Page 1

Linkages for MEP-5000 and MEP-1200 Actuators

Installation Guide

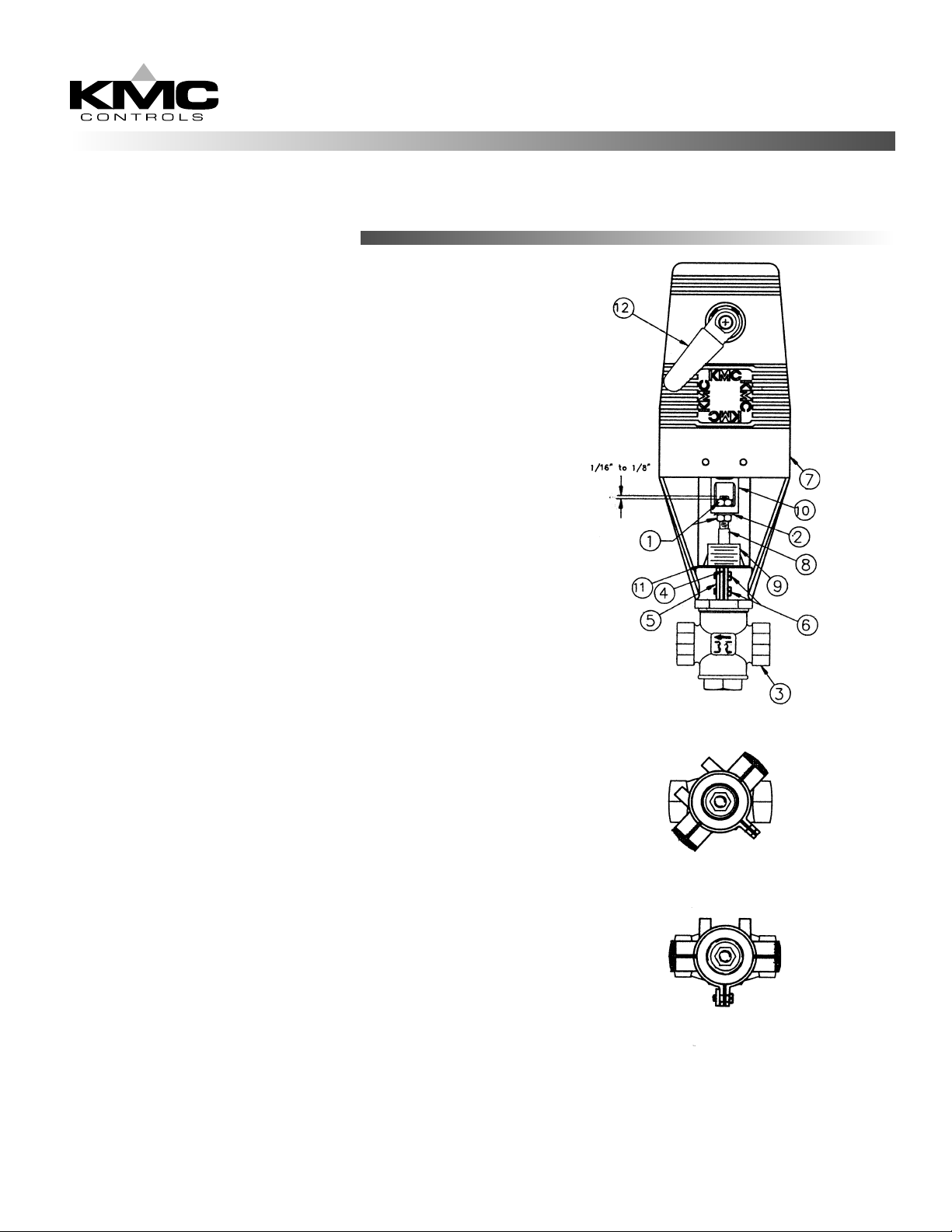

Mounting Linkage to Valve

1. Thread nut (1) onto valve stem (8) approximately 1".

2. Place flat washer (2) on top of nut (1).

3. Screw linkage (7) onto valve bonnet (9) until base of

linkage contacts the base of valve bonnet.

4. Rotate linkage to the position shown in FIG. 2.

NOTE: To properly position the linkage on the valve and

prevent the flange on the bonnet adaptor (11) from pulling

into the base of linkage, use a flat screwdriver to spread

the tabs apart slightly.

5. Gently tap the base of linkage housing, around the bonnet

adaptor (11), with a rubber mallet to properly seat the

housing against the adaptor.

6. Assemble washer plate (4) and threaded plate (5)

onto the housing tabs with 2 screws (6). Tighten the tab

screws (6) evenly until snug against the tabs.

7. Rotate the linkage to align it with the valve ports as shown

in FIG. 3.

8. Evenly torque the tab screws (6) to 25-30 in-lbs.

9. Face the lever (12) and rotate it counterclockwise until the

connecting rod (10) contacts the lower valve stem nut (1).

10. Thread the upper valve stem nut (1) onto the valve stem (8)

until 1/16" to 1/8" of valve stem is visible above the nut (1).

11. Rotate the lever (12) clockwise to lift the connecting rod

(10) up and around the upper valve stem nut flats (1).

12. Hold the connecting rod (10) with a wrench to keep it from

twisting and tighten the lower valve stem nut (1) against

the connecting rod.

13. Rotate the lever (12) until valve stem is in the full up

position.

14. Loosen the set screws on the lever (12). Reposition the

lever so that the end of the handle is just inside the left

side of the linkage housing. Tighten the 2 set screws on

lever.

Proceed to actuator mounting instructions.

HPO-5201 and 5202

FIG. 1

FIG. 2

FIG. 3

Page 2

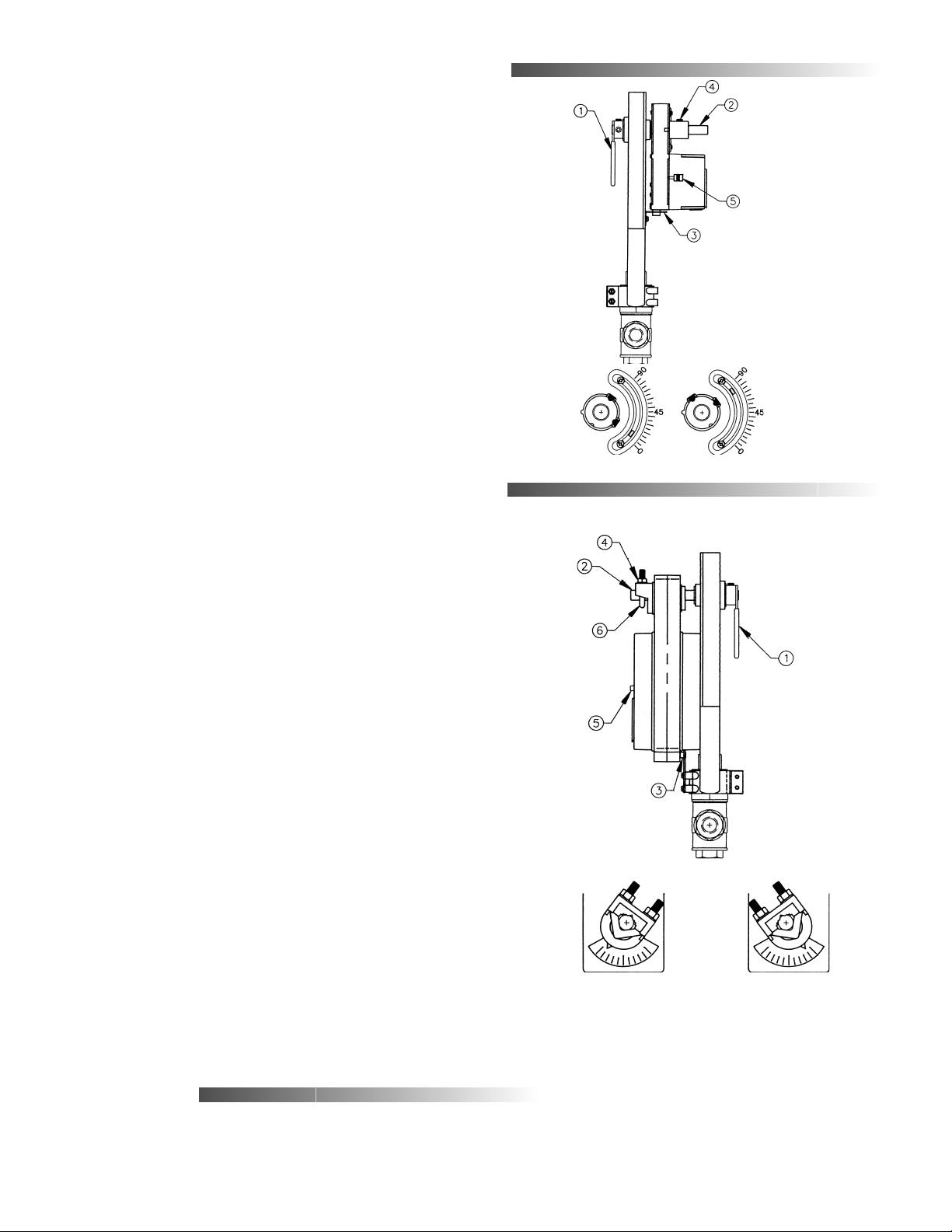

Mounting MEP-5000 Actuators to Linkage

1. Rotate the valve linkage lever (1) so that the valve stem is

fully down.

2. Depress the actuator’s disengagement button (5) and

manually position the edges of actuator pointer between

the 10° and 15° marks.

3. Place the actuator over the linkage shaft (2) and the nonrotation bracket (3).

4. Tighten 2 set screws (4) on the actuator output hub while

holding the linkage lever to ensure that the valve stem

stays down.

5. Confirm the unit’s operation by depressing the

disengagement button (5) and rotating the linkage lever (1)

in each direction.

NOTE: The pointer MUST NOT rotate past the 5° or 85°

marks (see FIG. 5 and FIG. 6).

6. If conditions in Step 5 are not met, loosen the 2 set screws

(4) and readjust.

Mounting MEP-1200 Actuators to Linkage

1. Rotate the valve linkage lever (1) so that valve stem is fully

down.

2. Depress the actuator’s disengagement button (5) and

manually position the pointer to the first mark from full

Clockwise (see FIG.8)

3. Place the actuator over the linkage shaft (2) and the nonrotation pin (3) until the cover on the actuator rests against

the linkage cover.

4. Finger tighten 2 coupler nuts (4) until the u-bolt (6) contacts

the linkage shaft (2).

5. Holding the linkage lever (1) to assure valve stem stays

down, and checking that the actuator cover is held against

the linkage, evenly torque the 2 coupler nuts (4) to 110-120

in-lbs.

6. Check final operation by depressing the disengagement

button (5) and rotating the linkage lever (1) in each

direction.

3-Way Valves: The valve seats should limit the actuator

pointer between the first mark from full clockwise (FIG. 8)

and the first mark from full counterclockwise (FIG. 9).

2-Way Valves: The valve seat should limit the actuator

pointer from passing the first mark from full clockwise

(FIG. 8).

7. Readjust, if needed, by loosening the 2 coupler nuts

(4) and adjusting.

Maintenance

No routine maintenance is required. Component are designed

for dependable, long term reliability and performance. Careful

installation will also ensure this performance.

FIG. 4

FIG. 5 FIG. 6

FIG. 8

KMC Controls

P.O. Box 497

19476 Industrial Drive

New Paris, IN 46553

TEL: 574.831.5250

www.kmccontrols.com

FIG. 7

FIG. 9

732-019-06B

Loading...

Loading...