Knick Stratos Pro A4..MSPH series, Stratos Pro A411N-MSPH, Stratos Pro A401N-MSPH Instruction Manual

www.knick.de

Latest Product Information:

Stratos®Pro A4... MSPH

Instruction Manual

2

Warranty

Warranty

Defects occurring within 3 years from delivery date shall be remedied

free of charge at our plant (carriage and insurance paid by sender).

Sensors, ttings, and accessories: 1 year.

Subject to change without notice.

Return of Products Under Warranty

Please contact our Service Team before returning a defective device.

Ship the cleaned device to the address you have been given.

If the device has been in contact with process uids, it must be

decontaminated/disinfected before shipment. In that case, please

attach a corresponding certi cate, for the health and safety of our

service personnel.

Disposal

Please observe the applicable local or national regulations concerning

the disposal of “waste electrical and electronic equipment”.

3

Documents Supplied

Stratos® Pro A411/A211 pH

QuickStart

Other languages: www.knick.de

Short Instructions ............................3

Kurzübersicht .................................15

Quick Start ......................................27

Быстрый старт .............................. 39

Inicio rápido ...................................51

Início rápido ...................................63

快速启动 ........................................75

CD-ROM

Complete documentation:

• Instruction manuals

• Safety instructions

• Short instructions

Safety Information

In o cial EU languages and others.

• ATEX / IECEX / FM / CSA

• EC Declarations of Conformity

Short Instructions

In German, English, French, Russian,

Spanish, Portuguese, Swedish, and Dutch.

More languages on CD-ROM and

on our website: www.knick.de

• Installation and commissioning

• Operation

• Menu structure

• Calibration

• Error messages and recommended actions

Stratos® Pro Series

Safety Instructions

www.knick.de

Speci c Test Report

4

Contents

Documents Supplied ..................................................................... 3

Introduction .................................................................................... 7

Intended Use ....................................................................................................7

Safety Information ......................................................................... 8

Safety Precautions for Installation ...........................................................9

Registered Trademarks ................................................................................. 9

Overview of Stratos Pro A4... MSPH..........................................10

Assembly ........................................................................................ 11

Package Contents .........................................................................................11

Mounting Plan, Dimensions .....................................................................12

Pipe Mounting, Protective Hood ............................................................13

Panel Mounting .............................................................................................14

Installation ..................................................................................... 15

Installation Instructions .............................................................................15

Rating Plates / Terminal Assignments...................................................16

Power Supply, Signal Lines .......................................................................17

Sensor Connection ......................................................................................18

Wiring Examples ...........................................................................................19

Protective Wiring of Relay Contacts ......................................................22

User Interface, Keypad ................................................................24

Display ............................................................................................ 25

Signal Colors (Display Backlighting) ......................................................25

Measuring Mode...........................................................................26

Selecting the Mode / Entering Values ......................................27

Operating Modes ..........................................................................28

Menu Structure of Modes and Functions ............................................29

HOLD Mode ....................................................................................................30

Alarm .................................................................................................................31

Configuration ................................................................................32

Menu Structure of Configuration ...........................................................32

5

Contents

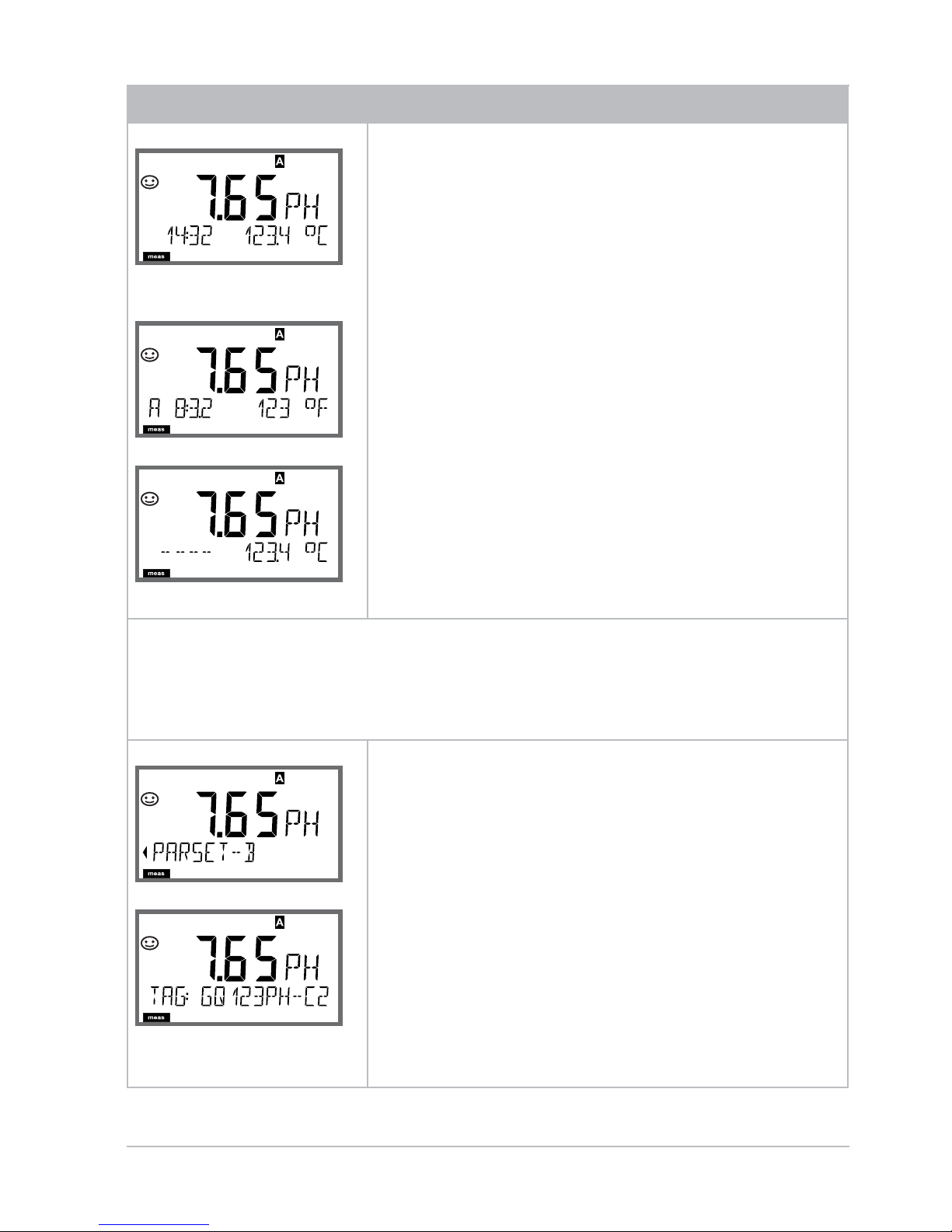

Parameter Set Selection ..............................................................34

Parameter Set A/B ........................................................................................34

Configuration ................................................................................35

Configuration (Original for Copy) ...........................................................39

Sensor ...............................................................................................................42

Current Output 1 ..........................................................................................50

Current Output 2 ..........................................................................................56

Temperature Compensation ....................................................................58

Alarm .................................................................................................................60

Limit Function ................................................................................................62

Pulse Length / Pulse Frequency Controller.........................................71

Controller .......................................................................................................72

WASH Contact ...............................................................................................76

Time and Date ...............................................................................................78

Tag Number ...................................................................................................78

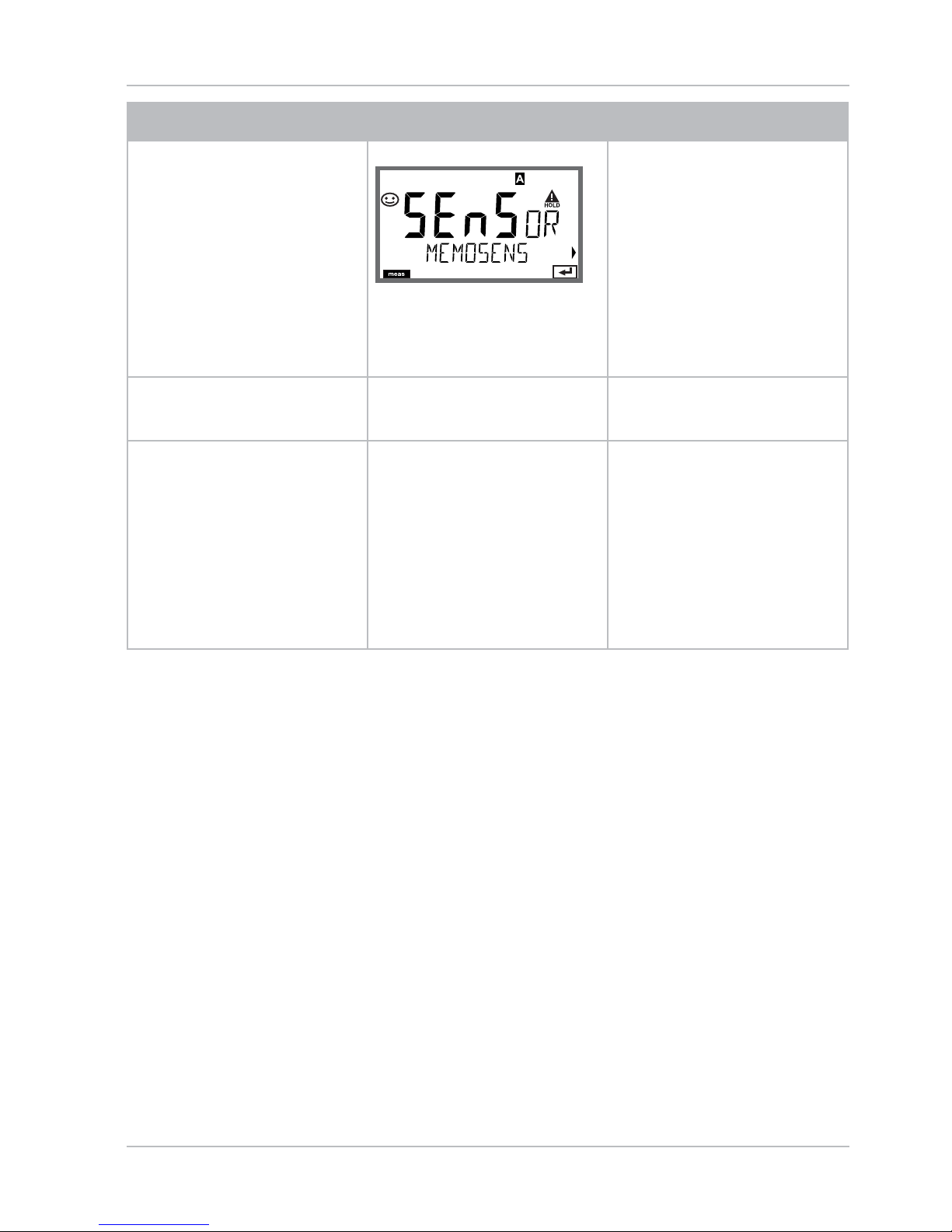

Digital Sensors ..............................................................................80

Operation ........................................................................................................80

Connecting a Digital Sensor .....................................................................81

Sensor Replacement ...................................................................................82

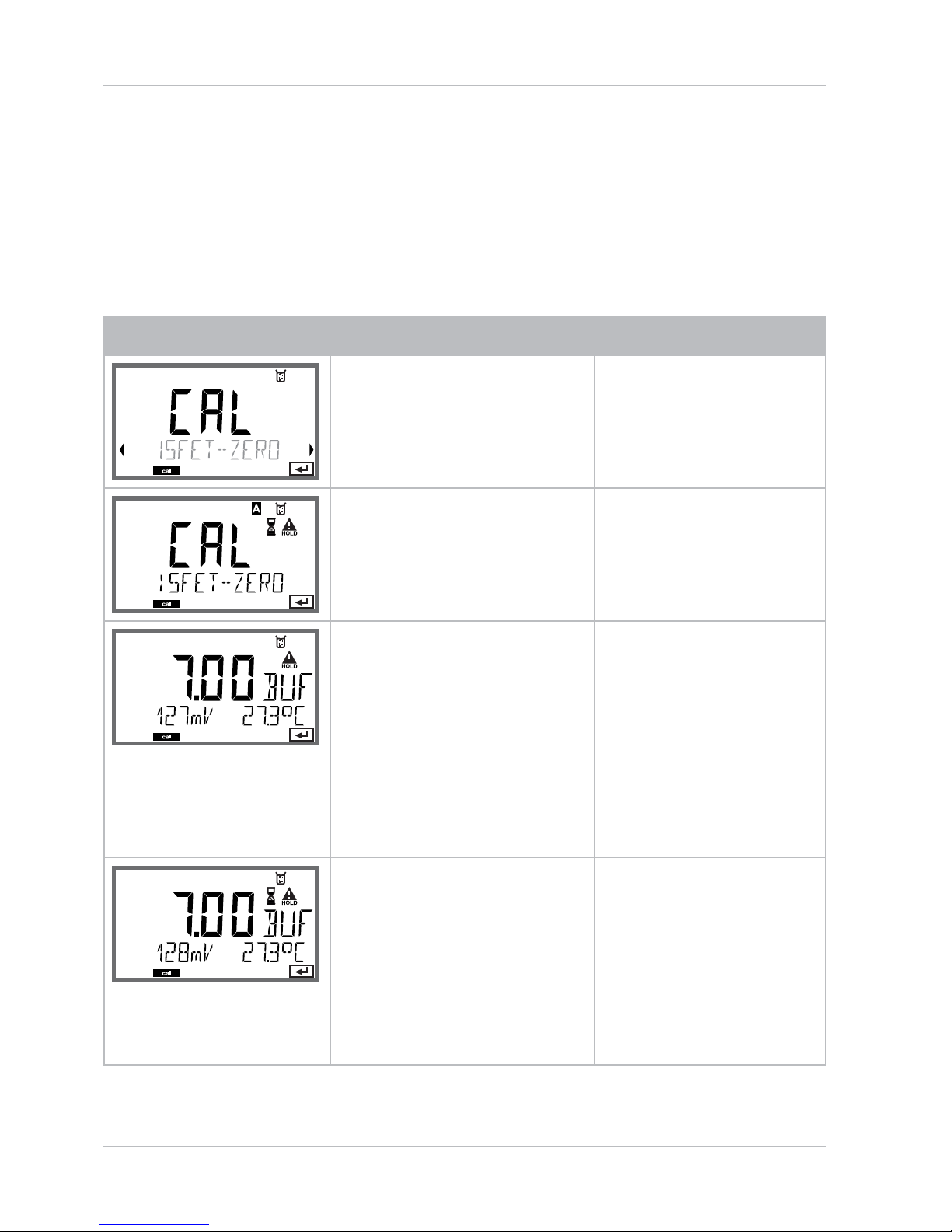

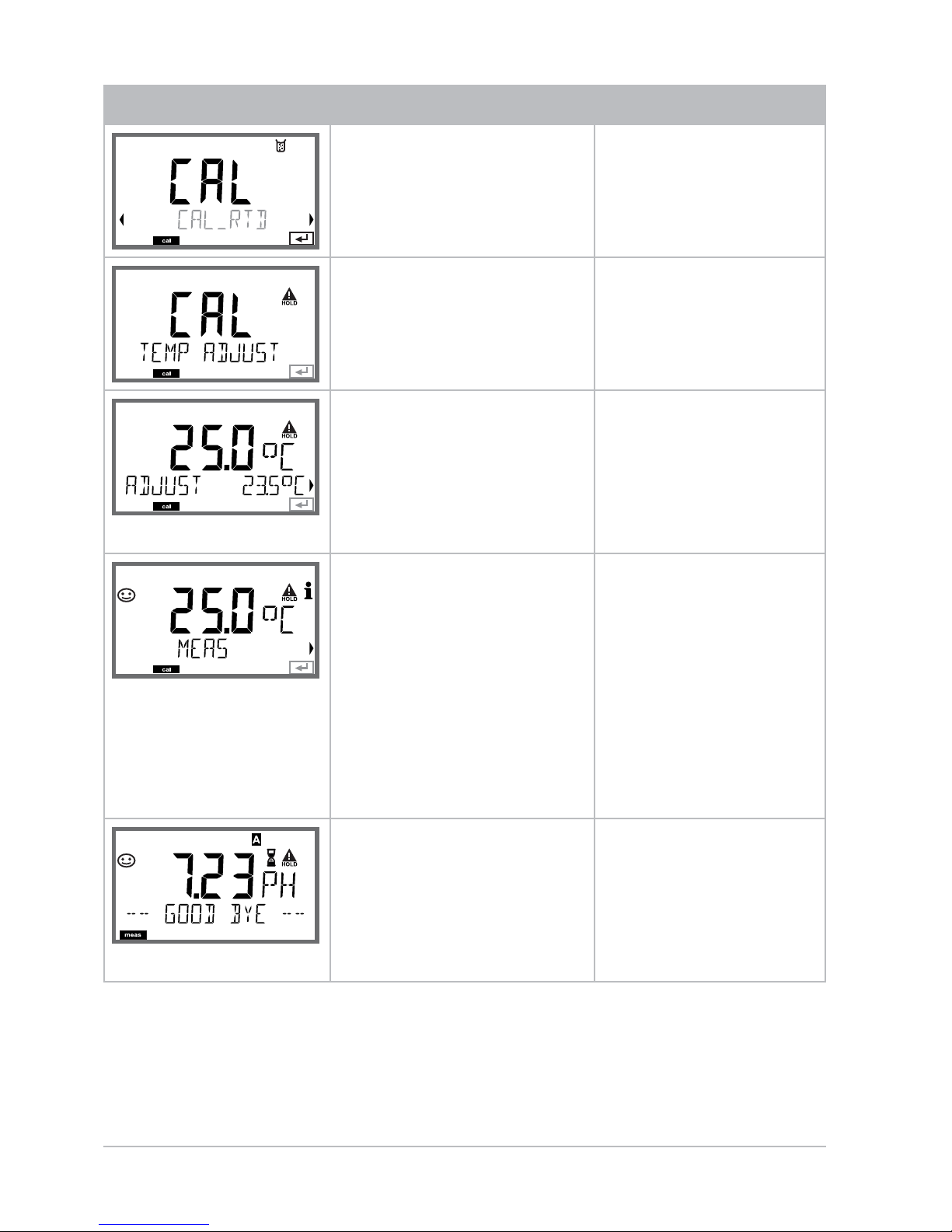

Calibration .....................................................................................84

Selecting a Calibration Mode ..................................................................85

Zero Adjustment (ISFET) ............................................................................86

Automatic Calibration (Calimatic) ..........................................................88

Manual Calibration with Buffer Entry ...................................................90

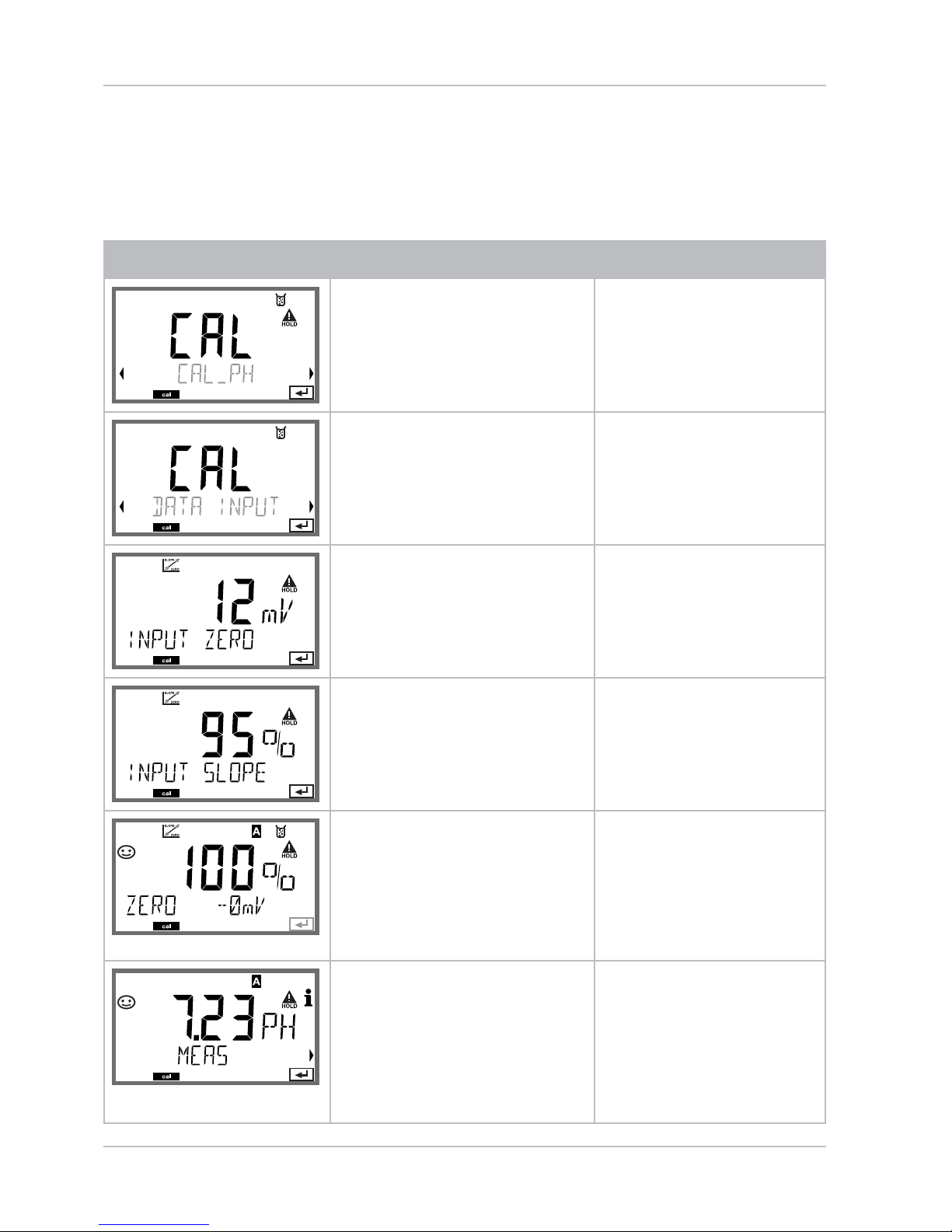

Data Entry of Premeasured Sensors ......................................................92

Product Calibration (pH) ............................................................................94

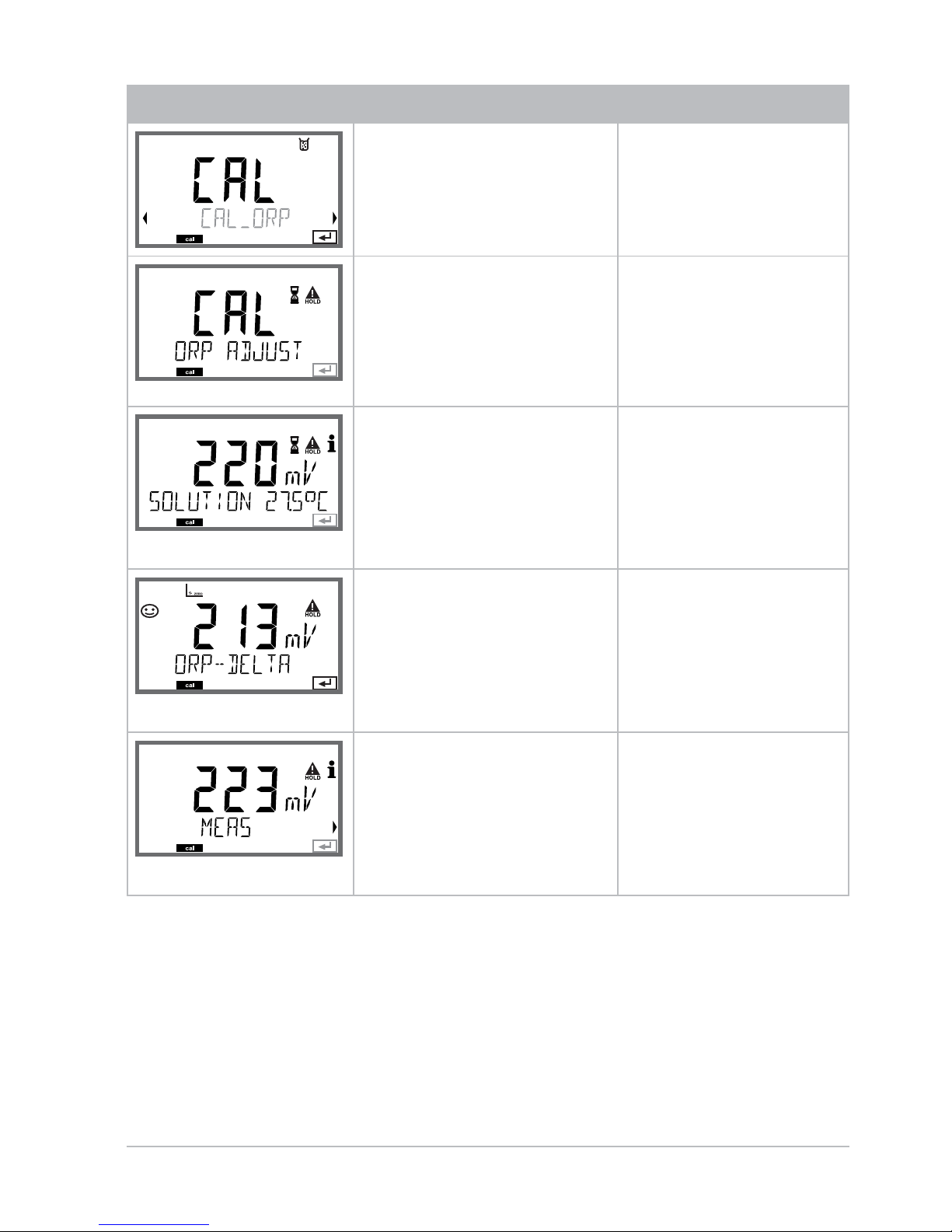

ORP ( Redox) Calibration ...........................................................................96

Temp Probe Adjustment ............................................................................98

Measurement ................................................................................99

Diagnostics ..................................................................................101

Service ..........................................................................................106

Operating States .........................................................................110

6

Contents

Product Line and Accessories ..................................................112

Specifications ..............................................................................113

Buffer Tables ................................................................................120

-U1- Specifiable Buffer Set .....................................................................129

Error Handling .............................................................................132

Error Messages ............................................................................133

Sensoface .....................................................................................136

FDA 21 CFR Part 11 ....................................................................139

Electronic Signature – Passcodes ........................................................139

Audit Trail ..................................................................................................... 139

Index .............................................................................................140

Passcodes .....................................................................................148

7

Introduction

Intended Use

The Stratos Pro A4... MSPH is used for pH/mV, ORP, and temperature

measurement in industry, environment, food processing, and sewage

treatment.

The sturdy molded enclosure can be xed into a control panel or

mounted on a wall or at a post. The protective hood, which is available as accessory, provides additional protection against direct

weather exposure and mechanical damage.

The device has been designed for digital sensors.

Plain-text messages in a large, backlit display allow intuitive operation. The colored display backlighting signals alarm messages (red) or

HOLD mode (orange).

The “Sensocheck“ automatic monitoring of glass and reference electrode and the “Sensoface“ function for clear indication of the sensor

condition provide excellent diagnostics. The internal logbook (TAN

SW-A002) can handle up to 100 entries – up to 200 with AuditTrail

(TAN SW-A003).

The device provides two parameter sets which can be switched

manually or via a control input for di erent process adaptations or

di erent process conditions (e.g. beer and CIP).

Password protection for granting access rights during operation can

be con gured.

Two oating, digital control inputs (“Hold“ and “Control“) are available

for external control.

The internal PID process controller can be con gured as pulse length

or pulse frequency controller.

The device provides two current outputs (for transmission of measured value and temperature, for example) and four oating relay

contacts. A time-controlled cleaning function can be con gured.

Current is provided through a universal power supply 24 ... 230 V AC/

DC, AC: 45 ... 65 Hz.

Approvals for Measurement in Hazardous Locations:

Stratos Pro A4...B MSPH: acc. to FM and CSA in Class I Div 2 / Zone 2

8

Safety Information

Safety information –

Be sure to read and observe the following instructions!

The device has been manufactured using state of the art technology

and it complies with applicable safety regulations.

When operating the device, certain conditions may nevertheless lead

to danger for the operator or damage to the device.

See also separate document:

“Safety Instructions“. •

(EC Declaration of Conformity, FM, CSA Certi cates)

CAUTION!

Please note:

Before commissioning it must be proved that the device may be connected with other equipment.

Commissioning must only be performed by trained personnel authorized by the operating company! Whenever it is likely that protection

has been impaired, the device shall be made inoperative and secured

against unintended operation.

The protection is likely to be impaired if, for example:

the device shows visible damage•

the device fails to perform the intended measurements•

after prolonged storage at temperatures above 70°C•

after severe transport stresses•

Before recommissioning the device, a professional routine test must

be performed. This test must be carried out at the manufacturer's factory.

9

Safety Information

Safety Precautions for Installation

The • electrical installation shall conform to the national regulations

for electrical installations and/or other applicable national or local

codes or regulations.

The power supply shall be disconnectable from the device by a •

two-poled circuit breaker.

Switch and circuit breaker shall be located in close proximity to the •

equipment and be easily accessible by the OPERATOR.

They shall be marked as disconnect switch for the device.

Be sure to disconnect the mains supply and any relay contacts •

which are connected to separate current sources before starting

maintenance operations.

Approvals for Application in Hazardous Locations

Stratos Pro A4...B MSPH: acc. to FM and CSA in Class I Div 2 / Zone 2

Terminals:

Screw terminal, suitable for single wires / exible leads up to 2.5 mm

2

(AWG 14).

Recommended torque for the terminal screws: 0,5 ... 0,6 Nm.

Further Information on Installation in Hazardous

Locations:

See also separate “Safety Instructions“ document.

Registered Trademarks

The following names are registered trademarks. For practical reasons

they are shown without trademark symbol in this manual.

Stratos

®

Sensocheck

®

Sensoface

®

Calimatic

®

GainCheck

®

InPro® is a registered trademark of Mettler-Toledo.

HART® is a registered trademark of the HART Communication

Foundation.

10

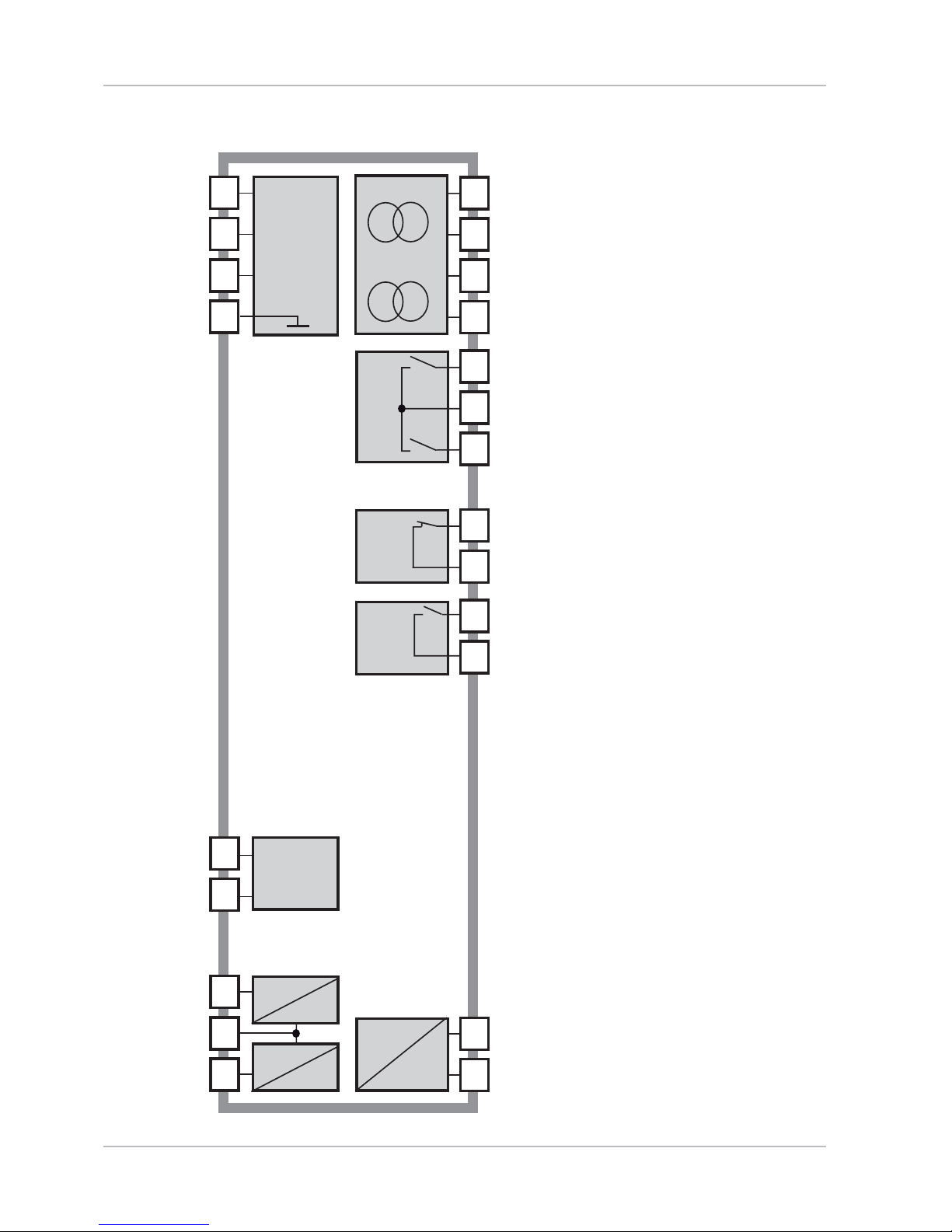

Overview

Overview of Stratos Pro A4... MSPH

7

8

14

15

16

17

18

19

20

21

22

10

9

5

6

11

12

13

Output 1

Input +

Input –

HOLD

HOLD /

CONTROL

CONTROL

+ Output 1 / HART

– Output 1 / HART

+ Output 2

– Output 2

REL 1

REL 2

REL 1/2

Alarm

Alarm

Wash

Wash

Power

Power

HOLD

Input

Input

Control

Output 2

R1

R2

Alarm

R3

R4

Wash

Power

1

2

3

4

RS 485

Power supply

RS 485 A

RS 485 B

GND/Shield

11

Assembly

Package Contents

Check the shipment for transport damage and completeness!

The package should contain:

Front unit, rear unit, bag containing small parts•

Specific t

est r

eport•

Documentation (cf Pg 3)•

CD-ROM•

Fig.: Assembling the enclosure

Jumper (3 x)1)

W

asher (1 x), f

or conduit 2)

mounting: Place washer

between enclosure and nut

Cable tie (3 x)3)

Hinge pin (1 x), insertable 4)

from either side

Enclosure screw (4 x)5)

Sealing insert (1 x)6)

Rubber reducer (1 x)7)

Cable gland (3 x)8)

Filler plug (3 x)9)

Hexagon nut (5 x)10)

Sealing plug (2 x), for sealing 11)

in case of wall mounting

11

10

9

8

76 5

4

1

2

3

12

Assembly

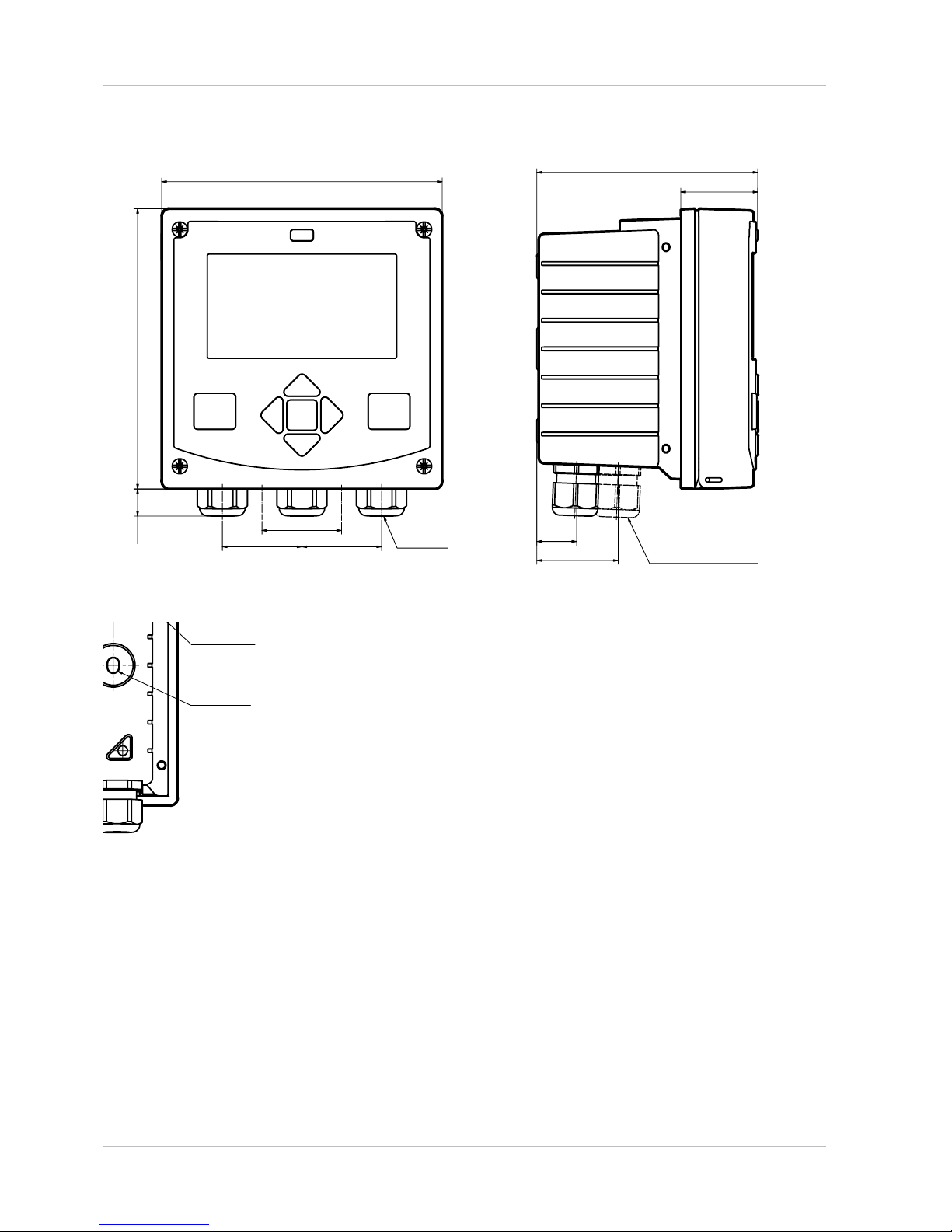

Mounting Plan, Dimensions

Fig.: Mounting plan (All dimensions in mm!)

Cable gland (3 x)1)

Knockouts for cable gland or 2)

½" conduit,

21.5 mm dia. (2 knockouts)

Conduits not included!

Knockout for pipe mounting 3)

(4 x)

Knockout for wall mounting 4)

(2 x)

148

148

42

42

42

14

117

41

21

43

1

2

34

80

74

6,2

4

3

13

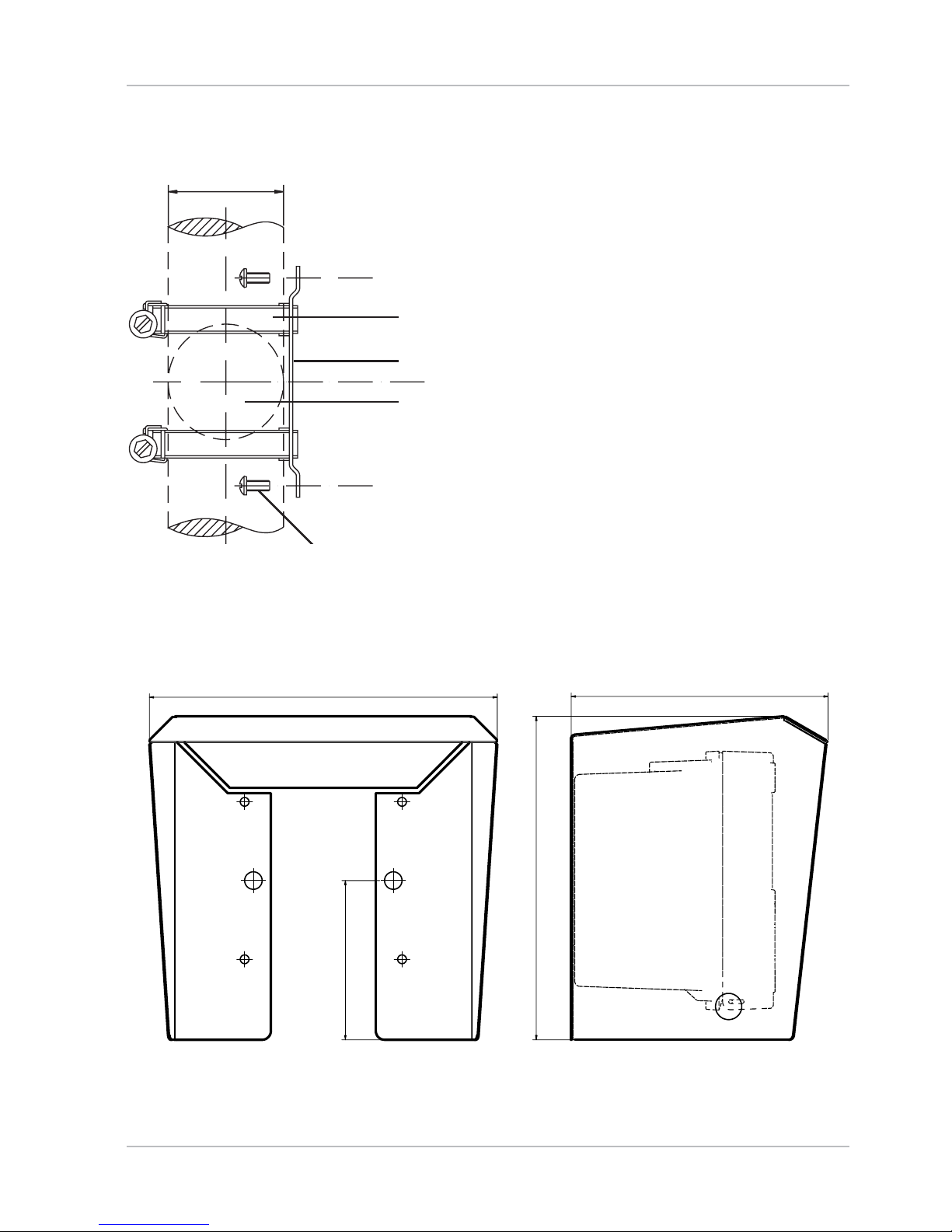

Assembly

Pipe Mounting, Protective Hood

Fig.: ZU 0737 protective hood for wall and pipe mounting

(All dimensions in mm!)

Fig.: ZU 0274 pipe-mount kit (All dimensions in mm!)

147199

91

185

1

2

3

4

Hose clamp with worm gear 1)

drive to DIN 3017 (2 x)

Pipe-mount plate (1 x)2)

For vertical or horizontal posts 3)

or pipes

Self-tapping screw (4 x)4)

ø40...ø60

14

Assembly

Panel Mounting

Fig.: ZU 0738 panel-mount kit (All dimensions in mm!)

Circumferential sealing 1)

(1 x)

S

cr

ew (4 x)2)

Position of control panel3)

Span piece (4 x)4)

Threaded sleeve (4 x)5)

Cutout

138 x 138 mm (DIN 43700)

<30 76 31

1...22

1

2345

15

Installation

Installation Instructions

Installation of the device must be carried out by trained experts in •

accordance with this instruction manual and as per applicable local

and national codes.

Be sure to observe the technical speci cations and input ratings •

during installation!

Be sure not to notch the conductor when stripping the insulation!•

Before connecting the device to the power supply, make sure that •

its voltage lies within the range 24 to 230 V AC/DC!

The supplied current must be galvanically isolated. •

If not, connect an isolator module.

All parameters must be set by a system administrator prior to •

commissioning!

Terminals:

suitable for single wires / exible leads up to 2.5 mm

2

(AWG 14)

Additional safety precautions have to be taken for operation

in hazardous locations

FM, CSA Cl. I Div 2 /

Zone 2!

(See separate “Safety Instructions“ document.)

16

Installation

Rating Plates / Terminal Assignments

Fig.: Terminal assignments of Stratos Pro A4...

Fig.: Stratos Pro A401N-MSPH rating plate at bottom of front

Fig.: Stratos Pro A411N-MSPH rating plate at bottom of front

17

Power Supply, Signal Lines

Connect the power supply for Stratos Pro A401/A411 MSPH

to terminals 21 and 22.

(24 ... 230 V AC, 45 ... 65 Hz / 24 ... 80 V DC)

Assignments

1 (BN) Power suppy

2 (GN) RS 485 A

3 (YE) RS 485 B

4 (WH) GND/shield

5 + input

6 – input

7 + out 2

8 – out 2

9 + out 1/HART

10 – out 1/HART

11 hold

12 hold/control

13 control

14 REL 1

15 REL 1/2

16 REL 2

17 alarm

18 alarm

19 wash

20 wash

21 power

22 power

Fig.: Terminals, device opened, back of front unit

Areas for placing the

screwdriver to pull out

the terminals

122

18

Connect the sensor lines with the sensor connection

(RS-485, terminals A...K).

Sensor Connection

Sensor connection

RS-485

Areas for placing the

screwdriver to pull out

the terminals

122

Fig.: Terminals, device opened, back of front unit

19

Wiring Examples

Example 1:

Measuring task: pH/ORP, temp, glass impedance, ref. impedance

Sensors ( example): SE 533/1-ADIN (Knick)

Cable (example): CA/003-NAADIN11 (Knick)

Sensor(s) Cable Device

1 2 3 4

3,3 V

RS 485 (A)

RS 485 (B)

GND/shield

Yellow

White/Clear

Shield (blue)

Brown

Green

20

21

1 2 3 4

3,3 V

RS 485 (A)

RS 485 (B)

GND/shield

Wiring Examples

Example 2:

Measuring task: pH/ORP, temp, glass impedance

Sensors (example): SE531/1-NMSN (Knick)

Yellow

White

Shield (clear)

Brown

Green

Sensor(s) Cable Device

22

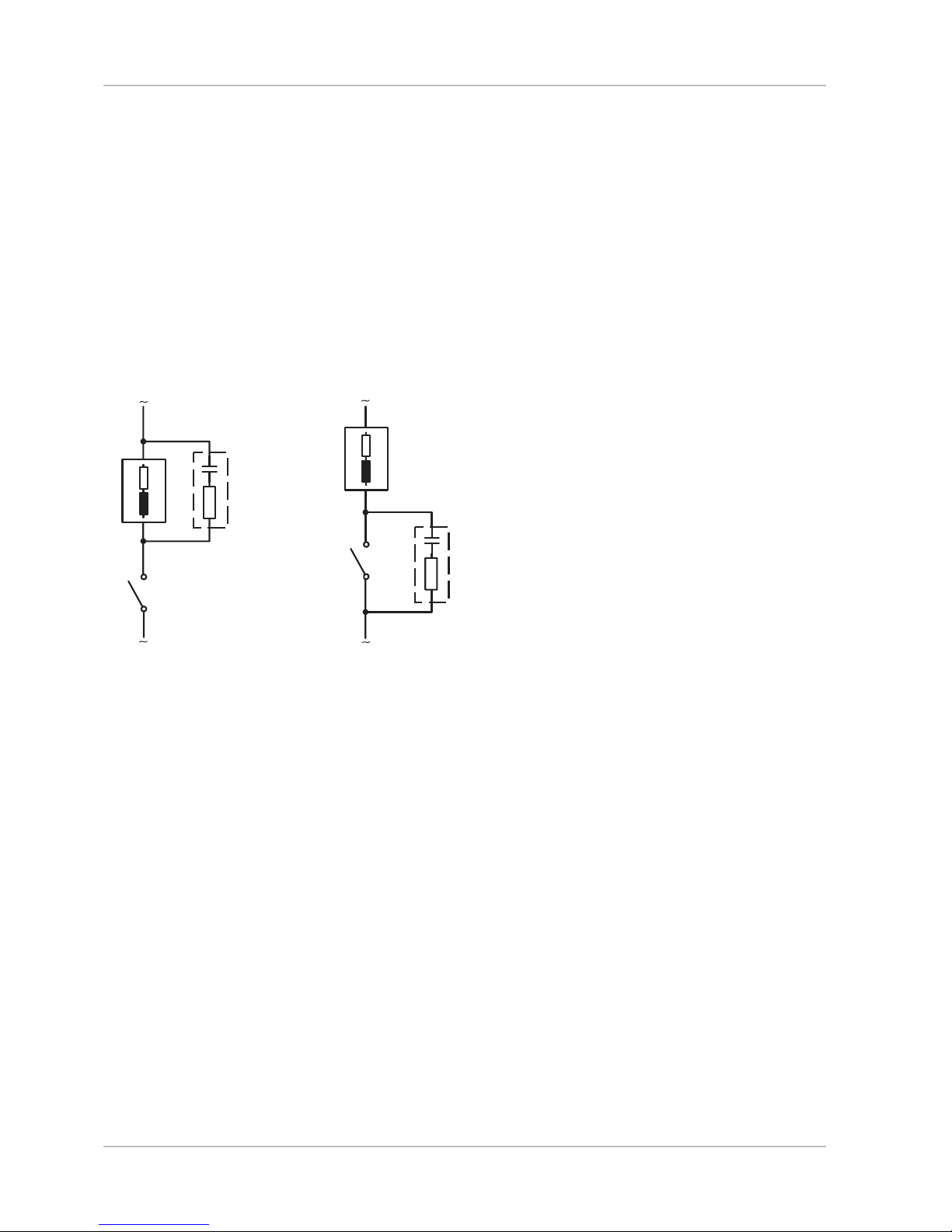

Protective Wiring of Relay Contacts

Protective Wiring of Relay Contacts

Relay contacts are subject to electrical erosion. Especially with

inductive and capacitive loads, the service life of the contacts will be

reduced. For suppression of sparks and arcing, components such as RC

combinations, nonlinear resistors, series resistors, and diodes should

be used.

Typical AC applications

with inductive load

Load1

RC combination,2

e.g. RIFA PMR 209

Typical RC combinations for

230 V AC:

capacitor 0.1 µF / 630 V,

resistor 100 Ω / 1 W

Contact3

1

2

3

1

2

3

23

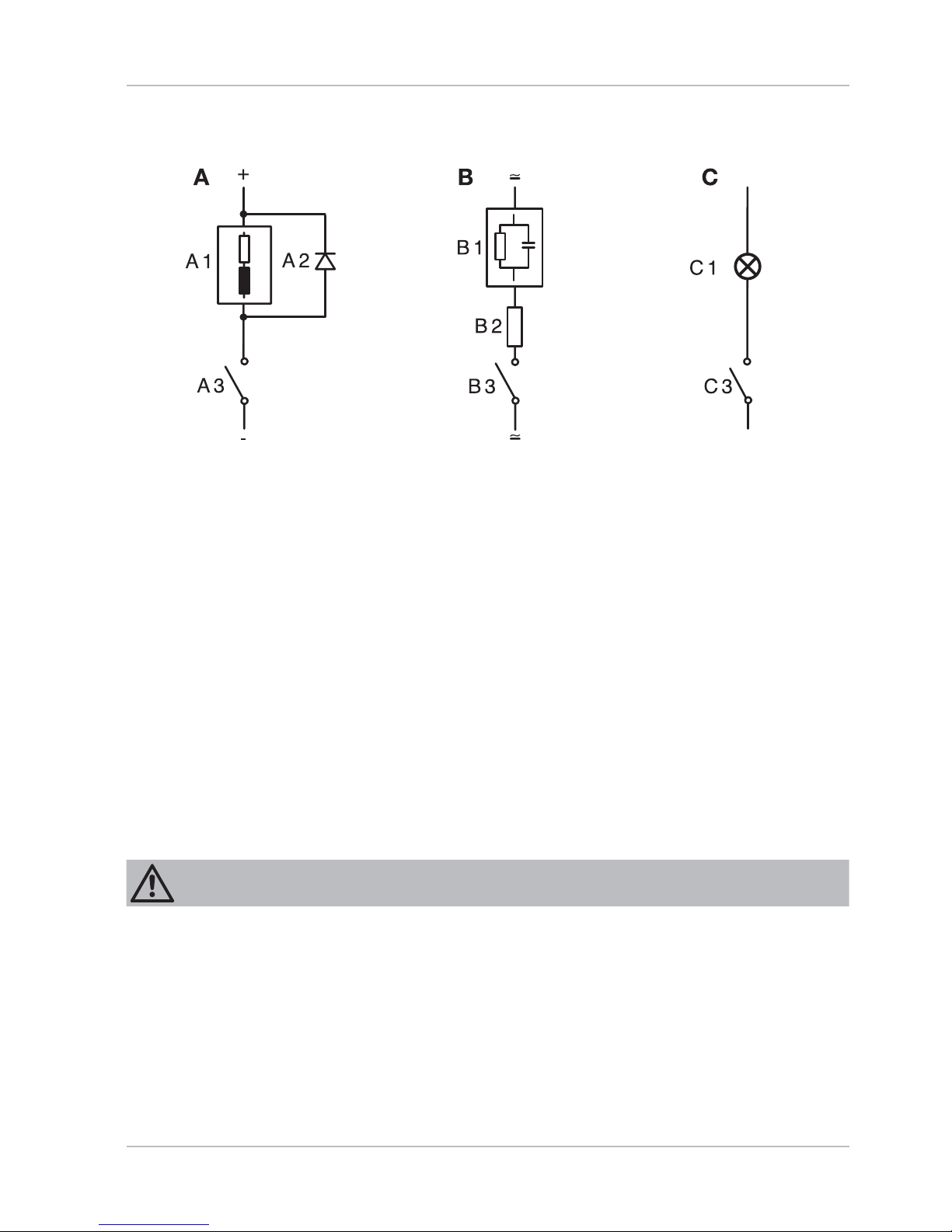

Protective Wiring of Relay Contacts

A: DC application with inductive load

B: AC/DC applications with capacitive load

C: Connection of incandescent lamps

A1 Inductive load

A2 Free-wheeling diode, e.g. 1N4007 (Observe polarity)

A3 Contact

B1 Capacitive load

B2 Resistor, e.g. 8 Ω / 1 W at 24 V / 0.3 A

B3 Contact

C1 Incandescent lamp, max 60 W / 230 V, 30 W / 115 V

C3 Contact

Make sure that the maximum ratings of the relay contacts are not

exceeded even during switching!

Typical Protective Wiring Measures

WARNING!

24

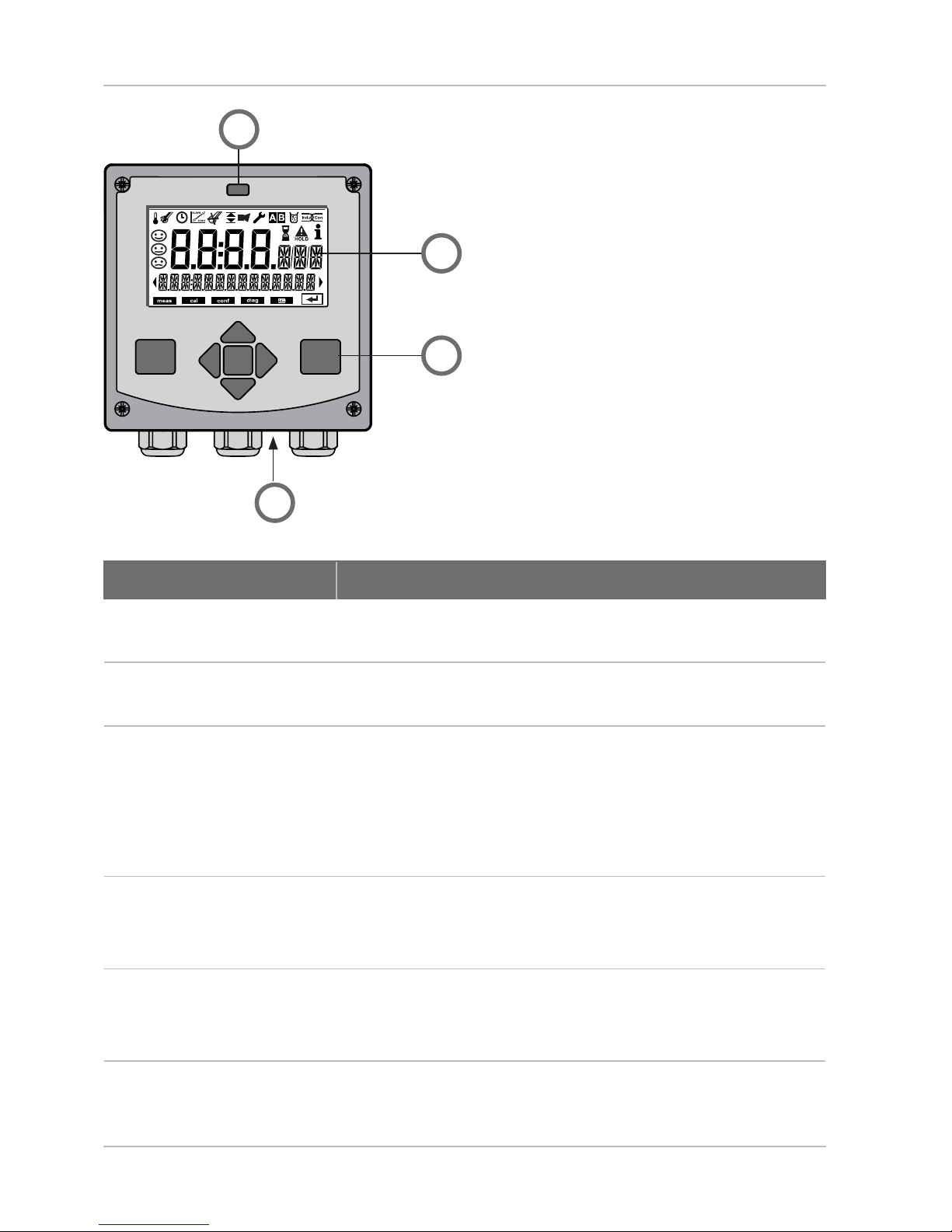

User Interface, Keypad

1 IrDA transmitter/receiver

2 Display

3 Keypad

4 Rating plate (bottom)

Key Function

meas Return to last menu level•

Directly to measuring mode (press > 2 s)•

info Retrieve information•

Show error messages•

enter Con guration: Con rm entries, •

next con guration step

Calibration:•

Continue program ow

Measuring mode: Display output current•

Arrow keys

up / down

Measuring mode: Call menu•

Menu: Increase/decrease a numeral•

Menu: Selection•

Arrow keys

left / right

Measuring mode: Call menu•

Menu: Previous/next menu group•

Number entry: Move between digits•

1

3

4

2

25

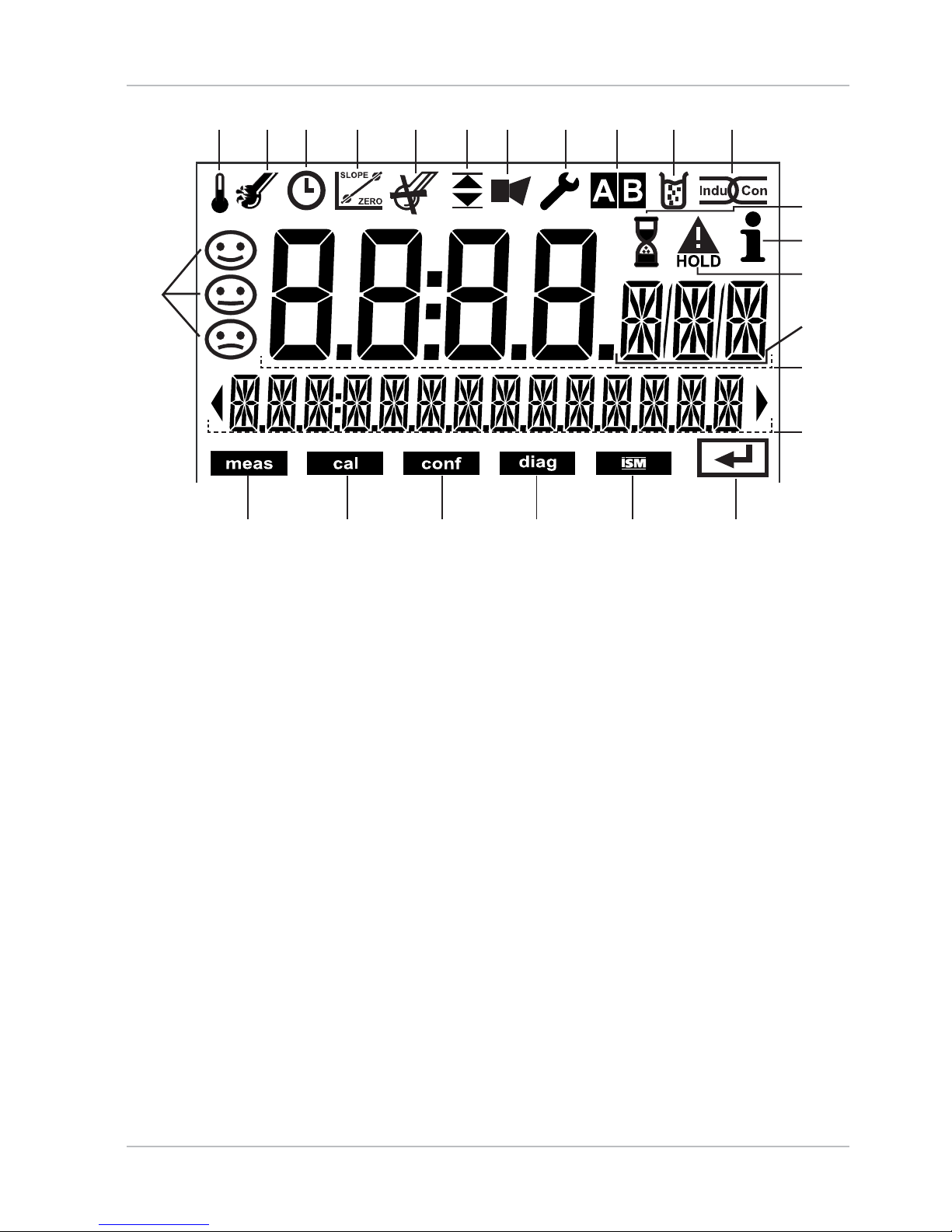

Display

1 Temperature

2 Sensocheck

3 Interval/response time

4 Sensor data

5 Digital sensor devaluated

6 Limit values

7 Alarm

8 Service

9 Parameter sets A/B

10 Calibration

11 Digital sensor

12 Waiting time running

13 Info available

14 HOLD mode active

15 Main display

16 Secondary display

17 Proceed with enter

18 Digital sensor

19 Diagnostics

20 Con guration mode

21 Calibration mode

22 Measuring mode

23 Sensoface

24 Measurement symbol

1234 5 67 891011

171819202122

12

13

14

15

16

23

24

Signal Colors ( Display Backlighting)

Red Alarm

Orange HOLD mode (Calibration, Con guration, Service)

Turquoise Diagnostics

Green Info

Purple Sensoface message

26

Measuring Mode

After the operating voltage has been connected, the device automatically goes to “Measuring“ mode. To call the measuring mode

from another operating mode (e.g. Diagnostics, Service):

Hold meas key depressed (> 2 s).

Process

variable

Temperature

Sensoface indicator

(sensor status)

Time

Mode indicator

(measuring)

Active

parameter set

enter key

In measuring mode the display indicates:

Measured value and time (24/12 h AM/PM) as well as temperature •

in °C or °F (formats selected during con guration)

By pressing the meas key in measuring mode you can view the

following displays (for approx. 60 sec):

Measured value and selection of parameter set A/B •

(if set to “Manual“)

Measured value and tag (point of measurement designation – •

entered during con guration)

Time and date•

Controller (if con gured), upper display: controller output Y,•

lower display: setpoint

Pressing the enter key shows the output currents. They are displayed

as long as enter is held depressed, then the measured-value display

will return after 3 sec.

The device must be con gured for the respective

measurement task!

Hold meas key

depressed to call the

measuring mode

(pressing once more

switches the display)

27

Selecting the Mode / Entering Values

To enter a value:

Select numeral: left / right arrow key5)

Change numeral: up / down arrow key6)

Con rm entry with 7) enter

To select the operating mode:

Hold 1) meas key depressed (> 2 s) (measuring mode)

Press any arrow key: the selection menu appears2)

Select operating mode using left / right arrow key3)

Press 4) enter to con rm the selected mode

Selection menu

Selected mode

(blinks)

1

2

3

4

5

6

7

28

Diagnostics

Display of calibration data, display of sensor data, performing a device

self-test, viewing the logbook entries, display of hardware/software versions of the individual components. The logbook can store 100 events

(00...99). They can be displayed directly on the device. The logbook can

be extended to 200 entries using a TAN (Option).

HOLD

Manual activation of HOLD mode, e.g. for replacing a digital sensor. The

signal outputs adopt a de ned state.

Calibration

Every sensor has typical characteristic values, which change in the

course of the operating time. Calibration is required to supply a correct measured value. The device checks which value the sensor delivers

when measuring in a known solution. When there is a deviation, the device can be “adjusted“. In that case, the device displays the “actual“ value

and internally corrects the measurement error of the sensor. Calibration

must be repeated at regular intervals. The time between the calibration

cycles depends on the load on the sensor. During calibration the device

is in HOLD mode.

During calibration the analyzer remains in the HOLD mode until it is

stopped by the operator.

Con guration

The analyzer must be con gured for the respective measurement

task. In the “Con guration“ mode you select the connected sensor, the

measuring range to be transmitted, and the conditions for warning and

alarm messages. During con guration the device is in HOLD mode.

Con guration mode is automatically exited 20 minutes after the last

keystroke. The device returns to measuring mode.

Service

Maintenance functions (current source, relay test, controller test)

, IrDA

operation, passcode assignment, reset to factory settings, enabling of

options (TAN).

Operating Modes

29

Menu Structure of Modes and Functions

Measuring

mode

TAG display

Manual activation of HOLD mode, e.g. for sensor replacement.

The signal outputs behave as configured (e.g. last measured value, 21 mA)

pH adjustment (as configured)

ORP adjustment

Product calibration

Z

er

o adjustment (for ISFET only)

Adjustment of temperature probe

Configuring parameter set A

Configuring parameter set B

Display of measured values for validation (simulators)

Current source, output 1

Curr

ent source, output 2

Relay test

C

ontr

oller: manual speci cation of controller output

Activating the IrDA interface

Specifying access codes for operating modes

Reset to factory setting

Enabling an option via TAN

Pressing any arrow key opens the selection menu.

S

elec

t the menu group using the left/right arrow keys.

Press enter to open a menu. Press meas to return.

(Access via

code, factory

setting:

5555)

meas

Controller

parameter display

(if configured)

meas

meas

after 60 s after 60 s

Display of calibration data

Display of sensor data

Self test: RAM, ROM, EEPROM, module

100 ev

ents with dat

e and time

Display of measured values (mV_pH, mV_ORP, RTD,

resistances of glass electrode, reference electrode)

Display of software version, model designation, serial number

CLK display

meas

30

HOLD Mode

The HOLD mode is a safety state during con guration and calibration.

Output current is frozen (Last) or set to a xed value (Fix).

Alarm and limit contacts are disabled.

The HOLD mode is indicated by orange display backlighting.

Terminating the HOLD Mode

The HOLD mode is ended by switching to measuring mode (hold

meas key depressed). The display reads “Good Bye“, after that, the

HOLD mode is exited.

When the calibration mode is exited, a con rmation prompt

ensures that the installation is ready for operation

(e.g.: sensor reinstalled, located in process).

HOLD mode, display icon:

HOLD active

21

4

HOLD active

Output current

[mA]

Output signal HOLD

Setting FIX = 21.0 mA

Output signal HOLD

Setting LAST

Output Signal During HOLD:

Output Signal Response

Last:• The output current is frozen at its last value. Recommended

for short con guration procedures. The process should not change

decisively during con guration. Changes are not noticed with this

setting!

Fix:• The output current is set to a value that is noticeably di erent

from the process value to signal the control system that the device

is being worked at.

31

Alarm

Manual Activation of HOLD

The HOLD can be activated manually from the HOLD menu.

This allows checking or replacing a sensor, for example, without

provoking unintended reactions of outputs or contacts.

Press meas key to return to selection menu.

Alarm

When an error has occurred, Err xx is displayed immediately.

Only after expiry of a user-de ned delay time will the alarm be

registered and entered in the logbook.

During an alarm the display blinks, the display backlighting turns red.

Error messages can also be signaled by a 22 mA output current

(see Con guration).

The alarm contact is activated by alarm and power failure, see also

“Con guration / Alarm Settings“.

2 sec after the failure event is corrected, the alarm status will be

deleted.

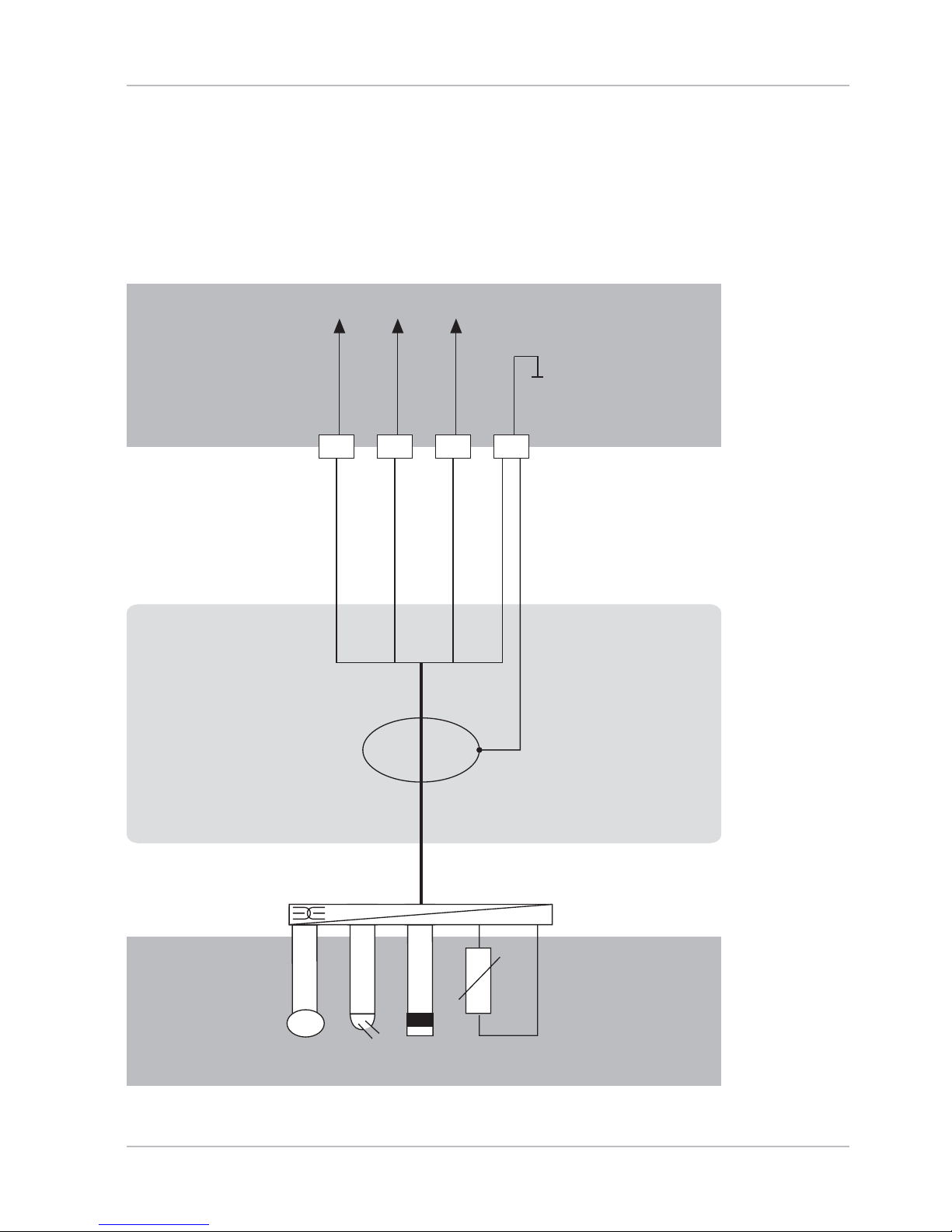

External Activation of HOLD

The HOLD mode can be activated from outside by sending a signal to

the Hold input (e.g. from the process control system).

10

11

Process control system

Power supply

12...24 V AC/DC

Stratos Pro A4...

Input

HOLD

HOLD inactive 0...2 V AC/DC

HOLD active 10...30 V AC/DC

32

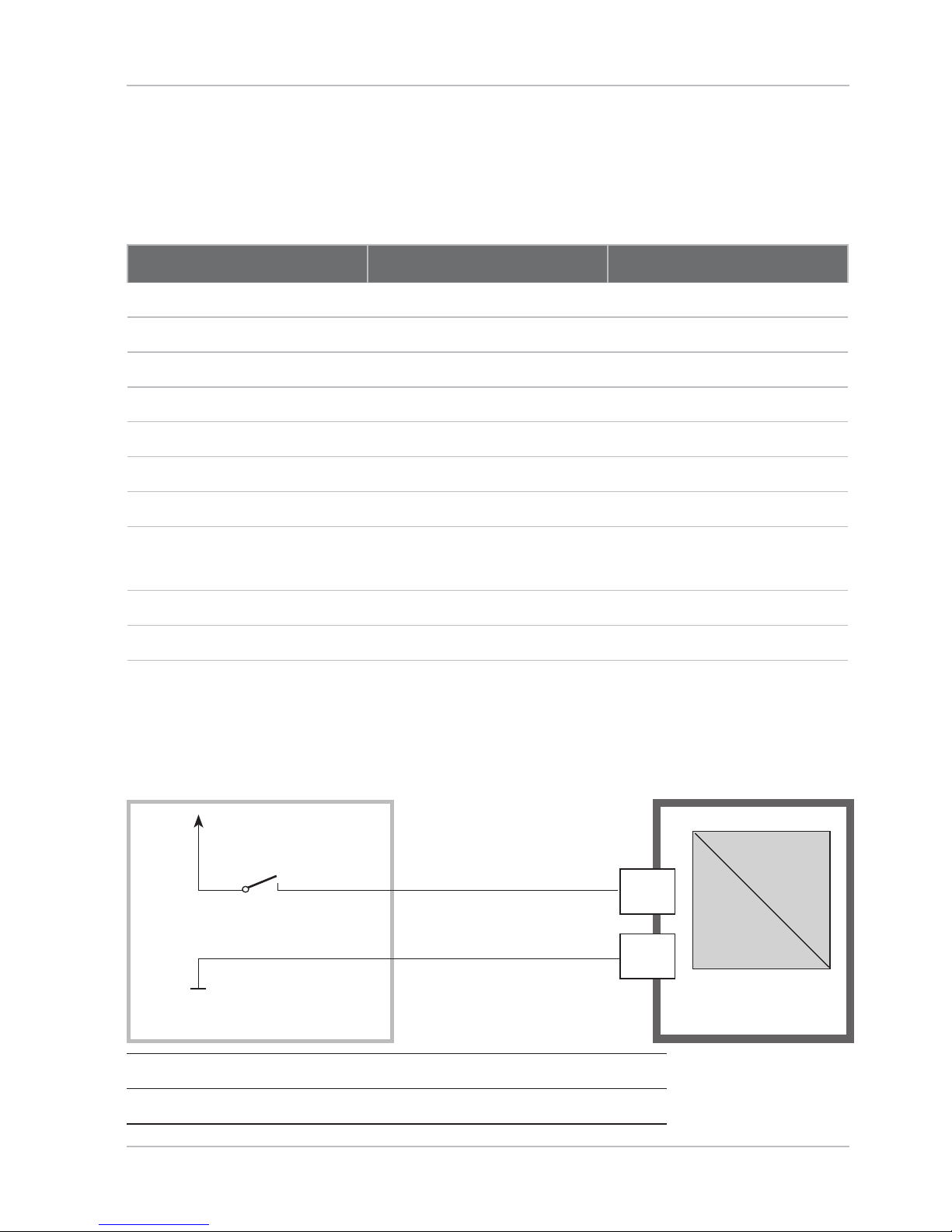

enter

enter

enter

enter

Select menu

group

Menu group Code Display

Select menu

item

Sensor selection SNS:

Menu item 1

...

Menu item ...

Current output 1 OT1:

Current output 2 OT2:

Compensation COR:

Alarm mode ALA:

Relay outputs REL:

Cleaning WSH:

Setting the clock CLK:

Tag number TAG:

Configuration

Menu Structure of Con guration

The device provides 2 parameter sets “A“ and “B“. By switching between the parameter sets you can adapt the device to different measurement situations, for example.

Parameter set “B“ only permits setting of process-related parameters.

The configuration steps are assigned to different menu groups.

Using and you can jump between the individual menu groups.

Each menu group contains menu items for setting the parameters.

Pressing enter opens a menu item.

The values are edited using and . Pressing enter confirms/stores the settings.

Return to measurement: Press meas.

33

Con guration

Parameter Set A/B: Con gurable Menu Groups

(Some parameters are identical in A and B. They are con gured in

parameter set A only.)

Menu group Parameter set A Parameter set B

SENSOR Sensor selection --OUT1 Current output 1 Current output 1

OUT2 Current output 2 Current output 2

CORRECTION Compensation Compensation

ALARM Alarm mode Alarm mode

REL 1/REL 2 Relay outputs Relay outputs

WASH Cleaning --PARSET Parameter set

selection

---

CLOCK Setting the clock --TAG Tag number ---

External Switchover of Parameter Sets A/B

You can switch between parameter sets A and B by applying a signal

to the CONTROL input. For parameter setting, see Pg 38.

12

13

e.g. process control system

Max. 30 V AC/DC

Stratos Pro A4...

input

Control

Parameter set A active 0...2 V AC/DC

Parameter set B active 10...30 V AC/DC

34

19

20

Parameter Set A/B

Manual Selection. Signaling via WASH Contact.

Display Action Remark

To switch between

parameter sets:

Press meas

Manual selection of

parameter sets must have

been preset in CONFIG

mode. Default setting is a

fixed parameter set A.

Wrong settings change

the measurement properties!

PARSET blinks in the

lower line.

Select parameter set

using and keys

Select

PARSET A / PARSET B

Con rm with enter

Cancel with meas

The active parameter set can be

displayed using the WASH contact:

If con gured correspondingly,

the WASH contact signals:

“Parameter set A“ (open contact)

“Parameter set B“ (closed contact)

Wash

W

ash

R4

Wash

Parameter Set Selection

35

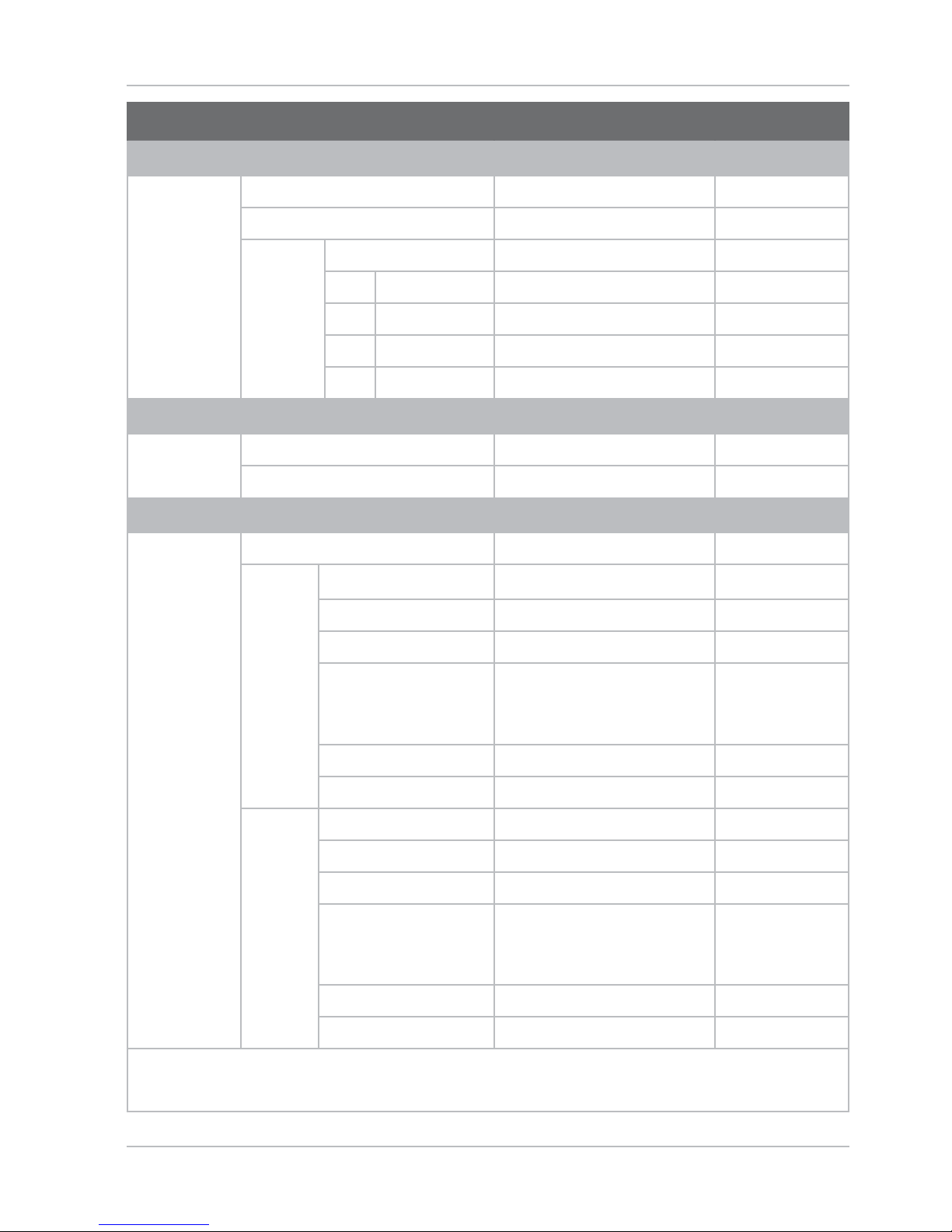

Configuration

Con guration Choices Default

Sensor (SENSOR)

SNS: MEMOSENS

INDUCON

MEMOSENS

TEMP UNIT °C / °F °C

TEMP MEAS AUTO

MAN

EXT

(only if enabled via

TAN)

AUTO

MAN –20...200 °C

(–4...392 °F)

025.0 °C

(077.0 °F)

TEMP CAL AUTO

MAN

EXT

(only if enabled via

TAN)

AUTO

MAN –20...200 °C

(–4...392 °F)

025.0 °C

(077.0 °F)

CAL MODE AUTO, MAN, DAT AUTO

AUTO

BUFFER SET

-00-...-09-, -U1Please note:

Pressing info displays

nominal buffer values

and manufacturers

-00-

U1

(For specifiable

buffer set,

see Appendix:

“Buffer Tables“)

EDIT BUFFER 1 (NO, YES) NO

Enter values for buffer 1

EDIT BUFFER 2 (NO, YES) NO

Enter values for buffer 2

CAL TIMER OFF, FIX, ADAPT OFF

ON CAL-CYCLE 0...9999 h 0168 h

DS

(InduCon)

CIP COUNT ON/OFF OFF

ON CIP CYCLES 0...9999 CYC 0025 CYC

SIP COUNT ON/OFF OFF

ON SIP CYCLES 0...9999 CYC 0025 CYC

36

Con guration

Con guration Choices Default

Output 1 (OUT1)

OT1: RANGE 0–20 mA, 4–20 mA 4-20 mA

CHANNEL PH/ORP/TMP PH

PH BEGIN 4mA (0 mA) –2.00...16 PH 00.00 PH

END 20 mA –2.00...16 PH 14.00 PH

ORP BEGIN 4mA (0 mA) –1999...1999 mV

END 20 mA –1999...1999 mV

TMP

°C

BEGIN 4mA (0 mA) –20...300 °C Select °C/°F

END 20 mA –20...300 °C for “Sensor“

TMP

°F

BEGIN 4mA (0 mA) –4...572 °F

END 20 mA –4...572 °F

FILTERTIME 0...120 SEC 0000 SEC

22mA-FAIL ON/OFF OFF

HOLD MODE LAST/FIX LAST

FIX HOLD-FIX (0) 4...22 mA 021.0 mA

Output 2 (OUT2)

OT2: RANGE 0–20 mA, 4–20 mA 4-20 mA

CHANNEL PH/ORP/TMP TMP

PH BEGIN 4mA (0 mA) –2.00...16 PH 00.00 PH

END 20 mA –2.00...16 PH 14.00 PH

ORP BEGIN 4mA (0 mA) –1999...1999 mV

END 20 mA –1999...1999 mV

TMP

°C

BEGIN 4mA (0 mA) –20...300 °C Select °C/°F

END 20 mA –20...300 °C for “Sensor“

TMP

°F

BEGIN 4mA (0 mA) –4...572 °F

END 20 mA –4...572 °F

FILTERTIME 0...120 SEC 0000 SEC

22mA-FAIL ON/OFF OFF

HOLD MODE LAST/FIX LAST

FIX HOLD-FIX (0) 4...22 mA 021.0 mA

37

Con guration

Con guration Choices Default

Temperature compensation (CORRECTION)

COR: TC LIQUID –19.99...19.99%/K 00.00%/K

TEMP EXT

*

ON/OFF OFF

ON I-INPUT 0...20 mA/4...20 mA 4...20 mA

°C BEGIN 4 mA –20...200 °C 000.0 °C

END 20 mA –20...200 °C 100.0 °C

°F BEGIN 4 mA –4...392 °F 032.0 °F

END 20 mA –4...392 °F 212.0 °F

Alarm (ALARM)

ALA: DELAYTIME 0...600 SEC 0010 SEC

SENSOCHECK ON/OFF OFF

Relay 1/2 (RL1/RL2)

REL: (Selected in text line) LIMITS, CONTROLLER LIMITS

RL1: CHANNEL PH/ORP/TMP PH

FUNCTION Lo LEVL, Hi LEVL Lo LEVL

CONTACT N/O, N/C N/O

LEVEL –2.00...16 PH

(-1999...1999 mV)

(-20...200 °C)

00.00 PH

HYSTERESIS 0...10.00 PH 00.50 PH

DELAYTIME 0...9999 SEC 0010 SEC

RL2 CHANNEL PH/ORP/TMP PH

FUNCTION Lo LEVL, Hi LEVL Hi LEVL

CONTACT N/O, N/C N/O

LEVEL –2.00...16 PH

(-1999...1999 mV)

(-20...200 °C)

14.00 PH

HYSTERESIS 0...10.00 PH 00.50 PH

DELAYTIME 0...9999 SEC 0010 SEC

*) is only displayed if enabled and SENSOR TEMP EXT has been selected.

38

Con guration

Con guration Choices Default

REL: CTR CHANNEL PH/ORP/TMP PH

TYPE PLC / PFC PLC

PLC PULSE LEN 0...0600 SEC 0010 SEC

PFC PULSE FREQ 0...0180 P/M 0060 P/M

SETPOINT –2.00...16 PH

–1500...1500 mV

07.00 PH

DEAD BAND 0...10.00 PH 01.00 PH

P-GAIN 10...9999% 0100%

I-TIME 0...9999 SEC 0000 SEC

D-TIME 0...9999 SEC 0000 SEC

HOLD MODE Y LAST/Y OFF Y LAST

Cleaning contact (WASH)

WSH: (Select text line) WASH

PARSET A/B

WASH

WASH WASH CYCLE 0.0...999.9 h 000.0 h

WASH TIME 0...9999 SEC 0060 SEC

CONTACT N/O, N/C N/O

Parameter set (PARSET)

PAR: Select fixed parameter set

(A) or switch between A/B

via control input or manually in measuring mode

PARSET FIX /

CNTR INPUT /

MANUAL

PARSET FIX

(fixed parameter

set A)

Real-time clock (CLOCK)

CLK: FORMAT 24 h / 12 h

24 h TIME hh/mm 00..23:00...59 00:00

12 h TIME hh/mm 00...11 AM/

PM:00...59

00.00

DAY/MONTH 01...31/01...12 31.12.

YEAR 2000...2099 2006

Tag number (TAG)

TAG: (Input in text line) ___

39

Configuration (Original for Copy)

Two complete parameter sets are stored in the EEPROM.

As delivered, the two sets are identical but can be edited.

Please note:

Fill in your con guration data on the following pages or use them as

original for copy.

Parameter Parameter set A Parameter set B

SNS: Sensor type

---

*)

SNS: Temperature unit

---

SNS: Temp measurement

---

SNS: Manual meas. temp

---

SNS: Calibration temp

---

SNS: Manual cal temp

---

SNS: Calibration mode

---

SNS: Select buffer set

(-U1-, see Appendix)

---

SNS: Calibration timer

---

SNS: Calibration cycle

---

SNS: CIP counter

---

SNS: CIP cycles

---

SNS: SIP counter

---

SNS: SIP cycles

---

OT1: Current range

OT1: Process variable

OT1: Current start

OT1: Current end

*) These parameters cannot be adjusted in parameter set B,

the values are the same as in parameter set A.

40

(Original for Copy) Con guration

Parameter Parameter set A Parameter set B

OT1: Filter time

OT1: 22 mA error current

OT1: HOLD mode

OT1: HOLD-FIX current

OT2: Current range

OT2: Process variable

OT2: Current start

OT2: Current end

OT2: Filter time

OT2: 22 mA error current

OT2: HOLD mode

OT2: HOLD-FIX current

COR: Temp coefficient

COR: Ext. temp input

COR: Current range

COR: Current start

COR: Current end

ALA: Delay

ALA: Sensocheck on/off

REL: Usage

RL1: Process variable

RL1: Function

RL1: Contact response

RL1: Setpoint

RL1: Hysteresis

RL1: Delay

RL2: Process variable

RL2: Function

RL2: Contact response

41

Con guration (Original for Copy)

Parameter Parameter set A Parameter set B

RL2: Setpoint

RL2: Hysteresis

RL2: Delay

CTR: Process variable

CTR: Controller type

CTR: Pulse length

CTR: Pulse frequency

CTR: Setpoint

CTR: Neutral zone

CTR: P gain

CTR: I time

CTR: D time

CTR: HOLD mode

WSH: Usage

---

*)

WSH: Wash cycle

---

WSH: Wash duration

---

WSH: Contact response

---

PAR:

Parameter set

selection

---

CLK: Time format

---

CLK: Time hh/mm

---

CLK: Day/month

---

CLK: Year

---

TAG: Tag number

---

*) These parameters cannot be adjusted in parameter set B,

the values are the same as in parameter set A.

42

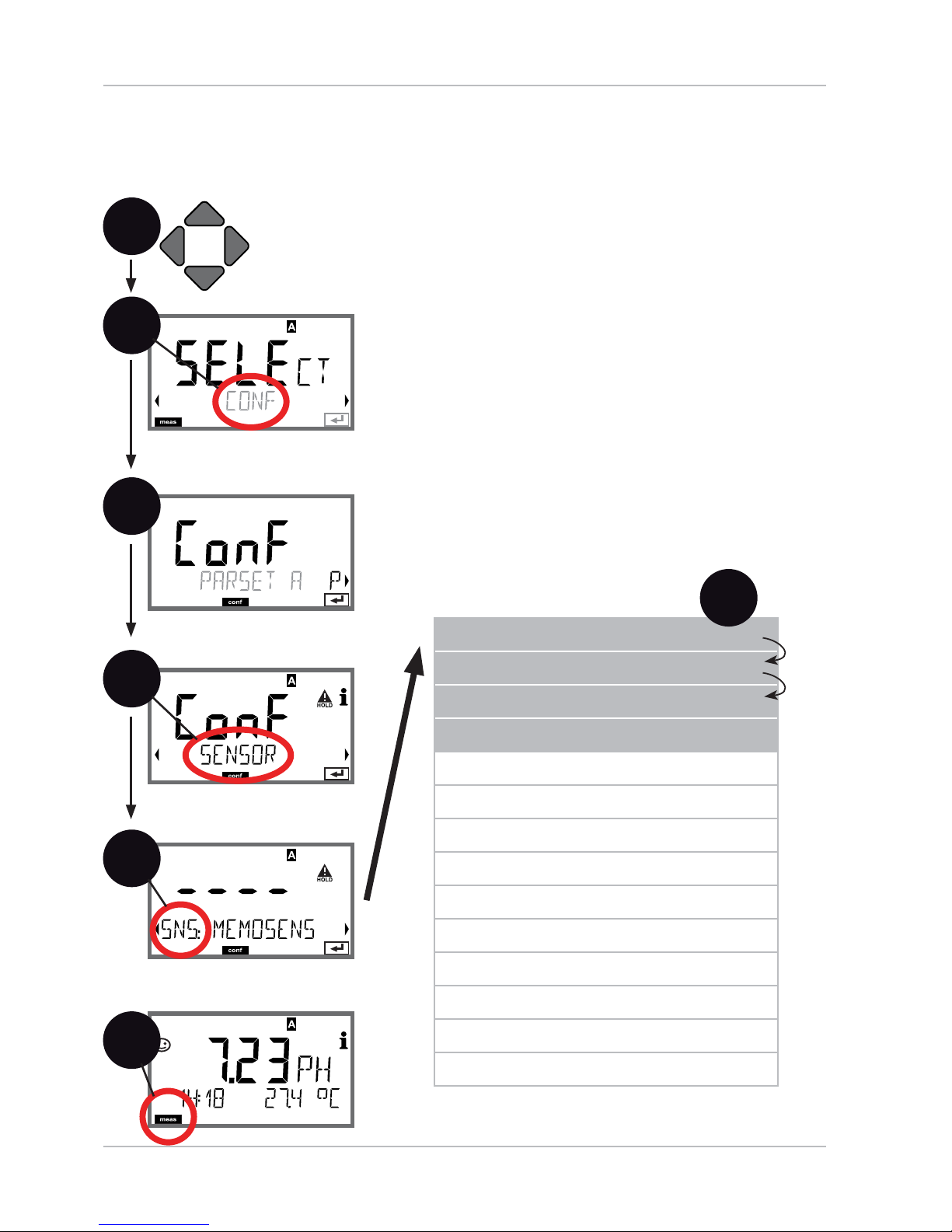

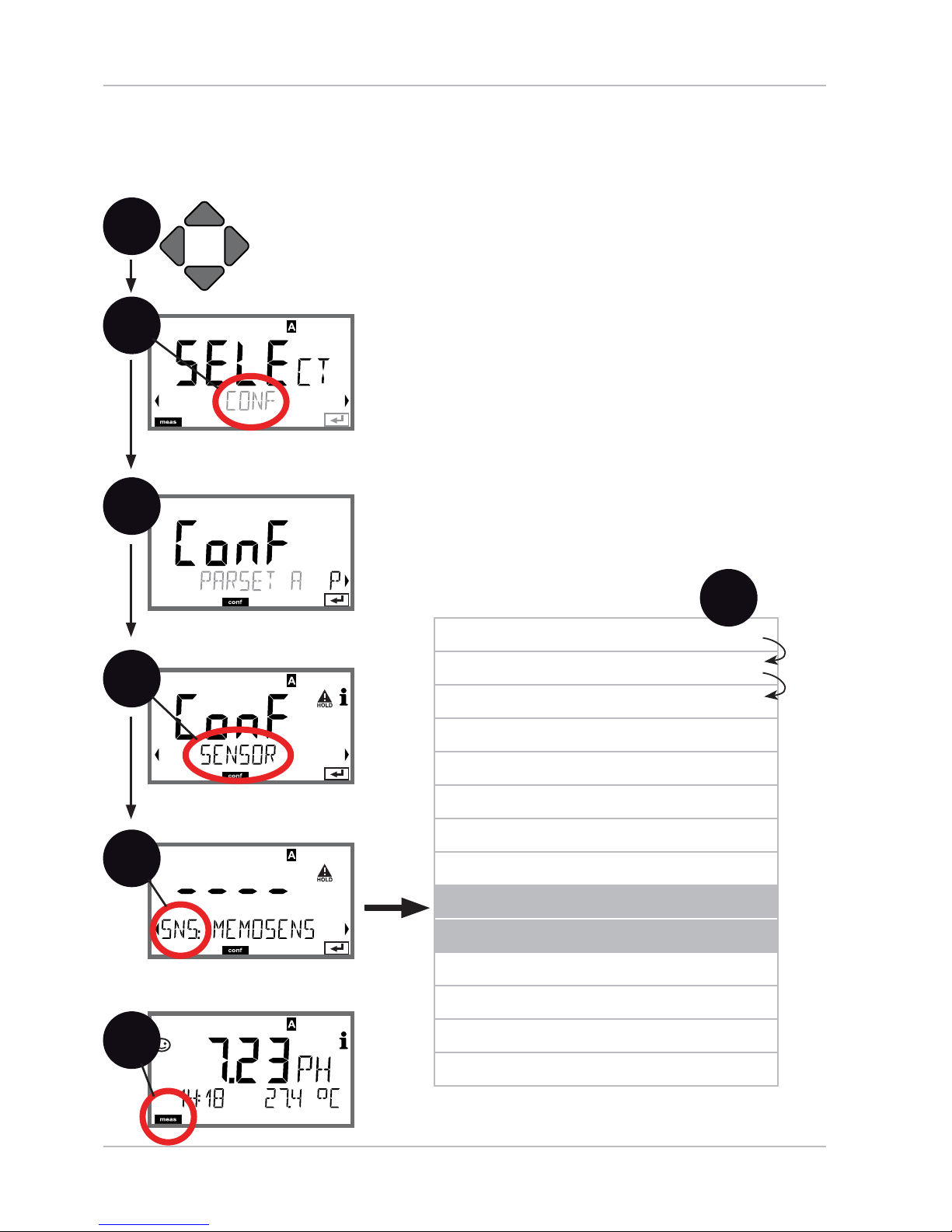

Con guration

1

Sensor

Select: sensor type, temperature unit,

temp detection during measurement

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set using 3 keys,

press enter.

Select 4 SENSOR menu using keys,

press enter.

All items of this menu group are indicated by 5

the “SNS:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

3

4

Select sensor type

Temperature unit

Temp detection during measurement

(Man. temperature)

Temp detection during calibration

(Man. temperature)

Calibration mode

(AUTO: Buffer set)

Calibration timer

Calibration cycle

Cleaning cycle counter

Cleaning cycles

Sterilization cycle counter

Sterilization cycles

5

enter

enter

6

enter

5

enter

meas

43

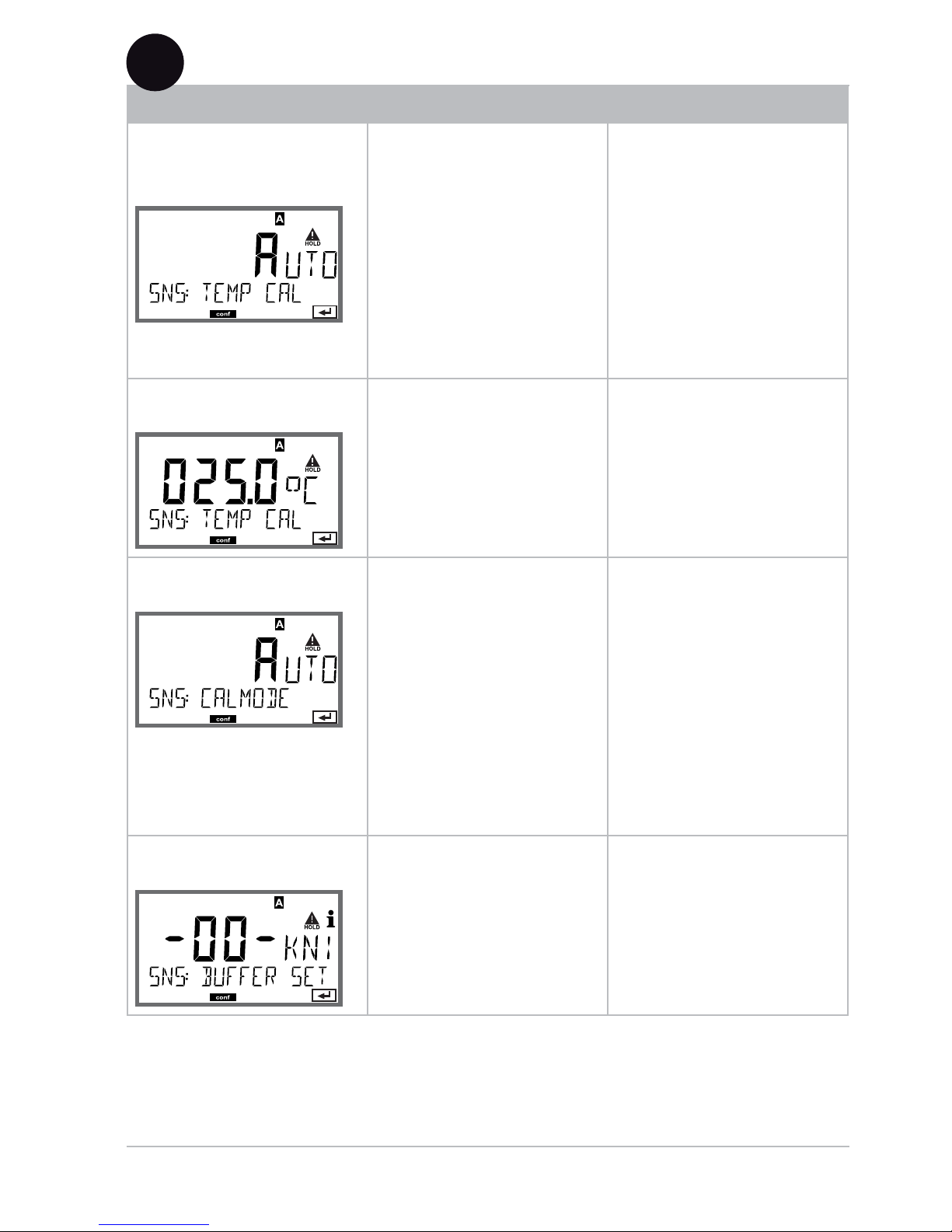

Con guration

Menu item Action Choices

Select sensor type

Select sensor type using

keys.

Confirm with enter

STANDARD

ISFET

INDUCON (DS)

ISM-DISO (DS)

MEMOSENS (DS)

Temperature unit

Select °C or °F using

keys.

Confirm with enter

°C / °F

Temp detection

during measurement

Select mode using :

AUTO: Measured by

sensor

MAN: Direct input of

temperature, no measurement (see next step)

EXT: Temperature specified via current input

(only if TAN E enabled)

Confirm with enter

AUTO

MAN

EXT

(Manual temperature)

Modify digit using ,

select next digit using

keys.

Confirm with enter

–20...200 °C

(–4...+392 °F)

5

44

Con guration

1

Sensor

Select: temp detection during calibration, calibration mode

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set using 3 keys,

press enter.

Select 4 SENSOR menu using keys,

press enter.

All items of this menu group are indicated by 5

the “SNS:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

4

Select sensor type

Temperature unit

Temp detection during measurement

(Man. temperature)

Temp detection during calibration

(Man. temperature)

Calibration mode

(AUTO: Buffer set)

Calibration timer

Calibration cycle

Cleaning cycle counter

Cleaning cycles

Sterilization cycle counter

Sterilization cycles

5

enter

enter

6

enter

5

enter

meas

3

45

Con guration

Menu item Action Choices

Temp detection

during calibration

Select mode using :

AUTO: Measured by

sensor

MAN: Direct input of

temperature, no measurement (see next step)

EXT: Temperature

specified via current input

(only if TAN E enabled)

Confirm with enter

AUTO

MAN

EXT

(Manual temperature)

Modify digit using ,

select next digit using

keys.

Confirm with enter

–20...200 °C

(–4...+392 °F)

Calibration Mode

Select CALMODE using

keys:

AUTO: Calibration with

Calimatic buffer set

recognition

MAN: Manual input of

buffer solutions.

DAT: Input of adjustment

data of premeasured

sensors

Confirm with enter

AUTO

MAN

DAT

(AUTO: Bu er set)

Select buffer set using

keys (see buf-

fer tables for nominal

values).

Confirm with enter

-00-...-09-, -U1-

Pressing the info key displays the manufacturer

and nominal values in the

lower line.

5

46

Con guration

1

Sensor

Adjust: calibration timer, calibration cycle

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set using 3 keys,

press enter.

Select 4 SENSOR menu using keys,

press enter.

All items of this menu group are indicated by 5

the “SNS:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

4

Select sensor type

Temperature unit

Temp detection during measurement

(Man. temperature)

Temp detection during calibration

(Man. temperature)

Calibration mode

(AUTO: Buffer set)

Calibration timer

Calibration cycle

Cleaning cycle counter

Cleaning cycles

Sterilization cycle counter

Sterilization cycles

5

enter

enter

6

enter

5

enter

meas

3

47

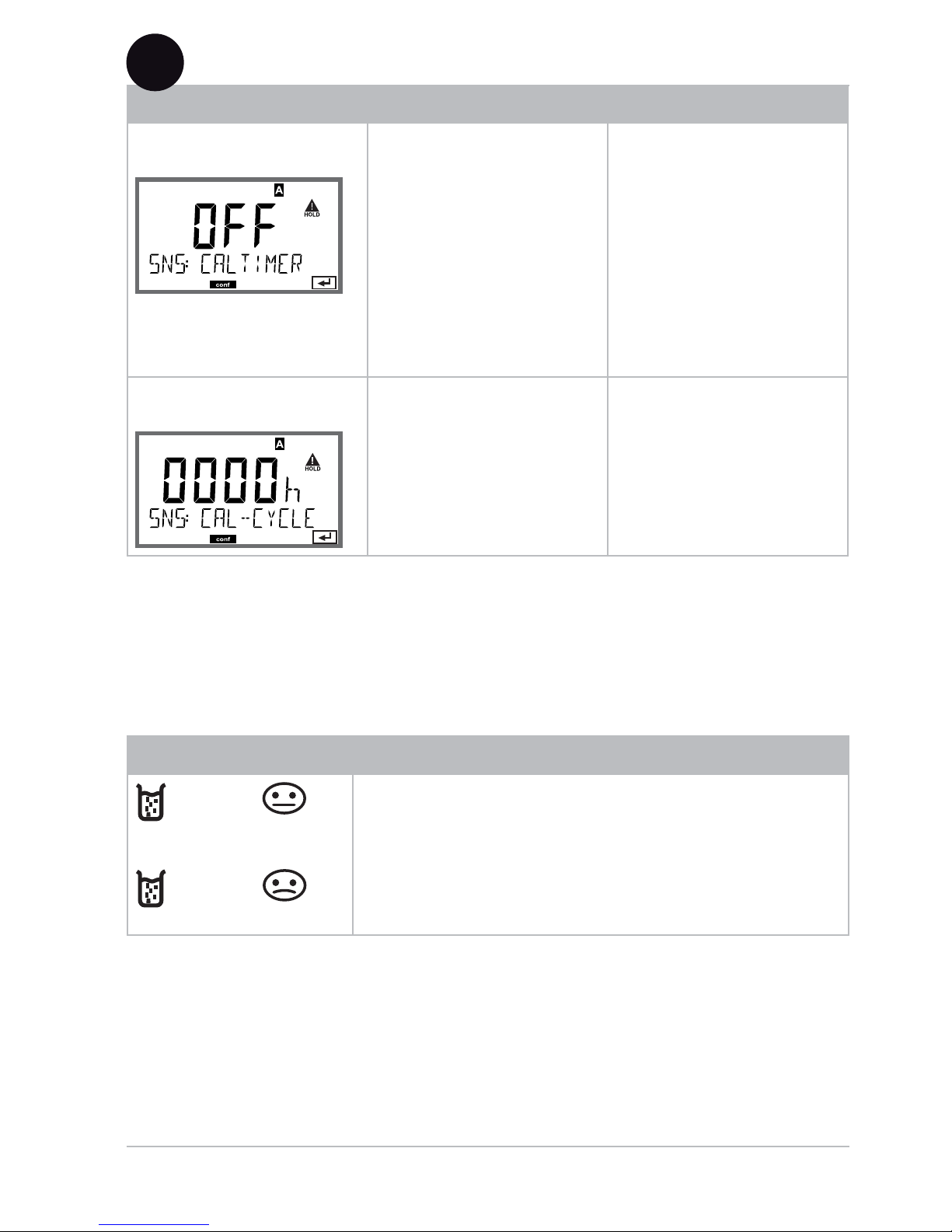

Con guration

Menu item Action Choices

Calibration timer

Adjust CALTIMER using

keys:

OFF: No timer

ADAPT: Maximum cal

cycle (adjust in the next

step)

FIX: Fixed cal cycle (adjust

in the next step)

Confirm with enter

OFF/ADAPT/FIX

With ADAPT, the calibration cycle is automatically

reduced depending on

the sensor load (high

temperatures and pH values) and for digital sensors also depending on

the sensor wear

Calibration cycle

Only with FIX/ADAPT:

Modify digit using

keys,

select next digit using

keys.

Confirm with enter

0...9999 h

5

Note for the calibration timer:

When Sensocheck has been ac

tivated in the Con guration > Alarm

menu, the expiration of the calibration interval is indicated by

Sensoface:

Display Status

+

+

Over 80% of the calibration interval has

already past.

The calibration interval has been exceeded.

The calibration timer settings apply to both parameter sets A and B.

The time remaining until the next due calibration can be seen in the

diagnostics menu (see Diagnostics chapter).

48

Con guration

1

Sensor

Adjust: CIP cleaning cycles, SIP sterilization cycles

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set using 3 keys,

press enter.

Select 4 SENSOR menu using keys,

press enter.

All items of this menu group are indicated by 5

the “SNS:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

4

Select sensor type

Temperature unit

Temp detection during measurement

(Man. temperature)

Temp detection during calibration

(Man. temperature)

Calibration mode

(AUTO: Buffer set)

Calibration timer

Calibration cycle

Cleaning cycle counter

Cleaning cycles

Sterilization cycle counter

Sterilization cycles

5

enter

enter

6

enter

5

enter

meas

3

49

Con guration

Menu item Action Choices

CIP / SIP

The following adjustments are possible for INDUCON digital sensors:

Cleaning cycle

counter

Select ON or OFF using

keys.

Activates/deactivates logging in extended logbook

and counters (if provided)

Confirm with enter

ON/OFF

Cleaning cycles

Only with CIP COUNT ON:

Enter value using

keys.

Confirm with enter

0...9999 CYC

(0025 CYC)

Not with Memosens

Sterilization cycle

counter

Select ON or OFF using

keys.

Activates/deactivates logging in extended logbook

and counters (if provided)

Confirm with enter

ON/OFF

Sterilization cycles

Only with SIP COUNT ON:

Enter value using

keys.

Confirm with enter

0...9999 CYC

(0025 CYC)

Not with Memosens

The cleaning and sterilization cycles are counted to measure the load

on the sensor.

Suitable for biochemical applications (process temp approx. 0...50 °C,

CIP temperature > 55 °C, SIP temperature > 115 °C).

5

50

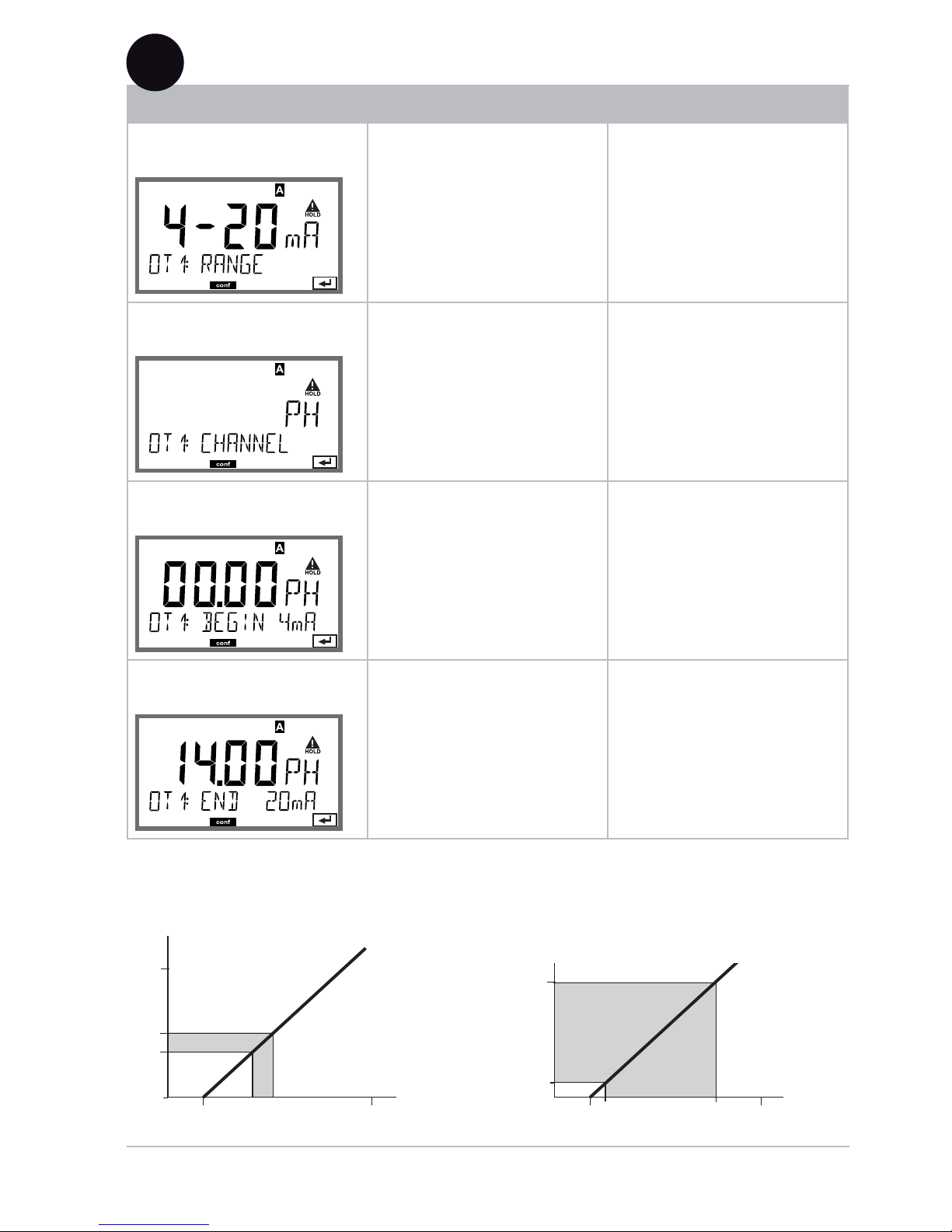

Con guration

Current range

Process variable

Current start

Current end

Time averaging lter

Output current during error

message

Output current during HOLD

Output current for HOLD FIX

Current Output 1

Output current range, current start, current end

1

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set using 3 keys,

press enter.

Select 4 OUT1 menu using keys,

press enter.

All items of this menu group are indicated by 5

the “OT1:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

4

5

enter

enter

6

enter

5

enter

meas

3

51

Con guration

Menu item Action Choices

Current range

Select 4-20 mA or

0-20 mA range using

keys.

Confirm with enter

4-20 mA / 0-20 mA

Process variable

Select using keys:

PH: pH value

ORP: Redox potential

TMP: Temperature

Confirm with enter

PH/ORP/TMP

Current start

Modify digit using ,

select next digit using

keys.

Confirm with enter

–2...16 pH (PH)

–1999...1999 mV (ORP)

–20...300 °C /

–4...572 °F (TMP)

Current end

Enter value using

keys.

Confirm with enter

–2...16 pH (PH)

–1999...1999 mV (ORP)

–20...300 °C /

–4...572 °F (TMP)

Assignment of measured values: Current start and current end

Output current

[pH]

20 4

14

0

20 4

7

5

[mA]

Example 1: Range pH 0...14

[mA]

Output current

7

5

5

Example 2: Range pH 5...7

Advantage: Higher resolution in

range of interest

[pH]

52

Con guration

Current Output 1

Adjust time interval of output lter

Current range

Process variable

Current start

Current end

Time averaging lter

Output current during error

message

Output current during HOLD

Output current for HOLD FIX

1

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set using 3 keys,

press enter.

Select 4 OUT1 menu using keys,

press enter.

All items of this menu group are indicated by 5

the “OT1:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

4

5

enter

enter

6

enter

5

enter

meas

3

53

Con guration

Menu item Action Choices

Time averaging

lter

Enter value using

keys.

Confirm with enter

0...120 SEC

(0000 SEC)

Time Averaging Filter

To smoothen the current output, a low-pass lter with adjustable lter

time constant can be switched on. When there is a jump at the input

(100 %), the output level is at 63 % after the time interval has been

reached. The time interval can be set from 0 to 120 sec. If the time

interval is set to 0 sec, the current output directly follows the input.

Please note:

The lter only acts on the current output, not on the display,

the limit values, or the controller!

During HOLD the lter is not applied. This prevents a jump at the

output.

Time interval 0...120 s

5

pH

0/4-20 mA

Time interval 0...120 s

Temp

Display / Controller

54

Con guration

Current Output 1

Output current during Error and HOLD

Current range

Process variable

Current start

Current end

Time averaging lter

Output current during error

message

Output current during HOLD

Output current for HOLD FIX

1

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set using 3 keys,

press enter.

Select 4 OUT1 menu using keys,

press enter.

All items of this menu group are indicated by 5

the “OT1:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

4

5

enter

enter

6

enter

5

enter

meas

3

55

Con guration

Menu item Action Choices

Output current

during error message

Select ON or OFF using

keys.

Confirm with enter

ON/OFF

Output current

during HOLD

LAST: During HOLD the

last measured value is

maintained at the output.

FIX: During HOLD a value

(to be entered) is maintained at the output.

Select using

Confirm with enter

LAST/FIX

Output current for

HOLD FIX

Only with FIX selected:

Enter current which is to

flow at the output during

HOLD

Enter value using

keys.

Confirm with enter

00.00...22.00 mA

(21.00 mA)

HOLD active

21

4

HOLD active

Output current

[mA]

Output signal HOLD

Setting FIX = 21.0 mA

Output signal for HOLD

LAST setting

Output Signal During HOLD:

5

56

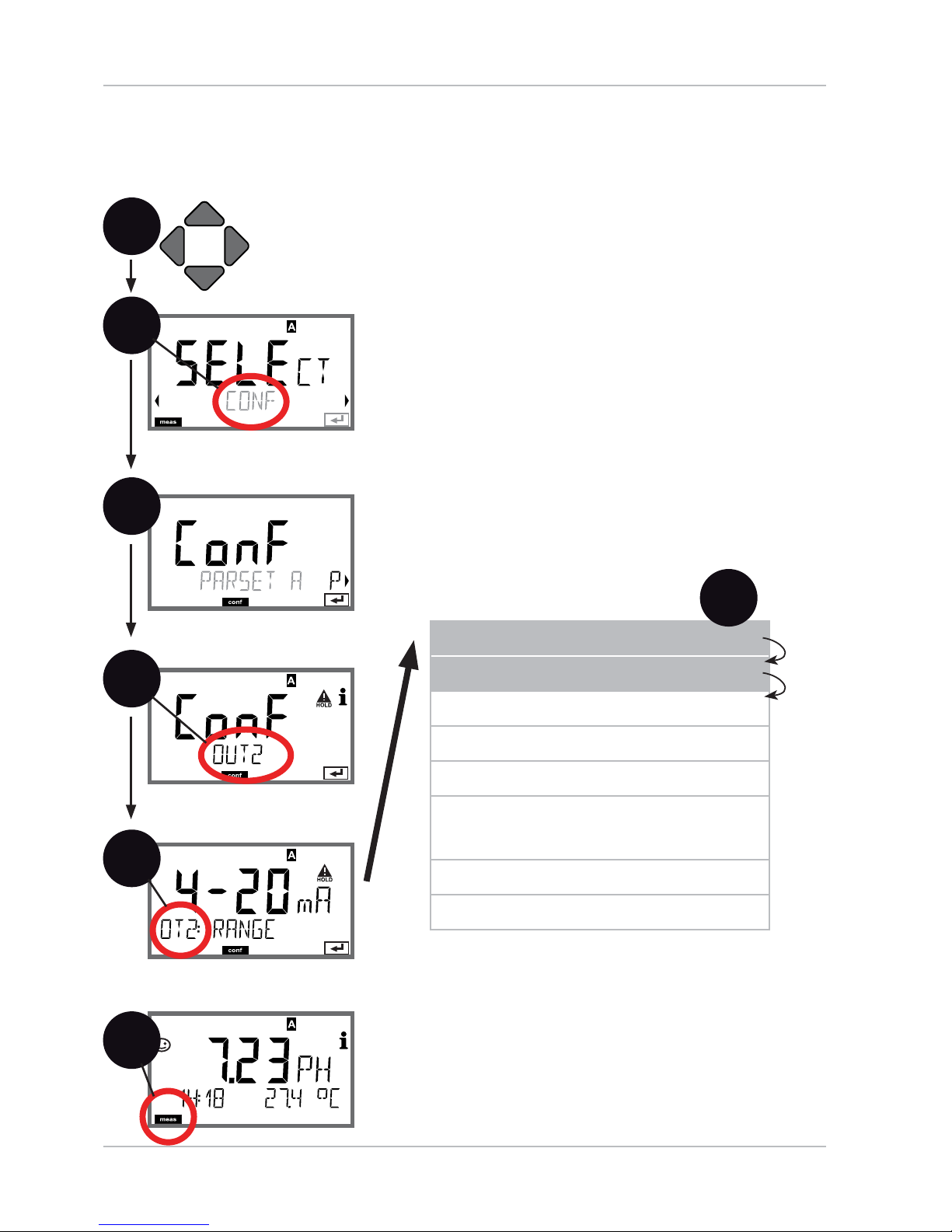

Con guration

Current Output 2

Output current range, current start, current end

Current range

Process variable

Current start

Current end

Time averaging lter

Output current during error

message

Output current during HOLD

Output current for HOLD FIX

1

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set using 3 keys,

press enter.

Select 4 OUT2 menu using keys,

press enter.

All items of this menu group are indicated by 5

the “OT2:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

4

5

enter

enter

6

enter

5

enter

meas

3

57

Con guration

Menu item Action Choices

Current range

Select 4-20 mA or

0-20 mA range using

keys.

Confirm with enter

4-20 mA / 0-20 mA

Process variable

Select using keys:

PH: pH value

ORP: Redox potential

TMP: Temperature

Confirm with enter

PH/ORP/TMP

.

.

.

All the following adjustments are made as for current output 1

(see there)!

5

58

Con guration

1

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set using 3 keys,

press enter.

Select 4 CORRECTION menu using keys,

press enter.

All items of this menu group are indicated by 5

the “COR:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

4

enter

enter

6

enter

5

enter

meas

Temperature compensation,

process medium

Current input for

ext. temperature measurement

Current range

Current start

Current end

5

3

Temperature Compensation

TC process medium, current input for temp measurement

59

Con guration

Menu item Action Choices

Temp compensation,

process medium

For pH measurement

only: Enter temperature

compensation of the

process medium.

Enter value using

keys.

Confirm with enter

–19.99...+19.99 %/K

Current input for

ext. temperature

measurement

Only if enabled via TAN

and selected during

configuration (SENSOR).

Select ON or OFF using

keys.

Confirm with enter

ON/OFF

Current range

Select desired range

using keys.

Confirm with enter

4-20 mA / 0-20 mA

Current start

Modify digit using ,

select next digit using

keys.

Confirm with enter

Input range:

–20...200 °C /

–4...392 °F

Current end

Enter value using

keys.

Confirm with enter

Input range:

–20...200 °C/

–4...392 °F

5

60

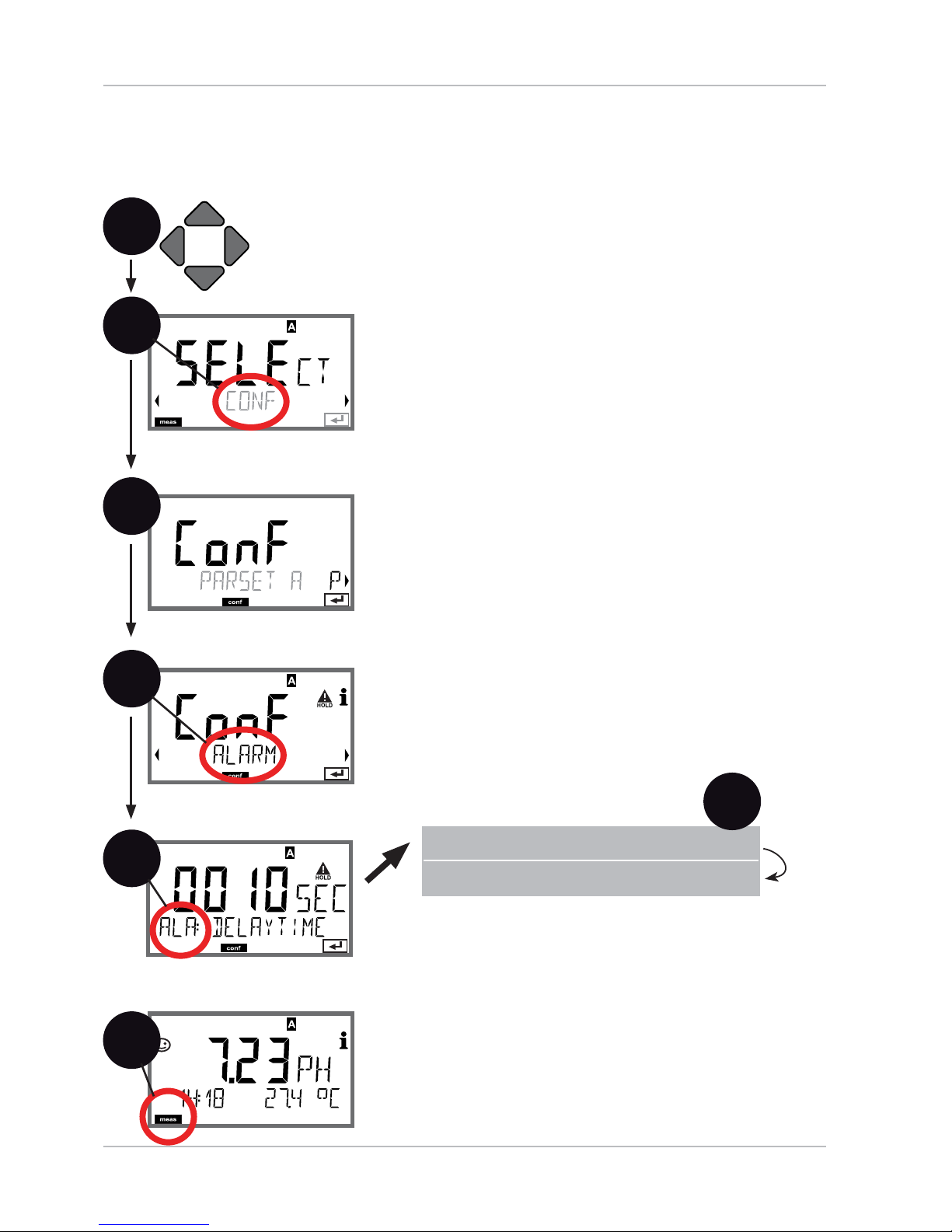

Con guration

Alarm

Alarm delay, Sensocheck

1

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set using 3 keys,

press enter.

Select 4 ALARM menu using keys,

press enter.

All items of this menu group are indicated by 5

the “ALA:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

4

enter

enter

6

enter

5

enter

meas

Delay

Sensocheck

5

3

61

Alarm Contact

The alarm contact is closed during normal operation

(N/C). It opens in the case of alarm or power outage.

As a result, a failure message is provided even in the

case of wer failure or line breakage (fail-safe behavior).

For contact ratings, see Specifications.

17

18

Alarm

R3

Error messages can also be signaled by a 22 mA output current (see Error messages

and Configuration Output 1/Output 2).

Operating behavior of the alarm contact: see Operating States table.

The alarm delay time delays the color change of the display backlighting to red,

the 22 mA signal (if configured), and the alarm contact switching.

Con guration

Menu item Action Choices

Alarm delay

Enter value using

keys.

Confirm with enter

0...600 SEC

(010 SEC)

Sensocheck

Select Sensocheck

(continuous monitoring

of glass and reference

electrode)

Select ON or OFF using

keys.

Confirm with enter.

(At the same time,

Sensoface is activated.

With OFF, Sensoface is

also switched off.)

ON/OFF

5

62

Con guration

Limit Function

Relay 1

1

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set using 3 keys,

press enter.

Select 4 REL1/REL2 menu using keys,

press enter.

All items of this menu group are indicated by 5

the “RL1:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

4

enter

6

enter

5

meas

Use of relays

Select process variable

Limit 1 switching characteristics

(function)

Limit 1 contact type

Limit 1 setpoint

Limit 1 hysteresis

Limit 1 delay

enter

5

3

enter

63

Con guration

Menu item Action Choices

Use of relays

Select in the text line

using keys:

Limit function (LIMITS)•

Controller •

(CONTROLLER)

Confirm with enter

LIMITS / CONTROLLER

Please note: Selecting

CONTROLLER leads to

Controller menu group

CTR.

Select process

variable

Select desired process

variable using keys.

Confirm with enter

PH/ORP/TMP

Limit 1 function

Select desired function

using arrow keys.

LoLevel: active if value

falls below / HiLevel:

active if value exceeds

setpoint

Confirm with enter

Lo LEVL / Hi LEVL

Limit 1

contact response

N/O: normally open

contact

N/C: normally closed

contact

Select using keys.

Confirm with enter

N/O / N/C

Limit 1 setpoint

Enter setpoint using

keys.

Confirm with enter

–2.00...16.00 PH

(00.00 PH) /

-1999...1999 mV /

–20...200 °C

5

64

Con guration

1

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set using 3 keys,

press enter.

Select 4 REL1/REL2 menu using keys,

press enter.

All items of this menu group are indicated by 5

the “RL1:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

4

enter

6

enter

5

meas

Use of relays

Select process variable

Limit 1 switching characteristics

(function)

Limit 1 contact type

Limit 1 setpoint

Limit 1 hysteresis

Limit 1 delay

enter

5

Limit Function

Relay 1

3

enter

65

Con guration

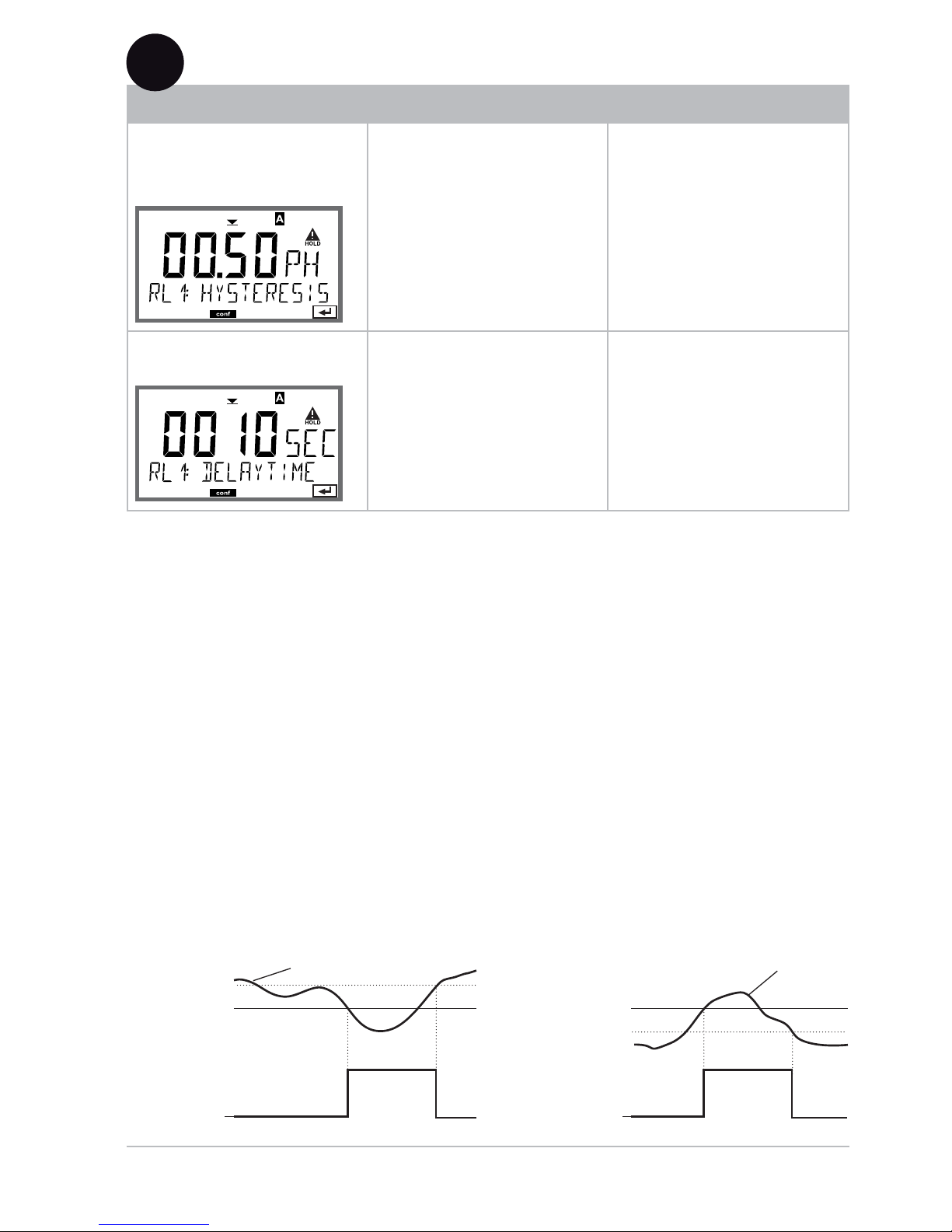

Menu item Action Choices

Limit 1

hysteresis

Select hysteresis using

keys.

Confirm with enter

0...10.00 PH

(00.50 PH)

Limit 1 delay

The contact is activated

with delay (deactivated

without delay)

Adjust delay using

keys.

Confirm with enter

0...9999 SEC

(0010 SEC)

Limit Lo

Hysteresis +

Setpoint

Contact

0

1

Signal

Limit Hi

Hysteresis -

Signal

Setpoint

Contact

0

1

5

Application of Hysteresis:

66

Limit Function

Relay 2

Con guration

1

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set using 3 keys,

press enter.

Select 4 REL1/REL2 menu using keys,

press enter.

All items of this menu group are indicated by 5

the “RL2:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

4

enter

6

enter

5

meas

Use of relays

Select process variable

Limit 2 switching characteristics

(function)

Limit 2 contact type

Limit 2 setpoint

Limit 2 hysteresis

Limit 2 delay

enter

5

enter

3

67

Con guration

Menu item Action Choices

Select process

variable

(CHANNEL)

Select desired process

variable using keys.

Confirm with enter

PH/ORP/TMP

Limit 2 function

(FUNCTION)

Select desired function

using arrow keys.

Confirm with enter

Lo LEVL / Hi LEVL

Limit 2 contact type

(CONTACT)

N/O: normally open

contact

N/C: normally closed

contact

Select using keys.

Confirm with enter

N/O / N/C

Limit 2 setpoint

(LEVEL)

Enter setpoint using

keys.

Confirm with enter

–2.00...16.00 PH

(14.00 PH) /

-1999...1999 mV /

–20...200 °C

Limit 2 hysteresis

(HYSTERESIS)

Select hysteresis using

keys.

Confirm with enter

0...10.00 PH

(00.50 PH)

Limit 2 delay

(DELAYTIME)

The contact is activated

with delay (deactivated

without delay)

Adjust delay using

keys.

Confirm with enter

0...9999 SEC

(0010 SEC)

Limit Lo

Hysteresis +

Setpoint

Contact

0

1

Signal

Limit Hi

Hysteresis -

Signal

Setpoint

Contact

0

1

5

Application of Hysteresis:

68

69

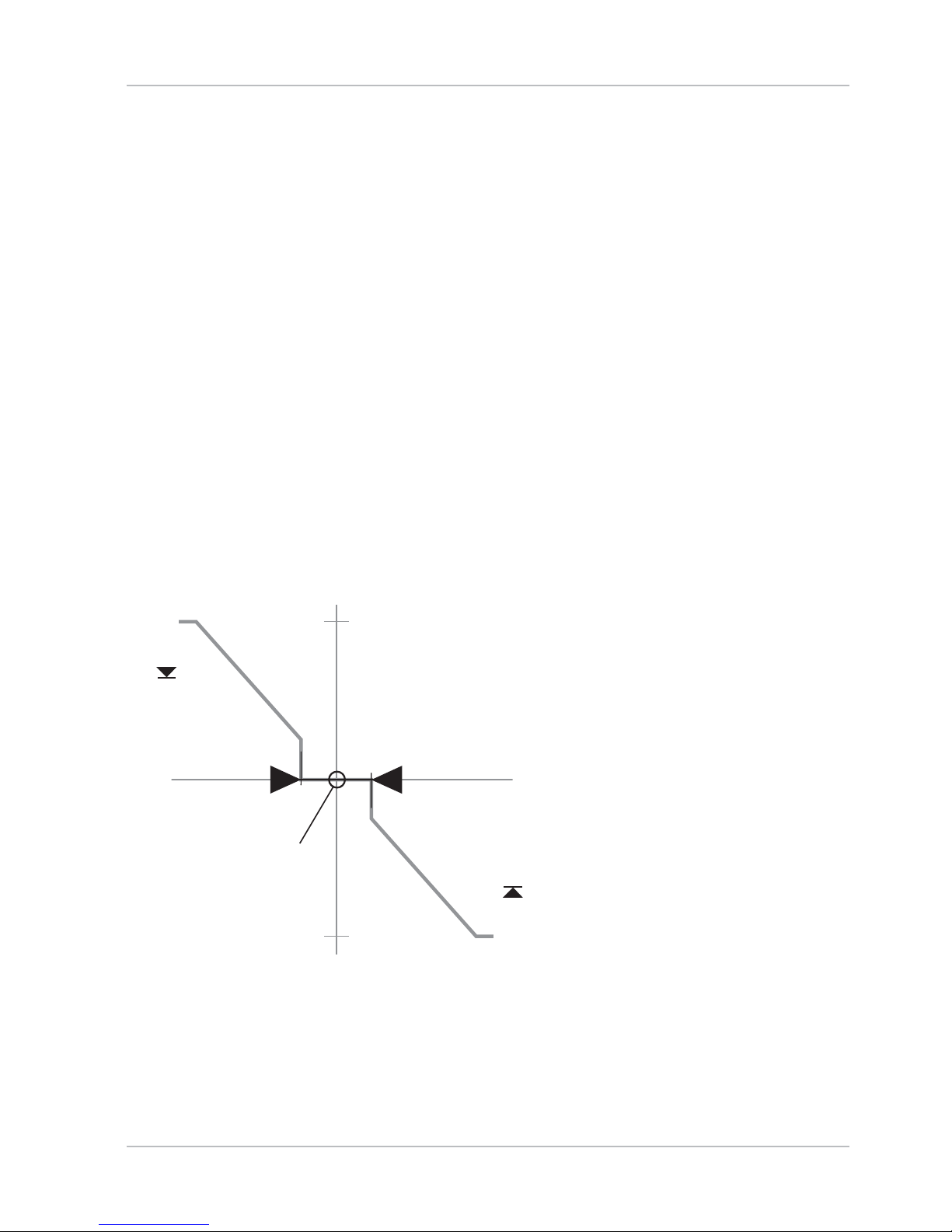

Controller Functions

Setpoint

Controller output

Yp [%]

+100 %

-100 %

Deviation Xw [pH]

Neutral zone Yp=0

Relay 1

Relay 2

Typical Applications

P Controller

Application for integrating control systems (e.g. closed tank, batch processes).

PI Controller

Application for non-integrating control systems (e.g. drains).

PID Controller

The additional derivative action compensates for measurement peaks.

Controller Characteristic

70

Controller Functions

Proportional action Y

P

Setpoint - Meas. value

Constant

Y

P

=

*

Controller output Y =

I action

with:

YP Proportional action

T

R

Reset time [s]

TD Rate time [s]

K

C

Controller gain [%]

Constant 5 (for pH)

500 mV (for ORP)

D action

dY

P

dt

1

T

R

P action

Controller Equations

YP +Y

P

dt + T

D

K

C

Neutral Zone

Tolerated deviation from desired value.

With the setting

“1 pH”, for example, a deviation of ± 0.5 pH from the

desired value is tolerated.

100 %

50 %

X

w

Process variables: pH/ (mV),

underneath: temp [K]

Controller

output Y

KC = 500 %

KC = 200 %

KC = 100 %

KC = 50 %

1 / (100) 2 / (200) 3 / (300) 4 / (400)

Proportional Action (Gradient KC [%])

Deviation

5 / (500)

[10] [20] [30] [40] [50]

71

Controller Functions

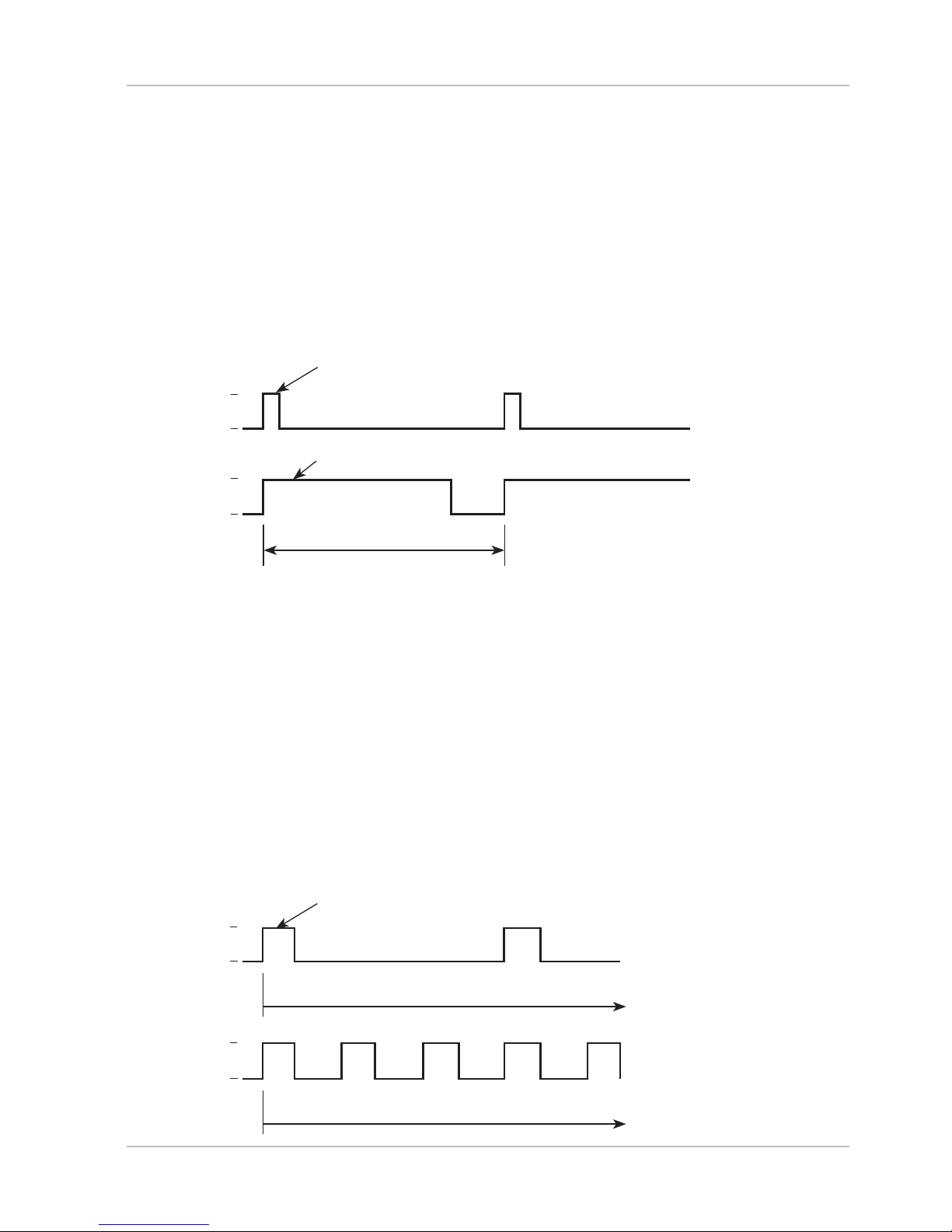

Pulse Length / Pulse Frequency Controller

Pulse Length Controller ( PLC)

The pulse length controller is used to operate a valve as an actuator.

It swit

ches the contact on for a time that depends on the controller

output. The period is constant. A minimum ON time of 0.5 sec is maintained even if the controller output takes corresponding values.

Output signal (relay contact) of pulse length controller:

ON time (Y = 80 %)

ON time (Y = 20 %)

Pulse length

1

0

1

0

Pulse Frequency Controller ( PFC)

The pulse frequency controller is used to operate a frequency c

ontrolled actuator (metering pump). It varies the frequency with

which the contacts are switched on. The maximum pulse frequency

[pulses/min] can be defined. It depends on the actuator.

The contact ON time is constant. It is automatically calculated from

the user-defined maximum pulse frequency:

Output signal (relay contact) of pulse frequency controller:

ON time

Pulse frequency (Y = 20%)

Pulse frequency (Y = 80%)

1

0

1

0

72

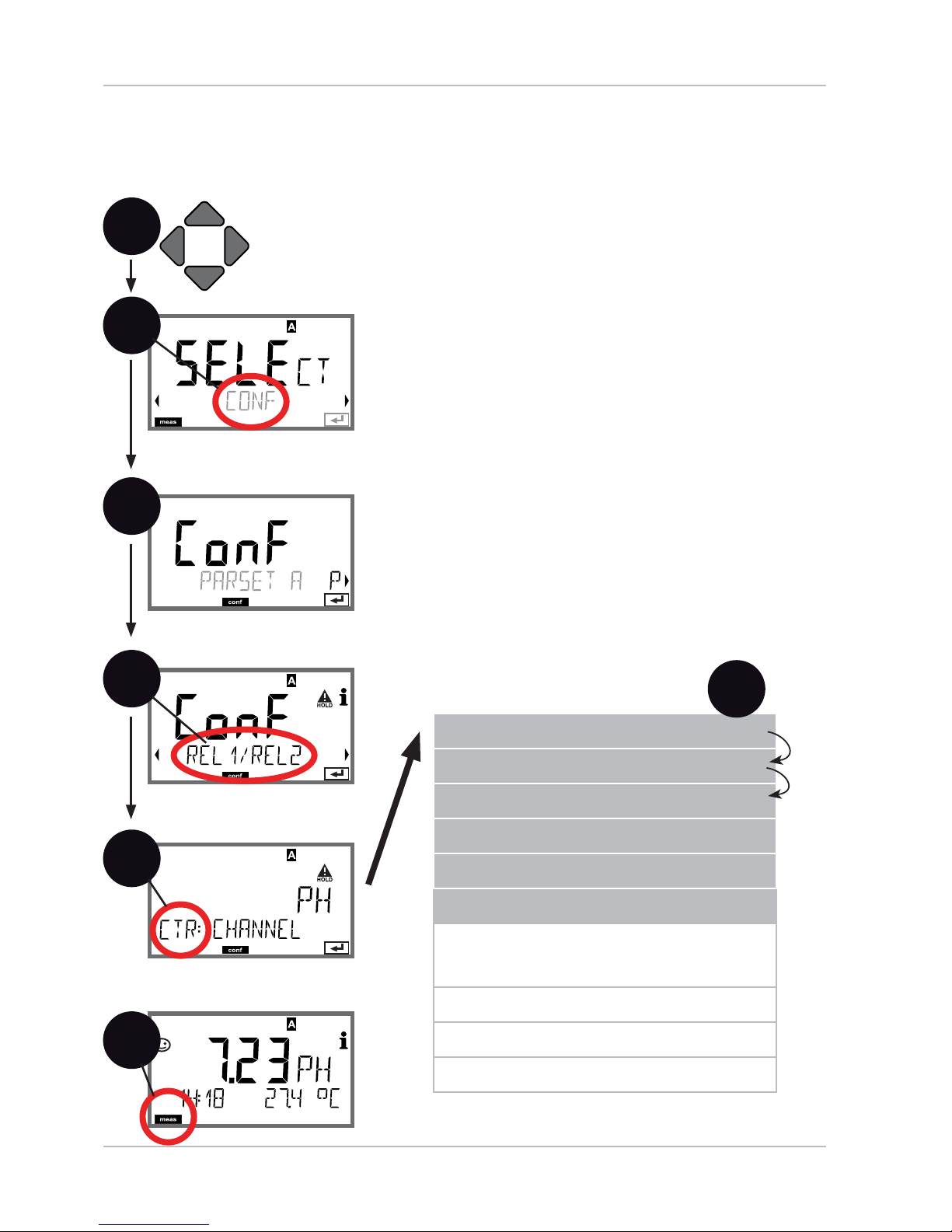

Con guration

Controller

(For description, see Controller Functions)

Process variable. Controller type. Setpoint.

1

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set using 3 keys,

press enter.

Select 4 REL1/REL2 menu using keys,

press enter.

All items of this menu group are indicated by 5

the “CTR:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

4

enter

6

enter

5

meas

Use of relays

Select process variable

Controller type

Pulse length

Pulse frequency

Setpoint

Neutral zone

Controller: P action

Controller: I action

Controller: D action

Behavior during HOLD

enter

5

enter

3

73

Con guration

Menu item Action Choices

Select process

variable

Select desired process

variable using keys.

Confirm with enter

PH/ORP/TMP

Controller type

Pulse length controller

(PLC)

or pulse frequency

controller (PFC)

Select using keys.

Confirm with enter

PLC / PFC

Pulse length

Only with PLC:

Pulse length

Adjust using

keys.

Confirm with enter

0...0600 SEC

(0010 SEC)

Pulse frequency

Only with PFC:

Pulse frequency

Adjust using

keys.

Confirm with enter

0...0180 P/M

(0060 P/M)

(pulses per minute)

Setpoint

Adjust setpoint using

keys.

Confirm with enter

–2.00...16.00 PH

(07.00 PH) /

–1500...1500 mV

5

74

Controller

(For description, see Controller Functions)

Neutral zone. P, I, D actions. Behavior during HOLD

1

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set using 3 keys,

press enter.

Select 4 REL1/REL2 menu using keys,

press enter.

All items of this menu group are indicated by 5

the “CTR:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

4

enter

6

enter

5

meas

Use of relays

Select process variable

Controller type

Pulse length

Pulse frequency

Setpoint

Neutral zone

Controller: P action

Controller: I action

Controller: D action

Behavior during HOLD

enter

5

Con guration

enter

3

75

Con guration

Menu item Action Choices

Neutral zone

Adjust neutral zone using

keys.

Confirm with enter

0...10.00 PH

(01.00 PH) /

0...2000 mV

Controller: P action

Adjust P action using

keys.

Confirm with enter

10...9999%

(0100%)

Controller: I action

Adjust I action using

keys.

Confirm with enter

0...9999 SEC

(0000 SEC)

Controller: D action

Adjust D action using

keys.

Confirm with enter

0...9999 SEC

(0000 SEC)

Behavior during

HOLD

Select response using

keys.

Confirm with enter

Y LAST / Y OFF

5

76

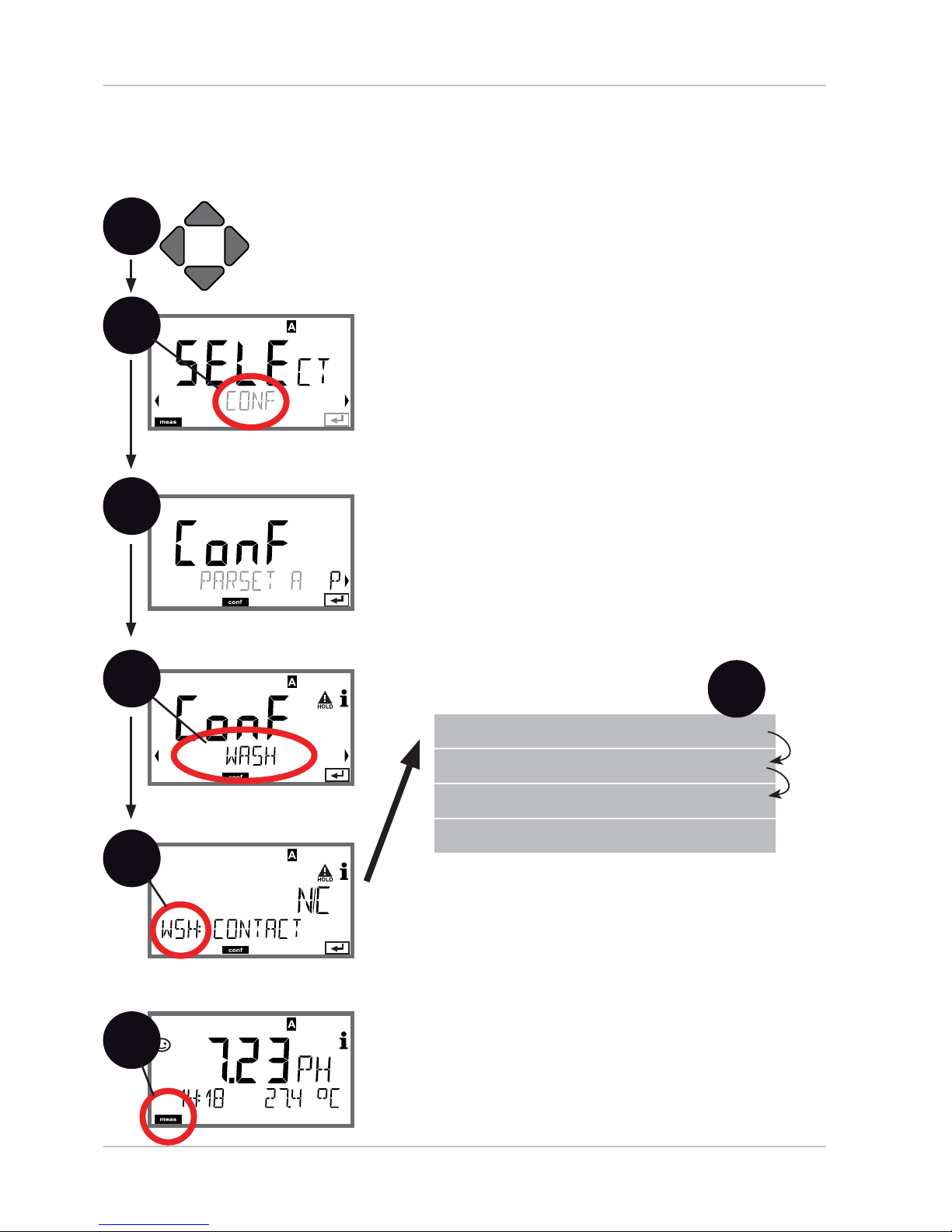

Con guration

WASH Contact

Control of rinsing probes or

signaling the parameter set

1

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set A using 3 keys,

press enter.

Select 4 WASH menu using keys, press

enter.

All items of this menu group are indicated by 5

the “WSH:” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 6 meas key until the [meas] mode

indicator is displayed.

2

3

4

enter

6

enter

5

enter

meas

Function

Cleaning interval

Cleaning duration

Contact type

enter

5

77

Con guration

Menu item Action Choices

Function

Select WASH contact

function using keys.

Confirm with enter

WASH / PARSET A/B

WASH: Control of rinsing

probes

With PARSET A/B selected,

the contact signals:

“Parameter set A“

(open contact)

“Parameter set B“

(closed contact)

Cleaning interval

Only with WASH:

Adjust value using

keys.

Confirm with enter

0.0...999.9 h (000.0 h)

Cleaning duration

Only with WASH:

Adjust value using

keys.

Confirm with enter

0...9999 SEC (0060 SEC)

Contact type

Only with WASH:

N/O: normally open

contact

N/C: normally closed

contact

Select using keys.

Confirm with enter

N/O / N/C

5

Cycle interval

Cleaning Relax time (approx. 20 s)

HOLD

78

Con guration

Time and Date

Tag Number

1

Press any arrow key.1

Select 2 CONF using keys,

press enter.

Select parameter set A using 3 keys,

press enter.

4 Press enter

Select 5 CLOCK or TA G using keys, press

enter.

All items of this menu group are indicated by 6

the “CLK:” or “TAG” code.

Press enter to select menu,

edit with arrow keys (see next page).

Confirm (and proceed) with enter.

End: Press 7 meas key until the [meas] mode

indicator is displayed.

2

3

4

enter

6

enter

5

enter

meas

Time format

Time

Day and month

Year

Tag number

enter

5

79

Time and Date

Control of the calibration and cleaning cycles is based on the time and

date of the integrated real-time clock.

In measuring mode the time is shown in the lower display.

When using InduCon sensors, the calibration data is written in the

sensor head.

In addition, the logbook entries (cf Diagnostics) are provided with a

time stamp.

Please note:

After prolonged power outage (> 5 days) the time display is •

replaced by dashes and cannot be used for processing.

Enter the correct time.

There is no automatic switchover from winter to summer time!•

Be sure to manually adjust the time!

Con guration

Menu item Action Choices

Tag number

Select character using

keys,

select next digit using

keys.

Confirm with enter

A...Z, 0...9, – + < > ? / @

The first 10 characters are

seen in the display without scrolling.

Tag Number (“ TAG“)

You can enter a designation for the point of measurement (tag

number) in the lower display line. Up to 32 digits are possible.

Pressing meas (repeatedly) in the measuring mode indicates the tag

number.

Being part of the device con guration, the “TAG“ can be read out via

IrDA.

A standardized tag number helps, for example, to correctly re-install a

device after repair.

5

80

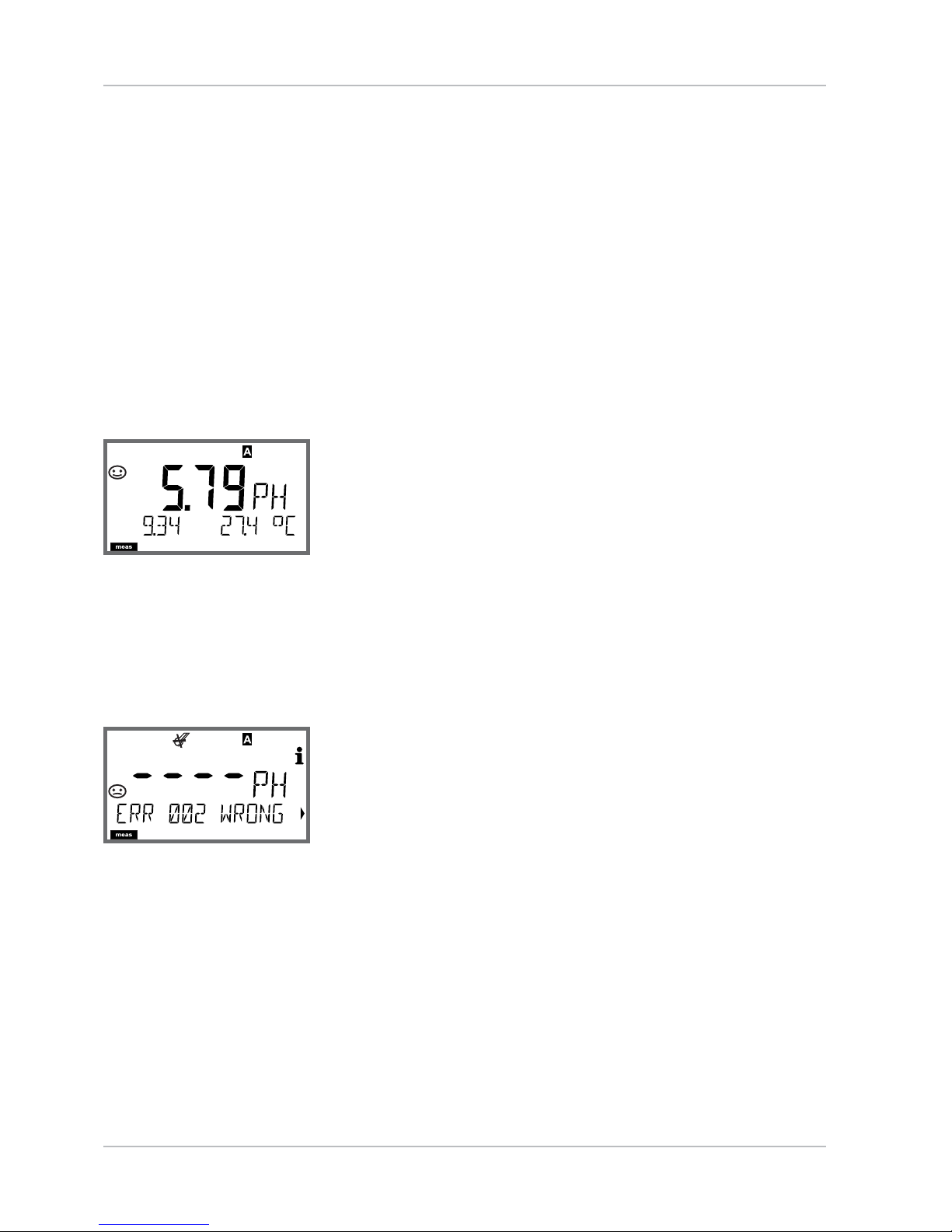

Digital Sensors

Operation

Stratos Pro can be operated with three di erent types of digital

sensors (Memosens, InduCon).

The following display examples refer to a transmitter and a digital

pH sensor (slight variations for other combinations).

The sensor type is selected during con guration.

The device only switches to measuring mode when the connected