LABOPORT®

A

Chemically-resistant Laboratory Pumps

with Modular

ccessories

Operating Instructions

for Laboratory Pumps N810, N820, N840, N842

and for LABOPORT Systems SR..., SH…, SC…, SCC…

Operating Instructions

Vacuum-Controller NC800 / NBC800

KNF 121722-121728 02/10

Translation of original Operating Instructions, english

KNF Neuberger UK Ltd

Ave 2, Station Lane Ind Est,

Witney, Oxfordshire,

OX28 4FA, UK

Tel: +44 (0) 1993 778373

Fax: +44 (0)1993 775148

E-Mail: info@knf.co.uk

www.knf.co.uk

LABOPORT Pumps and Systems Content

Content Page

1.

About this document 4

1.1. Using the Operating Instructions 4

1.2. Symbols and Markings 4

2. Use 5

2.1. Proper Use 5

2.2. Improper Use 5

3. Safety 6

4. System overview 8

5. Technical Data 10

5.1. Pumps 10

5.2. Electrical Supply Unit 17

5.3. Vacuum Controller 17

5.4. Vacuum Systems 18

6. Design and Function 19

6.1. Pump 19

6.2. Separator 20

6.3. High Performance Condenser 21

6.4. Vacuum Controller 22

7. Installation, mounting and

connection 23

7.1. Connect pump 23

7.2. Baseplate 24

7.3. Separator 24

7.4. High Performance Condenser 25

7.5. Electrical Supply Unit and

Vacuum Controller 25

7.6. Gas Ballast 28

7.7. Mounting of Systems 28

7.7.1. System SR 28

7.7.2. System SH 29

7.7.3. System SC 30

7.7.4. System SCC 31

7.7.5. Retrofitting from System SC to

System SCC 32

9.2.3. Emptying and Cleaning the

Separator 37

9.2.4. Emptying and Cleaning the

Condenser 37

9.3. Changing Diaphragm and Valve

Plates/Sealings 38

10. Troubleshooting 42

10.1. Pump/System without Vacuum

Controller 42

10.2. System with one Vacuum

Controller 43

10.3. System with two Vacuum

Controllers 45

10.4. Fault cannot be rectified 45

11. Ordering Information 46

11.1. Pumps and Spare Parts 46

11.2. Accessories for Pump Systems 46

12. Decontamination Declaration 47

8. Operation 33

8.1. Pump 33

8.1.1. Preparing for Start-up 33

8.1.2. Starting 33

8.2. Switching Pump/System on and

off 35

8.3. Notices related to System

Operation 35

8.3.1. Separators 35

8.3.2. High Performance Condenser 35

8.3.3. Vacuum Controller 36

8.3.4. Gas Ballast 36

9. Servicing 37

9.1. Servicing Schedule 37

9.2. Cleaning 37

9.2.1. Flushing Pump 37

9.2.2. Cleaning Pump 37

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 3

About this document LABOPORT Pumps and Systems

1. About this document

1.1. Using the Operating Instructions

The Operating Instructions are part of the pump/system.

Carefully study the Operating Instructions before using a pump

or system.

Always keep the Operating Instructions handy in the work

area.

Pass on the Operating Instructions to the next owner.

Project systems and pumps

Customer-specific project systems or pumps (systems and pump

models which begin with “PJ” or “PM”) may differ from the Operating Instructions.

For project systems and pumps, also observe the agreed upon

specifications.

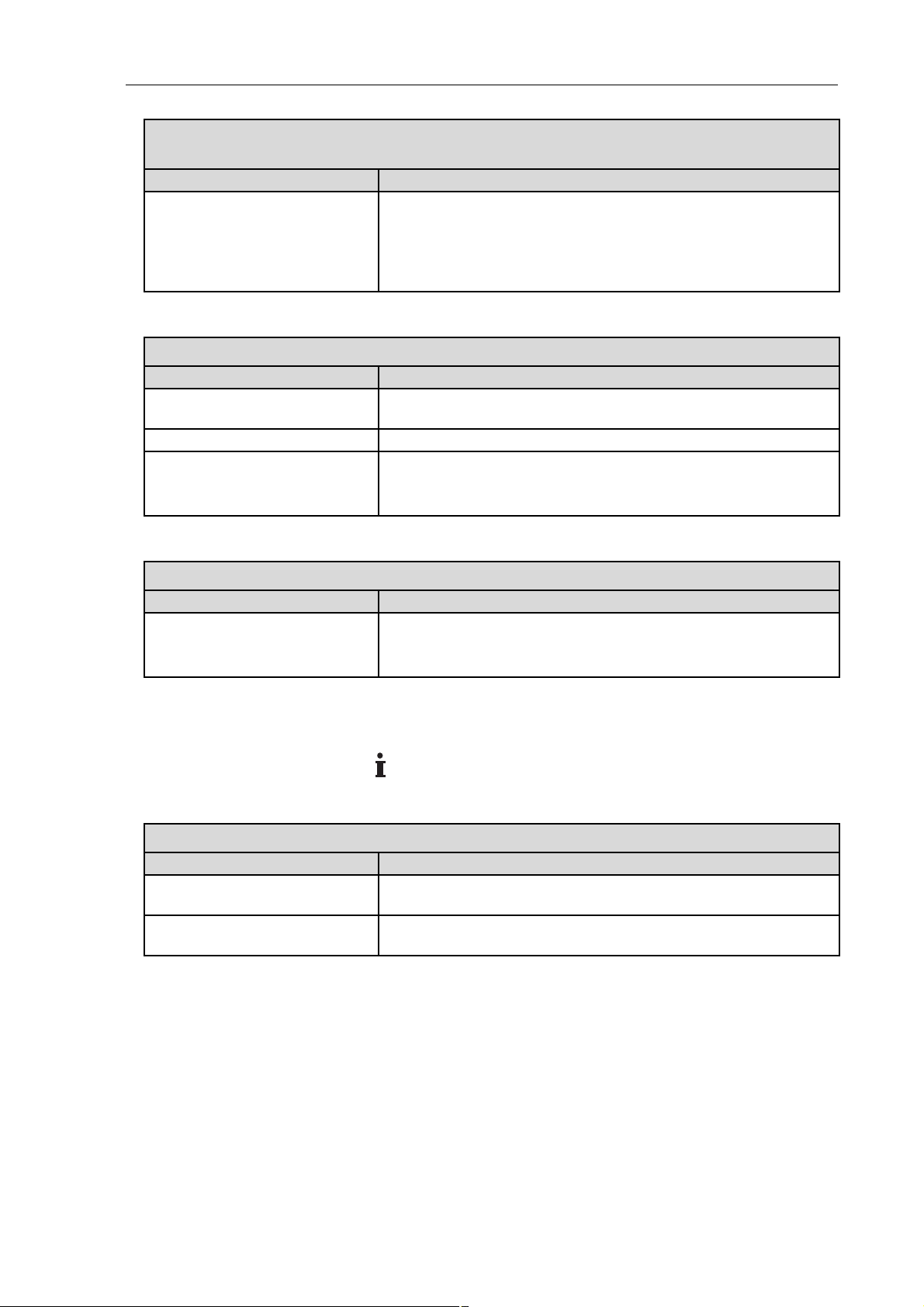

1.2. Symbols and Markings

Warning

A danger warning is located here.

Possible consequences of a failure to observe the

warning are specified here. The signal word, e.g.

WARNING

Danger levels

Signal word Meaning Consequences if not observed

DANGER

WARNING

CAUTION

Tab. 1

Other information and symbols

Warning, indicates the danger level.

Measures for avoiding the danger and its conse-

quences are specified here.

warns of immediate danger

warns of possible

danger

warns of a possibly

dangerous situation

Death or serious injuries

and/or serious damage are the

consequence.

Death or serious injuries

and/or serious damage are

possible.

Minor injuries or damage are

possible.

An activity to be carried out (a step) is specified here.

1. The first step of an activity to be carried out is specified here.

Additional, consecutively numbered steps follow.

This symbol refers to important information.

4 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Use

2. Use

2.1. Proper Use

The pump/system is exclusively intended for transferring gases

and vapors.

Owner's responsibility

Operating parameters and

conditions

Requirements for

transferred medium

High performance condenser

Accessories

Only install and operate the pump/system under the operating

parameters and conditions described in chapter 5, Technical data.

Make sure that the installation location is dry and the pump/system

is protected against rain, splash, hose and drip water.

Before using a medium, check the compatibility of the materials of

the pump head, diaphragm and valves with the medium.

Before using a medium, check whether the medium can be transferred danger-free in the specific application case.

Only transfer gases which remain stable under the pressures and

temperatures occurring in the pump.

The high performance condenser must be installed on the outlet

side of the pump; if it is installed on the inlet side there is a danger

of implosion.

Observe the correct usage of the gas- and cooling liquidconnections on the high performance condenser. Inlet and outlet

connections for the gas are not interchangeable.

Laboratory equipment or additional components connected to a

pump/system have to be suitable for use with the pneumatic capabilities of the pump (see chapter 5.1, page 10).

2.2. Improper Use

The pump/system may not be operated in an explosive atmosphere.

The pump/system is not suitable for transferring dusts.

The pump/system is not suitable for transferring liquids.

For LABOPORT systems with vacuum controller: The vacuum

system must not be used if the entry of air or gas into the vacuum

system during venting (pump vent valve) could result in the creation of reactive, explosive or otherwise hazardous mixtures (e.g.

with the medium).

The pump/the system must not be used to create vacuum and

overpressure simultaneously.

An overpressure must not be applied to the suction side of the

pump/ the system.

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 5

Safety LABOPORT Pumps and Systems

3. Safety

Note the safety precautions in chapters 7. Installation, mounting and connection, and 8. Operation.

The pump/system is built according to the generally recognized

rules of technology and in accordance with the occupational safety

and accident prevention regulations. Nevertheless, dangers can

result during their use which lead to injuries to the user or others,

or to damage to the pump/system or other property.

Only use the pump/system when it is in a good technical and

proper working order, in accordance with its intended use, observing the safety advice within the operating instructions, at all times.

Personnel

Working in a safety-

conscious manner

Fig. 1: Notice sticker

Handling dangerous media

Handling flammable media

Make sure that only trained and instructed personnel or specially

trained personnel work on the pump/system. This especially applies to assembly, connection and servicing work.

Make sure that the personnel has read and understood the operating instructions, and in particular the "Safety" chapter.

Observe the accident prevention and safety regulations when

performing any work on the pump/system and during operation.

Do not expose any part of your body to the vacuum.

Open housing parts with notice sticker (see fig. 1) only after

separating mains plug from power source.

When transferring dangerous media, observe the safety regulations when handling these media.

Be aware that the pump/system is not designed to be explosionproof.

Make sure the temperature of the medium is always sufficiently

below the ignition temperature of the medium, to avoid ignition or

explosion. This also applies for unusual operational situations.

Note that the temperature of the medium increases when the pump

compresses the medium.

Hence, make sure the temperature of the medium is sufficiently

below the ignition temperature of the medium, even when it is

compressed to the maximum permissible operating pressure of the

pump. The maximum permissible operating pressure of the pump

is stated in the technical specifications (see chapter 5.1, page 10).

If necessary, consider any external sources of energy, such as

radiation, that may add heat to the medium.

In case of doubt, consult the KNF customer service.

Environmental protection

6 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

Store all replacement parts in a protected manner and dispose of

them properly in accordance with the applicable environmental

protection regulations. Observe the respective national and international regulations. This especially applies to parts contaminated

with toxic substances.

LABOPORT Pumps and Systems Safety

Standards

Customer service and

repairs

®

The KNF LABOPORT

pumps conform to the safety regulations of

the EC Directive 2004/108/EC concerning Electromagnetic Compatibility and the EC Directive 2006/42/EC concerning Machinery.

The requirements of the following harmonised standards are

fulfilled:

DIN EN 61010-1

DIN EN 61326-1

DIN EN 61000-3-2/3

The pumps correspond to IEC 664:

the overvoltage category II

the pollution degree 2

Only have repairs to the pump/system carried out by the KNF

Customer Service responsible.

Only authorized personnel should open those parts of the housing

that contain live electrical parts.

Use only genuine parts from KNF for servicing work.

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 7

System overview LABOPORT Pumps and Systems

4. System overview

1 Electrical supply unit

2 Vacuum controller

3 Vent valve at vacuum

controller

4 On/off switch of vacuum

controller

5 Pump vent valve

6 Vacuum valve

7 High performance con-

denser

8 Hose connector

9 Angled nozzle for coolant

10 Spring clamp

11 Flask for condenser

12 Support for high perform-

ance condenser

13 Locating pin for pump

14 Separator

15 Holder for Separator

16 Support for vacuum control-

ler

17 Baseplate

18 Vacuum pump

19 On/off switch of pump

Fig. 2: Full expanded LABOPORT System SCC..., for example pump

model N 840.3 FT.18 (symbolic)

8 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems System overview

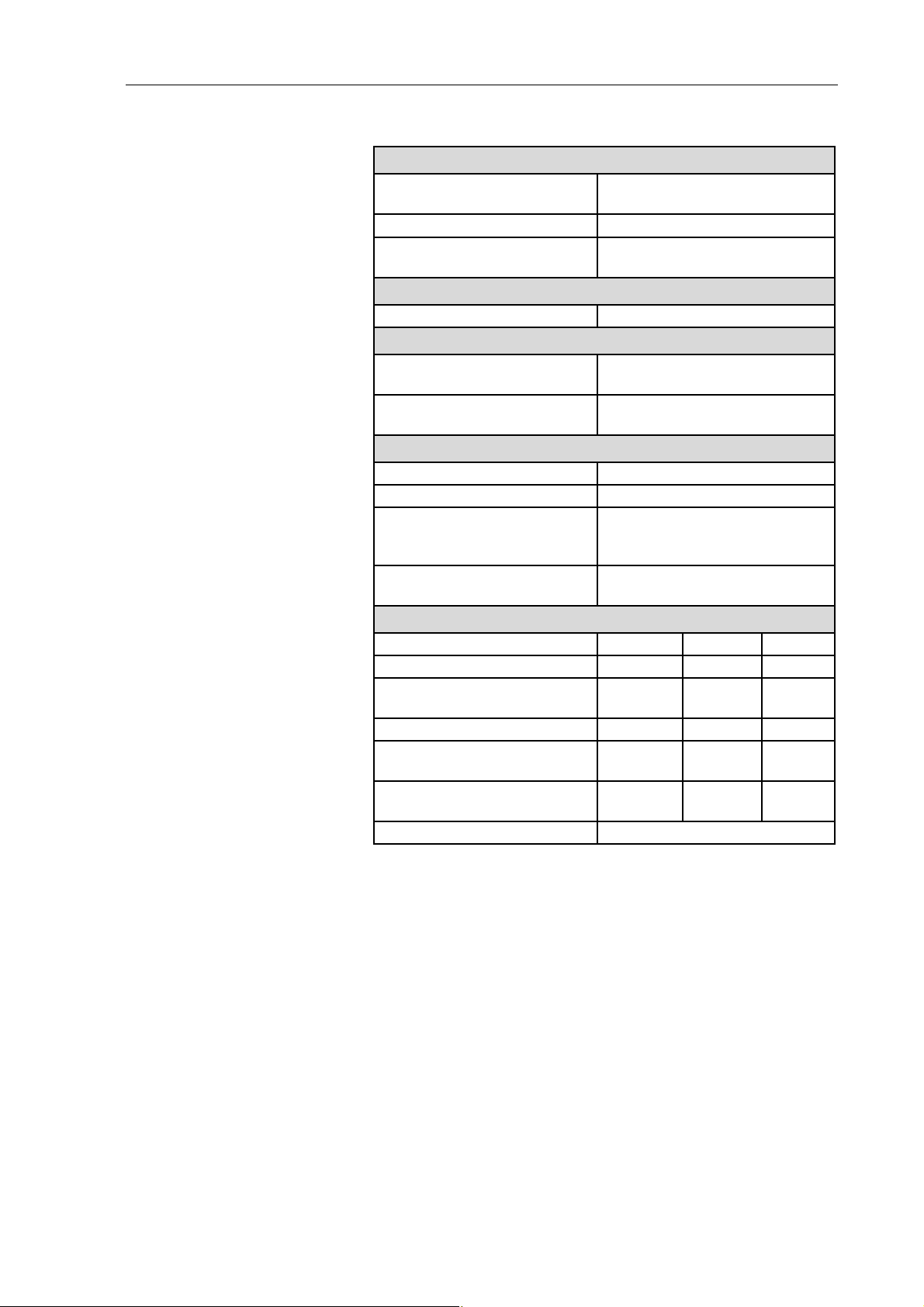

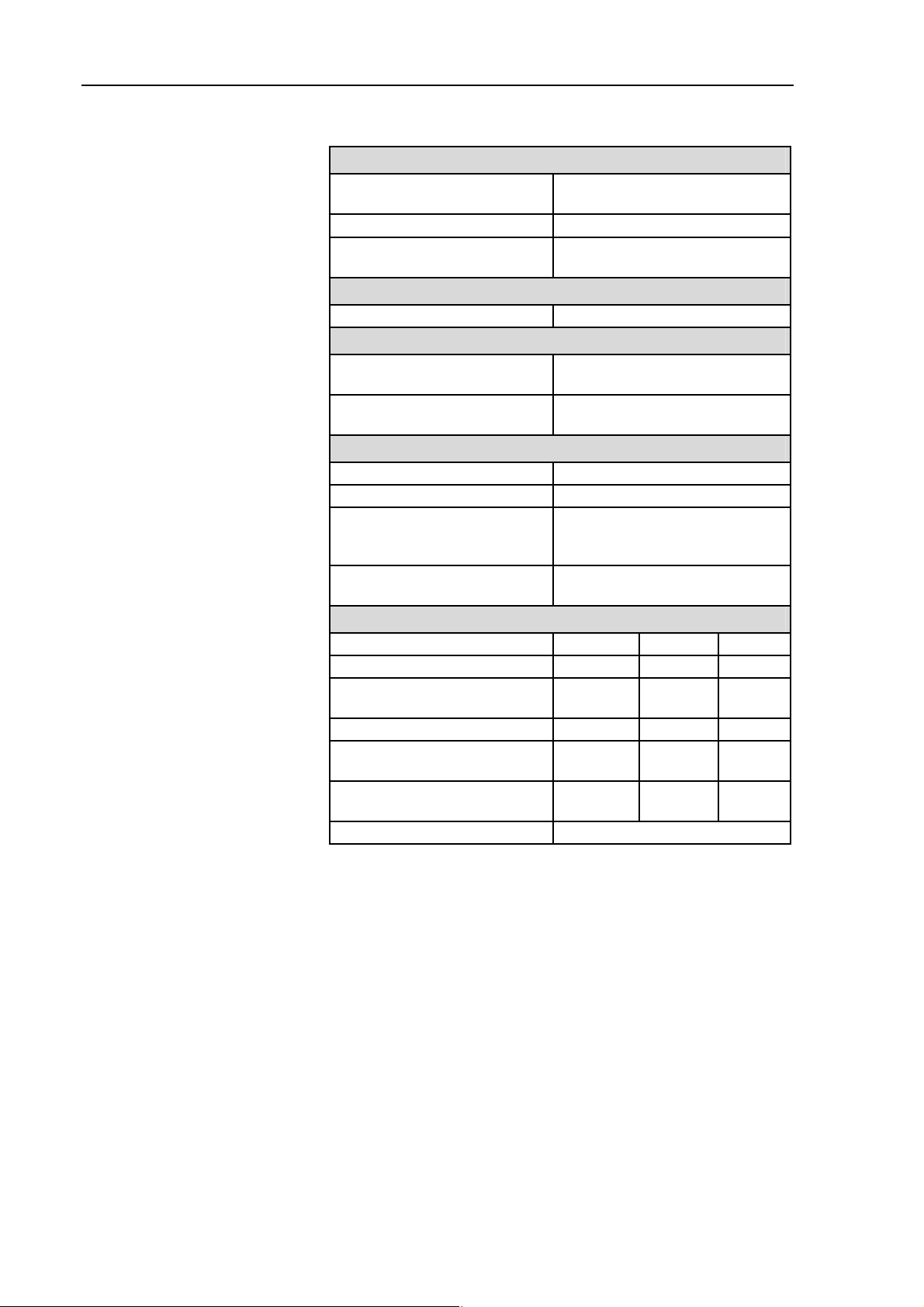

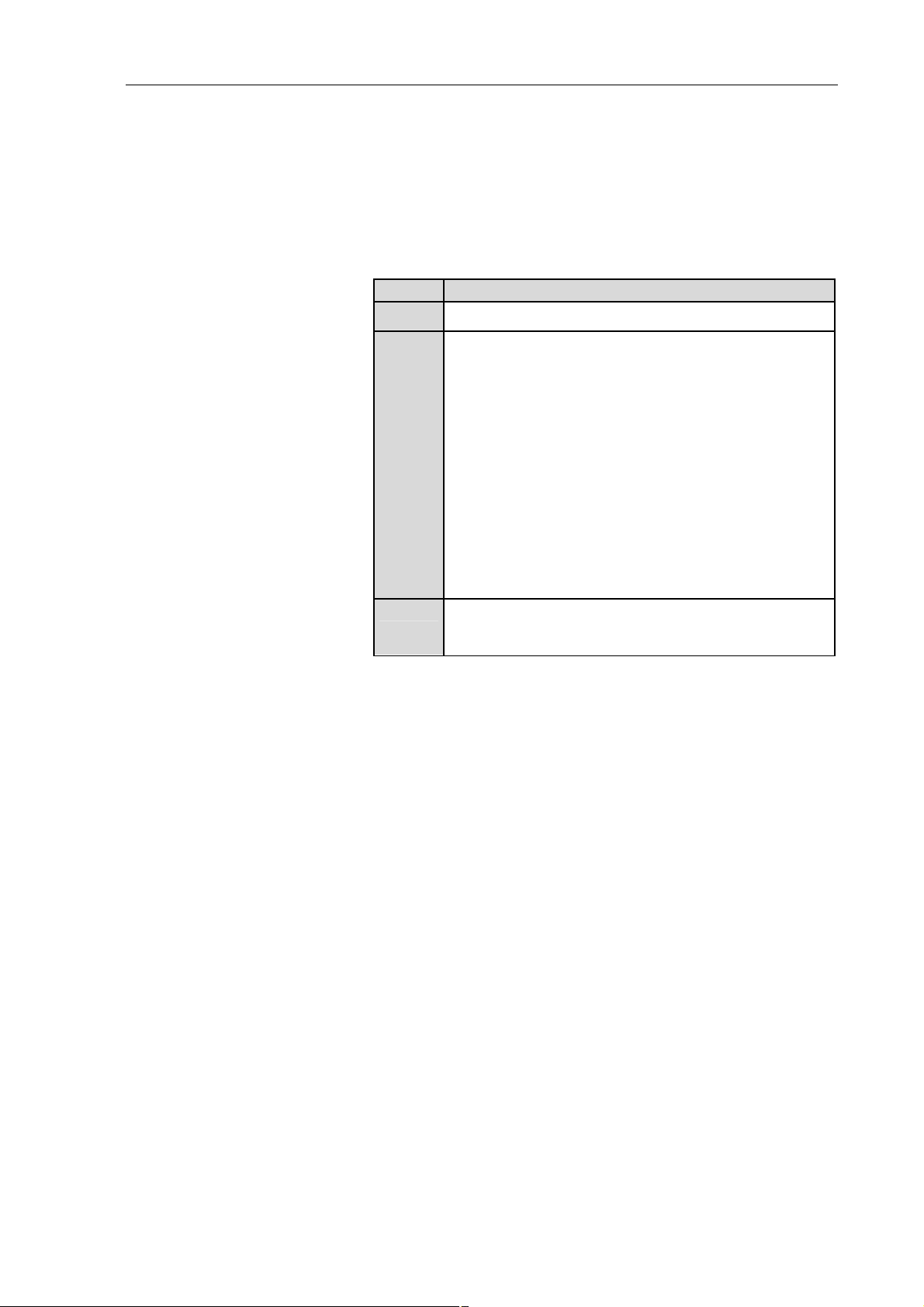

Fig. 3: LABOPORT Systems

Module SR... SH... SC... SCC...

System

Pump X X X X

Baseplate X X X X

2 separators X

1 separator X X X

High performance

X X X

condenser

Electrical supply unit X X

1 vacuum controller X

2 vacuum controllers X

Tab. 2

Each pump and all systems can be expanded modularly up to

a full system SCC… (see chapter 7.7, page 28).

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 9

Technical Data LABOPORT Pumps and Systems

5. Technical Data

5.1. Pumps

All pumps are secured against overheating with thermal

switches and are equipped with a mains fuse.

Pump materials (for all pump types) *

Pump head PTFE

Diaphragm PTFE coated

Valve FFPM

Tab. 3 *according to DIN ISO 1629 and 1043.1

Refer to the type plate for the pump’s electrical configuration.

N 810 FT.18

Pneumatic performance

Max. permissible operating

1.0

pressure [bar g]

Ultimate vacuum [mbar abs.]

Delivery rate at atm. pressure

≤ 100

max. 10

[l/min]*

Pneumatic connection

Hose connection [mm] ID 10

Ambient and media temperature

Permissible

+ 5 °C to + 40 °C

ambient temperature

Permissible media temperatu-

+ 5 °C to + 40 °C

re

Other parameters

Weight [kg] 5.9

Dimensions: L x H x W [mm] 256 x 187 x 146

Maximum permissible ambient

relative humidity

80 % for temperatures up to

31 °C, decreasing linearly to

50 % at 40 °C

Maximum altitude of site

2000

[m above sea level]

Electrical Data

Voltage [V] 100 115 230

Frequency [Hz] 50/60 60 50

Maximum current consump-

1.4 1.3 0.6

tion [A]

Power consumption pump [W] 110 110 100

Maximum permitted mains

+/- 10 % +/- 10 % +/- 10 %

voltage fluctuation

Fuse pump

2.5 2.5 1.25

(2x) T [A]

Protection class motor IP44

Tab. 4 * Liters in standard state (1,013 mbar)

10 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Technical Data

N 820 FT.18

Pneumatic performance

Max. permissible operating

1.0

pressure [bar g]

Ultimate vacuum [mbar abs.]

Delivery rate at atm. pressure

≤ 100

max. 20

[l/min]*

Pneumatic connection

Hose connection [mm] ID 10

Ambient and media temperature

Permissible

+ 5 °C to + 40 °C

ambient temperature

Permissible media temperatu-

+ 5 °C to + 40 °C

re

Other parameters

Weight [kg] 7.1

Dimensions: L x H x W [mm] 268 x 207 x 159

Maximum permissible ambient

relative humidity

80 % for temperatures up to

31 °C, decreasing linearly to

50 % at 40 °C

Maximum altitude of site

2000

[m above sea level]

Electrical Data

Voltage [V] 100 115 230

Frequency [Hz] 50/60 60 50

Maximum current consump-

2.2 1.9 0.9

tion [A]

Power consumption pump [W] 145 145 130

Maximum permitted mains

+/- 10 % +/- 10 % +/- 10 %

voltage fluctuation

Fuse pump

4.0 3.15 2.0

(2x) T [A]

Protection class motor IP44

Tab. 5 * Liters in standard state (1,013 mbar)

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 11

Technical Data LABOPORT Pumps and Systems

N 840 FT.18

Pneumatic performance

Max. permissible operating

1.0

pressure [bar g]

Ultimate vacuum [mbar abs.]

Delivery rate at atm. pressure

≤ 100

max. 34

[l/min]*

Pneumatic connection

Hose connection [mm] ID 10

Ambient and media temperature

Permissible

+ 5 °C to + 40 °C

ambient temperature

Permissible media temperatu-

+ 5 °C to + 40 °C

re

Other parameters

Weight [kg] 10.3

Dimensions: L x H x W [mm] 297x 226 x 171

Maximum permissible ambient

relative humidity

80 % for temperatures up to

31 °C, decreasing linearly to

50 % at 40 °C

Maximum altitude of site

2000

[m above sea level]

Electrical Data

Voltage [V] 100 115 230

Frequency [Hz] 50/60 60 50

Maximum current consump-

4.4 3.2 1.5

tion [A]

Power consumption pump [W] 200 220 180

Maximum permitted mains

+/- 10 % +/- 10 % +/- 10 %

voltage fluctuation

Fuse pump

6.3 6.3 3.15

(2x) T [A]

Protection class motor IP44

Tab. 6 * Liters in standard state (1,013 mbar)N 810.3 FT.18

12 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Technical Data

N 810.3 FT.18

Pneumatic performance

Max. permissible operating

1.0

pressure [bar g]

Ultimate vacuum [mbar abs.]

Delivery rate at atm. pressure

≤ 8

max. 10

[l/min]*

Pneumatic connection

Hose connection [mm] ID 10

Ambient and media temperature

Permissible

+ 5 °C to + 40 °C

ambient temperature

Permissible media temperatu-

+ 5 °C to + 40 °C

re

Other parameters

Weight [kg] 6.9

Dimensions: L x H x W [mm] 281 x 187 x140

Maximum permissible ambient

relative humidity

80 % for temperatures up to

31 °C, decreasing linearly to

50 % at 40 °C

Maximum altitude of site

2000

[m above sea level]

Electrical Data

Voltage [V] 100 115 230

Frequency [Hz] 50/60 60 50

Maximum current consump-

1.4 1.3 0.6

tion [A]

Power consumption pump [W] 100 110 90

Maximum permitted mains

+/- 10 % +/- 10 % +/- 10 %

voltage fluctuation

Fuse pump

2.5 2.5 1.25

(2x) T [A]

Protection class motor IP44

Tab. 7 *Liters in standard state (1,013 mbar)

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 13

Technical Data LABOPORT Pumps and Systems

N 820.3 FT.18

Pneumatic performance

Max. permissible operating

1.0

pressure [bar g]

Ultimate vacuum [mbar abs.]

Delivery rate at atm. pressure

≤ 8

max. 20

[l/min]*

Pneumatic connection

Hose connection [mm] ID 10

Ambient and media temperature

Permissible

+ 5 °C to + 40 °C

ambient temperature

Permissible media temperatu-

+ 5 °C to + 40 °C

re

Other parameters

Weight [kg] 9.3

Dimensions: L x H x W [mm] 312 x 207 x 144

Maximum permissible ambient

relative humidity

80 % for temperatures up to

31 °C, decreasing linearly to

50 % at 40 °C

Maximum altitude of site

2000

[m above sea level]

Electrical Data

Voltage [V] 100 115 230

Frequency [Hz] 50/60 60 50

Maximum current consump-

1.8 1.2 0.7

tion [A]

Power consumption pump [W] 130 130 120

Maximum permitted mains

+/- 10 % +/- 10 % +/- 10 %

voltage fluctuation

Fuse pump

3.15 2.5 1.6

(2x) T [A]

Protection class motor IP44

Tab. 8 *Liters in standard state (1,013 mbar)

14 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Technical Data

N 840.3 FT.18

Pneumatic performance

Max. permissible operating

1.0

pressure [bar g]

Ultimate vacuum [mbar abs.]

Delivery rate at atm. pressure

≤ 8

max. 34

[l/min]*

Pneumatic connection

Hose connection [mm] ID 10

Ambient and media temperature

Permissible

+ 5 °C to + 40 °C

ambient temperature

Permissible media temperatu-

+ 5 °C to + 40 °C

re

Other parameters

Weight [kg] 12.6

Dimensions: L x H x W [mm] 341 x 226 x 166

Maximum permissible ambient

relative humidity

80 % for temperatures up to

31 °C, decreasing linearly to

50 % at 40 °C

Maximum altitude of site

2000

[m above sea level]

Electrical Data

Voltage [V] 100 115 230

Frequency [Hz] 50/60 60 50

Maximum current consump-

4.4 3.2 1.5

tion [A]

Power consumption pump [W] 220 250 245

Maximum permitted mains

+/- 10 % +/- 10 % +/- 10 %

voltage fluctuation

Fuse pump

6.3 6.3 3.15

(2x) T [A]

Protection class motor IP44

Tab. 9 *Liters in standard state (1,013 mbar)

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 15

Technical Data LABOPORT Pumps and Systems

N 840.1.2 FT.18

Pneumatic performance

Max. permissible operating

1.0

pressure [bar g]

Ultimate vacuum [mbar abs.]

Delivery rate at atm. pressure

≤ 90

max. 60

[l/min]*

Pneumatic connection

Hose connection [mm] ID 10

Ambient and media temperature

Permissible

+ 5 °C to + 40 °C

ambient temperature

Permissible media temperatu-

+ 5 °C to + 40 °C

re

Other parameters

Weight [kg] 12.6

Dimensions: L x H x W [mm] 341 x 226 x 160

Maximum permissible ambient

relative humidity

80 % for temperatures up to

31 °C, decreasing linearly to

50 % at 40 °C

Maximum altitude of site

2000

[m above sea level]

Electrical Data

Voltage [V] 100 115 230

Frequency [Hz] 50/60 60 50

Maximum current consump-

5.1 4.2 1.9

tion [A]

Power consumption pump [W] 275 280 270

Maximum permitted mains

+/- 10 % +/- 10 % +/- 10 %

voltage fluctuation

Fuse pump

6.3 6.3 3.15

(2x) T [A]

Protection class motor IP44

Tab. 10 *Liters in standard state (1,013 mbar)

16 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Technical Data

N 842.3 FT.18

Pneumatic performance

Max. permissible operating

1.0

pressure [bar g]

Ultimate vacuum [mbar abs.]

Delivery rate at atm. pressure

≤ 2

max. 34

[l/min]*

Pneumatic connection

Hose connection [mm] ID 10

Ambient and media temperature

Permissible

+ 5 °C to + 40 °C

ambient temperature

Permissible media temperatu-

+ 5 °C to + 40 °C

re

Other parameters

Weight [kg] 13.4

Dimensions: L x H x W [mm] 341 x 223 x 167

Maximum permissible ambient

relative humidity

80 % for temperatures up to

31 °C, decreasing linearly to

50 % at 40 °C

Maximum altitude of site

2000

[m above sea level]

Electrical Data

Voltage [V] 100 115 230

Frequency [Hz] 50/60 60 50

Maximum current consump-

4.4 3.2 1.5

tion [A]

Power consumption pump [W] 260 290 245

Fuse pump

6.3 6.3 3.15

(2x) T [A]

Protection class motor IP44

Tab. 11 *Liters in standard state (1,013 mbar)

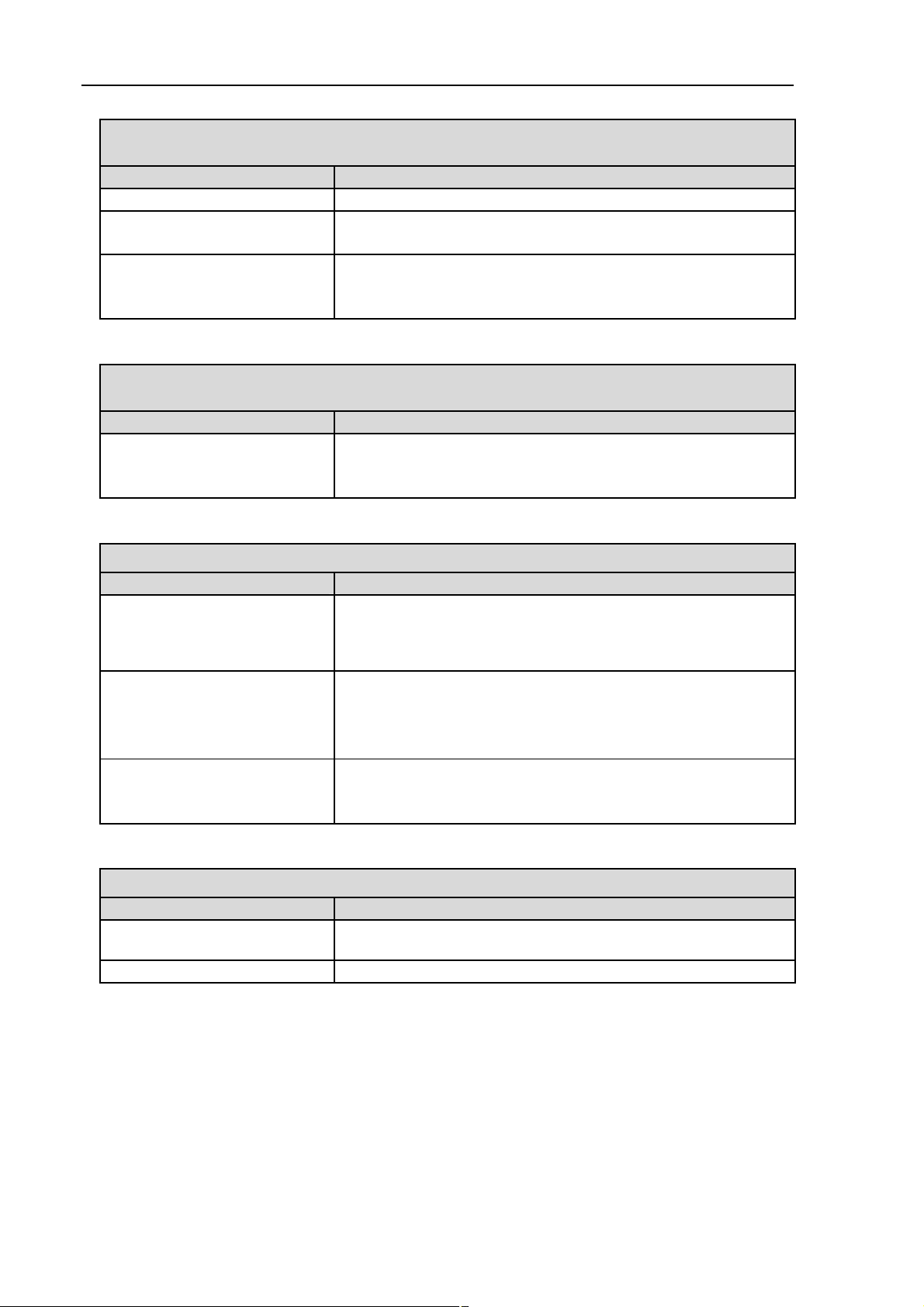

5.2. Electrical Supply Unit

Electrical Data

Voltage [V] 100 115 230

Frequency [Hz] 50/60 60 50

Power consumption* [W] 270 300 295

Fuse pump

6.3 6.3 3.15

(2x) T [A]

Tab. 12

* includes the power consumption of the whole system (inclusive pump

and vacuum controller); for pumps N 840.1.2 FT.18 and N 842.3 FT.18

power consumption raises by approx. 50 W.

5.3. Vacuum Controller

See Operating Manual of the vacuum controller.

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 17

Technical Data LABOPORT Pumps and Systems

5.4. Vacuum Systems

Ambient temperature

Permissible

+ 5 °C to + 40 °C

ambient temperature

Operating parameters of coolant (only for high performance condensers)

Permissible pressure [bar g] 3

Permissible temperature - 15 °C to + 20 °C

Condenser connectors For tube 8mm ID

Tab. 13

18 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Design and Function

6. Design and Function

6.1. Pump

Design

1 Connection piece

2 Pneumatic connection

3 Pump head

4 Outlet (pressure side)

5 Inlet (suction side)

6 Power switch

1 Outlet valve

2 Inlet valve

3 Transfer chamber

4 Diaphragm

5 Eccentric

6 Connecting rod

7 Pump drive

Fig. 4: Diaphragm pump (shown: pump N 840.3 FT.18)

Function Diaphragm pump

Fig. 5: Pump head

Diaphragm pumps transfer, compress (depending on pump version) and evacuate gases and vapors.

The elastic diaphragm (4) is moved up and down by the eccentric

(5) and the connecting rod (6). In the downward stroke it aspirates

the gas to be transferred via the inlet valve (2). In the upward

stroke, the diaphragm presses the medium out of the pump head

via the outlet valve (1). The transfer chamber (3) is hermetically

separated from the pump drive (7) by the diaphragm.

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 19

Design and Function LABOPORT Pumps and Systems

6.2. Separator

Design

1 Tubing

2 Hose nozzle

3 Separator container

4 Holder for separator

1

2

3

4

Fig. 6: Separator (shown: LABOPORT system SR with pump

N 840.3 FT.18 as example)

Function

Condensable components in the gas can be separated on the

pressure side of the pump. On the suction side the separator

collects particular matter and droplets. This protects the pump from

contamination.

The separator is made of a specially treated glass and features

implosion protection.

20 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Design and Function

6.3. High Performance Condenser

Design

1 Hose nozzle

2 High Performance Con-

denser

3 Angled nozzle for coolant

4 Tubing

5 Spring clamp

6 Flask

7 Support

3

Fig. 7: High performance condenser (shown: LABOPORT system SH with

pump N 840.3 FT.18 as example)

Function

1

2

3

4

5

6

7

The high performance condenser at pump outlet enables condensable components in the vapour to be separated out.

The condensate is collected in a glass flask. The flask is attached

to the condenser flange with a clamp. The condensation temperature is maintained by running cold water or recirculated coolant

through the condenser.

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 21

Design and Function LABOPORT Pumps and Systems

6.4. Vacuum Controller

1 Tubing

2 Power switch

3 Support

4 Electrical supply unit

5 Vacuum controller

5

5

4

Fig. 8: Vacuum controller (shown: LABOPORT system SCC with pump

N 840.3 FT.18 as example)

12231

Function

In laboratory systems without a vacuum controller the pump runs

continuously and works against its vacuum. If there is a vacuum

controller, it will switch the pump off once the selected target

vacuum has been reached.

With two vacuum controllers it becomes possible to simultaneously

run two different and independent processes with just one pump.

Once one vacuum controller’s set point has been reached, that

vacuum controller will close the valve it is controlling. If two

vacuum controllers are used, the pump will continue to work until

the second controller’s set point has been reached. Then the

second vacuum controller will close the valve it is controlling. The

pump switches off and the pump vent valve is opened.

If one of the two vacuum values falls below the hysteresis range,

the pump will switch back on.

Refer to the vacuum controller’s operating instructions for more

information.

22 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Installation, mounting and connection

7. Installation, mounting and connection

Only install and operate the pumps/systems under the operating

parameters and conditions described in chapter 5, Technical data.

Observe the safety precautions (see chapter 3, page 6).

Before installation, store the pump/the accessories at the

installation location to bring it up to room temperature.

Dimensions

Cooling air supply

Installation location

Connected components

Pump exhaust

See chapter 5, Technical data, for the dimensions of system.

Install the pump/system so that the motor fan can intake suffi-

cient cooling air.

Make sure that the installation location is dry and the

pump/system is protected against rain, splash, hose and drip

water.

Choose a safe location (flat surface) for the pump/system.

Protect the pump/system from dust.

Protect the pump/system from vibrations and jolts.

7.1. Connect pump

Only connect components to the pump which are designed for

the pneumatic data of the pump (see chapter 5.1, page 10).

If the pump is used as a vacuum pump, safely discharge the

pump exhaust at the pump’s pneumatic outlet.

A marking on the pump head shows the direction of flow.

1. Remove the protective plugs from the pneumatic connectors of

the pump.

2. Connect the suction line and pressure line.

3. Lay the suction and pressure line at a downward angle to

prevent condensate from running into the pump.

4. Insert the power cable’s plug into a properly installed

shockproof socket.

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 23

Installation, mounting and connection LABOPORT Pumps and Systems

7.2. Baseplate

Condition

Fig. 9: Installation of the mounts at

the pump

Conditions

Tools and material

Pump disconnected from mains

1. Unscrew the pump`s rubber feet (1) anti-clockwise.

2. Install the mounts (2) onto the pump.

3. Stand the pump (fitted with the mounts) onto the baseplate

4. Aligne the mounts on the pump and the baseplate.

5. Slide the locating pin (see fig. 2/13) through the mount holes

on the baseplate and on the pump until they are fully engaged.

6. Check that the pump is securely fastened to the baseplate via

both mounts.

7.3. Separator

Baseplate mounted (see chapter 7.2)

Pump disconnected from mains

Qty Material

1 Phillips-head screwdriver No. 3

Tab. 14

1. Slide the container for the separator (see fig. 6/4) into the

baseplate’s upward-pointing slotted bar.

2. Fix the holders by tighten the screw in the bottom of them.

3. Place the glass separators into the holders.

Laying hoses: depending on system configuration see chapter

7.7.1 (system SR), 7.7.2 (system SH), 7.7.3 (system SC), 7.7.4

(system SCC) or 7.7.5 (retrofitting from system SC to system

SCC).

24 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Installation, mounting and connection

7.4. High Performance Condenser

The high performance condenser is delivered installed on a

support.

Conditions

Touls and material

Baseplate mounted (see chapter 7.2, page 24)

Pump disconnected from mains and de-energized

Qty Material

1 Allen key 5 mm

Tab. 15

Installing the high performance condenser

Danger of implosion if installed improperly

There is a danger of implosion if the high

performance condenser is installed on the pump

WARNING

1. Slide the support of high performance condenser (see fig. 7/7)

into the baseplate’s upward-pointing slotted bar.

inlet.

Connect the high performance condenser to the

pump outlet only.

Conditions

Tools and material

2. Fix the support to the baseplate by tightening the allen screw.

3. Align the high performance condenser so that the hose

connection at the inlet is lower than the pump outlet.

Laying hoses: depending on system configuration see chapter

7.7.2 (system SH), 7.7.3 (system SC), 7.7.4 (system SCC) or

7.7.5 (retrofitting from system SC to system SCC).

7.5. Electrical Supply Unit and Vacuum Controller

The vacuum controller(s) is (are) delivered with the ventilation

valve and pump vent valve installed on a support.

When retrofitting from system SC to system SCC, the second

vacuum controller is delivered complete with the ventilation

valve installed on a new support. Install the existing vacuum

controller on the new support. For more information about

retrofitting from system SC to system SCC, refer to chapter

7.7.5, page 32.

Baseplate mounted (see chapter 7.2, page 24)

Pump disconnected from mains

Qty Material

1 Allen key 4 mm

1 Allen key 5 mm

Tab. 16

Mounting the electrical supply unit

1. Slide the electrical supply unit (see fig. 8/4) with both tightening

nuts into the baseplate’s lateral slotted bar.

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 25

Installation, mounting and connection LABOPORT Pumps and Systems

2. Tighten the allen screws at the bottom of the electrical supply

unit.

Mounting the vacuum controller

1. Slide the support’s attachment part (see fig. 8/3) into the

baseplate’s lateral, upward-pointing slotted bar.

2. Tighten the allen screw at the bottom of the support.

Wire and connect with each other the electrical supply unit

and the vacuum controller

Figures 11 and 12 provide an overview of the electrical

connections for LABOPORT systems SC and SCC.

1. Connect signal socket of the vacuum controller with the eletrical supply unit socket marked VC 1 (fig. 10/5) using the connection cable.

2. When using two vacuum controllers, connect the second

vacuum controller’s signal socket to the electrical supply unit’s

VC2 connection (6).

Fig. 10: Connections of the electri-

cal supply unit

3. Insert the vacuum controller power cord plug into the designated electrical supply unit socket (2).

4. When using two vacuum controllers, insert the vacuum valves’

plugs into the electrical supply unit’s VV1 (3) und VV2 (4)

connections.

5. Insert the pump vent valve plug into the electrical supply unit

socket marked PRV (7).

6. Insert the vacuum pump power cord plug into the designated

electrical supply unit socket (1).

7. Tuck all of the wires into the electrical supply unit and secure

the cover.

8. Make sure power switches on the pump and on the vacuum

controller(s) are switched off.

9. Insert the electrical supply unit`s system power cord plug into a

shockproof socket.

26 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Installation, mounting and connection

to vacuum pump

System

power

connect

Electrical

supply unit

Fig. 11: Electrical connection LABOPORT System SC

Vacuum

valve 1

to vacuum pump

System

power

connect

Vacuum

valve 2

Pump vent

valve

Pump vent

valve

Vacuum controller (rear)

Coolant valve (optional)

Vacuum controller 1 (rear)

Vacuum controller 2

Electrical

supply unit

Fig. 12: Electrical connection LABOPORT System SCC

Laying hoses: depending on system configuration see chapter

7.7.3 (system SC), 7.7.4 (system SCC) or 7.7.5 (retrofitting

from system SC to system SCC).

Mounting coolant valve for high performance condenser

(optional)

With a coolant valve it becomes possible to stop the flow of

coolant if the system’s control operation is interrupted or

terminated.

Danger of the high performance condenser bursting

Make sure that the coolant valve is mounted

between the coolant supply and the coolant inlet

WARNING

port of high performance condenser.

1. Connect the coolant valve to the coolant supply.

2. Insert the coolant valve’s plug into the vacuum

controller’s VV1 socket (see fig. 10/3).

See fig. 16, page 29 for coolant inlet and outlet.

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 27

Installation, mounting and connection LABOPORT Pumps and Systems

7.6. Gas Ballast

Only for two-headed pumps.

Condition

12

4

Fig. 13: Mounting the gas ballast

Motor disconnected from mains and de-energized

Mounting

1. Disconnect the tubes from the inlet (4) and the outlet (3) of the

3

pump.

2. Remove the pump from the baseplate.

3. Open the connection (2) of the pump heads.

4. Screw out the connecting piece (1) of the vacuum side head.

5. Screw the gas ballast into the pump head.

6. Remount the connection (2) between the both pump heads.

7.7. Mounting of Systems

The displayed system tube configuration is for two-headed

pumps only.

Tools and material

Contact KNF Service for information about laying tubes for

one-headed pumps and pumps with aluminum heads (“A” in

the type designation).

7.7.1. System SR

The system SR consists of:

baseplate

two separators

Qty Material

1 Phillips-head screwdriver No. 3

2 Tubes (see fig. 14)

Resistant to the medium employed

Inside diameter 10 mm

Length: approx. 150 mm

Tab. 17

1. Attach pump to the baseplate (see chapter 7.2, page 24).

2. Install the separators (chapter 7.3, page 24).

3. Lay tubes for separators (see fig. 14).

Fig. 14: Tubing system SR

28 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Installation, mounting and connection

7.7.2. System SH

The system SH consists of:

Baseplate

1 separator

1 high performance condenser

Tools and material

Qty Material

1 Phillips-head screwdriver No. 3

1 Allen key 5 mm

2 Tubes (see fig. 15)

Resistant to the medium employed

Inside diameter 10 mm

Length: (1) approx. 150 mm, (2) approx. 220 mm

Tab. 18

Danger of the high performance condenser bursting

Make sure that the high performance con-

denser´s upper gas outlet is not blocked.

WARNING

Fig. 15: Tubing system SH

Fig. 16: Coolant supply of high

performance condenser

Improper laying of hoses will result in damage to the

pump

Correctly assign gas and coolant hose

DANGER

connections.

Do not reverse the gas connections’ inlets and

outlets.

1. Attach pump to the baseplate (see chapter 7.2, page 24).

2. Install the separator (see chapter 7.3, page 24).

3. Install the high performance condenser (see chapter 7.4, page

25).

4. Lay hoses for system (see fig. 15).

The condenser-connectors for the coolant require connection

tubing with an inside diameter of 8 mm.

Coolant inlet and outlet see fig. 16.

When using a coolant valve:

Danger of the high performance condenser bursting

WARNING

Make sure that the coolant valve is mounted

between the coolant supply and the coolant inlet

port of high performance condenser.

1 Coolant inlet

2 Coolant outlet

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 29

Installation, mounting and connection LABOPORT Pumps and Systems

7.7.3. System SC

The system SC consists of:

Baseplate

1 separator

1 high performance condenser

Electrical supply unit with 1 vacuum controller

Tools and material

Qty Material

1 Phillips-head screwdriver No. 3

1 Allen key 4 mm

1 Allen key 5 mm

4 Tubes (see fig. 17)

Resistant to the medium employed

Inside diameter 10 mm

Length: (1,4) approx. 220 mm, (2) approx. 300 mm,

(3) approx. 150 mm

Tab. 19

1. Attach pump to the baseplate (see chapter 7.2, page 20).

Fig. 17: Tubing system SC

2. Install the separator (see chapter 7.3, page 20).

3. Install the high performance condenser (see chapter 7.4, page

21).

4. Install the electrical supply unit and the vacuum controller (see

chapter 7.5, page 21).

5. Lay hoses for system (see fig. 17).

Coolant inlet and outlet see fig. 16.

When using a coolant valve:

Danger of the high performance condenser bursting

Make sure that the coolant valve is mounted

between the coolant supply and the coolant inlet

WARNING

port of high performance condenser.

6. Wire and connect with each other the electrical supply unit and

the vacuum controller (see chapter 7.5, page 21).

30 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Installation, mounting and connection

7.7.4. System SCC

The system SCC consists of:

Baseplate

1 separator

1 high performance condenser

Electrical supply unit with 2 vacuum controllers

Tools and material

Qty Material

1 Phillips-head screwdriver No. 3

1 Allen key 4 mm

1 Allen key 5 mm

8 Tubes (see fig. 18)

Resistant to the medium employed

Inside diameter 10 mm

Length: (1) approx. 320 mm, (2) approx. 260 mm,

(3,4) approx. 120 mm, (5) approx. 220 mm, (6) approx.

135 mm, (7) approx. 175 mm, (8) approx. 350 mm

Tab. 20

1. Attach pump to the baseplate (see chapter 7.2, page 20).

Fig. 18: Tubing system SCC

2. Install the separator (see chapter 7.3, page 20).

3. Install the high performance condenser (see chapter 7.4, page

21).

4. Install the electrical supply unit and both vacuum controllers

(see chapter 7.5, page 21).

5. Lay hoses for system (see fig. 18).

Coolant inlet and outlet see fig. 16.

When using a coolant valve:

Danger of the high performance condenser bursting

Make sure that the coolant valve is mounted

between the coolant supply and the coolant inlet

WARNING

port of high performance condenser.

6. Wire and connect with each other the electrical supply unit and

the vacuum controller (see chapter 7.5, page 21).

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 31

Installation, mounting and connection LABOPORT Pumps and Systems

7.7.5. Retrofitting from System SC to System SCC

The second vacuum controller is delivered complete with the

vent valve installed on a new support (length: 410 mm). Install

the existing vacuum controller on the new support.

Conditions

Pump removed from operation (see chapter 8.2, page 35)

Pump disconnected from mains

Tools and material

Qty Material

1 Allen key 4 mm

1 Allen key 5 mm

See chapter 7.7.4 for the required hoses

Tab. 21

Removing the existing vacuum controller

The following item numbers refer to fig. 2, page 8.

1. Disconnect the tubes from the pump vent valve (5) as well as

from the controller (2) vent valve (3).

Fig. 19: Tubing system SCC

2. Pull out all plugs from the electrical supply unit (1).

3. Remove the vacuum controller from the support (16) after

loosening the clamp assembly.

4. Remove the lateral support from the main support after loosening the clamp assembly.

5. Loosen the allen screw at the foot of the main support.

6. Slide the support out of the baseplate (17) mounting slot assembly.

Mount new vacuum controller

The following item numbers refer to fig. 2, page 8.

1. Slide the removed vacuum controller (2) into the slot on the

new support (16) and fix it in place with the clamp connection.

2. Slide the support’s attachment part into the baseplate’s (17)

lateral upward-pointing slotted bar.

3. Tighten the allen screw at the foot of the support.

4. Mount the lateral support onto the main support.

5. Slide two additional vacuum valves(6) onto the lateral support

mounting slot and fix the device with help of the clamping assembly.

6. Lay hoses for system (see fig. 19).

7. Wire and connect with each other the electrical supply unit and

the vacuum controller (see chapter 7.5, page 25).

32 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Operation

8. Operation

8.1. Pump

8.1.1. Preparing for Start-up

Before switching on the pump/system, observe the following

points:

Operational requirements

Pump All hoses attached properly

Pump/

System

System Clamp connections are tight

Tab. 22

8.1.2. Starting

Only operate the pump under the operating parameters and

conditions described in chapter 5, Technical data.

Make sure the pumps are used properly (see chapter 2.1,

page 5).

Fan openings not blocked

Specifications of the power supply correspond with

the data on the pump’s/the electrical supply unit’s

type plate.

The pump outlet is not closed or constricted.

When using two vacuum controllers: The media

are compatible with each other (when running two

different processes simultaneously)

When using a gas ballast: No explosive or

poisonous mixtures may be produced when

ventilating the vacuum system through the air inlet.

All cables attached properly

Make sure the pumps are not used improperly (see chapter

2.2, page 5).

Observe the safety precautions (see chapter 3, page 6).

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 33

Operation LABOPORT Pumps and Systems

A

Hazard of the pump head bursting due to excessive

pressure increase

Do not exceed max. permissible operating

WARNING

Excessive pressure (with all of the related hazards) can be

prevented by placing a bypass line with a pressure-relief valve

pressure (see chapter 5.1, page 10).

Monitor pressure during operation.

If the pressure exceeds the maximum permissi-

ble operating pressure, immediately shut down

pump and eliminate fault (see chapter 10, page

42).

Only throttle or regulate the air or gas quantity in

the suction line to prevent the maximum permissible operating pressure from being exceeded.

If the air or gas quantity in the pressure line is

throttled or regulated, make sure that the maximum permissible operating pressure of the

pump is not exceeded.

between the pressure and suctions sides of the pump. For

further information, contact our technical adviser.

Pump standstill

With the pump at a standstill, open pressure and suction lines

to normal atmospheric pressure.

Automatic starting can cause personal injury and

pump damage

When the operation of the pump is interrupted by the

WARNING

thermal switch, the pump will restart automatically

after cooling down.

fter triggering of the thermal protection or in the

event of power failure, remove the pump’s mains

plug from the socket so that the pump cannot

start uncontrollably.

Attempt work on the pump or system only if the

pump/system is separated from mains power.

34 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Operation

r

8.2. Switching Pump/System on and off

Switching pump on

The pump may not start up against overpressure during

switch-on. This also applies in operation following a brief powe

failure. If a pump starts against pressure, it may block. This

activates the thermal switch, and the pump switches off.

Make sure that no pressure is present in the lines during

switch-on.

Switch on pump with mains switch (see fig. 2/19)

Switching off the pump/removing from operation

When transferring aggressive media, flush the pump prior to

switch-off to increase the service life of the diaphragm (see

chapter 9.2.1, page 37).

Switch off pump with mains switch (see fig. 2/19).

Open pressure and suction lines to normal atmospheric pres-

sure.

Tools and material

Disconnect the power source.

8.3. Notices related to System Operation

8.3.1. Separators

You can move the holders for the separator vessels after

loosening the attachment screw.

8.3.2. High Performance Condenser

Danger of high performance condenser bursting

Make sure that the high performance

condenser’s upper gas outlet is not blocked.

CAUTION

A high performance condenser may be used only with a coldwater connection or recirculated cooling system.

Adjustment of the high performance condenser altitude level

Qty Material

1 Allen key 5 mm

Tab. 23

1. Loosen the both allen screws at the foot of the high performance condenser.

2. Remove the high performance condenser’s clamp assembly in

the support mounting slot.

3. Retighten the allen screws.

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 35

Operation LABOPORT Pumps and Systems

p

8.3.3. Vacuum Controller

Personal injury caused by poisoning or explosion

and damage to the pump.

Make sure that no reactive or explosive mixtures

WARNING

will be produced when ventilating the vacuum

system through the air inlet.

Make sure that the media are compatible with

each other (when running two different

processes simultaneously).

Use the mains switch to switch the vacuum controller on and

off.

Each vacuum controller can be set individually and will work

independently of the other.

Refer to the vacuum controller’s operating instructions for more

information.

8.3.4. Gas Ballast

closed

o

en

Fig. 20: Gas ballast operating

knob

Personal injury caused by poisoning or explosion

and damage to the pump.

Ensure that the creation of reactive, explosive or

WARNING

otherwise hazardous mixtures during the supply

of air is prevented.

If the gas ballast valve is open the maximum achievable vacuum level is reduced. The gas ballast is adjusted with the

button (see fig. 20).

36 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Servicing

9. Servicing

9.1. Servicing Schedule

Component Servicing interval

Pump/system Regular inspection for external damage or

leaks

Diaphragm and

valve

plates/sealings

Tab. 24

9.2. Cleaning

When cleaning, make sure that no liquids enter the inside of

the housing.

9.2.1. Flushing Pump

Before switching off the pump, flush it with air (if necessary for

safety reasons: with an inert gas) for about five minutes under

atmospheric conditions (ambient pressure).

9.2.2. Cleaning Pump

Replace at the latest, when pump output

decreases

Only clean pump with a damp cloth and non-flammable clean-

ing agents.

9.2.3. Emptying and Cleaning the Separator

1. Unscrew the connecting nozzles (fig. 2/8, page 8).

2. Remove separator (fig. 2/14) from the holder (fig. 2/15) and

dispose of contents according to applicable regulations in your

area. Then rinse out the separator.

3. Replace separator into the holder.

4. Screw the connecting nozzles back on.

9.2.4. Emptying and Cleaning the Condenser

1. Carefully remove the spring clamp (fig. 2/10) while supporting

the flask (fig. 2/11).

2. Empty and clean the flask – observing safety precautions.

3. Re-connect the flask to the condenser and replace the spring

clamp.

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 37

Servicing LABOPORT Pumps and Systems

9.3. Changing Diaphragm and Valve

Plates/Sealings

Conditions

Tools and material

Information on procedure

Pump is switched off and mains plug is removed from the

socket

Pump is clean and free of hazardous materials

Tubes removed from pump’s pneumatic inlet and outlet

Pump is removed from baseplate (if pump is integrated into a

system)

Qty Material

1 Phillips-head screwdriver No. 2

1 Service Set (see chapter 11.1, page 46)

1 Felt-tip pen

Tab. 25

Always replace diaphragm and valve plates/sealings together

to maintain the pump performance.

With multi-head pumps, parts of the individual pump heads can be

confused.

Replace the diaphragm and valve plates/sealings of the indi-

vidual pump heads consecutively.

Health hazard due to dangerous substances

in the pump!

WARNING

Depending on the substance transferred, caustic

burns or poisoning are possible.

Wear protective clothing if necessary, e.g.

protective gloves.

Flush pump before replacing the diaphragm and

valve plates/sealings (see chapter 9.2.1, page

37).

38 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Servicing

Removing pump head

Pump N 842.3 FT.18 has a round shape of head, not a

hexagonal.

1. For two-headed pumps: On the pneumatic head connection

(3), loosen the union nuts (2) by hand. Then slightly loosen the

angle-fitting (1) in the pump head (4) by turning it anticlockwise, so that the connecting tube can be pulled out.

2. Mark the position of top plate (fig. 24/5), head plate (fig. 24/6),

intermediate plate (fig. 24/8) and adapter relatively to each

other by a drawing line (for two-headed pumps: at both pump

heads) with a felt-tip pen (1). This helps to avoid incorrect assembly later.

Fig. 21: Removing pump head

be loosened in the next work step.

3. Loosen the outer screws (5) on the pump head/pump heads.

In version N 842.3 FT.18, twelve (instead of six) screws must

4. Carefully remove pump head / pump heads.

Change diaphragm

Fig. 22: Changing structured

diaphragm

Replace the diaphragms of two-headed pumps consecutively

in order to ensure that the same number of diaphragm spacers

is used as before.

1. For two-headed pumps: Push down one diaphragm until other

diaphragm is pushed upwards to its highest position.

2. Carefully unscrew the upper diaphragm (1) anti-clockwise

using both hands.

3. Replace spacer thick (2) and spacers thin (3) onto the screw

thread of the new diaphragm (same number and order).

4. Screw in the new diaphragm and tighten it by hand.

5. With a two-headed pump: Complete steps 1 through 4 for the

second pump head.

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 39

Servicing LABOPORT Pumps and Systems

Change valve plates/sealings

Replacing the valve plates/sealings of two-headed pumps

consecutively.

In version N 842.3 FT.18, three (instead of one) screws must

be loosened in the first work step.

1. Loosen screw(s) (1) in the center of the top plate (2). With a

two-headed pump: loosen the screw(s) from just one pump

head.

2. Remove top plate (2) and head plate (3) from intermediate

plate (5).

Valve plates/sealings are visible.

3. Remove old valve plate/sealings.

Fig. 23: Changing valve

plates/sealings

1

2

3

4

5

6

7

8

Fig. 24: Refitting pump head

4. Clean intermediate plate (5) carefully (if there should be depos-

its in the recesses in the intermediate plate).

5. Insert new valve plates/sealings (4) in the recesses in the

intermediate plate (5).

6. For two-headed pumps: Carry out the steps 1 to 5 for the

second pump head.

7. Dispose of the old diaphragm(s) and valve plates/sealings

properly.

Refitting pump head

1. Apply pressure all around the edge of the diaphragm. With a

two-headed pump: Apply pressure to diaphragm on only one

pump.

2. Place the intermediate plate (8) with valve plates/sealings on

the adapter in accordance with the felt-tip pen marking.

3. Place the head plate (6) on the intermediate plate (8) in the

position indicated by the guide pin (7).

4. Place the top plate (5) on the head plate (6) in accordance with

the felt-tip pen marking.

5. Gently tighten screws (4) in diagonal order.

In version N 842.3 FT.18, three (instead of one) screws must

be tightened in the next work step.

6. Insert screw(s) (1) with disk springs (2, 3) in the center of the

top plate (5). In doing so, make sure that the disk springs are

arranged properly (see fig. 24).

7. Screw in the screw/screws (1) in the centre of the pump top

plate (5) until it is flush with the top plate (they are flush with

the top plate); then screw one final half turn to tighten.

8. For two-headed pumps: Carry out steps 1 to 7 for the second

pump head.

9. For two-headed pumps: Refit the pneumatic head connection:

Place tube onto the connecting part of the angle fitting, turn

angle fitting to a straight position and tighten the union nut.

40 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Servicing

Final steps

1. Remount the pump to the baseplate (if applicable).

2. Reconnect suction and pressure line to the pump.

3. Reconnect the pump to the electricity supply.

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 41

Troubleshooting LABOPORT Pumps and Systems

10. Troubleshooting

Extreme danger from electrical shock!

Disconnect the pump power supply before working

on the pump.

DANGER

Check the pump (see Tab. 26 to 35).

10.1. Pump/System without Vacuum Controller

Pump does not transfer

Cause Fault remedy

No voltage in the power source Check room fuse and switch on if necessary.

Make sure the pump is de-energized and secure.

Thermal switch has operated

following to over-heating.

Connections or lines blocked. Check connections and lines.

External valve is closed or filter

is clogged.

Condensate has collected in

pump head.

Diaphragm or valve plates/

sealings are worn.

Flow rate, pressure or vacuum too low

The system/the pump does not achieve the output specified in the Technical data or the data sheet.

Cause Fault remedy

Condensate has collected in

pump head.

There is gauge pressure on

pressure side and at the same

time vacuum or a pressure

above atmospheric pressure on

suction side.

Pneumatic lines or connection

parts have an insufficient cross

section or they are throttled.

Leaks occur on connections,

lines or pump head.

Connections or lines completely

or partially jammed.

Head parts are soiled. Clean head components.

Disconnect pump from mains.

Allow pump to cool.

Trace cause of over-heating and eliminate it.

Remove blockage.

Check external valves and filters.

Detach the condensate source from the pump.

Flush pump (see chapter 9.2.1, page 37).

Replace diaphragm and valve plates/sealings (see chapter

9.3, page 38).

Tab. 26

Detach the condensate source from the pump.

Flush pump (see chapter 9.2.1, page 37).

Change the pressure conditions.

Disconnect pump from system to determine output values.

Eliminate throttling (e.g. valve) if necessary.

Use lines or connection parts with larger cross section if

necessary.

Check that tubes sit correctly on hose nozzles.

Replace leaky tubes.

Eliminate leaks.

Check connections and lines.

Remove the jamming parts and particles.

Diaphragm or valve

plates/sealings are worn.

42 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

Replace diaphragm and valve plates/sealings,

(see chapter 9.3, page 38).

LABOPORT Pumps and Systems Troubleshooting

Flow rate, pressure or vacuum too low

The system/the pump does not achieve the output specified in the Technical data or the data sheet.

Cause Fault remedy

After diaphragm and valve

plates/sealings have been

replaced.

Check that the spacers have been replaced onto the dia-

phragm screw thread.

Check head connection and hose connections.

Possibly carefully tighten the outer screws (fig. 21/5, page

39) of the top plate crosswise.

Tab. 27

Pump is switched on, but does not run, the on/off-switch on the pump is not lit

Cause Fault remedy

Pump is not connected with the

Connect pump to mains power.

power source.

No voltage in the power source

Fuse in the pump is defective.

Check room fuse and switch on if necessary.

Remove pump’s mains plug from the socket.

Loosen marked lid on underside of the pump.

Select and replace suitable fuse (see chapter 5.1, page 10).

Tab. 28

Pump is switched on, but does not run, the on/off-switch on the pump is lit

Cause Fault remedy

The thermal switch has opened

due to overheating.

Remove pump’s mains plug from the socket.

Allow pump to cool.

Trace cause of over-heating and eliminate it.

Tab. 29

10.2. System with one Vacuum Controller

See also chapter 10.1, pump/system without vacuum

controller, table 26 and 27.

Sufficient vacuum is not reached

Cause Fault remedy

Solid particles in the pump vent

valve

Condensate in pump head

Clean pump vent valve.

Let the pumpe run to the ultimate vacuum (Drying Mode, see

Operating Manual of Vacuum Controller).

Tab. 30

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 43

Troubleshooting LABOPORT Pumps and Systems

Vacuum Controller is switched on and set on "Regulation Mode", the desired vacuum level

is not reached, pump does not run, the on/off-switch on the pump is not lit

Cause Fault remedy

Pump is not switched on.

Incorrect electrical connection of

controller

Fuse in the pump is defective.

Switch on pump.

Switch off system and separate from power supply.

Check cabling.

Remove pump’s mains plug from the socket.

Loosen marked lid on underside of the pump.

Select and replace suitable fuse (see chapter 5.1, page 10).

Tab. 31

Vacuum Controller is switched on and set on "Regulation Mode", the desired vacum level is

not reached, pump does not run, the on/off-switch on the pump is lit

Cause Fault remedy

The thermal switch has opened

due to overheating.

Remove pump’s mains plug from the socket.

Allow pump to cool.

Trace cause of over-heating and eliminate it.

Tab. 32

Vacuum Controller is switched on, no LED-indication

Cause Fault remedy

In the electrical supply unit the

vacuum controller plug is

plugged into the socket for the

Make sure that the vacuum controller’s mains plug is plugged

into the socket (on the electrical supply unit) for vacuum

controllers (see fig. 10, page 26, position 2).

pump.

The fuse in the vacuum control-

ler is defective.

Switch off system and separate from power supply.

Select an appropriate fuse (refer to the vacuum controller’s

operating instructions).

Replace fuse above the circuit closer/circuit breaker.

The fuse in the electrical supply

unit is defect.

Switch off system and separate from power supply.

Select suitable fuse (see chapter 5.2, page 17).

Replace fuse on the front side, below the mains connection.

Tab. 33

Vacuum Controller shows unrealistic values

Cause Fault remedy

The factory-set pressure

Contact KNF (see page 47).

equalization has changed.

Sensor is defective Contact KNF (see page 47).

Tab. 34

44 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Troubleshooting

10.3. System with two Vacuum Controllers

See also chapter 10.2, system with one vacuum controller.

System does not work, despite one Vacuum Controller (both controllers) being set on

"Regulation Mode"

Cause Fault remedy

In the electrical supply unit the

connecting wires for the vacuum

controllers are plugged in incorrectly.

In the electrical supply unit the

connecting wires for the vacuum

valve are plugged incorrectly.

Exchange the plugs between vacuum controller 1 and vac-

uum controller 2.

Exchange the plugs between vacuum valve 1 and vacuum

valve 2.

Tab. 35

10.4. Fault cannot be rectified

If you are unable to determine any of the specified causes, send

the pump to KNF Customer Service (see page 47 for the address).

1. Flush the pump to free the pump head of dangerous or ag-

gressive gases (see chapter 9.2.1, page 37).

2. Remove the pump.

3. Clean the pump (see chapter 9.2.2, page 37).

4. Send the pump to KNF with a filled out decontamination decla-

ration (see chapter 12) and specification of the medium transferred.

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 45

Ordering Information LABOPORT Pumps and Systems

11. Ordering Information

11.1. Pumps and Spare Parts

A service set contains:

1 diaphragm and 2 valve plates/sealings for one-headed

pumps

2 diaphragms and 4 valve plates/sealings for two-headed

pumps

Pump type Order-No. pump Order-No. Service Set

N 810 FT.18 057986 058077

N 820 FT.18 057901 058078

N 840 FT.18 057911 058079

N 810.3 FT.18 057500 057357

N 820.3 FT.18 057501 057358

N 840.3 FT.18 057502 057359

N 840.1.2 FT.18 057571 057359

N 842.3 FT.18 057634 057359

Tab. 36

11.2. Accessories for Pump Systems

Accessory

Baseplate and mounting

Baseplate and mounting

Separator complete including tray

High performance condenser (in-

cluding support)

Gas ballast

Gas ballast

Vacuum controller (including support

and electrical supply unit)

Vacuum controller (including sup-

port) *

Two vacuum controllers (complete

including support and electrical

supply unit)

Vacuum chemical tubing for pneumatic connection** (yard ware***)

Tab. 37 * For retrofitting from system SC to SCC

** Material: Norprene A60G

*** Please specify the required length (in whole meters).

Type

N 810 FT.18

N 820 FT.18

N 840 FT.18

N 810.3 FT.18

N 820.3 FT.18

N 840.3 FT.18

NP 810/820 X X X X 028129

NP 840 X X X X 028128

NR 800 X X X X X X X X 026225

NH 800

NG 810 X 028476

NG 820/840 X X X 028477

NC 800A

NC 800B

NC 800A/B

X X X X X X X X 026231

X X X X X X X X 046380

X X X X X X X X 046381

X X X X X X X X 046382

X X X X X X X X 028187

N 840.1.2 FT.18

Order-No.

N 842.3 FT.18

46 Translation of original Operating Instructions, english, KNF 121211-121345 01/10

LABOPORT Pumps and Systems Decontamination Declaration

12. Decontamination Declaration

The condition for the repair of a pump by KNF is the certification of the customer on the transferred media and on the

cleaning of the pump (decontamination declaration).

Copy this page.

KNF Neuberger UK Ltd

Ave 2, Station Lane Ind Est,

Witney, Oxfordshire

OX28 4FA, UK

Tel: +44 (0)1993 778373

Fax +

44 (0)1993 775148

E-mail: info@knf.

www.knf.

co.uk

,

co.uk

Enter the pump model, the Serial No. and the transferred

media in the form below and sent the signed form together with

the flushed and cleaned pump to KNF Customer Service.

Customer decontamination declaration for

repair order

We herewith confirm that the following media have been pumped

with the pump listed below, and that the pump has been flushed

and cleaned.

Pump model

Serial No.

Fed media

The pump contains neither aggressive, biological, radioactive,

poisonous nor other dangerous media.

Company Date/Signature

Translation of original Operating Instructions, english, KNF 121211-121345 01/10 47

NC 800/NBC 800

Vacuum Controller

for Laboratories

Operating Manual

Carefully study the Operating Instructions and observe at all times the relevant instructions to avoid dangerous situations.

INNOVATIVE

TECHNOLOGY

WORLDWIDE

KNF 121205-121650 02/10

Translation of original Operating Instructions, english

Table of Contents Page

1. Description 2

1.1 Unit Functions 2

1.2 Arrangement in

Vacuum Systems 2

1.3 Mechanical Attachment 2

1.4 Electrical Connection 2

1.5 Pneumatic Connection 2

1.6 Switching on/off 2

1.7 Explanation of Display

Elements 3

1.8 Explanation of Control

Panel 3

2. General Safety

Precautions 3

3. General Operating

Instructions 3

3.1 Operating Conditions 3

3.2 Starting 3

3.3 Shutdown 4

4. Manual Operation 4

4.1 Controlling Profiles 4

4.2 Setting Values 5

4.3 Running 5

4.3.1 Controlling 5

4.3.2 Controlling with soft

setpoint start 5

4.3.3 Controlled Pressure

Reduction 5

4.4 Temporary Mode 6

4.4.1 Function and Operation 6

4.4.2 Aeration during Distillation 6

4.4.3 Experimental Use 6

4.5 Uncontrolled Evacuation/

Drying Mode 6

5. Automatic Operation 7

5.1 Controlling Profiles 7

5.2 Setting Values 7

5.3 Running 7

6. Changing of Pressure unit 8

7. Calibration 8

8. Trouble Shooting 8

9. Specifications 8

10. Ordering Information 8

10.1 Accessories 8

10.2 Vacuum Controller and

Vacuum Valves 8

1. Description

NC 800: For use at LABOPORT vacuum

systems.

NBC 800: Workstation vacuum controller for use e. g. at vacuum supply

points.

Technical data: see chapter 8.

1.1 Unit Functions

The vacuum controller NBC 800 regulates vacuum on an individual basis in

the laboratory working place. Several

different functions are possible:

Evacuation at pressure setpoint;

regulation by pressure setpoint and

pressure differential (manual operation);

defined post distillation;

experimental use;

automatic search for distillation

point (automatic operation).

1.2 Arrangement in Vacuum Systems

See fig. 1.

1.3 Mechanical Attachment

The Vacuum Controller NBC 800 can be

attached to a round support by means

of the connection on its back side

(maximum support diameter: 13 mm).

Other types of connection on request.

Attachment in LABOPORT®Sys-

tems: see LABOPORT Operating

Manual.

1.4 Electrical Connection

Electrical supply:

The socket is located on the back

of the unit.

Cooling water valve and vacuum

valve:

Both can be connected either to

the side socket or the socket on

the back (6-pin). Proper connections are ensured by means of

different pin arrangements.

Insert plug into a properly installed

safety socket.

Electrical Connection in

LABOPORT®Systems: see

LABOPORT Operating Manual.

1.5 Pneumatic Connection

The pneumatic connection is made

at the valve block on the hose shaft

(tube ID 10mm).

Pneumatic Connection in

LABOPORT®Systems: see

LABOPORT Operating Manual.

1.6 Switching on/off

The vacuum controller is switched

on and off by the switch on the

side.

Symbols: = Position in the illustration, = Important point, = Task, = Advice to users, = Product information Warning

2 Translation of original Operating Instructions, english, KNF 121205-121650 02/10

Fig. 1: Arrangement of vacuum controller in vacuum system

Specification:

1 Vacuum controller NBC 800

2 Vacuum pump

3 High Performance Condenser of

Vacuum System

4Vacuum valve

5 Venting valve (internal)

6 Condensate recipient

7 Vacuum installation

8 Suction line

9Cleaning gas connection/Aeration

10 Coolant valve (accessory)

11 Cooling water tubing

1.7 Explanation of Display Elements

See fig 2.

„mode“:

Displays operating mode

Changing of pressure unit see

section 6.

Changing of pressure unit see

section 6.

OFF: No mode entered.

A 1: Automatic Mode

(see section 5).

bP: Boiling Point

- distillation point

(see section 5).

H 1: Manual Mode 1:

(see section 4).

H 2: Manual Mode 2:

Pressure differential

with soft setpoint start

(only NBC 800)

(see section 4).

PU: Uncontrolled evacuation

(see section 4.5).

„setp“:

Displays pressure setpoint in mbar.

„mbar“:

Displays actual pressure in mbar

and operating parameters.

Description of operating

parameters:

h: Pressure differential;

d: Defined post distillation;

t: Post distillation time.

LED for pressure display in mbar

Changing of pressure unit see

section 6.

LED for pressure display in torr

Changing of pressure unit see

section 6.

1.8 Explanation of Control Panel

See fig. 2.

SET-Key

To view and change currently

inserted values.

DOWN-Key

(for inserting values):

One-touch:

Single step adjustment.

Hold down:

Running adjustment.

UP-Key/Aeration

(for inserting values):

One-touch:

Single step adjustment.

Hold down:

Running adjustment.

Keep key held down for aearation (see

section 4.4.2).

STOP-Key

Stops the programm running. The

venting valve is opened until

atmospheric pressure is reached.

Then the valve closes.

MAN-Key

Starts manual mode.

AUTO-Key

Starts automatic mode.

Status LED for AUTO

Status LED for MAN

Power switch

2. General Safety Precautions

Observe all applicable accident

prevention regulations as well as

generally recognised Health &

Safety rules.

Carefully study the operating

instructions before using the

vacuum controller and observe at

all times the relevant instructions

to avoid dangerous situations.

Always keep the operating manual

handy in the work area.

Ensure that the vacuum controller

is used only for those applications

for which it is intended.

Plug the vacuum controller only

into properly installed grounded

outlets.

The vacuum controller must not be

used in areas where there is the

danger of explosion.

The vacuum controller must not be

used if the entry of air into the

system during venting could result

in the creation of reactive, explosive or otherwise hazardous mixtures (e.g. with the medium).

Prior to any use of the vacuum

controller, ensure that the creation

of reactive, explosive or otherwise

hazardous mixtures during the supply of air is prevented.

When cleaning the unit make sure

that no fluids come into contact

with the inside of the casing

The coolant valve (accessory)

must be connected to a water supply. It must on no account be

installed in the water drain line, or

after the condenser (danger of

pressure build-up in condenser).

3. General Operating Instructions

3.1 Operating Conditions

Permissible ambient :

+0... +40 °C.

The vacuum controller must not be

used in areas where there is the

danger of explosion.

The vacuum controller must not be

used if the entry of air into the

system during venting could result

in the creation of reactive, explosive or otherwise hazardous mixtures (e.g. with the medium).

Protect vacuum controller against

humidity.

3.2 Starting

Attach Vacuum Controller to the

support

section 1.3

Connect Vacuum Controller electri-

cally

section 1.4

Connect Vacuum Controller pneu-

Fig. 2: Display elements and control panel