KMC Controls SimplyVAV BAC-8001, SimplyVAV BAC-8205, SimplyVAV BAC-8005, SimplyVAV BAC-8007 Application And Installation Manual

Page 1

SimplyVAV

Application and Installation Guide

Revision H

Page 2

KMC Controls, Inc.

©2018, KMCControls, Inc.

NetSensor, WinControl, and the KMC logo are registered trademarks of KMC Controls, Inc.

AppStat, BACstage, FlexStat, FullBAC, KMC Connect, KMC Connect Lite, KMC Converge,

KMC Converge GFX, KMC Conquest, TotalControl, SimplyVAV, and the SimplyVAV logo are

trademarks of KMC Controls, Inc.

All rights reserved. No part of this publication may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any language in any form by any means

without the written permission of KMC Controls, Inc.

Printed in U.S.A.

The material in this manual is for information purposes only. The contents and the product it

describes are subject to change without notice. KMC Controls, Inc. makes no

representations or warranties with respect to this manual. In no event shall KMC Controls,

Inc. be liable for any damages, direct or incidental, arising out of or related to the use of this

manual.

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

U.S.A.

TEL: 1.574.831.5250

FAX: 1.574.831.5252

info@kmccontrols.com

2 Revision H

Page 3

SimplyVAV Contents

C o n t e n t s

Contents 3

Section 1: About the controllers 5

Specifications 6

Accessories and replacement parts 9

Available models 10

Safety considerations 10

Section 2: Installing the controllers 13

Setting the rotation limits 13

Mounting on a VAV terminal box 14

Connecting an airflow sensor 15

Connecting inputs and outputs 15

Connecting room temperature sensors 15

Connecting a DAT sensor 16

Connecting power 17

Maintenance 18

Section 3: Changing the room setpoint 19

Section 4: Configuring the controllers 21

Getting started with configuration 21

Entering system temperature setpoints and limits 23

Configuring the VAV Box options 27

Set the airflow setpoints 29

Advanced options 33

Restore Application 35

Section 5: Balancing airflow 37

Section 6: Application drawings 41

Cooling or heating without reheat 42

Staged reheat 43

Modulating reheat 44

Time proportional reheat 45

Floating reheat 46

Dual-duct application 47

Section 7: Sequences of operation 49

Input sources 49

Occupancy sequence 50

Automatic occupancy 50

Occupied 50

Unoccupied 51

Standby 51

Space setpoints 51

Types of setpoints 51

Setpoint limits 52

PID control loops 52

Airflow setpoints sequence 53

Changeover 53

Discharge Air Temperature (DAT) limiting 53

Revision H 3

Page 4

Contents KMC Controls, Inc.

System diagnostic indicators 54

NEED AHU (BV1) 55

NEED COLDER SUPPLY (BV2) 55

NEED MORE STATIC (BV3) 55

NEED HOTTER SUPPLY (BV7) 55

Damper operation 55

Fan operation 56

Series Fan 56

Parallel Fan 56

Reheat sequence 57

Modulating reheat 58

Staged reheat 58

Time proportioned reheat 59

Floating reheat 59

Balancing airflow sequence 60

Dual duct 61

Section 8: System integration and networking 63

Connecting to an MS/TP network 63

Connections and wiring 64

End of line termination switches 64

Network bulbs 64

Setting up network communications 65

BACnet objects 67

Input objects 67

Output objects 67

Value objects 68

Loop objects 70

Appendix A: K-factors 71

Index 73

4 Revision H

Page 5

SimplyVAV

Sec tion 1: About the cont roll er s

This section provides a description of the SimplyVAV series of controllers. It also

introduces safety information. Review this material before selecting, installing, or

operating the controllers.

The SimplyVAV series of controllers are an easy and unique approach to operating a wide

variety of VAV terminal units. The integrated actuators, internal airflow sensors, and wide

variety of application programs make these BACnet Application Specific controllers ideal for

either new or retrofit installations.

The controllers feature simple, menu driven setup choices when used with a SimplyVAV

digital sensor. No special programming skills or software tools are required to choose

applications, enter setpoints, set networkaddressing, and balance airflow. All options can

be set by using only an STE-8001 sensor which can be installed as the permanent room

sensor ortemporarily connected as a technician’s service tool.

All models are BACnet Application Specific Controllers that are ready to connect to a BACnet

MS/TP network. Device instance, MAC address, and baud rate are set from an STE-8001

sensor without special software.

BAC-8001Model BAC-8001 is supplied with inputs, outputs, and sequences of operation for

the following functions.

l Single duct heating and cooling VAV

l Automatic heating/cooling changeover including morning warmup

l Occupancy setback—requires STE-8201

l System diagnostic indicators

l Airflow balancing

BAC-8005 and BAC-8205 Models BAC-8005 and BAC-8205 are supplied with inputs,

outputs, and sequences of operation forthe following functions.

l Single duct heating and cooling VAV

l Modulating, floating, time proportional, and staged reheat

l Series and parallel fan control

l Automatic heating/cooling changeover including morning warmup

l Discharge air temperature limiting

l Occupancy setback—requires STE-8201

l Actuator position feedback fortrue damper positioning (BAC-8205 only)

l System diagnostic indicators

l Airflow balancing

Revision H 5

Page 6

Section 1: About the controllers KMC Controls, Inc.

BAC-8007Model BAC-8007 is supplied with inputs, outputs, and sequences of operation for

the following functions.

l Dual-duct VAV heating and cooling

l Occupancy setback—requires STE-8201

l System diagnostic indicators

l Airflow balancing

Additional topics in this section

Specifications 6

Accessories and replacement parts 9

Available models 10

Safety considerations 10

Specifications

SimplyVAV controller specifications are subject to change without notice.

Inputs and outputs

All inputs and outputs are factory programmed and application specific. No field

configuration is required. For details on input and output connections, see the topic

Application drawings on page 41. For a detailed listing of input and output objects, see the

topic BACnet objects on page 67.

Analog inputs

Analog inputs represent BACnet analog input. Not all input are applicable or required for all

models.

Key features Standard units of measure.

Overvoltage input protection

Connectors RJ-45 room sensor jack

Screw terminals for wire sizes 12-26 AWG

Conversion 12–bit analog–to–digital conversion

Input range Passive, 10 kΩ pull-up to 3.3 volts DC

Analog outputs

Analog outputs are configured to represent BACnet analog output objects. No field

configuration is required. For details on application specific outputconnections see the

section Application drawingson page 41.

Key features Output short protection

Standard units of measure

Connector Screw terminals for wire size 12-26AWG

Conversion 12–bit digital-to-analog conversion

Output voltage 0–10 VDC

Output current 30 mA per output, 30 mA total for all analog outputs

6 Revision H

Page 7

SimplyVAV Section 1: About the controllers

Binary outputs

Binary outputs are configured to represent BACnet binary output objects. No field

configuration is required. For details on application specific outputconnections see the

section Application drawingson page 41.

Key features Optically isolated triac output

Connector Screw terminals for wire size 12-26AWG

Output range Maximum switching 24 Volts AC

1 ampere per external output, 3 amperes total

Communications—BACnet MS/TP

l EIA–485 operating at rates up to 76.8 kilobaud.

l Removable screw terminal block.

l Wire size 12-26AWG

l Switch selected end of line termination

Memory

l Programs and program parameters are stored in nonvolatile memory.

l Auto restart on power failure

Air flow sensor features

l Configured as BACnet analog inputobject.

l CMOS differential pressure 0-2 inches of water (0-500 Pa) measurement range.

Internally linearized and temperature compensated.

l Span accuracy 4.5% of reading.

l Zero point accuracy 0.0008 in. H2O/0.2 Pa at 25° C

l Barbed connections for 1/4 inch FR tubing.

Actuator specifications

Torque 40 in-lb. (4.5 N•m)

Angular rotation 0 to 95°

Adjustable end stops at 45° and 60° rotation

Motor timing

BAC-8001, BAC-8005,

BAC-8007

Motor timing

BAC-8205

Shaft size Directly mounts on 3/8 to 5/8inch (9.5to16mm) round or 3/8

90 sec./90° at 60 Hz

108 sec./90° at 50 Hz

60 sec./90° at 60 Hz

to 7/16 inch (9.5to11 mm) square damper shafts.

Revision H 7

Page 8

Section 1: About the controllers KMC Controls, Inc.

Regulatory

l UL 916 Energy Management Equipment

l BACnet Testing Laboratory listed as an application specific controller (ASC).

l CE compliant

l FCC Class B, Part 15, Subpart B and complies with Canadian ICES-003 Class B

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may

cause undesired operation.

Installation

Supply voltage 24 volts AC, -15%, +20% 5 VA,

Weight 13.2ounces (376 grams)

Case material Flame retardant plastic

Environmental limits

Operating 32 to 120° F (0 to 49° C)

Shipping –40 to 140° F (–40 to 60° C)

Humidity 5–93% relative humidity (non-condensing)

50/60 Hz

8 Revision H

Page 9

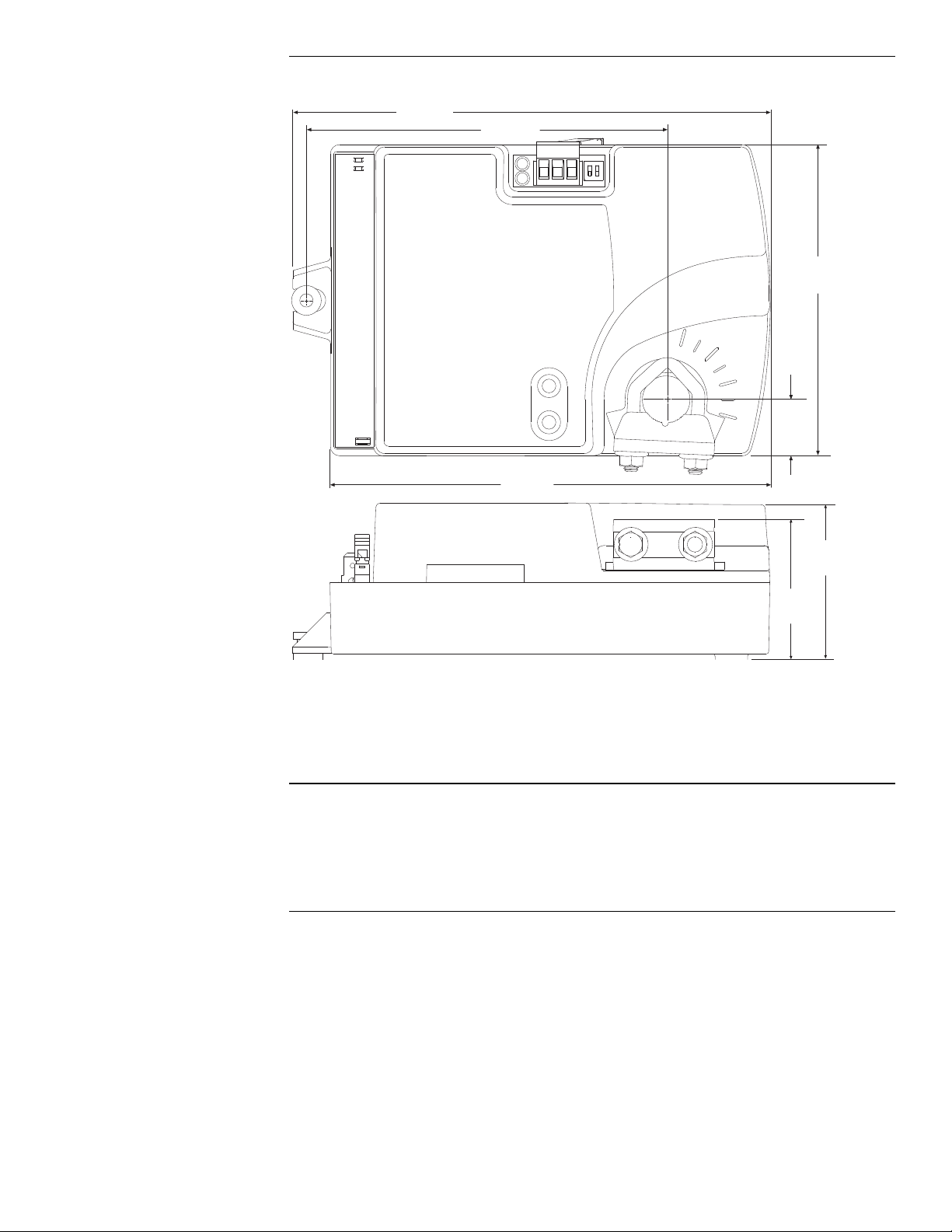

ON CTS

1 2

1.92 in.

49 mm

6.53 in.

166 mm

4.89 in.

124 mm

4.25 in.

108 mm

0.77 in.

19 mm

6.00 in.

152 mm

2.14 in.

54 mm

SimplyVAV Section 1: About the controllers

Dimensions

Accessories and replacement parts

The following accessories and replacement parts are available from KMC Controls, Inc.

Power transformer

XEE-6111-50 Transformer, 120-to-24VAC, 50 VA, single-hub

XEE-6112-50 Transformer, 120-to-24VAC, 50 VA, dual-hub

XEE-6311-100 Transformer, 120, 277 -to-24 VAC, 50/60 Hz, 96 VA, dual-hub

Sensors

STE-8001W80 SimplyVAV sensor and digital display

STE-8201W80 SimplyVAV sensor and digital display with motion sensor

STE-6010W80 Discrete temperature sensor with RJ-45 connector

STE-6014W80 Discrete temperature sensor with rotary setpoint dial, RJ-45

STE-6017W80 Discrete temperature sensor with rotary setpoint dial, override

HPO-9005 Room Sensor Adapter

connector

button, RJ-45 connector

Revision H 9

Page 10

Section 1: About the controllers KMC Controls, Inc.

Sensor cables

HSO-9001 Cable: Ethernet, 50 foot

HSO-9011 Cable: Ethernet, 50 foot, Plenum Rated

Surge suppressors

KMD-5567 EIA-485 surge suppressor for MS/TPnetworks

Replacement parts

HPO-0054 Replacement bulbs

HPO-0063 Replacement two-pin jumper

Dual duct actuator

TSP-8001 VAV actuator with airflow inputs (required for dual duct)

Airflow sensors

For VAV terminal units withoutairflow pickup tubes, order one of the following sensors.

SSS-1012 3-5/32 in. length (80 mm)

SSS-1013 5-13/32 in. length (137 mm)

SSS-1014 7-21-32 in. length (195 mm)

SSS-1015 9-29/32 in. length (252 mm)

KIT-8001 A 3-5/32 inch sensor and 3 feet of FR tubing

Available models

The following is a list of SimplyVAV available models.

Description Models

BACnet ASC: VAV Cooling/Heating only, 40 in-lbs, 90second actuator BAC-8001

BACnet ASC: VAV Fan and Reheat, 40 in-lbs, 90second actuator BAC-8005

BACnet ASC: VAV Dual Duct, 40 in-lbs, 90second actuator BAC-8007

BACnet ASC: VAV Fan and Reheat, True damper position, 40 in-lbs, 60

second actuator

BAC-8205

Safety considerations

KMC Controls assumes the responsibility for providing you a safe product and safety

guidelines during its use. Safety means protection to all individuals who install, operate, and

service the equipment as well as protection of the equipment itself. To promote safety, we

use hazard alert labeling in this manual. Follow the associated guidelines to avoid hazards.

10 Revision H

Page 11

Danger

Warning

Caution

SimplyVAV Section 1: About the controllers

Danger represents the most severe hazard alert.

Bodily harm or death will occur if danger guidelines

are not followed.

Warning represents hazards that could result in

severe injury or death.

Caution indicates potential personal injury or

equipment or property damage if instructions are not

followed.

Note: Notes provide additional information that is important.

Tip: Provides programing tips and shortcuts that may save time.

Revision H 11

Page 12

Section 1: About the controllers KMC Controls, Inc.

12 Revision H

Page 13

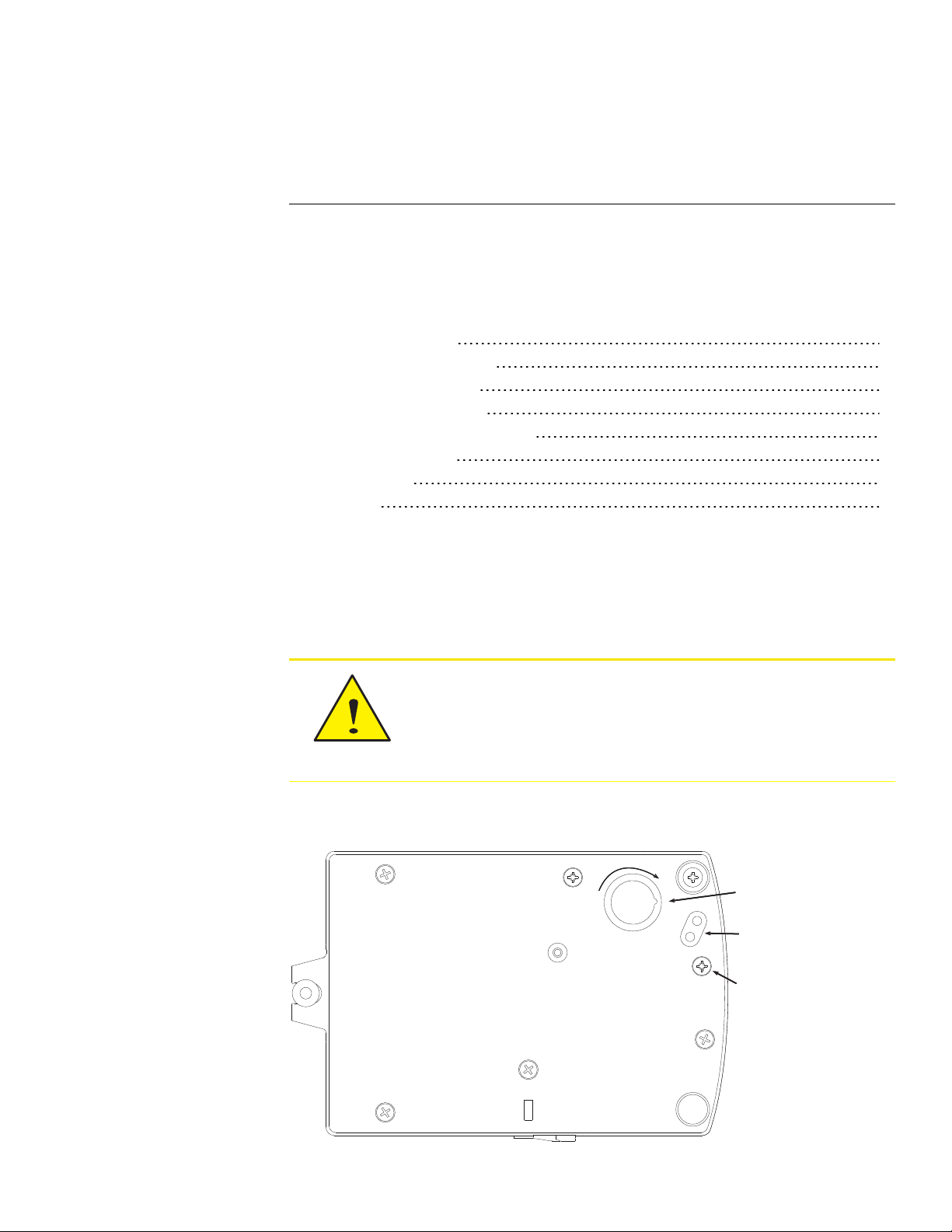

Caution

45

60

Position notch

as shown

Stop position

holes

Stop screw in

storage

Rotate CW

SimplyVAV

Sec tion 2: Instal l ing the controllers

This section provides important instructions and guidelines for installing the SimplyVAV

controllers. Carefully review this information before installing the controller.

Installing SimplyVAV includes the following topics that are covered in this section.

Installation topics in this section

Setting the rotation limits 13

Mounting on a VAV terminal box 14

Connecting an airflow sensor 15

Connecting inputs and outputs 15

Connecting room temperature sensors 15

Connecting a DAT sensor 16

Connecting power 17

Maintenance 18

Setting the rotation limits

SimplyVAV controllers are manufactured for a damper that rotates 90 degrees from open to

close. If the VAV damper is not a 90 degree damper, set the rotation limits to 45 or 60

degrees before mounting the controller.

Illustration 2–1 Controller rotation limit selections

Before setting the rotation limits on the controller, refer to the

damper position specifications in the VAV control box to which

the controller will be attached. Setting rotation limits that do not

match the VAV damper may result in improper operation or

equipment damage.

Revision H 13

Page 14

ON CTS

1 2

COMM

READY

AI1

AI5

GND

AO4

AO3

SC

BO8

BO5

BO6

SC

BO7

24VAC

AI6

GND

AI7

T-STAT/

SENSOR

-A

+B

S

EOL

BACnet MS/TP

Status LEDs

Mounting

tab

Mounting

bushing

Gear clutch button

Drive hub

and V-bolt

Section 2: Installing the controllers KMC Controls, Inc.

To set the rotational limits, do the following

1 Turn the controller over so you have access to the back.

2 Manually rotate the actuator fully clockwise as viewed from the back.

3 Remove the stop screw from its storage location and clean any debris from the

threads.

4 Insert the screw into the correct stop position hole.

5 Tighten the screw only until the head touches the plastic in the bottom of the recess.

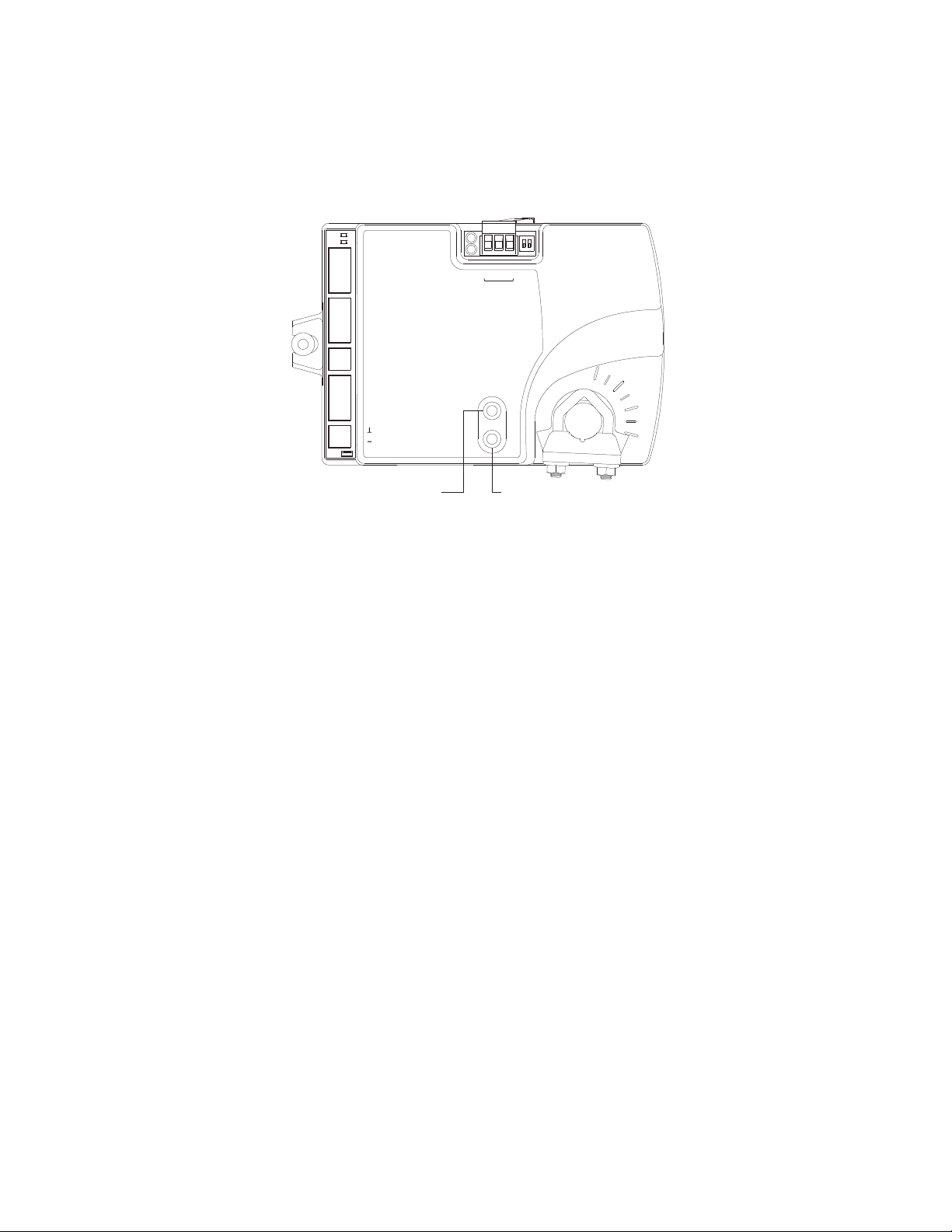

Mounting on a VAV terminal box

Mount the controller inside of a metal enclosure. To maintain RF emissions specifications,

use either shielded connecting cables or enclose all cables in conduit.

Mount the controller directly over the damper shaft. A minimum shaft length of 2.0 inch

(51mm) is required.

Note: SimplyVAV controllers are designed to directly mount to 3/8 to 5/8inch (9.5to16mm)

round or 3/8 to 7/16 inch (9.5to11 mm) square damper shafts.

Illustration 2–2 Controls and indicators

Mount the controller as follows:

1 Manually rotate the damper on the VAV box to the fully open position.

2 On the controller, press the gear clutch button and rotate the drive hub in the same

direction that opened the damper. Turn the hub until it reaches a rotation limit.

3 Loosen the nuts on the V-bolt until the damper shaft can fit through the collar.

4 Place the controller over the damper shaft.

5 Finger tighten the nuts on the V-bolt to position the shaft in the drive hub.

6 Center the mounting bushing in the mounting tab and fasten it with a #8 sheet metal

screw.

14 Revision H

7 Evenly tighten the V-bolt nuts on the drive hub to 30-35 in-lbs.

Page 15

ON CTS

1 2

COMM

READY

24VAC

T-STAT/

SENSOR

-A

+B

S

EOL

BACnet MS/TP

Total airflow (high) Static airflow (low)

SimplyVAV Section 2: Installing the controllers

Connecting an airflow sensor

An airflow sensor is incorporated as one of the inputs to the controller. Remove the plugs

and connect the tubing from the pitot assembly to the airflow sensor inputs next to the drive

hub.

Illustration 2–3 Airflow sensor inputs

Typically, airflow sensors are supplied by the manufacturer as part of the VAV terminal unit.

If a sensor is needed, choose a sensor listed in the topic Accessories and replacement

parts on page 9.

Connecting inputs and outputs

SimplyVAV series controllers have preconfigured inputs and outputs to support only the

supplied programs and applications.

l For input and output connection information, see the topic Application drawingson

page 41.

l To connect room temperature sensors, see the topic Connecting room

temperature sensors on page 15

l To connect a DAT sensor, see the topic Connecting a DAT sensor on page 16.

l For the BACnet object descriptions of the inputs and outputs, see the topic BACnet

objects on page 67.

Connecting room temperature sensors

Connect any of the following sensors to the RJ-45 thermostat and sensor jack. The

controller automatically detects the type of sensor. No programming or configuration is

required.

Revision H 15

l STE-6010W80

l STE-6014W80

l STE-6017W80

l STE-8001W80

l STE-8201W80

Page 16

Ethernet cable

Maximum 75 feet

DAT sensor

Prefered location

DAT sensor

Changeover only

Section 2: Installing the controllers KMC Controls, Inc.

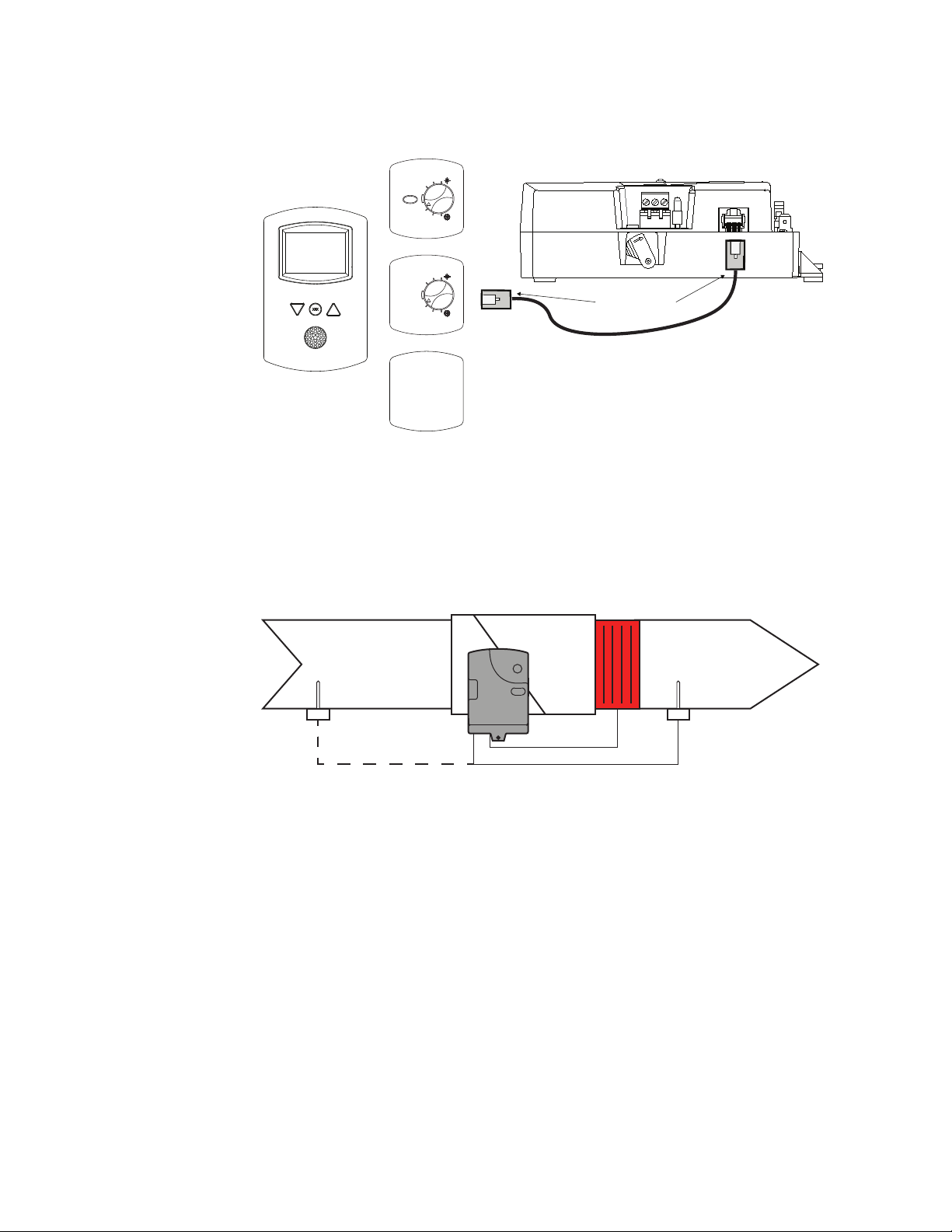

Connect the controller to sensors with standard Ethernet cables up to 75 feet long. See the

installation guide supplied with the sensors for sensor installation instructions.

Illustration 2–4 Connecting to a sensor

Connecting a DAT sensor

The Discharge Air Temperature sensor is required forautomatic changeover and for VAV

terminal units with reheat.

Illustration 2–5 Discharge air temperature sensor location

16 Revision H

Page 17

T

COMM

READY

AI1

GND

AO4

AO3

Blue

Brown

24 VAC

Class 2

ON CTS

1 2

COMM

READY

AI1

AI5

GND

AO4

AO3

SC

BO8

BO5

BO6

SC

BO7

24VAC

AI6

GND

AI7

T-STAT/

SENSOR

-A

+B

S

EOL

BACnet MS/TP

SimplyVAV Section 2: Installing the controllers

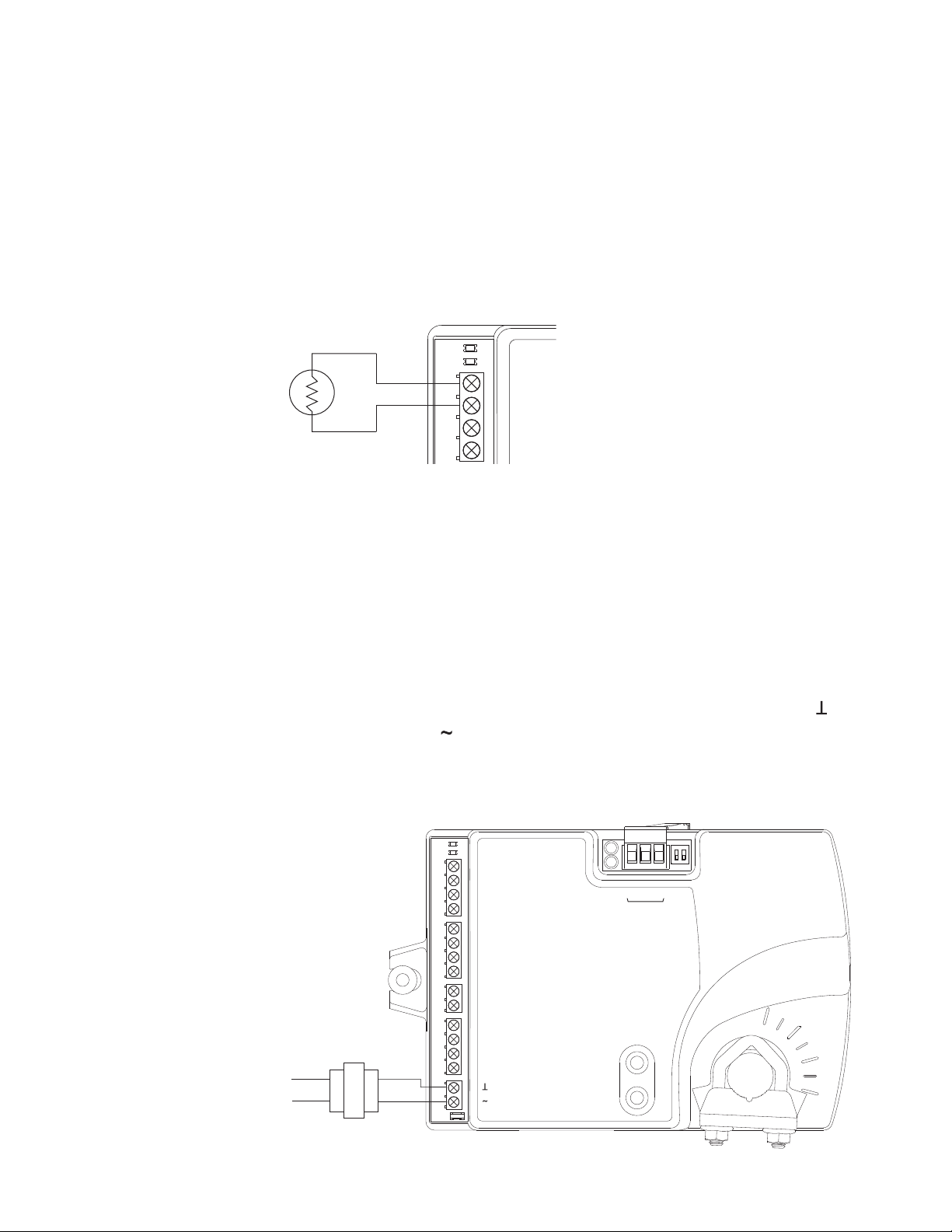

Connect a 10 kΩ, Type 3 thermistor temperature probe to the discharge air temperature

input. The input includes the internal pull-up resistor. An STE-1401 sensor is suitable for this

application. Follow the instructions supplied with the sensor for installation.

l For DAT limiting and reheat, install the sensor in the airflow after the reheat unit. See

the topic, Advanced options on page 33 to enable discharge air temperature control.

l When the DAT sensor is used only to detect primary air temperature, the sensor can be

placed in either location shown in the illustration Discharge air temperature

sensor location.

Illustration 2–6 Discharge air temperature input details

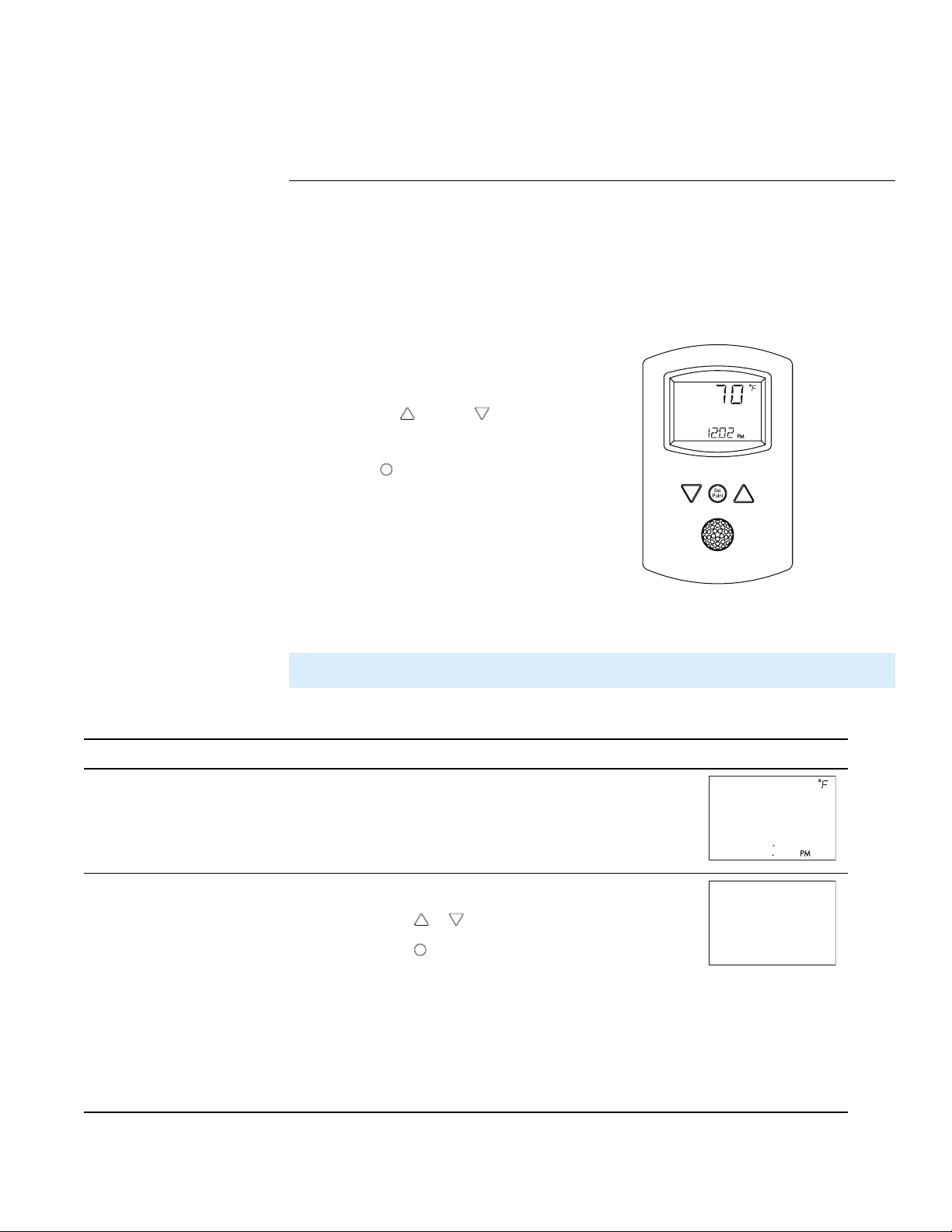

Connecting power

The controllers require a 24 volt, AC power source. Use the following guidelines when

choosing and wiring transformers to the controller.

l Use a Class–2 transformer of the appropriate size to supply power to the controller.

l KMC Controls recommends powering only one controller from each transformer.

l Do not run 24 volt, AC power from within an enclosure to external controllers.

Connect the 24 volt AC power supply to the power terminal block on the lower right side of

the controller. Connect the ground side of the transformer to the ground terminal and the

AC phase to the phase terminal. Power is applied to the controller when the transformer is

connected to power.

Illustration 2–7 Controller power terminals

Revision H 17

Page 18

Section 2: Installing the controllers KMC Controls, Inc.

Maintenance

SimplyVAV controllers require no routine maintenance. If necessary, clean with a damp cloth

and mild soap.

18 Revision H

Page 19

Set

Point

72

12S1

Set

Point

PSW1

OOOO

SimplyVAV

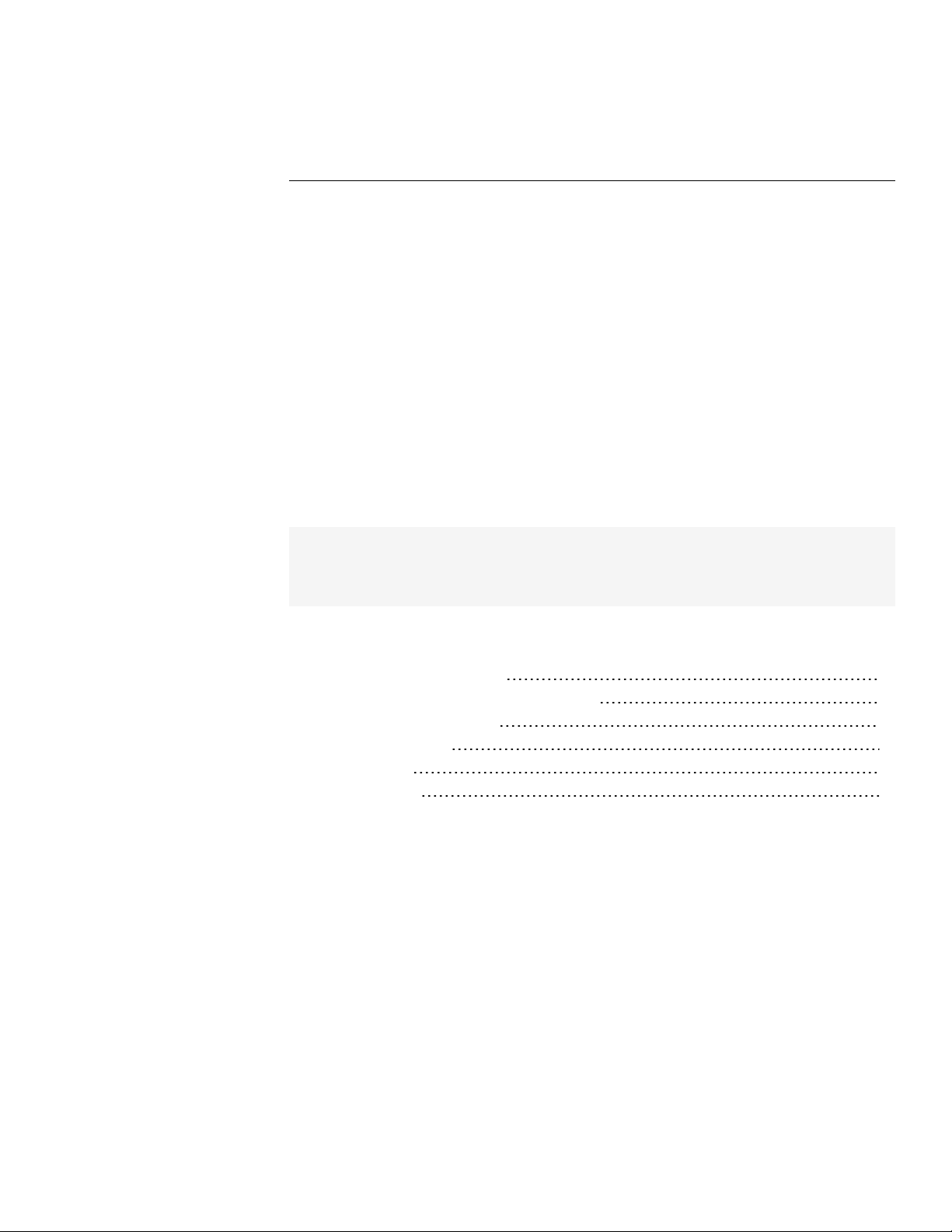

Sec tion 3: Chan g i n g t h e r oom s et p oi nt

This section covers topics for the end user in a facility.

Changing the SimplyVAV user functions with an STE-8001 or STE-8201 are limited to

changing the active setpoints in a room. The setpoints are entered or changed using the

buttons and display on the front of the sensor.

Quick start to changing setpoints

1. Press any button to begin changing setpoints.

2. If required, enter Password 1.

Press the up or down buttons to change a

3.

setpoint value.

Press the

4.

button to save the value or

advance to the next function.

To enter or change the active setpoints you may need Password 1.

Tip: Once the following procedure is started, all steps must be completed in order.

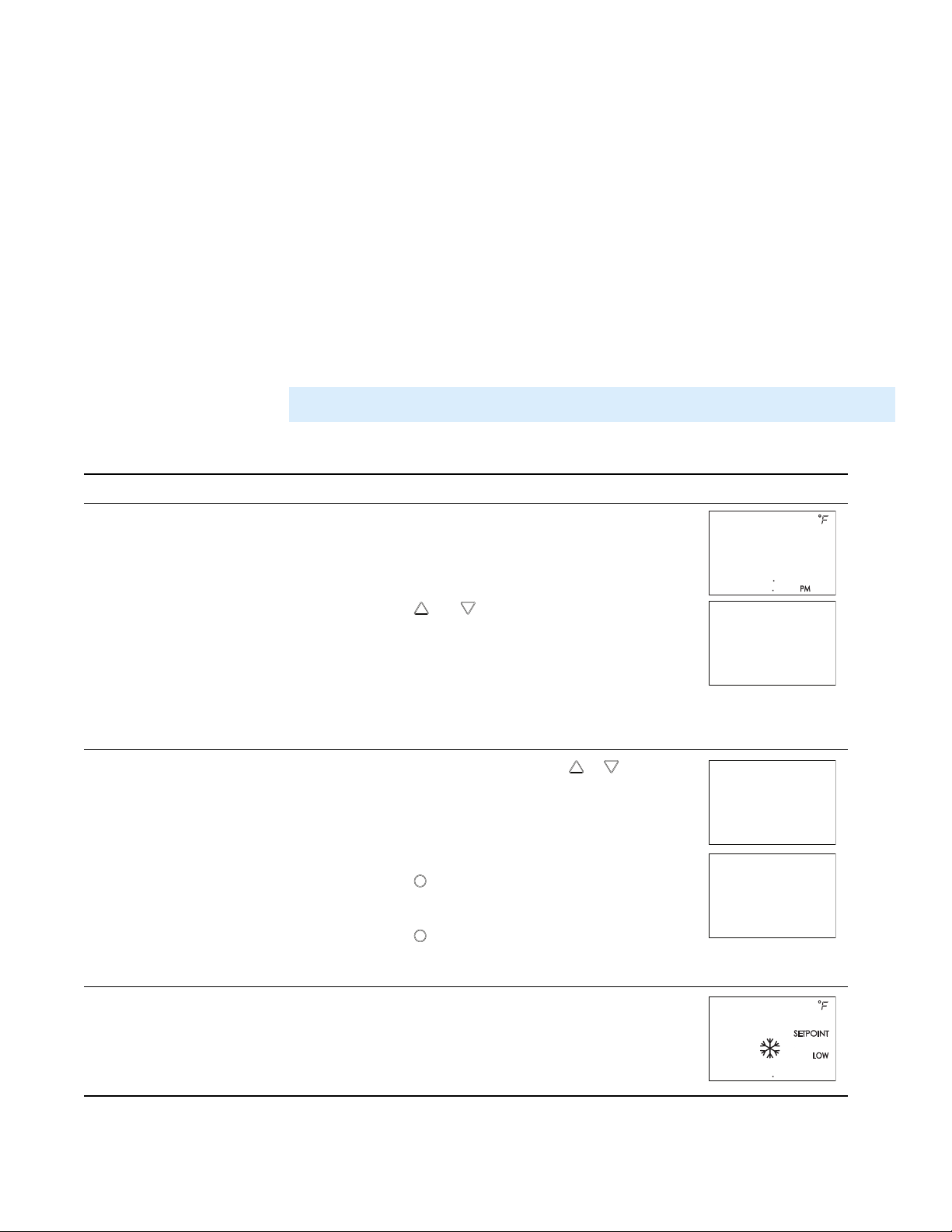

Changing room setpoints

Procedure Steps Sensor display

1 Starting display

2 Enter Password 1.

Start from the temperature display.

1. Press any button. The display changes to PSW1.

Revision H 19

Press the or buttons to change the first digit.

2.

Press the

3.

button to select the next digit. Repeat

for all four digits.

Note: If Password 1 has not previously been entered,

the display will change to the occupied cooling

setpoint display after Step 1.

Page 20

Set

Point

745

COOLING

Set

Point

685

HEATING

Section 3: Changing the room setpoint KMC Controls, Inc.

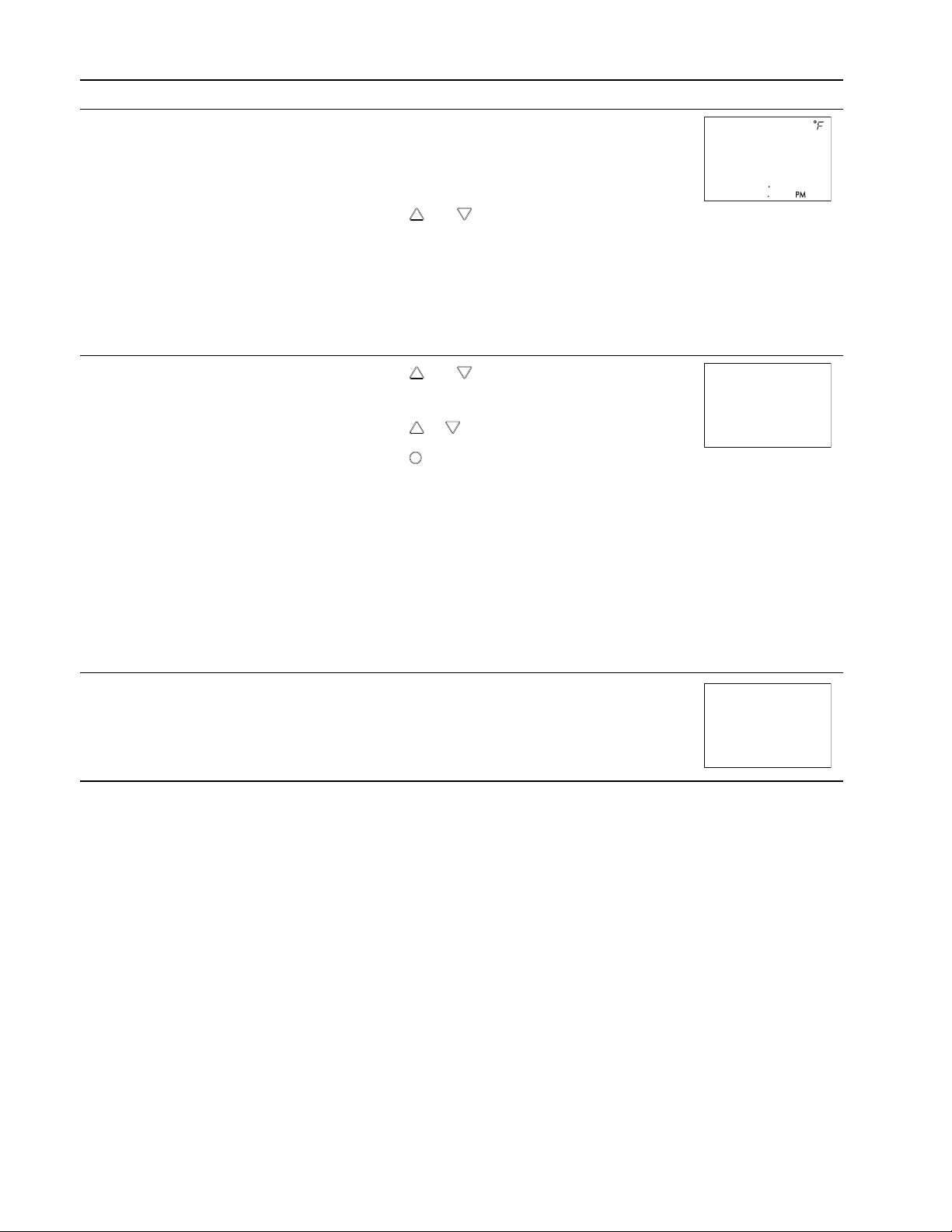

Changing room setpoints (continued)

Procedure Steps Sensor display

3 Set the active cooling setpoint.

4 Set the active heating setpoint.

Press the or buttons to change the cooling

1.

setpoint temperature. The setpoint changes in

increments of 0.5 degrees.

Press the

2.

button to save the value.

The display advances to set the heating setpoint.

Press the or buttons to change the heating

1.

setpoint temperature. The setpoint changes in

increments of 0.5 degrees.

Press the

2.

button to save the value.

The display returns to the temperature display.

20 Revision H

Page 21

SimplyVAV

Sec tion 4: Configuring the cont roll er s

This topics in this section are advanced topics for control technicians and engineers.

The configuration functions that are accessible through an STE-8000 series digital sensor

are all of the values and settings that are entered during the installation and commissioning

of a VAV terminal unit. Typically, these functions do not change after the installation and

commissioning process.

To set up the configuration functions, you will need the following items and information.

l Details about the VAV terminal unit including the configuration for fans and reheat.

l An STE-8001 orSTE-8201 digital sensor to use as a configuration tool.

l The building automation system plans for controllers connected to a network.

Users may change the active heating and cooling setpoints without accessing the

configuration functions. This procedure is covered in the topic Changing the room

setpoint on page 19.

Note: The instructions for the configuration functions cover all of the functions that a digital

sensor can set up in the SimplyVAV series of controllers. Not all functions are available on

every model of controller.

Configuration topics

Getting started with configuration 21

Entering system temperature setpoints and limits 23

Configuring the VAV Box options 27

Set the airflow setpoints 29

Advanced options 33

Restore Application 35

Getting started with configuration

For access to the configuration functions you will need the Password 2.

l If the controller has not been previously set up, no password is required.

l A new Password 2 can be entered or changed in the advance functions. See the topic

Advanced options on page 33.

Revision H 21

Page 22

72

12S1

Set

Point

PSW2

OOOO

CNFG

Section 4: Configuring the controllers KMC Controls, Inc.

Enter the configuration mode

Procedure Detailed steps Sensor display

1 Starting display

2 Enter Password 2.

1. Start at the temperature display.

Press the and buttons together.

2.

l If Password 2 is not required, the display

changes to CNFG.

l If required, enter Password 2. The display

changes to CNFG when Password 2 is correct.

Press the and buttons together and hold them

1.

down until the display changes to PSW2.

Press the or button to change the first digit.

2.

Press the

3.

for all four digits.

4. When the button is pushed for the fourth correct digit,

the display changes to COMM.

button to select the next digit. Repeat

3 Select a configuration

function.

Note: If Password 2 has not previously been entered

the display will change to the CNFG display after

Step 1.

Access to the configuration functions always start at the

CNFG display.

22 Revision H

Page 23

72

12S1

PSW2

OOOO

Set

Point

Set

Point

CNFG

STPT

MIN

68O

SimplyVAV Section 4: Configuring the controllers

Entering system temperature setpoints and limits

The system temperature setpoints set the operational parameters and limits for the VAV

terminal unit.

The temperature setpoints include the following items.

l Minimum cooling and maximum heating setpoints

l Occupied and unoccupied cooling setpoints

l Occupied and unoccupied heating setpoints

l Changeover differential setpoint

l Standby differential setpoint

Setting the temperature setpoints requires entering Password 2 which is described in detail

in the topic Getting started with configuration on page 21.

Tip: Once the following procedure is started, all steps must be completed in order.

Procedure to set the temperature setpoints

Procedure Detailed steps Sensor display

1 Start at the temperature

display.

1. Start at the temperature display.

Press the and buttons together.

2.

l If Password 2 is not required, the display

changes to CNFG.

l If required, enter Password 2. The display

changes to CNFG when Password 2 is correct.

2 Select the setpoint display.

From the CNFG display, press the or buttons to

1.

show STPT.

Press the

2.

button to select the CNFG options. The

display changes to STPT.

Press the

3.

button to select STPT. The display

changes to MIN.

3 Set the minimum cooling

Revision H 23

setpoint.

This setpoint limits the lowest temperature that a user

can enter as the active setpoint.

Page 24

Set

Point

Set

Point

MAX

78O

Set

Point

OCCL

74O

Set

Point

OCHT

7OO

Section 4: Configuring the controllers KMC Controls, Inc.

Procedure to set the temperature setpoints (continued)

Procedure Detailed steps Sensor display

Press the or buttons to set the minimum

1.

cooling setpoint. The setpoint will change in 0.5°

increments.

4 Set the maximum heating

setpoint.

5 Set the occupied cooling

setpoint.

Press the

2.

button to save the setpoint and advance

to the next function.

This setpoint limits the highest temperature a user can

enter as the active setpoint.

Press the or buttons to set the maximum

1.

heating setpoint. The setpoint will change in 0.5°

increments.

Press the

2.

button to save the setpoint and advance

to the next function.

This setpoint is used as the active setpoint when the

space is occupied.

Press the or buttons to set the occupied

1.

cooling setpoint. The setpoint will change in 0.5°

increments.

Press the

2.

button to save the setpoint and advance

to the next function.

6 Set the occupied heating

setpoint.

Note: This setpoint can also be changed as

described in the topic Changing the room

setpoint on page 19.

This setpoint is used as the active setpoint when the

space is occupied.

Press the or buttons to set the occupied

1.

heating setpoint. The setpoint will change in 0.5°

increments.

Press the

2.

button to save the setpoint and advance

to the next function.

Note: This setpoint can also be changed as

described in the section Changing the room

setpoint on page 19.

24 Revision H

Page 25

Set

Point

UNCL

8OO

Set

Point

UNHT

62O

Set

Point

74

CHNG

Set

Point

O5

DIFF

Set

Point

OS

SimplyVAV Section 4: Configuring the controllers

Procedure to set the temperature setpoints (continued)

Procedure Detailed steps Sensor display

7 Set the unoccupied cooling

setpoint.

8 Set the unoccupied heating

setpoint.

9 Set the supply air temperature

changeover setpoint.

This setpoint is used as the active setpoint when the

space is unoccupied.

Press the or buttons to set the unoccupied

1.

cooling setpoint. The setpoint will change in 0.5°

increments.

Press the

2.

button to save the setpoint and advance

to the next function.

This setpoint is used as the active setpoint when the

space is unoccupied.

Press the or buttons to set the unoccupied

1.

heating setpoint. The setpoint will change in 0.5°

increments.

Press the

2.

button to save the setpoint and advance

to the next function.

This setpoint sets the supply air temperature at which

the controller will change between heating to cooling.

Not used in all models.

10Set the minimum temperature

differential setpoint.

11Set the standby differential

setpoint.

Press the or buttons to set the changeover

1.

setpoint. The setpointwill change in 1° increments.

Press the

2.

button to save the setpoint and advance

to the next function.

The minimum allowable temperature value between the

cooling and heating setpoints.

Press the or buttons to set the differential

1.

setpoint. The setpointwill change in 1° increments.

Press the

2.

button to save the setpoint and advance

to the next function.

The standby setpoint is calculated by adding or

subtracting the offset value to or from the value of the

occupied setpoint.

Press the or buttons to set the standby

1.

differential setpoint. The setpoint will change in 1°

increments.

Revision H 25

Press the

2.

to the next function.

button to save the setpoint and advance

Page 26

Set

Point

STPT

Section 4: Configuring the controllers KMC Controls, Inc.

Procedure to set the temperature setpoints (continued)

Procedure Detailed steps Sensor display

12Select a new configuration

function or exit.

Press the or buttons to select one of the

1.

following:

l BOX, FLOW, ADVC, or RSTR options

l BACK to choose another configuration function.

l EXIT to return to the temperature display.

Press the

2.

button to select the next function.

26 Revision H

Page 27

72

12S1

PSW2

OOOO

Set

Point

Set

Point

CNFG

STPT

BOX

9O4

PKFT

SimplyVAV Section 4: Configuring the controllers

Configuring the VAV Box options

The box options set the controller for the specific mechanical installation of the VAV terminal

unit. The box options include the following items.

l The K-factor for the VAV terminal unit. If the K-factor is not available, see the topic

K-factors on page 71.

l Reheat configuration (optional)

l Fan configuration (optional)

l Direction of damper to close

Setting the box options requires entering Password 2 which is described in the topic

Getting started with configuration on page 21.

Tip: Once the following procedure is started, all steps must be completed in order.

Procedure to set the box functions

Procedure Detailed steps Sensor display

1 Starting display

2 Select the box settings display.

1. Start at the temperature display.

Press the and buttons together.

2.

l If Password 2 is not required, the display

changes to CNFG.

l If required, enter Password 2. The display

changes to CNFG when Password 2 is correct.

From the CNFG display, press the or buttons to

1.

show the BOX display.

Press the

2.

display changes to STPT.

Press the or buttons to change the display to

3.

BOX.

button to select the CNFG options. The

3 Set the primary VAV terminal

Revision H 27

unit K-factor.

Press the

4.

The K-factor is supplied by the manufacturer of the VAV

terminal unit. Typically it is on the label with the unit

airflow information.

button to select BOX.

Page 28

Set

Point

Set

Point

9O4

SKFT

Set

Point

NONE

REHT

Set

Point

NONE

FAN

Section 4: Configuring the controllers KMC Controls, Inc.

Procedure to set the box functions (continued)

Procedure Detailed steps Sensor display

Press the or buttons to set the primary K-

1.

factor.

4 Set the secondary VAV

terminal unit K-factor.

Not used in all models.

5 Set the mode of reheat for the

terminal unit.

Not used in all models.

Press the

2.

button to save the entry and advance to

the next function.

The K-factor is supplied by the manufacturer of the VAV

terminal unit. Typically it is on the label with the unit

airflow information.

Press the or buttons to set the secondary K-

1.

factor.

Press the

2.

button to save the entry and advance to

the next function.

Press the or buttons to choose one of the

1.

following reheat options.

None—Reheat is not enabled.

Staged—Enables staged reheat.

Modulating—The analog reheat output varies from

0-10 volts DC.

6 Set the fan option.

Not used in all models.

Floating—The reheat outputs control a tristate

actuator.

Time proportional—A 24-volt triac output controls a

thermal wax valve.

Press the

2.

button to save the reheat option and

advance to the next function.

Press the or buttons to choose one of the

1.

following fan options.

None—No fan is connected to the controller.

Series—The VAV unit includes a series fan.

Parallel—The VAV unit includes a parallel fan.

Press the

2.

button to save the fan option and

advance to the next function.

28 Revision H

Page 29

Set

Point

CCW

DDIR

Set

Point

BOX

SimplyVAV Section 4: Configuring the controllers

Procedure to set the box functions (continued)

Procedure Detailed steps Sensor display

7 Set the damper direction to

close.

8 Select a new configuration

function or exit.

Press the or buttons to which direction to

1.

damper moves to close.

CCW—The actuator turns counterclockwise to close

the damper.

CW—The actuatorturns clockwise to close the

damper.

Press the

2.

button to save the damper option and

advance to the next function.

Press the or buttons to select one of the

1.

following:

l STPT, FLOW, ADVC. or RSTR options

l BACK to choose another configuration function

l EXIT to return to the temperature display.

Press the

2.

button to select the next function.

Set the airflow setpoints

The airflow setpoints set the airflow limits for the VAV terminal unit.

l Airflow heating and cooling minimum and maximum limits

l Auxiliary flow setpoint (optional)

l Minimum and maximum fan speeds (optional)

Setting the airflow setpoints requires entering Password 2 which is described in the topic

Getting started with configuration on page 21.

Note: If the VAV unit is a heat only or cooling only unit, the airflow setpoints for the unused mode

must be set within the range of the mode in use. Failure to set the unused setpoints

correctly will result in unpredictable or erroneous air balancing settings.

Tip: Once the following procedure is started, all steps must be completed in order.

Revision H 29

Page 30

72

12S1

PSW2

OOOO

Set

Point

Set

Point

CNFG

STPT

FLOW

Set

Point

OO

MNCL

Set

Point

3SO

MXCL

200

AUXF

Section 4: Configuring the controllers KMC Controls, Inc.

Procedure to set the airflow setpoints

Procedure Detailed steps Sensor display

1 Starting display

2 Select the flow setpoint

display.

1. Start at the temperature display.

Press the and buttons together.

2.

l If Password 2 is not required, the display

changes to CNFG.

l If required, enter Password 2. The display

changes to CNFG when Password 2 is correct.

From the CNFG display, press the or buttons to

1.

show the CNFG display.

Press the

2.

display changes to STPT.

Press the or buttons to change the display to

3.

FLOW.

button to select the CNFG options. The

3 Set the cooling minimum

airflow limit.

4 Set the cooling maximum

airflow limit.

5 Set the axillary airflow

setpoint.

Not used for all models.

Press the

4.

changes to MNCL.

Press the or buttons to set the minimum limit

1.

for cooling airflow. The setpoint changes in 1 CFM

increments.

Press the

2.

to the next function.

Press the or buttons to set the maximum limit

1.

for cooling airflow. The setpoint changes in 1 CFM

increments.

Press the

2.

to the next function.

This setpoint sets the airflow forwhen reheat is active

auxiliary airflow.

button to select FLOW. The display

button to save the setpoint and advance

button to save the setpoint and advance

30 Revision H

Page 31

Set

Point

Set

Point

OO

MNHT

Set

Point

3SO

MXHT

Set

Point

2O

MINF

Set

Point

1OO

MAXF

Set

Point

1OO

DLMN

SimplyVAV Section 4: Configuring the controllers

Procedure to set the airflow setpoints (continued)

Procedure Detailed steps Sensor display

Press the or buttons to set a value for the

1.

auxillary airflow. The setpoint changes in 1 CFM

increments.

6 Set the heating minimum

airflow limit

7 Set the heating maximum

airflow limit.

8 Set the minimum limit for fan

speed.

Not used for all models.

Press the

2.

button to save the setpoint and advance

to the next function.

Press the or buttons to set the minimum limit

1.

for heating airflow. The setpoint will change in 1 CFM

increments.

Press the

2.

button to save the setpoint and advance

to the next function.

Press the or buttons to set the maximum limit

1.

for heating airflow. The setpoint will change in 1 CFM

increments.

Press the

2.

button to save the setpoint and advance

to the next function.

Press the or buttons to set the minimum limit

1.

for the fan speed. The setpoint will change in 1%

increments.

Press the

2.

button to save the setpoint and advance

to the next function.

9 Set the maximum limit for fan

10Set the dual duct minimum

Revision H 31

speed.

Not used for all models.

airflow.

Not used for all models.

Press the or buttons to set the maximum limit

1.

for the fan speed. The setpoint will change in 1%

increments.

Press the

2.

button to save the setpoint and advance

to the next function.

This setpoint is for the minimum airflow when a dualduct system is at temperature setpoint.

Press the or buttons.

1.

Press the

2.

button to save the setpoint and advance

to the next function.

Page 32

Set

Point

FLOW

Section 4: Configuring the controllers KMC Controls, Inc.

Procedure to set the airflow setpoints (continued)

Procedure Detailed steps Sensor display

11Select a new configuration

function or exit.

Press the or buttons to select one of the

1.

following:

l STPT, BOX, ADVC, or RSTR options

l BACK to choose another configuration function

EXIT.

Press the

2.

button to select the next function.

32 Revision H

Page 33

72

12S1

PSW2

OOOO

Set

Point

Set

Point

CNFG

STPT

ADVC

Set

Point

PSW1

OOOO

SimplyVAV Section 4: Configuring the controllers

Advanced options

The advanced options set up passwords and special features in the controller.

l Establish or change Password 1 and Password 2

l Set timers for standby and override (optional)

l Enable automatic occupancy (optional)

l Enable discharge air temperature control (optional)

l Calibrate the sensor

Setting the advance options requires entering Password 2 which is described in the topic

Getting started with configuration on page 21.

Tip: Once the following procedure is started, all steps must be completed in order.

Table 4–1 Procedure to set the advanced options

Procedure Steps Sensor display

1 Starting display

2 Select the advanced display.

1. Start at the temperature display.

Press the and buttons together.

2.

l If Password 2 is not required, the display

changes to CNFG.

l If required, enter Password 2. The display

changes to CNFG when Password 2 is correct.

From the CNFG display, press the

1.

button to show

the STPT display.

Press the or buttons to change the display to

2.

ADVC.

3 Change Password 1.

Revision H 33

Press the

3.

button to select ADVC.

Note: Entering four zeros (0000) removes the password.

Press the or buttons to change the first digit.

1.

Press the

2.

button to select the next digit. Repeat

for all four digits.

Page 34

Set

Point

Set

Point

Set

Point

PSW2

OOOO

Set

Point

3O

OVRD

Set

Point

15

Set

Point

DISABLE

DAT

Set

Point

DISABLE

AUMD

Section 4: Configuring the controllers KMC Controls, Inc.

Procedure to set the advanced options (continued)

Procedure Steps Sensor display

4 Change Password 2.

5 Set the local unoccupied

override timer.

Applies only to STE-6017

sensors.

6 Set the standby time

Applies only to STE-8201

digital sensors.

When the

3.

button is pressed for the last digit, the

new password is saved and the display advances.

Note: Entering four zeros (0000) removes the password.

Press the or buttons to change the first digit.

1.

Press the

2.

button to select the next digit. Repeat

for all four digits.

When the

3.

button is pressed for the last digit, the

new password is saved and the display advances.

Press the or buttons to set the local

1.

unoccupied override timer. The value will change in 1

minute increments.

Press the

2.

button to save the setpoint and advance

to the next function.

Press the or buttons to set the time for the

1.

standby time. The value will change in 1 minute

increments.

Press the

2.

button to save the setpoint and advance

to the next function.

7 Set discharge air temperature

limiting.

Not used for all models.

Required for reheat.

8 Set the automatic occupancy

mode.

Requires a discharge air

temperature sensor.

Press the or buttons to enable or disable

1.

discharge air temperature limiting.

Press the

2.

button to save the setpoint and advance

to the next function.

Press the or buttons to enable or disable

1.

automatic occupancy.

Press the

2.

button to save the setpoint and advance

to the next function.

Enable The controller will automatically changed

to the unoccupied state when it detects the loss

of primary air supply.

Disable The controller will remain in the occupied

mode regardless of the primary air supply.

34 Revision H

Page 35

Set

Point

OO

CALIB

Set

Point

ADVC

Caution

SimplyVAV Section 4: Configuring the controllers

Procedure to set the advanced options (continued)

Procedure Steps Sensor display

9 Set the temperature sensor

calibration constant.

10Select a new configuration

function or exit.

Press the or buttons to set the calibration

1.

constant. The setpoint will change in0.1 minute

increments.

l For a low input reading enter a positive correction

value.

l For a high input reading enter a negative

correction value.

Press the

2.

button to save the setpoint and advance

to the next function.

Press the or buttons to select one of the

1.

following:

l STPT, FLOW, BOX, or RSTR options

l BACK to choose .another configuration function

l EXIT to return to the temperature display.

Press the

2.

button to select the next function.

Restore Application

Choose the RSTR function to reset the SimplyVAV controller to the original configuration and

settings. Use it also to change the units of measure to display on a SimplyVAV sensor.

There are two versions of the application program in the controller.

l The Metric version displays temperature in Celsius and uses metric values for units of

measure.

l The English version displays temperature in Fahrenheit and uses English values for

units of measure.

Access to the Restore Application function requires entering Password 2 which is described

in the topic Getting started with configuration on page 21.

Tip: Once the following procedure is started, all steps must be completed in order.

Choosing RSTR deletes all previously configured values

including balancing values and passwords. Only the

BACnet communications settings will remain unchanged.

Revision H 35

Page 36

72

12S1

PSW2

OOOO

Set

Point

Set

Point

CNFG

STPT

RSTR

Set

Point

METRIC

RSTR

ENGLISH

RSTR

Section 4: Configuring the controllers KMC Controls, Inc.

Procedure to restore application

Procedure Detailed steps Sensor display

1 Starting display

2 Select the restore settings

display.

1. Start at the temperature display.

Press the and buttons together.

2.

l If Password 2 is not required, the display

changes to CNFG.

l If required, enter Password 2. The display

changes to CNFG when Password 2 is correct.

From the CNFG display, press the or buttons to

1.

show the CNFG display.

Press the

2.

display changes to STPT.

Press the or buttons to change the display to

3.

RSTR.

button to select the CNFG options. The

3 Choose the application.

Caution: Choosing RSTR deletes all previously

entered values and returns the controller to the

manufacturer's settings. Only the BACnet

communications settings will remain unchanged.

Press the

4.

Press the or buttons to choose ENGLISH or

1.

METRIC.

Metric The sensor displays temperature in Celsius

and uses metric values for units of measure.

English The sensor displays temperature in

Fahrenheit and uses English values for units of

measure.

Press the

2.

the next function.

button to select RSTR.

button to save the entry and advance to

36 Revision H

Page 37

72

12S1

PSW2

OOOO

SimplyVAV

Sec tion 5: Balan c i n g airf l o w

Topics in this section are for control technicians or engineers who will be balancing the

airflow in the controllers.

The airflow balancing procedure described in this section requires the following items.

l A flow hood or other accurate method to measure airflow.

l An STE-8001 orSTE-8201 wall sensor. If the system does not include one of these

sensors, temporarily disconnect the installed sensor and connect an STE-8001 as a

service tool.

l The engineering design specifications for the minimum and maximum airflow

setpoints.

l Password 2 which is described in the topic Getting started with configuration on

page 21.

Note: If the VAV unit is a heat only or cooling only unit, the airflow setpoints for the unused mode

must be set within the range of the mode in use. Failure to set the unused setpoints

correctly will result in unpredictable or erroneous air balancing settings. See Set the

airflow setpoints on page 29 for the procedure to adjust the setpoints.

Note: Starting the balancing procedure erases all previous airflow correction factors. The airflow

readings displayed by the digital sensor are the actual uncorrected airflow readings as

measured by the controller.

Tip: Once the following procedure is started, all steps must be completed in order.

Table 5–1 The airflow balancing procedure

Procedure Steps Sensor display

1 Starting display

1. Start at the temperature display.

Press the and buttons together.

2.

l If Password 2 is not required, the display

changes to CNFG.

Revision H 37

l If required, enter Password 2. The display

changes to CNFG when Password 2 is correct.

Page 38

Set

Point

Set

Point

CNFG

COMM

BLNC

PRI

Set

Point

Set

Point

PMAX

OO

PMIN

OO

Section 5: Balancing airflow KMC Controls, Inc.

The airflow balancing procedure (continued)

Procedure Steps Sensor display

2 Select the CNFG display.

3 Measure and enter the actual

maximum primary airflow

From the CNFG display, press the or buttons to

1.

advance to COMM and the BLNC display.

Press the

2.

button to select BLNC. The display

advances to PRI.

Press the

3.

button to select PRI.

The display begins flashing PMAX and also displays the

actual airflow at the bottom.

Note: The airflow will attempt to stabilize on the

highest value for either the cooling or heating

maximum airflow even if only one mode is

operational.

4 Measure and enter the actual

minimum primary airflow

Note: The airflow displayed by the digital sensor in

this stepf is the actual, uncorrected airflow.

1. Wait for the maximum airflow value to stabilize.

2. With a flow hood, measure the actual airflow.

Press the

3.

PMAX stops flashing.

Press the or buttons to enter the measured

4.

button to advance to the entry display.

airflow.

Press the

5.

button to save the measured airflow.

The display changes to PMIN.

The display begins flashing PMIN and also displays the

actual airflow at the bottom.

38 Revision H

Page 39

Set

Point

Set

Point

Set

Point

PRI

SEC

Set

Point

Set

Point

SMAX

OO

SimplyVAV Section 5: Balancing airflow

The airflow balancing procedure (continued)

Procedure Steps Sensor display

Note: The airflow will attempt to stabilize on the

lowest value foreither the cooling or heating

minimum airflow even if only one mode is

operational.

Note: The airflow displayed by the digital sensor in

this step is the actual, uncorrected airflow.

1. Wait for the minimum airflow value to stabilize.

2. With a flow hood, measure the actual airflow.

5 Advance or exit

6 Measure and enter the actual

maximum secondary airflow

Press the

3.

button to advance to the entry display.

PMIN stops flashing.

Press the or buttons to enter the measured

4.

airflow.

Press the

5.

button to save the measured airflow.

The display advances to PRI.

1. Press the or buttons to select one of the following:

l SEC to balance the secondary VAV for dual duct

systems. Choosing SEC advances to the SMAX

display. This is available only on dual duct

models.

l BACK to choose another commissioning function

l EXIT to return to the temperature display.

Press the

2.

button to select the next function.

The display begins flashing SMAX and also displays the

actual airflow at the bottom.

Revision H 39

Note: The airflow displayed by the digital sensor in

this step is the actual, uncorrected airflow.

1. Wait for the maximum airflow value to stabilize.

2. With a flow hood, measure the actual airflow.

Press the

3.

button to advance to the entry display.

SMAX stops flashing.

Press the or buttons to enter the measured

4.

airflow.

Press the

5.

button to save the measured airflow.

The display advances to SMIN.

Page 40

Set

Point

Set

Point

SMIN

OO

Set

Point

SEC

Section 5: Balancing airflow KMC Controls, Inc.

The airflow balancing procedure (continued)

Procedure Steps Sensor display

7 Measure and enter the actual

minimum secondary airflow

8 Advance or exit

The display begins flashing SMIN and also displays the

actual airflow at the bottom.

Note: The airflow displayed by the digital sensor in

this step is the actual, uncorrected airflow.

1. Wait for the minimum airflow value to stabilize.

2. With a flow hood, measure the actual airflow.

Press the

3.

button to advance to the entry display.

SMIN stops flashing.

Press the or buttons to enter the measured

4.

airflow.

Press the

5.

button to save the measured airflow.

The display advances to SEC.

Press the or buttons to select one of the

1.

following:

l PRI to balance the primary VAV fordual duct

systems

l BACK to choose another configuration function.

l EXIT to return to the temperature display.

Press the

2.

button to select the next function.

40 Revision H

Page 41

SimplyVAV

Sec tion 6: Application drawi ngs

This section covers the drawings, materials, and instructions for specific VAV

applications.

Each SimplyVAV model is designed for a specific set of applications. The following topics

are for control technicians and engineers that will plan for and install controllers for

SimplyVAV applications.

Submittal sheets for all of these applications are available from the BAC-8000 series page at

KMCControls.com.

Application drawings in this section

Cooling or heating without reheat 42

Staged reheat 43

Modulating reheat 44

Time proportional reheat 45

Floating reheat 46

Dual-duct application 47

Revision H 41

Page 42

24 VAC

Duct

Temp

Sensor

ON CTS

1 2

COMM

READY

AI1

AI5

GND

AO4

AO3

SC

BO8

BO5

BO6

SC

BO7

24VAC

AI6

GND

AI7

T-STAT/

SENSOR

-A

+B

S

EOL

BACnet MS/TP

Section 6: Application drawings KMC Controls, Inc.

Cooling or heating without reheat

The BAC-8001 is configured forsingle-duct cooling VAV control without reheat. Connect the

controller as shown in the illustration Cooling or heating application drawing on page 42.

A BAC-8005 or BAC-8205 may also be used for this application.

For cooling and heating, a duct temperature sensor is required for Discharge Air Temperature

limiting and automatic changeover. See the topic Advanced optionson page 33 for

instructions to enable Discharge Air Temperature limiting.

Submittal sheets for several variations of this application are available from the BAC-8000

series page at KMCControls.com.

Illustration 6–1 Cooling or heating application drawing

42 Revision H

Page 43

ON CTS

1 2

COMM

READY

AI1

AI5

GND

AO4

AO3

SC

BO8

BO5

BO6

SC

BO7

24VAC

AI6

GND

AI7

T-STAT/

SENSOR

-A

+B

S

EOL

BACnet MS/TP

Fan

Speed

Duct

Temp

Sensor

Stage 1

Stage 2

Stage 3

24VAC

Fan start

Reheat

24 VAC

SimplyVAV Section 6: Application drawings

Staged reheat

The staged reheat application is for BAC-8005 or BAC-8205 controllers. The controllers are

configured to switch reheat units that are controlled with 24 volts AC. Reheat units with up to

three stages of reheat can be controlled by these controllers.

l For one-stage, electric reheat or hot water reheat with an on/off valve, use only output

terminal BO6.

l For two-stage reheat use output terminals BO6 and BO7.

l For three-stage reheat use output terminals BO6, BO7, and BO8.

For cooling and heating, a duct temperature sensor is required for Discharge Air Temperature

limiting and automatic changeover. See the topic Advanced optionson page 33 for

instructions to enable Discharge Air Temperature limiting.

When connecting the controller to a fan powered VAV unit, the fan circuits must be

compatible with the following specifications.

l The fan start circuit is a 24 volt AC pilot duty output.

l The fan speed output is 0-10 volts DC.

Submittal sheets for several variations of this application are available from the BAC-8000

series page at KMCControls.com.

Illustration 6–2 BAC-8005 and BAC-8205 with three-stage reheat

Revision H 43

Page 44

ON CTS

1 2

COMM

READY

AI1

AI5

GND

AO4

AO3

SC

BO8

BO5

BO6

SC

BO7

24VAC

AI6

GND

AI7

T-STAT/

SENSOR

-A

+B

S

EOL

BACnet MS/TP

Fan

Speed

0-10 VDC

Duct

Temp

Sensor

Analog

Heat

24VAC

Fan start

24 VAC

Class 2

Section 6: Application drawings KMC Controls, Inc.

Modulating reheat

The modulating reheat application is for a BAC-8005 or BAC-8205 controller. The modulating

option for reheat can control either an electric reheat unit with an analog input or a

modulating hot water valve. The analog reheat output at output terminal AO3 varies between

0 and 10 volts DC.

For cooling and heating, a duct temperature sensor is required for Discharge Air Temperature

limiting and automatic changeover. See the topic Advanced optionson page 33 for

instructions to enable Discharge Air Temperature limiting.

When connecting the controller to a fan powered VAV unit, the fan circuits must be

compatible with the following specifications.

l The fan start circuit is a 24 volt AC pilot duty output.

l The fan speed output is 0-10 volts DC.

Submittal sheets for several variations of this application are available from the BAC-8000

series page at KMCControls.com.

Illustration 6–3 Modulating reheat

44 Revision H

Page 45

ON CTS

1 2

COMM

READY

AI1

AI5

GND

AO4

AO3

SC

BO8

BO5

BO6

SC

BO7

24VAC

AI6

GND

AI7

T-STAT/

SENSOR

-A

+B

S

EOL

BACnet MS/TP

Fan

Speed

Duct

Temp

Sensor

24VAC

Fan start

24 VAC

24VAC THERMAL

ACTUATOR

SimplyVAV Section 6: Application drawings

Time proportional reheat

The time proportional reheat application is for BAC-8005 or BAC-8205 controllers. This

application is typically used in hydronic systems with a hot water reheat coil and a wax top

control valve. The reheat outputis a triac that can switch up to 1ampere at 24volts AC.

For cooling and heating, a duct temperature sensor is required for Discharge Air Temperature

limiting and automatic changeover. See the topic Advanced optionson page 33 for

instructions to enable Discharge Air Temperature limiting.

When connecting the controller to a fan powered VAV unit, the fan circuits must be

compatible with the following specifications.

l The fan start circuit is a 24 volt AC pilot duty output.

l The fan speed output is 0-10 volts DC.

Submittal sheets for several variations of this application are available from the BAC-8000

series page at KMCControls.com.

Illustration 6–4 Time proportional reheat

Revision H 45

Page 46

ON CTS

1 2

COMM

READY

AI1

AI5

GND

AO4

AO3

SC

BO8

BO5

BO6

SC

BO7

24VAC

AI6

GND

AI7

T-STAT/

SENSOR

-A

+B

S

EOL

BACnet MS/TP

Fan

Speed

Duct

Temp

Sensor

24VAC

Fan start

24 VAC

Open

Close

Common

Section 6: Application drawings KMC Controls, Inc.

Floating reheat

The floating reheat application is for BAC-8005 orBAC-8205 controllers. Use this application

in hydronic systems that are controlled by an actuator with tri-state inputs. The reheat

outputs are triacs that can switch up to 1ampere at 24volts AC.

For cooling and heating, a duct temperature sensor is required for Discharge Air Temperature

limiting and automatic changeover. See the topic Advanced optionson page 33 for

instructions to enable Discharge Air Temperature limiting.

When connecting the controller to a fan powered VAV unit, the fan circuits must be

compatible with the following specifications.

l The fan start circuit is a 24 volt AC pilot duty output.

l The fan speed output is 0-10 volts DC.

Submittal sheets for several variations of this application are available from the BAC-8000

series page at KMCControls.com.

Illustration 6–5 Floating reheat

46 Revision H

Page 47

ON CTS

1 2

COMM

READY

AI1

AI5

GND

AO4

AO3

SC

BO8

BO5

BO6

SC

BO7

24VAC

AI6

GND

AI7

T-STAT/

SENSOR

-A

+B

S

EOL

BACnet MS/TP

P2

CW

COM

P1

CCW

24VAC

P OUT

MOTOR

F.B.

POT

24 VAC

BAC-8007

TSP-8001

SimplyVAV Section 6: Application drawings

Dual-duct application

The dual-duct application is for a BAC-8007 controller. Dual-duct VAV requires a TSP-8001

actuator to be used with the BC-8007 as shown in the illustration Dual-duct wiring

diagram on page 47.

Submittal sheets for several variations of this application are available from the BAC-8000

series page at KMCControls.com.

Illustration 6–6 Dual-duct wiring diagram

Revision H 47

Page 48

Section 6: Application drawings KMC Controls, Inc.

48 Revision H

Page 49

SimplyVAV

Sec tion 7: Seq u e nces of operat ion

Topics in this section cover the sequences of operation forthe SimplyVAV controllers.

These are advanced topics for control technicians and engineers.

These sequences of operation are descriptions of each major component of the SimplyVAV

programming. They are provided as an aid to understanding on how the controllers operate.

This section covers the following sequences of operation.

Input sources 49

Occupancy sequence 50

Space setpoints 51

PID control loops 52

Airflow setpoints sequence 53

Changeover 53

Discharge Air Temperature (DAT) limiting 53

System diagnostic indicators 54

Damper operation 55

Fan operation 56

Reheat sequence 57

Balancing airflow sequence 60

Dual duct 61

Input sources

The SimplyVAV controllers require specific sensors to measure room temperature, airflow,

and discharge air temperature. All sensors are automatically detected and the programming

is automatically set up for the sensors.

l SimplyVAV digital wall sensors

l STE-6000 series discreet temperature sensors

l Discharge air temperature sensor

l Airflow sensors and pickups

SimplyVAV digital wall sensors—The SimplyVAV digital wall sensors include a room

temperature sensor, a digital display, and a push button interface for entering setpoints and

configuring the controllers. If a SimplyVAV digital wall sensor is detected, the sensor's

temperature is mapped to the Space Temperature Reference value object as the

temperature input value. See the topic BACnet objects on page 67 foradditional

information on value objects.

The SimplyVAV digital wall sensor model BAC-8201 includes also a motion sensor to detect

when the zone is temporary unoccupied. This is described in the topic Occupancy

sequence on page 50.

Revision H 49

Page 50

Section 7: Sequences of operation KMC Controls, Inc.

STE-6000 series discreet temperature sensors—There are three models of the STE-6000

series sensors compatible with the SimplyVAV controllers. If one of the three sensors is

detected, the sensor's temperature is mapped to the Space Temperature Reference value

object as the temperature input value. See the topic BACnet objects on page 67 for

additional information on value objects.

Models STE-6014 and STE-6017 also include a dial for adjusting the setpoint . If either of

these two sensors is detected, the dial position sets the Active setpoint a few degrees

above or below the Occupied setpoint.

The STE-6017 includes a button that when pushed will override the unoccupied state. This

is described in the topic Occupancy sequence on page 50.

Discharge air temperature sensor—The DAT sensor is an optional Type-III, 10 kΩ

thermistor and is required forVAV heating applications. If the controller detects that this

sensor is connected, then the controller will use discharge air temperature to determine

when to change between heating and cooling. The DAT sensor input is used also to control

reheat. See the topics Discharge Air Temperature (DAT) limiting on page 53 and

Changeover on page 53.

Airflow sensors and pickups—VAV airflow is calculated by measuring the high and low

duct pressures with the built-in airflow sensor which is connected to airflow pickup tubes.

The high and low pressure measurements along with the K-factor of the VAV terminal unit

are used to calculate the airflow through the VAV unit.

Occupancy sequence

A SimplyVAV controller is designed to operate as a stand-alone controller and determine

occupancy based only on the availability of primary airflow and motion in the zone. The

controller can be in any one of the following occupancy states.

l Occupied on page 50

l Unoccupied

l Standby

Occupancy can also be commanded by another BACnet device or an operator workstation

connected the building automation network. See the topic System integration and

networking on page 63 for details.

Automatic occupancy

If Automatic Occupancy is enabled, the controller will automatically toggle between

Unoccupied, Occupied, and Standby based on the presence of primary airflow and

motion in the zone.

The default for Automatic Occupancy is Disabled. See the topic Advanced optionson

page 33 to change Automatic Occupancy.

Occupied

For controllers without a connected motion sensor, the controller changes to Occupied

upon the detection of primary airflow.

50 Revision H

Page 51

SimplyVAV Section 7: Sequences of operation

Controllers with a connected motion sensor change to Occupied upon the detection of

primary airflow and motion in the space. The unit will remain in the OCCUPIED state as long

as periodic motion is detected and primary airflow continues. If motion stops, the controller

changes to STANDBY.

Unoccupied

The controller Occupancy mode changes to UNOCCUPIED when it detects a loss of

primary airflow. While in the UNOCCUPIED state, the controller will fully open the damper in

an attempt to reach the maximum airflow setpoint.

Loss of primary airflow is defined as less than 25% of the requested flow for at least 5

minutes. The Occupancy mode changes to Occupied or Standby once the actual airflow

is at least 30% of the requested flow.

Standby

In units with a connected motion sensor, the controller starts in STANDBY and changes to

OCCUPIED after detecting motion in the space. Motion in the space is defined as two

movements detected within 5 minutes. The controller will change back to STANDBY after a

lack a lack of motion for the period specified by the variable Standby Time.

Standby mode is not valid for controllers without a motion sensor, unless commanded by a

building management system.

Space setpoints

There are fourtemperature setpoints each for heating and cooling for a total of eight

setpoints.

l Active cooling

l Occupied cooling

l Unoccupied cooling

l Standby cooling

Types of setpoints

The SimplyVAV controllers may use any of the following setpoints based on a user entered

setpoint or the state of occupancy and standby which is described in the topic Occupancy

sequence on page 50.

l Active heating

l Occupied heating

l Unoccupied heating

l Standby heating

Revision H 51

Page 52

Section 7: Sequences of operation KMC Controls, Inc.

Active setpoint—The active setpoint is the current setpoint. The active setpoint is

determined by the following.

l If the space is occupied, the controller uses the occupied setpoint as the active

setpoint.

l If an STE-6014 and STE-6017 is connected, the Active setpoint is set by the dial to be a

few degrees above or below the Occupied setpoint. The range of adjustment is set by

the variable STBY OFFSET. The dial setting does not change the setpoint when in the

Unoccupied or Standby state.

l If the space is unoccupied the controller uses the unoccupied setpoint as the active

setpoint.

l If controller is in standby, the controller calculates the standby setpoint.

l A user with Password 1 can enter an active setpoint from a SimplyVAV digital wall

sensor. This entry will change the occupied setpoint within the setpoint limits.

Occupied setpoint—A temperature setpoint entered by the controls technician during

controller setup and system commissioning. This is the setpoint used when the controller is

occupied which is determined by primary airflow and, on controllers equipped with motion

sensors, motion in the zone.

Unoccupied setpoint—A temperature setpoint entered by the controls technician during

controller setup and system commissioning. This is the setpoint used when the system is

unoccupied .

Standby setpoint—The standby setpoint is used when the controller is in the standby state.

It is a value calculated from the occupied setpoint and the variable STBY OFFSET. The

standby offset value is entered by the controls technician during controller setup and system

commissioning. See the topic Occupancy sequence on page 50.

Setpoint limits

The programming in the controller limits the setpoint entry so that no heating setpoint is set

higher than its corresponding cooling setpoint.

If a user is adjusting a setpoint and it falls within the range set by the value of Minimum

Setpoint Differential, the corresponding setpoint will be changed to maintain the differential.

For example, the Minimum Setpoint Differential is 4°F and the Occupied Heating setpoint is

70°F. If the user lowers the Occupied Cooling setpoint to 71°F, the controller recalculates

the Occupied Heating setpoint and changes it to 67°F.

PID control loops

A PID control loop calculates an error value from the difference between the measured room

temperature and the active setpoint. The error value is expressed as a percentage and is

typically used in a BAS controller to control the state of an output. When the difference

between the setpoint and room temperature is large, the erroris large. As the system

reduces the difference between the setpoint and space temperature, the error becomes

smaller.

52 Revision H

Page 53

SimplyVAV Section 7: Sequences of operation

The SimplyVAV controllers use up to three PID loops.

l The heating PID loop.

l The cooling PID loop.

l The discharge air temperature (DAT) loop.