Page 1

Installation and Operation Guide

KMD-5220

Input Module

For use with KMD-5210

Revision C

883-019-05C

Page 2

KMC Controls

Important notices ©2013, KMC Controls, Inc.

WinControl, NetSensor, and the KMC logo are registered trademarks of KMC

Controls, Inc.

TotalControl, BACstage, and FullBAC are trademarks of KMC Controls, Inc.

All rights reserved. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language in any

form by any means without the written permission of KMC Controls, Inc.

Printed in U.S.A.

Disclaimer The material in this manual is for information purposes only. The contents and

the product it describes are subject to change without notice. KMC Controls, Inc.

makes no representations or warranties with respect to this manual. In no event

shall KMC Controls, Inc. be liable for any damages, direct or incidental, arising

out of or related to the use of this manual.

KMC Controls

P. O . Box 497

19476 Industrial Drive

New Paris, IN 46553

U.S.A.

TEL: 1.574.831.5250

FAX: 1.574.831.5252

E-mail: info@kmccontrols.com

Revision C2

Page 3

KMD–5220 Installation and Operation

Contents

Section 1

Introduction

Specifications ........................................................................................................................ 5

Accessories ............................................................................................................................ 7

Safety considerations ..........................................................................................................8

Section 2

Installation

Mounting .............................................................................................................................. 9

Planning for input modules ............................................................................................... 9

Module installation ........................................................................................................... 10

Connecting inputs ............................................................................................................. 11

Section 3

Operation

Status LED .......................................................................................................................... 13

Auxiliary power fuse ........................................................................................................ 14

Power On/Off .................................................................................................................... 14

Maintenance ....................................................................................................................... 14

Revision C 3

Page 4

KMC Controls

Revision C4

Page 5

SECTION 1

Introduction

This section provides an introduction to the KMD-5220 Input

Module. You will also find Safety Considerations included in this

section. Review this material in its entirety before installing or

operating the module.

The KMD-5220 Input Module is an auxiliary device for the KMD-5210 LAN

Controller. The Input Module takes up to 16 separate inputs and processes the

information for input to the LAN Controller. The module can process active,

passive, current loop or pulse inputs.

The module also provides a fused, auxiliary power terminals for connecting up

to 6 external transducers.

The KMD-5220 Input Module is designed to accept digital or analog inputs from

active and passive sensor and control devices and process those inputs for use

by the KMD-5210 LAN Controller.

Specifications Input

Universal inputs 16

Key features Each input software selectable for analog or digital

Connector Removable screw terminal block, wire size

Pull–up resistors Selected by moveable jumper for 1KΩ, 10KΩ

Input impedance 1KΩ or 10KΩ for 1KΩ or 10KΩ pullup

Overvoltage protection 24 volts AC, continuous

Input range 0–5 volts DC

Weight 16 ounces (454 grams)

Indicators Status LED flashes when card is accessed

Ambient Limits

Operating 0 to 120°F (–18 to 49°C)

Shipping –40 to 140°F (–40 to 60°C)

Humidity 0–95% RH, non-condensing

signals. Standard and custom units of measure.

Pull-up resistors for switch contacts and other

unpowered equipment.

AWG

14–22

4-20mA or none.

250Ω for 4–20 mA

100KΩ without jumper

Revision C 5

Page 6

Introduction

A

B

C

E

D

F

Specifications

KMC Controls

Regulatory UL 916 Energy Management Equipment listed

CE compliant

FCC Class B, Part 15, Subpart B

SASO PCP Registration KSA R-103263

Dimensions

Table 1-1 Dimensions

A B C D E F Height (not shown)

4.50 in. 9.00 in. 4.00 in. 0.25 in. 6.00 in. 1.50 in.

114 mm 229 mm 102 mm 6 mm 152 mm 38 mm

0.98 in.

25 mm

6

Revision C

Page 7

KMD–5220 Installation and Operation

Accessories

Ribbon cables

KMD-5660 6 inch (15 cm) ribbon cable

KMD-5668 9 inch (23 cm) ribbon cable

KMD-5661 14 inch (36 cm) ribbon cable

KMD-5662 19 inch (48 cm) ribbon cable

KMD-5663 24 inch (61 cm) ribbon cable

Introduction

Accessories

Revision C

7

Page 8

Introduction

Danger

Warning

Caution

Note

Detail

Safety considerations

KMC Controls

Safety

considerations KMC Controls assumes the responsibility for providing you a safe product and

safety guidelines during its use. Safety means protection to all individuals who

install, operate, and service the equipment as well as protection of the

equipment itself. To promote safety, we use hazard alert labeling in this manual.

Follow the associated guidelines to avoid hazards.

Danger represents the most severe hazard alert. Bodily harm or death will

occur if danger guidelines are not followed.

Warning represents hazards that could result in severe injury or death.

Caution indicates potential personal injury or equipment or property damage

if instructions are not followed.

Notes provide additional information that is important.

Provides programing tips and shortcuts that may save time.

8

Revision C

Page 9

KMD–5220 Installation and Operation

SECTION 2

Installation

This section provides important instructions and guidelines for

installing the KMD-5220 Input Module. Carefully review this

information before installing a KMD-5220 module.

Mounting Mount KMD-5220 input modules and the KMD-5210 to which they are

connected inside of a metal enclosure. KMC Controls recommends using a ULapproved Enclosed Energy Management Equipment Panel such as a KMC

model HCO–1034, HCO–1035 or HCO–1036. Use the two mounting holes on

each side of the module to fasten it securely to a flat surface with #6 or #8

hardware. See

dimensions. To maintain RF emissions specifications, use either shielded

connecting cables or enclose all cables in conduit.

Dimensions on page 6 for mounting hole locations and

Installation

Mounting

Planning for input modules

To connect inputs devices to a KMD-5210 controller, use one or more KMD-5220

input modules. The KMD-5210 controller includes eight universal I/O ports for

up to eight KMD-5220 input modules, eight KMD-5221 output modules or any

combination of up to eight modules.

Each module connects to the controller using a flat ribbon cable. Connect the

first KMD-5220 input module to connector

modules from left to right.

I/O Card 1; continue adding input

Revision C

Illustration 2-1 Input module connections

9

Page 10

Installation

Note

Caution

Pin 1 edge

(Red)

I/O port

connection

Input/Output card

connection

Fold gently

Pin 1 edge

(Red)

Fold back

Module installation

Module

KMC Controls

installation

1. Position and mount the modules near the KMD-5210 to which it will

connect. Input modules connect at position I/O Card #1.

2. Connect the ribbon cable to the KMD-5210 LAN Controller. Estimate the

required cable length and select from one of the cables from KMC Controls.

See Ribbon cables

on page 7 in the Accessories section.

Observe the orientation of the cable header. If the pin 1 edge is reversed, the

controller will not communicate with the module.

Illustration 2-2 Ribbon cable orientation

3. Connect the other end of the ribbon cable to the input module. You may

find it necessary to fold the cable to properly route it to the module.

To accommodate turns, fold the cable gently to change direction. To make a fold,

overlay the cable at a right angle and press gently until the cable holds the fold

as shown in

Illustration 2-3.

10

Illustration 2-3 Ribbon cable fold

Do not crimp the cable in a tight fold. This may result in separation of cable

strands and result in unreliable operation of the module.

4. Connect input devices to the modules.

Revision C

Page 11

KMD–5220 Installation and Operation

Connecting

Installation

Connecting inputs

inputs

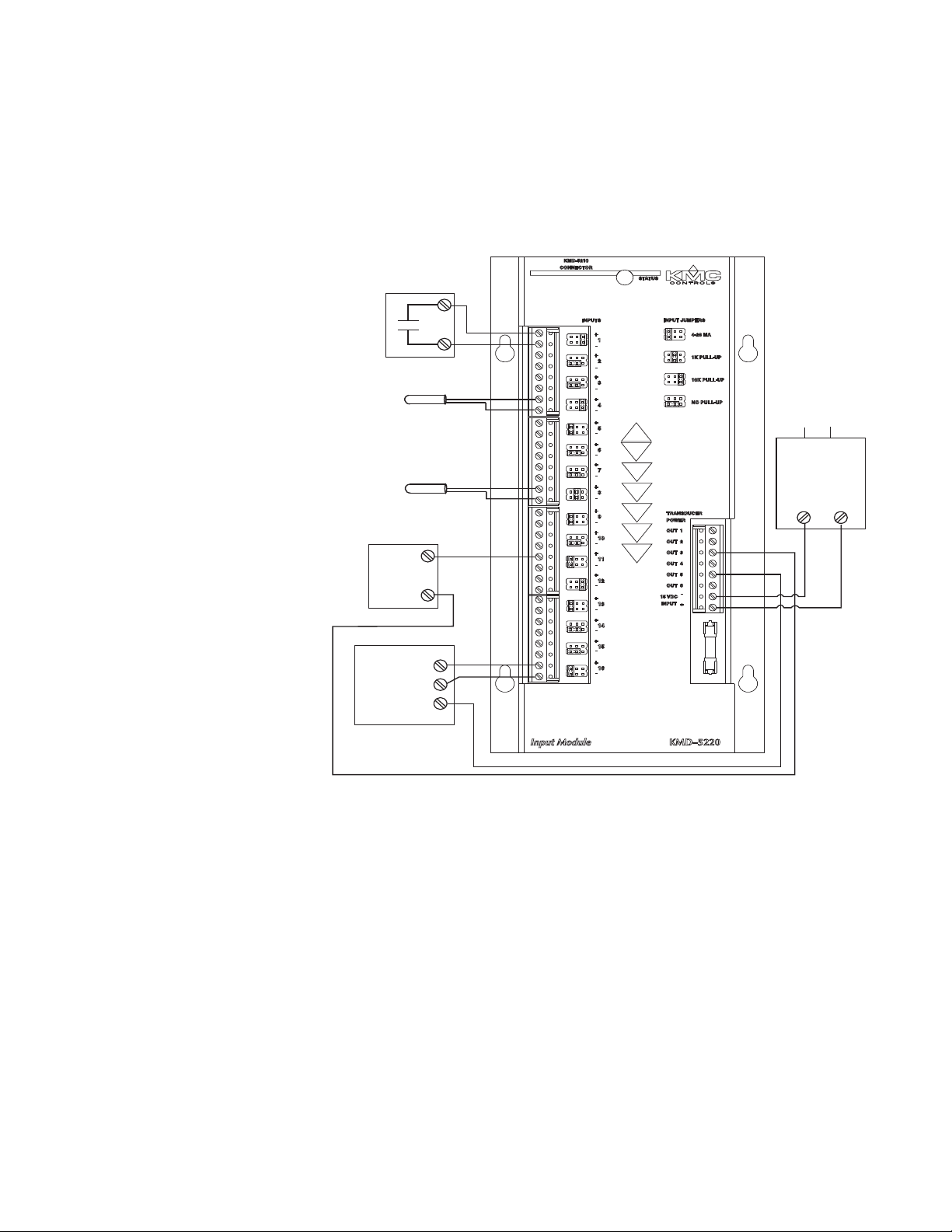

The controllers include 16 universal inputs. Each input can be configured with

software to receive either analog or digital signals. By using the optional pullup

resistors, either passive or active devices may be connected to the inputs. For

additional information, see

Appendix C, Connecting Inputs and Outputs in the

WinControl XL Plus manual.

Pull–up resistors

For passive input signals, such as thermistors or switch contacts, use a pull-up

resistor. For KMC thermistors and most other applications place the moveable

jumper in the

10K position. For 1kΩ platinum RTD sensors, place the moveable

jumper in the 1K position.

Pulse inputs

Connect pulse inputs under the following conditions:

◆ Use only the input module installed in the card #1 position for pulse inputs.

◆ If the pulse input is a passive input such as switch contacts, then place the

input pull-up in the 10K position.

◆ If the pulse is an active voltage (up to a maximum of +5 volts DC ), then

place the input pull-up jumper in the None position.

4–20 mA inputs

To use a 4–20 current loop input, place the moveable jumper in the 4-20mA

position. This places a 250 ohm resistor across the input terminals which will

convert the current input to a voltage which can be read by the controller’s

analog-to-digital converter.

Revision C

11

Page 12

Installation

4-20 Sig

(–) Com

(+) Pwr

(–)

(+)

24 VAC

Regulated

DC Power

Supply

(–)

(+)

10K thermistor

1K platinum RTD

4–20 mA

transmitter

4–20 mA

transmitter

Switch

contacts

Connecting inputs

KMC Controls

Ground terminals

Ground terminals (-) are located next to each input terminal. Up to two wires,

size 12–22 AWG, can be clamped into each ground terminal. If more than two

wires must be joined at a common point, use an external terminal strip to

accommodate the additional wires.

12

Illustration 2-4 Typical input configurations

Auxiliary transducer power

The KMD-5220 Input Module has provisions for supplying power to six external

transducers. These terminals are located on the lower right side of the module.

The maximum output of all six outputs cannot exceed 1 ampere or the fuse will

open.

The negative power supply terminal is common to the analog input grounds.

For example, on a two–wire device the power is drawn from one of the six

outputs and the return goes to one of the inputs terminals. On a three–wire

transducer, the input negative can be run to the transducer to provide a power

supply reference. See

Illustration 2-4 for example of input connections.

Revision C

Page 13

KMD–5220 Installation and Operation

Status LED

Auxiliary

power fuse

SECTION 3

Operation

This section provides general operating instructions for your

KMD-5220 input module. Carefully review this information before

operating the module.

Once the input module is wired and powered up, operation is automatic.

Operation

Status LED

Illustration 3-1

Status LED The status LED at the top of the module will illuminate when the module is

communicating with the LAN controller too which it is connected. Under

normal operation the LED blinks at a regular rate. The LED glows steady until

the LAN controller to which it is connected is programmed in HCM and at least

one input is configured with WinControl XL Plus.

Revision C

13

Page 14

Operation

Caution

Auxiliary power fuse

Auxiliary power

KMC Controls

fuse

If the output of all six auxiliary power terminals exceeds 1 ampere, the fuse will

open. The fuse must be replaced with a fuse of equivalent rating.

Do not use a larger rated fuse as this may result in damage to the KMD-5220.

Power On/Off The input module does not use an On/Off switch or a power jumper. After the

module is connected to a LAN controller and the LAN controller is powered, the

module is also powered.

Maintenance The KMD-5220 does not require routine maintenance. If cleaning is required, wipe

soft, damp cloth and mild soap.

with a

14

Revision C

Loading...

Loading...