KNF LIQUIPORT 100**.18 Series, LIQUIPORT 300**.18 Series, LIQUIPORT 1.100**.18 Series, LIQUIPORT 1.300**.18 Series Operating Instructions Manual

LAB

LIQUIPORT

NF 100_ _.18

NF 1.100_ _.18

NF 300_ _.18

NF 1.300_ _.18

OPERATING INSTRUCTIONS

DIAPHRAGM

LABORATORY PUMP

KNF Flodos AG

Wassermatte 2

6210 Sursee, Switzerland

Tel +41 (0)41 925 00 25

Fax +41 (0)41 925 00 35

www.knf.com

Operating Instructions LIQUIPORT EN Content

1. General information 5

1.1 Information about the instructions 5

1.2 Warnings 6

1.3 Symbols 7

1.4 Disclaimer of liability 8

1.5 Manufacturer's address 8

1.6 Year of manufacture 8

1.7 Other applicable documents 8

1.8 Copyright 8

1.9 Warranty conditions 8

2. Safety 9

2.1 Intended use 9

2.2 Reasonably foreseeable misuse 9

2.3 Owner's responsibility 10

2.4 Personnel requirements 10

2.5 Product-specific dangers 11

2.6 Personal protective equipment 12

2.7 Safety equipment 12

2.8 Environmental protection considerations 13

2.9 Danger areas 13

2.10 Declaration of conformity 14

3. Technical data 15

3.1 Items included in delivery 15

3.2 Storage conditions 15

3.3 Pump materials 15

3.4 Product key 16

3.5 Dimensions 17

3.6 Installation location requirements 18

3.7 Electrical connections and performance data 18

3.8 Other parameters 19

3.9 External actuation (RC version only) 20

3.10 Hydraulic ratings 21

3.11 Hydraulic connections 22

3.12 Transferred medium 23

4. Assembly and function 24

4.1 Metering pump assembly 24

4.2 Operating principle 24

5. Shipment 25

5.1 Checking delivery 25

5.2 Registering a complaint 25

5.3 Arranging for return 25

6. Installation and initial start-up 26

6.1 Safety 26

6.2 Installation 27

6.3 Initial start-up 30

7. Operation 31

7.1 Safety 31

7.2 Operating controls 32

7.3 Starting the pump 32

7.4 Stopping the transferring operation 32

7.5 Adjusting the flow rate 33

8. RC version – external actuation 34

8.1 External actuation analog input 34

8.2 Start/Stop pulse input 35

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 3

Content Operating Instructions LIQUIPORT EN

8.3 Digital output 36

8.4 Shutting down the pump in an emergency 36

9. Cleaning and maintenance 37

9.1 Safety 37

9.2 Maintenance plan 37

9.3 Cleaning the pump 38

9.4 Cleaning / replacing valve plates and pump diaphragm 39

9.5 Checking that pump is leak-tight 42

10. Shutdown 43

10.1 Safety 43

10.2 Procedure 43

11. Troubleshooting 44

11.1 Safety 44

11.2 Rectifying transfer problems 45

12. Spare parts and accessories 46

12.1 Spare parts 46

12.2 Accessories 46

13. Decontamination declaration 47

4 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN General information

Contents

Storage location

Passing on

Project pumps

Illustrations in the instructions

1. General information

1.1 Information about the instructions

The Operating Instructions contain important notes on how to use the

pump. In order to ensure safe working and proper functioning it is essential to observe all the specified safety precautions.

These Operating Instructions are part of the product, and must be

stored in its immediate vicinity in a location accessible to personnel at

all times.

These Operating Instructions are part of the product, and must be

passed on to the next owner if the device is resold.

Customer-specific project pumps (pump models which begin with "PL"

or "PML") may differ from the Operating Instructions, in which case the

agreed specification is also applicable. It is listed with the other applicable documents.

Illustrations in these Operating Instructions may be to scale, but do not

have be.

The illustrations may differ slightly from the actual product.

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 5

General information Operating Instructions LIQUIPORT EN

DANGER

Indicates a dangerous situation which will lead directly to death or serious injury if it is not avoided.

WARNING

Indicates a dangerous situation which may lead to death or serious

injury if it is not avoided.

CAUTION

Indicates a dangerous situation which may lead to moderate or minor

injuries if it is not avoided.

NOTE

Indicates a situation which may cause damage to property if it is not

avoided.

1.2 Warnings

Warnings in the Operating Instructions are identified with the danger

symbol, keywords and colours. These provide an indication of the extent of the danger.

6 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN General information

WARNING

Danger of injuries and property damage caused by illegible labels

The labelling on the device may become illegible with time.

- Maintain labels on the device in a legible condition.

- Replace any illegible labels.

Recycling

Not to be disposed of with household waste

General danger symbol

Further details of the nature of the danger are provided in the warning highlighted by this symbol.

Electrical danger

Fire danger

Danger of caustic burns or burns

Danger of automatic start-up

Disconnect device from power supply by pulling out the mains plug

1.3 Symbols

The following symbols appear in the Operating Instructions, on labels

on the device, and on its packaging:

The following symbols in the Operating Instructions and on the device

and its packaging indicate environmental protection considerations:

The following symbols in safety precautions and on the device indicate

the nature of the danger:

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 7

General information Operating Instructions LIQUIPORT EN

1.4 Disclaimer of liability

In preparing the contents of these Operating Instructions, account has

been taken of applicable regulations and the state of the art.

The manufacturer can accept no liability for any damage or malfunctions caused by failure to follow the Operating Instructions.

The manufacturer can accept no liability for any damage or malfunctions caused by modification or conversion of the device or improper

handling.

The manufacturer can accept no liability for any damage or malfunctions caused by the use of non-approved spare parts and accessories.

1.5 Manufacturer's address

KNF Flodos AG

Wassermatte 2

6210 Sursee, Switzerland

Tel +41 (0)41 925 00 25

Fax +41 (0)41 925 00 35

www.knf.com

1.6 Year of manufacture

The year of manufacture is shown on the device's type plate.

1.7 Other applicable documents

The documents listed must also be taken into consideration.

▪ Chemical resistance list

▪ Sales documents

▪ GTCs

1.8 Copyright

The information, texts and illustrations in these Operating Instructions

are protected by copyright. The contents of these Operating Instructions must not be copied, translated or passed to third parties without

the written consent of the manufacturer.

1.9 Warranty conditions

The applicable warranty conditions are set out in the General Terms

and Conditions of Business and the sales documents.

The warranty does not cover the following:

▪ Malfunctions caused by particles/fibres in the valve system

▪ Sticking of the valve system as a result of inadequate flushing

8 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Safety

2. Safety

2.1 Intended use

This pump is intended exclusively for use as follows:

▪ For transferring and metering liquids.

▪ For indoor operation.

▪ For temporary operation in laboratories for research pur-

poses.

▪ For operation in accordance with the operating parameters

specified in the technical data (see Chapter 3) and other applicable documents.

▪ For transferring media which meet the requirements in the

technical data and other applicable documents.

▪ For operation in fully assembled condition.

▪ For upright operation on a firm table top.

2.2 Reasonably foreseeable misuse

The pump may not:

▪ be operated in an explosive atmosphere;

▪ be used to transfer explosive media;

▪ be used to produce foodstuffs or pharmacological products

(additional certifications are required for this purpose);

▪ be used to transfer media whose compatibility with the pump

head, valves, diaphragm and seals has not been established;

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 9

Safety Operating Instructions LIQUIPORT EN

WARNING

Danger of injuries and property damage caused by insufficiently

qualified staff

Improper use of the pump may result in serious injury and damage to

property.

- All activities must be performed only by adequately qualified

personnel.

Trained personnel

Specialist personnel

Unauthorised personnel

2.3 Owner's responsibility

The operator is responsible for compliance with the safety precautions

in these Operating Instructions and with any safety, accident prevention and environmental protection regulations which apply to the medium to be transferred and the range of applications of the device.

These include the following in particular:

▪ The operator must perform a risk assessment to identify any

additional risks which may arise from the specific working conditions at the pump's installation location and the nature of the

medium to be transferred. The operator must convert these

into instructions for operating the device.

▪ The operator must ensure that any employees working with

the pump have read the Operating Instructions.

▪ The operator must train personnel at regular intervals and in-

form them of the risks involved.

▪ The operator must provide personnel with the necessary pro-

tective equipment as specified in the safety data sheet for the

medium to be transferred.

▪ The operator must maintain the pump in perfect working or-

der.

▪ The operator must ensure compliance with the maintenance

intervals described in the Operating Instructions.

2.4 Personnel requirements

The following qualifications are specified for various activities in the

Operating Instructions:

These have been instructed in the task assigned to them and made

aware of potential dangers and risks. This training is the minimum

qualification for working on the device. Where no other qualification is

specified, the activity must be performed by a trained individual as a

minimum.

The specialist training, knowledge and experience of such personnel,

together with their knowledge of the relevant regulations, standards

and directives, allow them to perform their assigned duties correctly,

and to independently identify and avoid potential dangers and risks.

Individuals whose reactions have been impaired by the consumption

of medicines, alcohol, drugs or by other causes and conditions are not

authorised to perform activities on the device.

10 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Safety

DANGER

Danger of injuries and property damage caused by leaks in connections and the pump head

Poisoning and caustic burns, or undesirable reactions caused by escaping hazardous materials

- Maintain the torque of connections (see hydraulic connec-

tions)

- Check tightening torque of head screws regularly

- Only use pump if it is in perfect working order

- Operate pump in accordance with the technical data

DANGER

Danger of injuries and property damage caused by medium escaping from the discharge outlet

Poisoning and caustic burns, or undesirable reactions caused by escaping hazardous materials

- Place the pump in a suitable collecting vessel

- Never close the discharge outlet

- If medium escapes from the pump's discharge outlet, stop

using the pump and contact your KNF dealer

DANGER

Risk of fire from escaping flammable media

Escaping or leaking flammable media can produce a combustible environment.

- Take fire protection precautions that are appropriate for the

transferred media

- Keep ignition sources away

- Keep suitable extinguishers accessible

- Use means of fire detection

WARNING

Danger of serious injuries or property damage caused by escaping media in the event of overpressure on the suction side

Excessive pressure on the suction side will result in uncontrolled escape of fluid, even if the pump is not operating

- Avoid overpressure on the suction side

2.5 Product-specific dangers

This chapter describes residual risks that have been identified in a risk

assessment. Safety precautions and warnings in this chapter and in

other chapters in the Operating Instructions must be observed in order

to avoid dangerous situations.

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 11

Safety Operating Instructions LIQUIPORT EN

Safety gloves

to protect skin from contact with the transferred medium in accordance with the safety data sheet.

Safety glasses

to protect the eyes from contact with the transferred medium in accordance with the safety data sheet.

Face protection

to protect skin and eyes from contact with the transferred medium in

accordance with the safety data sheet.

DANGER

Danger of injuries and property damage caused by medium escaping from the discharge outlet

Poisoning and caustic burns, or undesirable reactions caused by escaping hazardous materials

- Place the pump in a suitable collecting vessel

- Check the discharge outlet regularly for leaks

- Never close the discharge outlet (see Fig. 1)

- If medium escapes from the pump's discharge outlet, stop

using the pump and contact your KNF dealer

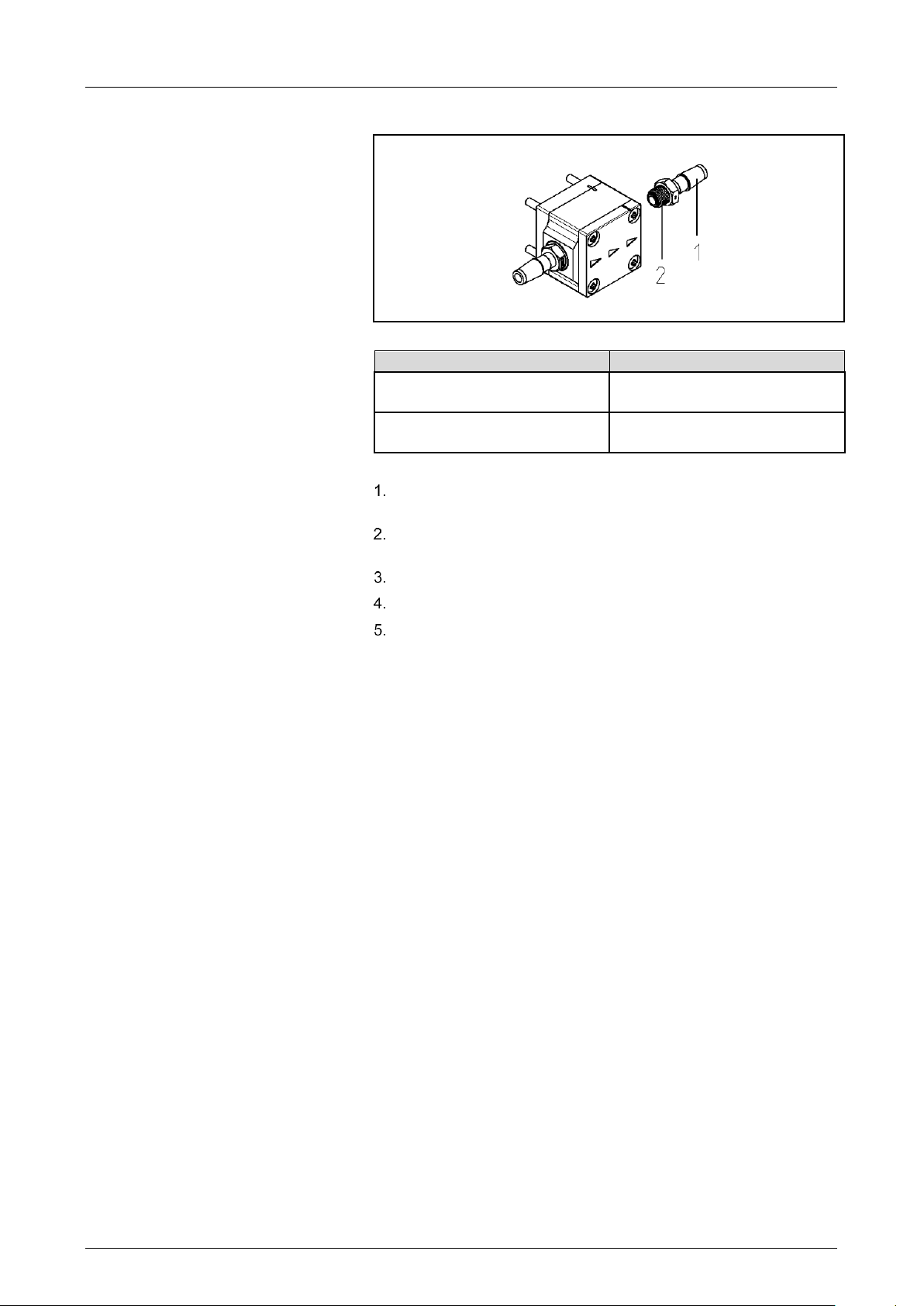

Fig. 1: Discharge outlet

2.6 Personal protective equipment

Special protective equipment must be used when performing certain

tasks. These are indicated separately in the individual chapters.

Where the wearing of protective equipment is concerned it is essential

to observe the safety data sheet for the medium to be transferred.

The following symbols appear in the working area or in the Operating

Instructions:

2.7 Safety equipment

2.7.1 Discharge outlet

If the pump diaphragm ruptures, the transferred medium is channelled

out of the pump through the discharge outlet (see Fig. 1).

2.7.2 Emergency Stop

Pulling out the mains plug acts as an Emergency Stop. If the pump is

installed permanently, an Emergency Stop and a maintenance switch

must be fitted.

12 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Safety

2.8 Environmental protection considerations

All replacement parts should be properly stored and disposed of in accordance with the applicable environmental protection regulations. Ensure adherence to the pertinent national and international regulations.

This applies especially to parts contaminated with toxic substances.

Dispose of any packaging material that is no longer required in an environmentally friendly manner. The packaging materials are recyclable.

Dispose of end-of-life equipment in an environmentally friendly manner. Use appropriate waste collection systems for the disposal of endof-life equipment. Used pumps contain valuable recyclable materials.

2.9 Danger areas

A discharge of aggressive, corrosive, ionizing, flammable or biological

liquids can be dangerous.

The pump danger area should be limited by safe workplaces. Safe

workplaces should comply with the requirements of local work safety

regulations.

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 13

Safety Operating Instructions LIQUIPORT EN

2.10 Declaration of conformity

14 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Technical data

Assembly

Material1)

Pump head

PP

Valve plate / seals

FFKM

Diaphragm

PTFE-coated

Housing

PA, TPE, PC

Assembly

Material1)

Pump head

PVDF

Valve plate / seals

FFKM

Diaphragm

PTFE-coated

Housing

PA, TPE, PC

Assembly

Material1)

Pump head

PTFE

Valve plate / seals

FFKM

Diaphragm

PTFE-coated

Housing

PA, TPE, PC

3. Technical data

3.1 Items included in delivery

▪ LIQUIPORT pump

▪ Mains plug

▪ Operating instructions

3.2 Storage conditions

▪ Pumps must be stored in a dry place and protected from con-

tamination.

▪ The storage temperature must be between 5°C and 40°C.

▪ The pump is supplied with protective caps. These protective

caps must be fitted during storage.

▪ Store pump upright and with protection.

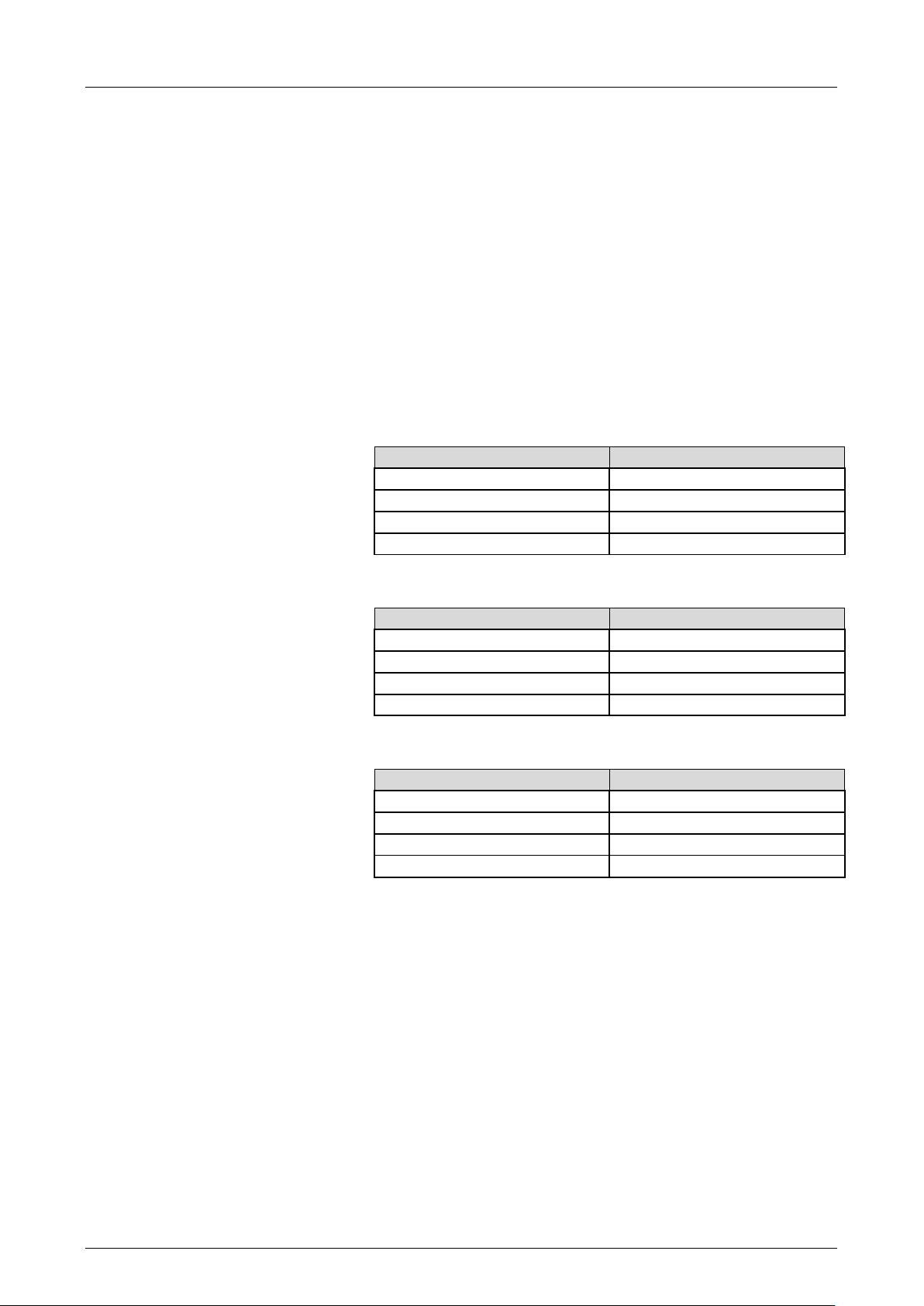

3.3 Pump materials

The type designation KT stands for:

Tab. 1: KT

1)

according to DIN ISO 1629 and 1043.1

The type designation TT stands for:

Tab. 2: TT

1)

according to DIN ISO 1629 and 1043.1

The type designation FT stands for:

Tab. 3: FT

1)

according to DIN ISO 1629 and 1043.1

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 15

Technical data Operating Instructions LIQUIPORT EN

Description

Meaning

PML / PL

Customer-specific designs

NF

Flodos liquid pump

100 / 1.100 / 300 / 1.300

Pump type

KT / TT / FT

Head material

.18

Laboratory device with housing

S / RC

S without external actua-

tion

RC with external actuation

(remote control)

NF 100 KT .18 S

.18

100 / 1.100 / 300 / 1.300

NF

S / RC

- / PMLxxxx / PLxxxx

3.4 Product key

Tab. 4: Product key

16 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Technical data

3.5 Dimensions

Fig. 2: Mounting dimensions LIQUIPORT 100 / LIQUIPORT 1.100

Fig. 3: Mounting dimensions LIQUIPORT 300 / LIQUIPORT 1.300

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 17

Technical data Operating Instructions LIQUIPORT EN

NOTE

An unsuitable location may cause damage to the device

- Install in a dry place

- Protect the installation location of the pump from water in

the form of rain, spray, splashes and drips

- Do not operate the pump in an aggressive or flammable en-

vironment

- Choose a safe location (a level, flat surface) for the pump

- Place the pump in a suitable collecting pan

- If the stability of the pump cannot be ensured, fasten the

pump in place using two screws

- Make sure that the hose connections can be fitted without

strain on the hoses

- Protect the pump against shocks, impacts and strong vibra-

tions

Pump type

LIQUIPORT

100

LIQUIPORT

1.100

Nominal mains voltage [V]

100 – 240V AC +/- 10%,

Frequency [Hz]

50-60 Hz

Max. power consumption AC

100 V / 115 V / 240 V [W]

12 / 12 / 12

15 / 15 / 16

Max. power consumption DC [W]

12

15

Pump DC voltage [V]

24V DC

Maximum operating current, DC

RMS 24 V [A]

0.5

0.63

Max. short-term peak current [A]

0.8

0.8

Power supply fuse

Electronic overload protection

Pump fuse

Electronic overload protection

Pump type

LIQUIPORT

300

LIQUIPORT

1.300

Nominal mains voltage [V]

100 – 240V AC +/- 10%,

Frequency [Hz]

50-60 Hz

Max. power consumption AC

100 V / 115 V / 240 V [W]

22 / 22 / 24

30 / 30 / 32

Max. power consumption DC [W]

22

29

Pump DC voltage [V]

24V DC

Maximum operating current, DC

RMS 24 V [A]

0.92

1.2

Max. short-term peak current [A]

1.3

1.3

Power supply fuse

Electronic overload protection

Pump fuse

Electronic overload protection

3.6 Installation location requirements

The pump is designed to be operated in an upright position.

3.7 Electrical connections and performance data

Tab. 5: Electrical data LIQUIPORT 100

Tab. 6: Electrical data LIQUIPORT 300

18 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Technical data

Pump type

LIQUIPORT 100

LIQUIPORT 1.100

LIQUIPORT 300

LIQUIPORT1.300

Pump weight [kg] 1)

1.0

1.5

Permissible ambient temperature [°C]

+5 to +40

Permissible media temperature

[°C]

+5 to +80

Permissible working height [m

above sea level]

2000

Max. humidity

90% (non-condensing)

Nominal speed [rpm]

3000 rpm

Noise level [dBA]

< 40dBA

Pump protection type

IP 65

Power supply protection type

IP 40

Protection class

III

3.8 Other parameters

Tab. 7: Other parameters

1)

The weight may differ slightly from the stated value, depending on

the version.

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 19

Technical data Operating Instructions LIQUIPORT EN

Parameter

Value

Analog input

Signal range

0-10V

Signal range optional 1)

0-20mA

Input resistance

133 k at 0-10 V

510 at 0-20mA

Dielectric strength

24V DC

Digital input

Signal range

Pull up to 24 V

Dielectric strength

24V DC

Voltage level without external wiring

19V typ.

Level low

≤ 4.0V = low

Level high

≥ 14.0V = high

Pull-up resistance

10 k

Resistance to ground/GND

43 k

Digital output – open-collector output (NPN transistor to GND)

Dielectric strength

24V DC

Loading capacity/output current

low level

0…10mA typ.

20mA max.

1 Analog input

Brown

2 External actuation jumper

White

3 Pulse input

Blue

4 Open collector output

Black

5 Ground

Grey

Pin no.

Lead colour

Description

Function

1

brown

Analog input

(0%) 15% to 100% flow

rate

2

white

External actuation

jumper

Switches pump over to

external actuation.

→ Control knob is deactivated

3

blue

Pulse input

Start/Stop via external

actuation

4

black

Open collector output

Operating mode output

(On/Off)

5

grey

Ground/GND

--

3.9 External actuation (RC version only)

Tab. 8: External actuation

1)

Optional on request.

Fig. 4: RC cable pin assignment

Tab. 9: RC cable pin assignment

20 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Technical data

Type

LIQUIPORT 100

LIQUIPORT 1.100

Flow rate [l/min]

1) 2)

0.2 – 1.3

0.2 - 1.3

Suction head [mWG]

3

3

Max. inlet pressure [bar g] 3)

0.4

0.4

Permissible pressure [bar g]

1.0

6.0

Permissible medium viscosity

[cSt]

150

150

3.10 Hydraulic ratings

Tab. 10: Hydraulic ratings LIQUIPORT 100 / LIQUIPORT 1.100

Fig. 5: Flow rate curve LIQUIPORT 100

Fig. 6: Flow rate curve LIQUIPORT 1.100

1)

Measured with water at 20°C

2)

Flow rates may vary from the values shown, depending on fluid vis-

cosity, pump head material and the hoses / hose connectors used.

3)

Overpressure on the suction side will result in uncontrolled escape of

fluid, even if the pump is not operating. The pressure increase via the

pump must be positive.

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 21

Technical data Operating Instructions LIQUIPORT EN

Pump type

LIQUIPORT 300

LIQUIPORT 1.300

Flow rate [l/min]

1) 2)

0.5 – 3.0

0.5 – 3.0

Suction head [mWG]

3 3 Max. inlet pressure [bar g] 3)

0.4

0.4

Permissible pressure [bar g]

1.0

6.0

Permissible medium viscosity

[cSt]

150

150

Pump type

Connection

LIQUIPORT 100

LIQUIPORT 1.100

Internal thread NPT 1/8" with hose connector for hose ID 8mm

LIQUIPORT 300

LIQUIPORT 1.300

Internal thread NPT 3/8" with hose connector for hose ID 12mm

Tab. 11: Hydraulic ratings

Fig. 7: Flow rate curve LIQUIPORT 300

Fig. 8: Flow rate curve LIQUIPORT 1.300

1)

Measured with water at 20°C

2)

Flow rates may vary from the values shown, depending on fluid vis-

cosity, pump head material and the hoses / hose connectors used.

3)

Overpressure on the suction side will result in uncontrolled escape of

fluid, even if the pump is not operating. The pressure increase via the

pump must be positive.

3.11 Hydraulic connections

22 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Tab. 12: Hydraulic connections

Operating Instructions LIQUIPORT EN Technical data

Parameter

Value

Permissible medium viscosity [cSt]

150

Ideally free of solids, max. particle size [µm]

< 70

Permissible media temperature1 [°C]

+5 to +80

WARNING

Poisoning and caustic burns

If corrosive, poisonous, ionising or biological media come into contact

with skin, eyes and the respiratory tract they may cause serious injuries

- Observe the safety data sheets for the media to be trans-

ferred

- Use personal protective equipment

- Operate the pump in a suitably protected area

- Check the resistance of any parts which come into contact

with the fluid (see chemical resistance list or consult your local

KNF dealer)

WARNING

Damage caused by ionising radiation

Radioactive materials cause serious damage to health and reduce the

service life of the pump.

- Decontaminate the pump

- Wear personal protective equipment

- Mark the pump

NOTE

If the absence of solid material in the pumped material is not ensured, a filter < 70 µm with a sufficiently large filtration surface area

must be installed upstream of the pump in order to prevent damage

to the pump.

NOTE

Before using a medium, check the compatibility of the materials of

the pump head, pump housing, diaphragm and valves with the medium.

- Check the resistance, see the resistance list

- Clarify resistance with KNF

3.12 Transferred medium

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 23

1

Applies to water and low-reactivity media. For aggressive media, re-

sistance is to be checked at a higher medium temperature.

Assembly and function Operating Instructions LIQUIPORT EN

1 On/Off button

2 Control knob

3 Flow rate indicator

4 Standby indicator

5 External indicator

6 Inlet

7 Pump head

8 Outlet

9 Power supply plug

10 External actuation plug (RC

version only)

1 Outlet valve

2 Inlet valve

3 Working chamber

4 Diaphragm

5 Eccentric

6 Connecting rod

7 Pump drive

4. Assembly and function

4.1 Metering pump assembly

Fig. 9: Diaphragm pump

4.2 Operating principle

Fig. 10: Pump assembly

The diaphragm liquid pumps are based on reciprocating displacement

pump technology. The elastic diaphragm (4) is moved up and down by

the eccentric (5) and the connecting rod (6). In the downward stroke it

aspirates the medium to be transferred via the inlet valve (2). In the

upward stroke the diaphragm pushes the medium out of the pump

head via the outlet valve (1). The diaphragm hermetically seals off the

working chamber (3) from the pump drive (7).

24 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Shipment

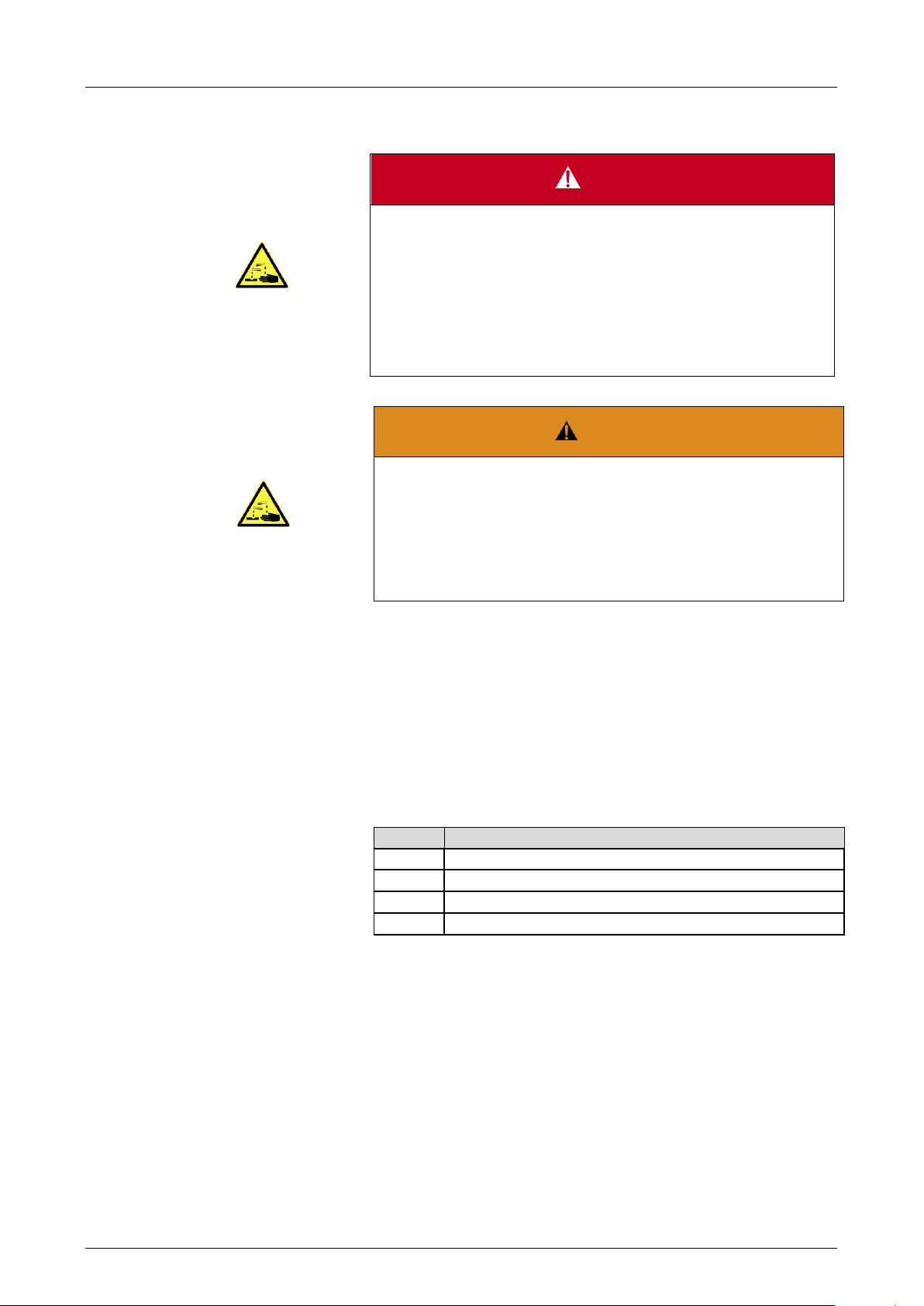

DANGER

Danger of poisoning, chemical burns, or radioactive contamination through contact with pump parts that are not decontaminated

Contact with pump parts that are not properly decontaminated will result in poisoning, chemical burns, or radioactive contamination.

- Use personal protective equipment

- Flush and decontaminate the pump until the possibility of

danger can be eliminated.

- Label any pumps that are used with particularly dangerous

media

- Only decontaminated pumps may be sent

Requirements

Procedure

Requirements

Procedure

Requirements

Procedure

5. Shipment

5.1 Checking delivery

▪ Device delivered and packaged

Check delivery for visible damage

Check that delivery is correct and complete using the packing list

In the event of a discrepancy, register a complaint.

Keep original packaging in case you have to return the item

5.2 Registering a complaint

▪ Device damaged or incomplete

If there are any visible signs of damage, only accept the delivery

with reservations.

Damage and complaints of any kind should be recorded on the

delivery note

Notify the manufacturer of any damage and complaints

5.3 Arranging for return

▪ Device damaged or incomplete

Contact KNF before returning the device

Flush and decontaminate pump

Fill out decontamination declaration and attach to the pump

Send the pump in its original packaging to a service location or

one of our product centres

The pump can be sent by parcel service or post in its original

packaging

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 25

Installation and initial start-up Operating Instructions LIQUIPORT EN

NOTE

KNF retains the right to refuse repair of pumps that are used to move

hazardous materials.

This applies particularly to the following materials:

- Poisons

- Radioactive media

- Elementary halogens (e.g. bromine)

WARNING

Danger as a result of incorrect installation

Injuries or damage to equipment caused by escaping media

- Follow installation instructions

- After assembly, test the system with a harmless liquid

- Only use pump if it is in perfect working order

WARNING

Danger of serious injuries or property damage caused by escaping media in the event of rupturing of the pump diaphragm

Poisoning and caustic burns caused by escaping media as a result of

rupturing of the pump diaphragm. If the pump diaphragm ruptures, the

medium is channelled out of the pump through the discharge outlet.

- When transferring critical media, operate the pump in a col-

lecting tank

- Check discharge outlet for leaks

WARNING

Danger of serious injuries or property damage caused by escaping media in the event of overpressure on the suction side

Overpressure on the suction side will result in uncontrolled escape of

fluid, even if the pump is not operating.

- Avoid overpressure on the suction side

Requirements

Personnel

Personal protective equipment

6. Installation and initial start-up

6.1 Safety

The following requirements apply to all the activities described in this

chapter:

▪ Device is in perfect working order

▪ The system is operated with water

▪ Must be assembled by specialist personnel

▪ Not required

26 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Installation and initial start-up

NOTE

For problem-free, safe operation the following instructions should be

followed:

- Install in a dry place.

- Protect the installation location of the pump from water in the

form of rain, spray, splashes and drips.

- Do not operate the pump in an aggressive or flammable envi-

ronment.

- Choose a safe location (a level, flat surface) for the pump.

- If the stability of the pump cannot be ensured, fasten the

pump in place using two screws.

- Make sure that the hose connections can be fitted without

strain on the hoses.

- Protect the pump against shocks, impacts and strong vibra-

tions.

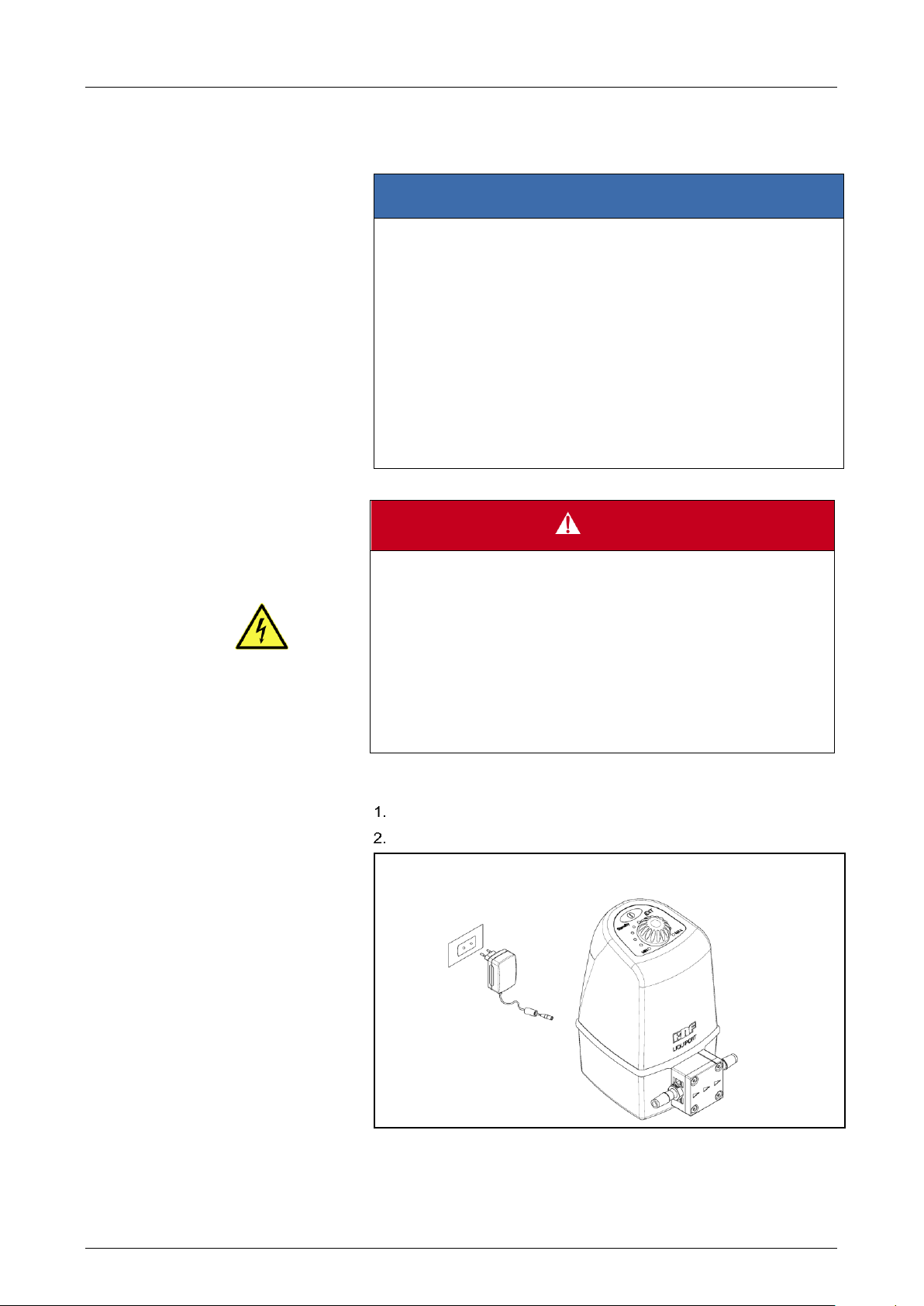

DANGER

Risk of electric shock

- Only operate the pump with the power supply unit supplied.

- Connect the cable from the mains plug to the pump's power

supply socket.

- Plug the mains plug into a correctly installed and properly

earthed mains socket.

- Ensure that the mains plug is protected from water splashes.

- Do not open pump housing or power supply unit.

- Disconnect pump from power supply during maintenance

work.

- If pump is installed permanently, fit a maintenance switch.

6.2 Installation

Before installation, store the pump at the installation location to bring it

up to ambient temperature.

6.2.1 Connect mains plug

When connecting the device to a power source, the relevant norms, directives, regulations and technical standards must be observed.

Use suitable adapters in the power supply unit

Connect power supply unit to pump

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 27

Fig. 11: Electrical connection

Installation and initial start-up Operating Instructions LIQUIPORT EN

NOTE

Arrows on the pump head indicate the flow direction.

1 Hose

2 Connector

3 Hose clip

Connected

components

Hoses

Customer-specific

pumps (PL, PML)

6.2.2 Connect hydraulics

Only connect components to the pump that are designed to han-

dle the hydraulic data of the pump (see Chapter 3).

Only use hoses that are suitable for the maximum operating pres-

sure of the pump (see Section 3).

Only use hoses that are sufficiently chemically resistant to the liq-

uids being transferred.

The connections described below apply to standard products. Dif-

ferent connections may apply for customer-specific projects (PML

or PL).

Use of hose connectors

Fig. 12: Hose connector ID 8mm or ID 12mm

Remove protective caps from connections.

Suction and pressure lines (LIQUIPORT 100 and LIQUIPORT

1.100: hose ID 8mm; LIQUIPORT 300 and LIQUIPORT 1.300:

hose ID 12mm), cut off straight with a sharp knife.

Push the hoses onto the connectors as far as they will go.

For pressure applications with LIQUIPORT 1.100 or LIQUIPORT

1.300, secure hoses with suitable hose clips.

Check that the hoses and transition joints (hose connector/hose)

are fitted correctly and securely.

Check that the system is leak-tight.

28 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Installation and initial start-up

1 Connector

2 Teflon sealing tape

Pump type

Internal thread

LIQUIPORT 100

LIQUIPORT 1.100

NPT 1/8"

LIQUIPORT 300

LIQUIPORT 1.300

NPT 3/8"

Use of internal threads

Fig. 13: Internal thread NPT 1/8"

Tab. 13: Internal thread

Remove protective cap and screwed-in connectors from the con-

nections.

Prepare required fitting with corresponding external thread with

suitable sealant (e.g. Teflon sealing tape).

Screw in fitting and tighten.

Check that the fitting is fitted correctly and securely.

Check that the system is leak-tight.

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 29

Installation and initial start-up Operating Instructions LIQUIPORT EN

CAUTION

Danger of rupture of the fluid system as a consequence of overpressure

The pump builds up pressure. In a closed system the max. permitted

operating pressure may be exceeded, thus causing damage to the

pump and/or the system

- In the case of parts that are in contact with the fluid, use only

those that are designed for the pump's operating pressure as

a minimum

- Do not transfer media against shut-off elements or closed sys-

tems, otherwise

- install pressure relief/safety valve and set to 6 bar (in the KNF

product range)

CAUTION

Danger of unexpected chemical reactions with water

Water residues left in the pump from testing in the factory may react

with the transferred medium.

- Before putting the pump into service, flush it with a non-criti-

cal medium

Prerequisites for start-up

▪ All hoses attached properly

▪ Specifications of the power supply must correspond with the

data on the pump and mains plug type plates.

▪ The pump outlet must be clear of any obstruction.

▪ All cables properly connected

6.3 Initial start-up

Before switching on the pump, check the following points:

Tab. 14: Prerequisites for start-up

Only operate the pump under the operating parameters and condi-

tions described in Section 3.

Ensure that the pump is used as intended

(see Section 2.1).

Avoid improper use of the pump

(see Section 2.2).

Observe safety precautions.

6.3.1 Test the system

In order to prevent damage, the safety, leak-tightness and functioning

of the test set-up should be checked using a suitable harmless medium, such as water.

30 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Operation

DANGER

Danger of injuries and property damage caused by hazardous

materials

Poisoning and caustic burns, or undesirable reactions caused by escaping hazardous materials

- Observe the safety data sheets for the media to be trans-

ferred

- Determine the resistance of the head materials

- Check tightening torque of head screws regularly (see Sec-

tion 9.4)

- Check that pump and system are leak-tight

- Maintain the pump regularly

- Only use pump if it is in perfect working order

- Operate pump in accordance with the technical data

WARNING

Danger of undetected diaphragm rupture

The diaphragm may be damaged by aggressive media, and the medium may escape from the discharge outlet

- Operate the pump in a collecting pan

- Flush pump thoroughly after use or if it is not to be used for

an extended period (see Chapter 9)

- Check the discharge outlet regularly for leaks

- Observe the service life of the diaphragm and other elasto-

mer parts (see Maintenance)

WARNING

Danger of splashing media

If corrosive, poisonous, ionising or biological media come into contact

with skin, eyes and the respiratory tract they may cause serious injuries

- Observe the safety data sheets for the media to be trans-

ferred

- Check that the system is leak-tight before use

- Use personal protective equipment

7. Operation

7.1 Safety

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 31

Operation Operating Instructions LIQUIPORT EN

1 On/Off button

2 Control knob

3 Flow rate indicator

4 Standby indicator

5 External indicator

An externally actuated pump will start as soon as a valid control

signal is present.

(see Chapter 8).

Requirements

Personnel

Personal protective equipment

Special tools required

Fig. 15: Starting / stopping the

pump

The following requirements apply to all the activities described in this

chapter:

▪ Device is in perfect working order.

▪ The system has previously been operated and tested with a

suitable harmless medium (e.g. water).

▪ Trained personnel

▪ The type of protective equipment required will depend on the

medium to be transferred.

▪ Observe safety data sheets and regulations for the handling

of the media to be transferred.

▪ At medium temperatures of over 50°C, take safety precau-

tions against burns.

▪ When transferring very aggressive, biological, flammable or

ionising media, a suitable work station with a safety and extraction system is to be used.

7.2 Operating controls

Fig. 14: Operating controls

7.3 Starting the pump

When it is connected to the power supply, the pump is in standby

mode by default, and the "Standby" indicator illuminates.

➔ Briefly press the “On/Off” button and the pump will start to trans-

fer.

The "Standby" indicator goes off.

7.4 Stopping the transferring operation

➔ Briefly press the “On/Off” button and the pump will stop.

The "Standby" indicator goes on.

32 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Operation

Type

Flow rate [l/min]

LIQUIPORT 100

0.2 to 1.3

LIQUIPORT 1.100

0.2 to 1.3

LIQUIPORT 300

0.5 to 3.0

LIQUIPORT 1.300

0.5 to 3.0

If the analog input is active, the "EXT" indicator illuminates and the

control knob has no function. The flow rate is then specified by the

analog input. See Chapter 8.1

The flow rate of the pump is reduced by counterpressure, suction

head and higher medium viscosity.

In the event of counterpressure, the pump will not start at low flow

rate settings.

Reduce counterpressure or select a higher setting.

Fig. 16: Adjusting the flow rate

Operation in the event of counter-

pressure

7.5 Adjusting the flow rate

Set the pump to the required flow rate using the control knob.

The flow rate setting is shown by the flow rate indicator around the

control knob.

Tab. 15: Specified flow

In the event of counterpressure the pump cannot be set to the lower

flow rates. The counterpressure must be reduced or a higher flow rate

must be selected.

Fig. 17: Operating range

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 33

RC version – external actuation Operating Instructions LIQUIPORT EN

WARNING

Danger of automatic start-up

The pump starts up by itself and without warning.

- Send the start command only when the system has been

tested and is ready for operation

- Mark remote-controlled pumps

- Before start-up, check that hoses and equipment are leak-

tight and working properly

- Do not operate the pump with hazardous media

External actuation functions are available only in the RC version.

When the analog input is active, the pump can be started only if a

valid analog signal is present.

The control knob is deactivated. Manual flow rate entry is blocked.

Name

Voltage range

0 – 10V

On threshold

≥ 0.2V

Off threshold

≤ 0.2V

Activating the analog input

1 Brown (analog input)

2 White (external jumper)

3 Blue

4 Black

5 Grey (ground)

6 Jumper

7 Analog signal 0-10V

Fig. 18: RC cable jumper

Fig. 19: "EXT" indicator

8. RC version – external actuation

Connection details and technical data are provided in Chapter 3.9

8.1 External actuation analog input

The analog input can be used to externally control a pump flow rate

from (0%) 15% to 100%.

The analog input must be activated by connecting the RC cable.

➔ With the RC cable connect the white lead (jumper) to the grey

lead (ground) or with the RC connector, connect pin 2 to pin 5.

See Fig. 18

➔ If external actuation is switched on, this is indicated on the pump

by the illuminated "EXT" symbol.

See Fig. 19

Control signals

Tab. 16: Analog input signals

34 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN RC version – external actuation

Input

Meaning

Signal

Pulse

Start/Stop on signal pulse

Falling edge below

4.0V

Pulse duration

Maximum pulse duration

200 ms

Activation

time

Minimum delay between activation pulse and deactivation

pulse

300 ms

Deactivation

time

Minimum delay between deactivation pulse and activation

pulse

400 ms

Following a pulse, there must be a delay before a new pulse is

sent. See Tab 17.

The pulse duration must not be longer than 200 ms.

The use of debounced switches is recommended.

1 Brown

2 White

3 Blue (pulse input)

4 Black

5 Grey (ground)

6 Pulse switch

Fig. 21: Pulse input

Fig. 20: range analog input

8.2 Start/Stop pulse input

The pump can be externally started and stopped via the pulse input.

➔ The falling signal edge at the pulse input triggers the starting or

stopping of the pump.

➔ If analog actuation is also used, a valid analog signal must be pre-

sent.

Control signals

Tab. 17: Signal pulse input

Fig. 22: Start/stop impulse control

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 35

RC version – external actuation Operating Instructions LIQUIPORT EN

The minimum switching times must be taken into consideration

when the foot switch is operated. See Chapter 8.2

The pump can also be switched on or off using the Start/Stop button at any time.

The open collector output is internally connected to the collector of

an NPN transistor (BC817-40) and to the internal 24V feed via a

diode.

A maximum of 24V may be connected to the output.

The maximum current via the open collector must be limited to

10mA.

Fig. 23: Foot switch

1 Brown

2 White

3 Blue

4 Black (digital output)

5 Grey (ground)

6 Open collector

Fig. 24: Digital output

Foot switch

With the RC version, the pulse foot switch (KNF Id. no. 155872) can

be connected to the RC connector as an accessory.

➔ When the foot switch is operated, the pulse signal is shorted to

ground, which switches the pump on.

➔ If it is operated again, the pump is switched off.

8.3 Digital output

The current operating status of the pump can be read out via the digital output.

The open collector is only switched on if the pump is transferring.

8.4 Shutting down the pump in an emergency

In order to shut the pump down in an emergency, pull out the mains

plug. Or shut the pump down using the "Stop" button.

36 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Cleaning and maintenance

DANGER

Danger of injuries caused by hazardous materials

Poisoning and caustic burns caused by contact with aggressive, flammable or radioactive media

- Flush the pump thoroughly (see Section 9.3)

- Decontaminate the pump if necessary

- Observe the safety data sheets for the media to be trans-

ferred

- Wear suitable protective equipment

WARNING

Danger of heat build-up as a result of chemical reactions with the

flushing liquid

Significant heat build-up will damage the diaphragm, O-rings and valve

system, resulting in leaks

- Avoid chemical reactions in the pump

- Observe the safety data sheets for the liquid to be transferred

- Observe the following advice

Component

Servicing interval

Pump

- Regular inspection for external

damage or leaks

Pump head

- Clean if the flow rate decreases,

the pump does not work or no

vacuum is created

- Replace parts if necessary

See Chapter 12

Pump diaphragm

- Replace pump diaphragm if the

pumping capacity decreases or

a leak occurs

- Replace pump diaphragm in the

event of repeated head installation

Filter (accessory)

- Replace if it is dirty

Requirements

Personnel

Personal protective equipment

Spare parts

9. Cleaning and maintenance

9.1 Safety

The following requirements apply to all the activities described in this

chapter:

▪ None

▪ Specialist personnel

▪ The type of protective equipment required will depend on the

medium to be transferred.

▪ Observe the safety data sheets for the media to be trans-

ferred.

Use only genuine parts from KNF for servicing work.

9.2 Maintenance plan

Tab. 18: Servicing schedule

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 37

Cleaning and maintenance Operating Instructions LIQUIPORT EN

IMPORTANT:

To ensure satisfactory start-up when the unit is restarted, it is important to ensure that the pump is free of any crystallising, adhesive or

curing media.

NOTE

Never flush non-polar solvents immediately with water

NOTE

The procedure described in Section 9.3.4 is not a sterilisation

9.3 Cleaning the pump

In order to maintain the service life of the pump, after each use and

before any long periods of inactivity the pump must be flushed through

with neutral media.

9.3.1 Acids

- Flush pump with a suitable neutralising liquid in a circular flow

for 10 minutes

- Then flush with distilled water for 5 minutes

9.3.2 Bases

- Flush pump with a suitable neutralising liquid in a circular flow

for 10 minutes

- Then flush with distilled water for 5 minutes

9.3.3 Organic solvents

- Flush pump with isopropyl alcohol (C3H8O) in a circular flow

for 10 minutes

9.3.4 Biological solution

- Flush pump with 10% hydrogen peroxide in a circular flow for

10 minutes

- Then flush with distilled water for 10 minutes

38 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Cleaning and maintenance

DANGER

Danger from hazardous materials

Poisoning and caustic burns or undesirable reactions caused by escaping hazardous materials as a result of incorrect maintenance/servicing or the transferring of incompatible media.

- Follow the maintenance instructions

- Ensure cleanliness during maintenance

(particles on seal faces cause leaks)

- Check that pump and system are leak-tight after mainte-

nance

WARNING

Danger of poisoning and caustic burns

If they come into contact with skin and eyes, aggressive media cause

poisoning and caustic burns.

- Cleaning the pump according to chapter 9.3

- flashing

- Wear protective equipment, e.g. protective gloves, safety

glasses.

Qty

Tools/materials

1

T20 Torx screwdriver

1

Phillips screwdriver no. 2

1

Spare parts kit (see Chapter 12)

1

Torque screwdriver that can be set to 1.5 Nm.

Requirements

Personnel

Personal protective equipment

Tools and materials

Information on procedure

9.4 Cleaning / replacing valve plates and pump diaphragm

▪ The pump must be switched off and disconnected from mains

▪ The pump must be free of any hazardous substances

▪ The hoses must be disconnected from the pump head

▪ Specialist personnel

▪ The type of protective equipment required will depend on the

medium to be transferred.

▪ Observe the safety data sheets for the media to be trans-

ferred.

Tab. 19: Tools/materials

Always replace valve disks, valve seats and seals at the same time to

maintain a satisfactory flow rate.

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 39

Cleaning and maintenance Operating Instructions LIQUIPORT EN

9.4.1 Dismantling the pump head

Fig. 25: LIQUIPORT100

Fig. 26: LIQUIPORT300

Loosen the four head screws (1) and remove the entire head.

40 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Cleaning and maintenance

9.4.2 Removing the valves and seals

Remove the connecting plate (5) from the intermediate plate (7).

Take the valve plate (6) out of the intermediate plate (7).

Remove the resonating diaphragm (3) from the connecting plate

(5).

Remove the O-ring (4) from the head plate.

Carefully grip the diaphragm (8) and remove by turning anti-clock-

wise. Remove the washers (9) and make sure that no washers 9

fall into the pump housing.

We recommend replacing the diaphragm (8).

9.4.3 Cleaning the parts

Clean the diaphragm (8), O-ring (4), resonating diaphragm (3),

valve plate (6), intermediate plate (7) and connecting plate (5) with

a cloth and then blow off with compressed air.

9.4.4 Installing the diaphragm

Place the same number of washers on the connecting rod (9) as

were there previously. Make sure that no washers (9) fall into the

pump housing.

Screw in the diaphragm (8).

By lightly pressing on the diaphragm push the ridge on the under-

side of the diaphragm into the groove of the housing.

9.4.5 Installing the valve plate

Place the dust-free valve plate(6) into the intermediate plate (7),

making sure it is in the correct position.

9.4.6 Installing the pump head

Insert the resonating diaphragm (3) in the connecting plate (5) and

cover with the head plate (2) fitted with a new O-ring (4).

The positions of the intermediate plate (7), the connecting plate

(5) and the head plate (2) with respect to one another are determined by the arrangement of the visible grooves.

Insert the four head screws (1) into the through holes of the pump

head.

Make sure that the flow direction of the pump head (see direc-

tional arrow on the head plate (2)) is the same as previously.

Place the pump head onto the pump housing and alternately

tighten the four head screws (1). The maximum tightening torque

is 1.5 Nm.

Check that pump and system are leak-tight after maintenance.

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 41

Cleaning and maintenance Operating Instructions LIQUIPORT EN

WARNING

Danger of fluid system bursting due to overpressure.

The pump builds up pressure. In a closed system the max. permitted

operating pressure may be exceeded, thus causing damage to the

pump and/or the system.

- In the case of parts that are in contact with the fluid, use only

those that are designed for the pump's operating pressure

- Do not transfer media against shut-off elements or closed

systems, otherwise

- install pressure relief/safety valve and set to 6 bar (in the

KNF product range)

9.5 Checking that pump is leak-tight

In order to ensure correct assembly and hence reliability, it is essential

to perform a leak test.

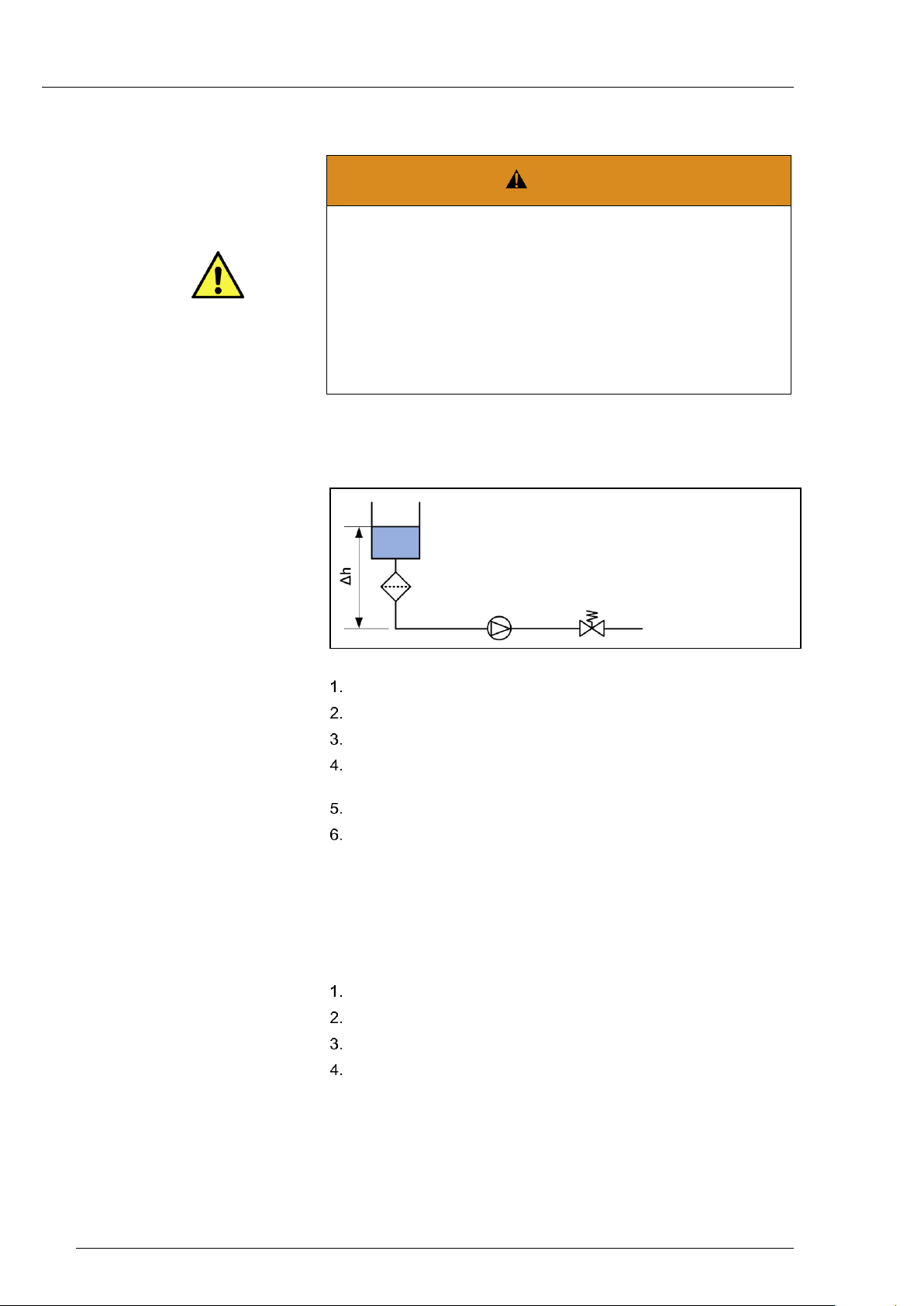

Fig. 27: Pressure test setup

Set up the system as shown in Fig. 27.

Use distilled water as a test medium.

Set pressure control valve to working pressure.

Make sure that the fitting is leak-tight

(see Section 6.2.2).

Operate pump carefully for 5 minutes.

Check pump for leaks.

If no traces of medium are visible on the head, the pump can be used

in accordance with its specification (see Chapter 3).

Caution!

If it is found that liquid is escaping, under no circumstances should the

pump continue to be used.

Check that connections are leak-tight.

Check tightening torque of head screws.

Check that elastomer parts are clean.

Check leak-tightness again.

If these actions have no effect, contact your local KNF dealer and do

42 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

not under any circumstances continue to use the pump.

Operating Instructions LIQUIPORT EN Shutdown

DANGER

Danger of injuries caused by hazardous materials

Poisoning and caustic burns caused by contact with aggressive, flammable or radioactive media

- Flush the pump thoroughly (see Section 9.3)

- Decontaminate the pump if necessary

- Observe the safety data sheets for the media to be trans-

ferred

- Wear suitable protective equipment

Requirements

Personnel

Personal protective equipment

10. Shutdown

10.1 Safety

The following requirements apply to all the activities described in this

chapter:

▪ System depressurised

▪ Specialist personnel

▪ The type of protective equipment required will depend on the

medium to be transferred.

▪ Observe the safety data sheets for the media to be trans-

ferred.

10.2 Procedure

Flush the whole system including the pump with a neutral liquid

Pump the pump empty (see Section 9.3)

Press the STOP button to end the transferring operation

Unplug the pump from the power supply

Dispose of pump properly

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 43

Troubleshooting Operating Instructions LIQUIPORT EN

Cause

Remedy

Pump not connected to the power

supply.

Connect pump to the power supply.

No voltage in the power supply.

Check room fuse and switch on if necessary.

Connections or hoses are blocked.

Check connections and hoses.

Remove blockage.

External valve is closed or filter is

clogged.

Check external valves and filters.

Worn diaphragm or valve

plates/seals.

Replace diaphragm and valve plates/seals (see Section 9.4).

External actuation connected without a signal

Check external actuation signal.

Pump overload protection has

tripped.

- Flow rate indicator flashing

- Standby indicator not illuminated

Pump unable to build up counterpressure

Pump transferring against pressure that is too high

Reduce pressure in system

Reduce flow rate

Requirements

Personnel

Personal protective equipment

11. Troubleshooting

11.1 Safety

Disconnect the mains plug from the power supply before working on

the pump head.

▪ Pump has been thoroughly flushed/decontaminated

▪ Specialist personnel

▪ None

Pump does not transfer

Tab. 20: Pump does not transfer

1)

Maximum pressure build-up depends on flow rate setting.

Please note: Pump not protected from overpressure.

44 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Operating Instructions LIQUIPORT EN Troubleshooting

Cause

Remedy

Presence of positive pressure on

the pressure side with simultaneous vacuum or positive pressure

on the suction side.

Change pressure conditions.

Cross-section of hydraulic hoses or

connectors too narrow or restricted.

Disconnect the pump from the system and determine output values.

Remove restriction (e.g. valve) if necessary.

If applicable, use larger-diameter hoses or connectors.

Leaks in connections, hoses or

pump head.

Repair leaks.

Connections or hoses completely

or partially obstructed.

Check connections and hoses.

Remove any parts or particles causing blockages.

Pump head components are

soiled.

Clean head components.

Worn diaphragm or valve

plates/seals.

Replace diaphragm and valve plates/seals (see Chapter 9.4).

Materials chemically damaged by

transferred media.

Select a type of material that is resistant and suitable.

11.2 Rectifying transfer problems

Flow rate, pressure, or vacuum are too low

The pump does not achieve the performance stated in the technical data or on the data sheet.

Tab. 21: Flow rate, pressure, or vacuum are too low

Fault cannot be rectified

If you are unable to identify the cause of the problem, please send the

pump to KNF customer service (see address on last page).

Flush the pump to clear the pump head of any hazardous or ag-

gressive liquids (see Section 9.4).

Dismantle the pump.

Clean the pump (see Section 9.3).

Send the pump, with completed decontamination declaration (see

Chapter 13), to KNF customer service stating the nature of the

transferred medium (see arranging for return).

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 45

Spare parts and accessories Operating Instructions LIQUIPORT EN

Spare parts

Order No.

LIQUIPORT 100 spare parts kit KT head

065262

LIQUIPORT 100 spare parts kit TT head

065262

LIQUIPORT 100 spare parts kit FT head 1)

152631

LIQUIPORT 1.100 spare parts kit KT head

065262

LIQUIPORT 1.100 spare parts kit TT head

065262

LIQUIPORT 1.100 spare parts kit FT head 1)

152631

LIQUIPORT 300 spare parts kit KT head

068691

LIQUIPORT 300 spare parts kit TT head

068691

LIQUIPORT 300 spare parts kit FT head 1)

151902

LIQUIPORT 1.300 spare parts kit KT head

069728

LIQUIPORT 1.300 spare parts kit TT head

069728

LIQUIPORT 1.300 spare parts kit FT head 1)

151903

Connection nipples

Order No.

Spare parts kit screw-in nipples

NPT1/8 ETFE/FFKM

168547

Spare parts kit screw-in nipples

NPT3/8 ETFE/FFKM

168551

Spare parts kit screw-in nipples

NPT1/8 ETFE/EPDM

168555

Spare parts kit screw-in nipples

NPT3/8 ETFE/EPDM

168549

Foot switch

Order No.

LIQUIPORT pulse foot switch

155872

Fasteners

Order No.

Tripod holder

160474

Mounting plate

160473

12. Spare parts and accessories

12.1 Spare parts

Tab. 22: Spare parts

1) The FT head is not compatible with the KT/TT pump housing.

12.2 Accessories

Tab. 23: Connection nipples

Tab. 24: Foot switch

46 KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English

Tab. 25: Fasteners

Operating Instructions LIQUIPORT EN Decontamination declaration

NOTE

KNF shall only undertake to repair the pump on condition that the

customer provides certification of the transferred media and the

cleaning of the pump (decontamination declaration).

Pump model

Serial no.

Transferred media

Company

Date/Signature

KNF Flodos AG

Wassermatte 2

6210 Sursee, Switzerland

Tel +41 (0)41 925 00 25

Fax +41 (0)41 925 00 35

www.knf.com

13. Decontamination declaration

Copy this page, or print out the decontamination declaration from

our website http://www.knf.com/downloads.

Enter the pump model, the serial no. and the transferred media in

the form below and send the signed form together with the flushed

and cleaned pump to KNF customer service.

Customer decontamination declaration for

repair order

We confirm that the pump below has been used to transfer the following media, and that the pump has been flushed and cleaned.

The pump does not contain aggressive, biological, radioactive, poisonous, or other dangerous media.

KNF Flodos | BA_LIQUIPORT_EN_11_153820.docx | Translation of original operating instructions, English 47

www.knf.com

Loading...

Loading...