Page 1

Installation & Operation Guide

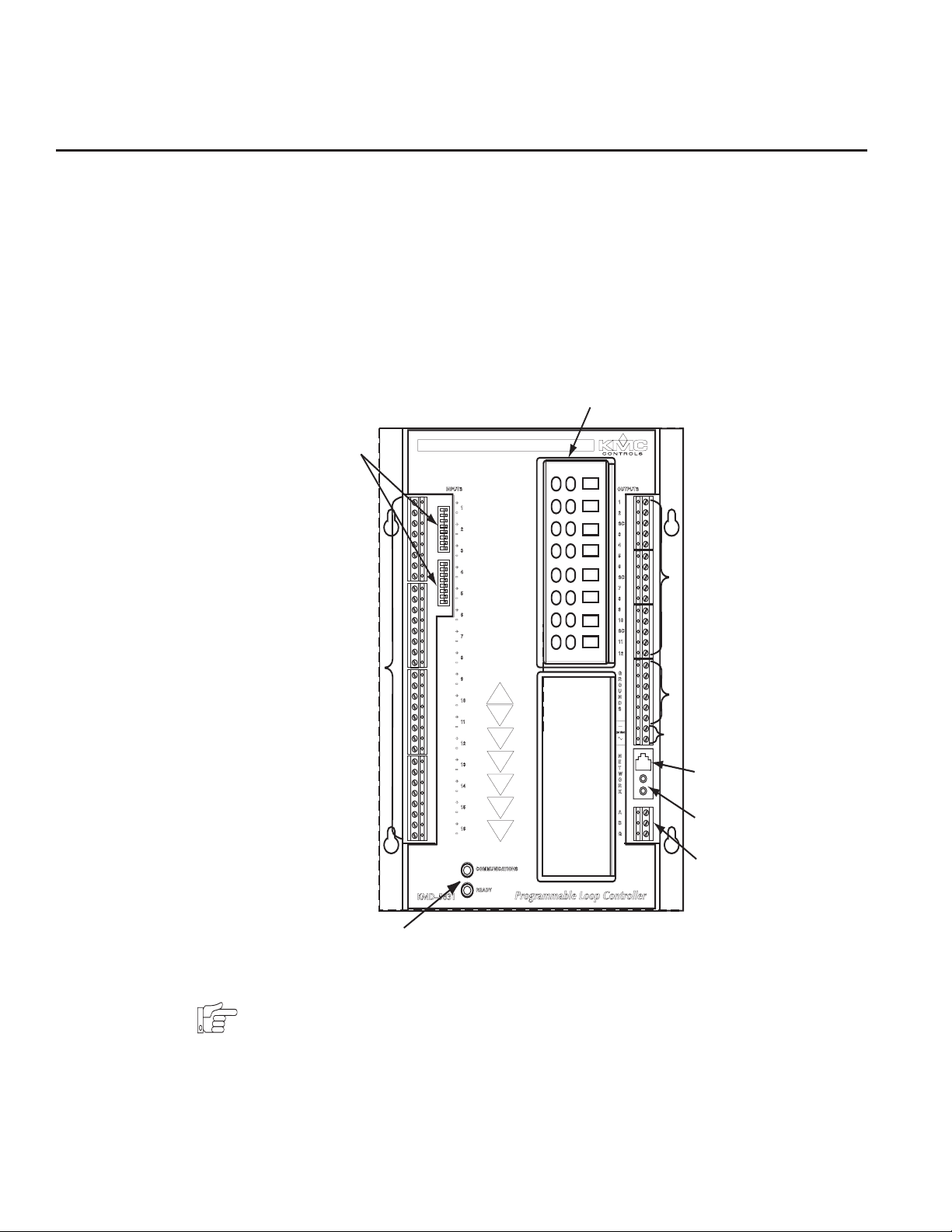

(Shown with optional Override Board Cover)

KMD-5831

Programmable Loop Controller PLC-28 Direct Digital Controller

902-019-04B

1

Page 2

Introduction

This section provides a brief overview of the KMD-5831 Programmable Loop

Controller PLC-28 and the KMD-5821 Programmable Loop Controller PLC-16 +

Direct Digital Controllers. Review this material before you attempt to install the

controller.

For clarity we will focus on the KMD-5831 but all installation and operating

instructions apply equally to the KMD-5821.

Illustration 1 shows the major controller components and their locations. The

KMD-5821has fewer inputs and outputs.

Override

Board

Cover

Input Pull-Up

Switches

Input Terminal

Blocks

O-RSTATUSH

O-RSTATUSH

O-RSTATUSH

O-RSTATUSH

O-RSTATUSH

O-RSTATUSH

O-RSTATUSH

O-RSTATUSH

O

A

1

O

A

2

O

A

3

O

A

4

O

A

5

O

A

6

O

A

7

O

A

8

Output Terminal

Blocks

Grounds

AC Power

Blank

Cover

Input

RJ–12

Connector

Isolation

Lamps

RS–485

Connector

Status LEDs

Illustration 1. Controller Components

Note:

Additional components are located under the blank cover. We will cover these in

detail later in this document.

2

Page 3

Installation

Mounting

This section provides important instructions and guidelines for installing the

KMD-5831 Programmable Loop Controller PLC-28 Direct Digital Controller.

Carefully review this information prior to attempting installation.

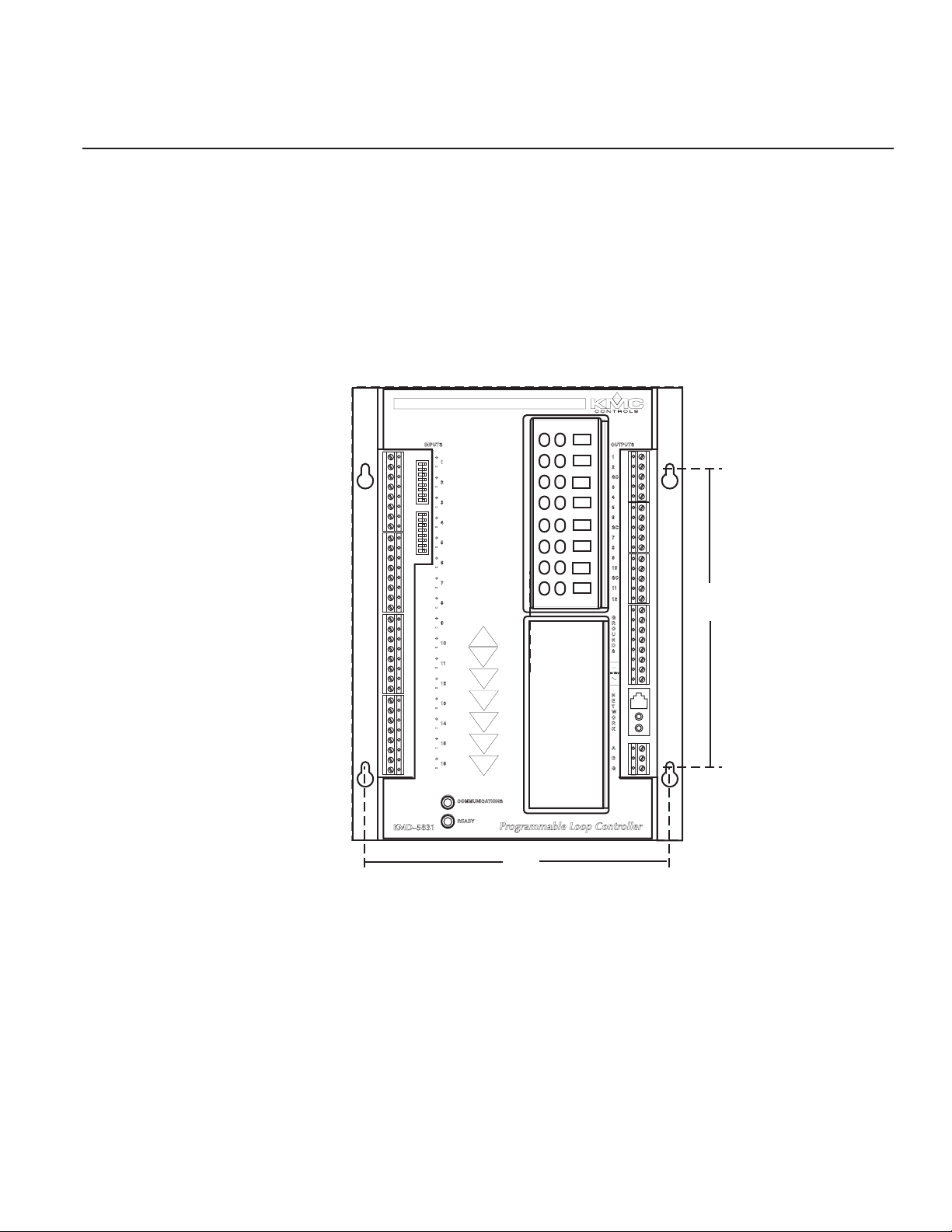

Use the four mounting holes to securely mount the controller using #6 hardware

inside a UL-approved Enclosed Energy Management Equipment Panel or other

suitable protective enclosure. Refer to Illustration 2.

O-RSTATUSH

O

A

O-RSTATUSH

O-RSTATUSH

O-RSTATUSH

O-RSTATUSH

O-RSTATUSH

O-RSTATUSH

O-RSTATUSH

1

O

A

2

O

A

3

O

A

4

O

A

5

O

A

6

O

A

7

O

A

8

6.00"

Input Connections

Universal Inputs

Wiring connections are made depending on the intended application. Sixteen

Universal Inputs are provided on the controller. Observe the following guidelines. (Refer to Illustration 2.)

◆ Connect device inputs to the input terminal connections (+).

◆ Connect input grounds to the associated ground terminal (-).

6.00"

Illustration 2. Connector Detail

3

Page 4

Installation KMD-5831 PLC-28 Direct Digital Controller Installation & Operation Guide

◆ If input pull-ups are required, refer to “Configuration” later in this section.

◆ Wiring terminals are suitable for up to two 12–22 AWG wires. If more than

two wires are required, use an external terminal strip for additional connections.

Note:

Pulse inputs may be used under the following conditions:

◆ If the pulse input does not use a voltage variation, then leave the input pull-up

in the “On” position.

◆ If the pulse produces voltage peaks (up to +5 VDC max.), then the input pull-

up must be set to the “Off” position.

◆ The maximum pulse rate is 8 HZ (8 pulse/sec).

Connecting Outputs

Twelve Universal Outputs are available for output connections labeled as 1–12 on

the output terminal blocks. The outputs are grouped into three groups of four

outputs each with a shared grounds (labeled “SC”) in each block.. Each output

can produce 50 mA at +12 VDC. If a greater current is required, KMC recommends the use of Override Boards discussed later in this section.

A separate ground block provides six additional ground connections.

Network Connections

The controller provides connections for two types of RS–485 circuits.

RJ-12

The RJ–12 connector provides a six-wire RS-485 connection to a modem or PC

using the KMD-5559 CommTalk Data Exchange Module. Simply connect a

suitable RJ-12 cable between the devices.

RS-485 Inputs

A RS–485 terminal is available for connections to a network of controllers If the

Controller is at the End-of-Line, refer to “Configuration” after connections are

completed.

Detail

The End-of-Line connection will have only one wire attached to the A and B

terminals.

◆ For reliable operation, use Belden cable model #82760 or equivalent (18 gauge,

twisted, shielded, 50 picofarads or less) for all network terminal block connections.

◆ Connect the nodes of the network in a daisy-chain arrangement. This means:

Connect the A terminal in parallel with all other A terminals.

Connect the B terminal in parallel with all other B terminals.

◆ Connect the shields of the cable together at each controller.

4

Page 5

KMD-5831 PLC-28 Direct Digital Controller Installation & Operation Guide Installation

r

◆ Connect the shields to an earth ground (DO NOT use a chassis ground) only at

one end of the segment; tape back the shield ground at the other end.

Wiring Notes

Use approved shielded cable and the following principles when connecting a

controller to a network:

◆ Connect no more than 124 Tier 2 KMC addressable controllers or devices to

the RS-485 network.

◆ Connect the nodes of the network in a daisy-chain arrangement. This means:

Connect the A terminal in parallel with all other A terminals.

Connect the B terminal in parallel with all other B terminals.

◆ Connect the shields of the cable together at each controller.

◆ Connect the shields to an earth ground at only one end of the segment; tape

back the shield ground at the other end.

◆ Use a KMD–5575 repeater between every 32 Tier 2 controllers or if the cable

length of the Tier 2 network exceeds 4000 feet (1220 meters). Use no more

than seven repeaters per network.

◆ Place a KMD–5567 surge suppressor in the cable where it exits a building.

Refer to Illustration 3 for an example of typical RS-485 connections.

Wiring

Shield

Wiring

Shield

Wiring

Shield

OR

KMC Controlle

Connections

Illustration 3. Typical RS-485 Wiring Configuration

5

Page 6

Installation KMD-5831 PLC-28 Direct Digital Controller Installation & Operation Guide

Override Cards

For large relays or devices that cannot be powered directly from a standard

output, you will need to install an output override card. Override cards provide:

◆ a wide choice of output signals.

◆ a slide switch for automatic or manual control.

◆ an LED for assessment of the output state.

The following Override Cards are available from KMC Controls.

rebmuNledoM epyTtuptuO

1076-OPH

2076-OPH

3076-OPH

4076-OPH

5076-OPH

Table 1. KMD-5831 Override Board Options

Note

Output cards must be powered with 24 VAC to enable the manual override

(HAND) function. However, this connection must not be made until the default

analog output jumper is removed.

Installing Override Boards

To install an Override Board:

.sselro

pmA1fosegatlovCAgnihctiwsrofdesu-yaleRcairT

gniriuqersnoitacilpparofdesU-edirrevOgolanA

.ecivedlortnocgolananafotnemtsujdalaunam

sdaolhctiwsotdesu-)AmroF(yaleRlacinahceM.O.N

anehwrostiucricCDgnihctiwsnehw,spmA2otpufo

FFOebtsumecivedehtdnaderiuqersitcatnocyrd

.devomersirewopnehw

launamgniriuqersnoitacilpparofdesu-Am02-4

.ecivedlortnocgolananafotnemtsujda

sdaolhctiwsotdesu-)AmroF(yaleRlacinahceM.C.N

anehwrostiucricCDgnihctiwsnehw,spmA2otpufo

nehwNOebtsumecivedehtdnaderiuqersitcatnocyrd

.devomersirewop

1. Remove the appropriate cover from the module. The upper cover is for outputs 1–8 the lower for outputs 9–12.

2. Remove the jumper from the mounting header.

3. Press the override board onto the header pins. The “Hand-Off-Auto” selection

switch is always positioned toward the output connections. (Refer to Illustration 4.)

4. If required, set the selection switch on the Override Board.

6

Page 7

KMD-5831 PLC-28 Direct Digital Controller Installation & Operation Guide Installation

Caution

DO NOT connect active 24 VAC circuits to the output block unless the associated jumper is removed first. Doing so will result in damage to the output and

prevent it from working.

If the associated output will be an analog output, leave the jumper in place.

5. Connect output devices to the module.

6. Connect required power to the input module.

Illustration 4 gives an example of a typical output module configuration.

LED

Illustration 4. Override Board Instalaltion

Selection Switch

Remove jumper

before installing

board

OR

Remove jumper

prior to connecting

active 24 VAC circuits

to the associated

output terminals

Configuration

Using Separate Banks

The outputs are grouped into three banks that share a common switched-terminal. This connection is marked as “SC” on the output block. If you connect a

circuit to this connector it then becomes common to all outputs in that bank.

Configuration settings may be required for the inputs or the RS-485 connection.

If you must activate or deactivate pull-ups on the inputs or set the end-of-line

termination for the RS-485 connection, refer to Illustration 1 to locate the input

switches and Illustration 6 for the End-of-Line switches.

7

Page 8

Installation KMD-5831 PLC-28 Direct Digital Controller Installation & Operation Guide

Input Pull-ups

A 10K ohm resistor is available as a pull-up to a +5 VDC source voltage for

passive or ‘dry” inputs on each input circuit. The resistor is switched “On” or

“Off” using the two dip-switches at the top of the controller. The top switch is

associated with the first 8 inputs and the lower switch is associated with the last 8

inputs. Illustration 5 shows on of these switches in greater detail.

OFF ON

OFF ON

Illustration 5. Typical Input Pull-Up Switch (1 of 2)

The default setting for each input is the “On” position. In this position, the

controller will provide +5 VDC to the input device.

If the input is an active input, that is it has it’s own current source, the pull-up for

that input must be switched to the “Off” position.

End-of-Line Switches

Illustration 6 shows the position of the End-of-Line switches associated with the

RS–485 terminal. You must remove the lower blank cover to gain access to these

switches

End-of-Line Switches

Illustration 6. RS–485 End-of-Line Switches

8

Page 9

KMD-5831 PLC-28 Direct Digital Controller Installation & Operation Guide Installation

Illustration 7 shows the switch in greater detail

ON

ON

OFF

OFF

Illustration 7. RS-485 End-of-Line Switch Detail

If the controller is located at the end of the network segment the switches must

both be placed in the default “ON” position. Otherwise, place the switches in the

“OFF” position.

Power Connection

Connect the 24 VAC supply voltage to the power connectors above the RJ–11

connector on the output side of the controller. Power is applied to the controller

when the power supply (or transformer) is plugged in, as long as the Power

jumper is in place. Illustration 6 shows a typical connection diagram for the

controller.

Configuration

Programming

Note:

The following guidelines apply.

◆ In general, use a separate Class 2 24 VAC transformer with the smallest VA

rating that matches the specification.

◆ If several controllers are mounted in the same cabinet, you can share a trans-

former between them PROVIDED the transformer does not exceed 100 VA

Prior to operating the controller, it must be configured using the Hardware

Configuration Manager (HCM) application supplied with WinControl. Refer to

the WinControl XL User’s Manual for additional information.

Note:

All controllers on the same network must be configured for the same baud rate.

Refer to the KMC Digital Applications Manual for information on how to program the controller.

9

Page 10

Operation

Once configured, programmed and powered up, the controller requires very

little user intervention.

Controls and Indicators

The following sections describe the controls and indicators found on the card.

Alternately, you may remove the RS-485 terminal block from the card to isolate

the card from the network without disrupting network communications to other

controllers.

Status LEDs

Two Status LEDs are located on the bottom left side of the controller. They are

used to indicate the following:

Communications – This yellow LED flashes whenever the controller is communicating with other controllers over the RS-485 network connection.

Ready– This green LED indicates the controller has power and is operating

normally. The LED will flash on and off at one second intervals.

Isolation Lamps

Two Isolation Lamps are located below the RJ–12 connector on the right side of

the controller. These lamps serve three functions:

◆ Removing the lamps will open the RS-485 circuit and isolate the controller

from the network.

◆ If one, or both, lamps are lit, it indicates the network is improperly phased.

This means that the ground potential of the controller is not the same as other

controllers on the network

◆ If the voltage or current on the network exceeds safe levels, the lamps operate

as fuses to protect the controller from damage.

Power Jumper

The power jumper, shown in Illustration 8, can be used to remove power from

the controller. This should be done anytime connections are made or changed on

the controller. Removing the jumper opens the 24 VAC supply circuit.

Resetting the Controller

If the controller appears to be operating incorrectly, or is not responding to

commands, you may need to reset the controller.

10

Page 11

KMD-5831 PLC-28 Direct Digital Controller Installation & Operation Guide Operation

Note

Resetting the controller will restore the factory default configuration. If the

devices cannot communite with the controller, or the controller cannot

commnicate with other controllers, it may be necessary to re-configure the

controller with HCM to establish normal communications and operation. Reprogramming may also be required.

To reset the controller, proceed as follows.

1. Remove the lower Override Board cover on the controller.

2. Locate the Reset button (see Illustration 8).

Power

Jumper

Watch Dog

Jumper

Reset Button

Illustration 8. RS-485 End-of-Line Switch Detail

3. Locate and remove the Power Jumper from the current position.

4. Depress and hold the Reset button.

6. Reinstall the Power Jumper. (

DO NOT release the Reset button.)

7. Continue to hold the Reset Button until the Communications LED flashes

rapidly.

8. Release the Reset Button.

This completes the reset sequence for the controller.

11

Page 12

Disclaimer

The material in this document is provided for information purposes only.

The contents and the product(s) described herein are subject to change

without notice. KMC Controls, Inc. makes no representations or warranties

with respect to this document. In no event shall KMC Controls, Inc. be

liable for any damages, direct or incidental, arising out of or related to the

use of this document.

Important Notices

The KMC logo is a trademark of KMC Controls, Inc.©2003, KMC Controls,

Inc. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any language in any form by

any means without the written permission of KMC Controls, Inc.Printed in

U.S.A.

Technical Support

If you have any questions about this technical document or need additional

details, please call KMC Controls technical services at 574-831-5250 or email us at techs@kmccontrols.com.

12

KMC Controls

P.O. Box 497

19476 Industrial Drive

New Paris, IN 46553

U.S.A.

TEL: 574.831.5250

FAX: 574.831.5252

E-mail: info@kmccontrols.com

902-019-04B

Loading...

Loading...