Page 1

Installation and Operation Guide

KMD-5210 LAN Controller

KMD-5210–001 LAN Controller with BACnet 802.3

KMD-5210–002 LAN Controller with BACnet MS/TP

Revision E

883-019-07E

Page 2

KMC Controls

Important notices ©2012, KMC Controls, Inc.

WinControl and WinControl XL is a registered trademark of KMC Controls, Inc.

TotalControl is a trademark of KMC Controls, Inc.

All rights reserved. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language in any form

by any means without the written permission of KMC Controls, Inc.

Printed in U.S.A.

Disclaimer The material in this manual is for information purposes only. The contents

and the product it describes are subject to change without notice. KMC

Controls, Inc. makes no representations or warranties with respect to this

manual. In no event shall KMC Controls, Inc. be liable for any damages, direct

or incidental, arising out of or related to the use of this manual.

KMC Controls

P.O. Box 497

19476 Industrial Drive

New Paris, IN 46553

U.S.A.

TEL: 1.574.831.5250

FAX: 1.574.831.5252

E-mail: info@kmccontrols.com

Revision E2

Page 3

KMD–5210 Installation and Operation

Contents

Section 1

About the LAN controller

Introduction .......................................................................................................................... 5

BACnet options .................................................................................................................... 5

Specifications ........................................................................................................................ 6

Options and Accessories ..................................................................................................... 9

Controls and Connections ................................................................................................ 10

Safety Considerations ....................................................................................................... 11

Section 2

Installation

Mounting ............................................................................................................................ 13

Network connections ........................................................................................................ 14

EIA–485 networks .............................................................................................................. 16

BACnet networks ............................................................................................................... 18

Planning for input and output modules ........................................................................ 20

Module installation ........................................................................................................... 21

Connecting Power ............................................................................................................. 22

Connecting to a Computer ............................................................................................... 23

Section 3

Operation

Applying power .................................................................................................................27

Lights and indicators ......................................................................................................... 27

Resetting the controller ..................................................................................................... 29

Section 4

Configuration and programming

Related materials ............................................................................................................... 31

Programming Considerations .......................................................................................... 31

Configuring a controller with HCM ............................................................................... 32

Programming for BACnet in WinControl XL ................................................................ 36

Access to the LAN Controller from BACnet ................................................................. 37

Firewalls and network communications ........................................................................ 37

System time keeping ......................................................................................................... 37

Revision E 3

Page 4

KMC Controls

Revision E4

Page 5

KMD–5210 Installation and Operation

SECTION 1

About the LAN controller

This section provides a general introduction to the KMD-5210 LAN

Controller. It also introduces safety information. Review this

material in its entirety before installing or operating the controller.

Introduction The KMD-5210 LAN Controller is a programmable, direct digital controller

used to facilitate high-level, peer-to-peer network communications for

facilities management purposes. The LAN Controller may be operated in a

stand alone configuration or as part of a fully networked digital system to

intelligently monitor and control HVACR equipment.

The KMD-5210 uses a token passing protocol in Tier 1 networks using an

Ethernet network to communicate with other LAN Controllers. The LAN

Controller also supports Tier

Up to 32 KMD-5210 controllers can be integrated into a single peer-to-peer

network, each supporting up to 124 nodes on a Tier

The controller also supports remote access through a modem port and

provides two ports for direct connection with up to two PCs. The firmware in

the controller uses a high-level, easy-to-learn programming language to

ensure reliability, rapid programming, and compatibility with future KMC

system. This programming function is available from within the KMC

Controls WinControl application.

2 networks with two dedicated EIA–485 ports.

2 network.

BACnet options BACnet 802.3 The KMD-5210-001 adds BACnet functionality to the LAN

Controller. Through Control Basic statements the controller communicates

with 802.3 BACnet devices on the same Ethernet broadcast segment.

BACnet MS/TP The KMD-5210-002 adds BACnet MS/TP functionality to the

LAN Controller functionality. By using Control Basic programming, the

controller exchanges data with native BACnet devices on an MS/TP network.

Revision E 5

Page 6

About the LAN controller

Specifications

Specifications

KMC Controls

Processor Motorola 68360, 32–bit, 33 MHz

Memory

Flash 2 megabytes, nonvolatile, operating programs

and data storage

RAM 2 megabytes, 72–hour capacitor backup

Inputs and Outputs The KMD-5210 controller includes eight

universal I/O ports for optional input and

output modules. Connect up to eight KMD-5220

input modules, eight KMD-5221 output

modules or a combination of input and output

modules in any combination.

I/O Ports Eight, 16–pin connectors. Software selectable as

analog or digital standard or custom units of

measure.

Inputs 16–bit analog-to-digital (A/D)

Software selectable as analog or digital standard

or custom units of measure. Install up to 8, 16

input modules for up to 128 universal inputs.

Output 12–bit digital to analog (D/A)

Communications

Tier 1 EIA–485 protocol at rates up to 38 kilobaud.

Connector type is a three-screw terminal block,

12–22 AWG wire.

Note: Use the Tier 1 connection only when

replacing KMD–5110 MultiNet controllers and

Ethernet is not available. Contact KMC Controls

techncial support for networking details.

Tier 2 A and B EIA–485 protocol at rates up to 38 kilobaud.

Connectors are three-screw terminal blocks,

12–22 AWG wire. Two ports, each of which

support up to 124 KMC Tier

2 controllers.

EIA–485 EIA–485 protocol at rates up to 38 kilobaud.

Connector is a three-screw terminal block,

AWG wire. Supports BACnet MS/TP in

12–22

KMD-5210–002.

Modem EIA–232 in parallel with Computer B. Dial-in

and dial-out for with alarm and paging

capability, 9–Pin (DB-9).

Computer A and B Two EIA–232 ports, operate up to 38.4 kilobaud.

Connectors are three-screw terminal blocks,

12–22 AWG wire.

Ethernet 10baseT, RJ–45 supports up to 31 networked

1 controllers and BACnet 802.3 in KMD-

Tier

5210–001

6

Revision E

Page 7

KMD–5210 Installation and Operation

Programmable Features

Control Basic Programs 128 user-definable program areas

Networked Points In 512 from each Tier 2 network

Networked Points Out 64 to each Tier 2 network

PID Control Loops 64 PID control loops

Program Variables 256 - Software selectable as analog or digital

Time keeping Real-time clock with power backup.

Ta bl es 5 user defined

Logging

Trend Logs 96 trend logs each supporting up to 6 analog,

Runtime Logs 28 runtime logs with time/date stamp and

About the LAN controller

Specifications

127 from Tier 1 network

64 out to a Tier 1 network

with standard or custom ranges, manually set or

program driven values

Programmable for automatic daylight saving

time by date, day of month and time of day.

digital, or virtual elements or points

cumulative runtime

Schedules

Weekly Schedule 32 schedules with 2 override days

Annual Schedule 16 for holiday schedules

Alarms Alarm buffering for up to 128 alarms

50 alarm messages for distribution

On-board 68-character alarm or maintenance

text messages

Power Loss Power fail with auto restart

On-board real-time clock with 72–hour

capacitor backup.

Security Six operator access levels

256 operator names with passwords

Custom Graphics 64 system groups each of which can manage 160

points with animated and color graphics.

Regulatory UL 916 Energy Management Equipment listed

CE compliant

FCC Class B, Part 15, Subpart B

SASO PCP Registration KSA R-103263

Revision E

7

Page 8

About the LAN controller

C

A

B

D

E

F

Specifications

KMC Controls

Power Supply Requires KMD–5563, International-ready 120/

240 VAC, 1.35 ampere power supply

Environmental Limits

Operating 32° to 120° F (0° to 49° C)

Shipping –40° to 140° F (–40° to 60° C)

Humidity 0–95% RH, non-condensing

Weight 1.8 pounds (816 grams)

Compatibility

Software WinControl XL Plus 1.06 or later

TotalControl 1.8.1 or later

Controllers Compatible with Tier 1 controllers firmware

build 2.01 or later

Dimensions

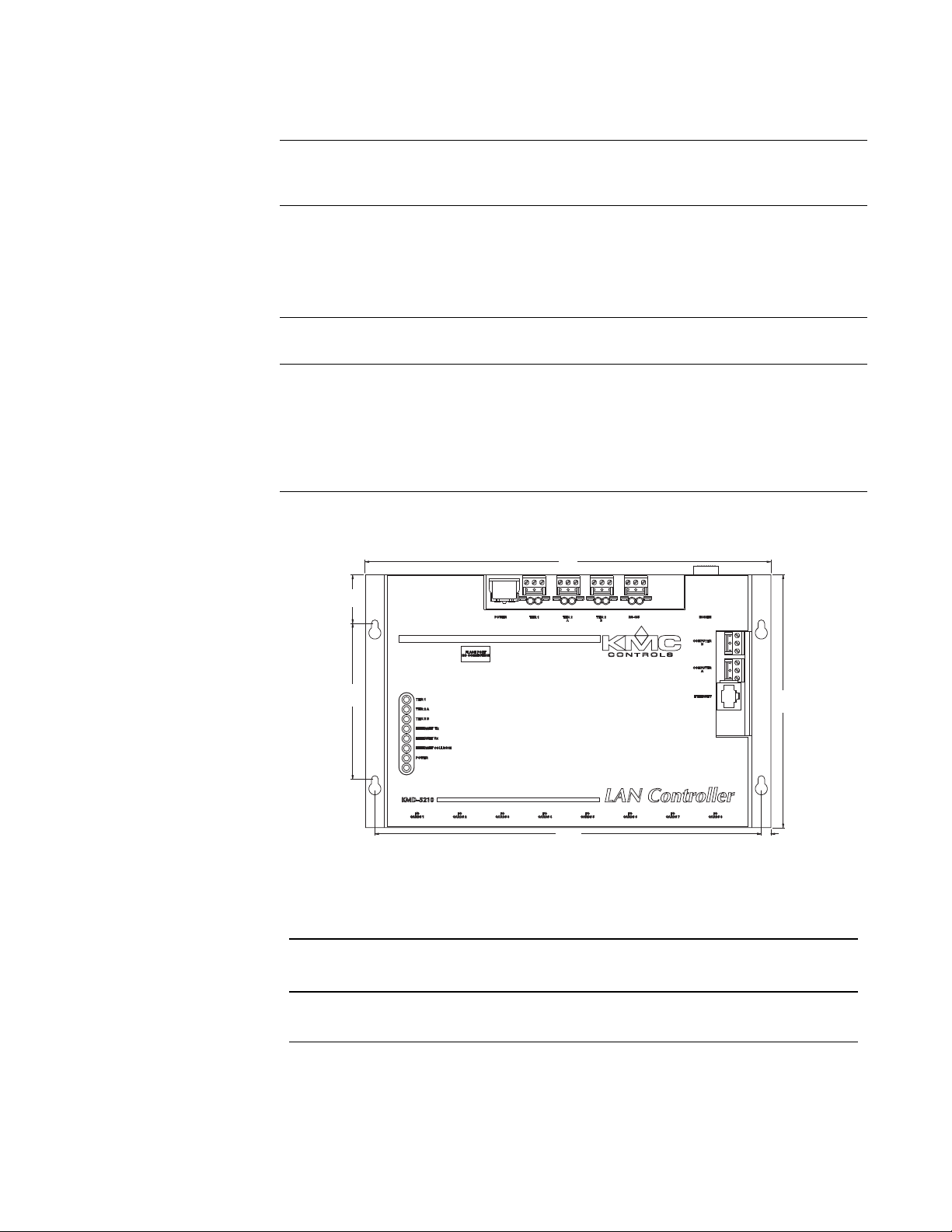

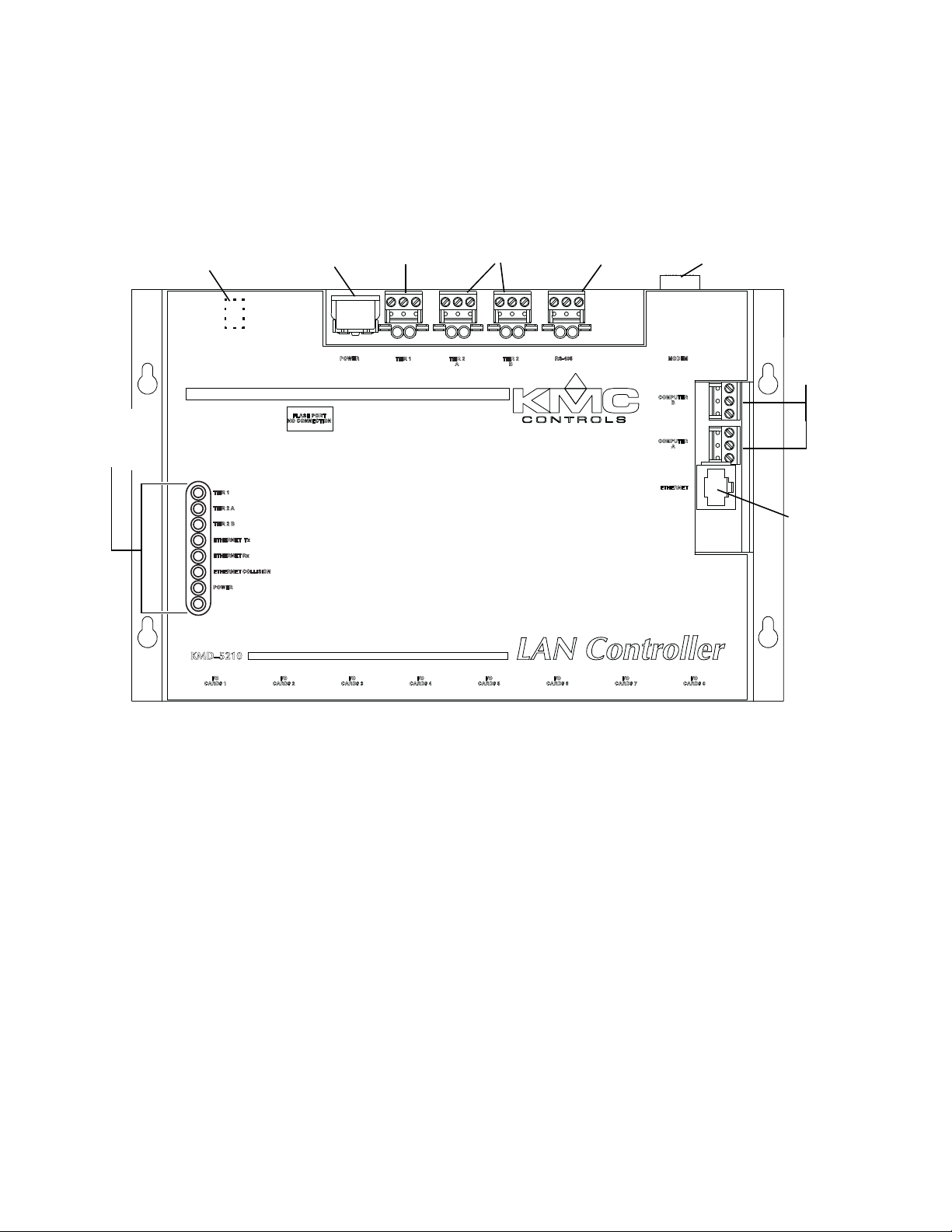

Illustration 1-1 KMD-5210 Components

Table 1-1 KMD-5210 Dimensions

ABCDEF

10.50 in. 6.50 in. 0.25 in. 10.00 4.00 in. 1.25 in. 0.98 in.

267 mm 165 mm 6 mm 254 mm 102 mm 32 mm 25 mm

Height

(not shown)

8

Revision E

Page 9

KMD–5210 Installation and Operation

Options and Accessories Modules

KMD-5220 Input Module

KMD-5221 Output Module

Ribbon Cables for Input and Output Modules

KMD-5660 6 inch (15 cm) ribbon cable

KMD-5668 9 inch (23 cm) ribbon cable

KMD-5661 14 inch (36 cm) ribbon cable

KMD-5662 19 inch (48 cm) ribbon cable

KMD-5663 24 inch (61 cm) ribbon cable

Power

KMD-5563 International-ready power supply, 120/240

XEE-6112-100 100 VA Transformer, 24 volts AC (required only

About the LAN controller

Options and Accessories

volts AC, 1.35 amperes

for KMD-5221 output module)

Upgrades

HTO-1102 Flash Kit Module; KMD/BAC-5XXX,

BAC-7XXX (Replaces KMD-5696)

Enclosures

HCO-1035 Panel Enclosure (20 x 24 x 6 inches)

x 610 x 152 mm)

(508

HCO-1036 Panel Enclosure (24 x 36 x 6 inches)

x 914 x 152 mm)

(610

Revision E

9

Page 10

About the LAN controller

Reset button

(Beneath cover)

Power

Tier 1

EIA–485

Tier 2

EIA–485 Modem

BACnet

MS/TP

EIA–232

for PC

Ethernet

and

BACnet

802.3

LED

Status

Display

Controls and Connections

KMC Controls

Controls and

Connections Before installing the KMD-5210 LAN Controller, take some time to become

familiar with the controller layout and components.

10

Illustration 1-2 Controls and indicators

Revision E

Page 11

Danger

Warning

Caution

Note

Detail

KMD–5210 Installation and Operation

About the LAN controller

Safety Considerations

Safety

Considerations KMC controls assumes the responsibility for providing you with a safe

product and safety guidelines for its proper use. Safety means protection to all

individuals who install, operate and service the equipment as well as

protection of the equipment itself. To promote safety, we use hazard alert

labeling in this manual. Follow the associated guidelines to avoid hazards.

Danger represents the most severe hazard alert. Bodily harm or death will

occur if danger guidelines are no t followed.

Warning represents hazards which could result in severe injury or death.

Caution indicates potential personal injury or equipment or property damage

if instructions are not followed.

Notes provide additional important information.

Provides programming tips and shortcuts which may save time.

Revision E

11

Page 12

About the LAN controller

Safety Considerations

KMC Controls

12

Revision E

Page 13

Note

Allow 1.5 in. (3.8 cm) for cables

Allow 3.0 in. (7.6 cm) for cables

Mounting

holes

Mounting

holes

KMD–5210 Installation and Operation

SECTION 2

Installation

This section provides important instructions and guidelines for

installing the KMD-5210 LAN Controller. Carefully review this

information prior to installation.

Mounting Mount the controller inside of a metal enclosure. KMC Controls recommends

using a UL-approved Enclosed Energy Management Equipment Panel such as

a KMC model HCO–1034, HCO–1035 or HCO–1036. Insert #6 or #8 hardware

through the two mounting holes on each side of the controller to securely

fasten it to a flat surface. See

locations and dimensions. To maintain RF emission specifications, use either

shielded connecting cables or enclose all cables in conduit.

Illustration 1-2 on page 10 for mounting hole

Provide sufficient clearance around the controller for cables and wiring.

◆ Allow a minimum of 3 inches (7.6 cm) of clearance at the top edge of the

controller for the power and modem connectors.

◆ Allow a minimum of 1.5 inches (3.8 cm) of clearance for the ribbon cables

at the bottom of the controller.

Illustration 2-1 Mounting details

Revision E 13

Page 14

Installation

~

+

1

+

2

+

3

+

4

+

5

+

6

+

7

+

8

+

9

+

10

+

11

+

12

+

13

+

14

+

15

+

16

STATUS

KMD-5210

CONNECTOR

OUTPUTS

SC

1-4

SC

5-8

SC

9-12

SC

13-16

SWITCHED

COMMONS

24 VAC

STATUS H O A

STATUS H O A

O-R

O-R

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

1

2

3

4

5

6

7

8

STATUS H O A

STATUS H O A

O-R

O-R

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

1

2

3

4

5

6

7

8

+

1

+

2

+

3

+

4

+

5

+

6

+

7

+

8

+

9

+

10

+

11

+

12

+

13

+

14

+

15

+

16

STATUS

KMD-5210

CONNECTOR

INPUT JUMPERS

4-20 MA

1K PULL-UP

10K PULL-UP

NO PULL-UP

TRANSDUCER

POWER

OUT 1

OUT 2

OUT 3

OUT 4

OUT 5

OUT 6

15 VDC

INPUT

+

INPUTS

~

+

1

+

2

+

3

+

4

+

5

+

6

+

7

+

8

+

9

+

10

+

11

+

12

+

13

+

14

+

15

+

16

STATUS

KMD-5210

CONNECTOR

OUTPUTS

SC

1-4

SC

5-8

SC

9-12

SC

13-16

SWITCHED

COMMONS

24 VAC

STATUS H O A

STATUS H O A

O-R

O-R

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

1

2

3

4

5

6

7

8

STATUS H O A

STATUS H O A

O-R

O-R

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

O-R STATUS H O A

1

2

3

4

5

6

7

8

+

1

+

2

+

3

+

4

+

5

+

6

+

7

+

8

+

9

+

10

+

11

+

12

+

13

+

14

+

15

+

16

STATUS

KMD-5210

CONNECTOR

INPUT JUMPERS

4-20 MA

1K PULL-UP

10K PULL-UP

NO PULL-UP

TRANSDUCER

POWER

OUT 1

OUT 2

OUT 3

OUT 4

OUT 5

OUT 6

15 VDC

INPUT

+

INPUTS

Modem

Power

Supply

RS-485

Tier 1

VAV

TERMINAL

CONTROLLER

U.V.

Terminal

Controller

Local

Controller

HEAT PUMP

TERMINAL

CONTROLLER

Vav

Terminal

Controller

Local

Controller

Tier 1 KMC Ethernet

(BACnet 802.3

Optional)

RS-485

(Optional BACnet

MS/TP)

INPUT MODULE

KMD-5220

INPUT MODULE

KMD-5220

OUTPUT MODULE

KMD-5221

OUTPUT MODULE

KMD-5221

Network connections

Network

KMC Controls

connections

Prior to making network connections, determine which connections will be

used and how the network will be configured. An example of a typical

installation is shown in

Illustration 2-2.

Each KMD-5210 in a KMC digital network may operate in either a stand-alone

mode or connected by network to other controllers. The LAN Controller may

be connect to other controllers using one or more of four network

technologies.

◆ KMC Tier 1 networks using standard 10BaseT, CAT 5 Ethernet cabling or

EIA–485 wiring and hardware.

◆ KMC Tier 2 networks using EIA–485 wiring and hardware.

◆ BACnet 802.3 networks using standard 10BaseT CAT 5 Ethernet cabling

(KMD-5210-001 only)

◆ BACnet MS/TP using EIA–485 wiring and hardware (KMD-5210-002

only)

Illustration 2-2 Typical network configuration

14

Revision E

Page 15

Note

Ethernet hub

or router

KMD–5210 Installation and Operation

Up to 32 LAN Controllers can be connected to the same Ethernet backbone in

a common Ethernet network. This configuration also allows multiple PCs to

access the system through the Ethernet network.

Connect the controller to the network by connecting a standard 10BaseT

Ethernet cable (CAT 5) to the Ethernet/BACnet port on the controller and to a

port on the network hub or router. (See “Ethernet Settings” later in this guide

for recommended Ethernet Software Settings.)

For reliable operation, use CAT 5 or equivalent Ethernet cables for all

connections. If cables are custom made, they must meet the CAT 5

specification.

Installation

Network connections

Revision E

Illustration 2-3 Typical Ethernet network configuration

15

Page 16

Installation

Note

Note

EIA–485 networks

KMC Controls

EIA–485 networks The KMD-5210 LAN Controller provides four active EIA–485 connection

ports.

◆ Tier 1

◆ Tier 2A

◆ Tier 2 B

◆ EIA–485 for BACnet MS/TP

Use the Tier 1 port (marked Main Net on older controllers) to connect several

KMD-5210. This is an alternative to connecting LAN Controllers to each other

with Ethernet. This port will allow up to 31 controllers to be connected

together by network.

The Tier 1 EIA–485 port is disabled when the controller is assigned an IP

address for operation on an Ethernet network. Tier 2 A and Tier 2 B will

function normally. Ethernet IP addresses are configured with Hardware

Configuration manager.

The Tier 2 A and Tier 2 B ports are for connection to Tier 2 networks. Each port

supports up to 124 individual controllers.

For reliable operation, use Belden cable model #82760 or equivalent (18 gauge,

twisted, shielded, 50 picofarads or less) for all EIA–485 network wiring.

Wiring notes

All EIA–485 network segments (KMC protocol or BACnet) use the same

wiring principles.

◆ Use approved shielded cable and the following principles when

connecting a controller to a Tier 2 (sub LAN) network:

◆ Connect no more than 31 KMC addressable controllers or devices to the

Tier 1 RS-485 connector.

◆ Connect no more than 124 KMC programmable controllers to the

Tier 2 A or Tier 2 B connectors.

◆ Connect the A terminal in parallel with all other A terminals.

◆ Connect the B terminal in parallel with all other B terminals.

◆ Connect the shields of the cable together at each controller.

◆ Connect the shields to an earth ground (if available) or chassis ground

only at one end of the segment; tape back the shield ground at the other

end.

◆ Use a KMD–5575 repeater between every 32 Tier 2 controllers or if the

cable length of a Tier 1 or Tier 2 network exceeds 4000 feet (1220 meters).

Use no more than seven repeaters per network.

◆ Place a KMD–5567 surge suppressor in the cable where it exits a

building.

16

Revision E

Page 17

G

A

B

G

G

B

A

G

B

A

A

B

KMC controller

connections

Input termination jumpers

(Two at each EIA–485 connector)

Jumpers set for end-of-line

termination removed.

KMD–5210 Installation and Operation

Refer to Illustration 2-4 for an example of typical EIA–485 connections.

Installation

EIA–485 networks

Illustration 2-4 Typical EIA–484 Wiring Configuration

End-of-line termination

Each EIA–485 network segment requires end-of-line termination for proper

operation of the network. Proper termination prevents signal degradation and

EMI type interference with other system wiring. Termination jumpers are

located on both sides of each EIA–485 connector (one each for the A and B

terminals; see

To activate the end-of-line termination, leave the jumpers in place. If

termination is not required, position the jumpers so they only cover one pin

on the header.

Illustration 2-5.)

Illustration 2-5 End-of-line Termination Jumpers

Revision E

17

Page 18

Installation

Note

Note

Install jumpersRemove jumpers

Install jumpers

BACnet networks

KMC Controls

The controller with only one EIA–485 cable connected is normally the

end-of-line. This is also the controller where the cable shield ground is tied to

earth or a chassis ground

.

Illustration 2-6 End-of-line termination jumper sample for a Tier 1 network

BACnet networks The KMD-5210 LAN Controller supports an optional Class 3 Conformance

Level of the BACnet specification. The BACnet protocol is implemented using

either one or the other of the following network configurations.

◆ Ethernet 802.3 specification in KMD-5210-001

◆ MS/TP EIA–485 in KMD-5210—002.

See the section Programming for BACnet in WinControl XL on page 36 for details on

BACnet features.

The BACnet options are licensed for each controller. To upgrade a KMD-5210

controller to BACnet, contact KMC Controls for license information.

BACnet 802.3

The KMD-5210–001, the BACnet 802.3 version of the LAN controller, connects

to the LAN in the same manner as the standard LAN controller. See

connections on page 14.

The BACnet internetwork most likely will use one or more BACnet routers to

manage the BACnet internetwork and devices. The KMD-5210–001 must be

connected to the same Ethernet broadcast domain segment as at least one

BACnet router and the router must be enabled for BACnet 802.3 traffic. To

configure a KMD-5210–002 for network connections, see

BACnet configuration

on page 35.

Network

18

Revision E

Page 19

Shield + –

KMD–5210 Installation and Operation

BACnet MS/TP

Connect a KMD-5210–002 controller to a BACnet MS/TP network at the

connector

techniques. To configure a KMD-5210–002 for network connections, see

BACnet configuration on page 35.

Installation

BACnet networks

EIA–485. See EIA–485 networks on page 16 for network wiring

Illustration 2-7 BACnet MS/TP connections

Revision E

19

Page 20

Installation

Planning for input and output modules

Planning for input

and output

KMC Controls

modules

To connect inputs or output devices to a KMD-5210 controller, use KMD-5220

input and KMD-5221 output modules. The KMD-5210 controller includes

eight universal I/O ports for up to eight KMD-5220 input modules, eight

KMD-5221 output modules or any combination of up to eight modules.

Each module connects to the controller using a flat ribbon cable. When

connecting input and output modules, use the following guidelines.

◆ Connect the first KMD-5220 input module to connector I/O Card 1; add

continue adding input modules from left to right

◆ Connect the first KMD-5221 output module to connector I/O Card 8 and

continue adding output modules from right to left.

◆ Use ribbon cables no longer than 24 inches (61 cm).

◆ KMD-5221 output modules require an output transformers.

20

Illustration 2-8 Typical input and output module connection

Revision E

Page 21

Note

Pin 1 edge

(Red)

I/O port

connection

Input/Output card

connection

Fold gently

Pin 1 edge

(Red)

Fold back

KMD–5210 Installation and Operation

Module installation

Installation

Module installation 1. Position and mount the modules in the enclosure using the supplied

mounting holes.

2. Connect the ribbon cable to the LAN Controller. Estimate the required

cable length and select from one of the cables from KMC Controls. See

Ribbon Cables for Input and Output Modules on page 9 in the Options and

Accessories section.

Observe the orientation of the cable header. If the pin 1 edge is reversed, the

controller will not communicate with the module.

Illustration 2-9 Ribbon cable orientation

3. Connect the other end of the ribbon cable to the input or output module.

You may find it necessary to fold the cable to properly route it to the

module.

To accommodate turns, fold the cable gently to change direction. To make a

fold, overlay the cable at a right angle and press gently until the cable holds

the fold as shown in

Illustration 2-10.

Illustration 2-10 Ribbon cable fold

Revision E

21

Page 22

Installation

Caution

Caution

Connecting Power

KMC Controls

Do not crimp the cable in a tight fold. This may result in separation of cable

strands and result in unreliable operation of the module.

4. Connect input and output devices to the modules. Refer to the manuals

supplied with the KMD-5220 input module and the KMD-5220 output

module for details.

Connecting Power Each KMD-5210 LAN Controller requires a KMD–5563 power supply for

operating power. Mount the power supply in a convenient location near the

KMD-5210 and route the supply cable to the controller.

The controller will automatically power on when the power connection is

complete. The controller does not use an power switch. See

page 27 for additional information.

Applying power on

Use only a KMC Controls power supply. Powering the controller with an

improper supply may result in damage to the controller.

22

Revision E

Page 23

Note

KMD–5569

modem

Standard 9–pin to

25–pin cable.

KMD–5210 Installation and Operation

Connecting to a Computer

Installation

Connecting to a

Computer To program the controller with WinControl, a computer must be able to access

the controller. Choose from one of the following connection methods.

◆ Modem

◆ Ethernet

◆ EIA–232 connection

Installing a modem interface

By adding an optional modem to the modem port, an off-site computer can

access the controller through a dial-up connection. The modem connection

also supports dial-in and the Control Basic functions TPAGE and NPAGE. If

the modem port is enabled, Computer B port is disabled and is not available

for direct connection with a computer.

KMC Controls recommends using U.S. Robotics modems for off-site

communications. KMC does not offer support for other modem installations.

Revision E

Illustration 2-11 KMD–5569 modem connection to KMD-5210 controller

To install a modem:

1. Connect a a standard DB-9 to DB-25 computer-to-modem cable between

the KMD–5569 modem and a serial port on a computer on which

WinControl is installed. This cable is available from computer supply

sources.

2. Connect the modem to a telephone line dedicated to the network system.

23

Page 24

Installation

Pin 2–Red

Pin 3–Black

Pin 5–Green

Red–Transmit

Ground–-Green

Black–Recieve

KMD–5672

Connecting to a Computer

KMC Controls

3. Verify the configuration switches on the back of the modem are in the

correct position for the firmware in the controller.

Table 2-1 Configuration switches: Firmware 4.0 and later

12345678

Up Up Down Down Down Up Up Down

Table 2-2 Configuration switches: Firmware earlier than 4.0

12345678

Up Up Down Down Up Up Up Down

4. Use HCM to initialize Computer Port B for modem operation.

Connecting a KMD-5210 to an Ethernet LAN

To connect a PC to the controller via the Ethernet, the PC a must have a valid

IP address on the Ethernet network that connects to the controller and install

the PC on the Ethernet. Refer to the section

page 32 for additional information.

Configuring a controller with HCM on

Direct Serial Port Connection

Two RS-232 ports are provided on the controller for connecting a PC directly

to the controller. Connect the PC to the controller using a KMD–5672 PC to

Controller cable. Refer to

Illustration 2-12.

24

Illustration 2-12 PC-controller cable connection

Revision E

Page 25

Note

KMD–5210 Installation and Operation

EIA–232 port B is assigned the same address as the modem port. When the

modem port is in use, a PC cannot be connected to the controller through serial

port B.

Installation

Connecting to a Computer

Revision E

25

Page 26

Installation

Connecting to a Computer

KMC Controls

26

Revision E

Page 27

KMD–5210 Installation and Operation

Operation

Applying power

SECTION 3

Operation

This section provides general operating instructions for your

KMD-5210 LAN Controller. Included are a description of the

Isolation Bulbs, the LED status display, and instructions for resetting

the controller. Carefully review this information as it applies to the

task at hand.

Applying power The KMD-5210 LAN Controller is automatically powered when the power

supply module is connected and plugged in. Verify all external connections

are complete before applying power to the controller.

If an error in an EIA–485 network is indicated by a glowing lamp near one of

the EIA–485 connectors, remove power and troubleshoot the circuit before

you reapply power to the controller. (See Isolation Bulbs in the following

section.)

Lights and indicators

The controller provides a number of different status and diagnostic indicators.

These are described in this section.

Isolation bulbs

Located near each EIA–485 connector you will find two small glass bulbs.

These serve as protective isolation devices for the Tier

EIA–485 networks. The bulbs serve three functions:

◆ When illuminated they indicate improper network phasing. Improper

phasing occurs when the ground potential of the controller is higher than

the phase or the ground potential of other controllers on the network.

◆ The bulbs protect the controller from damage by limiting the input

signal. If voltage or current exceeds safe operating conditions, the bulbs

will act as fuses and open the connections between the controller and the

network.

◆ By removing the bulbs from their sockets you can isolate the controller

from the associated network.

The illustration Isolation bulbs on page 28 locates the isolation bulbs on the LAN

Controller.

2 and BACnet MS/TP,

Revision E

27

Page 28

Operation

Isolation bulbs

(Two at each EIA–485 connector)

Lights and indicators

KMC Controls

Illustration 3-1 Isolation bulbs

LED Indicators

The LAN Controller uses seven LEDs to indicate the status of the controller

and the different networks connected to the controller. The following table

lists the LEDs and their functions.

Table 3-1 Status LED descriptions

LED Function

Tier 1 This green LED indicates the status of the MAIN EIA–485 network.

This LED blinks whenever the controller is transmitting data.

Tier 2A This yellow LED indicates the status of the Tier 2 A EIA–485

network. This LED blinks whenever the controller is transmitting

data.

Tier 2B This yellow LED indicates the status of the Tier 2 B EIA–485

network. This LED blinks whenever the controller is transmitting

data.

Ethernet Tx This green LED blinks when the controller is transmitting data to

the Ethernet network.

Ethernet Rx This green LED blinks when the controller is receiving data from

the Ethernet network.

Ethernet Collision This red LED blinks when there is a collision of data packets on

the Ethernet. While collisions are normal, excessive collisions

indicate a problem somewhere in the network.

Power The green power LED indicates the status of the controller:

Steady Blink – If the controller is operating normally, the LED

blinks at a steady rate.

Dark/Not Lit – If the LED is not lit, it may indicate the controller is

locked or does not have power. You can try resetting the controller

or you can reload the panel information using the KMC Flash

Wizard.

28

Erratic or Repeating Pattern Blink – If the LED is blinking, but not

at a steady rate, the controller is indicating there is a problem with

the license. Contact KMC Controls for assistance.

Revision E

Page 29

Caution

Reset button

KMD–5210 Installation and Operation

Resetting the

Operation

Resetting the controller

controller

Should the controller appear to lock up or stop operating, you must reset the

controller to the factory default state. After the controller is reset, you must

reload any existing panel files to restore normal operation. (See the section

Configuring a controller with HCM on page 32 for additional details

Locate the Reset Button beneath the cover in the upper left corner of the

controller. See

Illustration 3-2 for the reset button location.

Illustration 3-2 Reset button location

To reset the LAN Controller:

1. Remove power from the controller by unplugging the power supply.

2. Remove the EIA–485 three–terminal connector blocks for all connected

EIA–485 ports. Also, remove Ethernet cables, modem cables, and any PC

connections.

3. Unplug all I/O ribbon cables.

4. Depress and hold the Reset Button while reestablishing power to the

LAN Controller.

5. Continue to hold the reset button until MAIN, Tier 2 A and Tier 2 B LEDs

light.

Revision E

Do not remove power during the reset process. Damage may result to the

board if this happens.

6. Release the Reset Button and allow the controller to continue to power

up steady blink Power LED).

7. Remove power from controller.

8. Return all cables and terminal blocks to their proper positions.

9. Reapply power to the LAN Controller and allow it to return to the

normal operating state (blinking Power LED).

10.If this is a new installation, the controller must be configured before it can

be placed into operation. Refer to

Configuration and programming on page 31

of this guide for instructions.

11.If you are resetting the controller but not replacing it, use the HCM

program to reload panel files.

12.Cycle power to the controller to establish the newly configured operating

parameters.

29

Page 30

Operation

Resetting the controller

KMC Controls

30

Revision E

Page 31

KMD–5210 Installation and Operation

Configuration and programming

Related materials

SECTION 4

Configuration and programming

This section describes the individual configuration instructions used

to establish the operating parameters for the KMD-5210 LAN

Controller. This section includes basic configuration, Ethernet

configuration, BACnet configuration and Ethernet verification.

Related materials In addition to the material presented in this installation and operation guide,

review and have available the following reference materials.

◆ WinControl XL Plus User’s Manual and installed help

◆ HCM reference guide

◆ TotalControl Design Studio Reference Guide

◆ System plans with controller addresses

Programming Considerations

The design of the KMD-5210 LAN Controller provides areas where specific

user programs may be stored. This allows a great deal of versatility and

function in the way the controller is used. It also allows for changes to the

system to meet changing requirements or conditions.

All programming functions are accomplished using the WinControl

WinControl XL Plus applications from KMC Controls. Please refer to the

current version of the WinControl User’s Manual for programming

instructions and functions.

Revision E

31

Page 32

Configuration and programming

Caution

Note

Configuring a controller with HCM

Configuring a

controller with

KMC Controls

HCM

Before placing a controller into service, it must be initialized and addressed

with the KMC

distributed with application programs; complete instructions for HCM are

included in the

help system built into HCM.

The Hardware Configuration Manager sets all controllers on the Tier 2

network to the same parameters. To prevent disruption to other controllers on

the network, disconnect the network cables or remove the isolation bulbs on

the controller prior to starting HCM.

1. Start HCM, connect the controller to the computer and establish

communications with the controller.

2. Make the entries as described in the section KMC digital network

configuration on page 33.

3. Setup the Ethernet routing table. See Ethernet routing table

4. If applicable, enter BACnet parameters. See BACnet configuration

page 35.

5. Cycle the power to the controller. The controller can now be connected to

a network and additional programming can be performed with

WinControl XL or the Acuity Configuration tool.

Hardware Configuration Manager (HCM) software. HCM is

Hardware Configuration Manager manual and the context sensitive

on page 34.

on

Ethernet settings do not take effect in a controller until the power is cycled.

32

Revision E

Page 33

KMD–5210 Installation and Operation

KMC digital network configuration

The entries in the table HCM Configuration Screen setup fields on page 33 are

required for controller-to-controller communications on a KMC controls

digital network.

Setting Description

Address Enter the address that is assigned to the controller on the network.

Last Panel Check this box only if the controller is assigned to the highest

SubLAN A

SubLAN B

Main Network

BACnet

Modem String For Firmware 4.0 and later: The string AT&A &B1 &C1 &D2 &H1

Configuration and programming

Configuring a controller with HCM

Table 4-1 HCM Configuration Screen setup fields

Valid numbers are 1–31. This address is also the BACnet MS/TP

MAC address in KMD-5210–002 controllers.

address number in the system. This controls token passing in the

network. Last Panel is not applicable for Tier 1 controllers

connected with Ethernet.

Sets the connection speed of the Tier1, Tier 2 or BACnet MS/TP port

to which the LAN controller is connected. Set each baud to match

the baud of the other controllers on each network.

&K0 &R1 is stored in Flash memory and cannot be changed. Entries

in Modem String are sent to the modem after the default string is

sent. This provides a method to override settings in the default

string. For example, entering ATS0=5 sets the modem to answer on

the fifth ring.

Firmware earlier than 4.0: The controller automatically transmits the

default initialization string AT&A &B1 &C1 &D2 &H1 &K0 &R1 to

the modem. The default string can be modified by making changes

in Modem String.

See Installing a modem interface

and switch settings.

Computer A Use this field to set the communication speed if a PC is directly

connected to this port.

Computer B Use this field to set the communication speed if a PC is directly

connected to this port. If you are using the modem port on the LAN

controller, check the Modem box to indicate a modem is attached

to the controller. If you have a modem attached, you cannot use the

Computer B connector.

I/O Card

Configuration

Use the fields in this area to enable communications with input or

output cards connected to the controller. Click on the button to step

through the choices. Input cards are connected to the controller

starting at position #1; output cards are connected starting at

position #8. If a port is unused, leave it marked as Unused in HCM.

on page 23 for modem installation

Revision E

33

Page 34

Configuration and programming

Note

Configuring a controller with HCM

Ethernet routing table

The Ethernet routing table is a list that associates the KMC network addresses

assigned to Tier 1 controllers with the IP addresses required by the LAN

protocol. If the controller is not configured correctly, it will not communicate

with other controllers and may cause problems with the rest of the network.

Before starting the HCM initializing process you will need information about

the controller and the LAN which is listed in

Setting Description

IP address Supplied by network administrator. Enter the address next to the

MTU 1400 or as supplied by system administrator

Gateway Use default (255.255.255.255) unless a router (gateway) is located

MAC address The MAC address is located on the white label on front of controller.

Broadcast

sever

Interval Sets the interval for the broadcast message. The broadcast message is

Subnet mask Set the Subnet Mask address to 255.255.255.0. or as supplied by

KMC Controls

Table 4-2.

Table 4-2 Tier 1 (LAN) controller Ethernet settings

panel address of the LAN Controller.

between two Tier 1 controllers. The router IP address is supplied by

the network system administrator.

MAC addresses for KMC Controls products begins with 00-D0-6F.

For controllers 1 - 16, select the Broadcast Server check box only for

the controller to which HCM is connected.

Select the Broadcast Server check box for all other controllers.

for KMD controllers and not a LAN broadcast message. The default

setting is 20 seconds.

network system administrator.

34

Ethernet settings do not take effect in a controller until the power is cycled.

Ethernet troubleshooting

If the controller does not appear Network Status in the WinControl program,

try the following.

1. Obtain a crossover cable (available in most stores that carry network

products).

2. Connect the crossover cable between the Ethernet connection on your

computer and the Ethernet connector on the LAN Controller.

3. Open an MS-DOS window on your computer and Ping the controller’s IP

address. If the controller is operating correctly, you should receive a

response to the ping command.

If you are unfamiliar with the above steps, contact KMC Controls for

assistance.

Revision E

Page 35

Detail

KMD–5210 Installation and Operation

BACnet configuration

If the controller is configured for BACnet and connected to a BACnet network,

the controller must be configured to communicate with the network. BACNet

is a licensed option in models listed below. This procedure applies only to

these models.

◆ KMD-5210–001 (BACnet 802.3)

◆ KMD-5210–002 (BACnet MS/TP)

Setting Description

Instance The device instance number as assigned by the BACnet system

Name A required 16-character label of the device. Name must be unique

Location Optional information used to further identify a piece of equipment.

Description Optional information used to further identify a piece of equipment.

APDU Timeout Indicates the period—in milliseconds— between retransmissions of

Max Master Enter the highest MAC address the controller will attempt to locate

Token Timeout Enter the period a controller must wait to see if a remote node

Configuration and programming

Configuring a controller with HCM

Table 4-3 Tier 1 BACnet settings

designer. Instance numbers are required, must be unique among all

devices on the internetwork and range from 0 to 4,194,303.

among all devices on the internetwork. The set of characters used

in Name is restricted to printable characters.

an APDU requiring an acknowledgement for which no

acknowledgment has been received. The default value is 3000

milliseconds.

while polling for a master device on the local network.

responds to a request or starts using the token. The range is 20-100

milliseconds.

Revision E

BACnet device settings are covered in more detail in the BACstage Reference

Guide that is available in Adobe Acrobat format on the KMC Controls web site.

See the topic Device Objects in the section The Object Menu.

35

Page 36

Configuration and programming

Programming for BACnet in WinControl XL

Programming for

BACnet in

KMC Controls

WinControl XL

The LAN Controller supports the BACnet object types listed in Table 4-4.

Table 4-4 Supported BACnet object types

Mnemonic Object type

AI Analog Input

AO Analog Output

BI Binary Input

BO Binary Output

AV Analog Value

BV Binary Value

Program the LAN Controller as would other KMD series controllers. Observe

the following details when programing an interface to a BACnet internetwork:

◆ Only inputs, outputs and variables within the LAN Controller appear as

objects in a device on the BACnet internetwork.

◆ A point configured as a KMD digital point will appear as a BACnet

binary object. Analog points appear as analog objects.

◆ To be visible as an object to BACnet devices or operator workstation,

configure the KMD point with both a description and a label in

WinControlXL Plus. In TotalControl configure the point with both a

description and name.

◆ Use BAC-SET, BAC-GET and BAC-RLQ in Control Basic to read and

write other objects on other BACnet devices.

36

KMC Controls recommends that all BACnet services have adequate error

handling protocols within your control program. A sample Control Basic code

segment is provided below to demonstrate reading the state of Binary Input 8

in a BACnet device with instance number 1.

Example: 250 G = BAC-GET( 1 , BI8 ) : REM BACnet read

260 ON-ERROR 280 : REM If error, bad read, don’t use it

270 1-VAR16 = G : REM Read was good, use the value.

280 WAIT 0:00:15 : REM Release so other CB programs can

run

290 END

Revision E

Page 37

Note

KMD–5210 Installation and Operation

Access to the LAN Controller from BACnet

To access the LAN Controller, use a BACnet operator workstation such as

BACstage.

◆ The LAN Controller will appear in the BACstage device list but cannot

be selected. Its objects are not accessible for configuration from the

BACstage Object menu.

◆ The configured points within the KMD-5210 are the only points visible in

BACnet.

◆ In BACstage, use BACnet Read/Write Property under the System menu in

BACstage to manually view or change properties.

◆ KMC BACnet controllers and third-party devices may read and write to

the objects in the KMD-5210 with off-panel reads and writes.

Firewalls and network communications

Firewalls are commonly installed on networks to prevent unauthorized traffic

or electronic probes from entering the network. If the LAN Controller must

communicate with a network where a firewall is in place the following actions

must be taken.

Configuration and programming

Access to the LAN Controller from BACnet

System time keeping

LAN controllers communicate through one of three Ethernet Ports:

◆ WinControl to LAN Controller: UDP 21068

◆ LAN Controller to LAN Controller: UDP 21069

◆ LAN Controller to LAN Controller: UDP 21070

These ports must be open for communications to pass through a firewall.

If the LAN Controller resides behind a Network Address Translation (NAT)

router, the IP address for the controller must be preceded by the lowercase

letter ‘r’ in the system menu. (For example, r128.1.1.5.)

Adding this prefix letter will cause WinControl to disregard the IP table and

download from the panel itself.

If you use this method you will only be able to connect one LAN Controller

through the router.

The controllers feature real-time clocks. Once the clock is set with

WinControl

loss. A KMC digital network uses the lowest addressed Tier

XL, the controller maintains accurate time even during power

1 (LAN)

controller with a real-time clock as the system time keeper.

Revision E

37

Page 38

Configuration and programming

System time keeping

KMC Controls

38

Revision E

Loading...

Loading...