Page 1

Installation Guide

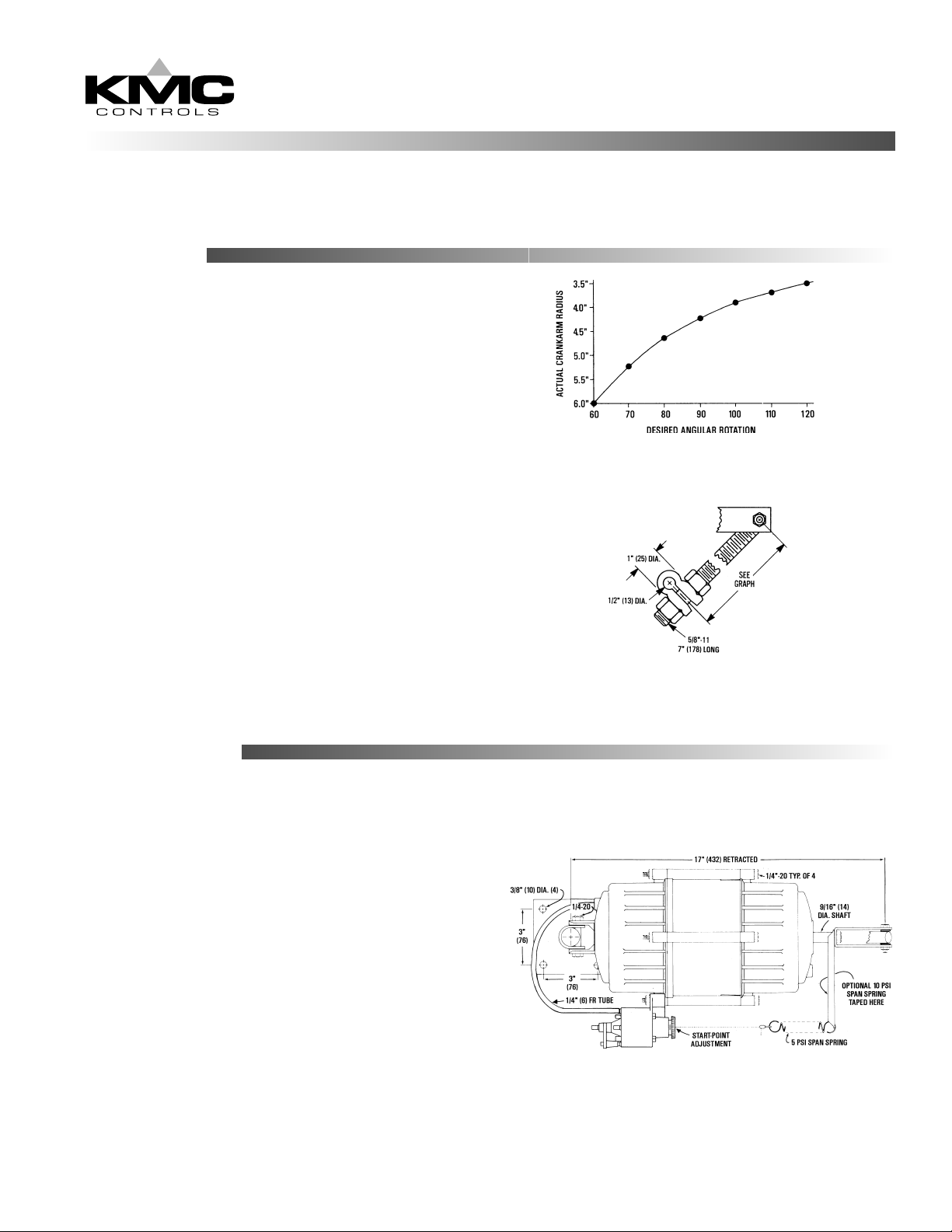

Mounting

The MCP-1160 MUST be mounted on a rigid

surface due to the force generated at, or near,

maximum air pressure.

1. Align the actuator with the controlled device.

The mounting joint allows the actuator to be

located in a different plane from the controlled

device.

2. Attach the actuator to the rigid surface through

the four 3/8" (4 mm) holes in the mounting

bracket.

3. Adjust the crankarm assembly from 60° to 120°

rotation as required.

6” Pneumatic Damper Actuator

MCP-1160 Series

4. DO NOT tighten the universal joint. The

actuator must be free to swivel as it operates.

Connections

MCP-1160 models ordered with positioners are

factory piped.

♦ Use 1/4" (6 mm) O.D. FR polyethlyene tubing.

♦ Use only clean, dry control air. No attempt

should be made to use any other medium.

1 Connect the actuator input to the positioner

output, Port “1”.

2. Connect the input signal to the positioner to Port

“2”.

3. Connect the main air (20 psi) to the center port.

NOTE: If the application requires operation near

the maximum temperature and maximum

pressure, add a tubing restraint to the actuator

connection.

Page 2

Adjustments and Calibration

DANGER

The MCP-1160 contains a large powerful spring.

Exercise extreme caution if disassembly is required.

The actuator shaft MUST be restrained to prevent

the spring from expanding.

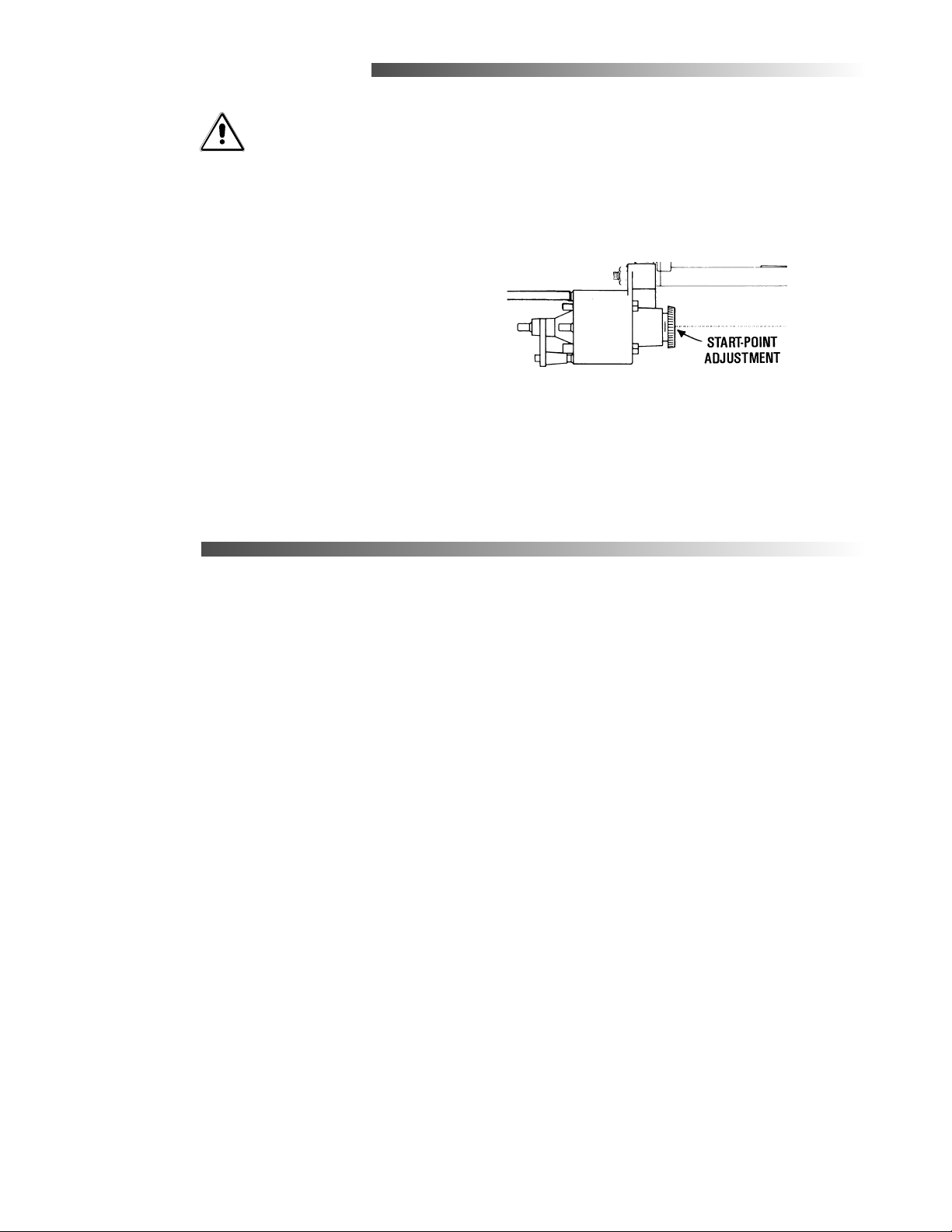

The MCP-1160 contains an 8-13 psi spring. A

positioner allows the unit to operate over any 5 psi

span with the start-point adjustable from 3-10 psi.

Replace the 5 psi spring with a 10 psi spring to widen

the span.

To change the positioner start-point:

1. Apply the desired signal pressure

2. Rotate the start-point adjuster until the actuator

starts to stroke.

Maintenance

The MCP-1160 actuator is designed for long term

reliability. No routine maintenance is required,

however care should be taken during any installation

or maintenance due to the power of the actuator.

KMC Controls

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www. kmccontrols.com

016-019-01

Loading...

Loading...