Page 1

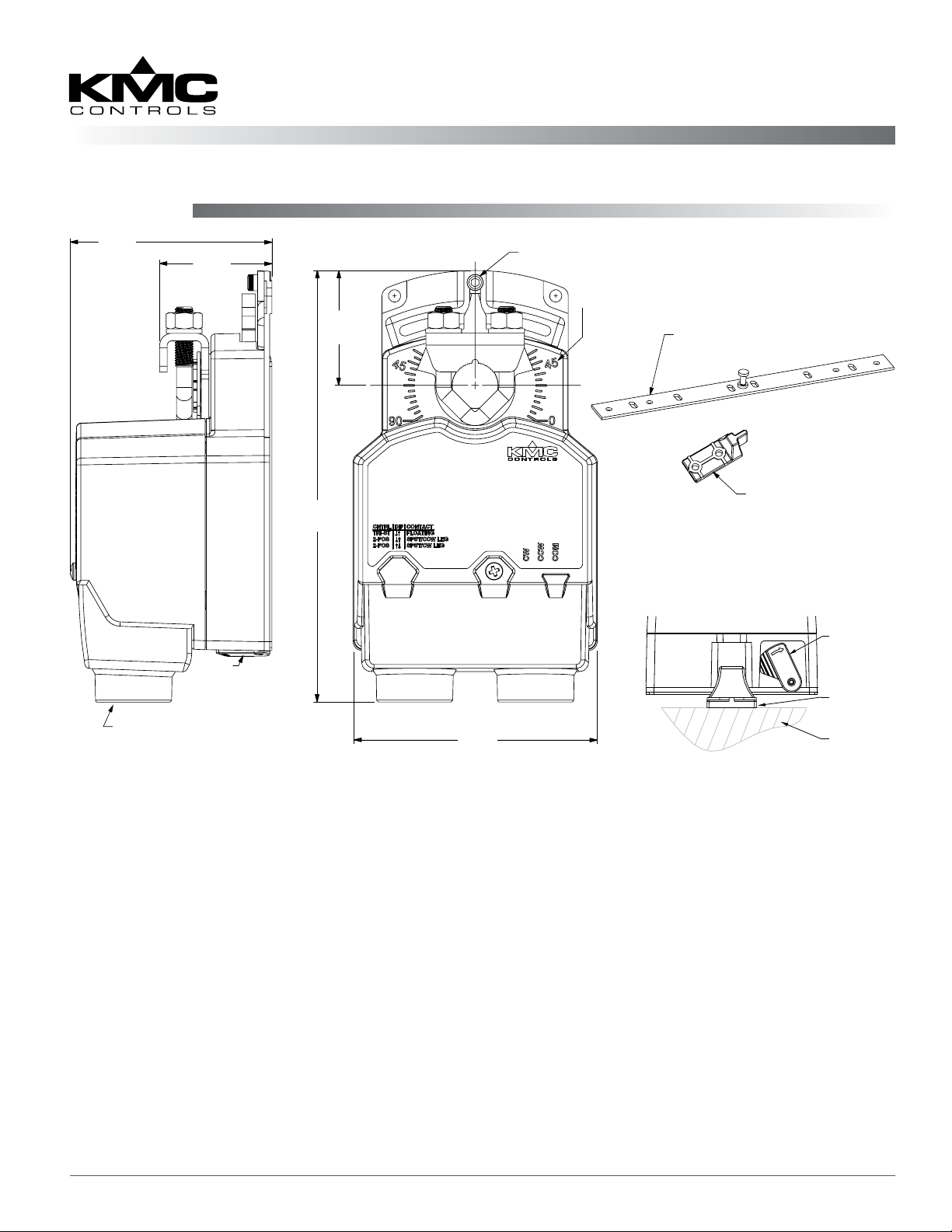

Mounting

2.812

(71.4)

1.563

(39.7)

Tri-State/Two-Position Actuators (25/45/90 in-lb.)

MEP-4201/4501/4901

Installation Guide

Adjustable

Stop

° Rotation

Indicators

1.625

(41.3)

6.000

(152.4)

HMO-4001 Non-Rotation “T”

Bracket included with MEP-4901

HMO-4002 Non-Rotation

Bracket included with

MEP-4201& MEP-4501

Gear

Disengagement

Lever

Removeable Conduit Fitting with

(2)1/2" NPS Threaded Holes (for

use with flexible conduit only)

Illustration 1—Overview (Direct-Coupled Mounting)

1. Ensure the damper can move freely through its

entire range of motion, and x any binding before

installing the actuator. Turn the damper blade to

its fully closed position.

2. Press (to the right) and hold the gear disengagement lever (see Illustration 1), rotate the actuator

to the fully closed position, and release the lever.

NOTE: Depending on the damper-seal design,

backing the actuator o its stop

approximately 5° may provide tight

damper shut-o.

3. Align the actuator and slide it onto the shaft.

4. Leaving a gap between the actuator and

mounting surface to prevent any binding, ngertighten the nuts on the V-bolt.

3.406

(86.5)

5. Insert the provided (HMO-4001/4002, dependent

on model) non-rotation bracket into the slot at the

base of the actuator and secure the non-rotation

bracket with two #8 or #10 self-tapping screws.

6. Evenly tighten the V-bolt nuts (30–35 in-lb.

on MEP-4201 model or 60–70 in-lb. on MEP4501/4901).

7. If desired, use a 7/64-inch hex key wrench to

loosen and position the end-stop screw.

NOTE: The two holes at the top of the actuator

are NOT for use in direct-coupled

applications. (They are for remote

mounting, such as with the optional

HLO-4001 Crank Arm Kit.) For mounting

to valves, see the appropriate valve

installation guide.

Gear

Disengagement

Lever

HMO-4002

Non-Rotation

Bracket

Mounting

Surface

MEP-4201/4501/4901 1 Installation Guide

Page 2

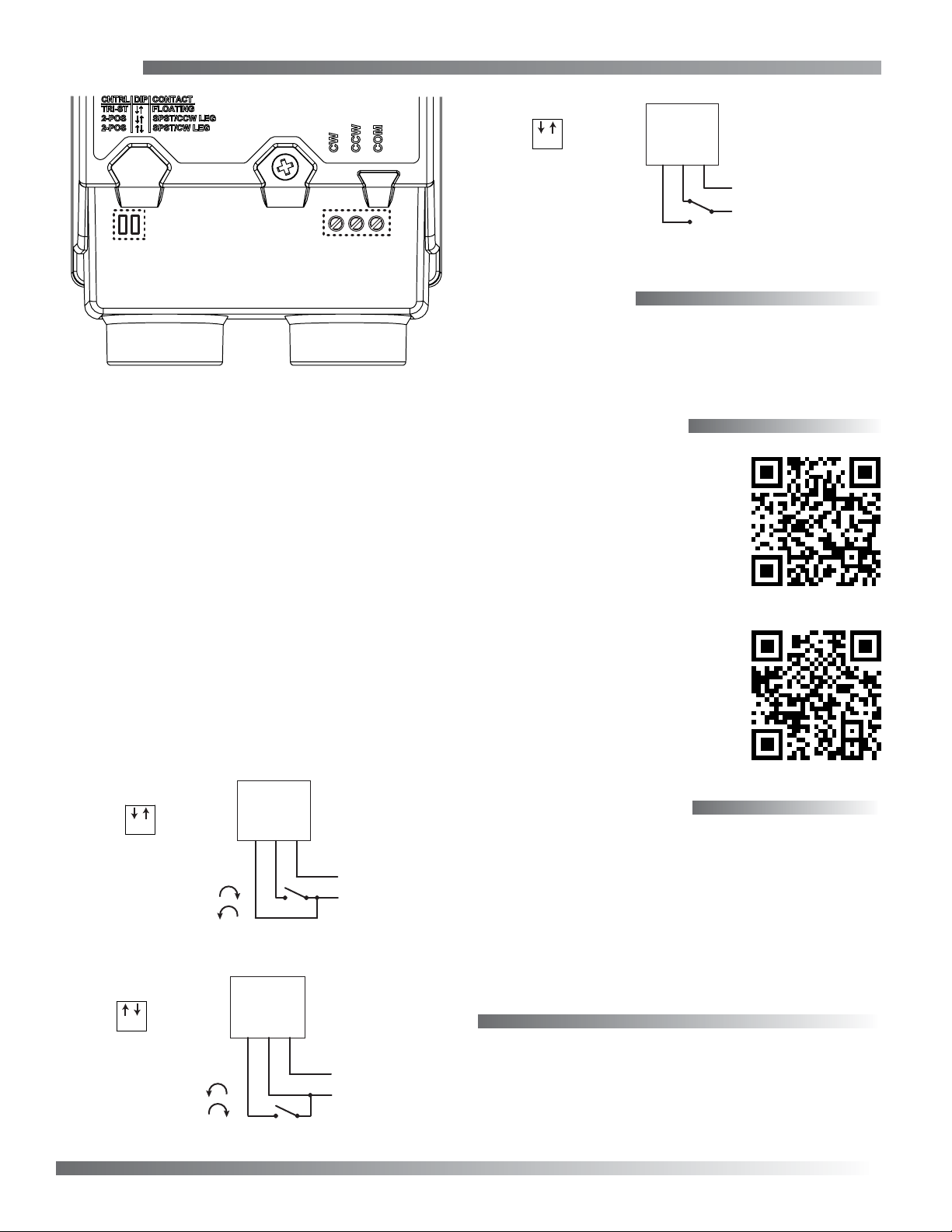

Wiring

Switch Position

Selector

Switches

(Under Conduit Fitting)

Power/Signal

Terminal Block

Illustration 2—Wiring Compartment

To wire the actuator:

1. Loosen the screw on the conduit ing and lift up

to remove the ing.

2. Using a utility knife or drill, cut the red plug

to accept wiring or replace the plug with an

application-specic ing.

NOTE: The red plug (or similar ing) protects

internal components from debris, helping

to ensure long actuator life.

3. Thread wires through the plugged opening and

connect to the terminal block according to the

relevant application. (See Illustrations 3 through

5.) Adjust the selector switch as needed.

4. Reinstall the conduit ing and tighten the screw.

1 2

CW

CCW

–

T

COM

–

Power Supply

24 VAC/VDC

~/+

Illustration 5—Tri-State Floating Point Control

Maintenance

No routine maintenance is required. Careful

installation will ensure long term reliability and

performance.

More Information

For models, specications, and

additional information, see

the MEP-4201/4501/4901 Data

Sheet on the KMC web site.

For accessories, troubleshooting, torque selection, links to

sample applications, and other

information, see the MEP-4xxx

Applications Guide on the

KMC web site.

Switch Position

Important Notices

The material in this document is for information

1 2

CW

T

CCW

COM

purposes only. The contents and the product it

Contact Position:

Open = CW Rotation

Closed = CCW Rotation

Illustration 3—Two-Position Control (3-Wire), CCW Leg

–

Power Supply

24 VAC/VDC

~/+

describes are subject to change without notice.

KMC Controls, Inc. makes no representations or

warranties with respect to this document. In no event

shall KMC Controls, Inc. be liable for any damages,

direct or incidental, arising out of or related to the

Switch Position

1 2

CW

T

CCW

COM

use of this document.

KMC Controls, Inc.

Contact Position:

Open = CCW Rotation

Closed = CW Rotation

Illustration 4—Two-Position Control (3-Wire), CW Leg

MEP-4201/4501/4901 2 Installation Guide

© 2014 KMC Controls, Inc. 039-019-02C

–

Power Supply

24 VAC/VDC

~/+

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com; info@kmccontrols.com

Loading...

Loading...