

Page10of34

TECHNICAL SPECIFICATIONS

Buoyancyforce of the BCDs:

Model GR 13: maximum buoyancy 120 Newtons 12,2 Kilograms 13 Ltrs

Model GR 13 TEK: maximum buoyancy 120 Newtons 12,2 Kilograms 13 Ltrs

Model GR 15: maximum buoyancy 150 Newtons 15,3 Kilograms 15 Ltrs

Model GR 15 TEK: maximum buoyancy 150 Newtons 15,3 Kilograms 15 Ltrs

Model GR 19: maximum buoyancy 170 Newtons 17,3 Kilograms 19 Ltrs

Model GR 19 TEK: maximum buoyancy 170 Newtons 17,3 Kilograms 19 Ltrs

Model GR 19 R: maximum buoyancy 180 Newtons 18,4 Kilograms 19 Ltrs

Bladder

It is made of Cordura polyurethane coated (Models GR13, 15, 19 and 19R) or nylon

polyurethane double-coated (Models GR TEK).

Harness

The harness are made of 50mm polyethylene reinforced polypropylene and are completed

by five “D” rings of AISI 304 stainless steel that allow to connect to the harness different

diving accessories. The buckle is also of AISI 304 stainless steel. The belt slides inside a

series of AISI 304 stainless steel loops in order to adapt the harness to any size between

the S and XXL.

Backplate:

The backplate is made of electro polished AISI 304 stainless steel or of aluminum; nuts

and bolts of AISI 304 stainless steel.

Power inflator and overpressure valves

For safety reasons, we recommend that the first time you try to use the inflate button

when you are in surface.

The power inflator of the BCD controls a large number of functions and allows to adjust

the BCD to get a neutral trim during the dive:

Load by the button of the inflator (side button); pressing this button inflates the

BCD; it can be inflated up to a pre-established pressure that depends on the

calibration of the overpressure valve; once the maximum pressure is reached, the

air is discharged from the valve.

The top button (at the end of power inflator) allows the inflation by mouth with a

special mouthpiece: push the button and in the same time blow inside the

mouthpiece.

The top button (at the end of power inflator) allows the deflation by raising the

corrugated upwards and pressing.

Page 11

Page11of34

DANGER :

Never use the inflator mouthpiece as a regulator. The BCD is not a breathing

device. Never breathe gas from inside the BCD, it may contain liquids or

contaminants that, if inhaled, could lead to serious injuries or, in extreme

situations, to death.

Overpressure valves

The BCDs are supplied with one overpressure valve located behind on the left side at the

bottom. The overpressure valves guarantee the quick dumping of air. The function of

these valves is to automatically reduce the inner pressure of the bladder in case of

excessive inflation or in case of eventual necessity during the various phases of diving.

The valves can be opened manually pulling the cable located on the valve itself.

WARNING :

To obtain complete redundancy, only the Model GR 19 R is composed of two

independent bladders coupled. Each bladder has a complete control unit and an

overpressure and rapid discharge valve: in this case the overpressure valves are located at

the bottom, right and left.

Page 12

Page12of34

USAGE

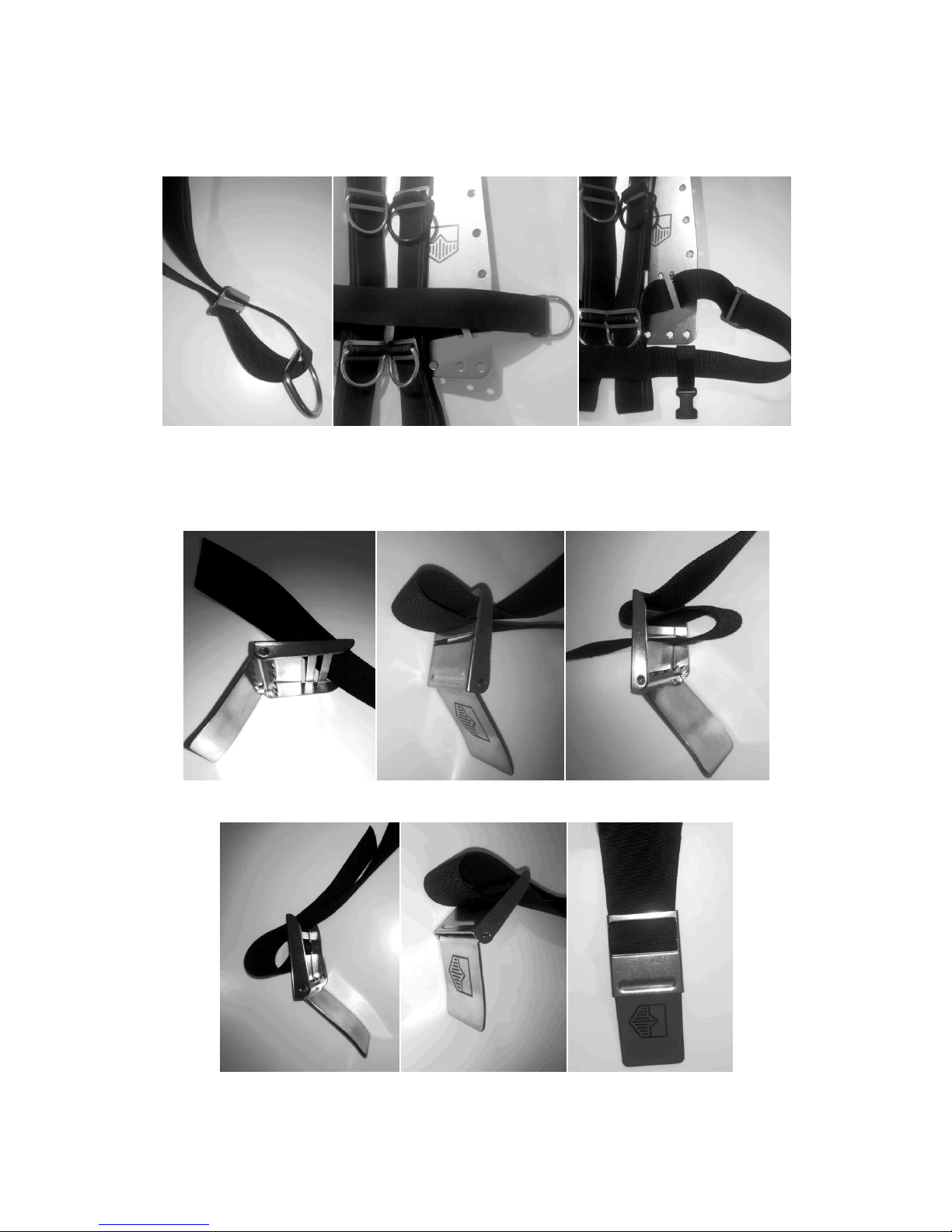

Harness assembly, “DIR” type

1) Insert the strap with the eyelet aligned in the upper back part of the backplate (Fig. 2)

and (Fig. 3).

(Fig. 1) (Fig. 2) (Fig. 3)

2) Run the strap through the upper horizontal slots of the backplate (Fig. 4) and (Fig. 5).

(Fig. 4) (Fig. 5)

Page 13

Page13of34

3) Insert a smooth loop and a "D" ring on the right belt (Fig. 6). Repeat the procedure on

the opposite side using the elastic accessory-holder ring (Fig. 7) and insert the retentive

band of the power inflator (Fig. 8).

(Fig. 6) (Fig. 7) (Fig. 8)

4) Insert a smooth loop and a "bent D" ring on both sides (Fig. 9) and (Fig. 10). Insert one

end of the strap from the inside outward through the inner lower sloped slot (Fig. 11).

Repeat the procedure on the opposite side (Fig.9-11).

(Fig. 9) (Fig. 10) (Fig. 11)

Page 14

Page14of34

5) Insert a toothed loop on the belt (Fig. 12) and slide it from the outside to the inside

through the sloped outer slit (Fig. 13). Repeat the procedure on the opposite side (Fig. 12-

14).

(Fig. 12) (Fig. 13)

(Fig. 14)

6) On the left belt end insert a smooth loop and a "D" ring about 15cm from the backplate

(Fig. 15) and (Fig. 16). Insert the female attach of the quick release buckle for the left

crotch strap (Fig. 17).

(Fig. 15) (Fig. 16) (Fig. 17)

Page 15

Page15of34

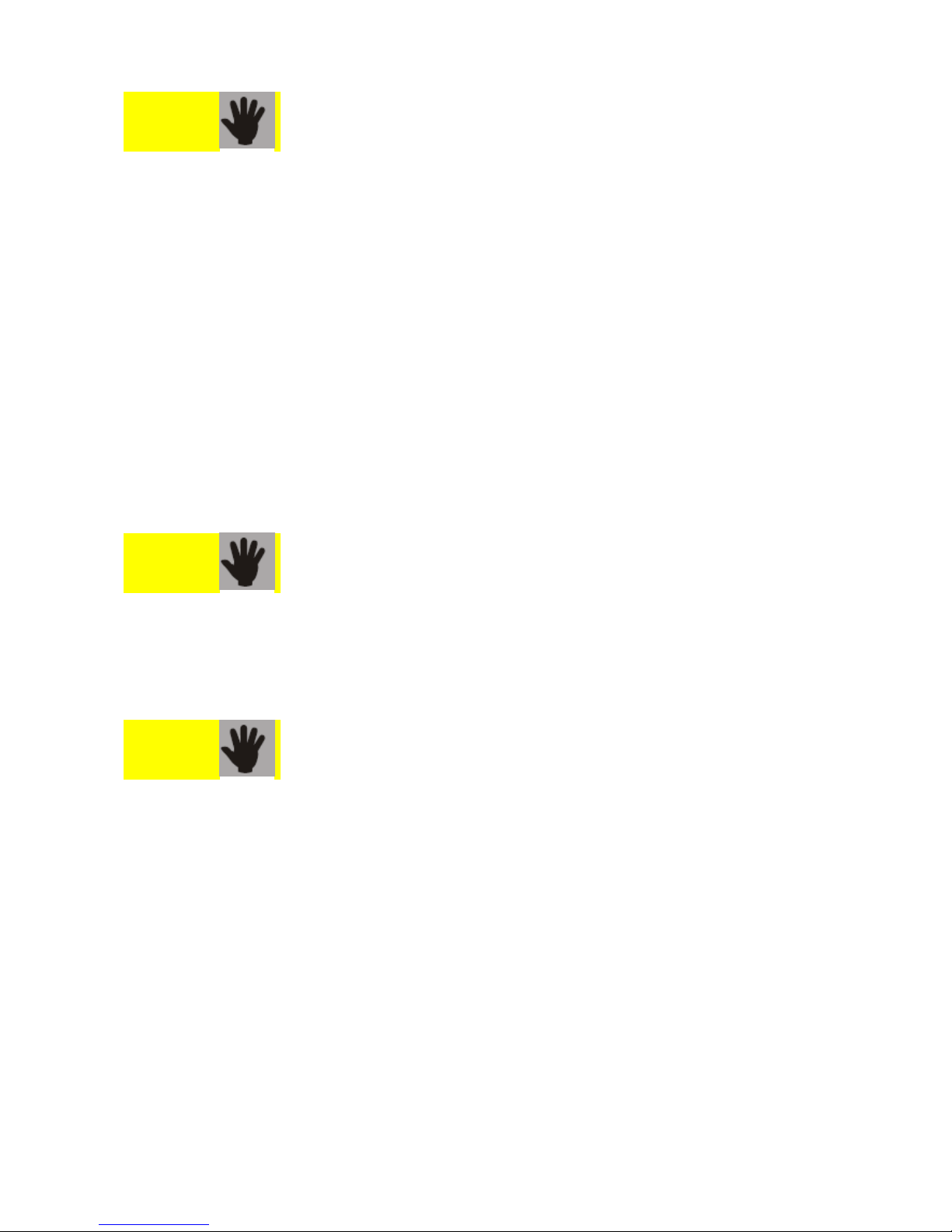

7) Still on the left belt insert the metal buckle passing and passing the belt on the buckle

following the steps illustrated by the following pictures (Fig. 18-23).

(Fig. 18) (Fig. 19) (Fig. 20)

(Fig. 21) (Fig. 22) (Fig. 23)

8) On the right belt end insert a smooth loop and a "D" ring about 15cm from the

backplate (Fig. 24). Insert the female attach of the quick release buckle for the right

crotch strap and lock it with a plastic toothed loop (Fig. 25).

(Fig. 24) (Fig. 25)

Page 16

Page16of34

9) Let's move on to the assembly of the crotch strap. Insert a smooth plastic loop (Fig. 26)

and secure the strap by passing it through the proper slot in the backplate (Fig. 27-29).

Mount the male attach of quick release buckles and insert them into the corresponding

attachments on the belt as shown in the following pictures (Fig. 30) and (Fig. 31).

Be very careful to fit the buckles in the correct direction otherwise they will not

remain in the set position.

(Fig. 26) (Fig. 27) (Fig. 28)

(Fig. 29) (Fig. 30) (Fig. 31)

Page 17

Page17of34

Harness assembly, adjustable type

1) Insert the strap with the eyelet aligned in the upper back part of the backplate (Fig. 33)

and (Fig. 34).

(Fig. 32) (Fig. 33) (Fig. 34)

2) Run the strap through the upper horizontal slots of the backplate (Fig. 35) e (Fig. 36).

(Fig. 35) (Fig. 36)

Page 18

Page18of34

3) Insert a smooth loop and a "D" ring on the right belt (Fig. 37). Repeat the procedure on

the opposite side using the elastic accessory-holder ring (Fig. 38) and insert the elastic

band of retention of the control unit (Fig. 39).

(Fig. 37) (Fig. 38) (Fig. 39)

4) Insert a smooth loop and a "bent D" ring (Fig. 40) on both shoulder straps (Fig. 41);

add two more smooth loops (Fig. 42).

(Fig. 40) (Fig. 41) (Fig. 42)

Page 19

Page19of34

5) Insert a female attach of a quick release buckle onto the right shoulder strap (Fig. 43)

and slide it back into the smooth loop (Fig. 44) e (Fig. 45).

(Fig. 43) (Fig. 44) (Fig. 45)

6) Insert the remaining strap under a "bent D" ring on the right shoulder strap (Fig. 46) so

that it remains locked (Fig. 47). Repeat the same procedure on the left shoulder strap

(Fig. 43-48).

(Fig. 46) (Fig. 47) (Fig. 48)

Page 20

Page20of34

7) Insert a male attach of a quick release buckle onto the belt that connects the right

shoulder strap to the belt (Fig. 49) e (Fig. 50). Pull the strap back from the inside to the

outside of the backrest through the sloped outer slit (Fig. 51).

(Fig. 49) (Fig. 50) (Fig. 51)

8) Insert a toothed loop on the right belt (Fig. 52) and slide it from the outside to the

inside through the sloped outer slit of the backplate (Fig. 53) e (Fig. 54). Repeat the same

procedure on the opposite side (Fig. 49-54).

(Fig. 52) (Fig. 53) (Fig. 54)

Page 21

Page21of34

9) On the right belt end insert a smooth loop and a "D" ring about 15cm from the

backplate (Fig. 56) e (Fig. 57). Insert the female attach of a quick release buckle for the

right crotch strap and lock it with a plastic toothed loop (Fig. 58) and (Fig. 59).

(Fig. 55) (Fig. 56) (Fig. 57)

(Fig. 58) (Fig. 59)

Page 22

Page22of34

10) On the left belt end insert a smooth loop and a "D" ring about 15cm from the

backplate (Fig. 60) e (Fig. 61). Insert the female attach of a quick release buckle for the

left crotch strap (Fig. 62).

(Fig. 60) (Fig. 61) (Fig. 62)

11) Still on the left belt insert the metal buckle passing and passing the belt on the buckle

following the steps illustrated by the following pictures (Fig. 63-68).

(Fig. 63) (Fig. 64) (Fig. 65)

(Fig. 66) (Fig. 67) (Fig. 68)

Page 23

Page23of34

12) Let's move on to the assembly of the crotch strap.

Insert a smooth plastic loop (Fig. 69) and secure the strap by passing it through the

proper slot in the backplate (Fig. 70-72). Mount the male attach of quick release buckles

and insert them into the corresponding attachments on the belt as shown in the following

pictures (Fig. 73) e (Fig. 74) be very careful to fit the buckles in the correct

direction otherwise they will not remain in the set position.

(Fig. 69) (Fig. 70) (Fig. 71)

(Fig. 72) (Fig. 73) (Fig. 74)

Page 24

Page24of34

Assembly of the Single Crotch Strap

On the crotch strap terminal insert a smooth loop and a steel "D" ring (Fig. 75) and pass

the belt through the specific slot in the backplate (Fig. 76).

Insert the belt into the smooth steel loop (Fig. 77) again, fold it and reinsert it once again

into the smooth steel loop (Fig. 78). Fold the belt and fasten it with the supplied rubber

band (Fig. 79).

(Fig. 75) (Fig. 76) (Fig. 77)

(Fig. 78) (Fig. 79)

Page 25

Page25of34

Assembly of the BCD with single cylinder adapter

(N.B. the operation should be performed only after having mounted the harness)

Stainless Steel Version

1) Get a 5 mm Allan Key and a 13 mm wrench (Fig. 80). Use only the material provided in

the assembly kit shown in (Fig. 80) (Long bolt, short bolt, 2 large washers, 2 self-locking

nuts and 4 smooth polyurethane washers)

2) Insert the polyurethane washer onto the long bolt and insert it into the upper hole of

the single-cylinder adapter (Fig. 81) and the Wing (Fig. 82).

(Fig. 80) (Fig. 81) (Fig. 82)

2) Insert the whole in the third hole of the backplate (N.B. pay attention to the

positioning in the correct hole otherwise the Wing will not work in an optimal way) and

apply the polyurethane washer (Fig. 83), then apply the steel washer and tighten the selflocking nut correctly (Fig. 84).

3) Repeat the procedure for the short bolt to be inserted in the lower hole (Fig. 85).

(Fig. 83) (Fig. 84) (Fig. 85)

Page 26

Page26of34

Alluminium version

1) Get a 5 mm Allan Key and a 13 mm wrench (Fig. 86). Use only the material provided in

the assembly kit shown in (Fig. 86) (Long bolt, short bolt, 2 small washers, 2 self-locking

nuts, 4 smooth polyurethane washers and 4 cordura washers).

2) Insert the polyurethane washer onto the long bolt and insert it into the upper hole of

the single-cylinder adapter (Fig. 87) then insert on the opposite side the cordura washer

(Fig. 88).

(Fig. 86) (Fig. 87) (Fig. 88)

2) Insert the whole into the upper hole of the wing (Fig. 89), the applied the cordura

washer (Fig. 90) and insert in the third hole of the backplate (N.B. pay attention to the

positioning in the correct hole otherwise the Wing will not work in an optimal way) and

apply the polyurethane washer (Fig. 91)

(Fig. 89) (Fig. 90) (Fig. 91)

Page 27

Page27of34

3) Apply the steel washer and tighten the self-locking nut correctly (Fig. 92).

4) Repeat the procedure for the short bolt to be inserted in the lower hole (Fig. 93)

(Fig. 92) (Fig. 93)

Example of correct backplate assembly and correct cylinder positioning for

steel versions (Fig. 94 - 95) and aluminium (Fig. 96 - 97)

(Fig. 94) (Fig. 95)

(Fig. 96) (Fig. 97)

Page 28

Page28of34

Assembly of the BCD with double tank

(N.B. the operation should be performed only after having mounted the harness)

1) Place the double tank on a floor with the outlets of the valve upwards; insert the

threaded pins with the free part upwards. (Fig. 98). Put the rear part of the bladder on the

double tank, taking care to insert the pins exactly into the stainless steel eyelets (Fig. 99).

(Fig. 98) (Fig. 99)

2) Place the metal backrest on the bladder inserting the threaded pins into the

appropriate holes and slot. insert the threaded pins in the third hole of the backplate

(N.B. pay attention to the positioning in the correct hole otherwise the Wing will not

work in an optimal way) (Fig. 100). Insert the washers on the threaded pins and lock

tightening the proper nuts (Fig. 101).

(Fig. 100) (Fig. 101)

Page 29

Page29of34

Example of correct backplate assembly and correct double tank positioning

(Fig. 102 - 103)

(Fig. 102) (Fig. 103)

PRE DIVE PREPARATION

The BCD is supplied as accessory with a low pressure hose (LP) with quick release

connection that provides low pressure air to the inflator. The hose must be connected in

one of the low pressure ports (LP) of your regulator.

WARNING :

Use only air to inflate the stabilizing jacket. The use of oxygen-enriched gas

may cause fire and explosion.

KNIGHT DIVERS Ltd always uses hoses certified according to EN 1809, EN 250 and EN

14225-2 standards, with working pressure up to 12 bars; the thread is the standard

3/8"UNF and the quick release can also be operated with thick gloves. The gas flow that

feeds the filling valve is abundant, no pressure drops occur even in conditions of intense

cold.

WARNING :

Never connect a low pressure (LP) hose to a high-pressure (HP) port of your

regulator. If a low pressure hose is connected to high-pressure, may stop

working without warning, causing serious injury to the person.

The first stages of the regulators have the low pressure ports (LP) smaller (3/8" X 24 UNF

thread) then the high pressure ports (HP) (7/16" X 20 UNF thread). In any case, it is

necessary to pay attention to the old regulators in which the HP and LP ports were all the

same. In most cases, the HP ports are marked HP. In any doubtful case, carefully check

output pressure. The maximum pressure of an LP port should be around 14 bars. Use a

common 4mm Allen wrench to remove the low pressure (LP) cap. Once it is localized the

low pressure port and has removed the plug, make sure the O-Ring is present on the hose

and in good condition. Also check the hose to make sure that the threads and O-Rings are

Page 30

Page30of34

free of dirt and debris. Install the threaded portion of the hose in the LP port using a

14mm wrench. Do not over tighten (exactly with a torque of 14.7 Nm).

WARNING :

If the hose supplied with your KNIGHT DIVERS BCD is bent, twisted or forced

when worn, the load valve may not work properly; replace it immediately with

a new hose KNIGHT DIVERS.

We advise you to follow our recommendations described here in order to avoid problems

during the dive.

Before every dive, verify that the rings nuts are firmly screwed on the inflator and the

valve; inflate completely the stabilizing jacket and wait at least 30 minutes to make sure

that it is kept expanded: if it is deflated, do not proceed to the dive before you fix the

problem.

The first step to be taken is to attach the BCD to the cylinder, positioning the cylinder with

the outlet valves facing you, insert the stabilizing jacket, maintaining the rear part of the

backrest in front of the valve. Tighten the band on the cylinder and close the special

buckles; secure any excess strap length using the special strips provided. By tightening

the band on the cylinder while dry you may notice loosening of tension when diving with

consequential slipping of the cylinder. We therefore recommend wetting the bands before

carrying out this operation.

If you use a double tank, follow the instructions on page 28.

Adjust the harness straps according to your size and sort of equipment used. Proper

adjustment will allow you maximum comfort, stability and safety.

At this point, put on the BCD and assume an erect position, lowering the nape of your

neck backwards: if your body position is correct, you should have no problem carrying out

this operation. At the same time, check that the base of the cylinder does not move

downwards excessively, disturbing your movements. We advise you to mark a fixed

reference point on the cylinder- for example, a strip of adhesive tape or painted line - so

that you can always re-assemble your BCD in the correct position.

Page 31

Page31of34

CAUTION :

The Optimal Position is obtained by fixing the cylinder to the BCD in such a way that

the valves are always placed above the upper edge of the Wing (Fig. 104-105) and that

the first stage of the regulator and the various hoses, of low and high pressure, do not

interfere with the free movement of the Wing.

(Fig. 104) (Fig. 105)

Remember that the attachment system is designed to assemble a single cylinder (with a

minimum diameter of 170mm and a maximum of 220mm). You can attach also twin

cylinders (maximum 12 + 12 with a minimum diameter of 170mm) with the appropriate

accessories.

After opening the cylinder valve, connect the quick release attach with the male connector

on the inflator taking between thumb and forefinger the collar of the quick release attach,

slide it back and press down firmly on the male connector of the inflator, then release the

collar. To disconnect the quick release attach simply slide back the collar and the hose will

release automatically.

Arrange the shoulder straps and the belts to the maximum expansion for easy donning.

Slide your arms through the shoulder straps taking care to leave over your shoulder all the

low and high pressure hoses. Inhale deeply and tightened the straps on the shoulders,

chest and abdomen, making it adheres well to the body so it does not hinder or impede

movement or cause any sensation of oppression. Attach the crotch strap to the belt and

proceed to wear the ballast belt.

Page 32

Page32of34

WARNING :

If you use a ballast belt, remember to place it above the crotch strap so that, in

an emergency, it can be quickly abandoned without getting caught in the

straps. Failure to observe this precaution could result in serious injury to the

diver.

Be careful, always partially deflate the stabilizing jacket before entering the water to

compensate for any additional weight.

Start the dive deflating the bag using:

Option 1 – put the inflator over your shoulders and press the exhaust button on the

top (slow discharge)

Option 2 – upside down, pull the knob on the cord of the pressure relief valve

(rapid discharge).

Once you start the descent, the speed tends to increase: short bursts of load button

allows you to adjust it. To the desired depth, by the load button, always established

neutral buoyancy with small inputs and calibrated air.

During the ascent, maintain a slightly negative attitude to earn the surface.

WARNING :

Improper use of the inflator can cause you to lose rapidly buoyancy and uncontrolled

ascents and descents, with serious consequences. In surface inflate the stabilizing jacket

to have a positive attitude; to undress the jacket open or loosen the abdominal buckle and

the crotch strap.

WARNING :

The stabilizing jacket is used to compensate underwater trim, cannot be used to lift heavy

objects from the bottom since this could cause uncontrolled ascents with serious

consequences.

Page 33

Page33of34

MAINTENANCE ROUTINE

All KNIGHT DIVERS BCD are manufactured and individually tested with strict criteria of

quality control. The proper maintenance of your stabilizing jacket will be extremely useful

to extend its life.

When you finish diving for the day, rinse thoroughly with fresh water both the external

and the internal face. To do this, enter the fresh water through the drain button air of the

inflator, then flip the jacket and empty it by pressing the same exhaust button. Rinse

carefully the drain and load valves. Dry the valves with compressed air after rinsing. Let

the jacket dry in the shade. Do not put the jacket with objects that could puncture or

damage the bladder, avoid contact with solvents, oils, gasoline. Put the jacket perfectly

dry, partially inflated, in a cool and airy place. Pay particular attention to the valves.

WARNING :

The valves of the stabilizing jacket must be cleaned after each use exactly as

your regulator. The load valve may be sticky due to the accumulation of salt.

The exhaust valves may be clogged due to deposits of salt or limestone inside

the mechanism.

CAUTION :

Do not hang your stabilizing jacket in full sun.

STORAGE OF THE STABILIZING JACKET

Proper storage will extend the life of your stabilizing jacket. Keep it in a cool, dry place

and away from direct sunlight. The place of storage should be free of ozone generators,

such as electrical machinery or gas.

The User Manual for Knight Divers BCD can be downloaded from

www.knightdivers.eu

WARRANTY

All KNIGHT DIVERS BCD are covered by a 2 year warranty period against manufacturing

defects.

Page 34

Page34of34

Loading...

Loading...