Page 1

Description

Valid late 2004 into 2008—

see Rev. C of this data

sheet for information on the

new case and board.

The KMC TPE–1483 series of pressure transducers

incorporates a Wet / Wet differential pressure

transmitter featuring low hysteresis, excellent

repeatability, and long-term stability.

Up to four field-selectable input ranges are available

in most models. The field selectable feature

provides a single model that can be configured to

cover all the input pressure ranges for any given

application.

Three output ranges are field selectable, 4 to 20mA,

0 to 5 VDC, and 0 to 10 VDC. The output signal is

factory calibrated and temperature compensated

for the highest start-up accuracy.

TPE–1483 Series

Pressure Transducer

The TPE–1483 can be powered from either a 24

VAC nominal or 12 to 30 VDC power source.

TPE–1483 incorporates a rugged NEMA 4

enclosure.

Features

◆ Push-button and remote zeroing terminal

◆ Uni-directional or bi-directional pressure range

selection switch

◆ High / low port swap switch to solve incorrect

plumbing for differential

◆ Normal or slow surge damping switch to

prevent false alarms and reduce noise

◆ Output polarity reverse switch

Models

The following models are available

TPE–1483–1 0 to 5/10/25/50 psig/d

TPE–1483–2 0 to 10/20/50/100 psig/d

TPE–1483–3 0 to 50/100/250/500 psig/d

Application

KMC TPE–1483 Pressure Transducers are suited for

any application requiring a reliable pressure

monitor providing a dependable conditioned and

compensated signal output.

The TPE–1483 may be used with any liquid or gas

that is compatible with 17–4 PH stainless steel.

DO NOT USE for these applications:

◆ Oxygen service

◆ Explosive/hazardous environments

◆ Flammable or combustible materials

Specifications and design subject to change without notice.

Page 2

Enclosure

Specifications

Media compatibility

17–4 PH stainless steel

Supply Voltage 24 VAC or 15 to 30 VDC

Supply Current 35 mA, maximum @ 24VDC

Output Signal 4 to 20mA, 0 to 5 or 0 to 10

VDC, field selectable

Pressure Ranges Field selectable:

TPE–1483–1 0 to 5/10/25/50 psig/d

TPE–1483–2 0 to 10/20/50/100 psig/d

TPE–1483–3 0 to 50/100/250/500 psig/d

Proof Pressure Max. 2X F.S. range

Burst Pressure Max. 5X F.S. range

Accuracy ±1% F.S. combined linearity,

hysteresis, and repeatability.

Range 4 accuracy ±2% F.S.

Pressure cycles > 100 million

Surge Damping normal 4-second averaging,

slow 8-second averaging,

switch selectable

Sensor Operating Range -40° to 220°F (-40° to

105°C)

Temperature Compensation Error

32° to 130°F (0° to 55°C)

Long term stability±0.25% typical (1 year)

Zero Adjust pushbutton auto-zero and

digital input

Operating Environment

32° to 122°F (0° to 50°C), 10

to 90% RH, non-condensing

Fittings 1/8" NPT female

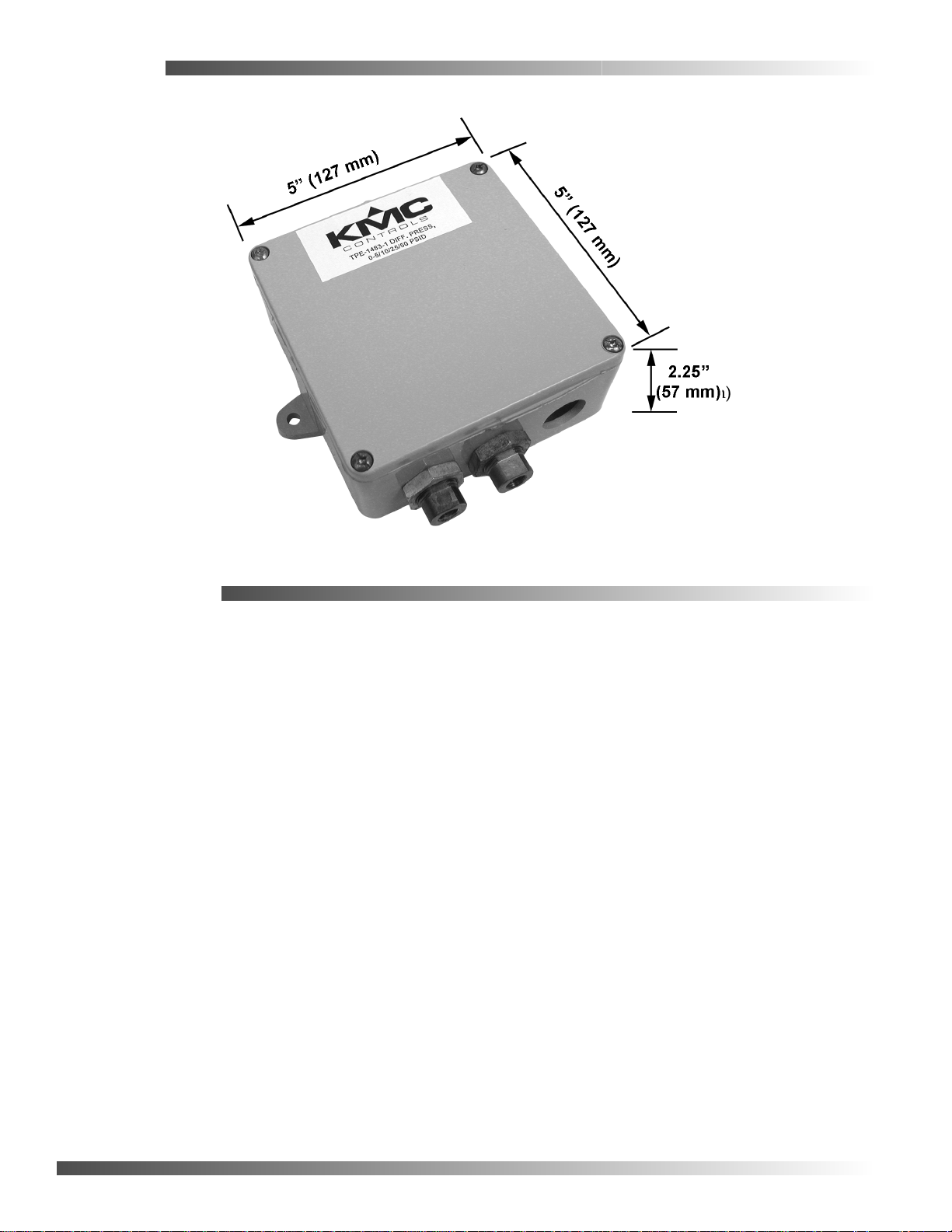

Enclosure 5" x 5" x 2.25" (127mm x

127mm x 57mm);

IP 54 (NEMA 4)

Shock 100G, 11 mSec, 1/2 sine

Vibration 20G peak 20 to 2400 Hz

Weight 1.33 lbs. (.60 kg)

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com

© 2005 KMC Controls Inc. 717-035-18B

Page 3

Wet-Wet Differential Pressure Transducer

Valid late 2004 into 2008—see Rev. A of this installation guide for information on the new case and board.

Installation Guide

Mounting

Avoid locations with severe vibrations or excessive

moisture. The enclosure has a standard ½" conduit

opening and may be installed with either a conduit

coupler or a cable gland type fitting.

1. Mount on a vertical surface with the pressure

port and cable entrance on the bottom.

2. Use screws in the tab holes to fasten the

assembly to the mounting surface.

3. Ensure there is enough space around the unit to

make the pressure and electrical connections.

TPE-1483 Series

WARNING:

Do not use in explosive or hazardous environments, with combustible or flammable gasses, as a safety or

emergency stop device, or in any other application where failure of the product could result in personal

injury.

!CAUTION:

Use electrostatic discharge precautions during installation and do not exceed device ratings.

Plumbing

1. Use an appropriately rated pressure tubing for connections.

2. Arrange the tubing to minimize stress on the connections.

3. Do not allow debris to fall into the pressure ports, contamination can damage the sensor.

Page 4

Wiring

Use 22 AWG shielded wiring for all connections. Do not locate device wires in the same conduit as

wiring supplying inductive loads.

1. Connect the positive DC voltage or the hot side of the AC voltage to the terminal marked PWR.

2. Connect the power supply common to the terminal marked COM. The device is reverse voltage

protected and will not operate if connected backwards.

The analog output signal is available on the OUT terminal. This signal is jumper selectable for either

voltage or 4 to 20 mA output. In voltage mode, either 0 to 5 or 0 to 10 VDC can also be selected.

The remote zero feature may be used by wiring a dry-contact (relay only) digital output to the ZERO

terminals. Do not apply voltage to the ZERO terminals.

Set-Up

CONFIGURATION

Push-on jumpers and switches are used to select the output signal type, the input pressure

range, and several features. The device is factory configured to operate in the 4 to 20 mA output

mode but can be changed to voltage mode by moving the two jumpers from the positions

marked 'Current' to the positions marked 'Voltage'.

NOTE: Output jumpers can only be changed while the power is removed.

CAUTION: Always note the current jumper position before moving them to the new

position. If the jumpers are rotated 90 degrees and installed incorrectly the

product will not work and damage may occur.

Page 5

Set-Up Continued

JUMPER SETTINGS

Refer to the detailed drawing for pin location, the letter

designations do not appear on the actual board.

♦ 0 to 5 VDC signal Connect A to B

♦ 0 1 to 10 VDC signal Connect B to C

♦ Voltage signal Connect G to H

♦ Current Signal Connect H to I

♦ For Backlight Connect J to K

♦ No Backlight Connect K to L

RANGE

PRESSURE RANGE

MODEL 1 2 3 4

1483-1 50 PSI 20 PSI 10 PSI 5 PSI

1483-2 100 PSI 50 PSI 20 PSI 10 PSI

1483-3 500 PSI 250 PSI 100 PSI 50 PSI

NOTE: Range and Options switches can be changed while the unit is operating.

BIDIRECTIONAL

This switch changes the range from “0 to full scale differential pressure” to “minus full scale

to plus full scale differential pressure”. The analog output will read ½ when the differential

pressure is zero.

PORT SWAP

Reverses the polarity of the pressure ports. It makes the HIGH port “low” and the LOW port

“high”. This is useful to correct plumbing errors.

SLOW DAMPING

The switch provides an 8-second averaging for surge dampening (normally it is 4-seconds).

OUTPUT REVERSE

Reverses the output signal polarity. In reverse mode the analog output is maximum when the

pressure differential is zero and decreases as pressure increases.

Page 6

Set-Up Continued.

OPERATION

For normal operation such as 0 to 100 PSI, the pressure applied to the High port must be higher than the

pressure applied to the Low port. If the pressure connection is reversed then the transmitter will always

output 4 mA or 0 V.

If the Low port is left open to ambient pressure, then the High port is used to measure a positive pressure

and 0 PSI = 4 mA and 100 PSI = 20 mA.

For bidirectional operation such as +/-100 PSI, the pressure applied to the High port should be higher than

the pressure applied to the Low port for a positive output response.

Negative pressure is indicated if the High pressure is less than the Low pressure. In this case –100 PSI = 4

mA and +100 PSI = 20 mA. Since the transmitter is linear 0 PSI = 12 mA.

CALIBRATION

With both ports open to the ambient pressure or equalized at 0 pressure:

1. Press and hold the auto-zero button or provide contact closure on the ZERO terminals for at least 3 seconds.

2. Release the button or terminals and the device will calculate and store the new zero point.

NOTE: To protect the unit from accidental zeroing this feature is enabled only when the detected pressure

on both ports is less than 5% of the full range.

It is not recommended that the span calibration be performed in the field unless a high quality

calibrator is available.

Maintenance

No routine maintenance is required. Each component is designed for dependable, long term reliability and

performance. Careful installation will also ensure long term reliability and performance.

KMC Controls

P.O. Box 497

19476 Industrial Drive

New Paris, IN 46553

U.S.A.

TEL: 574.831.5250

FAX: 574.831.5252

E-mail: info@kmccontrols.com

717-019-06

Loading...

Loading...