Page 1

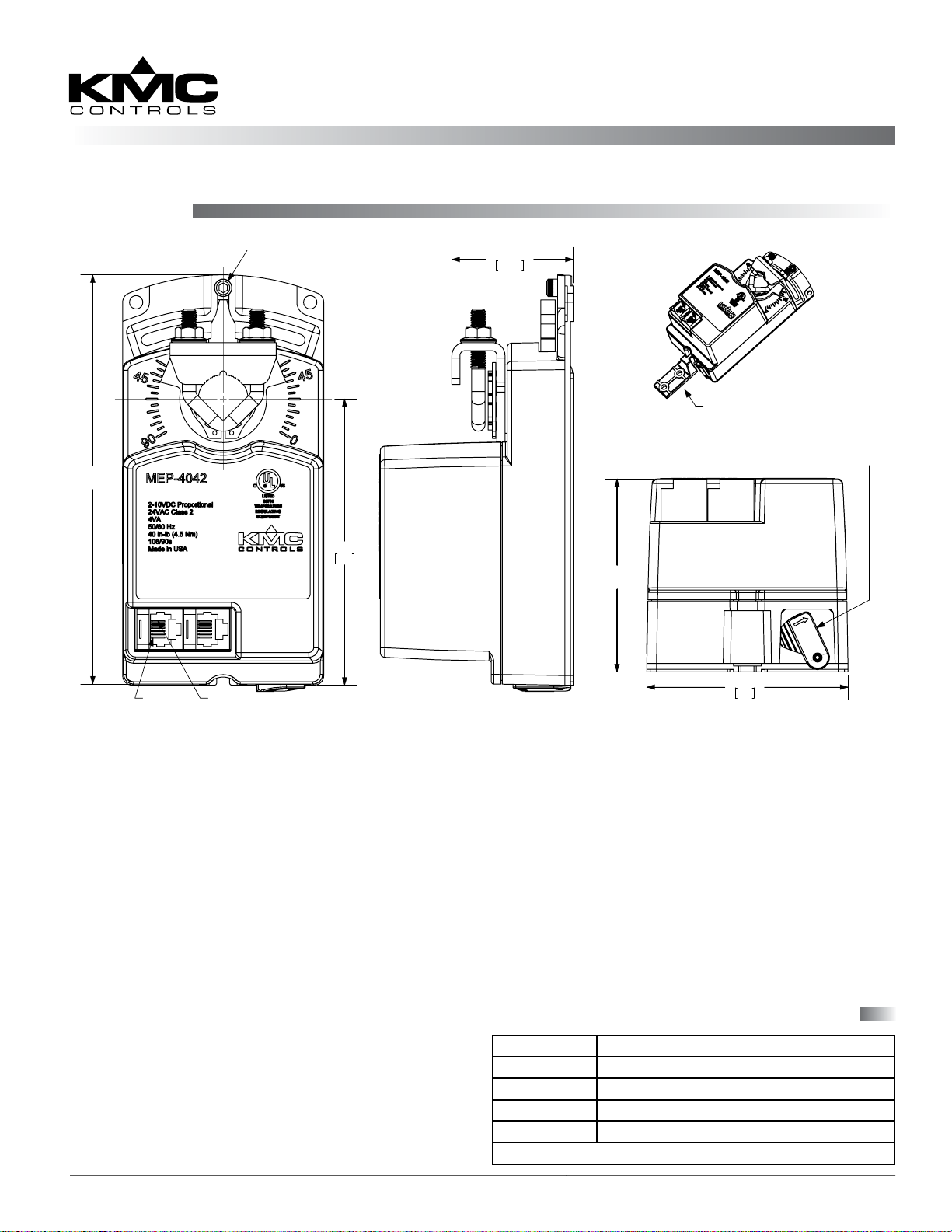

Mounting

Direct-Coupled ControlSet® Actuators (40/80 in-lb.)

MEP-4042/4842

Installation Guide

5.300

[135]

PIN 1

PIN 6

ADJUSTABLE

STOP

3.700

94

1.568

39.8

2.500

[63.5]

NON-ROTATION BRACKET

PROVIDED (HMO-4002)

GEAR DISENGAGEMENT

2.600

66

LEVER

1. Ensure the damper can move freely through its

entire range of motion, and x any binding before

installing the actuator. Turn the damper blade to

its fully closed position.

2. Press (to the right) and hold the gear

disengagement lever (see the illustration above),

rotate the actuator to the fully closed position,

and release the lever.

NOTE: Depending on the damper-seal design,

backing the actuator o its stop

approximately 5° may provide tight

damper shut-o.

3. Align the actuator and slide it onto the shaft.

4. Leaving a gap between the actuator and

mounting surface to prevent any binding, ngertighten the nuts on the V-bolt.

5. Insert the non-rotation bracket (HMO-4002

supplied or HMO-4001 “T” bracket available

separately) into the slot at the base of the actuator.

(See the illustration above).

6. Secure the non-rotation bracket with two (2) #8 or

#10 self-tapping screws.

7. Evenly tighten the V-bolt nuts 30 to 35 in-lbs. on

the MEP-4042, or 60 to 70 in-lbs. on the MEP-4842.

8. If desired, use a 7/64-inch hex key wrench to

loosen and position the end-stop screw.

NOTE: The two holes at the top of the actuator

are NOT for use in direct-coupled

applications. They are for remote mounting,

such as with the optional HLO-4001 Crank

Arm Kit (see the installation guide for the

MEP-4000/4800 series actuators).

Connector Pin Voltage Reference

Connector Pins* Function

1 and 6 ~ 24 VAC (phase side)

2 and 5 Common

3 17.4 VDC out @ 10 mA Max. (powers CTE-5201-16)

4 Signal input (2–10 VDC)

*See the pin designators in the lower left of the illustration above.

MEP-4042/4842 1 Installation Guide

Page 2

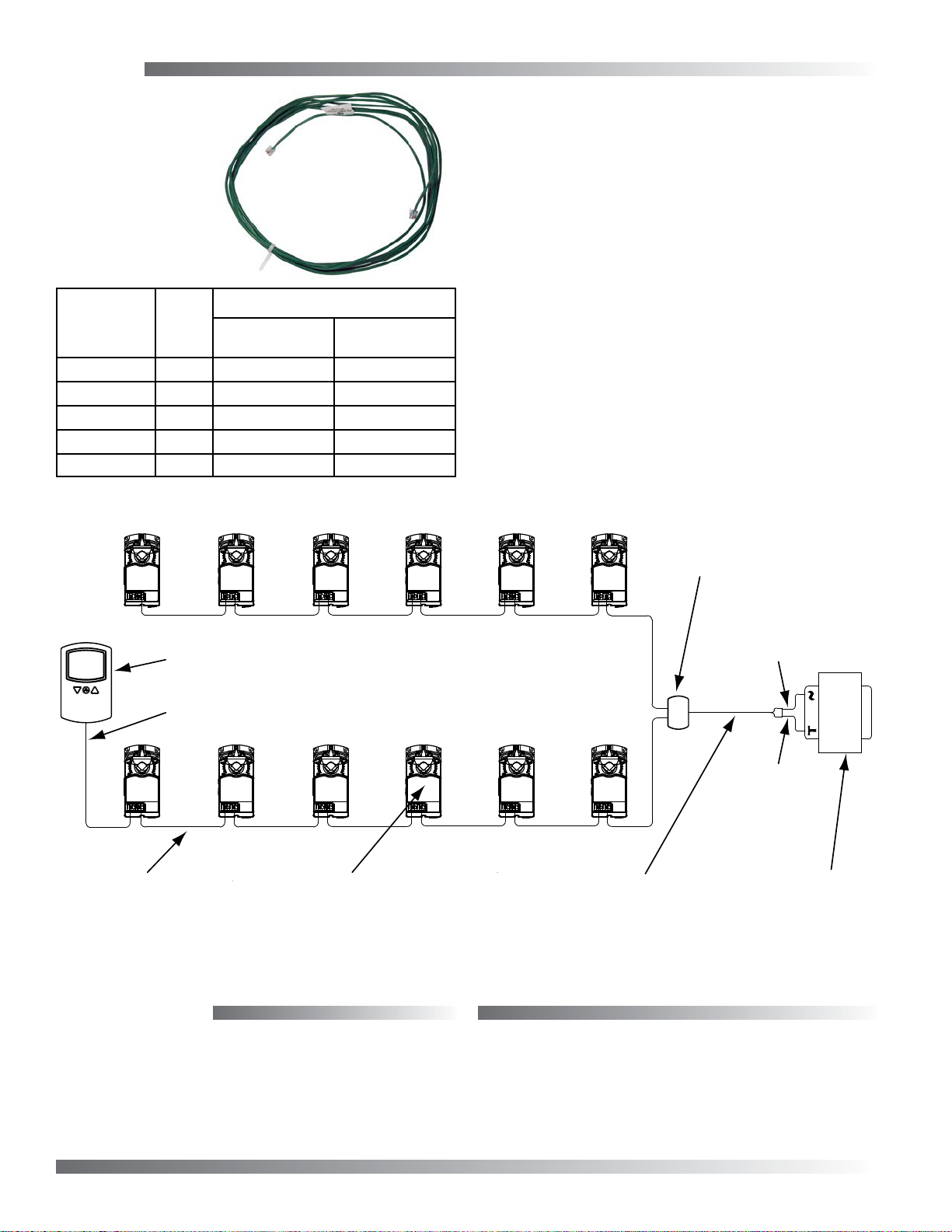

Wiring

Use HSO-22xx

cables to connect

the actuators,

using the modular

connectors, as

shown in the

chart and sample

application below.

Cable P/N

HSO-2203 3 feet 6 12

HSO-2206 6 feet 6 12

HSO-2212 12 feet 6 12

HSO-2220 20 feet 4 8

HSO-2250 50 feet 2 4

Cable

Length

Max. # of Daisy-Chained MEP-4x42s

WithOUT

HSO-5010

WITH

HSO-5010

NOTE: The transformer must have an internal

circuit breaker such as the XEE-6311-050

or equivalent 2.25 A external fuse in the

secondary circuit!

NOTE: See the table on the left for the maximum

number of actuators that may be daisy

chained for a given cable length. If an

HSO-5010 “Y” connector is used (as shown

below), the total number of actuators is

doubled (with half on each side of the

transformer). The example below shows

12 actuators with HSO-2212 cables and an

HSO-5010.

NOTE: For MEP-4042/4842 specications,

accessories, and additional important

information, see the data sheet. See also the

sample applications in the data sheets for

the BAC-5841/5842 and BAC-5841-16/5842-

16 of controllers.

HSO-5010 3-Way

“Y” Modular Connector

CTE-5201-16 Analog Electronic Thermostat

HSO-2250 Thermostat Cable, 50-foot (typical)

HSO-2212

actuator cable,

12-foot length

between actuators

Up to 6 MEP-4x42s

on each side

of the transformer

(with HSO-2212s)

Maintenance

No routine maintenance is required. The motors

are permanently lubricated and all internal geartrain components are oil-impregnated. Careful

installation will also ensure long term reliability and

performance.

Wires: Orange

& Orange Stripe

T

Wires: Green

& Green Stripe

HSO-2121

Transformer Cable

XEE-6xxx-xxx

Transformer

24 VAC (+20/–15),

4 VA Per Actuator

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com; info@kmccontrols.com

MEP-4042/4842 2 Installation Guide© 2013 KMC Controls, Inc. 036-019-02xB

Loading...

Loading...