Page 1

Mounting

Gauge Pressure Transducers

TPE-1464 Series

Installation Guide

NOTE: This document is for units available start-

ing in late 2008. See the original installation

guide available on the KMC web site for installation and conguration information on

older units with a dierent case and board.

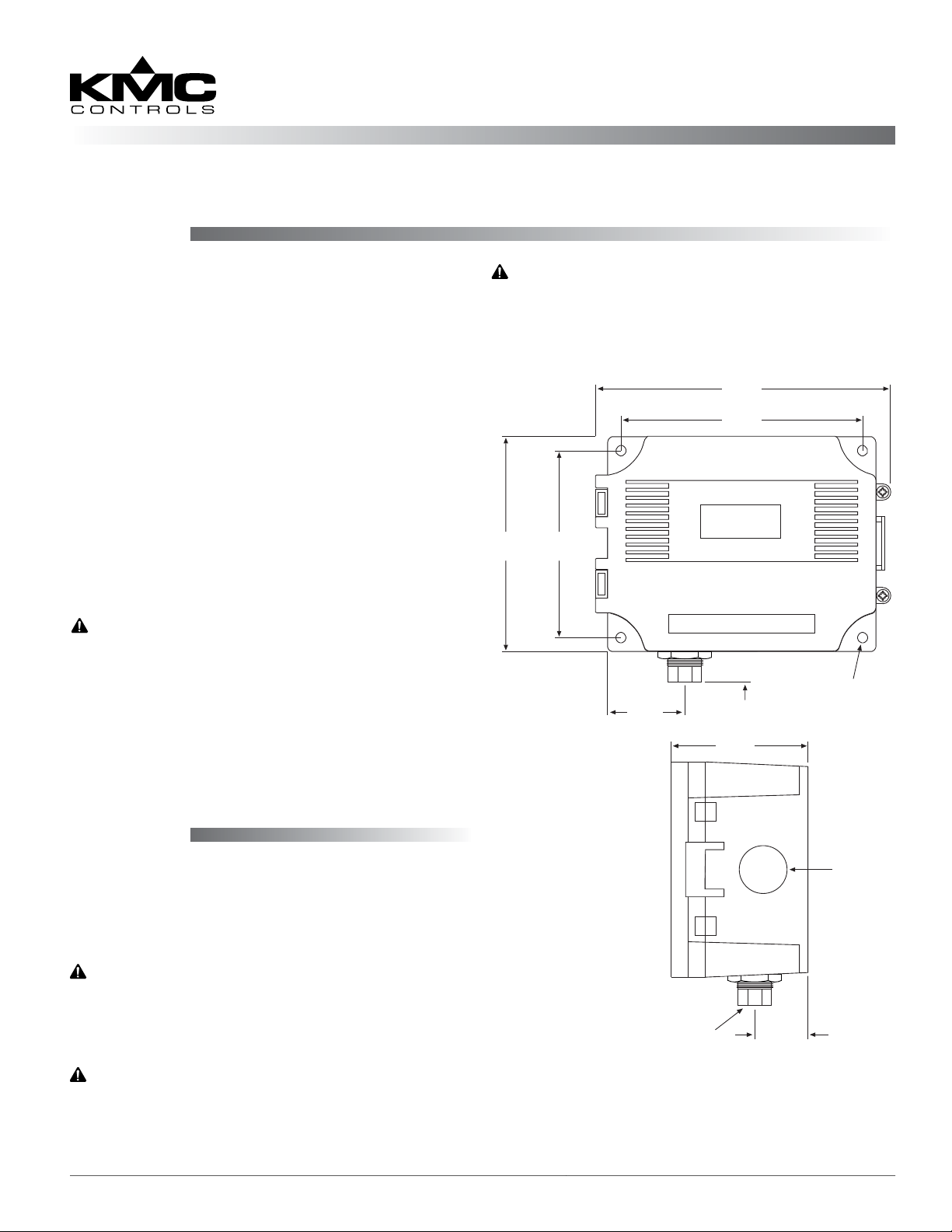

Avoid locations with severe vibrations or excessive

moisture. The enclosure has a standard 1/2" conduit

opening and may be installed with either a conduit

coupler or a cable gland type ing.

1. Mount on a vertical surface with the pressure

ports on the boom.

2. Use screws in the tab holes to fasten the assembly

to the mounting surface.

3. Ensure there is enough space around the unit to

make the pressure and electrical connections.

WARNING

Do not use:

• In an explosive or hazardous environment.

• With combustible or flammable gasses.

• As a safety or emergency stop device.

• In any other application where failure of the

product could result in personal injury.

CAUTION

Use electrostatic discharge precautions during

installation.

145 mm

5.7"

114.3 mm

4.5"

3.95"

88.9 mm

3.5"

34.93 mm

1.375"

19 mm

0.75"

64 mm

2.5"

100 mm

Mounting Holes

(X4) Ø 0.200”

Plumbing

1. Use appropriately rated pressure tubing for the

1/8" NPT female connection.

2. Arrange the tubing to minimize stress on the

connections.

CAUTION

Ensure that the maximum individual port

pressure does not exceed the maximum

pressure range of the unit.

1/8” NPT Female

25.4 mm

1"

CAUTION

Do not allow debris to get into the pressure

ports since contamination can damage the

sensor.

TPE-1464 Series Gauge Pressure Transducers 1 Installation Guide

Ø 0.850”

Page 2

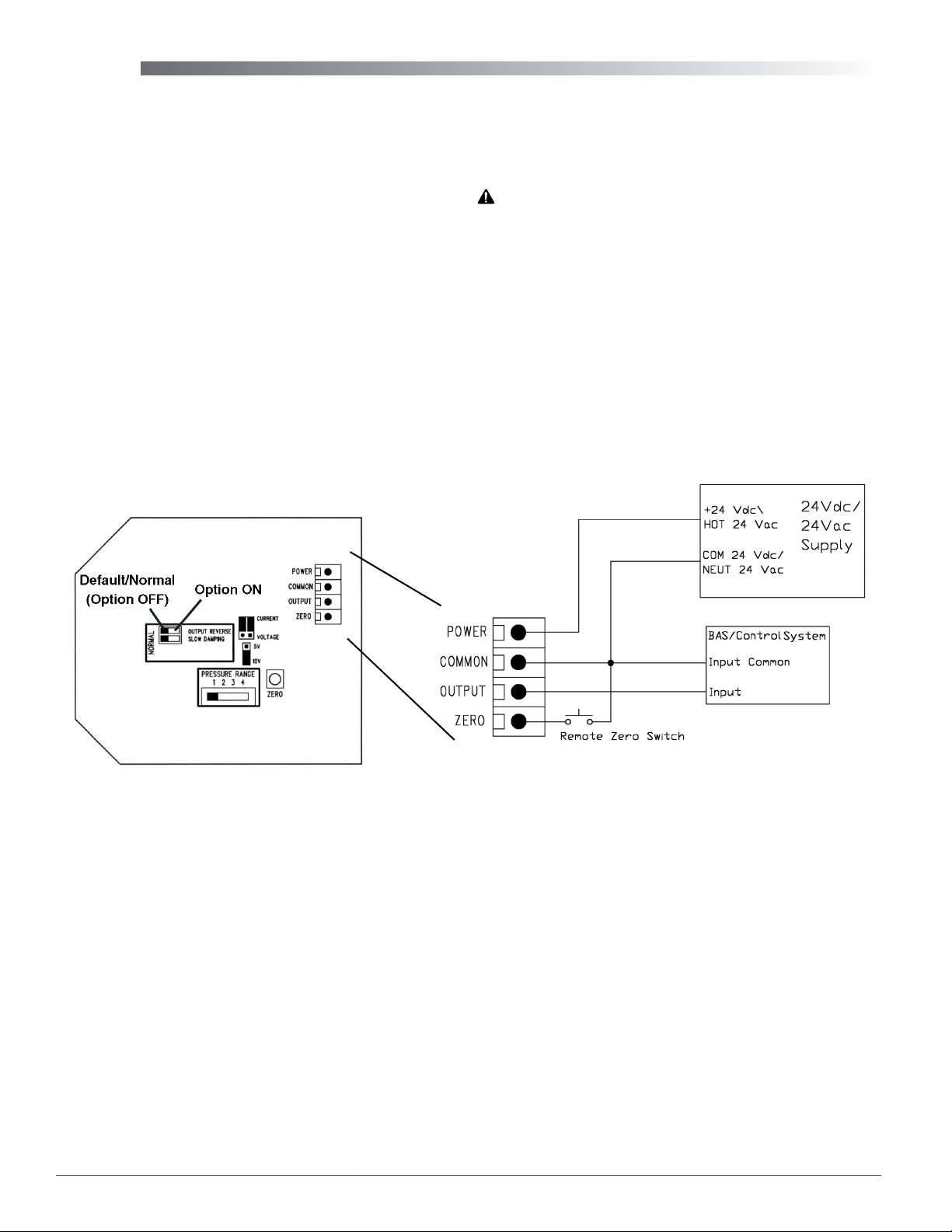

Wiring

This device is a 3-wire sourcing type transmier.

Use 22 AWG shielded wiring for all connections.

Do not locate device wires in the same conduit as

wiring supplying inductive loads (such as motors).

Disconnect the power supply before making any

connections to prevent electrical shock or equipment

damage. Make all connections in accordance with

national and local electrical codes.

1. Connect the positive DC voltage or the hot side of

the AC voltage to the terminal marked PWR.

2. Connect the power supply common to the

terminal marked COM. The unit is reverse-

voltage protected and will not operate if

connected backwards.

The analog output signal is available on the OUT

terminal. This signal is jumper selectable for either

voltage or 4 to 20 mA output. In voltage mode, either

0 to 5 or 0 to 10 VDC can also be selected.

CAUTION

Do not connect power to the OUT terminal

because the device will be damaged.

The remote zero feature may be used by wiring a

dry-contact (relay only) digital output to the ZERO

terminals. Do not apply voltage to the ZERO termi-

nals.

NOTE: This is an active device. Turn O the

relevant input pull-up resistor selector

switches on KMDigital and BACnet

controllers.

TPE-1464 Series Gauge Pressure Transducers 2 Installation Guide

Page 3

Set-Up

Configuration

Jumpers and switches are used to select the output

signal type, the input pressure range, and several

options. The device is factory congured to operate

in the 4 to 20 mA output mode but can be changed to

voltage mode by moving the two jumpers from the

CURRENT positions to the VOLTAGE positions.

CAUTION

Change the output jumper positions only while the

power is removed.

Always note the current jumper position before

moving them to the new position. If the jumpers

are rotated 90 degrees and installed incorrectly

the product will not work and damage may occur.

Jumper Settings

For voltage/current/range selection, see the illustration for jumper seings.

4–20 mA output 0–10 VDC output 0–5 VDC output

JUMPER SETTINGS

Output Reverse

This switch reverses the output signal polarity. In

reverse mode the analog output is maximum when

the pressure dierential is zero and decreases as

pressure increases.

Operation

For normal operation such as 0 to 100 psi, the port is

used to measure a positive pressure and 0 psi = 4 mA

or 0 VDC and 100 psi = 20 mA or or 10 VDC (on 10 V

range).

Calibration

With the port open to the ambient pressure or

equalized at 0 pressure:

1. Press and hold the auto-zero button or provide

contact closure between the ZERO and COMMON

terminals for at least 3 seconds.

2. Release the button, and the device will calculate

and store the new zero point.

NOTE: To protect the unit from accidental zeroing

this feature is enabled only when the

detected pressure on both ports is less than

5% of the full range.

Range

NOTE: Range and Options switches can be

changed while the unit is operating, but

change the Output jumpers only with the

power removed.

Model

1464-1 100 psi 50 psi 20 psi 10 psi

1464-2 200 psi 100 psi 40 psi 20 psi

1464-3 500 psi 250 psi 100 psi 50 psi

0 to x Pressure Range (Switch Position)

1 2 3 4

Slow Damping

For surge dampening, this switch provides an

averaging period of 8 seconds instead of the default

4 seconds.

Maintenance

No routine maintenance is required. Each component is designed for dependable, long-term reliability

and performance. Careful installation will also

ensure long-term reliability and performance.

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com

info@kmccontrols.com

TPE-1464 Series Gauge Pressure Transducers 3 Installation Guide

© 2014 KMC Controls, Inc. 717-019-03B

Loading...

Loading...