Page 1

Installation and

KMD-5205

LanLite Controller

KMD-5270

WebLite Controller

Operation Guide

909-019-01JRevision J

Page 2

KMC Controls

Important notices ©2013, KMC Controls, Inc.

WinControl, NetSensor, and the KMC logo are registered trademarks of KMC Controls,

Inc.

TotalControl, BACstage, and FullBAC are trademarks of KMC Controls, Inc.

All rights reserved. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language in any form by

any means without the written permission of KMC Controls, Inc.

Printed in U.S.A.

Disclaimer The material in this manual is for information purposes only. The contents and the

product it describes are subject to change without notice. KMC Controls, Inc. makes no

representations or warranties with respect to this manual. In no event shall KMC

Controls, Inc. be liable for any damages, direct or incidental, arising out of or related to

the use of this manual.

KMC Controls

P.O. Box 497

19476 Industrial Drive

New Paris, IN 46553

U.S.A.

TEL: 1.574.831.5250

FAX: 1.574.831.5252

E-mail: info@kmccontrols.com

Revision J2

Page 3

KMD-5205 and KMD-5270 Installation and Operation

Contents

Section 1

About the controllers

Introduction .......................................................................................................................... 5

Internet operation ................................................................................................................ 5

BACnet 8802-3 option ......................................................................................................... 5

Modbus option ..................................................................................................................... 5

Specifications ........................................................................................................................ 6

Models and options ........................................................................................................... 10

Accessories and replacement parts ................................................................................. 10

Controls and connections ................................................................................................. 11

Safety considerations ........................................................................................................ 12

Section 2

Installing the controllers

Mounting ............................................................................................................................ 13

Connecting inputs ............................................................................................................. 13

Connecting outputs ........................................................................................................... 14

Connecting to networks .................................................................................................... 15

KMC Tier 1 networks ........................................................................................................ 15

KMC Tier 2 networks ........................................................................................................ 15

BACnet 8802-3 (optional) ................................................................................................. 17

Modbus (optional) ............................................................................................................. 18

Connecting power ............................................................................................................. 20

Connecting to a computer through the serial port ....................................................... 21

Connecting to a modem .................................................................................................... 22

Section 3

Operating the controller

Lights and indicators ......................................................................................................... 23

Powering the controller .................................................................................................... 24

Maintenance ....................................................................................................................... 24

Replacing the fuse .............................................................................................................. 24

Resetting the controller ..................................................................................................... 25

Section 4

Configuration and programming

Initializing with HCM ....................................................................................................... 27

Setting up for BACnet networks ..................................................................................... 30

Control Basic programming for BACnet ........................................................................ 31

Setting up for Modbus networks ..................................................................................... 32

Programming for Modbus in WinControl XL Plus ...................................................... 32

Firewalls and network communications ........................................................................ 33

System time keeping ......................................................................................................... 33

System graphics ................................................................................................................. 34

Revision J 3

Page 4

Section 5

Using a web browser (KMD-5270 models only)

Applicable models ............................................................................................................. 35

Browser requirements ....................................................................................................... 36

Opening the WebLite home page .................................................................................... 36

Viewing and editing .......................................................................................................... 38

PID controllers ................................................................................................................... 40

Trend Logs .......................................................................................................................... 40

Schedules ............................................................................................................................ 42

KMC Controls

Revision J4

Page 5

KMD-5205 and KMD-5270 Installation and Operation

SECTION 1

About the controllers

This section provides a description and specifications—including the

BACnet and Modbus options—for models KMD-5205 LANLite and

KMD-5270 WebLite controllers. Safety information is included also.

Review this material before installing or operating the controllers.

Introduction The KMD-5205 and KMD-5270 both provide programmable control and

high-level LAN connectivity for facilities management systems. These powerful,

direct-digital-controllers operate on a peer-to-peer, token passing protocol, using

either Ethernet or EIA-485 networks.

◆ Ethernet for KMD Tier 1 controllers and optional BACnet 8802.3 devices.

◆ EIA-485 for either KMD Tier 2 or Modbus RTU controllers

The operating software in the controllers use a high level, easy to learn

programming language to ensure reliability, rapid programming and

compatibility with future KMC system enhancements.

Internet operation

KMD-5270 models only The embedded internet server in the KMD-5270 models make them ideal

controllers for schools and businesses with an Ethernet infrastructure. System

operation can be changed using a standard internet browser such as Netscape or

Microsoft® Internet Explorer. In addition to changing settings, you can view

system groups, trend and runtime logs with the browser.

BACnet 8802-3 option

Models with the BACnet option adds open-system functionality to these

controllers.

◆ BACnet devices see input, output and variables in the controller as BACnet

input, output and value objects.

◆ When installed on the same Ethernet broadcast domain segment as a

BACnet 8802-3 network, use Control Basic to retrieve data from any

accessible BACnet object on the internetwork.

Modbus option Connect directly to Modbus RTU equipment with the Modbus option. Modbus

registers are mapped to variables in the controller that are then available for use

by other KMD controllers, BACnet devices or Control Basic.

Revision J 5

Page 6

About the controllers

Specifications

KMC Controls

Specifications Specifications for the KMD-5205 and KMD-5270 series of controllers are

subject to change without notice.

Inputs 8 universal inputs

Key features Software selectable for analog or digital signals.

Standard and custom units of measure.

Pull-up resistors for switch contacts and other

unpowered equipment.

Connector Removable screw terminal block, wire size

12–22 AWG

Conversion 12-bit analog–to–digital

Pulse Counting Up to 1000 Hz

Input impedance 100 kΩ without pull-up resistors

Analog input range 0–5 volts DC, 4–20 milliamperes DC

Digital input range 0–5 volts DC and pulse counting

Pull-up resistors None, 1kΩ and 10kΩ selected with movable

jumper

Outputs 8 universal outputs

Key features Software programmable for analog or digital

signals. Standard and custom units of measure.

Slots for KMC output override boards

Connector Removable screw terminal block, wire size

12–22 AWG

Conversion 12-bit digital-to-analog

Analog output range 0–10 volts DC, 50 milliamperes maximum

Programmable features

Control Basic programs 10 user-definable program areas

Networked points in 127 from Tier 1 controllers

512 from Tier 2 controllers

Networked points out 64 to Tier 1 controllers

64 to Tier 2 controllers

PID control loops 8 PID control loops

Program variables 256 — Software selectable as analog or digital

with standard and custom units of measure

Time keeping Real-time clock with power backup for 72

hours.

Programmable for automatic daylight saving

time by date, day of month and time of day.

Ta bl e s 5 user defined

Schedules

Weekly schedules 8 each with 2 override days

Annual schedules 4

6

Revision J

Page 7

KMD-5205 and KMD-5270 Installation and Operation

Logging

Trend logs 16 trend logs each supporting up to 6 analog,

Runtime logs 16 runtime logs with time and date stamp and

Custom graphics 32 system groups each of which can manage 64

Security Six operator access levels

About the controllers

Specifications

digital or virtual elements or points. Trend logs

displayed as text or graphics.

cumulative runtime

points with animated and color graphics.

Requires WinControl XL Plus to view and edit

graphics.

KMD-5270 models serves the background

system group graphic to browser accessible web

pages.

256 names with passwords

Alarms Alarm buffering up to 16 alarms

On-board 68-character alarm or maintenance

text messages

Memory

Flash memory 2 megabyte non-volatile flash memory

Ram 2 megabyte with six-hour backup

Programs and program parameters are stored in

non-volatile memory.

Communication ports

Ethernet One Ethernet 10Base-T port for KMD Tier 1 and

optional BACnet 8802.3

RS-485 Connects to either KMC Tier 2 or Modus RTU

controllers.

Connector type is removable screw terminal

block. Wire size 14–22 AWG

Serial Serial 9-pin connector for directly connecting to

a computer serial port or optional external

modem for remote operation.

Revision J

7

Page 8

About the controllers

Specifications

KMC Controls

Supported network protocols

KMDigital All WebLite controllers support connections to

controllers on KMDigital networks.

Tier 1—10Base-T Ethernet port supports

connection to 31 KMC Tier 1 controllers.

Tier 2—Supports connections to 64 KMDigital

controllers on the RS–485 port. KMD Tier 2 is

not available on models with Modbus RTU

protocol.

BACnet Connects to the BACnet internetwork as a

BACnet Ethernet 8802.3 device.

Modbus Supports connection to Modbus slave

controllers over the RS-485 port.

RS-485, half-duplex (2-wire)

9600, 19,200 or 38,400 baud.

Power loss Automatic restart on power failure

Compatibility

Software For full feature capability use WinControl XL

Plus 2.1 or later.

Controllers Compatible with Tier 1 controllers firmware

build 2.0 or a later release.

Regulatory UL 916 Energy Management Equipment

FCC Class A, Part 15, Subpart B

CE mark

Internet (KMD-5270 models only)

Browser access Use a standard internet browser to view and

change the following: Inputs. Outputs,

Variables, Controllers, System Groups, Trend

Logs, Run Time Logs, Weekly and Annual

Schedules, Alarm Summary.

E-mail Requires access to SMTP e-mail server with

static IP address. Sends text messages, logs and

data points.

Supply voltage 24 volts AC, –15%, +20% 25 VA

Environmental limits

Operating 32 to 120°F (0 to 49°C)

Shipping –40 to 140°F (–40 to 60°C)

Humidity 0–95% non-condensing relative humidity

Weight 16 ounces (454 grams)

8

Revision J

Page 9

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

1

2

3

4

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

5

6

7

8

PWR

S-LAN

PC

COLL

Rx

Tx

A

B

C

D

KMD-5205 and KMD-5270 Installation and Operation

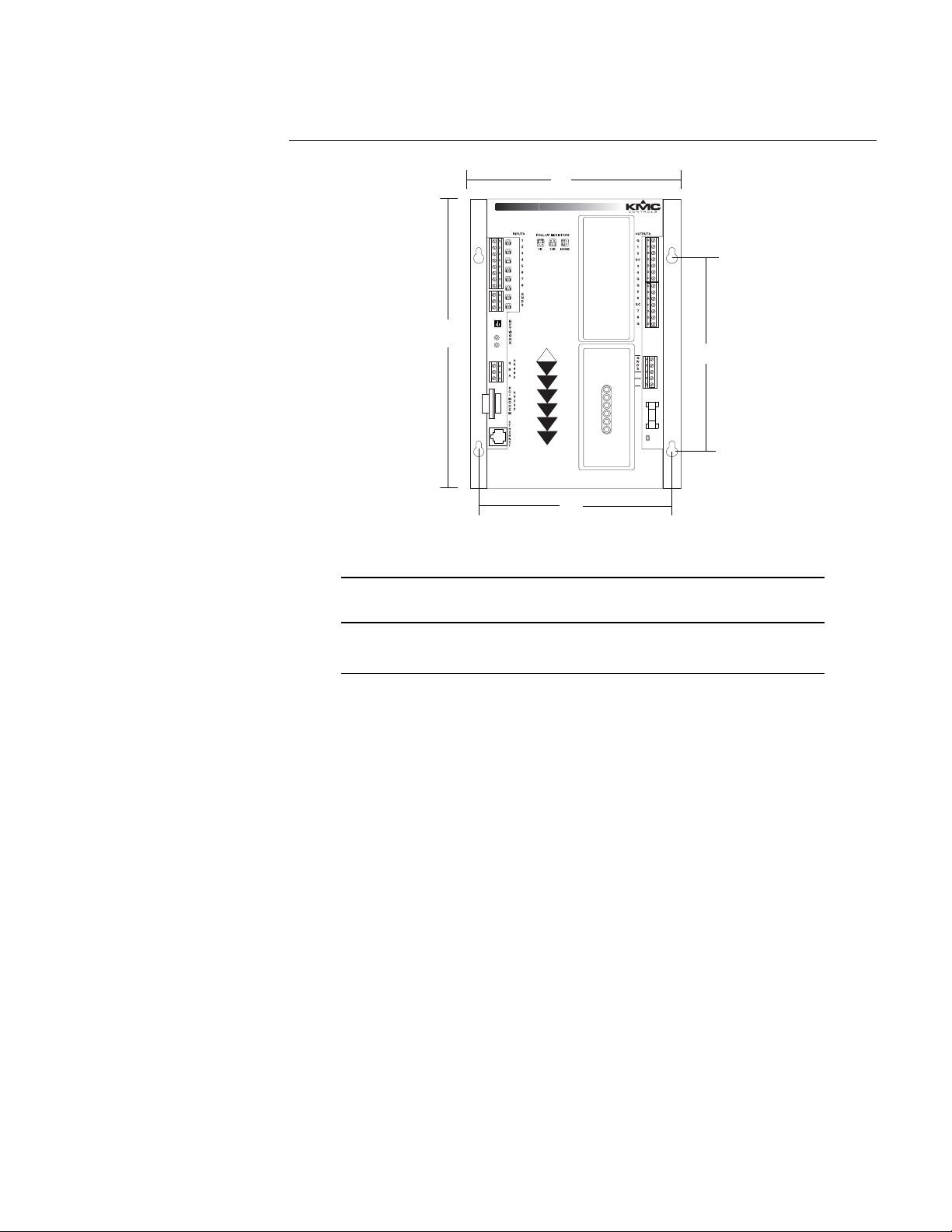

Dimensions

About the controllers

Specifications

Table 1-1 Mounting dimensions

A B C D Height (not

shown)

6.56 in. 9.00 in. 6.00 in. 6.00 in. 0.98 in.

167 mm 229 mm 152 mm 152 mm 25

Revision J

9

Page 10

About the controllers

Models and options

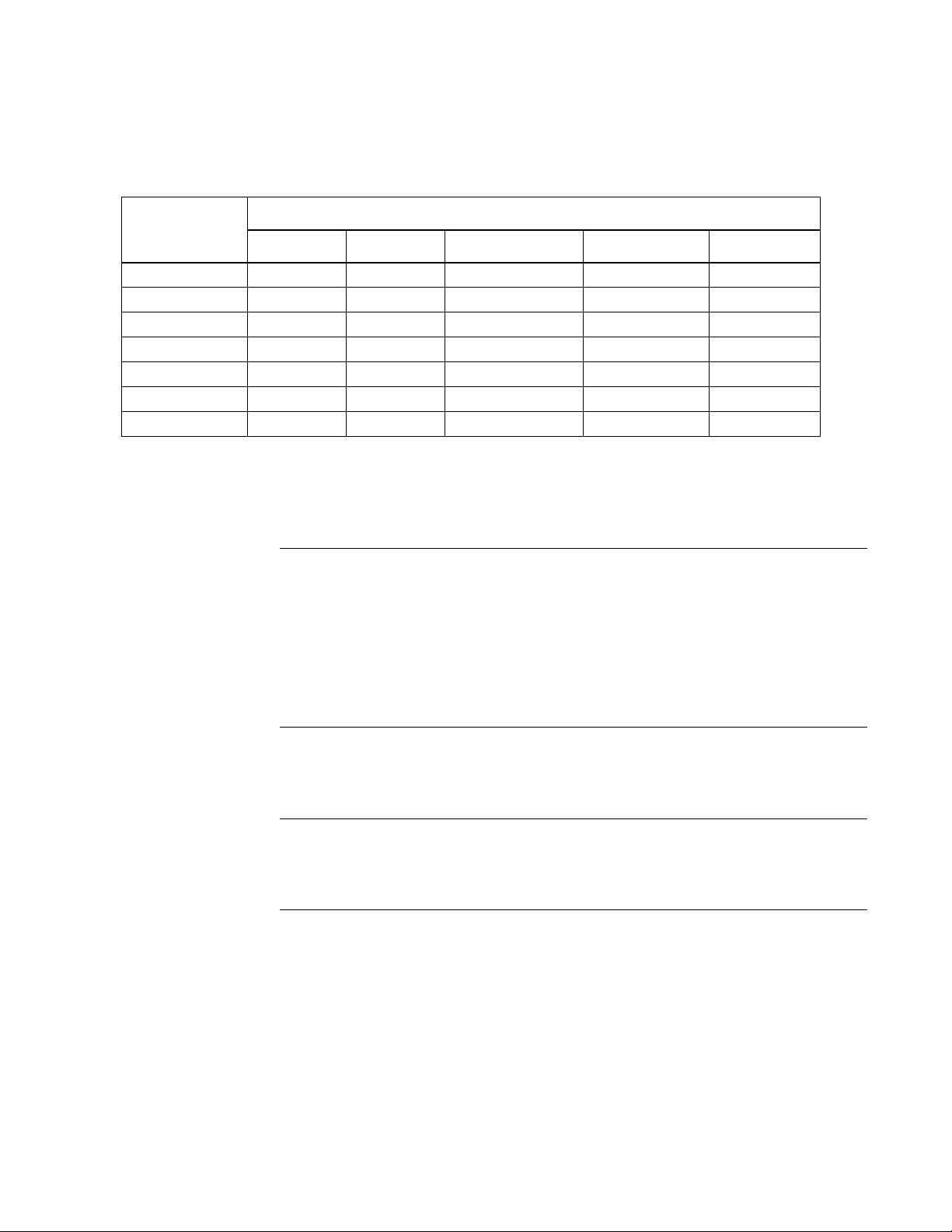

Models and options See Table 1-2 on page 10 for available models and protocols.

Table 1-2 Available models

Protocol

Model

KMD Tier 1 KMD Tier 2 Browser enabled BACnet 8802.3 Modbus RTU

KMD-5205

KMD-5205-005

KMD-5205-006

KMD-5270

KMD-5270-001

KMD-5270-005

KMD-5270-006

◆◆

◆ ◆

◆◆◆

◆ ◆◆

◆◆◆ ◆

◆◆ ◆

◆◆◆◆

KMC Controls

Accessories and replacement parts

The following accessories and replacement parts are available from KMC

Controls, Inc.

Output override boards

HPO-6701 Triac output

HPO-6702 Short protected analog output

HPO-6703 Relay, normally open contacts

HPO-6704 4–20mA current loop

HPO-6705 Relay, normally closed contacts

HPO-6802 Cover for output boards

Power transformer

XEE-6111-40 Single-hub 120 volt transformer

XEE-6112-40 Dual-hub 120 volt transformer

Connecting cables

KMD-5673 Six-foot computer-to-controller cable

KMD-5674 six-foot modem-to-controller cable

Replacement parts

902-600-05 Fast-acting, 1.6 Ampere 5 x 20 mm fuse

HPO-0054 FUSE BULB 863-617-03 (10/Pkg Min Qty)

HPO-0063 2-PIN KMD JUMPER (5/Pkg Min Qty)

10

Revision J

Page 11

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

1

2

3

4

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

5

6

7

8

PWR

S-LAN

PC

COLL

Rx

Tx

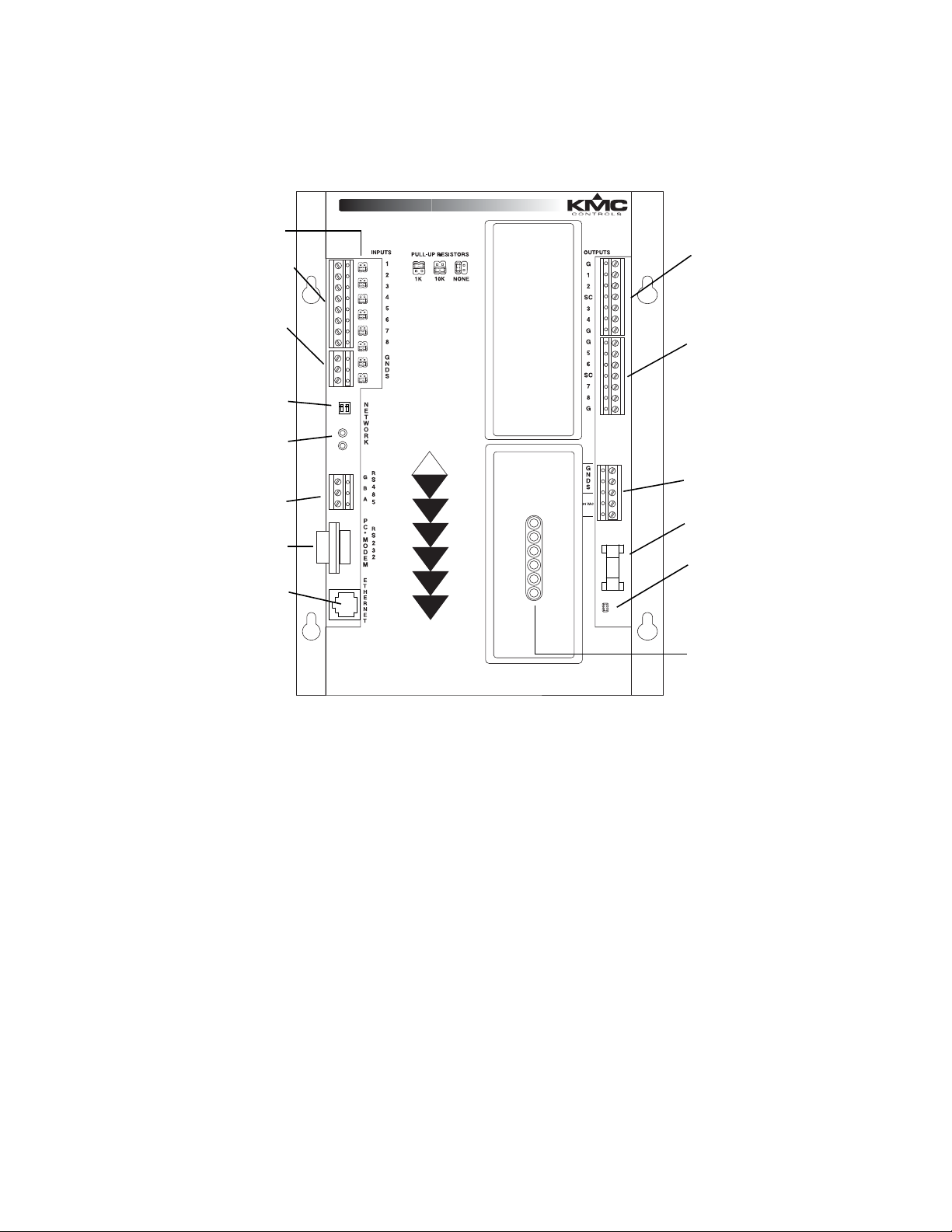

Pull-up jumpers

Input terminals

Input ground

terminals

RS-485 end-of-line

termination switches

Isolation bulbs

RS-485

RS-232

Ethernet

Output bank 1

Output bank 2

Input power

Power supply fuse

Power jumper

Indicator LEDs

KMD-5205 and KMD-5270 Installation and Operation

About the controllers

Controls and connections

Controls and

connections

Before installing a KMD-5205 or KMD-5270, take some time to become familiar

with the location of the components of the controller.

Illustration 1-1 Control and connection terminal locations

Revision J

11

Page 12

About the controllers

Danger

Warning

Caution

Note

Detail

Danger

Safety considerations

KMC Controls

Safety considerations KMC Controls assumes the responsibility for providing you a safe product and

safety guidelines during its use. Safety means protection to all individuals who

install, operate, and service the equipment as well as protection of the equipment

itself. To promote safety, we use hazard alert labeling in this manual. Follow the

associated guidelines to avoid hazards.

Danger represents the most severe hazard alert. Bodily harm or death will

occur if danger guidelines are not followed.

Warning represents hazards that could result in severe injury or death.

Caution indicates potential personal injury or equipment or property damage

if instructions are not followed.

Notes provide additional information that is important.

Provides programing tips and shortcuts that may save time.

12

Revision J

Page 13

KMD-5205 and KMD-5270 Installation and Operation

SECTION 2

Installing the controllers

This section provides important guidelines for installing KMC direct

digital controllers. Review this information carefully for proper

installation.

Mounting Mount the controller inside of a metal enclosure. KMC Controls recommends

using a UL-approved Enclosed Energy Management Equipment Panel such as a

KMC model HCO-1034, HCO-1035 or HCO-1036. Insert #6 hardware through the

two mounting holes on each side of the controller to securely fasten it to a flat

surface. See

maintain RF emission specifications, use either shielded connecting cables or

enclose all cables in conduit.

Dimensions on page 9 for mounting hole locations and dimensions. To

Connecting inputs The controllers include eight universal inputs. Each input can be configured with

software to receive either analog or digital signals. By using the optional pull-up

resistors, either passive or active devices may be connected to the inputs. For

additional information, see the application note AN0504L, Connecting inputs and

outputs to KMC controllers.

Pull-up resistors

For passive input signals, such as thermistors or switch contacts, use a pull-up

resistor. For KMC thermistors and most other applications place the moveable

jumper in the

4–20 mA inputs

To use a 4–20 current loop input, connect a 250 ohm resistor from an input to

ground. The resistor will convert the current input to a voltage which can be read

by the controller analog-to-digital converter. Place the moveable pull-up jumper

NONE position.

in the

Pulse inputs

Connect pulse inputs under the following conditions:

◆ If the pulse input is a passive input such as switch contacts, then place the

input pull-up jumper to the 10K position.

◆ If the pulse is an active voltage (up to a maximum of +5 volts DC), then place

the input pull-up jumper in the NONE position.

10K position.

Revision J 13

Page 14

Installing the controllers

Connecting outputs

KMC Controls

Ground terminals

Three input ground terminals are located next to the input terminals. Up to two

wires, size 12–22 AWG, can be clamped into each ground terminal. If more than

two wires must be joined at a common point, use an external terminal strip to

accommodate the additional wires.

Connecting outputs All eight outputs are universal and can be configured by software to operate

either analog or digital devices. Connect the device under control between the

output terminal and one of the ground (G) terminals on the same bank.

Override cards

For large relays or devices that cannot be powered directly from a standard

output, install an output override card. Override cards provide:

◆ A wide choice of output signals.

◆ A slide switch for automatic or manual control.

◆ An LED for assessment of the output state.

Install the output override cards in the area under the plastic cover next to the

output terminals. The following output cards are available from KMC Controls.

Table 2-1 Output override cards

Card model number Output type

HPO-6701 Triac

HPO-6702 0–10 volts DC analog

HPO-6703 Normally open contact

HPO-6704 4–20 milliampere current loop

HPO-6705 Normally closed contact

Grounds and Switched Commons

When using an output override card, use the SC terminal instead of the ground

(G) terminal as signal common. Use the

the output terminal.

SC terminal in the same output bank as

14

Revision J

Page 15

Note

KMD-5205 and KMD-5270 Installation and Operation

Installing the controllers

Connecting to networks

Connecting to

networks

Each controller in a KMC digital network may be used as either a stand-alone

controller or connected to other controllers in a network. The KMD-5205 and

KMD-5270 controllers can be connected to other KMC controllers through two

different types of networks.

◆ Connections to KMD Tier 1 controllers and BACnet 8802–3 devices use

standard Ethernet wiring and hardware.

◆ KMD Tier 2 controllers and Modbus controllers use EIA–485 wiring and

hardware.

KMC Tier 1 networks LAN connections

Connect a standard Ethernet cable between the Ethernet connector on the

controller and a port on a network hub or router. You may connect up to 31 Tier

controllers in a system using Ethernet. In addition to allowing the maximum LAN

controllers, multiple computers can access the system through the network. See

Initializing with HCM on page 27 for Ethernet configuration.

KMC Tier 2 networks Connect KMC Tier 2 controllers to a KMD-5205 or KMD-5270 at the RS-485

connector. The KMC Tier 2 network uses shielded twisted pair cable to connect

controllers together. See

controller for Tier 2 network operation.

Initializing with HCM on page 27 for configuring a

1

KMD Tier 2 controllers cannot be connected to KMD-5205 or KMD-5270 when

the Modus option is enabled.

Revision J

15

Page 16

Installing the controllers

A

B

G

B

G

A

G

B

A

G

B

A

B

A

G

B

A

G

Earth ground

Ground shield in

one place only.

KMC Tier 2 networks

KMC Controls

Tier 2 wiring

You may connect up to 64 KMDigital controllers to the RS–485 connector. Use

approved shielded cable and the following principles when connecting a

controller to a Tier

◆ Use 18 gauge, twisted pair, shielded cable with capacitance of no more than

50 picofarads per foot for all network wiring. Belden cable model #82760

meets the cable requirements.

◆ Connect the A terminal in parallel with all other A or -A terminals.

◆ Connect the B terminal in parallel with all other B or +B terminals.

◆ Connect the shields of the cable together at each controller.

◆ Connect the shield to an earth ground at the other end.

◆ Use a KMD–5575 repeater if the cable length will exceed 4000 feet

(1220 meters). Use no more than seven repeaters per Tier 2 network.

◆ Place a KMD–5567 surge surpressor in the cable where it exits a building.

2 (sub LAN) network:

16

Illustration 2-1 Connecting controllers to a Tier 2 network

Tier 2 end of line termination switches

The controllers on the physical ends of the RS-485 wiring segment must have

end-of-line termination installed for proper network operation. Set the end-of-line

termination to

On using the EOL switches. The KMD-5205 and KMD-5270

end-of-line termination is set with two switches located near the RS–485

connector. Termination in other KMC controllers may be set with moveable

jumpers or fixed resistors.

Revision J

Page 17

Note

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

1

2

3

4

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

5

6

7

8

PWR

S-LAN

PC

COLL

Rx

Tx

WD

Termination On

Termination switch

O-RSTATUS H O A

O-RSTATUS H O A

O-RSTATUS H O A

O-RSTATUS H O A

1

2

3

4

O-RSTATUS H O A

O-RSTATUS H O A

O-RSTATUS H O A

O-RSTATUS H O A

5

6

7

8

PWR

S-LAN

PC

COLL

Rx

Tx

O-RSTATUS H O A

O-RSTATUS H O A

O-RSTATUS H O A

O-RSTATUS H O A

1

2

3

4

O-RSTATUS H O A

O-RSTATUS H O A

O-RSTATUS H O A

O-RSTATUS H O A

5

6

7

8

PWR

S-LAN

PC

COLL

Rx

Tx

Set end-of-line termination to

On in these controllers only

KMD-5205 and KMD-5270 Installation and Operation

Set the End-of-Line termination at the controllers where only one wire is

attached to the A and B terminals.

Installing the controllers

BACnet 8802-3 (optional)

Illustration 2-2 Termination switches

BACnet 8802-3

(optional)

Revision J

Illustration 2-3 End-of line termination

Connect models with the BACnet option to the BACnet internetwork through the

same Ethernet 10Base-T connection as the Tier 1 connection. For access to devices

on a BACnet internetwork you must do the following:

◆ The BACnet internetwork must include at lease one 8802-3 network.

◆ The controller must be connected to the same Ethernet broadcast domain

segment as one of the BACnet 8802-3 networks.

◆ If the internetwork does not include an 8802-3 network, install a router to

route traffic from the existing BACnet network protocols to Ethernet 8802-3.

For internetworks that include MS/TP or BAcnet IP, use a BAC-5050. For

addition details on BACnet networks, see application note AN0404A,

Planning BACnet Internetworks, which is available on the KMC web site.

17

Page 18

Installing the controllers

Note

A

B

G

+

-

+

-

B

G

+

+

A

Ground shield in

one place only.

KMD-5205 or

KMD-5270

with Modbus

Modbus

devices

Modbus (optional)

KMC Controls

Modbus (optional) Connect Modus slave controllers to a KMD-5205 or KMD-5270 at the RS-485

connector. The Modbus network uses shielded twisted pair cable to connect

controllers together. To set up the controller, see

and Setting up for Modbus networks on page 32 for configuration details.

Modbus wiring

Connect Modbus slave devices to the RS-485 connector. Use approved shielded

cable and the following principles when connecting a controller to a Modbus

network:

◆ Use 18 gauge, twisted pair, shielded cable with capacitance of no more than

50 picofarads per foot for all network wiring. Belden cable model #82760

meets the cable requirements.

◆ Connect the A terminal of the KMD controller in parallel with the minus (-)

terminals on the Modbus devices.

◆ Connect the B terminal of the KMD controller in parallel with the plus (+)

terminals on the Modbus devices.

◆ Connect the shields of the cable together at each controller.

◆ Connect the shield to an earth ground at one end only.

◆ Place a KMD-5567 surge surpressor in the cable where it exits a building.

Initializing with HCM on page 27

In addition to these Modus wiring requirements, verify equipment specific

Modbus wiring requirements in the manuals supplied with the Modus devices.

18

Illustration 2-4 Connecting the Modbus network

Revision J

Page 19

Note

Set end-of-line

termination to On

in these controllers

only

KMD-5205 and KMD-5270 Installation and Operation

Modbus end-of-line termination switches

The controllers on the physical ends of the Modus wiring segment must have

end-of-line termination installed for proper network operation. For the KMD

controllers the end-of-line termination is set with two switches located near the

RS-485 connector. Set the end-of-line termination to

End-of-line termination for the connected Modbus devices may be set with

moveable jumpers or fixed resistors. Verify termination methods for the Modbus

devices in the manuals supplied with the Modbus devices.

Set the end-of-line termination at the controllers where only one wire pair is

attached to the A and B terminals.

Installing the controllers

Modbus (optional)

On using the EOL switches.

Illustration 2-5 End-of-line termination

Revision J

19

Page 20

Installing the controllers

Connecting power

KMC Controls

Connecting power The controllers require an external, 24 volt, AC power source. Use the following

guidelines when choosing and wiring transformers.

◆ Use a KMC Controls Class–2 transformer of the appropriate size to supply

power to the controllers.

◆ When installing a controller in a system with other controllers, you may

power multiple controllers with a single transformer as long as the total

power drawn from the transformer does not exceed its rating and phasing is

correct.

◆ If several controllers are mounted in the same cabinet, you can share a

transformer between them provided the transformer does not exceed 100 VA

or any regulatory requirements.

◆ Do not run 24 volt, AC power from within an enclosure to external

controllers.

20

Revision J

Page 21

2

3

5

2

3

5

Nine-pin, female D-shell connector

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

1

2

3

4

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

5

6

7

8

PWR

S-LAN

PC

COLL

Rx

Tx

KMD–5673 cable

KMD-5205 and KMD-5270 Installation and Operation

Installing the controllers

Connecting to a computer through the serial port

Connecting to a

computer through

the serial port

Multiple computers may access the same controller at the same time. However,

unpredictable operation may occur if two or more operators are making

simultaneous changes.

To initialize or address the controller with the KMC Hardware Configuration

Manager or to program with WinControl XL Plus, connect a KMD-5673 cable

between a serial port on the computer and the RS-232 port on the controller.

◆ See Illustration 2-6 for cable details.

◆ See the section Configuration and programming on page 27 for procedures on

initializing and programming the controller.

Illustration 2-6 Computer to controller cable

Revision J

Illustration 2-7 Direct connection to KMD-5205 and KMD-5270

21

Page 22

Installing the controllers

Detail

Detail

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

1

2

3

4

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

5

6

7

8

PWR

S-LAN

PC

COLL

Rx

Tx

KMD–5674 cable

Connecting to a modem

KMC Controls

Connecting to a

modem

By adding an optional modem to the controller, an off-site computer can access

the controller through a dial-up connection. The modem connection also supports

dial-in and the Control Basic functions TPAGE and NPAGE. If the modem

function is enabled, the serial port is not available for direct connection with a

computer.

KMC Controls recommends using U.S. Robotics modems for off-site

communications. KMC does not offer support for other modem installations.

To install a modem:

1. Use HCM to configure the controller for the modem function. See

Initializing with HCM on page 27 for setup details.

2. Connect a KMD-5674 computer-to-modem cable between the KMD-5569

modem and the nine-pin modem connector on the controller.

3. Connect the modem to a telephone line dedicated to the network system.

4. Verify the configuration switches on the back of the modem are in the

following positions.

Table 2-2 Modem configuration switches

12345678

Up Up Down Down Up Up Up Down

22

Illustration 2-8 Modem connection to KMD-5205 and KMD-5270

Use only the KMD-5674 cable between the controller and the modem. A

standard modem cable will not work.

Revision J

Page 23

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

1

2

3

4

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

5

6

7

8

PWR

S-LAN

PC

COLL

Rx

Tx

WD

Reset

button

Indicator

LEDs

Power

jumper

Isolation

bulbs

Termination

switch

KMD-5205 and KMD-5270 Installation and Operation

SECTION 3

Operating the controller

This section provides general operating parameters of your KMC

controller and a detailed description of the front panel display.

Lights and indicators Isolation bulbs

Two small bulbs located next to the RS-485 connector are protective isolation

bulbs for the Tier 2 networks. These bulbs serve three functions:

◆ When illuminated they indicate improper network phasing. Improper

phasing occurs when the ground potential of the controller is higher than the

phase or the ground potential of other Tier 2 or Modbus controllers on the

network.

◆ The bulbs protect the controller from damage by limiting the network signal.

If voltage or current exceeds safe operating condition, the bulbs will open

the connections between the controller and the network.

◆ By pulling the bulbs from their sockets you can disconnect the controller

from the network.

Illustration 3-1 Controls and indicators

Revision J 23

Page 24

Operating the controller

Powering the controller

KMC Controls

LED indicators

Six LEDs on the front of the controller display system status. Use the LEDs to

confirm proper operation or as an aid when troubleshooting.

PWR Flashes green during normal operation. The normal cycle is one second on

and one second off.

S-LAN Momentarily flashes yellow during the time when data is being

transmitted to either the KMD Tier 2 network controllers or to the connected

Modbus devices.

PC Flashes when sending or receiving data from a computer.

COL Momentarily flashes red when a collision occurs in Ethernet traffic.

Rx Flashes green when Ethernet traffic is being received.

Tx Flashes green when Ethernet traffic is being transmitted.

Powering the

controller

Use the jumper located next to the power terminal to disconnect the 24 volt AC

power from the controller while making wiring changes. Remove the power

terminal or disconnect the power feeding the transformer before removing the

controller. The controller begins operation as soon as power is applied.

Maintenance The controller does not require routine maintenance. If cleaning is required, wipe

with a

soft, damp cloth and mild soap.

Replacing the fuse If a fuse opens, investigate the cause, and then replace the fuse. To replace the

fuse:

1. Remove the power connection to the module.

2. Carefully pull out the open fuse from the fuse holder.

3. Carefully snap an identical 1.6 ampere, fast-acting, fuse into the fuse

holder.

4. Reconnect the power.

24

Revision J

Page 25

Caution

Caution

KMD-5205 and KMD-5270 Installation and Operation

Operating the controller

Resetting the controller

Resetting the

controller

Use the reset button for either of the following functions.

◆ Restore the modem settings.

◆ Restore all configuration settings to the factory default settings.

Restoring the controller erases all programs and point configuration. Connect

to the controller through Ethernet or a dial-up modem and use either

WinControl XL Plus or TotalControl to save the programming in a panel file

before resetting the controller.

To restore only the modem settings

A controller that has been set for modem operation with HCM cannot directly

connect to a computer at the RS–232 port unless it is changed with the reset

button.

To change the controller from modem connection to direct computer connection

do the following:

1. Remove the plastic cover surrounding the six LEDs.

2. Press the reset button for one second and then release it.

Restoring to factory settings

Restoring a controller to factory settings changes the controller as follows:

◆ Removes all programming.

◆ Removes all configuration settings.

◆ Restores the controller to factory default settings.

Resetting the controller erases all configuration and programming. After

resetting to factory settings, you must configure and program the controller to

establish normal communications and operation.

To reset the controller to factory settings.

1. If possible, use WinControl XL Plus or TotalControl Design Studio to

backup the controller.

2. Remove the plastic cover surrounding the six LEDs.

3. Remove the power jumper. See the illustration

page 23 for the location.

4. Press and hold the red restart button.

5. Replace the power jumper while continuing to hold the restart button.

6. Release the restart button when the SUBLAN and PC LEDs illuminate.

Controls and indicators on

Revision J

25

Page 26

Operating the controller

Resetting the controller

KMC Controls

26

Revision J

Page 27

Caution

Note

KMD-5205 and KMD-5270 Installation and Operation

SECTION 4

Configuration and programming

This section lists initialization settings and describes programming

functions that are unique to configuring the KMD-5205 and

KMD-5270 controllers. Other programming features and more

detailed instructions are covered in the

Manual

.

WinControl XL User’s Plus Reference

Initializing with HCM

Before a controller is placed into service, it must be initialized and addressed with

the KMC

the WinControl XL software CD; complete operating instructions are included in

the Hardware Configuration Manager help files or the HCM Reference Guide

available on the KMC Controls web site.

The Hardware Configuration Manager sets all controllers on the Tier 2

network to the same parameters. To prevent disruption to other controllers on

the network, disconnect the network cables at the RS-485 port or remove the

isolation bulbs on the controller prior to starting HCM.

Ethernet settings do not take effect in a controller until the power is cycled.

1. Unplug the Tier 2 or Modbus network connection from the RS-485 port.

2. Connect a serial cable between the controller and the computer on which

3. Start HCM and establish communications with the controller.

4. Make the entries as described in the section

5. Set up the Ethernet routing table. See

6. On applicable models, do the following:

7. Return the network connection to the RS-232 port.

Hardware Configuration Manager (HCM) software. HCM is distributed on

HCM will run. See

on page 28.

• Enter BACnet parameters. See Setting up for BACnet networks on page 30.

• Set up the Modus communications. See

page 32.

Connecting to a computer through the serial port on page 21.

KMC digital network configuration

Ethernet routing table on page 29.

Setting up for Modbus networks on

Revision J 27

Page 28

Configuration and programming

Initializing with HCM

KMC Controls

8. Cycle the power to the controller. The controller can now be connected to

a network and additional programming can be performed with

WinControl XL Plus or TotalControl.

KMC digital network configuration

The entries in the table HCM Configuration Screen setup fields on page 28 are required

for controller-to-controller communications on a either KMD Tier 1 or KMD Tier 2

networks.

Table 4-1 HCM Configuration Screen setup fields

Setting Description

Address Enter the address that is assigned to the controller on the KMD

Tier 1 network. Valid entries are 1–31.

Last Panel Not applicable on any KMD-5205 or KMD-5270 models.

SubLAN A Sets the connection speed of the Tier 2 port to which the

controller is connected. Set the baud to match the baud of the

other controllers on the Tier 2 network.

Modem Select to indicate a modem is connect to the nine-pin serial

connector. If Modem is selected, a computer cannot be directly

connected to the nine-pin connector.

Modem String The controller automatically transmits initialization strings for

U.S. Robotics modems. If you are using a different modem,

enter the initialization string here. This can normally be found

in the modem manual.

The default initialization string is AT&A &B1 &C1 &D2 &H1

&K0 &R.

Computer Port Enter the communication speed for a PC is directly connected

to this port or the modem-to-computer baud if a modem is

connected to the controller.

SMPT IP Address Enter the IP address of the e-mail SMTP server. This address is

required to

send e-mail with KMD-5270 models. The

address is supplied by the network system administrator.

28

Revision J

Page 29

Note

KMD-5205 and KMD-5270 Installation and Operation

Ethernet routing table

The Ethernet routing table is a list that associates the KMC network addresses

assigned to Tier 1 controllers with the IP addresses required by the LAN protocol.

If the controller is not configured correctly, it will not communicate with other

controllers and may cause problems with the rest of the network. Before starting

the HCM initializing process you will need information about the controller and

the LAN which is listed in Table 4-2.

Table 4-2 Tier 1 controller Ethernet settings in HCM

Setting Description

IP address Supplied by network administrator. Enter the address next to the

panel address of the LAN Controller.

MTU 1400 or as supplied by system administrator

Gateway Use default (255.255.255.255) unless a router (gateway) is

located between two Tier 1 controllers. The router IP address is

supplied by the network system administrator.

MAC address The MAC address is located on the white label on the front of the

controller. MAC addresses for KMC Controls products begin with

00-D0-6F.

Broadcast sever Check if this controller is a broadcast server.

Interval Set the interval for the broadcast message. The broadcast

message is for KMD controllers and not a LAN broadcast

message.

Subnet mask Set the Subnet Mask address to 255.255.255.0. or as supplied by

network system administrator.

Configuration and programming

Initializing with HCM

Ethernet settings do not take effect in a controller until the power is cycled.

Ethernet troubleshooting

If the controller does not appear Network Status in the WinControl program, try

the following.

1. Obtain a crossover cable (available in most stores that carry network

products).

2. Connect the crossover cable between the Ethernet connection on your

computer and the Ethernet connector on the LAN Controller.

3. Open an MS-DOS window on your computer and Ping the controller’s

IP address. If the controller is operating correctly, you should receive a

response to the ping command.

If you are unfamiliar with the above steps, contact KMC Controls for assistance

Revision J

29

Page 30

Configuration and programming

Detail

Setting up for BACnet networks

KMC Controls

Setting up for

BACnet networks

These topics apply only to the following models:

◆ KMD-5205-006

◆ KMD-5270-001

◆ KMD-5270-006

If the controller is licensed for BACnet and connected to a BACnet network, the

controller must be configured to communicate with the network.

Table 4-3 BACnet settings in HCM

Setting Description

Instance The device instance number as assigned by the BACnet system

designer. Instance numbers are required, must be unique among all

devices on the internetwork and range from 0 to 4,194,303.

Name A required 16-character label of the device. Name must be unique

among all devices on the internetwork. The set of characters used

in Name is restricted to printable characters.

Location Optional information used to further identify a piece of equipment.

Description Optional information used to further identify a piece of equipment.

APDU Timeout Indicates the period—in milliseconds— between retransmissions of

an APDU requiring an acknowledgement for which no

acknowledgment has been received. The default value is 3000

milliseconds.

Max Master Not applicable to KMD-5205 or KMD–5270 models.

Token Timeout

Not applicable to KMD-5205 or KMD–5270 models.

BACnet device settings are covered in more detail in BACstage or TotalControl

help. The BACstage and TotalControl reference guides are available also in

Adobe Acrobat format on the KMC Controls web site.

30

Revision J

Page 31

Caution

KMD-5205 and KMD-5270 Installation and Operation

Configuration and programming

Control Basic programming for BACnet

Control Basic programming for BACnet

These topics apply only to the following models:

◆ KMD-5205-001 ◆ KMD-5270-001

◆ KMD-5205-006 ◆ KMD-5270-006

Control Basic programming for BACnet

For Control Basic programming, the KMD–5270 models support the BACnet

object types that are listed in Table 4-4.

Table 4-4 Supported BACnet object types

Mnemonic Object type

AI Analog Input

AO Analog Output

BI Binary Input

BO Binary Output

AV Analog Value

BV Binary Value

Program the controllers as you would other KMD series controllers. Observe the

following details when programing an interface to a BACnet internetwork:

◆ Only input, output and variable points within a BACnet licensed controller

appear as objects in a device on the BACnet internetwork.

◆ A point configured as a KMD digital point will appear as a BACnet binary

object. Analog points appear as analog objects.

◆ To be visible as an object to BACnet devices, configure the KMD point with

both a description and a label.

◆ Use BAC-SET, BAC-GET and BAC-RLQ in Control Basic to read and write

other objects on other BACnet devices.

KMC Controls recommends that all BACnet services have adequate error

handling protocols within your control program. The following Control Basic

code segment demonstrates reading the state of binary input BI8 in a BACnet

device with instance number 1.

The WAIT statement in the following example is required. Do not delete it or

the program will not run correctly.

Example: 250 G = BAC-GET( 1 , BI8 ) : REM BACnet read

260 ON-ERROR 280 : REM If error, bad read, don’t use it

270 1-VAR16 = G : REM Read was good, use the value.

280 WAIT 0:00:15 : REM Release so other CB programs can run

290 END

Revision J

31

Page 32

Configuration and programming

Note

Setting up for Modbus networks

KMC Controls

Access to the controllers from BACnet

To access the BACnet licensed controller, use a BACnet operator workstation such

as BACstage.

◆ The WebLite will appear in the BACstage device list but cannot be selected.

Its objects are not accessible for configuration from the BACstage Object

menu.

◆ The configured points within the WebLite are the only points visible in

BACnet.

◆ In BACstage, use BACnet Read/Write Property under the System menu in

BACstage to manually view or change properties.

◆ In TotalControl the BACnet licensed controllers are added to the Network

Manager list.

◆ KMC BACnet controllers and third-party devices may read and write to the

objects in the WebLite with off-panel reads and writes.

Setting up for

Modbus networks

Programming for Modbus in WinControl XL Plus

These topics apply only to the following models:

◆ KMD-5205-005 ◆ KMD-5270-005

◆ KMD-5205-006 ◆ KMD-5270-006

Set the following Modbus communication parameters with HCM. All Modbus

devices connected to the same network—including the KMD-5205 and KMD 5270

models—must be set to the same mode, baud and parity.

Table 4-5 Modbus settings in HCM

Setting Description

Mode Select only RTU.

Baud Set to 9600, 19,200 and 38,00 baud.

Data Set to even, odd or no parity bits

Use WinControl XL Plus to map Modbus registers to variables in the KMD-5205

and KMD-5270 Modbus licensed controllers. Once the registers are mapped to

variables, the variables are handled with Control Basic to read from and write to

the registers. The procedures for mapping the registers to variables are covered in

WinControl XL Plus help and the WinControl XL Plus Reference manual.

32

WinControl XL Plus 2.1 or later is required to map Modbus registers to

variables in the KMD-5205-005 and KMD-5270-005 controller.

Revision J

Page 33

Note

KMD-5205 and KMD-5270 Installation and Operation

Configuration and programming

Firewalls and network communications

Firewalls and

network

communications

Firewalls are commonly installed on networks to prevent unauthorized traffic or

electronic probes from entering the network. If the controller must communicate

with a network where a firewall is in place, the following actions must be taken.

Tier 1 controllers communicate through one of three Ethernet Ports:

Tabel 4-6 Firewall ports

Connection UDP Port

WinControl to Tier 1 controller 21068

Tier 1 controller to Tier 1 controller 21069

Tier 1 controller to Tier 1 controller 21070

These ports must be open for communications to pass through a firewall.

If the controller resides behind a Network Address Translation (NAT) router, the

IP address for the controller must be preceded by the lowercase letter ‘r’ in the

WinControl system menu. (For example, r128.1.1.5.)

Adding this prefix letter will cause WinControl to disregard the IP table and

download from the panel itself.

If you use this method you will only be able to connect one Tier 1 controller

through the router.

System time keeping The controllers feature real-time clocks. Once the clock is set with WinControl XL,

the controller maintains accurate time even during power loss. A KMC digital

network uses the lowest addressed Tier 1 controller with a real-time clock as the

system time keeper.

Revision J

33

Page 34

Configuration and programming

Detail

Caution

System graphics

System graphics These topics apply only to the following models:

◆ KMD-5270 ◆ KMD-5270-005

◆ KMD-5270-001 ◆ KMD-5270-006

The KMD-5270 WebLite models can store up to eight system group background

graphics which can then be served to a standard web browser. Use the following

procedure in WinControl XL Plus to make a graphic available for browser access.

WinControl XL Plus 2.1 or later is required to load browser graphics into a

KMD–5270 WebLite.

1. Connect to the controller with WinControl XL Plus over Ethernet.

2. Choose Control menu, System Groups. and then Graphics.

3. Enter the file name of the background graphic to be stored in the

KMD-5270 for viewing with a web browser.

4. Enter the same name in the Bitmap/JPEG column in the System Groups

list window.

KMC Controls

34

Illustration 4-1 Web graphics file list

A background graphics file name may be compatible with WinControl XL Plus

but not with the browser. WinControl XL Plus will send a background graphic

with an incompatible file name to the controller but the browser may not

display it. Use the following guidelines for best results.

◆ Use the file name without the extension.

◆ The file type must be JPG format and cannot be larger than 50kB.

◆ Place the file in the Pictures directory in the job folder. This is the same

location for other system group graphics.

◆ Use only file names that are compatible with web browsers. If unsure about

browser compatibility, use only letters and numbers.

◆ File names are limited to 10 characters by WinControlXL Plus.

Revision J

Page 35

KMD-5205 and KMD-5270 Installation and Operation

SECTION 5

Using a web browser (KMD-5270 models only)

This section explains how to view and control a KMD-5270 with a

web browser.

Through the embedded HTTP server in the KMD-5270, you can use a web

browser to view and make changes to the following functions in the controller.

Table 5-1 WebLite view and change functions

Function Control

System Groups Views text and background graphics.

Inputs Change value and manual mode status

Outputs Change value and manual mode status

Variables Change value and manual mode status

PID Controllers Change value and manual mode status

Weekly Schedules Change times

Annual Schedules Change dates

These functions are fully described in the section The Control Menu of the

WinControl XL Plus User’s Manual.

Applicable models The topics in this section apply only to the following models:

◆ KMD-5270 ◆ KMD-5270-005

◆ KMD-5270-001 ◆ KMD-5270-006

Revision J 35

Page 36

Using a web browser (KMD-5270 models only)

Note

Click to change to

compatibility mode.

Enter IP

address

Click to log in

Enter operator name

and password

Browser requirements

KMC Controls

Browser

requirements

Opening the WebLite home page

Use only Microsoft Internet Explorer to view the web pages in a KMD-5270

controller. The browser requires the Java Virtual Machine, a product of Oracle, to

view the trend graphs in the controller. Download the Java Virtual Machine at the

following address.

www.oracle.com.

If you are using Internet Explorer version 10, which will only run on Windows 7

or Windows 8, you must enable the Compatibility View to get the WebLite web

pages to work correctly. If you open the WebLite web page and the Login button is

not present, change the compatibility mode by clicking the Compatibility icon

in the address bar.

Illustration 5-1 Changing to compatibility mode in IE 10.

To access a WebLite with a web browser, open a browser window and then enter

the IP address for the controller in the address bar. The WebLite home page opens.

Two IP addresses may be assigned to a WebLite. The network system

administrator will provide the address.

◆ Use the internal IP address if you are connected to the same network as the

WebLite.

◆ Use the IP address assigned for viewing with a browser if you are

connecting to the WebLite through an internet service or network firewall.

36

Illustration 5-2 WebLite home page

Revision J

Page 37

Choose available

functions from

the Controller

Data list

Click to log out

KMD-5205 and KMD-5270 Installation and Operation

Log in and security

When the home page is open, click Login and then enter your user name and

password. Only assigned operators can view or make changes to a WebLite

controller. Security levels are assigned with WinControl XL Plus and correspond

to WebLite permissions as follows:

Operator level Permission

1 View only

3 Changes permitted only to the initial system group

5 View and make changes

After a logging in, the home screen displays a list of available functions.

Using a web browser (KMD-5270 models only)

Opening the WebLite home page

Table 5-2 Password permissions

that opens for the operator at sign-on.

Revision J

Illustration 5-3 WebLite home page

Log out

Click the Logout button in the upper right corner of the home page to close the

connection with the WebLite. Logging out maintains security and prevents

unauthorized modifications to the system.

37

Page 38

Using a web browser (KMD-5270 models only)

Note

Edit link

Viewing and editing

KMC Controls

Viewing and editing Controlling a system through a WebLite is limited to making changes to values,

setting the state of manual overrides and changing times and dates in schedules.

When you choose a point such as Input, a monitor window opens. Below the data

displayed in the window is an edit link which opens an additional window with

the edit page.

Illustration 5-4 View only monitor window

Descriptions, labels and units can be changed only by using WinControl XL

Plus.

38

Revision J

Page 39

Calculator

button

Click OK to send

changes

Calculator

pop-up

Click Reset to

restore to original

state

KMD-5205 and KMD-5270 Installation and Operation

To ma ke c ha nge s t o va lu es:

1. Click Edit. The Edit window opens.

2. Enter a new value.

3. Click

Ok and the change is sent to the controller.

Using a web browser (KMD-5270 models only)

Viewing and editing

Illustration 5-5 Input edit window

Clicking the calculator button opens an additional window with calculator

functions. The value in the calculator pop-up is sent to the edit page when you

close the calculator pop-up or click

until you click

OK in the edit page.

Ok. The change is not sent to the controller

Revision J

39

Page 40

Using a web browser (KMD-5270 models only)

Note

PID controllers

KMC Controls

PID controllers PID controllers are managed the same as the input function described in Viewing

and editing on page 38.

Illustration 5-6 PID control loop

Trend Logs Trend logs may be viewed as either a table or graph.

Viewing trend log graphs require the Sun Microsystems Java Virtual Machine

to be installed on your computer. Download the Virtual Machine at http://

java.sun.com/getjava/download.html

To view a trend log:

1. Choose Trend Log from the Controller Data list. A trend log list window

opens.

2. Choose a trend log from the list. A window opens and displays the trend

log in table format.

3. Click

4. Passing the cursor over a point on the graph displays the data value and

To zoom in on a specific detail:

1. Left click and drag from left to right over the points you want to examine.

Open Graph. A new window opens in which the controller will graph

the data.

the time it was collected in the

Pointer Coordinates box.

40

Revision J

Page 41

KMD-5205 and KMD-5270 Installation and Operation

2. Click No Zoom to return to normal view.

Using a web browser (KMD-5270 models only)

Trend Logs

Illustration 5-7 Trend log graph

Revision J

41

Page 42

Using a web browser (KMD-5270 models only)

Schedules

KMC Controls

Schedules Weekly and annual schedules are managed much the same as with WinControl.

The method for editing a weekly schedule is described in

page 38.

Viewing and editing on

42

Illustration 5-8 Weekly and annual schedules

Revision J

Loading...

Loading...