KMC Controls FlexStat BAC-12xx36 Series, FlexStat BAC-13xx36 Series, FlexStat BAC-14xx36 Series Installation Manual

Page 1

BAC-12xx36/13xx36/14xx36 Series FlexStat

3 Relays, 6 Analog Outputs, 6 External Inputs

Installation Guide (3/6 Outputs)

MountingQuick Start

™

CAUTION

This document is for 3-relay, 6-analog-output,

6-external-input BAC-12xx36/13xx36/14xx36 series

only. THESE MODELS ARE NOT COMPATIBLE

WITH THE BACKPLATES OF OLDER BAC-10000

SERIES FLEXSTATS (WITH ONLY 3 EXTERNAL

INPUTS)! If replacing an older 3-input FlexStat,

replace the backplate as well. See other installation

guides for other models.

To select and use a FlexStat in an application:

1. Select the appropriate model for the intended

application and options (see the FlexStat Data

Sheet).

2. Mount and wire the unit (see this Installation

Guide).

3. Congure/program the unit (see the FlexStat

Operation and Application Guides).

4. If necessary, troubleshoot any issues (see the

FlexStat Operation Guide).

5. Operate the unit (see the FlexStat Operation

Guide).

NOTE: This document gives basic mounting,

wiring, and setup information only. For

conguration, programming, operation,

and other information, see the KMC

Controls web site for the latest documents.

Models

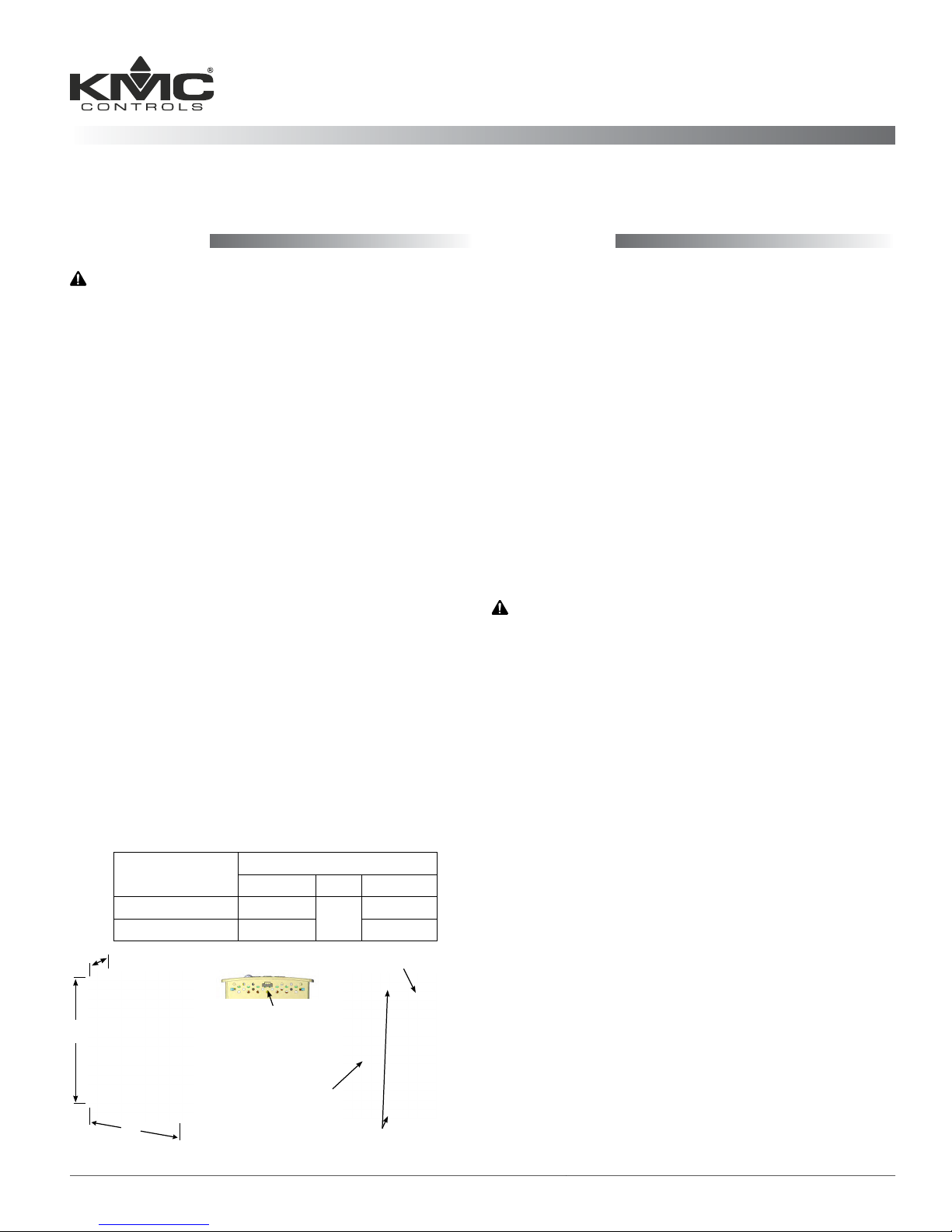

BAC-12xxxx (shown) 1.125 (29)

BAC-13xxxx/14xxxx 1.437 (36.5) 5.192 (132)

A

Dimensions in Inches (mm)

A B C

4.192 (106)

5.551

(141)

Embossed “UP” indicator

For optimum temperature sensor performance,

the FlexStat must be mounted on an interior wall

and away from heat sources, sunlight, windows,

air vents, and air circulation obstructions (e.g.,

curtains, furniture). Additionally, for a model with

an occupancy sensor option, install it where it will

have unobstructed view of the most typical trac

area. (See the FlexStat Application Guide for more

information.)

If replacing an existing thermostat, label wires as

needed for reference when removing the existing

thermostat.

1. Complete rough-in wiring at each location prior

to thermostat installation. Cable insulation must

meet local building codes.

CAUTION

To prevent mounting screw heads from touching the

circuit board in the thermostat, use only the mounting

screws supplied by KMC Controls. Using other screws

may damage the FlexStat. Do not turn screws in

farther than necessary to remove the cover.

2. If the cover is locked on the backplate, turn the

hex screws in the boom and top of the FlexStat

CLOCKWISE until they (just) clear the cover.

(See Illustration 1.) Pull the cover away from the

backplate (mounting base).

3. Route the wiring through the backplate.

4. With the embossed “UP” and arrows toward the

ceiling, fasten the backplate to a wall handy-box.

BAC-12xxxx models mount directly on vertical 2

x 4 inch boxes, but they require an HMO-10000/

HMO-10000W wall mounting plate for horizontal

or 4 x 4 boxes. BAC-13xxxx/14xxxx models mount

directly on any of those types of boxes.

EIA-485 data

B

port (for quick

network access)

5. Make the appropriate connections to the terminal

blocks. (See Connections and Wiring on page 2.)

6. Place the FlexStat cover over the backplate while

Terminal blocks on

backplate (rotated on

BAC-13xxxx/14xxxx)

C

Illustration 1—Dimensions and Installation

BAC-12xx36/13xx36/14xx36 Series FlexStat 1 Installation Guide, Rev. E

Cover locking hex screws

being careful not to pinch or dislodge any

wiring. Back the hex screws (counterclockwise)

out of the brackets until they engage the FlexStat

cover and hold it in place.

Page 2

Connections and Wiring

Wiring Considerations

• Because of the many connections (power,

network, inputs, outputs, and their respective

grounds or switched commons), be sure wiring

is well planned before installation of conduit!

• Make sure that conduit for all wiring has adequate diameter for all necessary wiring. Using

1-inch conduit and junction boxes is recommended! Use external junction boxes above the ceiling

or in another convenient location as needed

to make connections that run to the FlexStat’s

junction box.

• To prevent excessive voltage drop, use a conduc-

tor size that is adequate for the wiring length!

Allow plenty of “cushion” to allow for tran-

sient peaks during startup.

• Using multiple conductor wires for all inputs

(e.g., 8 conductor) and outputs (e.g., 12 conductor) is recommended. Grounds for all the inputs

can be combined on one wire.

CAUTION

To avoid damage from ground loops and other

communication issues in networked FlexStats,

correct phasing on MS/TP network and power

connections on ALL the networked controllers is

critically important.

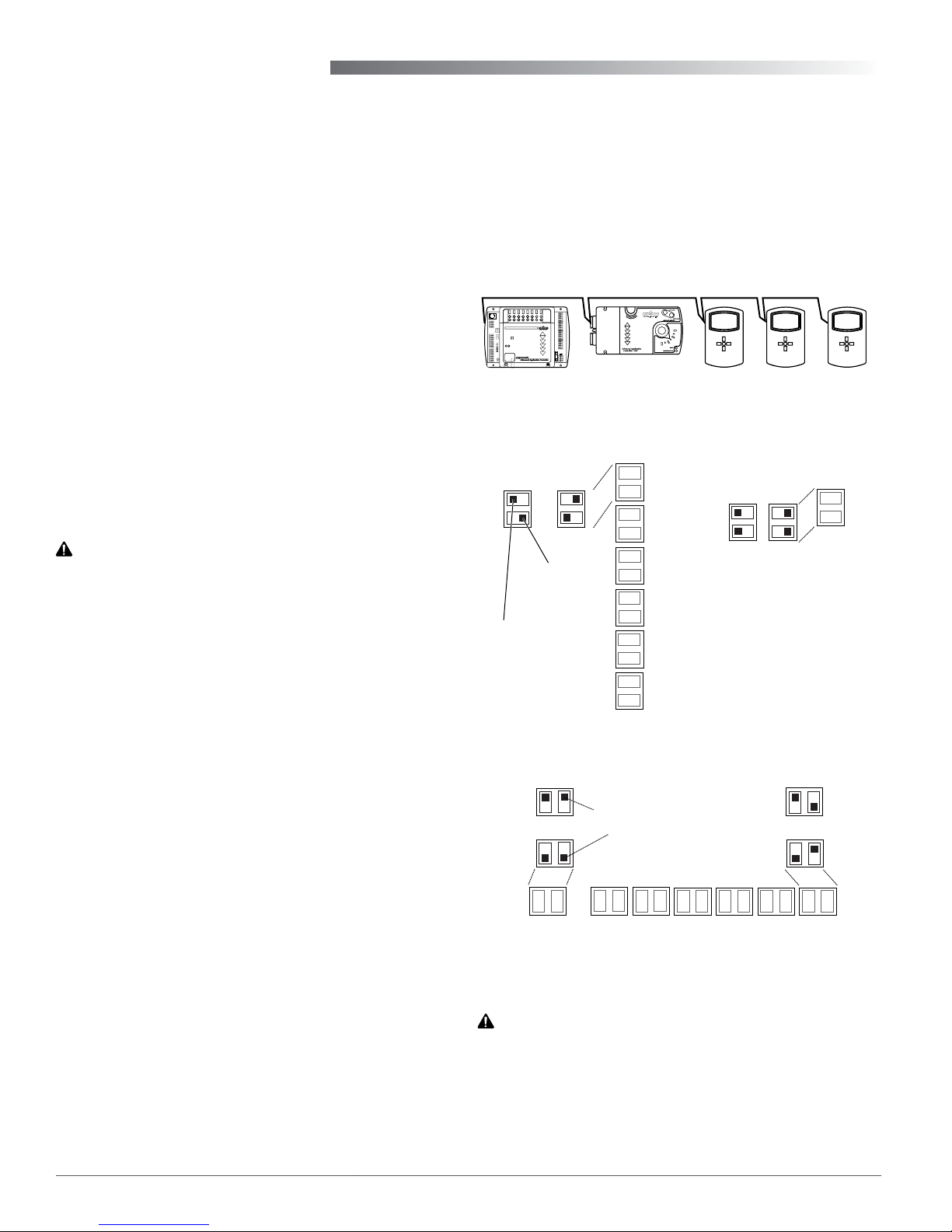

Network Wiring

For Ethernet or IP communications, plug an Ethernet

cable into the RJ-45 jack on the back of the FlexStat.

MS/TP EOL (End-Of-Line) Termination

The controllers/thermostats on the physical ends of

an EIA-485 wiring segment must have end-of-line

termination installed for proper network operation.

(See Illustrations 2 through 4.) If a FlexStat is at the

physical end of the MS/TP network line, set both the

EOL termination switches to On (to the right/up)

on the back of the circuit board. If not on the end,

ensure that both switches are O (left/down).

Illustration 2—MS/TP Network End-Of-Line Termination

Input Pull-Up Switches

EOL Switches

OFF

ON

NOTE: EOL = End

Of Line of BACnet

MS/TP network.

NOTE: 10K Ω inputs

are configurable for

Type II or Type III

thermistors in

FlexStat’s menu.

Left

0-12 V

Switch

Pushed

Right

IN9

IN8

IN7

IN4

IN3

IN2

10K Ω

Switch

Pushed

Illustration 3—BAC-12xxxx EOL/Pull-Up Switch Positions

For MS/TP communications, connect the –A terminals in parallel with all other –A terminals on the

network and the +B terminals in parallel with all

other +B terminals. (See Illustrations 2 and 5.) Connect the shields of the cable (Belden cable #82760 or

equivalent) together at each device. Use a wire nut or

the S terminal in KMC BACnet controllers. (FlexStats,

however, do not have an S terminal.) Connect the

cable shield to a good earth ground at one end only.

NOTE: The S terminal in KMC controllers is

provided as a connecting point for the

shield. The terminal is not connected to the

ground of the controller. When connecting

to controllers from other manufacturers,

verify the shield connection is not

connected to the controller’s ground.

For more information on principles and good practices when connecting an MS/TP network, see Planning

BACnet Networks (Application Note AN0404A).

BAC-12xx36/13xx36/14xx36 Series FlexStat 2 Installation Guide, Rev. E

ON

Switch Pushed Up

OFF

EOL

Switches

Illustration 4—BAC-13xxxx/14xxxx Switch Positions

Pushed Down

IN2 IN3 IN4 IN7 IN8

Input Pull-Up Switches

0-12 VDC

10K Ohm

IN9

CAUTION

This document is for 3-relay, 6-analog-output,

6-external-input BAC-12xx36/13xx36/14xx36 series

ONLY. THESE MODELS ARE NOT COMPATIBLE WITH

THE BACKPLATES OF OLDER BAC-10000 SERIES

FLEXSTATS (WITH ONLY 3 EXTERNAL INPUTS)!

If replacing an older 3-input FlexStat, replace the

backplate as well.

Page 3

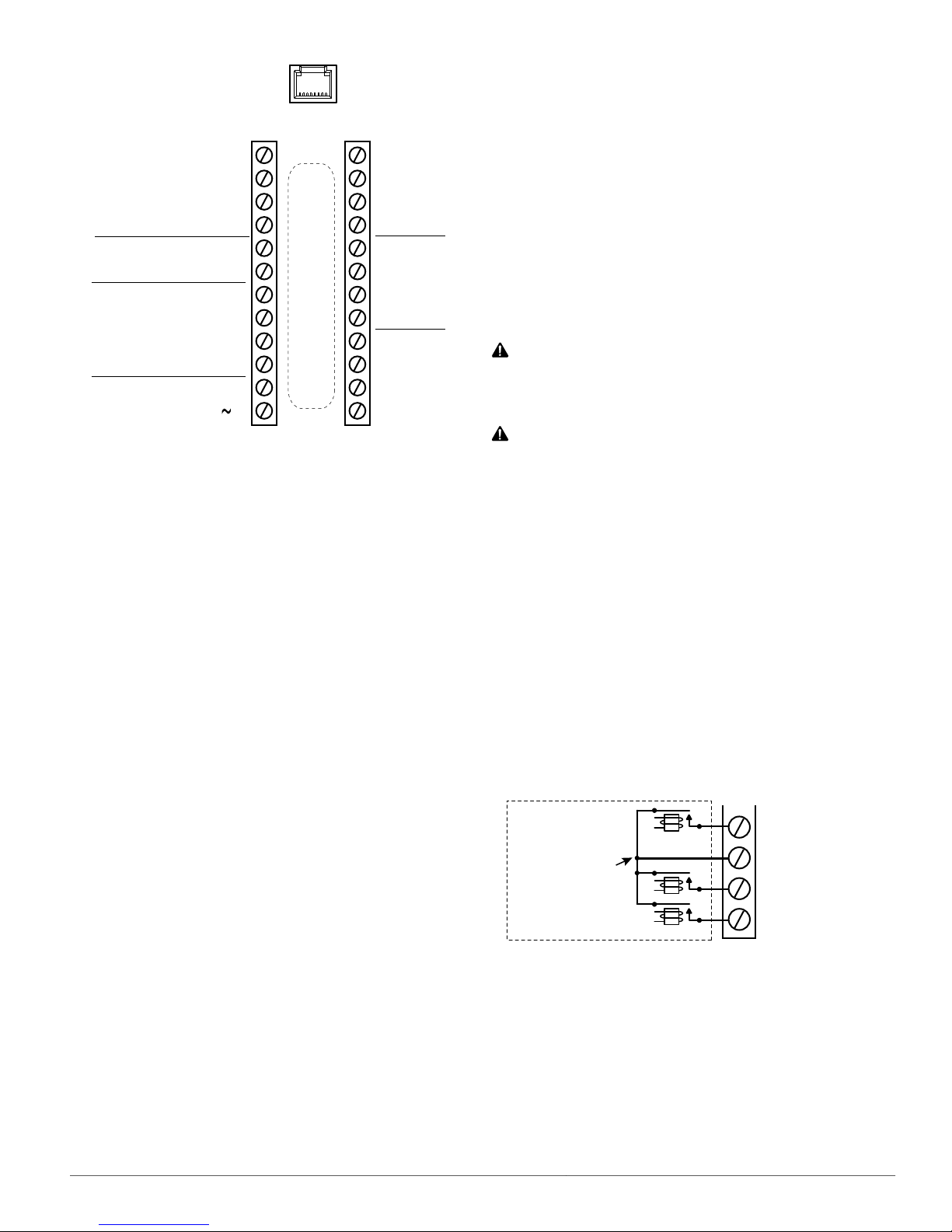

NOTE: SC = Switched

(relay) Common

NOTE: IN1 and IN5–6 are

reserved for internal sensors

Inputs

(Wiring is

dependent on

application)

MS/TP

Network

Inputs

24 VAC

Illustration 5—(BAC-12xx36) Terminals and Connections

Common/–/C

Phase/ /R

IN9

IN8

GND

IN7

+B

–A

IN4

IN3

GND

IN2

(Wiring Cutout in Backplate)

IP/Ethernet

Network

(Optional)

Outputs

Analog 9

GND 7–9

Analog 8

Analog 7

Analog 6

GND 4–6

Analog 5

Analog 4

Relay 3

SC 1–3

Relay 2

Relay 1

NOTE: On BAC-13xxxx/14xxxx models, terminals

are rotated 90° CCW.

Input Connections

Passive input devices require pull-up resistors in the

circuit. For passive input devices (e.g., switch contacts and 10K ohm thermistors) on IN2 through IN4

and IN7 through IN9, set the pull-up switches on

the back of the circuit board to the 10K position. For

active voltage devices, set the switches to the 0–12

VDC position. (See Illustrations 3 through 5.)

NOTE: Unlike the EOL switch pairs, the INPUT

switch pairs must NOT have both switch-

es set to the same direction—if one of the

pair’s switches is set to the left, for example,

the other must be set to the right (or vice

versa). ALL the input pull-up resistor

switch pairs must be fully latched in either 10K Ohm or 0–12 VDC position even

if a switch pair has no input connected! A

single incorrect switch position may cause

errors in multiple inputs.

NOTE: To use a 4–20 current loop input or map

analog inputs as binary values, see the

FlexStat Application Guide.

NOTE: To use a remote SAE-10xx CO

sensor, see

2

the FlexStat Operation Guide.

NOTE: For more information on wiring specic

applications (AHU and FCU), see Appli-

cations on page 5. (These applications

are the packaged programs selectable from

the Advanced > Application menu in the

BAC-1xxx36 models.) See also the FlexStat

Application Guide.

CAUTION

Relays are for Class-2 voltages (24 VAC) only. Do not

connect line voltage to the relays!

CAUTION

Do not mistakenly connect 24 VAC to an analog

output ground. This is not the same as a relay’s

switched common. See the backplate’s terminal

label for the correct terminal.

Output Connections

Connect the device under control between the desired

output terminal and the related SC (Switched Com-

mon for relays) or GND (Ground for analog outputs)

terminal. (See Illustration 5). For the bank of three

relays, there is one Switched (relay) Common connection (in place of the GND terminal used with analog

outputs). (See Illustration 6.) For the relay circuit, the

phase side of the AC should be connected to the SC

terminal.

One Switched

Common

Connection in

Bank of Three

Normally

Open Relays

Relay 3

SC (Phase) 1–3

Relay 2

Relay 1

NOTE: Type II or III 10K ohm thermistors can be

selected by changing the menu seing in

Advanced > Inputs > Input # > Sensor (see

Conguration on page 4). If a remote

space temperature sensor is connected to

AI7, space temperature can be congured

for onboard, remote, averaging of the two,

the lowest reading, or the highest reading.

NOTE: FlexStat inputs do not support 1K ohm

RTDs.

BAC-12xx36/13xx36/14xx36 Series FlexStat 3 Installation Guide, Rev. E

Illustration 6—Switched (Relay) Common and Relays

Do not aach a device that draws current exceeding

the FlexStat’s output capacity:

• Maximum output current for individual ANALOG outputs (4–9) is 20 mA @ 12 VDC (each).

• Max. output current is 1 A for individual RELAYS

@ 24 VAC/VDC or a total of 1.5 A for relays 1–3.

Page 4

For example, (discontinued) KMC REE-3211 relays

would exceed the FlexStat’s analog output capacity,

but they can be used with the FlexStat’s internal

relays 1–3 as shown in the following applications

pages. (Use a Core Components CVR11C-0/LD96200

in the REE-3211’s place in those applications.)

FlexStat relays 1–3 are NO, SPST (Form “A”). (To

emulate binary outputs with the analog outputs, set

the output voltage to be either 0 or 12 VDC in Control

Basic.)

NOTE: Applications on pages 5–11 are the

packaged programs selectable from the

Advanced > Application menu in the

BAC-1xxx36 (only) models. Other FlexStat

models have other applications.

NOTE: Humidity, motion, and CO

sensor options

2

in menus are dependent on the FlexStat

model and selected application.

For detailed conguration, operation, troubleshoot-

ing, and other information, see the FlexStat Opera-

tion Guide.

Power Connection

The FlexStat requires an external, 24 volt, AC power

source. Use a KMC Controls Class-2 transformer to

supply power. Connect the transformer’s neutral

lead to the 24 VAC Common/–/C terminal and the

AC phase lead to the 24 VAC Phase/~/R terminal.

(See Illustration 5.) Power is applied to the FlexStat

when the transformer is powered.

KMC Controls recommends powering only one controller/thermostat from each transformer. If installing

a FlexStat in a system with other controllers/thermostats powered from a single transformer, however,

phasing must be correct and the total power drawn

from the transformer must not exceed its rating.

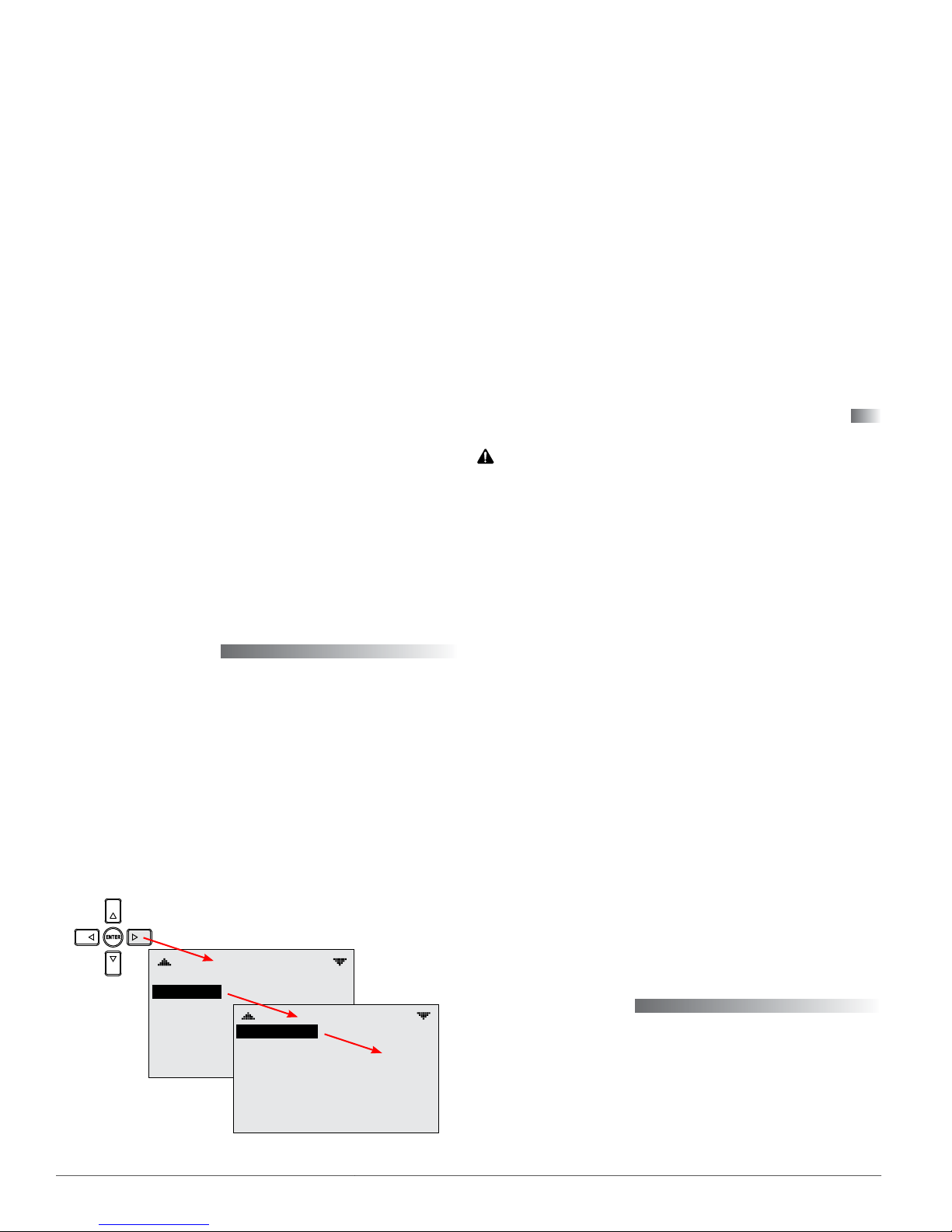

Configuration

To congure the FlexStat, navigate the menus and

change seings by pressing a combination of buons.

Press the Right (Menu) buon and then the:

• Enter buon to select and/or exit value editing.

• Up/Down buon to move among entries (up/

down lines).

• Left/Right buon to move among value elds

(left/right spaces).

• Left buon to return to the Home screen.

MAIN MENU

ABOUT

ADVANCED

ALARM

DATE/TIME

SCHEDULE

SETPOINTS

SYSTEM

Illustration 7—Configuration Screens

ADVANCED

APPLICATION

CB PROGRAMS

COMMUNICATION

DATE/TIME

DEVICE

INPUTS

LIMITS

(See

menus

on the

following

pages)

For additional wiring, customization, programming, and application information, see the FlexStat

Application Guide.

Applications Notes and Cautions

CAUTION

Relays are for Class-2 voltages (24 VAC) only. Do not

connect line voltage to the relays!

Do not mistakenly connect 24 VAC to an analog

output ground.

NOTE: Although typical terminal code leers are

shown, check the schematics of your unit

for wiring details!

NOTE: These applications are for 3 relay and 6 ana-

log output BAC-12xx36/13xx36/14xx36 series

only. See other installation guides for other

models.

NOTE: CO2, humidity, and motion sensor options

are dependent on FlexStat model.

NOTE: For Bill of Materials listings of the various

accessories shown in the sample diagrams,

see the FlexStat Application Guide.

NOTE: Since the KMC REE-3211 is discontin-

ued, use Core Components CVR11C-0/

LD96200 in its place. Do not use either

with analog outputs! See Output Connec-

tions on page 3.

Maintenance

Remove dust as necessary from the holes in the top

and boom. Clean the display with a soft, damp

cloth and mild soap.

To maintain maximum sensitivity of the built-in

motion sensor, occasionally wipe dust or dirt o the

lens—but do not use any uid on the sensor.

BAC-12xx36/13xx36/14xx36 Series FlexStat 4 Installation Guide, Rev. E

Page 5

Applications

FCU (Fan Coil Unit)—2 Pipe, Modulating

APPLICATION

DEGREES SCALE: °F

APP:

FAN COIL

OPT: 2–PIPE

ADDITIONAL SETUP

VEB-43 Valve with MEP-4002V Actuator

NOTE: In rmware earlier than R2.1.0.18,

XEE-6311-050 Transformer

SET SWITCHES FOR...

OPERATION: CCW

INPUT RANGE: 0–10 VDC

an option for a DAT on IN2 was

available for a built-in trend log.

For later rmware, use KMC

Connect or TotalControl to create

a custom trend if this is desired.

ADDITIONAL SETUP

FAN

OPTIMUM START

SENSORS

VALVE

STE-1454

Strap-On Temp. Sensor, Type III

CSE-1102

Air Differential Pressure Switch

Output

Terminals

Analog 9 AO9

GND

Analog 8 AO8

Analog 7 Valve (VLV) AO7

Analog 6 AO6

GND

Analog 5 AO5

Analog 4 AO4

Relay 3 Fan 3 BO3

SC 1–3

Relay 2 Fan 2 BO2

Relay 1 Fan 1 BO1

Input Terminals FCU Input Connections BACnet Objects

IN9 Opt. Remote CO

IN8 AI8

IN7 Opt. Remote Temp. Sensor* AI7

IN4 AI4

IN3 Supply Water Temp. (W-TMP)** AI3

GND Ground

IN2 Optional FST* AI2

*Fan Status (FST) and (not shown on the diagram) remote temp./CO

sensors are optional inputs. Set pull-up resistor switch positions

appropriately (see the Input Connections section).

**Input for Supply Water Temp is typically a 10K,Type III thermistor.

FCU Output

Connections

Ground (for

analog output

terminals 7–9)

24 VAC (for relay

terminals 1–3)

Sensor* AI9

2

BACnet

Objects

2

NOTE: Do not use REE-

3211/CVR11C-0/

LD96200 relays with

analog outputs! See

Output Connections

on page 3.

FCU 2-PIPE MODULATING LAYOUT

REE-3211 or CVR11C-0/LD96200 Multi-Voltage Relays

BAC-12xx36/13xx36/14xx36 Series FlexStat 5 Installation Guide, Rev. E

Page 6

FCU—4 Pipe, Modulating

APPLICATION

DEGREES SCALE: °F

APP:

FAN COIL

OPT: 4–PIPE

ADDITIONAL SETUP

NOTE: In rmware earlier than R2.1.0.18, an option

for a DAT on IN2 was available for a built-

in trend log. For later rmware, use KMC

Connect or TotalControl to create a custom

trend if this is desired.

XEE-6311-050 Transformer

ADDITIONAL SETUP

FAN

HUMIDITY

OPTIMUM START

SENSORS

VALVE

Input Terminals FCU Input Connections BACnet Objects

IN9 Opt. Remote CO

Sensor* AI9

2

IN8 AI8

IN7 Opt. Remote Temp. Sensor* AI7

IN4 AI4

IN3 AI3

GND Ground

IN2 Optional Fan Status (FST)* AI2

*Fan Status (FST) and (not shown on the diagram) remote temp./CO

sensors are optional inputs. Set pull-up resistor switch positions

appropriately (see the Input Connections section).

NOTE: Do not use REE-3211/CVR11C-0/LD96200

relays with analog outputs! See Output

Connections on page 3.

2

SET SWITCHES FOR...

OPERATION: CCW

INPUT RANGE: 0–10 VDC

VEB-43 Valves with

MEP-4002V Actuators

SET SWITCHES FOR...

OPERATION: CW

INPUT RANGE: 0–10 VDC

CSE-1102

Air Differential Pressure Switch

XEE-6311-050 Transformer

SET SWITCHES FOR...

OPERATION: CCW

FAIL-SAFE: CW

INPUT RANGE: 2–10 VDC

VEB-43 Fail-Safe Valve with MEP-4x52V Actuator

REE-3112 Control Relay

Output

Terminals

FCU Output

Connections

BACnet

Objects

Analog 9 AO9

Ground (for

GND

analog output

terminals 7–9)

Analog 8

Analog 7

Heat Valve

(HTV)

Cool Valve

(CLV)

AO8

AO7

Optional

Analog 6

Humidication

Valve (HUM or

AO6

HUMV)

Ground (for

GND

analog output

terminals 4–6)

Analog 5 AO5

Analog 4 AO4

Relay 3 Fan 3 BO3

24 VAC (for

SC 1–3

relay terminals

1–3)

Relay 2 Fan 2 BO2

Relay 1 Fan 1 BO1

REE-3211 or CVR11C-0/LD96200 Multi-Voltage Relays

BAC-12xx36/13xx36/14xx36 Series FlexStat 6 Installation Guide, Rev. E

FCU 4-PIPE MODULATING LAYOUT

Page 7

AHU (Air Handler Unit)—1 Heat and 1 Cool

APPLICATION

DEGREES SCALE: °F

APP:

AIR HANDLER

OPT: 1H/1C

ADDITIONAL SETUP

ADDITIONAL SETUP

DAMPER

FAN

HUMIDITY

OPTIMUM START

SENSORS

NOTE: Do not use REE-3211/CVR11C-0/LD96200

relays with analog outputs! See Output

Connections on page 3.

NOTE: For MAT sensor use with rmware earlier

than R2.1.0.18, see the FlexStat Economizer

Change of MAT to DAT Service Bulletin

available on the KMC Partners web site.

XEE-6311-075 or XEE-6311-100 Transformer

SET SWITCHES FOR...

OPERATION: Opposite of Fail-Safe

FAIL-SAFE: In Direction Actuator

Rotates to Open Return Damper

INPUT RANGE: 2–10 VDC

MEP-4552 or MEP-7x52 Actuators

SET SWITCHES FOR...

OPERATION: Opposite of Fail-Safe

FAIL-SAFE: In Direction Actuator

Rotates to Close Outside Air Damper

INPUT RANGE: 2–10 VDC

STE-1402 Duct

Sensor, Type III

See also the

AHU—Additional

Options section

on the last page

for network,

humidification,

and fan speed

CSE-1102 Air Differential

Pressure Switch

options.

Input Terminals AHU Input Connections BACnet Objects

IN9 Opt. Remote CO

Sensor* AI9

2

IN8 AI8

IN7 Opt. Remote Temp. Sensor* AI7

IN4 Opt. Outside Air Temp. (OAT)** AI4

IN3 Opt. Discharge Air Temp. (DAT)** AI3

GND Ground

IN2 Optional Fan Status (FST)* AI2

*Fan Status (FST), Discharge Air Temperature (DAT), and (not shown

on the diagram) remote temp./CO

pull-up resistor switch positions appropriately (see the Input

sensors are optional inputs. Set

2

Connections section).

**When using the optional Outside Air Damper, DAT/OAT inputs must

also be connected.

Output

Terminals

AHU Output Connections

BACnet

Objects

Analog 9 Optional Outside Air Damper (OAD/RTD)* AO9

GND Ground (for analog output terminals 7–9)

Analog 8 AO8

Analog 7 AO7

Analog 6

Optional Humidication Valve (HUM or

HUMV)

AO6

GND Ground (for analog output terminals 4–6)

Analog 5 AO5

Analog 4 Optional Fan Speed AO4

Relay 3 Heat 1 (W1) BO3

SC 1–3 24 VAC (for relay terminals 1–3)

Relay 2 Cool 1 (Y1) BO2

Relay 1 Fan 1 (G) BO1

*If optional Outside Air Damper is used, must also have DAT/OAT

inputs.

STE-1451 OAT Sensor, Type III

XEE-6311-050 Transformer

REE-3211 or CVR11C-0/LD96200 Multi-Voltage Relays

BAC-12xx36/13xx36/14xx36 Series FlexStat 7 Installation Guide, Rev. E

AHU 1H/1C LAYOUT

Page 8

AHU—1 or 2 Heat and Modulating Cool

APPLICATION

DEGREES SCALE: °F

APP:

AIR HANDLER

OPT: 2H/MOD C

ADDITIONAL SETUP

NOTE: Do not use REE-3211/CVR11C-0/LD96200

relays with analog outputs! See Output

Connections on page 3.

NOTE: For MAT sensor use with rmware earlier

than R2.1.0.18, see the FlexStat Economizer

Change of MAT to DAT Service Bulletin

available on the KMC Partners web site.

ADDITIONAL SETUP

DAMPER

FAN

HUMIDITY

OPTIMUM START

SENSORS

STAGING

Input Terminals AHU Input Connections BACnet Objects

IN9 Opt. Remote CO

Sensor* AI9

2

IN8 AI8

IN7 Opt. Remote Temp. Sensor* AI7

IN4 Opt. Outside Air Temp. (OAT)** AI4

IN3 Opt. Discharge Air Temp. (DAT)** AI3

GND Ground

IN2 Optional FST* AI2

*Fan Status (FST), Discharge Air Temperature (DAT), and (not shown

on the diagram) remote temp./CO

pull-up resistor switch positions appropriately (see the Input

sensors are optional inputs. Set

2

Connections section).

**When using the optional Outside Air Damper, DAT/OAT inputs must

also be connected.

XEE-6311-075 or XEE-6311-100 Transformer

OPERATION: Opposite of Fail-Safe

FAIL-SAFE: In Direction Actuator

Rotates to Open Return Damper

INPUT RANGE: 2–10 VDC

MEP-4552 or MEP-7x52 Actuators

OPERATION: Opposite of Fail-Safe

FAIL-SAFE: In Direction Actuator

Rotates to Close Outside Air Damper

INPUT RANGE: 2–10 VDC

STE-1402 Duct Sensor, Type III

CSE-1102 Air Differential

Pressure Switch

STE-1451 OAT Sensor, Type III

SET SWITCHES FOR...

SET SWITCHES FOR...

See also the

AHU—Additional

Options section

on the last page

for network,

humidification,

and fan speed

options.

Output

Terminals

AHU Output Connections

BACnet

Objects

Analog 9 Optional Outside Air Damper (OAD/RTD)* AO9

GND Ground (for analog output terminals 7–9)

Analog 8 AO8

Analog 7 Cooling Valve (CLV) AO7

Analog 6 Optional Humidier Valve (HUM or HUMV) AO6

GND Ground (for analog output terminals 4–6)

Analog 5 AO5

Analog 4 Optional Fan Speed AO4

Relay 3 Optional Heat 2 (W2) BO3

SC 1–3 24 VAC (for relay terminals 1–3)

Relay 2 Heat 1 (W1) BO2

Relay 1 Fan 1 (G) BO1

*If optional Outside Air Damper is used, must also have DAT/OAT

inputs.

AHU 1 OR 2 H / MODULATING C LAYOUT

XEE-6311-050 Transformer

SET SWITCHES FOR...

OPERATION: CCW

FAIL-SAFE: CW

INPUT RANGE: 2–10 VDC

VEB-43 Fail-Safe Valve with MEP-4x52V Actuator

REE-3211 or CVR11C-0/LD96200 Multi-Voltage Relays

BAC-12xx36/13xx36/14xx36 Series FlexStat 8 Installation Guide, Rev. E

Page 9

AHU—Modulating Heat and 1 or 2 Cool

APPLICATION

DEGREES SCALE: °F

APP:

AIR HANDLER

OPT: MOD H/2 C

ADDITIONAL SETUP

NOTE: Do not use REE-3211/CVR11C-0/LD96200

relays with analog outputs! See Output

Connections on page 3.

NOTE: For MAT sensor use with rmware earlier

than R2.1.0.18, see the FlexStat Economizer

Change of MAT to DAT Service Bulletin

available on the KMC Partners web site.

ADDITIONAL SETUP

DAMPER

FAN

HUMIDITY

OPTIMUM START

SENSORS

STAGING

Input Terminals AHU Input Connections BACnet Objects

IN9 Opt. Remote CO

Sensor* AI9

2

IN8 AI8

IN7 Opt. Remote Temp. Sensor* AI7

IN4 Opt. Outside Air Temp. (OAT)** AI4

IN3 Opt. Discharge Air Temp. (DAT)** AI3

GND Ground

IN2 Optional FST* AI2

*Fan Status (FST), Discharge Air Temperature (DAT), and (not shown

on the diagram) remote temp./CO

pull-up resistor switch positions appropriately (see the Input

sensors are optional inputs. Set

2

Connections section).

**When using the optional Outside Air Damper, DAT/OAT inputs must

also be connected.

XEE-6311-075 or XEE-6311-100 Transformer

OPERATION: Opposite of Fail-Safe

FAIL-SAFE: In Direction Actuator

Rotates to Open Return Damper

INPUT RANGE: 2–10 VDC

MEP-4552 or MEP-7x52 Actuators

OPERATION: Opposite of Fail-Safe

FAIL-SAFE: In Direction Actuator

Rotates to Close Outside Air Damper

INPUT RANGE: 2–10 VDC

STE-1402 Duct Sensor,

Type III

CSE-1102 Air Differential

Pressure Switch

STE-1451 OAT Sensor, Type III

SET SWITCHES FOR...

SET SWITCHES FOR...

See also the

AHU—Additional

Options section

on the last page

for network,

humidification,

and fan speed

options.

Output

Terminals

AHU Output Connections

BACnet

Objects

Analog 9 Optional Outside Air Damper (OAD/RTD)* AO9

GND Ground (for analog output terminals 7–9)

Analog 8 Heating Valve (HTV) AO8

Analog 7 AO7

Analog 6 Optional Humidier Valve (HUM or HUMV) AO6

GND Ground (for analog output terminals 4–6)

Analog 5 AO5

Analog 4 Optional Fan Speed AO4

Relay 3 Optional Cool 2 (Y2) BO3

SC 1–3 24 VAC (for relay terminals 1–3)

Relay 2 Cool 1 (Y1) BO2

Relay 1 Fan (G) BO1

*If optional Outside Air Damper is used, must also have DAT/OAT

inputs.

AHU MODULATING H / 1 OR 2 C LAYOUT

XEE-6311-050 Transformer

SET SWITCHES FOR...

OPERATION: CW

FAIL-SAFE: CCW

INPUT RANGE: 2–10 VDC

VEB-43 Fail-Safe Valves with MEP-4x52V Actuators

REE-3211 or CVR11C-0/LD96200 Multi-Voltage Relays

BAC-12xx36/13xx36/14xx36 Series FlexStat 9 Installation Guide, Rev. E

Page 10

AHU—Modulating Heat and Modulating Cool

APPLICATION

DEGREES SCALE: °F

APP:

AIR HANDLER

OPT: MOD H/MOD C

ADDITIONAL SETUP

NOTE: Do not use REE-3211/CVR11C-0/LD96200

relays with analog outputs! See Output

Connections on page 3.

NOTE: For MAT sensor use with rmware earlier

than R2.1.0.18, see the FlexStat Economizer

Change of MAT to DAT Service Bulletin

available on the KMC Partners web site.

XEE-6311-075 or XEE-6311-100 Transformer

MEP-4552 or MEP-7x52 Actuators

Rotates to Close Outside Air Damper

XEE-6311-075 Transformer

INPUT RANGE: 2–10 VDC

VEB-43 Fail-Safe Valves with MEP-4x52V Actuators

INPUT RANGE: 2–10 VDC

ADDITIONAL SETUP

DAMPER

FAN

HUMIDITY

OPTIMUM START

SENSORS

VALVE

SET SWITCHES FOR...

OPERATION: Opposite of Fail-Safe

FAIL-SAFE: In Direction Actuator

Rotates to Open Return Damper

INPUT RANGE: 2–10 VDC

SET SWITCHES FOR...

OPERATION: Opposite of Fail-Safe

FAIL-SAFE: In Direction Actuator

INPUT RANGE: 2–10 VDC

SET SWITCHES FOR...

OPERATION: CCW

FAIL-SAFE: CW

SET SWITCHES FOR...

OPERATION: CW

FAIL-SAFE: CCW

See also the

AHU—Additional

Options section

on the last page

for network,

humidification,

and fan speed

options.

Input Terminals AHU Input Connections BACnet Objects

IN9 Opt. Remote CO

Sensor* AI9

2

IN8 AI8

IN7 Opt. Remote Temp. Sensor* AI7

IN4 Opt. Outside Air Temp. (OAT)** AI4

IN3 Opt. Discharge Air Temp. (DAT)** AI3

GND Ground

IN2 Optional FST or DAT* AI2

*Fan Status (FST), Discharge Air Temperature (DAT), and (not shown

on the diagram) remote temp./CO

pull-up resistor switch positions appropriately (see the Input

sensors are optional inputs. Set

2

Connections section).

**When using the optional Outside Air Damper, DAT/OAT inputs must

also be connected.

Output

Terminals

AHU Output Connections

BACnet

Objects

Analog 9 Optional Outside Air Damper (OAD/RTD)* AO9

GND Ground (for analog output terminals 7–9)

Analog 8 Heating Valve (HTV) AO8

Analog 7 Cooling Valve (CLV) AO7

Analog 6 Optional Humidier Valve (HUM or HUMV) AO6

GND Ground (for analog output terminals 4–6)

Analog 5 AO5

Analog 4 Optional Fan Speed AO4

Relay 3 BO3

SC 1–3 24 VAC (for relay terminals 1–3)

Relay 2 BO2

Relay 1 Fan BO1

*If optional Outside Air Damper is used, must also have DAT/OAT

inputs.

AHU MODULATING H / MODULATING C LAYOUT

STE-1402 Duct Sensor, Type III

CSE-1102 Air Differential Pressure Switch

STE-1451 OAT Sensor, Type III

REE-3211 or CVR11C-0/LD96200 Multi-Voltage Relays

BAC-12xx36/13xx36/14xx36 Series FlexStat 10 Installation Guide, Rev. E

Page 11

AHU—Additional Options

XEE-6311-075 Transformer

CAUTION

This document is for 3-relay, 6-analog-output,

6-external-input BAC-12xx36/13xx36/14xx36 series

only. THESE MODELS ARE NOT COMPATIBLE WITH

THE BACKPLATES OF OLDER BAC-10000 SERIES

FLEXSTATS (WITH ONLY 3 EXTERNAL INPUTS)!

If replacing an older 3-input FlexStat, replace the

backplate as well of the new FlexStat will be damaged.

SET SWITCHES FOR...

OPERATION: CCW

FAIL-SAFE: CW

INPUT RANGE: 2–10 VDC

VEB-43 Fail-Safe Valve with MEP-4x52V Actuator

NOTE: HUMIDITY OPTIONS REQUIRE

A MODEL BAC-1x136C FLEXSTAT.

NOTE: EITHER THE HUMIDIFIER

VALVE (HUMV) OR THE HUMIDIFIER

CONTROL RELAY (HUM) CAN BE

USED, BUT NOT BOTH.

REE-3112 Control Relay

NOTE: Do not use REE-3211/CVR11C-0/LD96200

relays with analog outputs! See Output

Connections on page 3.

Additional Resources

The latest support les are always available on the

KMC Controls web site (www.kmccontrols.com). To

see all available les, you will need to log-in to the

Partners site

For specications and accessories, see the BAC-

12xxxx/13xxxx/14xxxx Series FlexStat Data Sheet.

For operation, conguration, troubleshooting,

and other information, see the FlexStat Operation

Guide.

For additional wiring, application, and programming information, see the FlexStat Application

Guide.

For additional instructions on programming, see

the Help system for KMC Connect, TotalControl, or

KMC Converge.

Important Notices

The material in this document is for information

purposes only. The contents and the product it

describes are subject to change without notice.

KMC Controls, Inc. makes no representations or

warranties with respect to this document. In no event

shall KMC Controls, Inc. be liable for any damages,

direct or incidental, arising out of or related to the

use of this document.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference,

and (2) this device must accept any interference

received, including interference that may cause

undesired operation. A BAC-12xxxx Class B digital

apparatus complies with Canadian ICES-003. A

BAC-13xxxx/14xxxx Class A digital apparatus complies with Canadian ICES-003 Class A.

BAC-12xx36/13xx36/14xx36 Series FlexStat 11 Installation Guide, Rev. E

© 2018 KMC Controls, Inc. 913-019-27E

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com

info@kmccontrols.com

Loading...

Loading...