Page 1

Thermic 2-Position or Time-Proportional Actuators

1

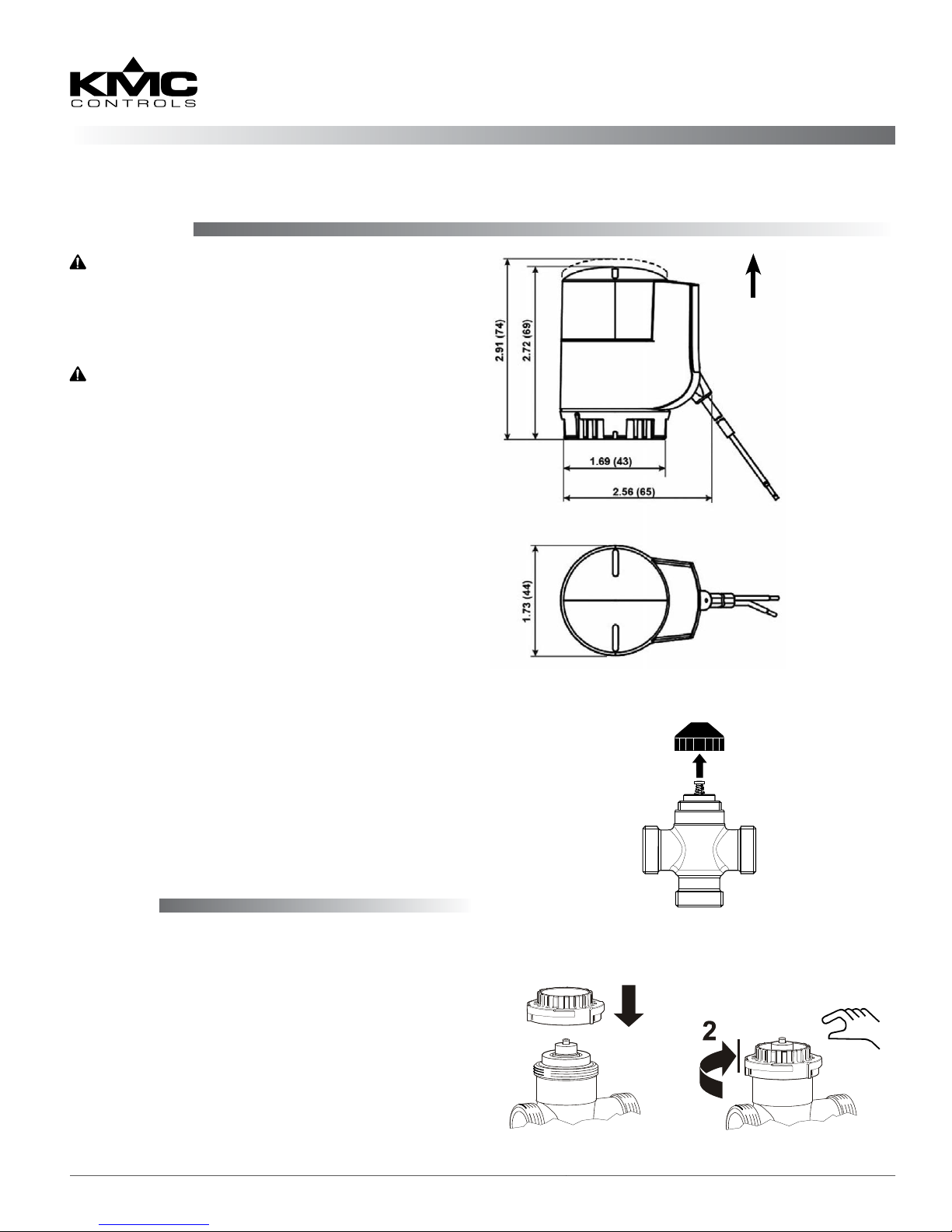

MEP-3001 (for VEP-12/22/34) and MEP-3006 (for VEP-11/21/37)

Installation and Operation Guide

Mounting

CAUTION

If mounting the actuator to a valve already in-line,

close the shut-off valves in the piping (upstream

first, then downstream) or switch off the pump to

allow the differential pressure in the valve to drop.

CAUTION

To prevent condensation from dripping onto the

actuator housing, mount the valve with the actuator

in the upright position or, at most, at a 45° angle.

1a. On a new valve body, remove the protective cap

covering the bonnet. (See Illustration 2.)

1b. To remove an existing (same model) actuator,

disconnect the wiring, wait at least six minutes

until the actuator has completely cooled, turn

the actuator bayonet ring (coupling piece)

counterclockwise until it is loose, and pull o the

actuator. Also unscrew the old black bayonet nut

if it stays on.

UP

Brown to 24 VAC Phase

Blue to 24 VAC Neutral

2a. If the new black bayonet nut is loose from the

new actuator, screw it on top of the valve body

and rmly hand-tighten (only). (See Illustration

3.) Then place the actuator over it and turn the

actuator bayonet ring clockwise until it is hand-

tight and locks into place.

2b. If the new black bayonet nut is rmly aached

inside the actuator, screw the entire actuator on

top of the valve body until it is hand-tight and

locks into place.

Wiring

Connect the brown wire to the phase side of 24 VAC

and the blue wire to neutral. (See Illustration 1.)

For two-position control, a simple switch or relay

can be used. For time-proportional (pulse-width

modulation) control, use a KMC REE-5017 or

REE-4106/5106 relay module. (See the relevant relay

module documentation for more information.)

NOTE: All wiring must conform to NEC and

local codes and regulations. Use a Class 2

transformer.

Illustration 1—Dimensions and Wiring

Illustration 2—Removing a Protective Cap

Illustration 3—Installing the Black Bayonet Nut

MEP-3001/3006 1 Installation and Operation Guide

Page 2

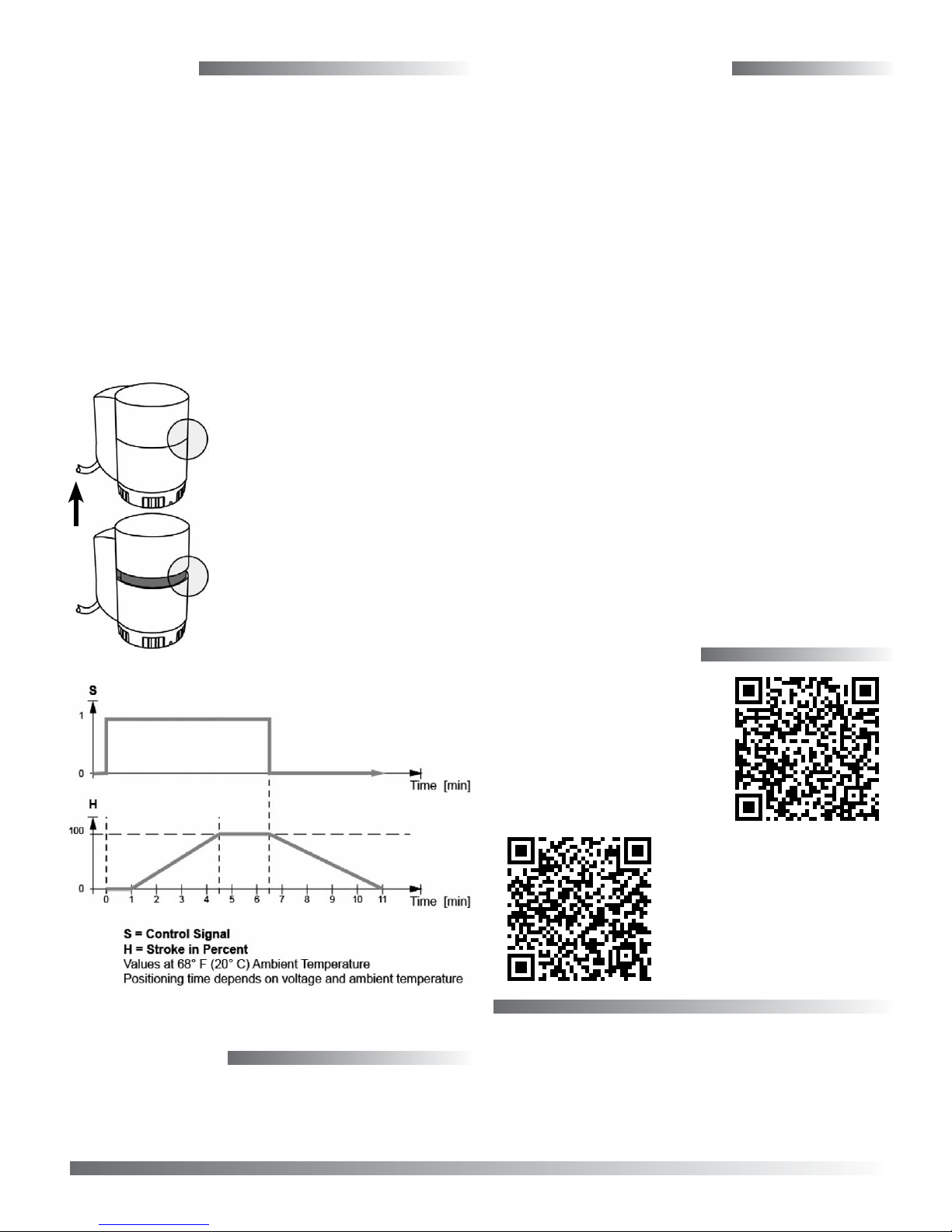

Operation

Select Specifications

After the mechanical and electrical installations have

been completed, cycle the actuator to verify opera-

tion. (See Illustrations 4 and 5.)

When power is applied to the actuator, the temperature of the heating element rises, causing the

solid expansion medium to expand and stroke the

aached valve body. The valve starts to open after

preheating for approximately 1 minute if the heating

element is switched on in a cold (room temperature)

state, and achieves the maximum stroke after (ap-

proximately) another 3-1/2 minutes. At power-o,

the expansion element cools down, and the spring

closes the valve.

De-energized position (gap closed):

• For MEP-3001s, the actuator shaft

is extended and the valve is closed.

• For MEP-3006s, the actuator shaft

is retracted and the valve is open.

(Fully) energized position (gap open):

UP

Illustration 4—Position Indication

• The MEP-3001 has been connected

to the power supply for at least

4-1/2 minutes. The actuator shaft is

retracted and the valve is open.

• The MEP-3006 has been connected

to the power supply for at least

4-1/2 minutes. The actuator shaft is

extended and the valve is closed.

Power 24 VAC (± 20%), 50/60 Hz,

Class 2 only, 6 VA max.

Control Two-position or time-propor-

tional

Primary Fuse Must supply externally

Nominal Force 22.5 in-lb. (100 N•m)

Stroke Maximum 0.18 inches (4.5 mm)

Positioning Time 270 sec. @ 68° F (20° C)

Weight 0.4 lb. (0.18 kg)

Mounting Location NEMA 3 (IP54), interior only

Approvals Conforms to CE requirements

De-energized Position

MEP-3001 (NC) Actuator shaft extended, valve

closed (for VEP-12/22/34 se-

ries)

MEP-3006 (NO) Actuator shaft retracted, valve

open (for VEP-11/21/37 series)

Temperature Limits

Medium 34 to 230° F (1 to 110° C)

Ambient 41 to 122° F (5 to 50° C) @ 0 to

85% RH (non-condensing)

Shipping –4 to 140° F (–20 to 60° C) @ 0

to 95% RH (non-condensing)

More Information

For more information

on applications, see the

REE-5017 on the KMC

web site.

Illustration 5—Opening and Closing Times

Maintenance

These actuators are noise-free and maintenance-free.

Careful installation will help ensure long-term reli-

ability and performance.

MEP-3001/3006 2 Installation and Operation Guide

© 2014 KMC Controls, Inc. 006-019-01A

See also, the REE-5106.

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com; info@kmccontrols.com

Loading...

Loading...