Page 1

Direct-Coupled Actuators (40 to 90 in-lb.)

Applications Guide

MEP-4xxx

Contents

Introduction .................................................................................................................................... 3

Important Notices........................................................................................................................... 3

Actuator Torque Selection ............................................................................................................... 4

Heat/Cool/VAV Applications (with the CTE-5202 Thermostat) ....................................................... 4

Accessories ..................................................................................................................................... 5

Ball Joint and Crank Arms ............................................................................................................5

Enclosure, Cord Grip, and Wiring Kits ......................................................................................... 6

Mounting (Non-Rotation) Brackets .............................................................................................. 7

Thermostat ..................................................................................................................................7

Transformers ................................................................................................................................7

VEB-4x Series Valves Mounting/Repair Kits ................................................................................. 8

Troubleshooting .............................................................................................................................. 9

Auxiliary Switch Does Not Work ................................................................................................. 9

Fail-Safe Does Not Work .............................................................................................................. 9

Feedback Does Not Work ............................................................................................................ 9

No Rotation ................................................................................................................................. 9

MEP-4xxx Direct-Coupled Actuators (40 to 90 in-lb.) 1 Applications Guide, AN0513A Rev. J

Page 2

Rotation in Wrong Direction ....................................................................................................... 9

Stroke Range Is Wrong ................................................................................................................ 9

Configuration ................................................................................................................................10

Proportional (MEP-4xx2) Models Setup ..................................................................................... 10

Wiring Issues ............................................................................................................................. 10

Two-Position Wiring (MEP-4001/3/4/5) ..................................................................................... 11

Tri-State/2-Position Rotation Direction ...................................................................................... 11

Auxiliary Switch (MEP-4x2x/4x7x) ............................................................................................12

Fail-Safe Direction (MEP-42/45/49xx) ....................................................................................... 13

Index ............................................................................................................................................. 13

Specifications, design, and operation are subject to change without notice.

MEP-4xxx Direct-Coupled Actuators (40 to 90 in-lb.) 2 Applications Guide, AN0513A Rev. J

Page 3

Introduction

Important Notices

This application guide gives torque selection, accessory, troubleshooting, and other related information.

For general mounting, connection, and congura-

tion details, see the relevant model’s installation

guide. For specications and other information,

see the relevant model’s data sheet and the selection

guide. The latest support les are always available

on the KMC Controls web site (www.kmccontrols.

com):

• KMC Actuators Selection Guide

• MEP-4000/4800 Series (40/80 in-lb., proportional

or tri-state) Data Sheet and Installation Guide

• MEP-4200/4500/4900 Series (fail-safe, 25/45/90 in-

lb., proportional or tri-state/two position) Data

Sheet and Installation Guide

• MEP-4201/4501/4901 (fast operating, 25/45/90

in-lb., tri-state/two position) Data Sheet and

Installation Guide

NOTE: For sample proportional single-zone

heating/cooling valve applications using

the CTE-5202 electronic thermostat, see the

CTE-5202 Applications Guide.

NOTE: The models MEP-4101 (tri-state, 10 in-

lb., with transluscent cover) and MEP-

4042/4842 (40/80 in-lb., proportional, with

modular connectors) are quite dierent

from the rest of the MEP-4xxx series. Also,

any particular MEP-4xxx model may

not have one or more features (e.g., failsafe, auxiliary switch) described in this

document. Use only the information from

this document that is relevant to the MEP-

4xxx model in use.

The KMC logo is a registered trademark of KMC

Controls, Inc. All rights reserved. No part of this

publication may be reproduced, transmied, transcribed, stored in a retrieval system, or translated

into any language in any form by any means without the wrien permission of KMC Controls, Inc.

The material in this document is for information

purposes only. The contents and the product it de-

scribes are subject to change without notice. KMC

Controls, Inc. makes no representations or warranties with respect to this document. In no event shall

KMC Controls, Inc. be liable for any damages, direct

or incidental, arising out of or related to the use of

this document.

WARNING

Risk of electrical shock in line-voltage models.

Disconnect ALL power before servicing. More

than one disconnect provided on models

with auxiliary switches. Failure to follow

electrical safety precautions with live electrical

components could result in injury or death.

WARNING

If both conduit connections are used in linevoltage models, they MUST be externally

connected during installation. The nonmetallic

enclosure does not provide grounding

connection between the two conduit

connections.

MEP-4xxx Direct-Coupled Actuators (40 to 90 in-lb.) 3 Applications Guide, AN0513A Rev. J

Page 4

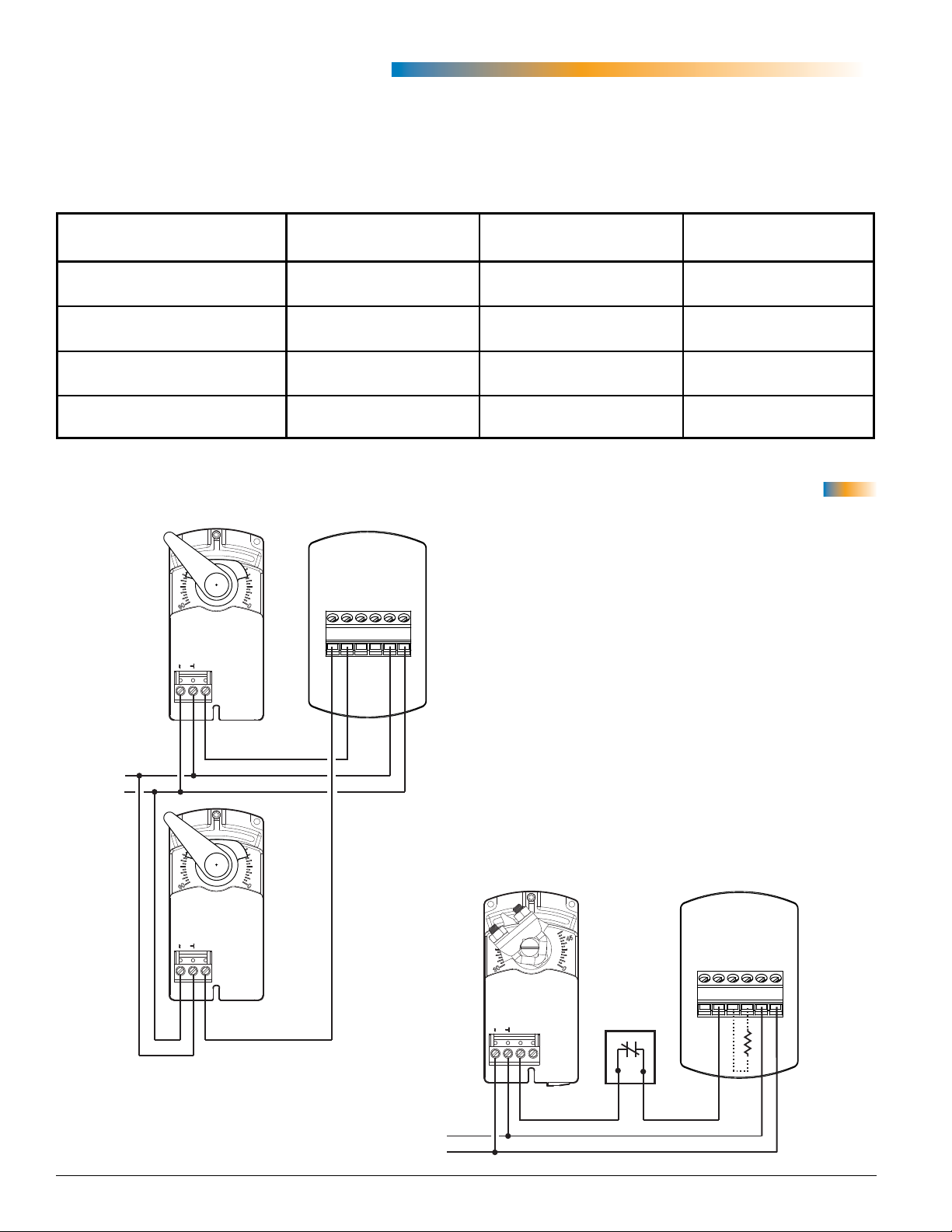

Actuator Torque Selection

Damper manufacturers should provide information

about the required minimum actuator torque. If

by multiplying the height and width in inches and

then dividing by 144.)

that information is not available, use the following

general guidelines to calculate the required torque.

(Square feet for a rectangular duct can be calculated

Damper Type

Opposed Blades Without Seals

Parallel Blades Without Seals

Opposed Blades With Seals

Parallel Blades With Seals

Up to 1000 FPM

3 in-lb. per square foot

4 in-lb. per square foot

5 in-lb. per square foot

7 in-lb. per square foot

After minimum torque is known, see the actuator

data sheets to select the appropriate model.

1000 to 2500 FPM

4.5 in-lb. per square foot

6 in-lb. per square foot

7.5 in-lb. per square foot

10.5 in-lb. per square foot

2500 to 3000 FPM

6 in-lb. per square foot

8 in-lb. per square foot

10 in-lb. per square foot

14 in-lb. per square foot

Heat/Cool/VAV Applications (with the CTE-5202 Thermostat)

MEP-4xxx actuators can be used in single zone proportional heating (baseboard heaters) and cooling

(chilled beams) with valves or SCR control as well as

pressure-dependent VAV applications. For details of

a variety of sample applications, see the CTE-5202

Applications Guide.

(For an example of a fail-safe application on an

outside air damper, see Fail-Safe Direction (MEP-

42/45/49xx) on page 13.)

Chilled

Beam

4-Pipe

Heating

and

Cooling

Cooling Valv e

24 VAC

Common

Input

CTE-5202

Thermostat

T

AO1

AO2

AI1

T

~

24 VA C

(Neutral)

(Phase)

–

~

Pressure Dependent VAV with

Auto and Override to Fully Closed

Heating Valv e

24 VAC

Common

Input

MEP-4002

Actuator

24 VAC

Common

Out

Input

24 VA C @ 5 VA

(Neutral)

(Phase)

MEP-4xxx Direct-Coupled Actuators (40 to 90 in-lb.) 4 Applications Guide, AN0513A Rev. J

–

~

NC SPST

Relay

(Override

to Fully

Closed)

CTE-5202

Thermostat

T

AO1

AO2

AI1

T

~

(5K–10K

Ohm Resistor

between AI1

and Common

for Heating

Mode Only)

Page 5

Accessories

Ball Joint and Crank Arms

VTD-0804

Ball Joints

Crank

Arm

1/4-28X3/4"

Cap Screw

1/4-28

Hex Nut

5/16" Dia. Rod

(not included)

The HLO-4001 crank arm

kit is used when direct

mounting of the actuator

is impractical. See also the

VTD-0804 replacement

ball joint and VTD-

14xx crank arms.

(Not included)

(3) Mounting Holes

for #8 screws

(not included)

Sloed crank arms are for aaching to dampers

or other shafts, and they can be used in conjunc-

tion with the HLO-4001 crank arm kit. In the VTD1403/1404 short crank arms, an aached ball joint

(see the VTD-0804) can be adjusted from 3/4 inches

(minimum) to 2-7/8 inches (maximum) from the cen-

ter of the shaft. In VTD-1405/1406 long crank arms,

the maximum is 4-5/8 inches.

VTD-1403 Short sloed, for 3/8" shafts

VTD-1404 Short sloed, for 1/2" shafts

VTD-1405 Long sloed, for 1/2" shafts

VTD-1406 Long sloed, for 3/8" shafts

KIT INCLUDES:

(1) Crank Arm

(2) 1/4-28 X 3/4" Cap Screws

(2) 1/4-28 Hex Nuts

(2) VTD-0804 Ball Joints

Three-hole crank arms are for aaching to dampers

or other shafts, and they can be used in conjunction

with the HLO-4001 crank arm kit. An aached ball

joint (see the VTD-0804) can be 1-9/16 inches (inner

hole), 2-3/16 inches (middle hole), or 2-7/8 inches

(outer hole) from the center of the shaft.

VTD-1414 Three-hole, for 3/8" shafts

VTD-1415 Three-hole, for 1/2" shafts

The VTD-0804 replacement ball joint is for sidemounted 5/16" diameter

rods (1/4-20 male mounting stud with locknut). See

also the HLO-4001 crank

arm kit.

MEP-4xxx Direct-Coupled Actuators (40 to 90 in-lb.) 5 Applications Guide, AN0513A Rev. J

Page 6

Enclosure, Cord Grip, and Wiring Kits

The HCO-1151 enclosure kit (consisting of a metal

mounting plate, plastic cover, non-rotation bracket,

plug caps, and screws) is designed to protect actuators from inclement conditions. See also the HMO4521 liquid-tight cord grip.

An HMO-4521 liquid-tight cord grip threads into

conduit ings on MEP-4xxx actuators (except the

MEP-4003) when an ingress protection rating of

IP54 is required. The HMO-4521 accepts 0.18 to 0.40"

diameter cables. There are ve per pack. See also the

HCO-1151, HPO-4001, and HPO-4051.

An HPO-4001 assembled wiring kit has an HMO-

4521 liquid-tight cord grip, a 3-foot plenum-rated

cable, conduit ing, and a pre-wired terminal block

for the following actuators:

• MEP-4001

• MEP-4002

• MEP-4801

• MEP-4802

NOTE: It is not compatible with the MEP-40x3,

MEP-402x, MEP-4813, and MEP-482x

actuators. However, the HMO-4521 cord

grip can be installed on those models

(except for the MEP-4003) to provide IP54-

rated ingress protection.

MEP-4xxx Direct-Coupled Actuators (40 to 90 in-lb.) 6 Applications Guide, AN0513A Rev. J

An HPO-4051 assembled wiring kit has an HMO-

4521 liquid-tight cord grip, a 3-foot plenum-rated

cable, and a conduit ing for the following actuators:

• MEP-4201

• MEP-4501

• MEP-4901

• MEP-4x51

• MEP-4x52

• MEP-4x54

NOTE: It is not compatible with the MEP-4x55 and

MEP-4x7x actuators, which are pre-wired

with cables. However, the HMO-4521 cord

grip can be installed on those models to

provide IP54-rated ingress protection.

Page 7

Non-Rotation “T” Bracket (HMO–4001) Order Separately

Non-Rotation Bracket (HMO–4002) Provided

Mounting (Non-Rotation) Brackets

An HMO-4002 non-rotation bracket is provided

with MEP-40xx/48xx/425x/455x actuators (but is not

for use with MEP-427x/457x/49xx models). See also

the HMO-4001.

The HMO-4001 non-rotation “T” bracket can be used instead of the HMO-4002 to span an open distance, or

it can be formed (bent) into a shape that increases the distance between the mounting surface and the actuator. It is provided with MEP-427x/457x/49xx actuators.

The HMO-4004 non-rotation bracket kit is used for

mounting to ball valves.

9" (229 mm)

[229]

9"

3/4" (19 mm)

[19]

3/4"

Thermostat Transformers

For sample proportional single-zone heating/cooling

and pressure-dependent VAV applications using the

CTE-5202 electronic thermostat, see the CTE-5202

Applications Guide.

MEP-4xxx Direct-Coupled Actuators (40 to 90 in-lb.) 7 Applications Guide, AN0513A Rev. J

An XEE-6000 series Class-2 transformer provides 24

VAC power to the actuator:

XEE-6111-050 120 to 24 VAC, 50 VA, single-hub

XEE-6112-050 120 to 24 VAC 50 VA, dual-hub

Page 8

VEB-4x Series Valves Mounting/Repair Kits

Handle

High-Low Screws

HPO-5074

assembled on

a Valv e Body

and an MEP-

4xxxV Actuator

Cover

12 mm Screws

(VFB-4303_SX Bodies

and VEB-4303_SDL Valves)

Beaded Tie

Locking

Bail/Clip

Valve Base

15 mm Screws

(VFB-4____BX Bodies

and VEB-4____B__ Valves)

The HPO-5074 kit is for adapting valve bodies for

use with (only) “quick mounting” MEP-4xxxV actu-

ators. MEP-4xxxV actuators have an aached handle

and shaft as well as a plastic mounting bracket on

the boom of the actuator. See the relevant data

sheet for more information.

Shaft

Thermal Break

Non-Rotation Bracket

Sub Shaft

Machine Screws

Screw

Plate Mount

The HPO-5073 repair kit is designed to replace linkages on VEP-43/45/83/85 and VEB-43/46 ball valves

for use with any standard (not quick-mounting “V”

series) MEP-4xxx actuator:

• VEP-43ABB7xx through VEP-43GBB7xx

• VEP-45A1x7xx through VEP-45H4x7xx

• VEB-43/46 series ending in CK or CF

Hardware for mounting the linkage to the valve, and

the actuator to the linkage, are included with the kit.

The actuator must be ordered separately.

MEP-4xxx Direct-Coupled Actuators (40 to 90 in-lb.) 8 Applications Guide, AN0513A Rev. J

Page 9

Troubleshooting

Auxiliary Switch Does Not Work

• Check the auxiliary switch seing. See Auxiliary

Switch (MEP-4x2x/4x7x) on page 12.

• Check the wiring. (See Wiring Issues on page

10.)

Fail-Safe Does Not Work

• After initial connection or reconnection to power

on MEP-42x2/45x2/49x2 proportional models,

proper fail-safe operation might be delayed

up to 30 seconds (until the capacitors are fully

charged).

• Check the Fail-Safe Direction switch. See Fail-

Safe Direction (MEP-42/45/49xx) on page 13.

Feedback Does Not Work

• Check the feedback switch seing. See Propor-

tional (MEP-4xx2) Models Setup on page 10.

• Check the wiring. (See Wiring Issues on page

10.)

• Check that the shaft moves freely. (Press and

hold the gear disengagement lever and manually

rotate the shaft.)

• Check for a tripped circuit breaker to the trans-

former (or power supply).

• Check polarity and strength of input signal.

• Check for proper supply voltage from the trans-

former (or power supply) and that it has enough

capacity (VA) for all connected devices. See their

respective data sheets and Tips for Connecting

24-Volt Power Application Note (AN0604D).

• Check the wiring. (See Wiring Issues on page

10.)

Rotation in Wrong Direction

• For proportional models, check the position of

the direction switch (Switch 2). See Proportional

(MEP-4xx2) Models Setup on page 10.

• For tri-state and tri-state/two-position models, check the CW/CCW wiring and rotation

direction switch if applicable. See Tri-State/2-

Position Rotation Direction on page 11.

No Rotation

• After initial power-up, proportional fail-safe

MEP-42x2/45x2/49x2 actuators delay enabling

motor operation until the fail-safe capacitors are

charged. No actuator rotation will take place for

at least the rst 30 seconds.

• Check that direction switches are fully engaged

in the proper position. See Proportional

(MEP-4xx2) Models Setup on page 10 and

Tri-State/2-Position Rotation Direction on page

11.

• For fail-safe operation, check the Fail-Safe

Direction switch. See Fail-Safe Direction (MEP-

42/45/49xx) on page 13.

Stroke Range Is Wrong

• For proportional models, check the auto-

mapping. See Proportional (MEP-4xx2) Models

Setup on page 10.

• Check the adjustable stop.

• Check the voltage from the controller or thermostat.

MEP-4xxx Direct-Coupled Actuators (40 to 90 in-lb.) 9 Applications Guide, AN0513A Rev. J

Page 10

Configuration

Wiring Issues

• Check for correct wiring for the application.

• Check the wiring at the connected devices.

• Use a voltmeter and ohmmeter to check the

terminals for expected values.

• See Tips for Connecting 24-Volt Power Applica-

tion Note (AN0604D).

NOTE: Wiring must be adequate to avoid exces-

sive voltage drop on long runs! Allow

plenty of “cushion” in measurements. A

meter may be too slow to register transient dips or peaks during startup.

WARNING

Risk of electrical shock in line-voltage models.

Disconnect ALL power before servicing. More

than one disconnect provided on models

with auxiliary switches. Failure to follow

electrical safety precautions with live electrical

components could result in injury or death.

Proportional (MEP-4xx2) Models Setup

NOTE: Before Jan. 2014, MEP-40x2/48x2

proportional models had 0–10 VDC inputs

and 0–5 or 0–10 VDC feedback (only).

From 2014 through July 2015, they had

2–10 VDC inputs and 1–5 or 2–10 VDC

(only) feedback instead. Starting in August

2015, all these options were available and

selectable via a jumper and slide switch.

NOTE: Before August 2015, the MEP-

42xx/45xx/49xx fail-safe proportional

models had 2–10 VDC inputs and 1–5 or

2–10 VDC feedback (only). Starting in

August 2015, 0–10 VDC inputs and 0–5 or

0–10 VDC feedback were also available and

switch-selectable.

NOTE: When the 0–10 VDC input is selected,

selectable feedback options are 0–5 or 0–10

VDC. When the 2–10 VDC input is selected,

feedback options are 1–5 or 2–10 VDC.

For instructions in direction, feedback, and au-

tomapping, see the relevant installation guide:

WARNING

If both conduit connections are used in linevoltage models, they MUST be externally

connected during installation. The nonmetallic

enclosure does not provide grounding

connection between the two conduit

connections.

• MEP-4000/4800 Series (40/80 in-lb.) Installation

Guide

• MEP-4200/4500/4900 Series (fail-safe, 25/45/90

in-lb.) Installation Guide

MEP-4xxx Direct-Coupled Actuators (40 to 90 in-lb.) 10 Applications Guide, AN0513A Rev. J

Page 11

Two-Position Wiring (MEP-4001/3/4/5)

COM (Black)

~24 V (Red)

Tri-State/2-Position Rotation Direction

MEP-4xx4/4xx5 two-position actuators have “traditional” two wires for 24 VAC/VDC or 100–250 VAC

signal/power.

T

Power Supply

~/+

–

24 V AC/VDC

(Fail-Safe) MEP-4xx4 Two-Position 24 VAC/VDC (Two-Wire)

Starting in January 2014, tri-state MEP-4xx1/4xx3

models (except MEP-4003) also oer two-position

functionality as an option. That option is dependent

on wiring conguration and selector switch position.

See Tri-State/2-Position Rotation Direction on page

11. The (tri-state) two-position option requires

“three-wire” (non-fail-safe) or “four-wire” (fail-safe)

wiring conguration.

Tri-state/two-position MEP-4xx1/4xx3 models (except MEP-4003) have switches for selecting rotation

direction. Be sure switches are set correctly for the

application.

• Non-fail-safe MEP-4xx1/4x13 models (beginning

in Jan. 2014) have a slide switch to the right

of the terminal block. See the MEP-4000/4800

Series Installation Guide for more information.

Switch Position:

1 = Rotation is

Direct

0 = Rotation is

Reversed

Power

Supply

–

~

CW

Feedback Potentiometer

COM

CCW

(MEP-4x13 Only)

Switch Position

COM

T

CW

1 2

Contact Position:

Open = CCW Rotation

Closed = CW Rotation

CCW

–

Power Supply

24 V AC/VDC

~/+

(NFS) MEP-4x01 Two-Position Control, CW Leg (Three-Wire)

See the MEP-4201/4501/4901 Installation Guide or

MEP-4000/4800 Series Installation Guide for more

information.

Switch Position

COM

T

CW

CCW

1 2

Contact Position:

Open = CCW Rotation

Closed = CW Rotation

(FS) MEP-4x51 Two-Position Control, CW Leg (Four-Wire)

~24 V

Power Supply

~/+

–

24 V AC/VDC

MEP-4xx1/4x13 Tri-State Wiring Conguration

• Fail-safe MEP-4x51 and fast-acting MEP-4x01

models have selector switches to the left of the

terminal block. See the MEP-4200/4500/4900 Se-

ries Installation Guide or MEP-4201/4501/4901

Installation Guide for more information.

Selector

Switches

(Under Conduit Fitting)

Aux. Switch

Cable

Power/Signal

Terminal Block

Power/Signal

Cable

See the MEP-4200/4500/4900 Series Installation

MEP-42xx/45xx/49xx Options

Guide for more information.

MEP-4xxx Direct-Coupled Actuators (40 to 90 in-lb.) 11 Applications Guide, AN0513A Rev. J

Page 12

Auxiliary Switch (MEP-4x2x/4x7x)

Actuator Shown

At 45° Rotation

Rotation

Indication

(45–90°)

Auxiliary

Switch

Setting

Dial

Actuator Rotation and (MEP-497x) Auxiliary Switch Dial

Rotation

Indication

(0–45°)

Method 2 (Setting where Rotation Trips)

1. While pressing the gear disengagement lever,

rotate the actuator to the point where the

auxiliary switch should trip.

2. Using a small, at-bade screwdriver, adjust the

rotary dial to “0”. For example, if the switch is

set to trip (dial at “0”) when the actuator rotation

position is at 45°, then Red connects to Black

from 0° to 45°, and Red connects to Blue from

45° to 90°. As the actuator rotates, the switch dial

arrow points to the current switch position (Red

connected to Blue vs. Red connected to Black).

3. Wire the desired auxiliary device(s) to the cable.

NOTE: In this method, if the dial is set to “90”

instead of “0” in Step 2, switch connections

will be reversed.

NOTE: On MEP-497x models, a second switch is

xed at 10° from full CW direction (Brown

is connected to Orange in the 0–10° range,

and Brown is connected to Yellow 11–90°).

The dial adjustment has no eect on it. (The

auxiliary switch cable is the left-hand cable,

looking from the top.)

In MEP-4x2x/4x7x models, the adjustable auxiliary

SPDT switch can be set to trip anywhere between 0°

(full CW rotation position) and 90° (full CCW). To

adjust the auxiliary switch position, two dierent

methods can be followed. (Method 2 is generally

more precise.)

Method 1 (Setting Desired Dial Degrees)

1. While pressing the gear disengagement lever,

rotate the actuator to the full clockwise position

(0°).

2. Using a small, at-bade screwdriver, adjust the

rotary dial to the desired number of degrees (as

shown on the dial) at which the switch should

trip. For example, if the switch is set to trip at 45°

(dial halfway between 0° and 90° when actuator

is at full CW position), then Red connects

to Black from 0° to 45°, and Red connects to

Blue from 45° to 90°. As the actuator rotates,

the switch dial arrow points to the current

switch position (Red connected to Blue vs. Red

connected to Black).

3. Wire the desired auxiliary device(s) to the cable.

MEP-4xxx Direct-Coupled Actuators (40 to 90 in-lb.) 12 Applications Guide, AN0513A Rev. J

Page 13

Index

Fail-Safe Direction (MEP-42/45/49xx)

OAD

Fail-Safe

MEP-4xxx

24 V AC

All fail-safe MEP-42xx/45xx/49xx models oer

selectable clockwise or counterclockwise direction.

(Proportional and tri-state models also oer the option to turn the fail-safe o—usually temporarily for

test purposes.) Using a small, at-bade screwdriver,

adjust the switch dial to the desired CW/OFF/CCW

option.

BAS

Symbols

0-5/0-10 vs. 1-5/2-10 VDC Feedback: 10

0-10 vs. 2-10 VDC Inputs: 10

A

Accessories: 5

Applications: 4

Auto-Mapping: 10

Auxiliary Switch: 9, 12

B

Brackets, Non-Rotation: 7

C

Cable: 6

Conduit Fitting: 6

Configuration: 10

Cooling: 4

Cord Grip: 6

Crank Arm Kit: 5

CTE-5202: 4, 7

Fail-Safe Direction Switch Dial

NOTE: After initial connection or reconnection

to power on MEP-42x2/45x2/49x2

proportional models, proper fail-safe

operation might be delayed up to 30

seconds (until the capacitors are fully

charged).

D

Damper Torque: 4

Direction: 9, 10, 11, 12

E

Enclosure Kit: 6

F

Fail-Safe: 9, 13

Feedback: 9, 10

H

HCO-1151: 6

Heating: 4

HLO-4001: 5

HMO-4001: 7

HMO-4002: 7

HMO-4004: 7

HMO-4521: 6

HPO-4001: 6

HPO-4051: 6

HPO-5073: 8

HPO-5074: 8

I

Important Notices: 3

Inputs: 10

MEP-4xxx Direct-Coupled Actuators (40 to 90 in-lb.) 13 Applications Guide, AN0513A Rev. J

Page 14

L

T

Line Voltage Precautions: 10

M

MEP-4x01: 11

MEP-4x2x: 12

MEP-4x7x: 12

MEP-4x13: 11

MEP-4x51: 11

MEP-4xx1: 11

MEP-4xx2: 10

MEP-4xxxV: 8

MEP-40x2/48x2: 10

MEP-40xx/48xx/425x/455x: 7

MEP-42xx/45xx/49xx: 10, 13

MEP-427x/457x/49xx: 7

MEP-497x: 12

MEP-4042: 3

MEP-4101: 3

MEP-4842: 3

Mounting: 7, 8

N

Non-Rotation Brackets: 7

O

OAD (Outside Air Damper): 13

P

Thermostat: 7

Torque Selection: 4

Transformers: 7

Tri-State/Two-Position: 11

Troubleshooting: 9

Two-Position Wiring: 11

Two-Wire vs. Three-Wire vs. Four-Wire for Two-Posi-

tion: 11

V

V Actuators: 8

Valves: 4, 8

Valves Mounting: 7, 8

VAV: 4

Voltage, Line, Precautions: 10

VTD-14xx: 5

VTD-0804: 5

W

Warnings: 10

Weather Shield Enclosure Kit: 6

Web Site: 3

Wiring: 10, 11

Wiring Kits: 6

X

XEE-6000 Series: 7

Proportional: 9, 10

Q

Quick-Mount MEP-4xxxV: 8

R

Rotation: 9, 11, 12

S

Stroke Range: 9

Support Files: 3

Switches

Auxiliary: 9, 12

Fail-Safe Direction: 9, 13

Feedback Voltage: 9

Rotation Direction: 9, 11

MEP-4xxx Direct-Coupled Actuators (40 to 90 in-lb.) 14 Applications Guide, AN0513A Rev. J

© 2017 KMC Controls, Inc. AN0513A Rev. J

KMC Controls

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

Fax 574.831.5252

www.kmccontrols.com

info@kmccontrols.com

Loading...

Loading...