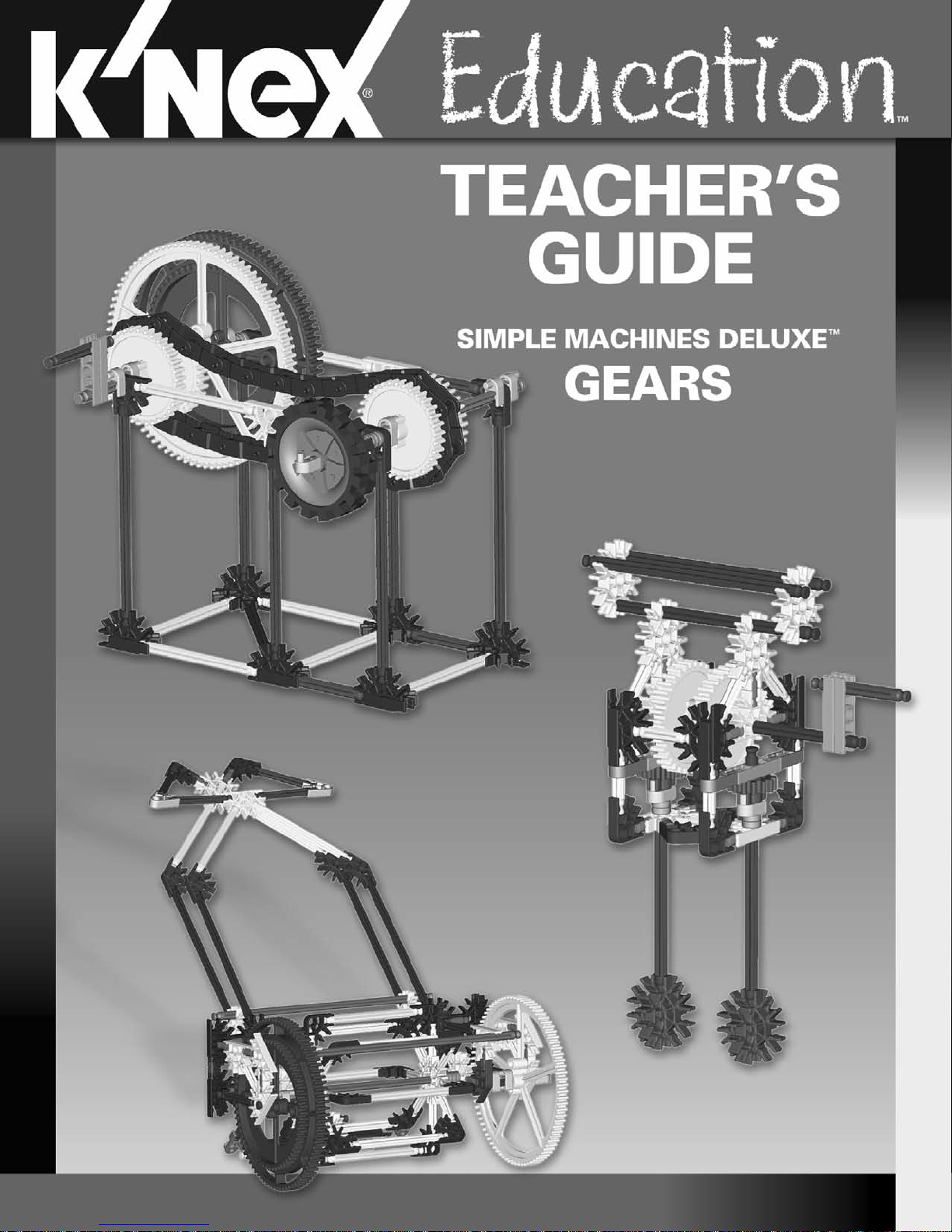

KNEX Education Simple Machines Deluxe GEARS Teachers Manual

TEACHER’S

GUIDE

M

SIMPLE MACHINES DELUXE

GEARS

T

KNX 79520-V1-11/10

©2011 K’NEX Limited Partnership Group

and its licensors.

K’NEX is a trademark of K’NEX Limited Partnership Group.

Website: www.knexeducation.com

Email: abcknex@knex.com

Phone: 1-888-ABC-KNEX (USA/CAN only)

K’NEX Limited Partnership Group

P.O. Box 700

Hatfield, PA 19440-0700

USA

Table of Contents

Simple Machines Deluxe Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Standard Alignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

All About Gears

What is a Gear? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Key Words and Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Key Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Student Reference Sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

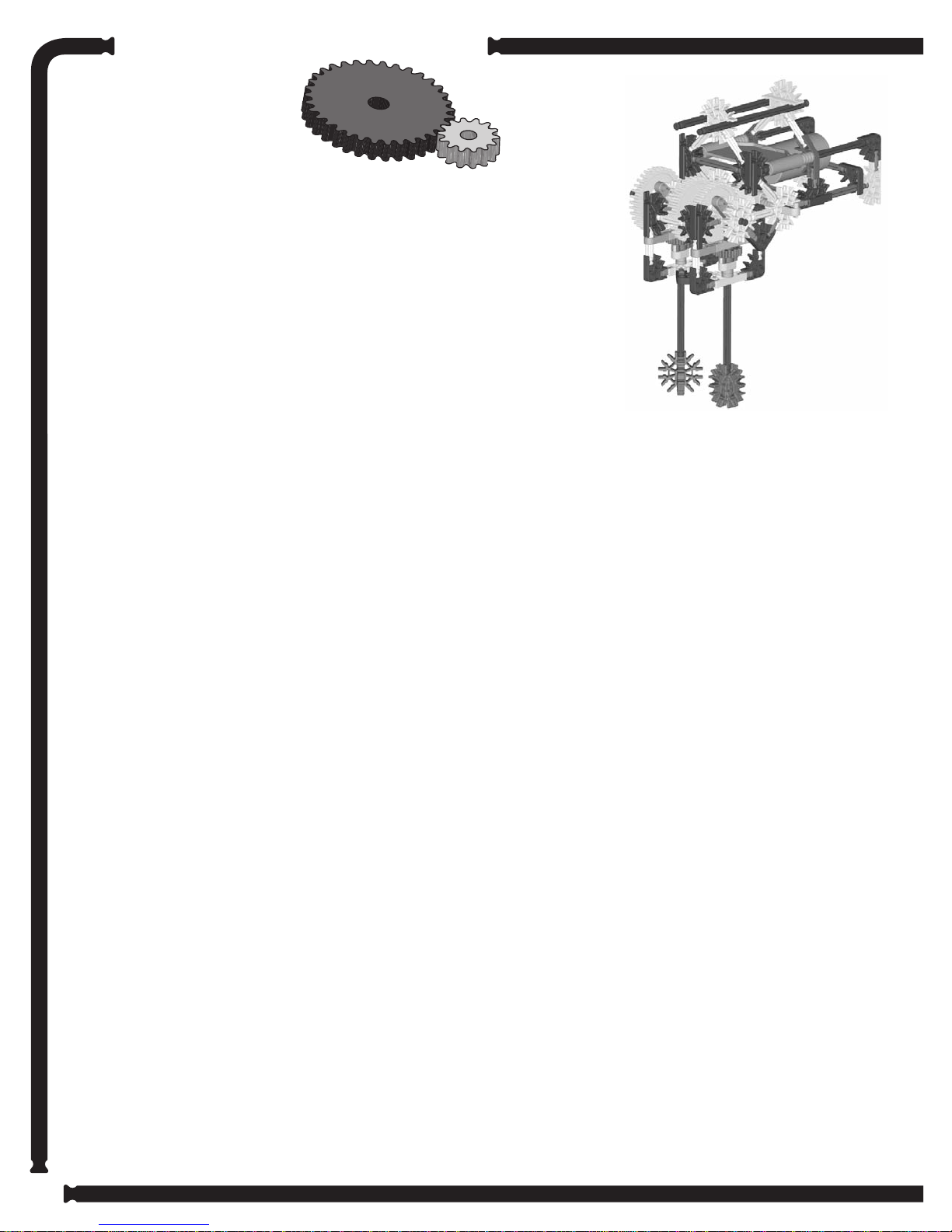

Spur Gears

Lesson Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Student Activity Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Sprocket Bicycle Gear

Lesson Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Student Activity Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Crown Gears

Lesson Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Student Activity Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Rack and Pinion Gears

Lesson Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Student Activity Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Worm and Worm Gear

Lesson Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Student Activity Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Planetary Gears

Lesson Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Student Activity Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Simple Transmission

Lesson Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Student Activity Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Car Window

Lesson Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Student Activity Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Lawnmower

Lesson Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Student Activity Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Eggbeater

Lesson Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Student Activity Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Food Mixer

Lesson Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Student Activity Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Differential

Lesson Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Student Activity Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Clock

Lesson Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Student Activity Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Part & Model List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Introduction:

OVERVIEW

This Teacher’s Guide has been developed to support you as your students investigate the

K’NEX Education Simple Machines Deluxe Set. In conjunction with the K’NEX materials and

individual student journals, the information and resources here can be used to build your

students’ understanding of scientific concepts and channel their inquiries into active and

meaningful learning experiences.

SIMPLE MACHINES DELUXE

This K’NEX Education set is designed to introduce students to the scientific concepts

associated with simple machines. Students are provided with the opportunity to acquire skills

using a hands-on, inquiry based approach to information and concepts. Working cooperatively,

students are encouraged to interact with each other as they build, investigate, discuss and

evaluate scientific principles in action.

TEACHER’S GUIDE

Designed as a resource for the teacher, this guide provides a glossary of key terms and

definitions, includes an overview of the concepts associated with the different simple machines,

identifies student objectives for each investigation, and offers plans and scripts to successfully

present selected models and their associated activities.We have also provided Student Activity

and Reference Sheets. These comprise illustrations and definitions of some of the concepts

featured in the model building activities. Most lessons can be completed in 30 to 45 minutes.

We recommend that teachers review their curriculum and science education standards to

identify those activities that best support their academic needs.

STUDENT JOURNALS

It is expected that students will have journals available for recording information.They should

be encouraged to enter initial thought at the start of an inquiry – what they “think” will happen.

These initial thoughts many be amended, based upon their ongoing inquiry and analysis, until the

students feel comfortable about drawing conclusions. Their journal entries will help make a

connection between the models they have built, the experiments they have conducted, and how

this information is applied to the real-world machines they use on a regular basis.The journals

will also provide students with a place to practice making drawings and diagrams of systems.

Finally, the journals will serve as a method of assessment for the Simple Machines units. Journal

Checklists are also included in the Teacher’s Guide for each model and it’s associated activities.

4

Alignment with National Standards Grades K-4

The National Science Education Standards

Unifying Concepts

and Processes

Physical Science

Science and Technology

Reprinted with permission from National Science Education Standards, 2001 by the National Academy of Sciences,

Courtesy of the National Academies Press,Washington,D.C.

• Systems, order, and organization

• Evidence, models, and explanation

• Change, constancy, and measurement

• Form and function

• Properties of objects and materials

• Position and motion of objects

• Abilities of technological design

• Understandings about science and

technology

Alignment with National Standards Grades 5 -8

The National Science Education Standards

Unifying Concepts

and Processes

Physical Science

Science as Inquiry

Science and Technology

Reprinted with permission from National Science Education Standards, 2001 by the National Academy of Sciences,

Courtesy of the National Academies Press,Washington,D.C.

• Systems, order, and organization

• Evidence, models, and explanation

• Change, constancy, and measurement

• Form and function

• Motions and Forces

• Transfer of Energy

• Abilities necessary to do scientific inquiry

• Understanding about scientific inquiry

• Abilities of technological design

• Understandings about science and

technology

5

Alignment with Standards for Technological Literacy Grades 3-5

Standards for Technological Literacy

The Nature of Technology

Design

Core Concepts of Technology

• Systems

• Processes

• Requirements

Relationships among technologies

• Technologies integrated

The Attributes of design

• Requirements of design

Engineering Design

• Engineering design process

• Creativity and considering all ideas

• Models

The role of troubleshooting, research and

development, invention and innovation, and

experimentation in problem solving

• Troubleshooting

• Invention and innovation

• Experimentation

Abilities of a Technological World

Used with permission of ITEEA (www.iteea.org)

6

Apply design process

• Collecting information

• Visualize a solution

• Test and evaluate solutions

• Improve a design

Alignment with Standards for Technological Literacy Grades 6 -8

Standards for Technological Literacy

The Nature of Technology

Design

Core Concepts of Technology

• Systems

• Processes

• Requirements

Relationships among technologies

• Interaction of systems

• Knowledge from other fields of study

and technology

The Attributes of design

• Design leads to useful products and

systems

• There is no perfect design

Engineering Design

• Brainstorming

• Modeling, testing, evaluating, and

modifying

The role of troubleshooting, research and

development, invention and innovation,

and experimentation in problem solving

• Troubleshooting

• Invention and innovation

• Experimentation

Abilities of a Technological World

Used with permission of ITEEA (www.iteea.org)

Apply design process

• Indentify criteria and constraints

• Test and evaluate

• Make a product or system

7

All About

GEARS

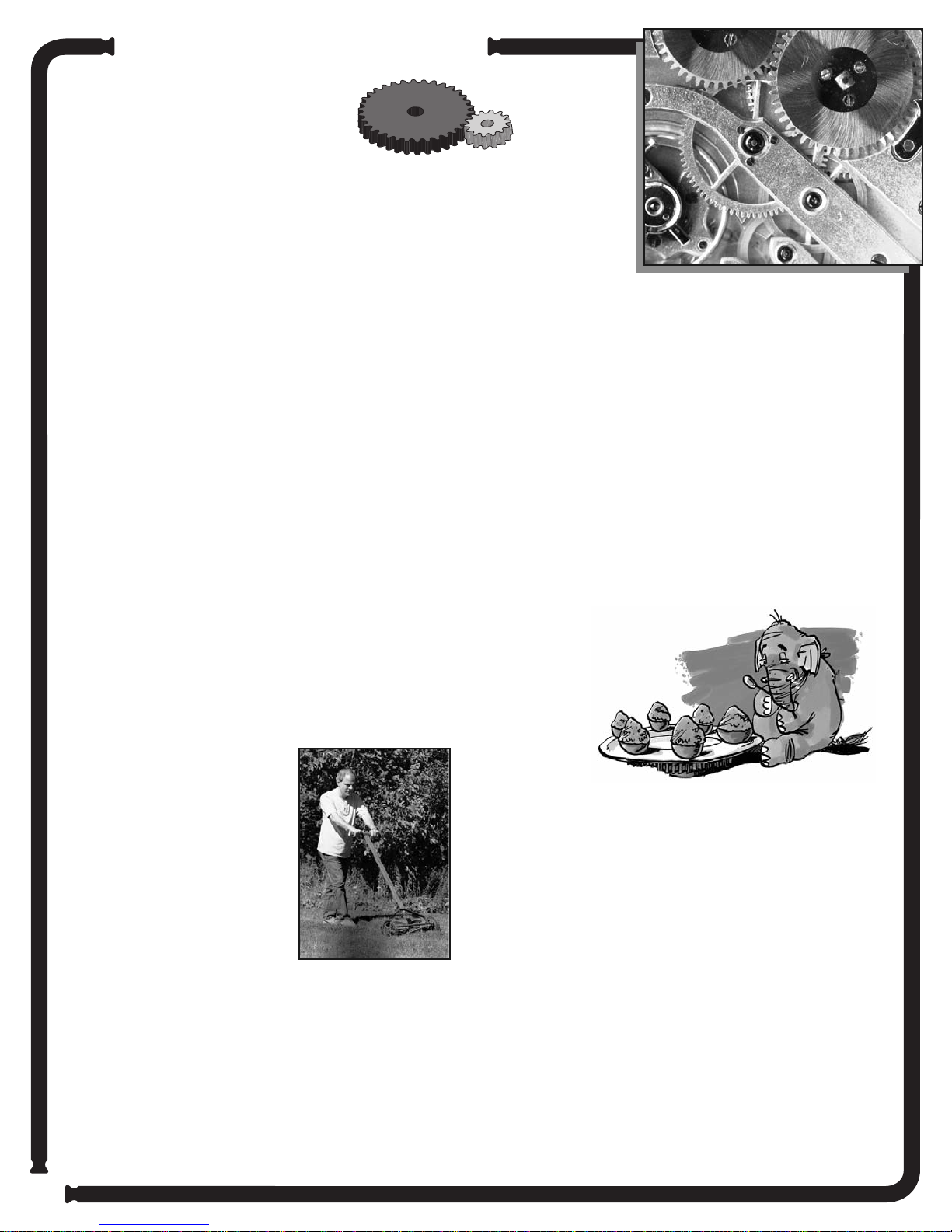

What is a Gear?

• A gear is a wheel with teeth along its outer edge.

• One gear can make another gear turn when the teeth of the

two gears interlock, mesh or connect.

• Gears can change the amount of force, the direction and the

speed of rotation needed to do a job.

Key Words and Definitions

Effort - the force that is applied to do work; the

push, pull, squeeze or lift provided to use gears to

move an object

Resistance - the force provided by the object on

which one is trying to do work; the object works

against (pushes back) the effort

Mechanical Advantage (MA) -

a mathematical calculation that reveals how many

times easier a job is to do

MA greater than 1 shows that the gear system

multiplied the effort force, but must move through

a greater distance. MA less than 1 shows that the

gear system requires greater effort force to

operate but the driven gear moves more quickly

MA =

number of teeth

(driven gear)

number of teeth

÷

(drive gear)

or

MA =

diameter

(driven gear)

diameter

÷

(drive gear)

Gear ratio - a mathematical relationship that

indicates the difference in the size of gears in a

gear system; the rate at which one gear turns

another based on the number of teeth or

diameter of each gear

Gear

Ratio

number of teeth

=

(large gear)

number of teeth

÷

(small gear)

or

MA =

Diameter - the distance through the center of an

object; a straight line passing through the center

of a circle ended at the circumference

Work - the job being done while using the gears

Load - the object (weight) lifted or moved; provides

resistance to the gears

Force -

Bevel - an angle that is not a right angle; slanted

diameter

(large gear)

any kind of push or pull applied to an object

diameter

÷

(small gear)

:1

:1

Key Concepts

How do gears help you?

• Gears can change the force needed to make

something move and the speed it moves.

• One gear affects the way another gear moves

based on how the gears are configured in

the system.

8

Graphics courtesy of ClickArt® 65,000 Incredible Image PakTM; ©1996-97,T/Maker Co. knexeducat io n. co m

• Many gears, working together in different

arrangements, allow a single machine to do work

at both different speeds and directions.

•

The Mechanical Advantage, or gear ratio, of a set

of gears, is determined by ratios of: the number of

teeth; the diameters; the speeds of the two gears;

and the amounts of force with which they turn.

Key Concepts

How do gears affect force?

• Gears can reduce the amount of force needed to

do a job.

• A small gear requires less force to turn than a big

gear but must be turned many times in order to

make the big gear turn once.

• When a small gear turns a big gear, the

Mechanical Advantage tells how many times

easier your job is.

How do gears affect speed?

• When using two gears of different sizes, the small

gear turns more quickly than the big gear.

• When a big gear turns a small gear, the gear ratio

tells how many times faster the job is done.

How do gears affect direction?

• When two gears are linked together, they turn in

opposite directions and can make different parts

of machines turn in opposite directions.

• Gears can change the angle of rotation when

a gear on a vertical plane turns a gear on a

horizontal plane.

• Special gear systems can change circular motion

into back-and-forth motion.

What are spur gears?

• Spur gears lie in the same plane and turn in

opposite directions when meshed.

• Different-sized spur gears turn at different

speeds and with different amounts of force.

What are sprocket gears?

• Sprocket gears are a special type of spur gears

consisting of two gears on the same plane, set

apart from each other and linked by a chain.

• Sprocket gears turn in the same direction.

• Different-sized sprocket gears turn at different

speeds and with different amounts of force.

What are crown gears?

• Crown gears lie in different planes (at right angles

to each other) and turn in opposite directions.

• Different-sized crown gears turn at different

speeds and with different amounts of force.

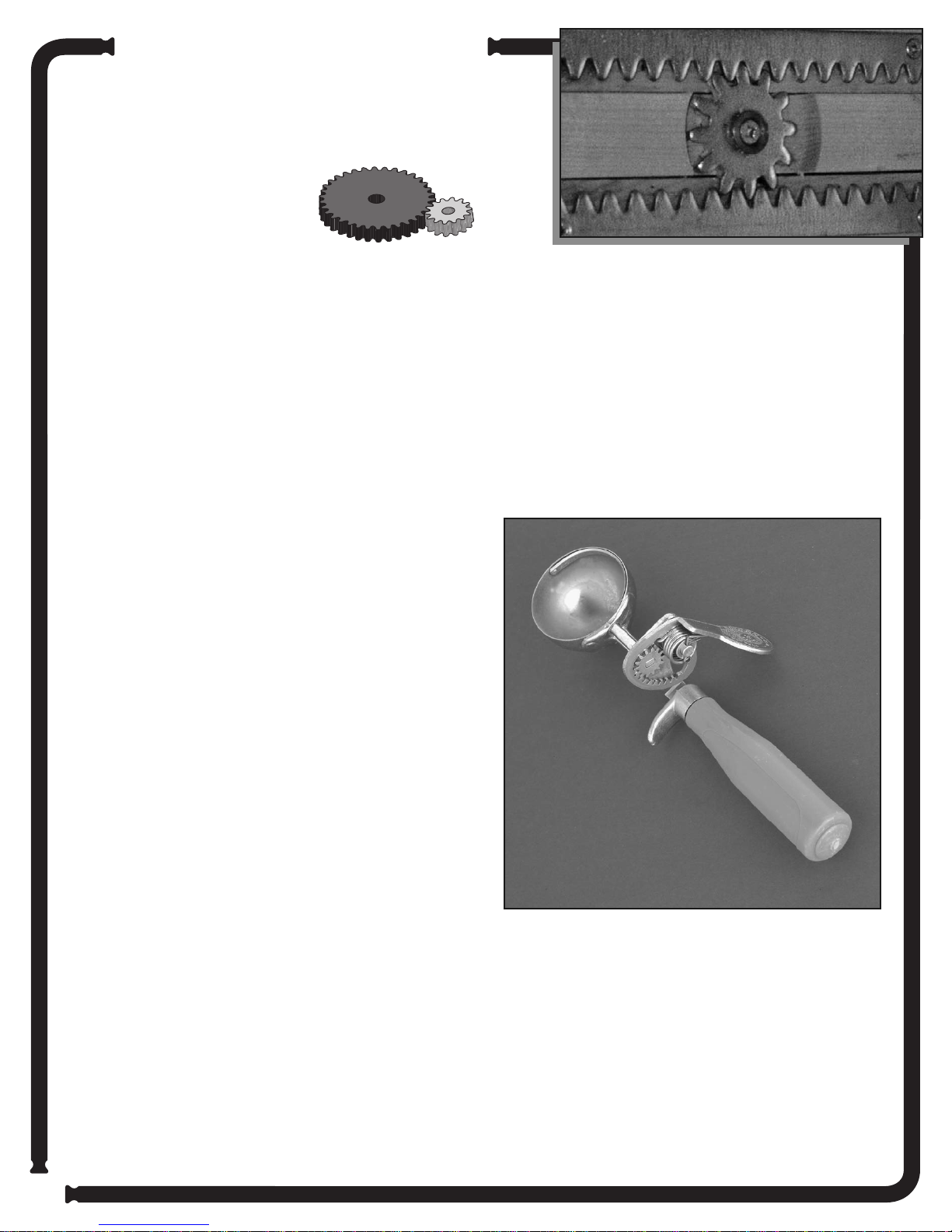

What are rack and pinion gears?

• Rack and pinion gears consist of a toothed bar

and a toothed wheel.

• Rack and pinion gears change circular motion

into back-and-forth motion.

What are worm gears?

• Worm gears consist of a spiral-edged cylinder

called the worm and a toothed wheel called the

worm gear.

• A worm and its worm gear turn in different

directions, at different speeds and with different

amounts of force.

• Worm gears change fast motion into slow

motion.

REMEMBER

Special types of gears can be used to

change the direction of circular motion

and to gear up or down depending on

the need for speed.

1-88 8- AB C- KNEX

9

STUDENT REFERENCE SHEET

Gettin

g Started

With Gears

What is a gear?

A gear is a wheel with teeth along its outer edge.

•

One gear can make another gear turn when the teeth of the

•

two gears interlock, mesh or connect.

Gears can make work easier by letting you use less force to do a job.

•

Some gears let you move a gear in one direction by turning another gear in a different direction.

•

Other gears help by changing the speed of the turning parts.

•

How do gears help you?

Gears can help you in three different ways.

Force

Gears can change the force you need to make

something move.When you turn a small gear, it

can make a big gear move. You have to turn it lots

of times to make the big gear turn around once,

but the small gear doesn’t take much force to

turn.

Speed

Gears can change the speed that a machine

moves. If two gears are different sizes, the smaller

gear will turn faster than

the larger gear.

Many machines use gears

of different sizes to make

certain parts of the

machine turn faster or

slower than others.

Direction

Gears can also change the

direction something

moves.When two gears

are linked together, they turn in opposite directions and can make parts of machines turn in opposite directions too. Gears can also be set up

where one gear is lying flat, but it makes an upright gear turn. Different arrangements of gears

make it possible for machines to do work in

many different directions.

Here’s an example of how gears

can help.

Imagine you work for a zoo. Your job is to build a

feeder to adjust the meals for an elephant named

Moe. Moe eats whatever food is put out for him so

his intake must be watched closely or he’ll overeat.

The zoo manager asked you to find a machine to

feed Moe specific amounts at the proper times. Impossible? NO! Not with the help of gears.

Picture this.

You could design a

huge plate which

rotates in a

circle. Along

the outside

of the plate are

large bowls with elephant-sized helpings for Moe’s

meals. Your design puts only one bowl in Moe’s

reach at a time. The speed the plate turns is controlled by a series of gears underneath the plate.

This allows it to run at the right speed so Moe gets

fed at the proper time without your help.

A Bright Idea!

Gears were a pretty modern invention. Conduct

research to find out about the earliest use of this

simple machine.

10

Graphics courtesy of ClickArt® 65,000 Incredible Image PakTM; ©1996-97,T/Maker Co. knexeducat io n. co m

STUDENT REFERENCE SHEET

What’s the

vantage?

al A

Mec

han

ic

How much do gears help you?

Just by counting the gear’s teeth and dividing a few numbers, you can

find out how much gears make work easier or faster.

Count the number of teeth on your driven Gear and the number on your drive

1

Gear.

2

Divide the driven number by the drive number. The answer is the Mechanical

Advantage (MA), which tells you how many times easier your job is.

d

MA = Number of teeth on driven Gear - Number of teeth on drive Gear

3

You can also figure out the MA by measuring the diameter of each Gear. Then, divide

the diameter of the driven Gear by the diameter of the drive Gear. Is your answer

about the same as your answer from Step 2?

MA= Diameter of driven Gear- Diameter of drive Gear

4

You can use the gear ratio to tell you how many times faster something can

move when you use a big Gear to turn a small Gear. Divide the number of

teeth on the big Gear by the number of teeth on the

small Gear to get this ratio.

:

Gear Ratio = Number of teeth on big Gear - Number of teeth on small Gear :1

Gears let you use less force

1

Imagine you want to turn a merry-go-round.

A big gear with 500 teeth is attached to the platform where people ride. A smaller gear with 20

teeth is attached to a motor.

MA=500-20

:

:

:

Gears give you speed

2

Imagine you are using a hand drill. You turn the

crank on the big gear, which has 60 teeth. The

small gear has 15 teeth.

Gear Ratio =60 -15 1

Gear Ratio =4 1

:

:

:

MA=25

A Mechanical Advantage of 25 means that the

motor turns the small gear 25 times for one turn

of the merry-go-round, but it takes 25 times less

force than it would to turn the big gear itself.

The MA shows the number of times the gear system multiplies the effort force applied to the small

gear.

1-88 8- AB C- KNEX

The gear ratio is 4:1, which means that the drill

bit turns four times faster than you turn the

crank since you are using a big gear to drive a

small gear. That helps you drill a hole quickly and

easily.

The gear ratio shows how many times faster the

small gear turns when you apply the effort force

to the big gear.

11

STUDENT REFERENCE SHEET

What

are

Spur Gears?

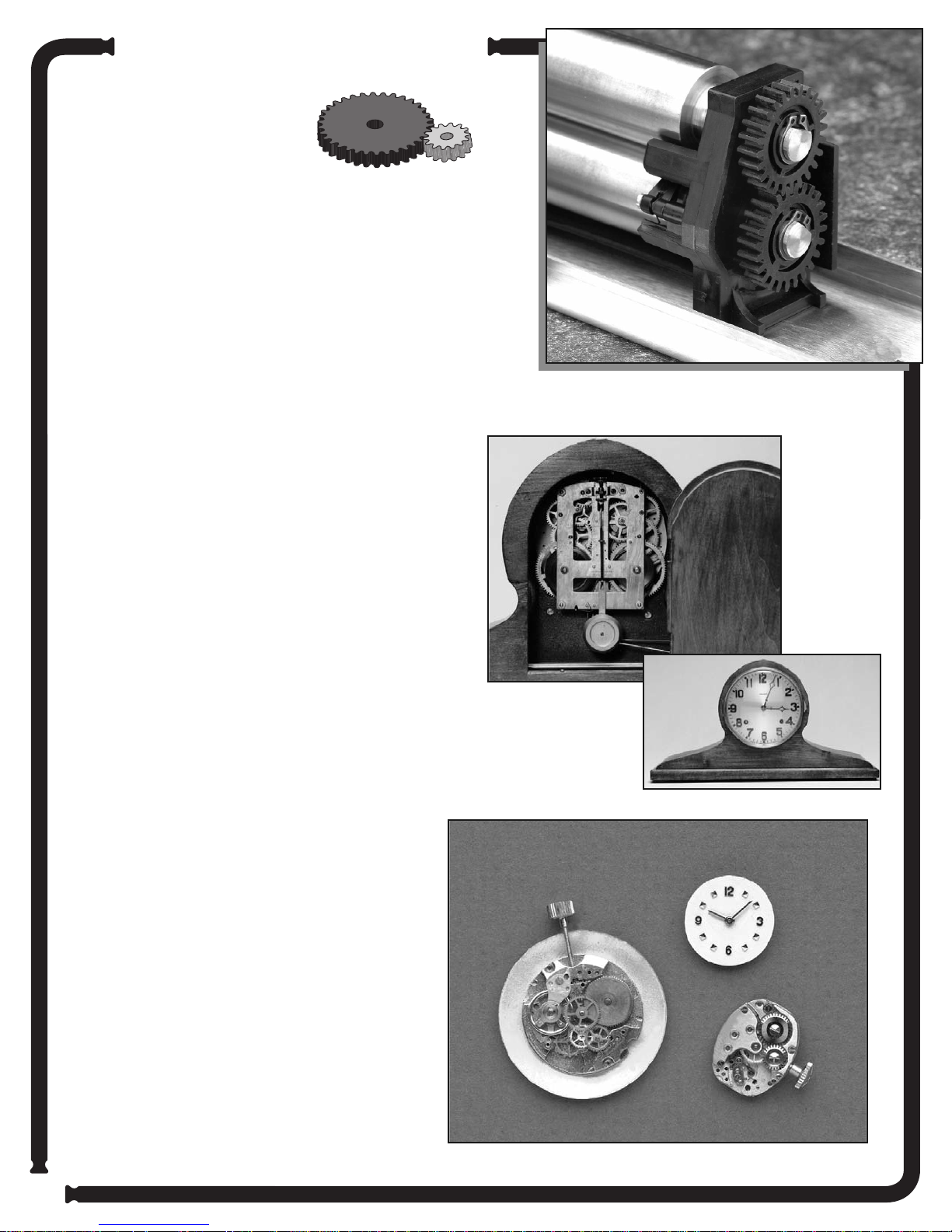

Spur gears are sets of gears that work together by

being set in the same position. The teeth on the edge

of one gear mesh with the teeth on the other gear.

When you turn one gear, the other gear turns in the

opposite direction.

Spur gears can be the same size or different sizes. If the

sizes are different, the gears will turn at different speeds

and with different amounts of force.

Here’s an example.

Spur gears inside a wristwatch make the hands

turn. When you wind the watch, you wind up a

spring that powers the gears. Small and large

spur gears work together to make the hands

turn at different rates, so you can tell the time.

How do spur gears help you?

Spur gears of different sizes can help you by

making parts of a machine turn at different

rates. When a small gear and a large gear work

together, the small gear turns faster than the

large gear. Its circumference is smaller, so it

doesn’t have as far to go to make one

complete turn.

In a wristwatch, small and large gears work

together to make the second hand turn a full

circle within a minute; the minute hand turn a

full circle within an hour and the hour hand

turn a full circle within twelve hours.

Different-sized spur gears also turn with different amounts of force.These gears can help

you when you use a machine that requires

extra force to do a job.

12

Graphics courtesy of ClickArt® 65,000 Incredible Image PakTM; ©1996-97,T/Maker Co. knexeducat io n. co m

STUDENT REFERENCE SHEET

What

are

Worm Gears?

Worm gears have two different parts: a worm gear and a worm.

The worm gear looks like most other gears, a wheel with teeth.

The worm got its name because its tube-like shape resembles a

worm with a ridge that wraps around it in a spiral. This ridge

meshes with the teeth of the worm gear, and together, they turn.

The worm and the worm gear turn at different speeds, with

different amounts of force and in different directions.

Here’s an example.

A crescent wrench uses worm gears. The worm is

easy to recognize. It’s the spiral part you turn to make

the jaws of the wrench come together. The worm gear

might not be so easy to identify. It has a toothed edge

along the bottom of its moving jaw. (You can just imagine

it’s the edge of a big wheel!)

How do worm gears help you?

Worm gears help by letting you turn part of a machine

at one speed while you make another part of the

machine turn at a much slower or faster speed.

Worm gears can do this, because the worm has to make

a full turn to make the worm gear move ahead by just

one tooth. As a result, the worm turns much more

quickly than the worm gear.

When you turn the worm on the crescent wrench, the

worm gear turns slowly. It makes the movable jaw of

the wrench move just a tiny bit–maybe a fraction of a

millimeter. Being able to make such tiny movements lets

you adjust the wrench just the right amount.

Since the worm and worm gear move at different

speeds, they also move with different amounts of force.

The worm gear turns with more force than the worm.

A worm and its worm gear turn in different directions.

If you imagine that the worm and the worm gear each

trace out a circle as they turn, the two circles are at

right angles to each other.

1-88 8- AB C- KNEX

13

STUDENT REFERENCE SHEET

What

Sproc

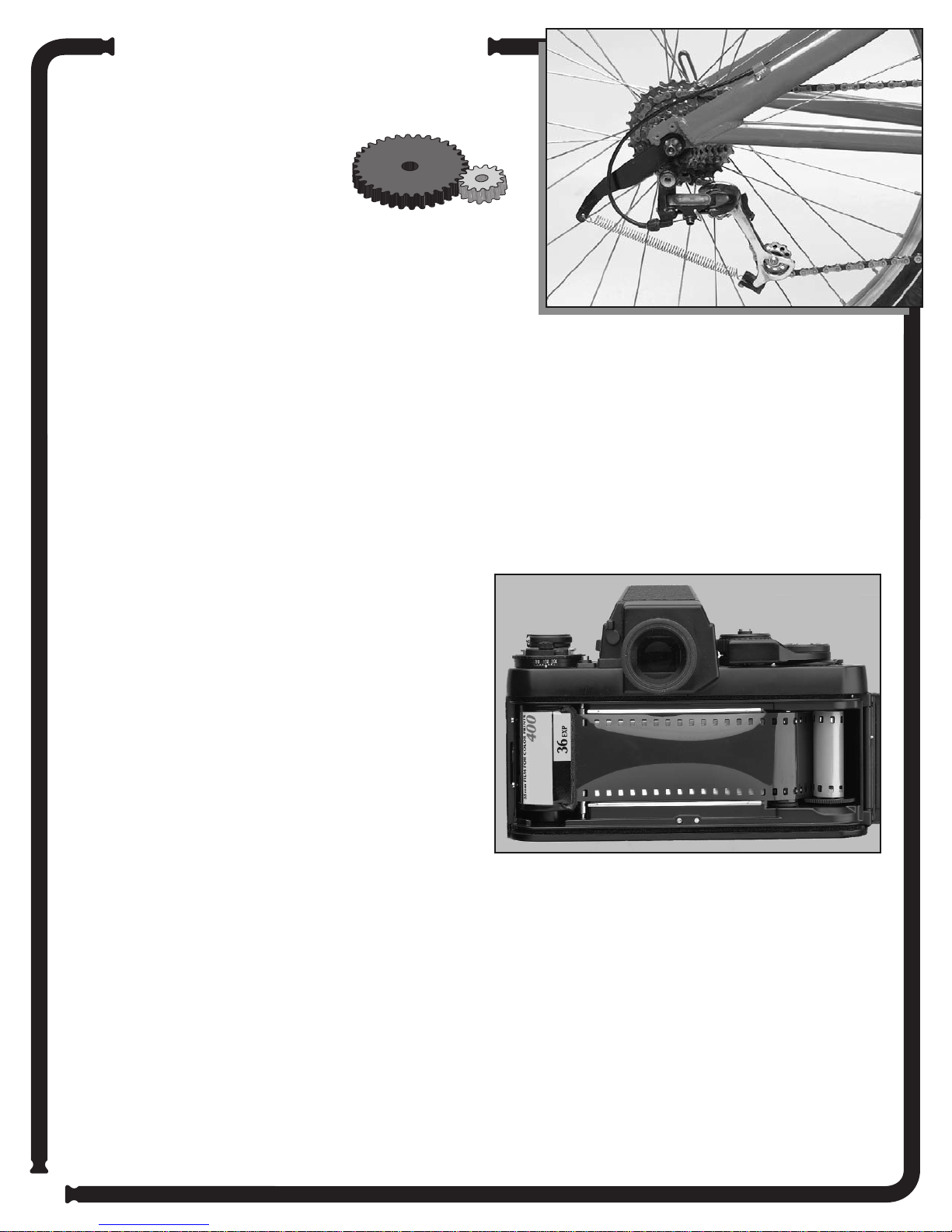

Sprocket gears are special types of spur gears.

Two sprocket gears are set in the same position,

but they are placed a certain distance apart.

A chain wraps around the gears. By turning one gear,

you make the chain move and the chain turns the

other gear. Both gears turn in the same direction.

The teeth on sprocket gears are specially shaped

to fit between the pegs or notches on a chain.

ket

are

Gears?

Here’s an example.

A bicycle uses sprocket gears to turn the back

wheel. You push the pedals, making the pedal gear

turn. The chain, which is wrapped around both

gears, then makes the back gear turn. The back

gear turns the wheel and off you go!

How do sprocket gears

help you?

A special feature of sprocket gears is that they let

you spread your turning action over a distance.

You don’t need to place the gears right next to

each other in order for them to work together.

In a bicycle, it helps to have the gears separated, so

you have room for your feet to turn the pedals and

to fit the big rear wheel next to the back gear.

Two sprocket gears connected by a chain move in

the same direction. Both gears turn clockwise or

both turn counterclockwise. That’s helpful in a

bicycle. Otherwise, you’d have to pedal backwards

to make the bike go forward!

Sprocket gears can vary in size. Like other spur

gears, they can turn at different speeds and with

different amounts of force. As a result, the pedal

gear turns at a different speed than the gear

attached to the wheel.

14

Graphics courtesy of ClickArt® 65,000 Incredible Image PakTM; ©1996-97,T/Maker Co. knexeducat io n. co m

STUDENT REFERENCE SHEET

What

rown

C

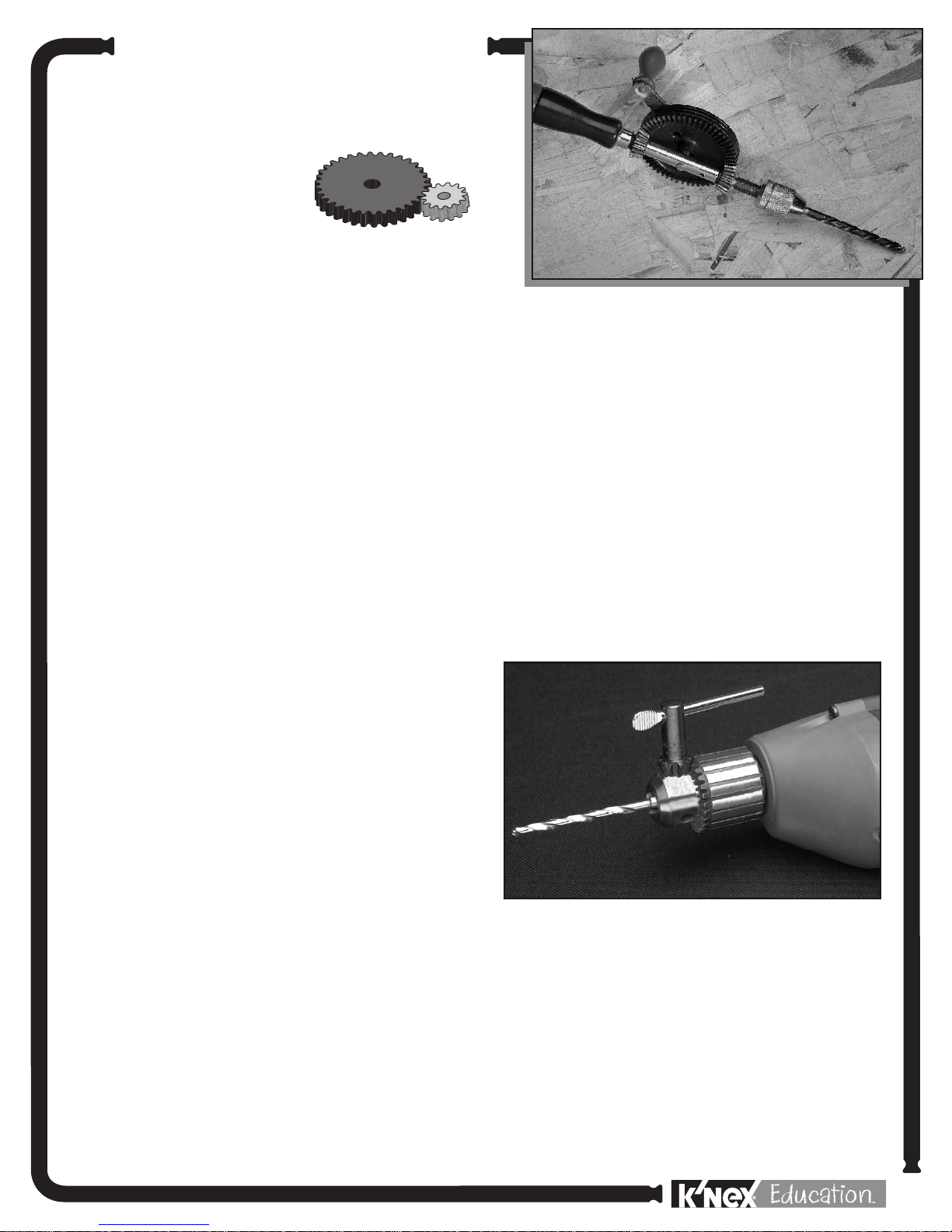

Crown gears are gears that work together but,

unlike spur gears, they are not set in the same

position. Instead, a pair of crown gears lie at angles to

each other–usually at right angles. One gear might

be upright, while the other lays flat. Another name

for crown gears is bevel gears. They are called bevel

gears because the word bevel means “slanted.”

are

Gears?

Here’s an example.

A hand drill has a crank to turn and a shaft that

holds the drill bit. When you turn the crank, the

drill bit spins to drill a hole. The drill’s crown gears

help you drill straight down while turning the crank

on the side of the drill.

How do crown gears help you?

Crown gears make different parts of machines turn

in different directions. On a hand drill, the crank is

connected to an upright gear. With the crank in

this position, your hand can easily turn it. If the drill

had a crank that turned around the drill’s shaft, it

would probably make the drill wobble as it turned

and the drill would be difficult to hold.

Like spur gears, crown gears can be different sizes.

Then, the crown gears will turn at different speeds

and with different amounts of force, in the same

way that spur gears do.

1-88 8- AB C- KNEX

Graphics courtesy of ClickArt® 65,000 Incredible Image PakTM; ©1996-97,T/Maker Co.

knexeducat io n. co m

15

STUDENT REFERENCE SHEET

k

What

are R

ac

and Pinion

Gears?

Rack and pinion gears have their own special shape and

their own kind of movement. The rack is a long, toothed

bar which moves back and forth.The pinion is a toothed

wheel which rotates.

Here’s an example.

Inside a car, rack and pinion gears control the way

the car turns. The car’s steering wheel is connected

to a pinion gear that turns round and round. It

moves the rack, which turns the front wheels to

the right or left, allowing the car to turn.

How do rack and pinion gears

help you?

Rack and pinion gears let you change round-andround motion into back-and-forth motion.

These gears make it easy to steer a car.You can

turn the wheel a little to make the car angle to the

right or left, or turn it a lot to make a sharp turn.

Imagine trying to steer if you didn’t have rack and

pinion gears.You’d have to shift the wheels in some

other way - perhaps with a lever. Rack and pinion

gears sure make things easier!

16

Graphics courtesy of ClickArt® 65,000 Incredible Image PakTM; ©1996-97,T/Maker Co. knexeducat io n. co m

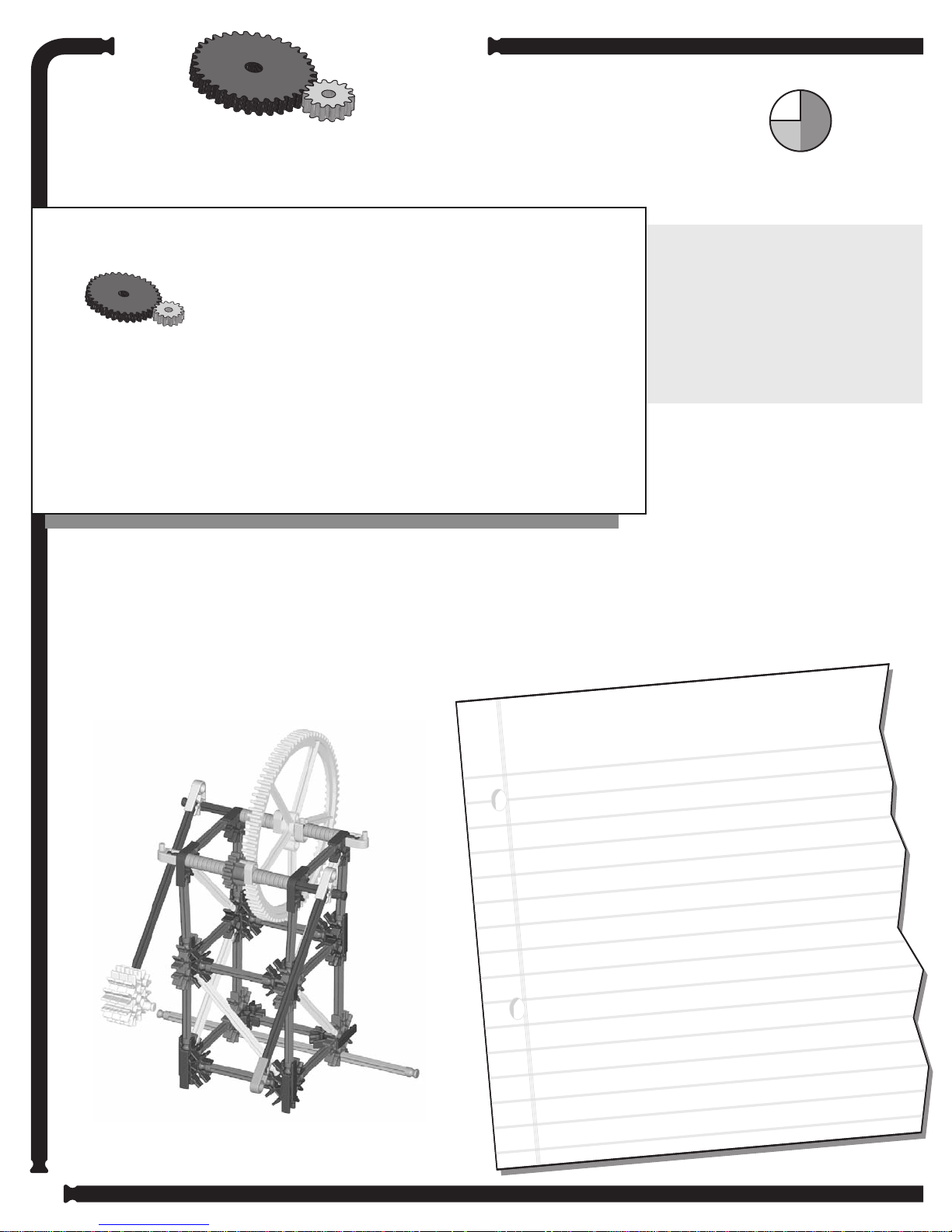

The Spur Gears Lesson Plan

Lesson Length:

30-45 minutes

Object

• Measure applied forces using a Rubber Band Scale and determine

Mechanical Advantage

• Determine if spur gears change force, speed or direction

• Practice creative design utilizing spur gears

• Compare and contrast spur gears with other gears

ives

• Identify a spur gear

• Demonstrate how spur gears function

• Explain the advantage offered by spur gears of different gear ratios and their effect on force and speed

Materials

-K’NEX Rubber Band Scale

-small weight, such as cup of

pennies or green Rods

-string

-extra K’NEX pieces

Every wheel and axle has a job to do

A salad spinner provides a great demonstration of spur gears. Count and compare the number of turns

of the salad spinner handle to the number of turns of the basket. Note that the spinner makes work

easier, because the basket spins fast enough to make the water fly away from the lettuce, but you don’t

have to turn the crank very fast.

17

Graphics courtesy of ClickArt® 65,000 Incredible Image PakTM; ©1996-97,T/Maker Co. knexeducat io n. co m

Journal

Explanati

✓

ar

ge

Explanation

✓

ratios based on observations

Force measurements and comparisons

✓

for 1:1 and 6:1 gear ratios

Explanatory paragraph for results

✓

of tests on 1:1 and 6:1 Spur

Gear models

Description of the difference between

✓

spur gear size and their functional

advantage(s)

Explanation of the relationship between

✓

spur gear arrangement and applied force

Check

on for how

s function

1 and 6:1 ge

of 1:

spur

ar

Loading...

Loading...