KMC Controls KMD-7001, KMD-7052, KMD-7051, KMD-7053, KMD-7003 Installation & Operation Manual

...Page 1

Installation & Operation Guide

Direct Digital VAV Controllers

KMD-7001/7051 - VAV Terminal Units

KMD-7002/7052 - Dual Duct VAV Units

KMD-7003/7053 - Fan Induction Units

907-019-01C

1

Page 2

Introduction

This section provides a brief overview of the KMD-7001, 7002 and 7003 Direct

Digital Controllers. These units are intended for use with standard 1/2” round or

3/8” square damper shafts.

Note:

For installations using a 3/8” round shaft, you will need the HFO-0011 shaft

adaptor.

Review this material before you attempt to install the controller.

Non-Rotational Bracket

Conduit

Plugs

Lock

Ta b

Removable

Conduit Plate

Access Cover

Gear Disengagement

Button

Drive Hub

Illustration 1. Controller Components

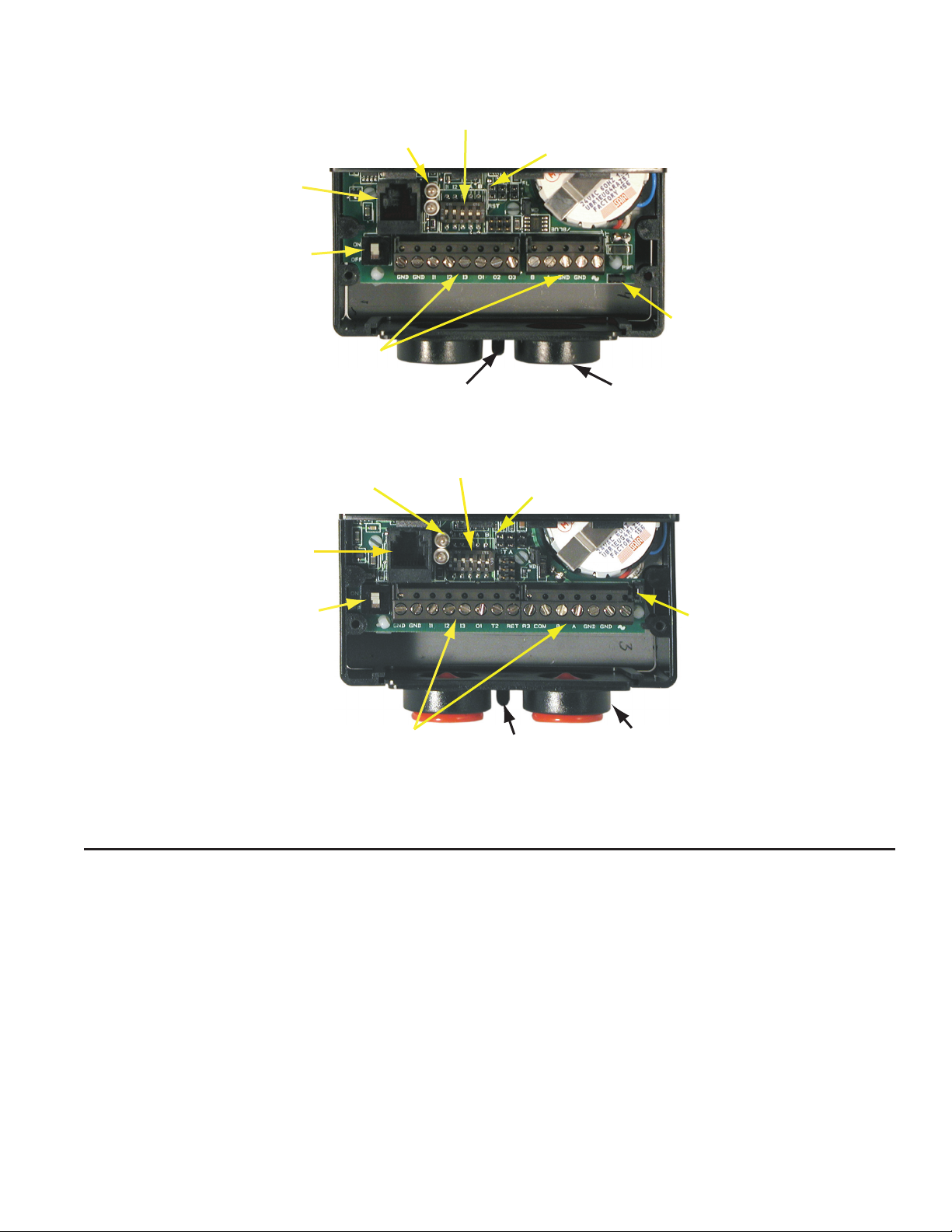

The following illustrations show the different model connection details.

Air Sensor Inputs

Status

LEDs

Isolation

Lamps

RJ-12

Conn.

Network

Switch

Terminal Connections

Input/EOL

Switches

RST Jumper

Power

Jumper

Conduit

Plate

Lock Tab

Illustration 2. KMD-7001 Controller Connector Detail

2

Page 3

Isolation Lamps

RJ–12

Conn.

Network

Switch

Terminal Connections

Illustration 3. KMD-7002 Controller Connector Detail

Lock Tab

Input/EOL

Switches

RST Jumper

Power

Jumper

Conduit

Plate

Installation

Isolation

Lamps

RJ–12

Conn.

Network

Switch

Terminal Connections

Input/EOL

Switches

RST Jumper

Lock Tab

Power

Jumper

Conduit

Plate

Illustration 4. KMD-7003 Controller Connector Detail

This section provides important instructions and guidelines for installing the

KMD-7001, 7002 and 7003 series controllers. Carefully review this information

prior to attempting installation.

Preparation

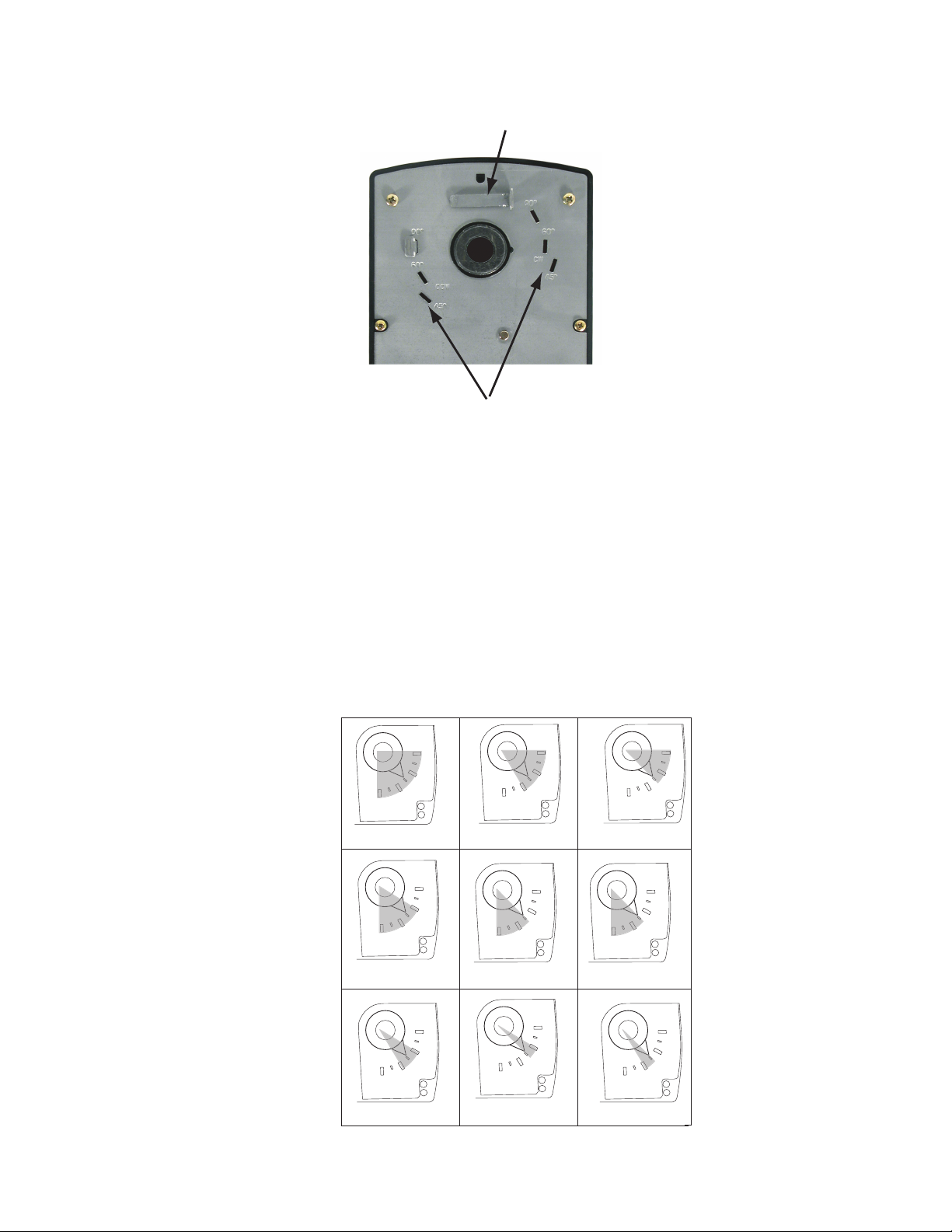

Prior to mounting the controller, the rotational limits must be set using stop pins.

These settings limit the shaft rotation in the clockwise (CW) and counterclockwise (CCW) directions. (Refer to Illustration 5.)

3

Page 4

90/90

5/90

90/

90/45

90/45

45/60

Installation KMD-7001/7002/7003 Direct Digital Controller Installation & Operation Guide

Stop Pin

(1 of 2)

Stop Selections

Illustration 5. Controller Stop Selections

To set the rotational limits:

1. Turn the controller over so you have access to the back.

2. Locate the two stop pins installed in the back of the unit. (You will find one

pin in a CCW setting and one in a CW setting.)

3. Identify the limits you wish to use.

The maximum amount of shaft rotation is 90°. Placing a stop pin in both 90°

slots allows the actuator the full 90° of travel. Placing a stop pin in any other slot

restricts actuator motion in the indicated direction (CW or CCW). Refer to

Illustration 6 for pin placement and travel. The first number represents the CCW

pin and the second the CW pin (CCW/CW).

60/90

4

60

60/60

Illustration 6. Controller Travel and Stop Selections

4

60/45

Page 5

KMD-7001/7002/7003 Direct Digital Controller Installation & Operation Guide Installation

Caution

Both stop pins must be installed to prevent actuator damage.

4. If the stop pins are positioned as required, you may leave them in place. If

not, remove the appropriate pin(s) and place it in the correct slot.

Mounting

The controller will be mounted directly over the damper shaft. A minimum shaft

length of 1-3/4” (45 mm) is required. The base of the controller must contact the

mounting surface to allow installation of a bracket to prevent the controller from

rotating.

Note:

The controller should be mounted close enough to the Pitot tubes to allow a

maximumn 24” length of tubing to reach the controller inputs.

Proceed as follows:

1. Back out the set screws in the shaft collar so the shaft can fit through the collar.

2. Place the controller on the damper shaft in the approximate final position.

3. Position the non-rotation bracket and secure it using #8 or #10 self-tapping

screws. Make certain the notch in the bracket securely engages the Lock tab

on the controller. (Refer to Illustration 1.)

4. Manually position the damper in the full open position.

5. Adjust the drive hub as follows:

A. If the damper rotates counter clockwise to close, depress the gear disengagement button and rotate the drive hub to the full clockwise position

then release the button.

B. If the damper rotates clockwise to close, depress the gear disengagement

button and rotate the drive hub to the full counter clockwise position then

release the button.

6. Tighten the two set screws in the drive hub to approximately 50–inch pounds

(5.65 N-m) to lock the hub to the shaft.

Wiring

The controller comes with a removable conduit plate. The plate provides two

1/2” female threaded conduit couplings. If conduit is to be used, note the

following:

◆ The conduit plate may be removed by removing the two screws that secure

the access cover and removing the cover. Connect the required conduit and

replace the plate in the controller housing.

◆ The plugs may also be sliced to allow wiring to enter the controller with a

minimum of outside contaminates.

5

Page 6

Installation KMD-7001/7002/7003 Direct Digital Controller Installation & Operation Guide

Input Connections

All input and output connections are made using the connectors beneath the

access cover. Remove the two screws that secure this cover to remove the cover

and complete input and output connections as discussed below.

Universal Inputs

Inputs are configured per the model.

7001/7051 and 7003/7053

Inputs are connected to the wire terminal strip using connections I1–I3. Observe

the following guidelines. (Refer to Illustration 2 and 4.)

◆ Connect device inputs to the input terminal connections for inputs I1–I3.

◆ Connect all grounds to the common GND reference terminals.

◆ If input pull-ups are required, refer to “Board Configuration” later in this

section.

Note:

RS-485 Inputs

Input #1 (I1) is typically assigned to the space temperature sensor input, otherwise it is available for use. Inputs 2 and 3 are available for optional inputs.

7002/7052

These inputs are the same as on the 7001/7003 series except for Input #3 (I3). The

I3 input on these models is dedicated to the TSP Slave Flow Sensor input. (Refer

to Illustration 3.)

To make connections to a KMC Tier 2 (RS-485) network use the RS-485 connections on the terminal strip. If the Controller is at the End-of-Line, refer to “Configuration” after connections are completed.

Detail

The End-of-Line connection will have only one wire attached to the A and B

terminals.

◆ For reliable operation, use Belden cable model #82760 or equivalent (18 gauge,

twisted, shielded, 50 picofarads or less) for all network terminal block connections.

◆ Connect the nodes of the network in a daisy-chain arrangement. This means:

Connect the A terminal in parallel with all other A terminals.

Connect the B terminal in parallel with all other B terminals.

◆ Connect the shields of the cable together at each controller.

◆ Connect the shield drain wire to an earth ground only at one end of the

segment; tape back the shield ground at the other end.

6

Page 7

KMD-7001/7002/7003 Direct Digital Controller Installation & Operation Guide Installation

Airflow Sensor

An Airflow Sensor is incorporated as one of the inputs to the controller. Remove

the plugs and connect the tubing from the Pitot assembly to the airflow sensor

inputs above the drive hub. (Refer to Illustration 1.)

Connecting Outputs

The Controller provides three output connection options configured according to

the model. Locate your model from the units discussed below:

7001/7051 and 7002/7052

These models provide three universal outputs O1, O2 and O3. They will provide

0/12 VDC at a maximum of 50 mA in Digital mode or 0-10 VDC at a maximum

of 30 mA in Analog mode. Returns are connected to the GND connections on the

left end of the strip. (Refer to Illustration 2 and 3.)

7003/7053

These models are unique as described below: (Refer to Illustration 4.)

Out 1 – This is a universal output that may be used as an output option. Output

ratings are the same as on the other models.

T2 – This Triac output will switch a maximum voltage of 30 VAC. It is rated for a

minimum current of 20 mA and a maximum of 1A. Use the RET terminal for

the triac return.

R3 – This output is assigned as the Normally Open Relay Output. The output

will switch up to 30 VAC/DC at up to 2A maximum. The return connects to the

COM terminal.

RJ-12

An RJ–12 connector is provided for connection to the KMD-1001 NetView or the

KMD-11xx Series NetSensor or a PC. Simply place the appropriate cable connector in the provided RJ–12 connector and connect the other end to the device.

Board Configuration

Configuration settings may be required for the inputs or the RS-485 connection.

If you must activate or deactivate pull-ups on the inputs or set the end-of-line

termination for the RS-485 connection, refer to Illustration 7 to locate the

switches for these settings.

7

Page 8

Installation KMD-7001/7002/7003 Direct Digital Controller Installation & Operation Guide

RJ–12

Conn.

Illustration 7. Typical Input Pull-up and EOL Switch Placement

Input Pull-Up/EOL

Switches

Proceed as follows:

1. If the access cover is still on the controller, remove the two screws that

secure the cover, then remove the cover.

2. Locate the switch next to the isolation lamps behind the terminal strip. (See

Illustrations 4.)

3. Set the switches as follows:

A. If the RS-485 connection is the End-of-Line controller, verify that both

switches 4 & 5 (A & B) are in the ON position. Otherwise, the switches

remain in the default “OFF” position.

B. If one or more inputs require a pull-up, verify that the appropriate

switches (I1–I3) is set to the default “ON” position. For devices supplying their own voltage/current for passive devices, move the switch to

the “OFF” position.

4. After you set the switches, replace the controller cover and secure it with

Power Connection

Connect the 24 VAC supply voltage to the power terminal block on the lower

right side of the controller near the PWR jumper. Connect the GND side of the

transformer to the GND terminal and the AC Phase side to the AC terminal.

Power is applied to the controller when the power supply (or transformer) is

plugged in and the PWR jumper is in place. Illustration 7 shows a typical connection diagram for the controller.

the screws you removed earlier.

8

Page 9

KMD-7001/7002/7003 Direct Digital Controller Installation & Operation Guide Installation

KMD-7003

REHEAT

RET

T2 R3

SERIES FAN

START CIRCUIT

FAN

COM

GNDBA

W

R

H

HWR

APPLICATION DRAWING FOR KMD-7003

VAV WITH FAN AND WET REHEAT

FROM PREVIOUS DEVICE "B"

FROM PREVIOUS DEVICE "A"

TO NEXT DEVICE "B"

TO NEXT DEVICE "A"

24VAC 120VAC

24VAC THERMAL

ACTUATOR

B

*

HWS

(OPTIONAL IN PLACE

OF NETSENSOR)

24" OF 1/4" TUBING

SSS-1000

Room ˚F

FLOW

NETSENSOR

KMD-1151 / KMD-1171

STE-5013

H

Min 0

Max 1

V. FCTR

MAXC. FCTRMIN

FLOW

RJ-12 PC/NETSENSOR PORT

L

6-CONDUCTOR CABLE

ROOMTEMP

GNDGND

IN1 IN2

IN3 OUT1

B

A

C

READY

L

H

COMMUNICATIONS

KMDIGITAL

KMC

ONTROLLER

IR

ARIABLE

OLUME

C

AVV

KMD-7003

*For electric reheat applications, use a separate 24 VAC transformer to isolate the relay through the Triac.

Illustration 8. Typical KMD-7003 Application

Note:

Typical Application Diagrams may be obtained by contacting KMC Controls

Technical Support at 574-831-5250 or e-mail us at techs@kmccontrols.com.

Network Configuration

Prior to operating the controller, it must be configured using the Hardware

Configuration Manager (HCM) application supplied with WinControl. Refer to

the WinControl XL User’s Manual and the KMC Digital Applications Manual for

additional information.

Note:

All controllers on the same network must be configured for the same baud rate

and each controller assigned a unique address.

Programming

Refer to the KMC Digital Applications Manual for information on how to program the controller.

9

Page 10

Operation

Once configured, programmed and powered up, the controller requires very

little user intervention.

Controls and Indicators

The following sections describe the controls and indicators found on the

controller.

Network ON/OFF

The network ON/OFF switch is located near the RJ–12 connector. Use this switch

to enable or disable the RS-485 network connection. When the switch is ON the

controller can communicate on the network; when it is OFF, the controller is

isolated from the network.

Alternately, you may remove the Isolation Lamps to isolate the controller from

the network.

Status LEDs

Two Status LEDs are located on the left side of the controller above the power

connector terminal. They are used to indicate the following:

Ready – This LED flashes rapidly whenever the controller is operating normally.

You can consider this the same as a power LED.

Communications – This LED indicates when the controller is transmitting over

the RS-485 network connection.

Isolation Lamps

Two Isolation Lamps are located near the RJ–11 connector. These lamps serve

three functions:

◆ Removing the lamps will open the RS-485 circuit and isolate the controller

◆ If one, or both, lamps are lit, it indicates the network is improperly phased.

◆ If the voltage or current on the network exceeds safe levels, the lamps operate

from the network.

This means that the ground potential of the controller is not the same as other

controllers on the network

as fuses and may protect the controller from damage.

10

Page 11

KMD-7001/7002/7003 Direct Digital Controller Installation & Operation Guide Operation

Resetting the Controller

If the controller appears to be operating incorrectly, or is not responding to

commands, you may need to reset the controller.

Note

Resetting the controller will restore the factory default configuration.

It may be necessary to re-configure the controller with HCM to establish

normal communications and operation. Re-programming may also be required.

To reset the controller, proceed as follows.

1. Remove the two screws that secure the Access Cover, then remove the

cover.

2. Locate the jumper block next to the input pull-up switches (see Illustration

8).

RST

Jumper

Illustration 8. Reset (RST) Jumper Location

3. Power off the controller. (Remove the PWR jumper.)

4. Locate the RST pins and place a jumper across them.

5. Power up the controller. Wait until the Ready LED flashes normally.

6. Power off the controller.

7. Remove the jumper from the RST pins.

8. Replace the PWR jumper.

8. Replace the controller cover.

9. Re-configure the controller if necessary.

11

Page 12

Disclaimer

The material in this document is provided for information purposes only.

The contents and the product(s) described herein are subject to change

without notice. KMC Controls, Inc. makes no representations or warranties

with respect to this document. In no event shall KMC Controls, Inc. be

liable for any damages, direct or incidental, arising out of or related to the

use of this document.

Important Notices

The KMC logo is a trademark of KMC Controls, Inc.©2003, KMC Controls,

Inc. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any language in any form by

any means without the written permission of KMC Controls, Inc.Printed in

U.S.A.

Technical Support

If you have any questions about this technical document or need additional

details, please call KMC Controls technical services at 574-831-5250 or email us at techs@kmccontrols.com.

12

KMC Controls

P.O. Box 497

19476 Industrial Drive

New Paris, IN 46553

U.S.A.

TEL: 574.831.5250

FAX: 574.831.5252

E-mail: info@kmccontrols.com

907-019-01C

Loading...

Loading...