Page 1

Installation Guide

E/I–P Transducer

XEC-3001/3002/3004

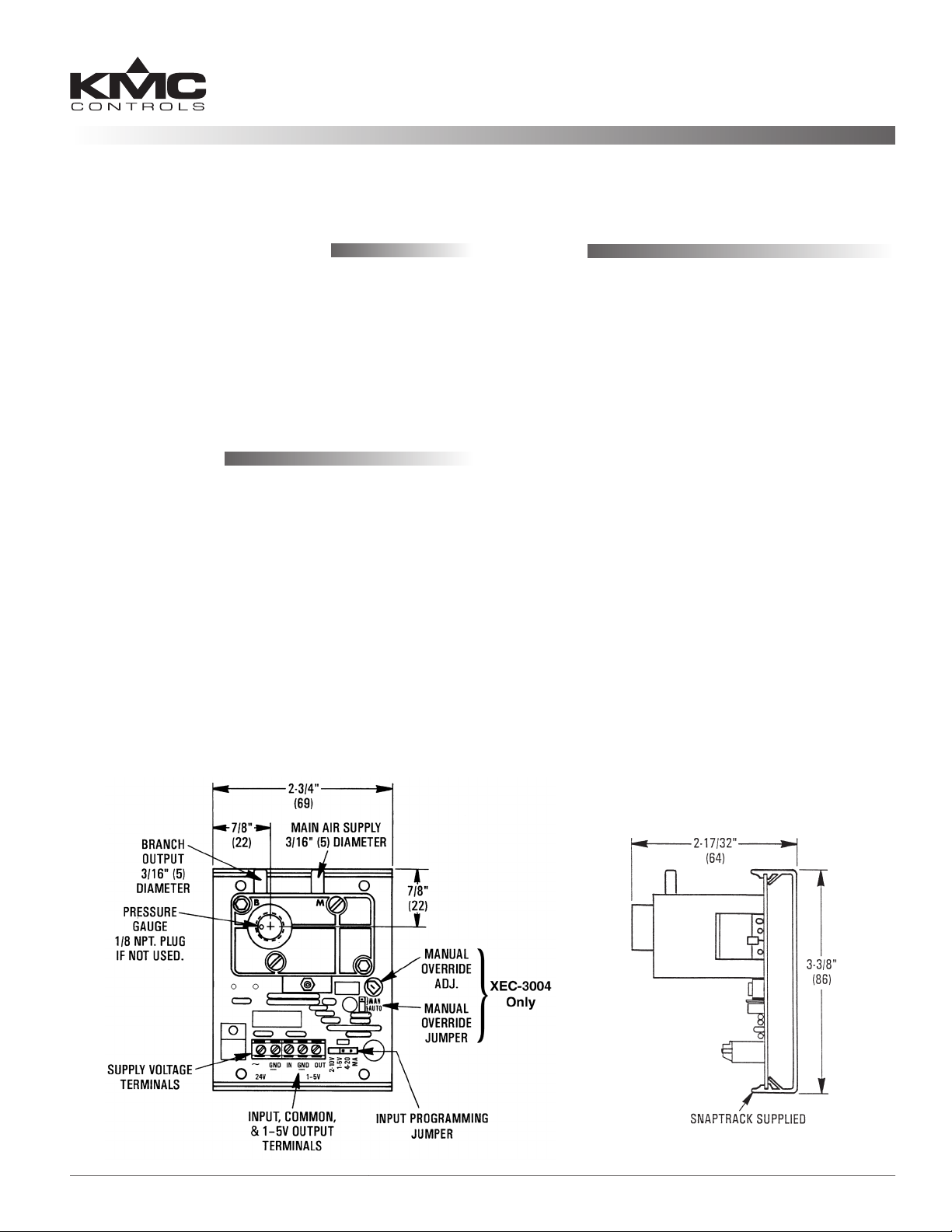

(Snap Track) Mounting

The transducers may be mounted in any position.

1. Carefully remove the circuit board from the Snap

Track.

2. Mount the track in the desired location.

3. Replace board in the track. Do not slide or ex the

circuit board while replacing.

Connections

A clean, dry, oil-free main air supply is required for

proper operation. An internal, non-replaceable lter

is used. If air supply contamination is suspected, use

an external HFO-0006 in-line lter.

The gauge port will accept a 1/8" male NPT pressure

gauge. This allows direct reading of the pressure

output. This port must be plugged if a pressure

gauge is not required.

1. Connect the 20 psi main air to the “M” port.

2. Connect the “B” port to the controlled device

(damper or valve actuator).

Wiring

1. Connect the power.

a. 24 VAC (+20%/–15%, Class 2 Only, 1 VA):

• Transformer phase lead to “~” (phase).

• Neutral lead to “GND” (common).

b. 24 VDC (+66%/–8%, 50 mA):

• Positive to “~” (phase).

• Negative to “GND.”

NOTE: Any other device connected to this

(Class 2 only) transformer must use the

same common. If you are not sure of the

other device’s polarity, use a separate

transformer. If the shared device is a coil,

use a spike-snubbing device across the coil

to prevent possible malfunctions.

2. Position Input Program Jumper to 1–5 VDC, 2–10

VDC, or 4–20 mA.

3. Connect the input signal wiring, positive to “IN”

and negative to “GND.”

4. Connect the output feedback signal (if required)

positive to “OUT 1–5” and negative to “GND.”

XEC-3001/3002/3004 1 Installation Guide

Page 2

Adjustments

Maintenance

Manual Override (XEC-3004 Only)

1. Move the “MAN/AUTO” jumper from “AUTO”

to “MAN.” (See the illustration on page 1.)

2. Adjust the potentiometer for desired output by

observing gauge or the 1–5 VDC output signal.

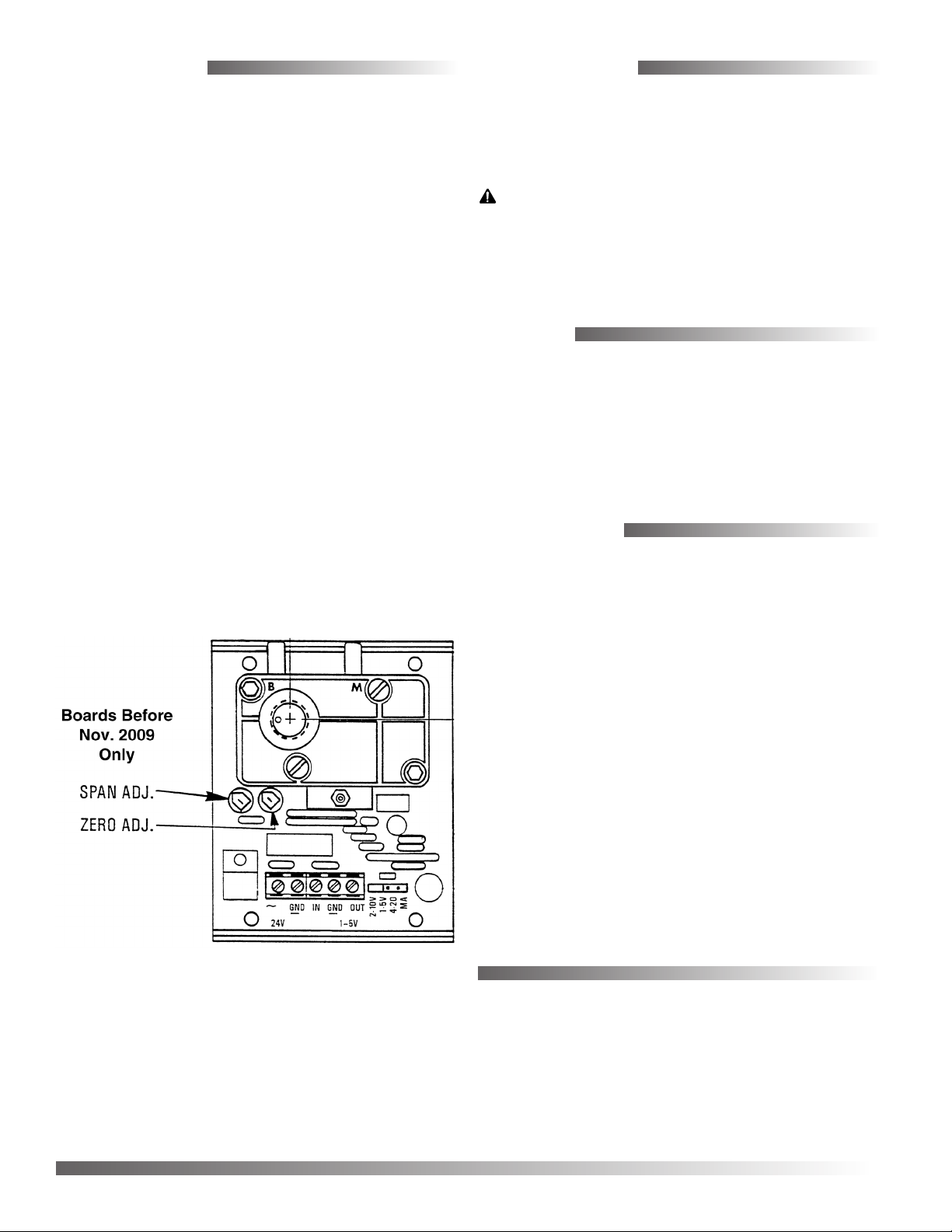

Span and Zero

The “Span and “Zero” adjustments are factory-set

and should never need adjusting. On boards manufactured before Nov. 2009 (only), this calibration may

be adjusted slightly as follows:

1. Disconnect the main air.

2. Adjust the “ZERO” potentiometer to 0.1 VDC

feedback output.

3. Reconnect the main air.

4. Apply an input voltage of 5.1 or 10.2 VDC or

input current of 20.4 mA.

5. Adjust the “SPAN” potentiometer for 15 psi

branch output pressure.

No routine maintenance is required. Each component is designed for dependable, long-term reliability, and performance. Careful installation will also

ensure long-term reliability and performance.

CAUTION

Pneumatic devices must be supplied with clean, dry

control air. Any other medium (e.g., oil or moisture

contamination) will cause the device to fail.

Models

XEC-3001 Module only

XEC-3002 Module mounted in an HCO-

1008 enclosure (not shown)

XEC-3004 Module only with manual over-

ride

Accessories

6. Apply an input voltage of 3 or 6 VDC or input

current of 12 mA.

7. Readjust the “ZERO” potentiometer for 9 psi.

HCO-1008 Enclosure (for XEC-3001/3004)

HFO-0006 In-line air lter

ICI-1005 2", 0–30 psi gauge

For other pneumatic accessories, such as connectors,

tubing, ings, lters, and gauges, see the Compressed Air Accessories section in the KMC Controls

Catalog (SP-071).

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com

info@kmccontrols.com

XEC-3001/3002/3004 2 Installation Guide

© 2013 KMC Controls, Inc. 871-019-01J

Loading...

Loading...