KNF 308918-308921 03/19

OEM

N 0150

TRANSLATION OF ORIGINAL OPERATING AND

INSTALLATION INSTRUCTION

ENGLISH

DIAPHRAGM PUMP

Note!

Before operating the pump and the accessories, please read the operating and installation instructions and

pay attention to the safety precautions!

KNF Neuberger GmbH

Alter Weg 3

79112 Freiburg

Germany

Phone +49-(0)7664/5909-0

Fax. 07664/5909-99

Email: info@knf.de

www.knf.com

Index

1 About this document ......................................................... 3

2 Use ...................................................................................4

3 Safety................................................................................ 5

4 Technical data ..................................................................7

5 Design and function ........................................................ 10

6 Transport ........................................................................13

7 Installation and connection ............................................. 15

8 Operation ........................................................................ 22

9 Servicing ......................................................................... 25

10 Troubleshooting .............................................................. 31

11 Spare parts and accessories ..........................................33

12 Returns ...........................................................................34

13 Appendix.........................................................................35

Diaphragm Pump N 0150 About this document

1 About this document

1.1 Using the operating and installation instructions

The operating and installation instructions are part of the pump.

à

The individual chapters of these operating and installation instructions

make reference to the operating instructions of the motor manufacturer

for capacitor and three-phase motors. They are appended to these operating and installation instructions.

à

Give the operating and installation instructions to the next owner.

à

Keep the operating and installation instructions within reach at all

times.

Project pumps For customer-specific project pumps (pump models that begin with "PJ" or

"PM"), there may be deviations from the operating and installation instructions.

à

For project pumps, also observe the agreed specifications.

1.2 Symbols and markings

Warning notice

A notice that warns you of danger is located here.

Possible consequences of a failure to observe the

warning notice are specified here. The signal

WARNING

word, e.g., warning, indicates the danger level.

à Measures for avoiding the danger and its

consequences are specified here.

Danger levels

Signal word Meaning Consequences if not

observed

DANGER warns of immediate

danger

WARNING warns of possible dan-

ger

CAUTION warns of a possibly

dangerous situation

Tab.1

Other notices and symbols

Death or serious injury

or serious damage will

result.

Death or serious injury

or serious damage are

possible.

Minor injuries or damage are possible.

à

An activity to be carried out is specified here (a step).

1. The first step of an activity to be carried out is specified here.

This symbol indicates important information.

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

3

Use Diaphragm Pump N 0150

2 Use

2.1 Proper use

The pumps are intended exclusively for transferring gases and vapors.

Responsibility of the owner

Operating parameters and

conditions

Requirements for the transferred

medium

Frequency converter Pumps with three-phase motor are designed for operation with frequency

Only install and operate the pumps in accordance with the operating parameters and conditions described in Chapter 4 Technical data.

Protect compressors with a pressure relief device between the pressure

side of the compressor and the first shut-off valve.

Only fully assembled pumps may be operated.

Make sure that the installation location is dry and that the pump is protected against rain, splash, gushing and drip water as well as from other

contaminants.

The tightness of the connections between the pipes of the application and

the pump (or the connection of the pump) is to be checked at regular intervals. Leaky connections carry the risk of releasing dangerous gases and

vapors from the pump system.

Before transferring a medium, check whether the medium can be transferred danger-free in the specific application.

Before using a medium, check the compatibility of the media-contacting

components (see 4 Technical data) with the medium.

Risk of dangerous gas mixtures during pump operation if diaphragm

breaks: Depending on the medium being transferred, breakage of the diaphragm can result in a dangerous mixture if the medium mixes with the

air in the compressor housing.

Only transfer gases that remain stable under the pressures and temperatures that arise in the pump.

converter in the speed range 500 – 1500 rpm (50 Hz) or 600 – 1600 rpm

(60 Hz) (see also Chapter 7.2 Electrical connection).

2.2 Improper use

The pumps may not be operated in explosive atmospheres.

The pumps are not suitable for transferring:

§

Dusts

§

Liquids

§

Aerosols

§

Biological and microbiological substances

§

Fuel

§

Explosives and flammable material

§

Fibers

§

Oxidants

§

Food

Pumps that can produce both vacuum as well as overpressure may not be

used to simultaneously produce vacuum and operating pressure.

No operating pressure may be applied to the suction side of the pump.

Pumps with capacitor motor are not intended for operation with a frequency converter.

4 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Safety

3 Safety

Observe the safety notices in chapters 7 Installation and connection

and 8.1 Operation.

The pumps are built in accordance with the generally recognized rules of

technology and the occupational safety and accident prevention regulations. Nevertheless, dangers can arise during their use that lead to injuries

to the user or third parties or to damage to the pump or other property.

Only use the pumps in perfect technical condition, for their intended use,

safely and aware of the dangers and in observation of the operating and

installation instructions.

The components that are to be connected to the pumps must be designed

according to the pneumatic data of the pumps.

When connecting the pumps to the electrical mains, observe the corresponding safety rules.

Personnel Make sure that only trained and instructed personnel or specially trained

personnel work on the pumps. This applies, in particular, to assembly, connection and servicing work.

Make sure that the personnel have read and understood the operating and

installation instructions, particularly the chapter on safety.

Working in a safety conscious

manner

Working with hazardous media Upon breakage of the diaphragm and/or leaks, the transferred medium

Working with combustible media Note that the pumps are not designed to be explosion-proof.

Environmental protection Store and dispose of all replacement parts in accordance with environmen-

Observe the regulations on accident prevention and safety during all work

on the pumps and during operation.

The pump heads heat up during operation; therefore avoid contact with

them.

Make certain that the pump is disconnected from mains and without

power.

Make sure that no dangers arise from flow when gas connections are

open, from noises or from hot, corrosive, dangerous and environmentally

hazardous gases.

Make sure that an EMC-compliant installation of the pump is ensured at all

times and that no dangerous situation can thereby arise.

mixes with the air in the surroundings and/or in the pump housing. Make

sure that a dangerous situation cannot arise as a result.

When transferring hazardous media, observe the safety regulations for the

handling of these media.

Make sure that the temperature of the medium is always sufficiently below

the ignition temperature of the medium so as to prevent ignition or explosion. This also applies for abnormal operating situations.

Note here that the temperature of the medium increases when the pump

compresses the medium.

Therefore, make sure that the temperature of the medium also remains

sufficiently below the ignition temperature of the medium even when it is

compressed to the maximum permissible operating pressure of the pump.

The maximum permissible operating pressure of the pump is stated in the

technical specifications (4 Technical data).

If applicable, also take into consideration external energy sources (e.g., radiation sources) that could add heat to the medium.

In case of doubt, contact KNF Customer Service.

tal regulations. Observe the respective national and international regulations. This applies in particular to parts that are contaminated with toxic

substances.

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

5

Safety Diaphragm Pump N 0150

EU/EC directives/standards With respect to the Machinery Directive 2006/42/EC, the pumps are partly

completed machinery and are, therefore, to be regarded as not ready for

use. Partly completed machinery may not be commissioned until it has

been determined that the machine into which the partly completed machinery is to be installed complies with the provisions of the Machinery Directive 2006/42/EC. The following fundamental requirements of Annex I of Directive 2006/42/EC (general principles) are applied and observed:

§

General principles no. 1

§

No. 1.1.2. / 1.1.3. / 1.3.1. / 1.3.3. / 1.3.4. / 1.4.1. / 1.5.1. / 1.5.2. /

1.5.8. / 1.5.9. / 1.7.4. / 1.7.4.1. / 1.7.4.3.

As these partly completed machines are built-in devices, the mains connections and equipment for disconnecting and switching off the partly completed machinery as well as overcurrent and overload protection gear must

be considered when mounting.

Furthermore, protection against contact with moving and hot parts, if

present, must be provided during installation.

The pumps comply with Directive 2011/65/EC (RoHS2).

The following harmonized standards are satisfied:

§ DIN EN 60034-1/5/6/9

§ DIN EN 60204-1

§ DIN EN 61000-6-1/2/3/4

§ DIN EN 50581

§ EN 60034-30-1 (only pumps with three-phase motor)

Customer service and repairs The pumps are maintenance-free. KNF does, however, recommend peri-

odically inspecting the pumps for noticeable changes to noises and vibrations.

Only have repairs to the pumps performed by the responsible KNF Customer Service.

Housings with live components may only be opened by specialist personnel.

Use only original parts from KNF during servicing work.

6 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Technical data

4 Technical data

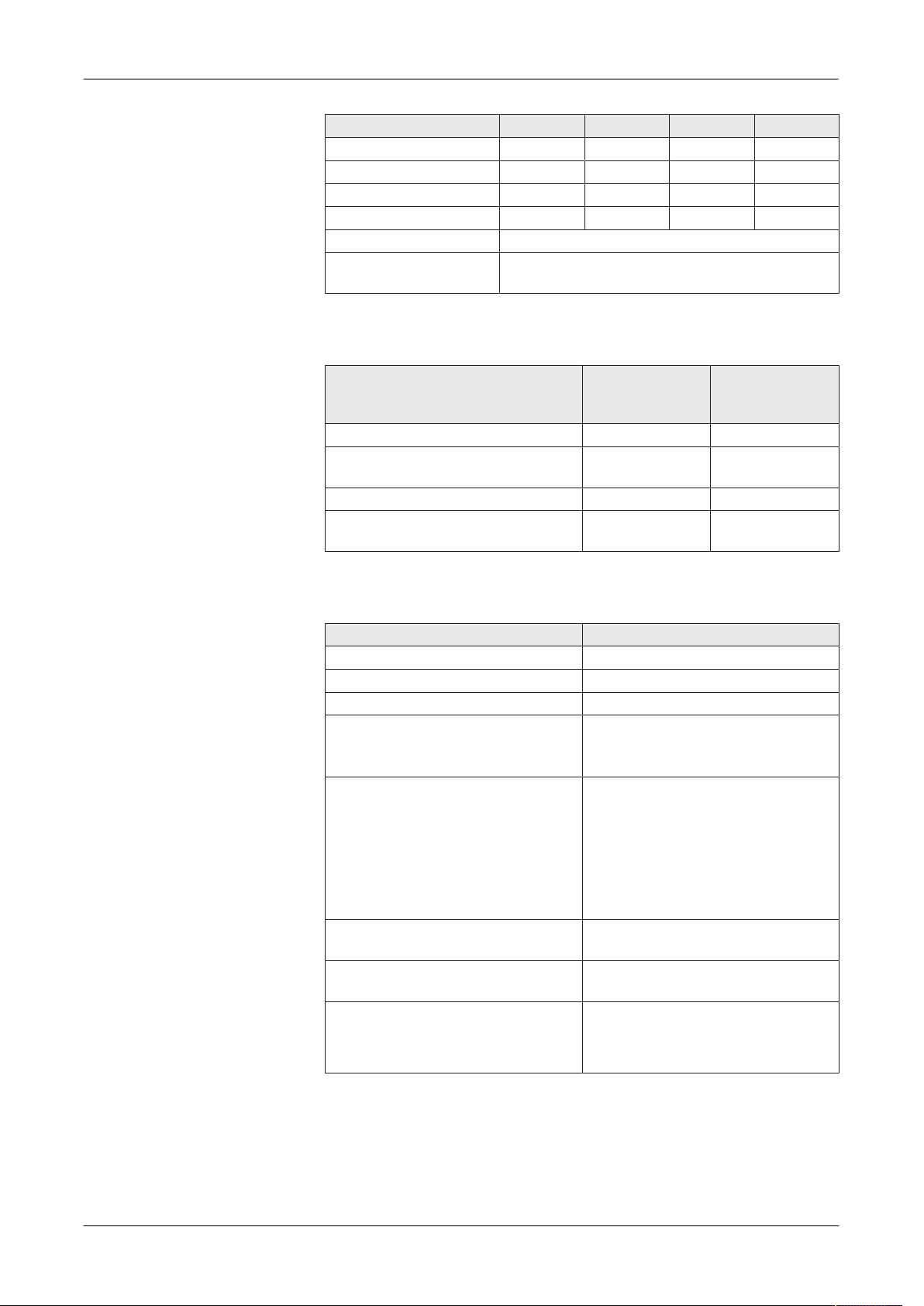

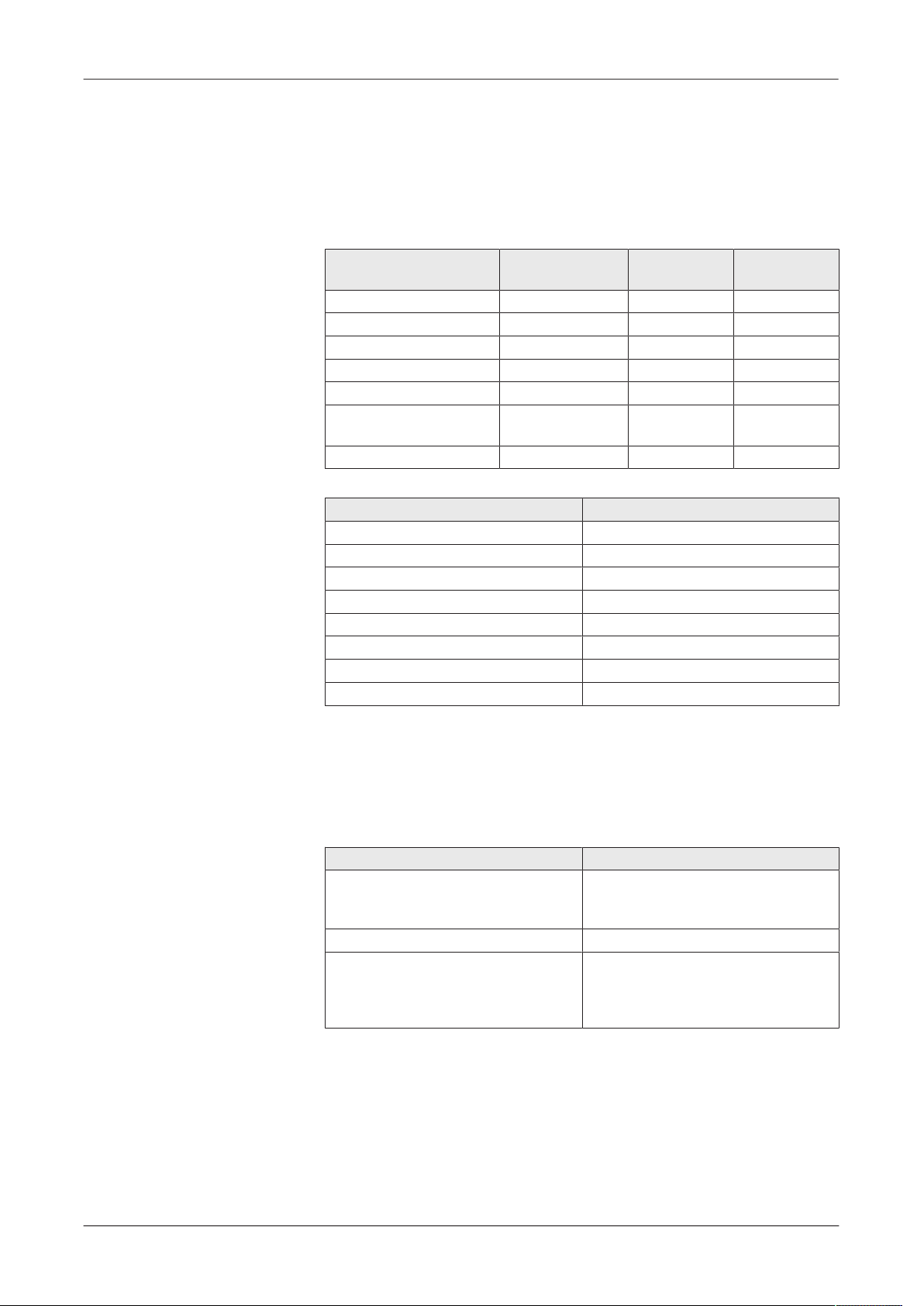

4.1 Technical data

Pump materials

N 0150

N 0150.3

Assembly MaterialAPMaterialSPMaterial

ST

Head plate, intermediate plate Aluminum Stainless

steel

Diaphragm EPDM EPDM PTFE-

Reed valves/valve stopper Stainless

steel

Retainer plate Stainless

steel

O-rings EPDM EPDM FPM

Pneumatic head connection (only

N 0150.3)

Tab.2

Steel Stainless

Stainless

steel

Stainless

steel

steel

Stainless

steel

coated

Stainless

steel

Stainless

steel

Stainless

steel

Pneumatic values

Parameter Value

N 0150APE

N 0150SPE

Max. permissible operating pressure

[bar rel*]

Ultimate vacuum [mbar abs.] 120 130

Flow rate at atm. pressure [l/

min]**

Tab.3 *Bar rel related to 1013 hPa

**Liters in standard state (1013 hPa, 20°C)

Parameter Value

Max. permissible operating pressure

[bar rel*]

Ultimate vacuum [mbar abs.] 25 30

Flow rate at atm. pressure [l/

min]**

Tab.4 *Bar rel related to 1013 hPa

**Liters in standard state (1013 hPa, 20°C)

1.0 1.0

130 ± 10% 100 ± 10%

N 0150.3APE

N 0150.3SPE

0.5 0.5

130 ± 10% 100 ± 10%

Value

N 0150STE

Value

N 0150.3STE

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

7

Technical data Diaphragm Pump N 0150

Pneumatic connections

Pump type Value

N 0150 Thread size G 1/4*

N 0150.3 Thread size G 1/4*

Tab.5 *Acc. to ISO 228

Electrical data for pumps with capacitor motor

N 0150

Parameter Value Value Value Value

Voltage [V]* 100 115 220 230

Frequency [Hz]* 50/60 60 60 50

Power P1 [W] ** ** ** 900

Current consumption [A] ** ** ** 7.8

Motor protection class See motor type plate

Max. permissible mains

See operating instructions for motor

voltage fluctuations

Tab.6 *For further voltage and frequency variants, see type plate

**See type plate

N 0150.3

Parameter Value Value Value Value

Voltage [V]* 100 115 220 230

Frequency [Hz]* 50/60 60 60 50

Power P1 [W] 1200 1000 ** 1000

Current consumption [A] 5 8.5 ** 9.3

Motor protection class See motor type plate

Max. permissible mains

See operating instructions for motor

voltage fluctuations

Tab.7 *For further voltage and frequency variants, see type plate

**See type plate

Electrical data for pumps with three-phase motor

N 0150

Parameter Value Value Value Value

Voltage [V]* 200/346 277/480 220/380 230/400

Frequency [Hz]* 50/60 60 60 50

Power P1 [W] ** ** ** 900

Current consumption [A] ** ** ** 6.1/3.5

Motor protection class See motor type plate

Max. permissible mains

See operating instructions for motor

voltage fluctuations

Tab.8 *For further voltage and frequency variants, see type plate

**See type plate

8 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Technical data

N 0150.3

Parameter Value Value Value Value

Voltage [V]* 200/346 277/480 220/380 230/400

Frequency [Hz]* 50/60 60 60 50

Power P1 [W] ** ** ** 900

Current consumption [A] ** ** ** 6.1/3.5

Motor protection class See motor type plate

Max. permissible mains

See operating instructions for motor

voltage fluctuations

Tab.9 *For further voltage and frequency variants, see type plate

**See type plate

Weight

Pump type Weight (kg)

Three-phase

Weight (kg)

Capacitor motor

motor

N 0150APE Approx. 34.5 Approx. 40.5

N 0150SPE

Approx. 40.5 Approx. 46.5

N 0150STE

N 0150.3APE Approx. 41.5 Approx. 46.5

N 0150.3SPE

Approx. 53.5 Approx. 58.5

N 0150.3STE

Tab.10

Other parameters

Parameter Value

Permissible ambient temperature + 5°C to + 40°C

Permissible media temperature + 5°C to + 40°C

Max. surface temperature* + 85°C

Dimensions

N 0150

N 0150.3

See Chapter 7.1 Installing the pump

Fig. 9

Fig. 8

Gas tightness** of the pump head

(Leak rate):

N 0150 _P.9 E/ N 0150.3_P.9 E/ N

< 6 x 10-3 mbar l/s***

0150 ST.9 E/ N0150.3ST.9E

N 0150 SP.13 E/ N 0150.3SP.13 E

< 6 x 10-6 mbar l/s***

N 0150 ST.13 E/ N 0150.3ST.13E

Highest permissible relative air humidity of the environment

Maximum installation altitude [m

< 6 x 10-5 mbar l/s***

80% for temperatures to 31°C, decreasing linearly to 50% at 40°C.

See operating instructions for motor

above sea level]

Protection class of pump:

N 0150

N 0150.3

Tab.11 *To reduce the surface temperature of the pump heads and to extend the

service life of the diaphragm, you can optionally attach a water cooling system (see

Chapter 7.4 Connecting water cooling (optional)).

**The gas tightness of the pump head is no longer ensured after the pump head is

opened or after changing diaphragm and reed valves. A leak test can be used to

determine whether the original gas tightness is again achieved.

***Values apply for helium leak test

IP 20

IP 20

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

9

Design and function Diaphragm Pump N 0150

1

2 3

4

5

1

2

3

4

5

5 Design and function

Design

1 Pneumatic pump outlet

2 Pneumatic pump inlet

3 Electrical terminal box

4 Motor

5 Motor fan cover

1 Pneumatic pump outlet

2 Pneumatic pump inlet

3 Electrical terminal box

4 Motor

5 Motor fan cover

Fig.1 Diaphragm pump N 0150 (three-phase motor)

Fig.2 Diaphragm pump N 0150 (capacitor motor)

10 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Design and function

5

4

6

3

2 2

7

1

5

6

4

3

2

2

7

1

1 Pneumatic pump outlet

2 Union nut

3 Pneumatic head connec-

tion

4 Motor

5 Motor fan cover

6 Electrical terminal box

7 Pneumatic pump inlet

Fig.3 Diaphragm pump N0150.3 (three-phase motor)

1 Pneumatic pump outlet

2 Union nut

3 Pneumatic head connec-

tion

4 Motor

5 Motor fan cover

6 Electrical terminal box

7 Pneumatic pump inlet

Fig.4 Diaphragm pump N0150.3 (capacitor motor)

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

11

Design and function Diaphragm Pump N 0150

Function of a diaphragm pump

1 Outlet valve

2 Inlet valve

3 Transfer chamber

4 Diaphragm

5 Eccentric

6 Connecting rod

7 Pump drive

Fig.5 Function of a diaphragm pump

Diaphragm pumps transfer, compress (depending on the version) and evacuate gases and vapors.

The elastic diaphragm (4) is moved up and down by the eccentric (5) and the

connecting rod (6). In the downwards stroke, it aspirates the gas to be transferred via the inlet valve (2). In the upwards stroke, the diaphragm presses the

medium out of the pump head via the outlet valve (1). The transfer chamber

(3) is hermetically separated from the pump drive (7) by the diaphragm.

12 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Transport

6 Transport

General

Personal injury and/or property damage due to incorrect or improper transport of the pump

In the event of incorrect or improper transport, the

CAUTION

CAUTION

pump can fall down, be damaged or injure persons.

àUse suitable auxiliary means if necessary

(carrying strap, lifting gear, etc.).

àWhere appropriate, wear suitable personal

protective equipment (e.g., safety shoes,

safety gloves).

Risk of injury from sharp edges on the packaging

There is a risk of injury from cutting on the sharp

edges when grabbing corners or when opening

the packaging.

à Where appropriate, wear suitable personal

protective equipment (e.g., safety shoes,

safety gloves).

à

Transport the pump in the original packaging to the installation location.

à

Store the original packaging of the pump (e.g., for later storage).

à

Inspect the pump for transport damage after receiving it.

à

Document any transport damage in writing.

à

Remove any transport safeguards on the pump prior to commissioning.

Parameter

Parameter Value

Storage temperature + 5°C to + 40°C

Transport temperature - 10°C to + 60°C

Permissible humidity (non-condensing)

Tab.12

Prior to commissioning, make sure that the pump has reached the

ambient temperature (4 Technical data).

30% to 85%

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

13

Transport Diaphragm Pump N 0150

Transport with carrying strap

Fig.6 Position of carrying strap (example)

1. Pull the carrying strap under the pump (see Fig. 6).

Fig.7

2. Fasten the carrying strap between compressor housing and motor

(Fig. 1, see Fig. 7).

3. Make certain that the lifting load cannot be transferred from the belt to

the pump connection.

4. Lift the pump from the packaging with the help of lifting gear.

5. Lower the pump carefully at the installation location.

14 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Installation and connection

7 Installation and connection

The pumps are only to be installed in accordance with the operating parameters and conditions described in Chapter 4 Technical data.

Observe safety notices (see Chapter 3 Safety).

7.1 Installing the pump

à

Before installing, store the pump at the installation location to allow it to

reach the ambient temperature.

Mounting dimensions

à

For mounting dimensions, see the following figures:

Fig.8 Mounting dimensions pump series N 0150.3

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

15

Installation and connection Diaphragm Pump N 0150

Cooling air supply

Immediate environment of the

hot pump parts

Installation location

Fig.9 Mounting dimensions pump series N 0150

Danger of getting burned by hot surfaces

Hot surfaces could occur if the pump overheats.

à When installing the pump, make sure that

WARNING

à

During installation, make sure that no combustible or thermally deformable objects are positioned in the immediate environment of the

hot pump parts (head, motor).

à

Make sure that the installation location is dry and that the pump is protected against rain, splash, gushing and drip water as well as from

other contaminants.

à

Make sure that the installation location is accessible for maintenance

and service.

à

Make sure that the pump is securely attached to the intended fastening

holes. If necessary, secure pump to base plate with rubber-bonded

metal (see accessories, Chapter 11.2 Accessories; observe details on

pump weight, Chapter 4 Technical data).

sufficient cooling air infeed and discharge is

ensured.

à

Make sure that access to moving parts (such as via the pump housing

from below) is avoided.

The IP protection class of the pump motor is specified on the type

plate.

à

Mount the pump at the highest point in the system to prevent condensate from collecting in the pump head.

à

Protect pump from dust.

à

Protect pump from vibration and impact.

16 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Installation and connection

Installation position

Protection against foreign

objects

à

The pump can be mounted in any installation position. Use metal

screws to fasten the pump at the indicated attachment points.

Personal injury and/or property damage from vibrations

Pump vibrations, in combination with adjacent

WARNING

components, can result in crushing and/or damage to these components.

à Make sure that pump vibrations cannot lead

to dangers in combination with adjacent components.

à

Take protective measures against touching and foreign objects which

could enter the pump.

7.2 Electrical connection

Danger to life from electric shock

àOnly have the pump connected by an autho-

rized specialist.

Fastening the connection cables

DANGER

à

When connecting to a power source, observe the applicable standards,

directives, regulations and technical standards.

à

When connecting to a power source, carefully read and observe the

motor operating instructions (including the notice on insulation resistance measurement).

à

Install a device for separating the pump motor from the electrical mains

in the electrical installation (in accordance with EN 60335-1).

à

Protect the pump motors in accordance with EN 60204-1 (overcurrent

protection, overload protection).

Refer to the pump type plate for the max. current consumption.

à

It is recommended that an additional emergency-off system be installed.

à

Mount the pumps in such a way that it is not possible to touch the electrically live parts (electrical connection).

à

Fasten the connection cables so that

– the cables do not come into contact with movable or hot parts.

– the cables cannot be worn or damaged on sharp corners or edges

àOnly have the pump connected if the power

supply is disconnected.

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

17

Installation and connection Diaphragm Pump N 0150

– no tensile and pressure forces are exerted on the connection point

of the cables (strain relief)

The three-phase motors are suitable for operation with frequency

converters.

Connecting the pump

1. Compare the data of the supply voltage with the details on the motor

type plate. See the pump type plate for the maximum current consumption of the pump.

For the permissible deviation of the supply voltage, see operating

instructions for motor.

2. Open the terminal box cover.

3. Connect the earth wire to the pump motor.

4. Connect the cables for the electrical voltage according to the operating

instructions for the motor.

Set the direction of rotation according to the arrow on the fan hood

(see 7.1 Installing the pump and operating instructions for the mo-

tor).

5. Close the terminal box cover again.

Connected components

Pressure relief device

Pump discharge

Decoupling

7.3 Pneumatic connection

Personal injury or property damage through

ejected plugs

If not removed, the plugs on the pressure side of

CAUTION

the pump can be ejected by the resulting operating pressure.

à Remove plugs during installation.

à

Only connect components to the pump that are designed for the pneumatic data and thermal requirements of the pump. (see Chapter 4

Technical data).

à

Protect compressors by means of a pressure relief device between the

pressure-side connections of the compressor and the first shut-off

valve.

à

If the pump is used as a vacuum pump, safely (with respect to medium

and noise) drain the hot pump discharge that may, under certain circumstances, occur at the pneumatic outlet of the pump.

à

KNF recommends mechanically decoupling the pump from the pipe

system, e.g., through the use of flexible hoses or pipes. In this way it is

possible to prevent the transfer of possible pump vibrations and noises

to the system.

18 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Installation and connection

Connecting the pump

A marking on the pump head indicates the flow direction.

Risk of injury from mixing up suction and pressure

side

Mixing up the suction and pressure side can result

CAUTION

in breakage of connected components on the suction and pressure side.

à Observe the marking of inlet and outlet.

1. Remove protective plugs from the hose connection threads.

2. Connect suction and pressure line (for mounting dimensions, see

Chapter 4 Technical data).

3. Lay the suction and pressure line at a downward angle to prevent condensate from running into the pump.

Pneumatic noises can be reduced or dissipated by using a silencer

(see Chapter 11.2 Accessories).

Secure the pressure-side connections with a fastener (e.g., hose/

pipe clamp) to prevent the hoses from slipping down from the connection.

7.4 Connecting water cooling (optional)

Water cooling (see 11.2 Accessories) can increase the service life

of the diaphragm, particularly with high pressures or high ambient

temperature.

Recommended parameters

Parameter Value

Water temperature + 5°C to + 30°C

Water flow rate [l/min] 1.0

Tab.13

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

19

Installation and connection Diaphragm Pump N 0150

Mounting dimensions For mounting dimensions see Fig. 10, Fig. 11 and Fig. 12:

The base plate is shown as an additional accessory on the following

dimensional drawings.

Fig.10 Mounting dimensions pump series N 0150.3

Fig.11 Mounting dimensions pump series N 0150

à

Operate the water connection up to max. 1.0 bar gauge.

20 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Installation and connection

à

Safely drain water discharge.

à

Flow in both directions is permissible.

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

21

Operation Diaphragm Pump N 0150

8 Operation

8.1 General

Risk of burns from hot pump parts and/or hot

medium

Some pump parts may be hot during or after oper-

WARNING

WARNING

ation of the pump.

àAllow pump to cool after operation.

àTake protective measures to protect against

touching hot parts.

Injury to eyes

Coming too close to the inlet/outlet of the pump

may result in injury to the eyes due to the present

vacuum/operating pressure.

à Do not look into the pump inlet/outlet during

operation.

à

Only operate the pumps in accordance with the operating parameters

and conditions described in Chapter 4 Technical data.

à

Ensure the proper use of the pumps (See Chapter 2.1 Proper use).

à

Eliminate the possibility of improper use of the pumps (see Chapter 2.2

Improper use).

à

Observe safety notices (Chapter 3 Safety).

à

The pumps are built-in devices. Before they are commissioned, it must

be ensured that the machines or systems into which the pumps are installed comply with the relevant provisions.

22 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Operation

Risk of bursting of pump head due to excessive

pressure increase

àDo not exceed the maximum permissible op-

WARNING

erating pressure (see 4 Technical data).

àMonitor the pressure during operation.

àIf the pressure exceeds the maximum permis-

sible operating pressure of the pump: immediately switch off the pump and remedy the fault

(see Chapter 10 Troubleshooting).

àOnly throttle or regulate the air or gas quantity

on the suction line to prevent the maximum

permissible operating pressure from being exceeded.

àIf the air or gas quantity on the pressure line is

throttled or regulated, make sure that the maximum permissible operating pressure at the

pump is not exceeded.

àEnsure that the pump outlet is not closed or

restricted.

Excessive pressure, with all of the associated hazards, can be prevented by means of a bypass line with a pressure relief valve between the pressure and suction sides of the pump. Further information is available from the KNF technical adviser (for contact data,

see www.knf.de).

Risk of dangerous gas mixtures during pump operation if the working diaphragm breaks

If the diaphragm should break, the medium will

WARNING

mix with the air in the compressor housing.

à The diaphragm must be replaced prior to fur-

ther operation (see Chapter 9 Servicing).

Personal injury and damage to the pump through

automatic start

If pump operation is interrupted by the thermal

WARNING

switch or the triggering device for the PTC thermistor sensor due to overheating, the pumps resume operation automatically after they have

cooled down.

à Ensure that no dangerous situations can

arise as a result.

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

23

Operation Diaphragm Pump N 0150

Operation with open suction-side gas connection can result in contaminants and objects being drawn in.

Pump standstill

Vapors as medium The service life of the diaphragm can be extended by preventing the for-

Switching off/decommissioning

pump

Recommissioning

Inspecting the pump

à

When the pump is at a pump standstill, establish normal atmospheric

pressure in the lines.

The pump must not be started up against pressure or vacuum during switch-on. This also applies during operation after a brief power

failure. If a pump starts up against pressure or vacuum, the pump

may block, thereby activating the thermal switch or triggering device

for the PTC thermistor sensors and switching off the pump.

à

Ensure that normal atmospheric pressure is present in the lines when

switching on.

mation of condensate in the pump. Therefore:

à

Only perform work with saturated or nearly saturated vapors with a

warm pump.

à

KNF recommends: When transferring aggressive media, flush the

pump before switching off (see Chapter 9.2.1 Flushing the pump) to ex-

tend the service life of the diaphragm.

à

Establish normal atmospheric pressure in the lines (relieve pump

pneumatically).

à

Before recommissioning, observe the applicable standards, guidelines,

regulations and technical standards at the electrical connection.

à

Inspect the pump periodically for external damage or leakage.

24 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Servicing

9 Servicing

9.1 Servicing schedule

Component Servicing interval

Pump

Hose connections

Diaphragm and reed valves

Tab.14

à

Periodic inspection for external

damage or leakage.

à

Periodic inspection for noticeable changes to noises and vibrations

à

Periodic inspection for external

damage or leakage.

à

Replace no later than if there is

a decrease in the pump flow

rate.

à

Replace if the pressure or flow

rate of the pump changes without apparent reason.

9.2 Cleaning

9.2.1 Flushing the pump

When transferring dangerous and environmentally hazardous media, KNF

recommends flushing the pump at atmospheric pressure for a few minutes

prior to switch-off (if necessary for safety reasons: with an inert gas) to extend the service life of the diaphragm.

à

Discharge the media safely.

9.2.2 Cleaning the pump

Risk of burns from hot pump parts

The pump head or motor may still be hot after operation of the pump.

CAUTION

WARNING

à Allow pump to cool after operation.

Health hazard due to dangerous substances in the

pump

Depending on the medium being transferred,

caustic burns or poisoning is possible.

àWear protective equipment if necessary, e.g.,

protective gloves, goggles.

àClean pump with suitable measures.

During cleaning work, ensure that no fluids enter the interior of the

housing.

à

Solvents should only be used during cleaning if head materials are not

affected (ensure resistance of the material).

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

25

Servicing Diaphragm Pump N 0150

à

If compressed air is available, blow out parts.

9.3 Changing diaphragm and reed valves

Requirements

à

Motor disconnected from mains and voltage-free

à

Pump and motor have cooled

à

Pump cleaned and free of hazardous materials

à

Hoses/pipes removed from pneumatic pump inlet and outlet.

With multi-headed pumps, parts may be interchanged between the individual pump heads.

à

Change the parts of the individual pump heads that are to be exchanged one after the next.

Health hazard due to dangerous substances in the

pump

Depending on the medium being transferred,

WARNING

caustic burns or poisoning is possible.

àWear protective equipment if necessary, e.g.,

protective gloves, goggles.

Spare parts

àClean pump with suitable measures.

Risk of burns from hot pump parts

The pump head or motor may still be hot after operation of the pump.

CAUTION

For two-headed pumps:

Servicing work should generally be performed on both heads at the

same time.

Spare part* Position designation** Quantity

Diaphragm (4) 1 (per pump head)

O-ring (2) 2 (per pump head)

O-ring (only .13) (8) 1 (per pump head)

O-ring (only .13) (10) 1 (per pump head)

Reed valve, suction

side

Reed valve, pressure

side

Screw (13) 4 (per pump head)

Tab.15 * According to spare parts list, Chapter 11.1 Spare parts

** According to Individual parts of the pump head

à Allow pump to cool after operation.

(17) 1 (per pump head)

(14) 1 (per pump head)

26 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Servicing

Tool and material

Quan-

Tool/material

tity

1 Size 4 Allen key with torque indicator

1 Size 5 Allen key with torque indicator

1 Screwdriver blade width 5.5 mm

1 Size 2 Phillips screwdriver (for fan assembly)

1 Adjustable face spanner wrench for nuts with two holes, pin di-

ameter 4 mm, length approx. 160 mm (available as wrench for

retainer plate as KNF accessory, see 11.2 Accessories).

1 Felt-tip pen

1 Hot-air blower

1 Adhesive (Delo ML5249) or comparable product

Tab.16 *According to accessory list, Chapter 11.2 Accessories

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

27

Servicing Diaphragm Pump N 0150

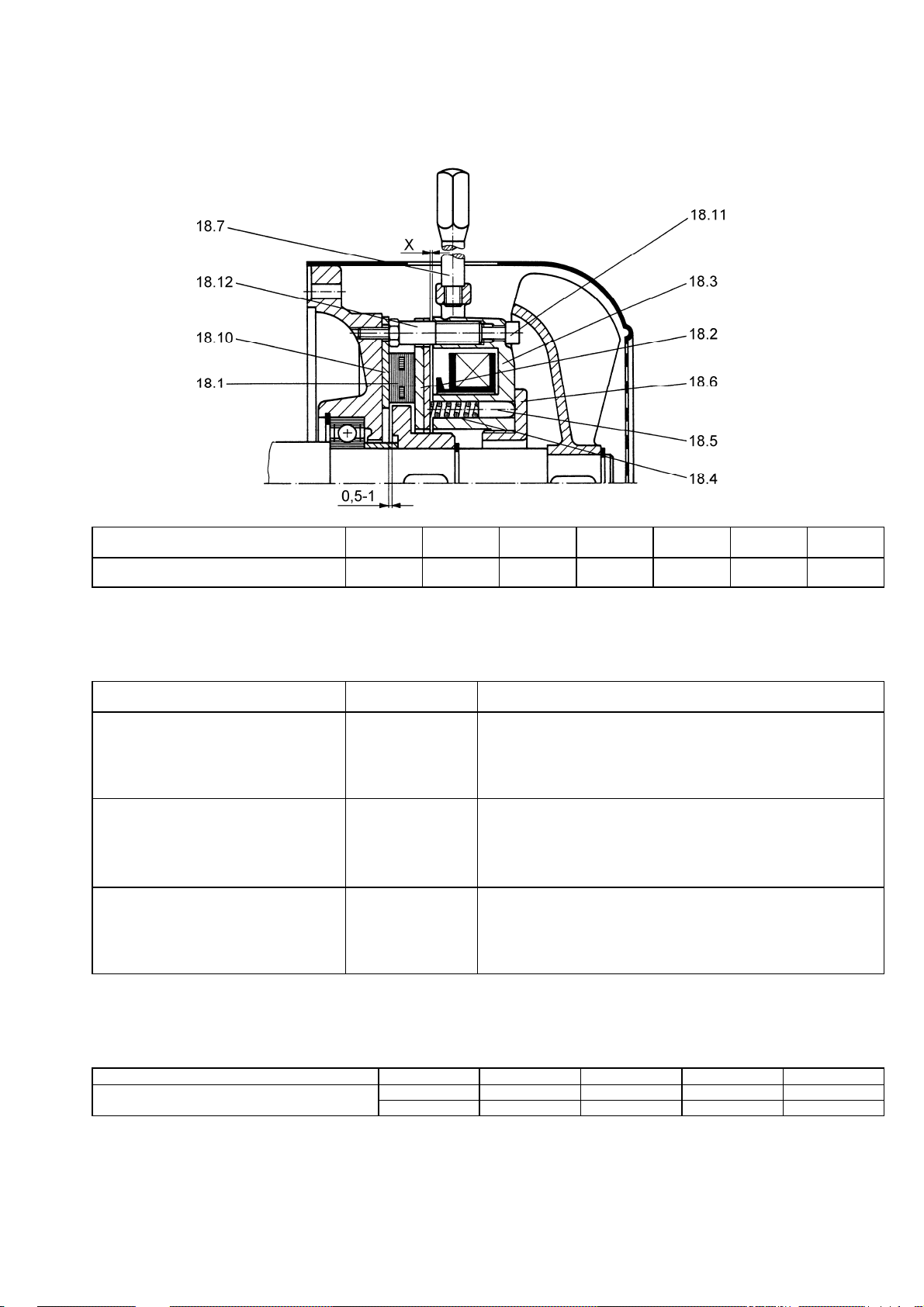

Union nut

Marking

1 Head plate

2 O-ring

3 Intermediate plate

4 Diaphragm

5 Housing

6 Shim ring(s)

7 Connecting rod

8 O-ring (only .13)

9 Conrod plate

10 O-ring (only . 13)

11 Retainer plate

12 Hexagon socket head

cap screws

13 Slotted cheese head

screw

14 Reed valve, pressure

side

15 Valve stopper, pres-

sure side

16 Hexagon socket head

cap screws

17 Reed valve, suction

side

18 Valve stopper, suction

side

Fig.12 Individual parts of the pump head

The following item numbers refer to Individual parts of the pump head

unless specified otherwise.

Removing pump head

1. Accessing the fan blades:

Loosen fastening screws of the motor fan cover (see Fig. 1 - Fig. 4) and

remove cover.

2. Only for two-headed pumps:

Remove the pneumatic connection between the pump heads; to do

this, mark the union nuts (see Fig. 3 and Fig. 4) according to Fig. 13

and loosen.

3. Mark head plate (1), intermediate plate (3) and housing (5) with a con-

Fig.13 Marking of the union nuts

tinuous line made with a felt-tip pen. This helps avoid incorrect assembly later.

4. Loosen the six hexagon socket head cap screws (12) as well as the

two screws (16); remove head plate (1) and intermediate plate (3).

5. For two-headed pumps:

Perform steps 3 and 4 for second pump head.

28 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Servicing

Changing the diaphragm

1. Heat retainer plate (11) with a hot-air blower (T=approx. 400°C) for approx. 5 minutes to approx. 100°C.

Risk of burns from hot parts

Burns may occur on skin contact with the hot retainer plate and countersunk screw or other

WARNING

heated pump parts.

àWear protective gloves

àLoosen retainer plate only with face spanner

wrench

àOnly place retainer plate and countersunk

screw on a heat-resistant surface.

2. Removing the retainer plate (11):

Loosen retainer plate from the conrod plate (9) with the wrench for retainer plate by turning counterclockwise and remove.

3. Remove diaphragm (4).

4. Only .13:

Remove the O-ring (10) from the housing (5).

5. Only .13:

Remove the O-ring (8) from the conrod plate (9).

6. Check all parts for soiling and clean if necessary.

There may be glue residue on the external thread of the retainer

plate as well as on the internal thread of the conrod plate. Remove

this.

Caution: Take care not to let the shim ring(s) fall into the pump

housing.

When removing the conrod plate, remove and set the shim ring(s)

aside for safe keeping.

When remounting, use the exact same number of shim ring(s).

7. Turn the fan blade to move the connecting rod (7) with conrod plate (9)

to the middle position.

8. Place new diaphragm (4) on conrod plate (9); make certain that the

bulges around the outer circumference and around the inner circumference of the diaphragm lie in grooves of the housing and conrod plate.

9. Only .13:

Insert new O-ring (10) in housing (5).

10. Only .13:

Insert new O-ring (8) in conrod plate (9).

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

29

Servicing Diaphragm Pump N 0150

11. Apply adhesive around the thread of the retainer plate (11) and in the

threaded hole of the connecting rod (7) and screw the retainer plate

into the connecting rod.

While screwing in, turn the retainer plate back one turn to allow the

adhesive to spread onto both thread flanks (retainer plate and conrod plate).

Attention: Note the use-by-date for the adhesive.

The adhesive may lose its effectiveness after the use-by-date has

passed.

12. Then securely tighten retainer plate (11) with the wrench for retainer

plate (tightening torque: 20 Nm).

Attention: Observe the harding time for the adhesive when recommissioning the pump.

The hardening time of the adhesive is approx. 24 hours.

13. For two-headed pumps:

Perform steps 1 to 12 for second pump head.

Changing reed valves

1. Remove the two O-rings (2) from the intermediate plate (3).

2. Use felt-tip pen to mark the position of the valve stopper of the suction

side (18) to the intermediate plate (3); Remove valve stopper (18) and

reed valve of the suction side (17) after loosening the screw (13).

3. Remove valve stopper of pressure side (15) and reed valve of pressure side (14) from intermediate plate (3) after loosening the screws

(13).

4. Mount the new reed valves on the suction and pressure side together

with the valve stoppers.

5. For two-headed pumps:

Perform steps 1 to 4 for second pump head.

Mounting pump head

1. Place intermediate plate (3) on housing (5) according to the felt-tip pen

marking (diaphragm should be held in middle position by holding the

fan blade).

2. Insert the two new O-rings (2) in intermediate plate (3).

3. Place head plate (1) on intermediate plate (3) according to the felt-tip

pen marking.

4. Screw in hexagon socket head cap screws (12) and (16) one to two

threads.

5. Tighten the two hexagon socket head cap screws (16) (tightening

torque: 6 Nm), then tighten the hexagon socket head cap screws (12)

crosswise (tightening torque: 9 Nm).

6. Check the pump for smooth running by turning the fan wheel.

7. For two-headed pumps:

Perform steps 1 to 6 for second pump head.

8. Remount motor fan cover (Fig. 1 - Fig. 4).

9. For two-headed pumps:

Remount the pneumatic connection between the pump heads. In doing

so, retighten the union nuts to the original position (as marked during

disassembly, see Fig. 13).

30 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Troubleshooting

10 Troubleshooting

Danger to life from electric shock

àAll work on the pump may only be performed

by authorized specialists.

DANGER

àDisconnect the pump power supply before

working on the pump.

àCheck and ensure that no voltage is present.

Check the pump (see following tables).

Pump does not transfer

Cause Fault remedy

Pump is not connected to the electrical mains.

No voltage in the electrical mains.

Connections or lines are blocked.

External valve is closed or filter is

clogged.

Condensate has collected in the

pump head.

Diaphragm or reed valves are worn

or defective.

Thermal switch or triggering device

for PTC thermistor sensor of the

motor has tripped.

Tab.17

à

Connect pump to the electrical mains.

à

Check room fuse and switch on if necessary.

à

Check connections and lines.

à

Remove blockage.

à

Check external valves and filters.

à

Separate the source of the condensate from the

pump.

à

Flush the pump with air at atmospheric pressure

for a few minutes (if necessary for safety reasons:

with an inert gas).

à

Replace diaphragm and reed valves (see Chapter

Changing diaphragm and reed valves).

à

Disconnect pump from electrical mains.

à

Allow pump to cool.

à

Determine cause of the overheating and rectify.

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

31

Troubleshooting Diaphragm Pump N 0150

Flow rate, pressure or vacuum too low

The pump does not achieve the flow rate specified in the technical specifications or

in the data sheet.

Cause Fault remedy

Condensate has collected in the

pump head.

There is overpressure on the pressure side and at the same time

vacuum or pressure above atmospheric pressure on the suction

side.

Pneumatic lines or connection

parts have insufficient cross section or are throttled.

Leaks occur at connections, lines

or pump head.

Connections or lines are completely or partially plugged.

Head parts are soiled.

Working diaphragm broken.

Diaphragm or reed valves are worn

or defective.

Tab.18

à

Separate the source of the condensate from the

pump.

à

Flush the pump with air at atmospheric pressure

for a few minutes (if necessary for safety reasons:

with an inert gas).

à

Change the pneumatic conditions.

à

Disconnect pump from the system to determine

the output values.

à

Eliminate throttling (e.g., valve) if necessary.

à

Use lines or connection parts with larger cross

section if necessary.

à

Eliminate leaks.

à

Check connections or lines.

à

Remove the parts and particles that are causing

the plugging.

à

Clean head components.

à

Stop pump immediately.

à

Replace diaphragm and reed valves (see Chapter

Changing diaphragm and reed valves).

Fault cannot be rectified

If you are unable to identify any of the specified causes, send the pump to

KNF Customer Service (contact data: see www.knf.com).

1. Flush pump with air at atmospheric pressure for a few minutes (if necessary for safety reasons: with inert gas) to free the pump head of dan-

gerous or aggressive gases (see Chapter 9.2.1 Flushing the pump).

2. Clean the pump (see Chapter 9.2.2 Cleaning the pump).

3. Send the pump together with completed Health and Safety Clearance

and Decontamination Form (see Chapter Health and safety clearance

and decontamination form) to KNF, stating the nature of the transferred

medium.

32 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Spare parts and accessories

11 Spare parts and accessories

11.1 Spare parts

Spare part set

A spare part set consists of:

Parts Item number* Quantity

N0150

Diaphragm (4) 1 2

O-ring (2) 2 4

O-ring (only .13) (8) 1 2

O-ring (only .13) (10) 1 2

Reed valve, suction side (17) 1 2

Reed valve, pressure

side

Screw (13) 4 8

Tab.19 *see Chapter 9.3 Changing diaphragm and reed valves

Spare part set Order number

N 0150_P.9 315468

N 0150SP.13 315469

N 0150ST.9 315471

N 0150ST.13 315472

N 0150.3_P.9 315473

N 0150.3SP.13 315474

N 0150.3ST.9 315476

N 0150.3ST.13 315477

Tab.20

(14) 1 2

Quantity

N0150.3

11.2 Accessories

Accessories Order number

Water cooling connection:

N 0150S_

N0150.3S_

Suction filter G1/4 316662

Base plate with rubber-bonded

metal:

N 0150

N 0150.3

Tab.21

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

305998

306765

304463

33

Returns Diaphragm Pump N 0150

12 Returns

When operating pumps and systems in various applications, such as laboratories or the process-based industry, there is a risk that components that

come into contact with media could be contaminated with poisonous, radioactive or other hazardous substances.

For this reason, customers who send any pumps and systems to KNF

must submit a Health and Safety Clearance and Decontamination Form in

order to avoid a hazardous situation for KNF employees. This Health and

Safety Clearance and Decontamination Form provides information on,

among other things:

§

physiological safety

§

whether cleaning of the components that come into contact with the

medium has been performed

§

whether decontamination was performed

§

media that have been transferred or used

Customers can conveniently provide all details that KNF requires for the

processing of the return using an online form in the "Product/Service" area

at www.knf.de. All steps necessary for the return to KNF are also provided

there.

34 Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

Diaphragm Pump N 0150 Appendix

13 Appendix

See also

§ Betriebsanleitung Drehstrommotormotor DE-EN.pdf

§ CE-Erklärung Drehstrommotor DE-EN.pdf

§ Betriebsanleitung Kondensatormotor DE-EN.pdf

§ CE-Erklärung Kondensatormotor DE-EN.pdf

Translation of Original operating and installation instruction, English, KNF 308918-308921 03/19

35

Deutsch / English

Betriebsanleitung für Drehstrommotoren

(IE2 + IE3 nach IEC 60034-30)

Operating Instructions for three-phase-motors

(IE2 + IE3 according to IEC 60034-30)

Baugröße / Frame size HEF IE2 80 L/.. - HEF IE2 355 L/..

HEF IE3 80 L/.. - HEF IE3 355 L/..

Ausgabe / Edition 07.15 Art.-Nr. / Art. No.: 187233 Ident.-Nr. / Ident No.: K.51.821.064

Alle Rechte vorbehalten! / All rigths reserved.

EMOD Motoren GmbH D-36364 Bad Salzschlirf Zur Kuppe 1

Fon 06648/51-0 Fax 06648/51143 info@emod-motoren.de www.emod-motoren.de

Deutsch

Die in dieser Betriebsanleitung enthaltenen Sicherheitshinweise sind unbe-

Sonderausführungen und Bauvarianten können in technischen

Details von der Grundtype abweichen. Bei eventuell auftretenden Unklarheiten wird dringend empfohlen sich mit der EMOD

Motoren GmbH in Verbindung zu setzen. Hierbei grundsätzlich

Motortype und Motornummer angeben.

1 Allgemeine Hinweise

1.1 Anwendungsbereich

Die Motoren können entsprechend der auf dem Leistungsschild gestempelten Schutzart, der vom Hersteller vorgesehenen Bauform laut

Katalog oder den Angaben des Kunden eingesetzt werden. Beim

Einsatz von Sondermotoren gelten zusätzlich die Angaben in Angebot und Auftragsbestätigung.

dingt zu beachten!

1.2 Sicherheit

und Erfahrung geeignetem Personal durchgeführt werden.

Hierbei sind besonders zu beachten:

-die technischen Daten und Angaben über die zulässige Verwendung

(Inbetriebnahme-, Umgebungs- und Betriebsbedingungen), die u.a.

im Katalog, der Betriebsanleitung, den Schildangaben und der

übrigen Produktdokumentation enthalten sind,

-die einschlägigen Errichtungs- und Unfallverhütungsvorschriften,

-der fachgerechte Einsatz von Werkzeugen, Hebe- und Transportein richtungen,

-das Anbringen eines Berührungsschutzes im eingebauten Zustand,

bei Gefährdung von Personen durch bewegliche Teile,

-die Benutzung persönlicher Schutzausrüstung.

Die Aufstellung, Inbetriebnahme, Wartung und Reparatur darf nur von qualifiziertem, auf Grund seiner Ausbildung

2 Transport und Lagerung

2.1 Transport

Antriebseinheiten nicht an den Motortransportösen anheben.

Die Motoren sind nach Eingang auf Transportschäden zu prüfen.

Eventuell vorhandene Schäden grundsätzlich schriftlich aufnehmen.

Motoren mit Zylinderollenlagern werden durch eine Transportsicherung gegen Lagerschäden geschützt. Vor dem Aufziehen der Übertragungselemente bzw. der Inbetriebnahme ist die Transportsicherung zu entfernen.

2.2 Lagerung

Der Lagerort sollte nach Möglichkeit trocken, sauber, temperaturkonstant und erschütterungsfrei sein.

Damit der Schmierfilm in der Motorlagerung und den Dichtungssystemen nicht abreißt, sollte bei längerer Einlagerungszeit die

Motorwelle von Hand, z.B. in monatlichen Abständen, um einige

Umdrehungen gedreht werden.

Die Wälzlager der Motoren sollten neu gefettet bzw. erneuert werden,

wenn der Zeitraum zwischen Lieferung und Inbetriebnahme mehr als

4 Jahre beträgt. Bei ungünstigen Lagerungsbedingungen verringert

sich dieser Zeitraum erheblich.

2.3 Überprüfung des Isolationswiderstandes

Spannungen und dürfen nicht berührt werden!

Beim Transport der komplett montierten

Antriebseinheit nur die dafür vorgesehenen Hebeösen benutzen. Komplette

Bei der Messung des Isolationswiderstandes und unmittelbar danach haben

die Klemmen teilweise gefährliche

Vor Inbetriebnahme des Motors, nach längerer Lagerungsdauer oder

Stillstandzeit (größer 6 Monate), muß der Isolationswiderstand der

Wicklung ermittelt werden. Wicklung mittels Isolationswertmeßgerät

(max. Gleichspannung 500 V) gegen Masse prüfen.

Ist der Mindest-Isolationswiderstand bei einer Wicklungstemperatur

von 25 C kleiner als 30 M oder bei einer Wicklungstemperatur von

75 C kleiner als 1 M muß die Motorwicklung getrocknet werden bis

der erforderliche Mindestisolationswiderstand erreicht ist.

Die Wicklungstemperatur darf hierbei 80 C nicht überschreiten!

Damit bei geschlossenen Motoren ein Luftaustausch erfolgen kann

Lagerschild lösen. Bei Trocknung der Wicklung durch Anschluß an

Niederspannung sind Anweisungen des Lieferwerkes einzuholen.

Nach einem Austrocknen der Wicklung ist eine Wartung der Lager

erforderlich (siehe entsprechendes Kapitel!).

3 Montage und Inbetriebnahme

3.1 Aufstellung

3.1.1 Standort

Die Motoren sollen leicht zugänglich, bei Umgebungs- bzw. Kühlmitteltemperaturen von max. -15 °C bis +60 C aufgestellt bzw.

angebaut werden. Aufstellhöhe max. 2000 m (ü.NN).

Die Kühlluft muß ungehindert zu- und abströmen können und darf

nicht unmittelbar wieder angesaugt werden. Die Luftein- und Luftaus-

trittssöffnungen sowie die Kanäle zwischen den Kühlrippen sind von

Verschmutzung freizuhalten.

Bei Aufstellung mit Wellenende nach oben und unten muß gewährleistet sein, daß in das obere Lager kein Wasser eindringen kann.

3.2 Befestigung von Motoren

Fußmotoren müssen auf ebener, erschütterungsfreier Auflagefläche

aufgestellt und befestigt werden. Alle Befestigungsfüße müssen

planflächig aufliegen; gegebenenfalls zum Ausgleich dünne Bleche

unterlegen.

Bei Flanschmotoren ist auf Planlauf des Gegenflansches zu achten.

Planlauffehler können zu Lagerschäden bzw. zum Ausfall von

Dichtungssystemen führen.

3.3 Kondenswasser-Abflußlöcher

Es ist darauf zu achten, daß vorhandene Kondenswasser-Abflußlöcher nach der Montage an der tiefsten Stelle des Motors liegen und

von Verunreinigungen freizuhalten sind.

Verschlossene Kondenswasser-Abflußlöcher sind von Zeit zu Zeit zu

öffnen und danach wieder zu verschließen.

3.4 Auswuchtung

Maßnahmen zum Berührungsschutz bei rotierenden Bauteilen

beachten!

Die Motorwellen sind am Wellenspiegel entsprechend DIN ISO 8821

mit der Auswuchtart gekennzeichnet:

Auswuchtung mit halber Passfeder „H“

Auswuchtung mit voller Passfeder „F“

Bei Montage des Abtriebselementes auf entsprechende Auswuchtart

achten!

Alle Arbeiten am Motor nur im elektrisch

spannungslosen Zustand durchführen!

Wird ein Motor ohne Antriebselement in

Betrieb genommen, so ist die Paßfeder

gegen herausschleudern zu sichern.

2

Deutsch / English

3.5 Elektrischer Anschluß

Der elektrische Anschluß darf nur durch einen Fachmann

entsprechend den geltenden Sicherheitsvorschriften vorgenommen

werden.

Netzspannung und -frequenz müssen mit den Daten auf dem

Leistungsschild übereinstimmen. 5 Spannungs- und/oder 2

Frequenzabweichung sind zulässig.

Bei Betrieb des Motors an einem Frequenzumrichter ist ein EMVgerechter Anschluß gemäß der Richtlinie 89/336 EWG vorzunehmen.

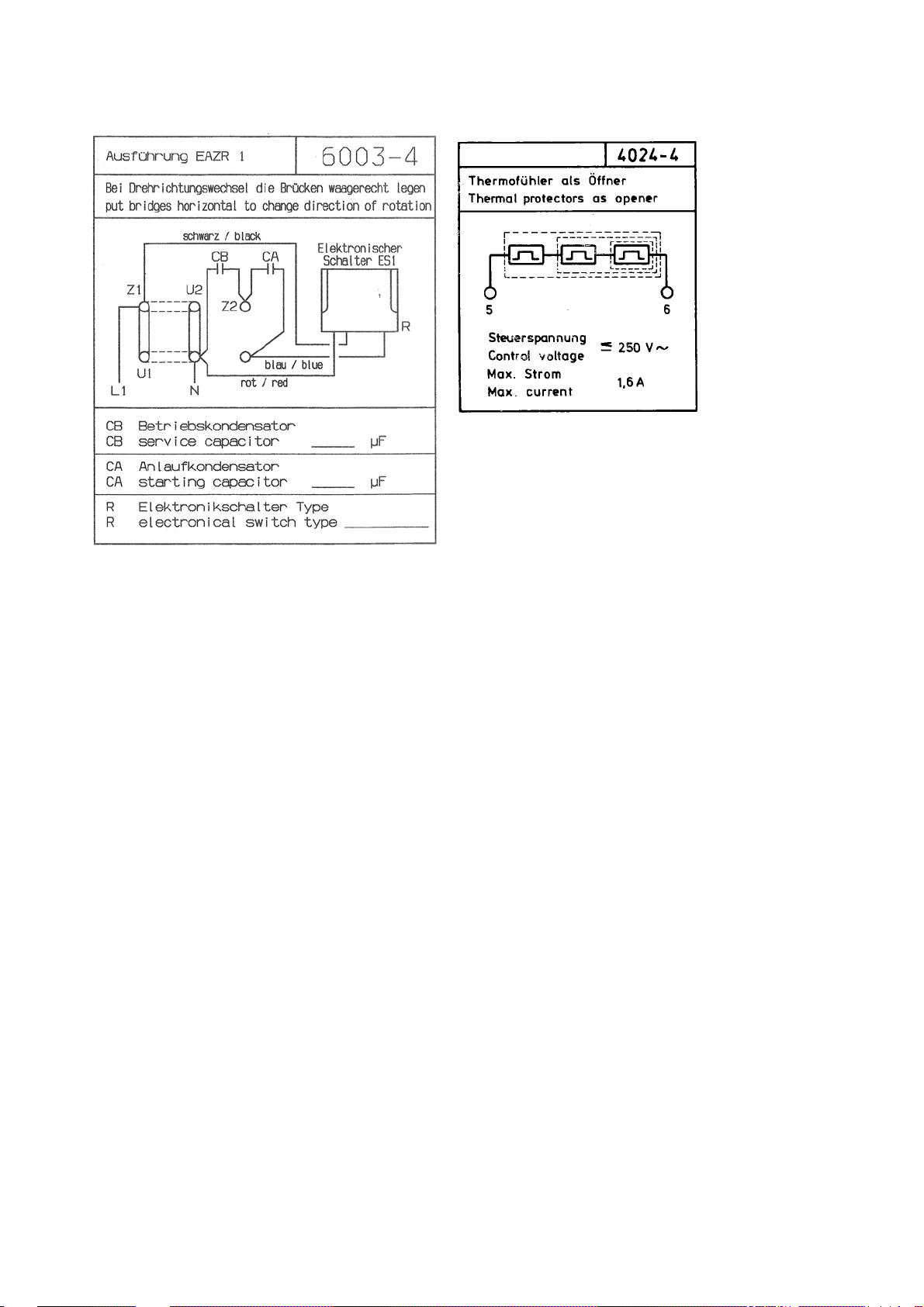

Ein Anschlußplan, Bild 3, befindet sich bei jedem Motor. Anschluß

des Motors und der Steuerung, Überlastungsschutz und Erdung sind

nach den VDE- und Installationsvorschriften, sowie den

landesüblichen, nationalen und internationalen Bestimmungen der

EVUs vorzunehmen.

Die Drehrichtung des abtriebseitigen Wellenendes ist vor der

Inbetriebnahme zu überprüfen. Die Umkehr der Drehrichtung ist

durch vertauschen von zwei beliebigen Netzzuleitungen möglich.

Die zur Zugentlastung oder als Verdrehschutz für die Zuleitungen

vorgesehenen Einführungsteile sind ordnungsgemäß anzuwenden.

Nicht benötigte Einführungsöffnungen verschließen.

Anziehdrehmomente für Schraubenverbindungen der Klemmbrettanschlüße siehe Bild 2

3.6 Motorschutz

Eingebaute Kaltleiter entsprechend dem im Anschlußkastendeckel

bzw. dem beim Motor befindlichen Anschlußplan mit dem Auslösegerät verbinden. Eventuell erforderliche Durchgangsprüfungen nur

mit Meßbrücke (max. 2,5 V) durchführen.

Ist zum Motorschutz ein Temperaturwächter als Öffner vorgesehen,

so ist dieser entsprechend dem Anschlußplan mit dem Hilfsstrom-

kreis in Reihe zu schalten (min. 25 ...... max. 250 V 1,6 A).

Um einen selbstständigen Wiederanlauf des Motors nach dessen

Abkühlung und der Rückschaltung der eingebauten

Temperaturüberwachung zu verhindern, sind entsprechende

schaltungstechnische Maßnahmen zu ergreifen.

3.7 Inbetriebnahme

3.7.1 Montage der Übertragungselemente

Zum Auf- und Abziehen der Übertragungselemente nur geeignete

Werkzeuge und Vorrichtungen verwenden. Auf die Motorlagerung

darf kein Druck oder Schlag übertragen werden.

3.7.2 Ausrichten bei Kupplungsbetrieb

Bei Kupplungsbetrieb sind die Wellen axial und radial gegeneinander

auszurichten. Das Einstellen der Luft zwischen den Kupplungshälften

ist nach den Angaben der Kupplungshersteller vorzunehmen.

Nur Kupplungen verwenden, die mittenversatz-, winkel-, längs- und

drehelastisch sind. Starre Kupplungen sind nicht zulässig und nur in

Ausnahmefällen nach Absprache mit dem Hersteller einsetzbar.

3.7.3 Vor Inbetriebnahme ist mindestens zu prüfen ob:

-der Läufer ohne anzustreifen gedreht werden kann,

-der Motor ordnungsgemäß ausgerichtet und montiert ist,

-die Abtriebselemente richtige Einstellbedingungen haben,

-alle elektrischen Anschlüsse, Verbindungselemente sowie Befestig ungsschrauben ordnungsgemäß angezogen und ausgeführt sind,

-vorhandene Zusatzeinrichtungen funktionsfähig sind,

-die Kühlmittelzuführung nicht beeinträchtigt ist,

-Berührungsschutzmaßnahmen für bewegte und spannungsführende

Teile getroffen sind.

Vorsicht Verbrennungsgefahr!

An der Motoroberfläche können hohe

Temperaturen von über 80 C auftreten.

Bei Bedarf Berührungsschutz vorsehen!

4 Instandhaltung

eventuell vorhandene Zusatz-oder Hilfstromkreise, insbesondere

Stillstandheizungen achten.

4.1 Inspektion

Je nach Schmutzbefall sind die Motoren regelmäßig entlang der gesamten Oberfläche, z.B. mit trockener Druckluft, zu säubern.

Erste Inspektion im Normallfall nach ca. 500 Betriebsstunden, spätestens 1 Jahr durchführen. Weitere Folgeinspektionen sollten je

nach Einsatzbedingungen in geeigneten Intervallen, wie z.B. Nachschmier- bzw. Fettwechselfristen, mindestens jedoch einmal im Jahr

durchgeführt werden.

Bei Inspektionen ist zu prüfen, daß

-die technischen Daten laut Typenschild eingehalten werden,

-keine Leckagen (Öl, Fett, Wasser) vorhanden sind,

-sich die Laufgeräusche der Lager sowie die Laufruhe des Motors

nicht verschlechtert haben,

-alle Befestigungsschrauben für elektrische und mechanische Ver-

bindungen fest angezogen sind,

-bei Kupplungsbetrieb die Ausrichtung des Motors in den zulässigen

Toleranzen liegt.

4.2 Lager

4.2.1 Lager mit Dauerschmierung

Die Lager der Motoren mit Fettdauerschmierung sind unter normalen

Betriebsbedingungen 10000 bis 20000 Betriebsstunden, längstens

jedoch 3 Jahre wartungsfrei.

Bei Motoren mit zwei Deckscheiben als Lagerabdichtung (2Z-Lager)

und einer Drehzahl bis 3600 min

triebsstunden, spätestens 3 Jahren erneuert werden.

Bei Motoren mit einer Deckscheibe (Z-Lager) oder einem Lagerabschlußdeckel als Lagerabdichtung sollte,

-bei Drehzahlen bis 1800 min

-bei Drehzahlen bis 3600 min

spätestens jedoch nach 3 Jahren das Fett und wenn erforderlich die

Lagerung erneuert werden.

4.2.2 Lager mit Nachschmierung

Bei Motoren mit Nachschmiereinrichtung sind Nachschmierfrist, Fettmenge und Fettqualität durch ein Zusatzschild am Motor angegeben.

Falls die im Schmierschild genannten Betriebsstunden innerhalb von

3 Jahren nicht erreicht werden sollte vorzeitig nachgeschmiert

werden. Nachschmieren nur bei drehendem Läufer, damit sich das

neue Fett im Lager verteilt!

Schmierstoffe (siehe Bild 1)

Das Mischen verschiedener Fettsorten ist zu vermeiden!

Achtung: Beim Nachschmieren der Lager müssen unbedingt die

Fettablaßschrauben am Lagerschild AS und BS geöffnet werden!

4.3 Instandsetzung

Ersatzteillisten und normale zeichnerische Darstellungen enthalten

keine detaillierten Angaben über Art und Abmessungen der Bauteile.

Deshalb beim Demontieren Zuordnung der jeweiligen Bauteile feststellen und diese für den Zusammenbau kennzeichnen.

4.3.1 Lagerwechsel

Motor im erforderlichen Umfang demontieren. Wälzlager mit

geeigneter Vorrichtung abziehen und Lagerstellen von

Verunreinigungen säubern!

Neues Wälzlager gleichmäßig auf ca. 80 C erwärmen und

aufziehen.

Alle Arbeiten am Motor nur im abgeschalteten, gegen Wiedereinschalten

gesicherten Zustand durchführen!

Neben den Hauptstromkreisen auch auf

-1

sollten die Lager nach 20000 Be-

-1

nach 20000 Betriebsstunden,

-1

nach 10000 Betriebsstunden,

3

Deutsch / English

Ca. 50% des freien Raumes im Lager sowie der Fetträume im Lagerschild bzw. Lagerdeckel mit Fett der zugelassenen Qualitäten füllen.

Dichtungselemente (z.B. Wellendichtringe) müssen vor dem Zusammenbau auf Funktion sowie Beschädigung überprüft und bei nicht

mehr ausreichender Wirksamkeit erneuert werden.

4.3.2 Fugenabdichtung

Bei Motoren der Schutzart IP56 oder höher (siehe Leistungsschild)

müssen die Teilefugen zwischen dem Motorgehäuse und den Lagerschilden durch eine geeignete, nicht aushärtende Dichtungsmasse

abgedichtet werden.

5 Ersatzteile

Bei Ersatzteilbestellungen bitte neben der genauen Teilebezeichnung unbedingt Motortype und Motornummer (Daten sind dem

Leistungsschild zu entnehmen) angeben.

6 Endgültige Außerbetriebnahme

(Demontage, Recycling, Entsorgung)

Motoren grundsätzlich so zerlegen das ein umweltgerechtes

Recycling und Entsorgen der Motorkomponenten möglich ist.

Bei Recycling und Entsorgung der demontierten Motorkomponenten

grundsätzlich die zum Zeitpunkt der endgültigen Außerbetriebnahme

gültigen gesetzlichen Vorschriften und Bestimmungen beachten!

English

The safety instructions in this operating

Special versions and variants may differ from the basic model in

terms of their technical details. In the event of any points being

unclear, you are urgently recommended to contact EMOD

Motoren GmbH, giving details of the motor type and motor serial

number.

manual are to be observed at all times.

1. General information

1.1 Area of application

The motors may be used in accordance with the protection type

specified on the rating plate, the model quoted by the manufacturer in

the catalogue or the details given by the client. When using special

motors the details in the quotation and confirmation of order also

apply.

1.2 Safety

suitable personnel who have been trained to do so and have

experience of this type of work.

The following points must be given particular consideration:

-the technical data and details on permissible uses (commissioning,

ambient and operating conditions) which are given in the catalogue,

the operating manual, the plates and the other product

documentation,

-the relevant installation and accident prevention regulations,

-the proper use of tools, lifting gear and transport equipment,

-the installation of a contact guard when the motor has been fitted, if

there is any risk to persons from moving parts,

-the use of personal safety equipment.

The installation, commissioning,

maintenance and repair of these motors

may only be completed by qualified,

2 Transport and storage

2.1 Transport

Complete drive units must not be lifted by the motor transporteyes.

The motors are to be checked on receipt for transport damage. Any

damage must be reported immediately in writing.

Motors with cylindrical roller bearings are protected from bearing

damage by a transport guard. Before connecting the transmission

elements or commissioning the motor, the transport guard is to be

removed.

2.2 Storage

The storage site should, if possible, by dry, clean, kept at a constant

temperature and not subject to shocks.

To protect the bearings and the lubricating system, the motor shaft

has to be turned around from some rotations from time to time.

The roller bearings in the motors should be greased or replaced if the

period between placing the motors in storage and commissioning

them exceeds four years. In poor storage conditions this period will

be considerably reduced.

When transporting the completely

assembled drive unit only use the lifting

eyes provided for this purpose.

4

English

2.3 To check the insulation resistance

dangerous

Before commissioning the motor, after it has been in storage or has

not been used for a lengthy period of time (longer than six months)

the insulation resistance of the coil must be measured. Check the coil

using an insulation resistance measuring instrument (max. direct

voltage 500 V) against the earth.

If the minimum insulation resistance at a coil temperature of 25 C is

less than 30 M or less than 1 M at a coil temperature of 75 C, the

motor coil must be dried until the required minimum insulation

resistance has been achieved.

The coil temperature must not be allowed to exceed 80 C. To ensure

that air exchange takes place in enclosed motors, loosen the bearing

plate. If you wish to dry the coil by connecting it to low voltage, seek

assistance from the supplier.

After drying the coil the bearings must be serviced (see relevant

section).

3 Installation and commissioning

3.1 Installation

3.1.1 Site

The motors should be installed where they allow easy access, at

ambient and coolant temperatures of max. -15 °C to +40 C (IEC

60034-30). Altitude of site max. 1000 m (above sea level).

The cooling air must be able to flow to and from the motor without

hindrance and must not be drawn in again immediately after being

fed out of the motor. The air intake and outfeed apertures and the

ducts between the cooling ribs are to be kept free of dirt.

If the motor is installed with its shaft ends pointing upwards and

downwards, it must be ensured that no water can ingress into the top

bearing.

3.2 Securing the motors

Motors with feet must be installed and secured on a flat, shockfree

surface. All the securing feet must lie flat on the surface; if necessary

place thin sheets of metal beneath the feet to compensate for

unevenness.

For flange motors attention must be given to ensuring that the

counter flange runs evenly. Even running errors may cause bearing

damage or the failure of sealing systems.

3.3 Condensation drain holes

It must be ensured that the existing condensation drain holes are at

the lowest point of the motor when it has been installed and are kept

free of dirt.

Sealed condensation drain holes are to be opened from time to time

and then sealed again.

3.4 Balancing

Take the appropriate action to prevent contact with rotating

parts.

The motors are marked on the shaft end face with the kind of balance

corresponding to DIN ISO 8821:

Balancing with a half featherkey „H“

Balancing with a full featherkey „F“

If the drive element is connected, consideration must be given to the

relevant balancing type.

voltages and must not be touched.

When measuring the insulation

resistance and immediately afterwards

the terminals may be carrying

Before completing any work on the

motor the voltage supply must be

disconnected.

If a motor is commissioned without a

drive element, the fitted spring is to be

secured to prevent it being thrown out.

3.5 Electrical connection

The electrical connection may only be performed by a specialist in

accordance with current safety regulations.

The mains voltage and frequency must comply with the data on the

rating plate. Tolerances of 5% for the voltage and/or 2% for the

frequency are permissible.

Operating the motor with a frequencyinverter, an EMC-compliant

connection in accordance with Directive 89/336 EEC is carried out.

A connection diagram, Figure 3, is supplied with every motor. The

connection of the motor and the controller, overload guard and earth

are to comply with the VDE and installation regulations as well the

country-specific, national and international regulations of the

electricity supply companies.

The direction of rotation from the shaft has to be checked befor

starting. The reversal of the direction of rotation is possible by

swapping any two mains wires.

The infeed parts used as a pull-relief and torsion guard for the supply

cables are to be used properly. Any infeed apertures which are not

required are to be sealed.

The tightening torques for screw connections on the terminal board

connectors are shown in Figure 2.

3.6 Motor protection

Connect the integral neutral conductors to the trip unit as shown on

the connection diagram in the connection box cover or supplied with

the motor. Any puncture tests which are necessary should only be

completed using a measurement bridge (max. 2.5 V).

If a temperature monitor is fitted as an opener to protect the motor, it

is to be connected in series as shown on the connection diagram to

the auxiliary power circuit (min. 25 V ..... max. 250 V 1,6 A).

In order to prevent an independent restart of the motor after it has

been cooled down and the downshift of the embedded sensors,

appropriate actions are taken.

3.7 Commissioning

If necessary fit a contact guard.

3.7.1 To install the transmission elements

Only use suitable tools and equipment to install and remove the

transmission element. No pressure or blows must be exerted on the

motor bearing.

3.7.2 Alignment for operation with a coupling

For operation with a coupling, the shafts are to be aligned axially and

radially against each other. The gap between the coupling halves is

to be adjusted as instructed by the coupling manufacturer.

Only use couplings which are elastic to central offset, angled,

longitudinal and rotary motion. Rigid couplings are not allowed and

may only be used in exceptional cases by agreement with the

manufacturer.

3.7.3 Before commissioning at least the following checks are to

be made:

-the rotor can be turned without catching,

-the motor has been aligned and installed properly,

-the output elements have correct settings,

-all the electrical connections, connection elements and securing

bolts have been properly tightened and made,

-any additional equipment is fully functional,

-the coolant supply is not defective,

-contact guards have been fitted for moving parts and live parts.

Caution - risk of burns.

Temperatures of over 80 C can be

generated on the surface of the motor.

5

English

4 Maintenance

main circuits, this also applies to any additional or auxiliary

circuits, particularly standstill heating systems.

4.1 Servicing

Depending on the amount of dirt they generate the motors are to be

cleaned on a regular basis over their entire areas, for example using

compressed air.

The first service is generally necessary after approx. 500 operating

hours, but at the latest after one year. Subsequent servicing is to be

carried out at suitable intervals, for example relubricating or grease

replacement intervals, but at least once per year.

During services checks are to be made that

-the technical data on the rating plate are observed,

-there are no leaks (oil, grease or water),

-the noises generated by the bearings and the smoothness of the

motor have not deteriorated,

-all the securing bolts for electrical and mechanical connections are

tight,

-if operating with a coupling, the alignment of the motor is within the

permissible tolerances.

4.2 Bearings

4.2.1 Bearings with permanent lubrication

The bearings for motors with permanent lubrication generally require

no maintenance in normal operating conditions for between 10000

and 20000 operating hours, but at most for three years.