Page 1

BAC-120063CW-ZEC FlexStat

Zoning Equipment Controller

Installation and Configuration Guide

MountingContents

™

Contents ..................................................................1

Mounting ................................................................1

Application Overview .............................................2

Roof Top Unit (RTU) ................................................3

Heat Pump Unit (HPU) ........................................... 4

Connections and Wiring .......................................... 5

Wiring Considerations .........................................5

Output Connections ............................................5

Input Connections ...............................................6

Power Connection ...............................................6

Network Wiring ..................................................6

Network EOL (End-Of-Line) Termination ............7

Configuration and Operation ..................................7

Configure the Application and Address ...............7

Setpoints .............................................................8

Heat/Cool, Fan, Occupancy, and Override .........9

Schedules ............................................................ 9

Trends .................................................................9

Sequence of Operation .........................................10

Zone Hysteresis (Changeover) ........................... 10

Zone Status .......................................................10

Troubleshooting ....................................................11

Maintenance ......................................................... 11

Customization ....................................................... 11

Remote (BAC-5051E) Interface .............................11

IoT (KMC Commander) Interface ..........................12

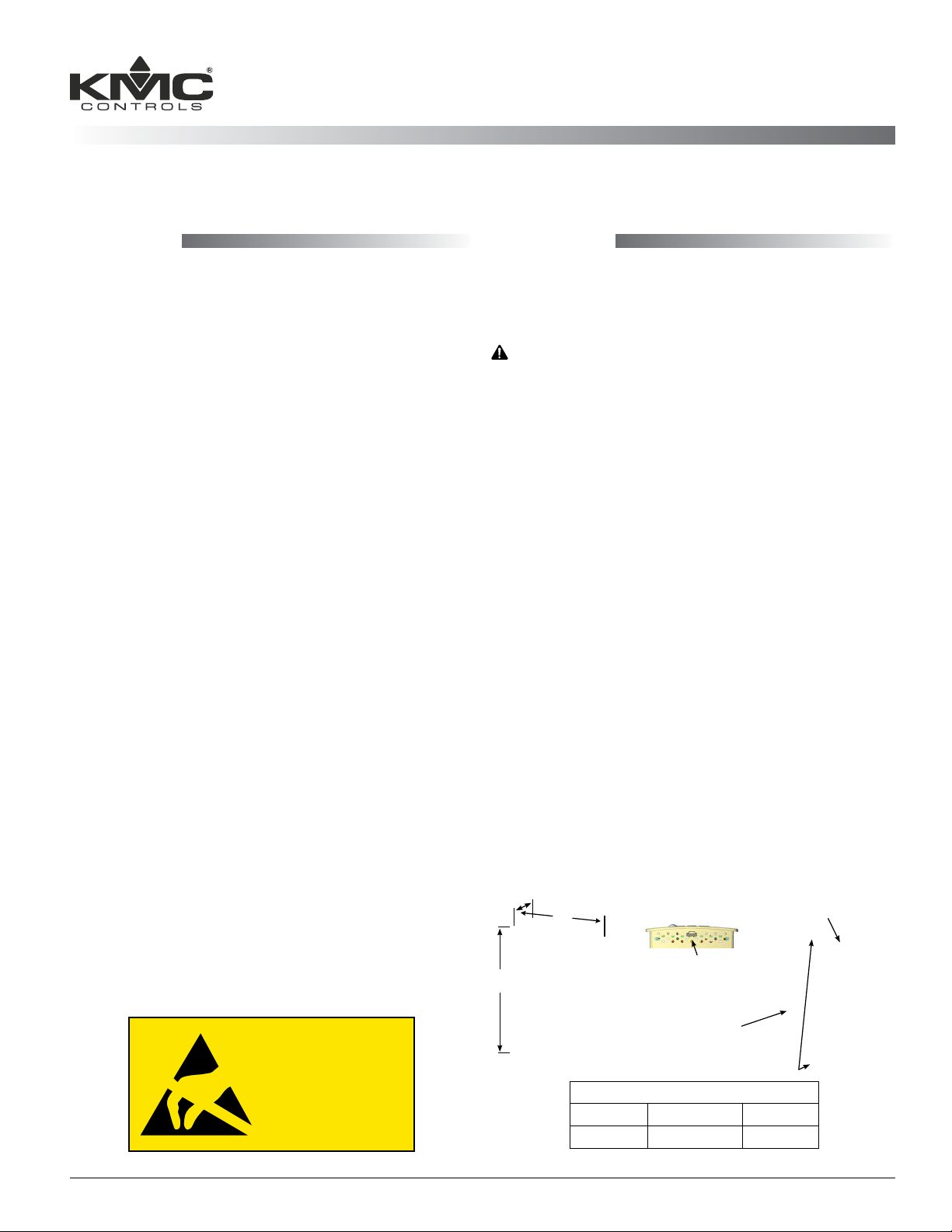

1. Complete rough-in wiring at each location prior

to the FlexStat’s installation. Cable insulation

must meet local building codes.

CAUTION

To prevent mounting screw heads from touching

the circuit board in the thermostat, use only the

mounting screws supplied by KMC Controls.

Using other screws may damage the FlexStat.

Do not turn screws in farther than necessary to

remove the cover.

2. If the cover is locked on the backplate, turn the

hex screws in the boom and top of the FlexStat

CLOCKWISE until they (just) clear the cover.

(See Illustration 1.) Pull the cover away from the

backplate (mounting base).

3. Route the wiring through the backplate.

4. With the embossed “UP” and arrows toward the

ceiling, fasten the backplate to a wall electrical

box. This FlexStat mounts directly on vertical 2 x

4 inch boxes but requires an HMO-10000W wall

mounting plate for horizontal or 4 x 4 boxes.

5. Make connections to the terminal blocks. (See

Connections and Wiring on page 5.)

6. Push the FlexStat cover over the backplate while

being careful not to pinch or dislodge any

wiring. Back the hex screws (counterclockwise)

out of the brackets until they engage the FlexStat

cover and hold it in place.

A

C

Embossed “UP” indicator

Additional Resources ............................................12

Important Notices ................................................. 12

B

NOTICE

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE DEVICES

Illustration 1—Dimensions and Installation

BAC-120063CW-ZEC FlexStat 1 Installation and Configuration Guide, Rev. G

A B C

1.125 (29) 5.551 (141) 4.192 (106)

EIA-485 data

port (for quick

network access)

Terminal blocks

on backplate

Cover locking hex screws

Dimensions in Inches (mm)

Page 2

Application Overview

Return Air

Supply Air

from RTU

Optional Bypass Damper

MS/TP Network

24 VAC

Roof Top Unit

(RTU)

CSP-4702

To HI

Port

Optional Static Pressure Signal and Setpoint

STE-140x

Temp

Sensor

Input from DAT

Output to RTU

SSS-101x Flow Sensor

1/4"

Tubing

Displayed

RTU Controller—MAC 20, Device Instance 1000000

VAV B ox

SSS-101x Flow

Sensor

STE-140x Temp

Sensor

Supply Air

To Low Pressure Port

on Pitot Tube

OR

to H or L Port on

SSS-100x Sensor

(Mounted Perpendicular

to Air Flow)

MS/TP Network

DAT

FlexStat

Supply Air

to Room

Supply Air

from RTU

1/4" Tubing

Ethernet Cable (Up to 75 Feet Long)

STE-8x01 Room Temp Sensor

and Configuration Tool

Zone 1—MAC 3, Device Instance 1000001

MS/TP Network

SSS-101x Flow

Sensor

1/4" Tubing

Ethernet Cable (Up to 75 Feet Long)

STE-8x01 Room Temp Sensor

and Configuration Tool

SimplyVAV

24 VAC

(Alternate STE-601x Room

Temperature Sensor)

VAV B ox

STE-140x Temp

Sensor

Supply Air

to Room

SimplyVAV

24 VAC

(Alternate STE-601x Room

Temperature Sensor)

Zone 16—MAC 19, Device Instance 1000016

Illustration 2—Sample Networked RTU Installation

BAC-120063CW-ZEC FlexStat 2 Installation and Configuration Guide, Rev. G

Page 3

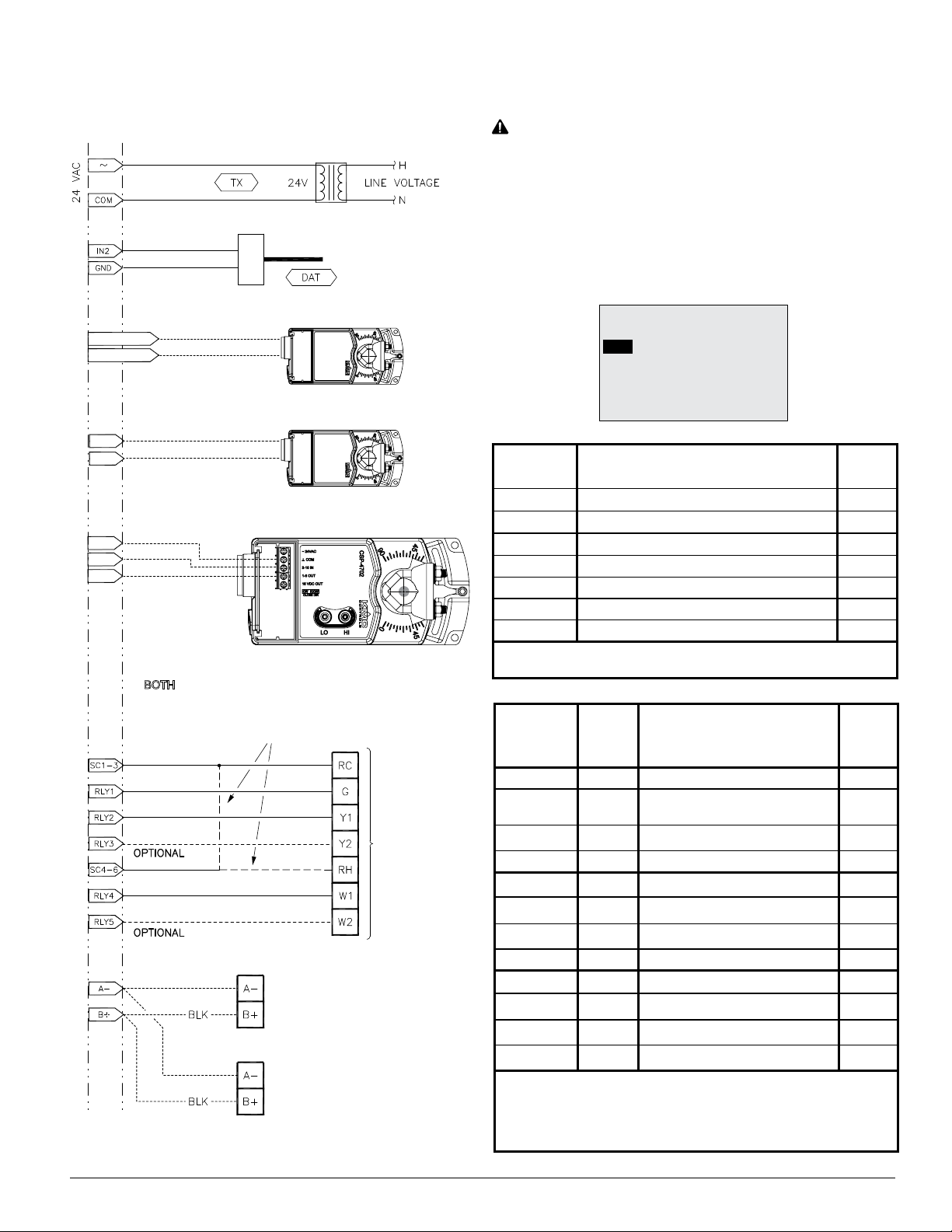

Roof Top Unit (RTU)

(1 or 2 Heat and 1 or 2 Cool)

XEE-6111-050 or XEE-6112-50 Transformer

CAUTION

Relays are for Class-2 voltages (24 VAC) only. Do not

connect line voltage to the relays!

Do not mistakenly connect 24 VAC to an analog

output ground.

STE-140x Duct Sensor, Type III

Optional Outside Air Damper

AO9 or Relay 6

GND or SC

Optional Heating/Cooling Coil Valve

AO8

GND

Optional Static Pressure Reading/Setpoint from/to CSP-4702

GND

AO7

IN9

TERMINALS

IF BOTH RC AND RH TERMINALS ARE PRESENT:

WIRE RC TO SC 1-3 AND RH TO SC 4-6.

IF ONLY ONE “R” TERMINAL IS PRESENT:

WIRE BOTH SC 1-3 AND SC 4-6 TO R.

NOTE: Althoughtypicalterminalcodeleersare

shown, check the schematics of your unit

for wiring details!

APPLICATION

DEGREES SCALE: °F

APP:

ROOF TOP

OPT: 1H/1C

ADDITIONAL SETUP

ZONE

Input

Terminals

IN9 Static Pressure Feedback (Optional) AI9

IN8 (Unused in this application) AI8

IN7 (Unused in this application) AI7

IN4 (Unused in this application) AI4

IN3 (Unused in this application) AI3

GND Ground

IN2 DAT * AI2

*NOTE: The DAT sensor is congured for IN2 in the ADVANCED >

APPLICATION > ADDITIONAL SETUP > SENSORS menu.

Output

Terminals

Typical

Terminal

Codes

RTU Input Connections

RTU Output Connections

(1 or 2 H and 1 or 2 C)

BACnet

Objects

BACnet

Objects

Analog 9 O. A. Damper (Optional) AO9

Ground

Optional Network

From

Previous

Network

Device

To

Next

Network

Device

RTU

Terminals

GND

Analog 8 Heat or Cool Valve (Optional) AO8

Analog 7 Static Pressure Setpoint (Optional) AO7

Relay 6 O. A. Damper (Optional) BO6

SC 4–6 RH/R 24 VAC (for Relay terminals 4–6)

Relay 5 W2 Heat 2 (Optional) BO5

Relay 4 W1 Heat 1 BO4

Relay 3 Y2 Cool 2 (Optional) BO3

SC 1–3 RC/R 24 VAC (for Relay terminals 1–3)

Relay 2 Y1 Cool 1 BO2

Relay 1 G Fan BO1

NOTE: Connections above are for rmware R2.0.0.4 and later. Earlier

rmware had the optional static pressure setpoint on Analog Output

9 instead of Analog Output 7, and it did not have the heating/cooling

coil valve option (Analog Output 8) or outside air damper (economizer)

option (Analog Output 9 or Relay 6).

(for Analog Output terminals 7–9)

Illustration 3—RTU Application Connections

BAC-120063CW-ZEC FlexStat 3 Installation and Configuration Guide, Rev. G

Page 4

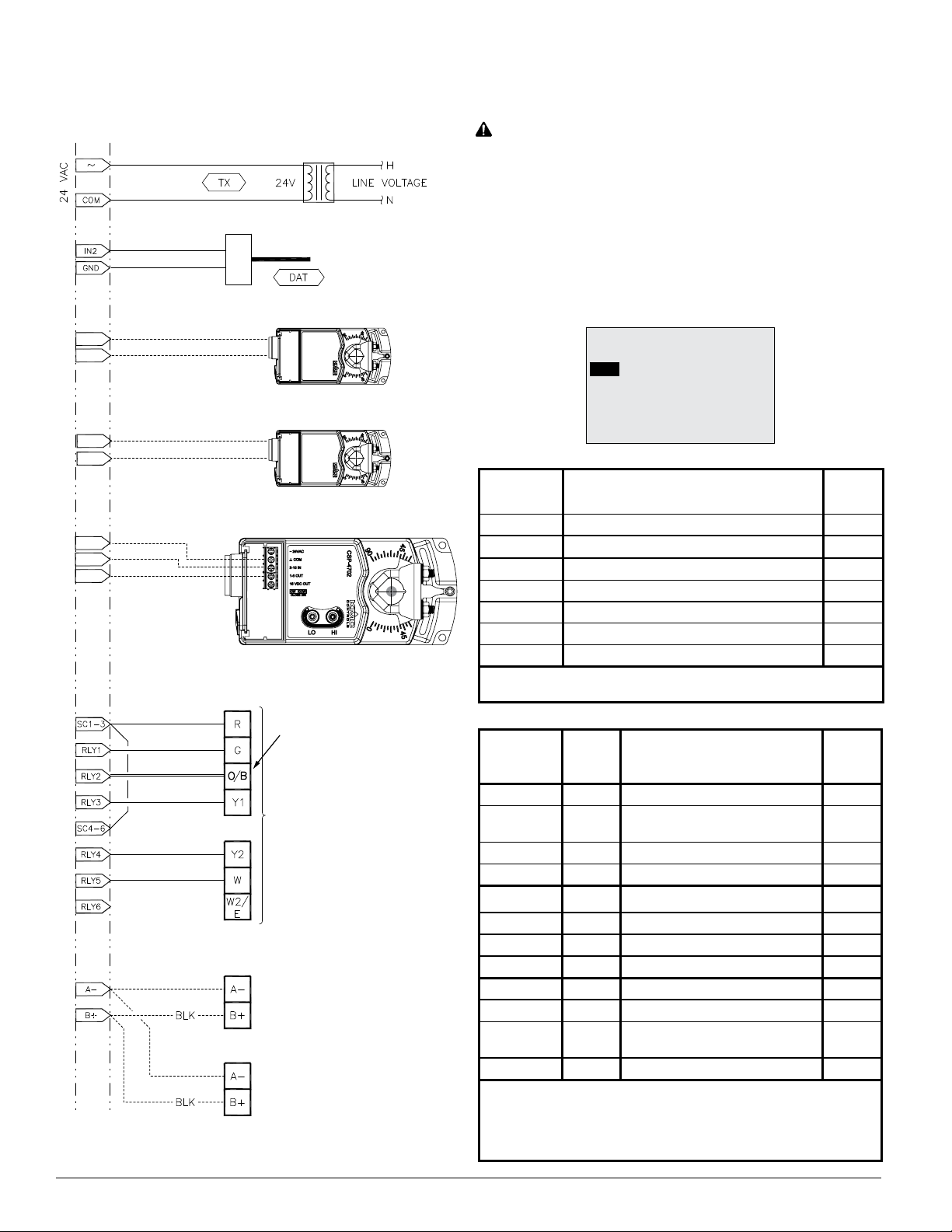

Heat Pump Unit (HPU)

1 or 2 Compressors with Auxiliary and Emergency Heat

XEE-6111-050 or XEE-6112-50 Transformer

STE-140x Duct Sensor, Type III

Optional Outside Air Damper

AO9

GND

Optional Heating/Cooling Coil Valve

AO8

GND

Optional Static Pressure Reading/Setpoint from/to CSP-4702

GND

AO7

IN9

TERMINALS

NOTE: Wire to “O” terminal if

reversing valve is energized in

cooling mode; wire to “B”

terminal if reversing valve is

energized in heating mode.

HPU

Terminals

From

Previous

Network

Device

Optional Network

To

Next

Network

Device

Illustration 4—HPU Application Connections

CAUTION

Relays are for Class-2 voltages (24 VAC) only. Do not

connect line voltage to the relays!

Do not mistakenly connect 24 VAC to an analog

output ground.

NOTE: Althoughtypicalterminalcodeleersare

shown, check the schematics of your unit

for wiring details!

APPLICATION

DEGREES SCALE: °F

APP:

HEAT PUMP

OPT: 1 STAGE

ADDITIONAL SETUP

ZONE

Input

Terminals

HPU Input Connections

IN9 Static Pressure Feedback (Optional) AI9

IN8 (Unused in this application) AI8

IN7 (Unused in this application) AI7

IN4 (Unused in this application) AI4

IN3 (Unused in this application) AI3

GND Ground

IN2 DAT * AI2

*NOTE: The DAT sensor is congured for IN2 in the ADVANCED >

APPLICATION > ADDITIONAL SETUP > SENSORS menu.

Output

Terminals

Typical

Terminal

Codes

HPU Output Connections

Analog 9 O. A. Damper (Optional) AO9

GND

(for Analog Output terminals 7–9)

Ground

Analog 8 Heat or Cool Valve (Optional) AO8

Analog 7 Static Pressure Setpoint (Optional) AO7

Relay 6 W2/E Emergency Heat (Optional) BO6

SC 4–6 R 24 VAC (for Relay terminals 4–6)

Relay 5 W Auxiliary Heat (Optional) BO5

Relay 4 Y2 Compressor 2 (Optional) BO4

Relay 3 Y1 Compressor 1 BO3

SC 1–3 R 24 VAC (for relay terminals 1–3)

Relay 2 O/B

Reversing Valve

(see O/B Note in schematic)

Relay 1 G Fan BO1

NOTE: Connections above are for rmware R2.0.0.4 and later. Earlier

rmware had the optional static pressure setpoint on Analog Output

9 instead of Analog Output 7, and it did not have the heating/cooling

coil valve option (Analog Output 8) or outside air damper (economizer)

option (Analog Output 9).

BACnet

Objects

BACnet

Objects

BO2

BAC-120063CW-ZEC FlexStat 4 Installation and Configuration Guide, Rev. G

Page 5

Connections and Wiring

Wiring Considerations

• Because of the many connections (power,

network, inputs, outputs, and their respective

grounds or switched commons), be sure wiring

is well planned before installation of conduit!

• Make sure that conduit for all wiring has adequate diameter for all necessary wiring. Using

1-inch conduit and junction boxes is recommended! Use external junction boxes above the ceiling

or in another convenient location as needed

to make connections that run to the FlexStat’s

junction box.

• To prevent excessive voltage drop, use a conduc-

tor size that is adequate for the wiring length!

Allow plenty of “cushion” to allow for transient peaks during startup.

• Using multiple conductor wires for all relevant

inputs and outputs is recommended. Grounds

for all the inputs can be combined on one wire.

CAUTION

Do not mistakenly connect 24 VAC to an analog

output ground. This is not the same as a relay’s

switched common. See the backplate’s terminal

label for the correct terminal.

CAUTION

Relays are for Class-2 voltages (24 VAC) only. Do not

connect line voltage to the relays!

CAUTION

To avoid damage from ground loops and other

communication issues in networked FlexStats,

correct phasing on MS/TP network and power

connections on ALL the networked controllers is

critically important.

NOTE: IN1 and IN5–6 are

reserved for internal sensors

Inputs

(Wiring is

dependent on

application)

MS/TP

Network

Inputs

24 VAC

Common/–/C

Phase/ /R

Illustration 5—Terminals and Connections

IN9

IN8

GND

IN7

+B

–A

IN4

IN3

GND

IN2

NOTE: SC = Switched

(relay) Common

Outputs

Analog 9

GND 7–9

Analog 8

Analog 7

Relay 6

SC 4–6

Relay 5

Relay 4

Relay 3

SC 1–3

(Wiring Cutout in Backplate)

Relay 2

Relay 1

Output Connections

Connect the device under control between the desired

output terminal and the related SC (Switched Com-

mon for relays) or GND (Ground for analog outputs)

terminal. (See Illustration 5).

Optional connections (for rmware R2.0.0.4 and later)

are:

• A static pressure setpoint signal to a CSP-4702

pressure controller used with the system for

pressure bypass control on AO7. (Earlier rmware

had it on AO9 instead.) The static pressure feedback signal is on AI9. The setpoint value can be

changed in the Setpoints menu.

• Outside air damper (economizer) on AO9 with

the Additional Setup menu options of None,

Modulating, Disable/Enable. Connect to AO9 for

modulating or (on RTU only) BO6 for enable/

disable.

• A modulating valve on a hot or cold water coil on

AO8. This can provide primary or supplemental

modulating heating or cooling to the staged

heating or cooling. The Additional Setup menu

options for actuator device type are 0–10, 10–0,

2–10, or 10–2 VDC.

BAC-120063CW-ZEC FlexStat 5 Installation and Configuration Guide, Rev. G

Page 6

One Switched

Common

Connection

Per Bank of

Three

Normally

Open Relays

Relay 3 (or 6)

SC (Phase) 1–3 (or 4–6)

Relay 2 (or 5)

Relay 1 (or 4)

NOTE: Type II or III 10K ohm thermistors can be

selected by changing the menu seing in

ADVANCED > INPUTS (see Conguration

and Operation on page 7).

NOTE: FlexStat inputs do not support 1K ohm

RTDs.

Illustration 6—Switched (Relay) Common and Relays

For the bank of three relays, there is one Switched

(relay) Common connection (in place of the GND terminal used with analog outputs). (See Illustration 6.)

For the relay circuit, the phase side of the AC should

be connected to the SC terminal.

FlexStat relays are NO, SPST (Form “A”).

Donotaachadevicethatdrawscurrentexceeding

the FlexStat’s output capacity:

• Maximum output current for individual ANALOG outputs (7–9) is 20 mA @ 12 VDC (each).

• Max. output current is 1 A for individual RELAYS @ 24 VAC/VDC or a total of 1.5 A per bank

of 3 relays (relays 1–3 and 4–6).

Input Connections

Passive input devices require pull-up resistors in the

circuit. For a passive input device (a DAT 10K ohm

thermistor on IN2), set (if not in the default position)

the pull-up switches on the back of the circuit board

to the 10K ohm position, with the upper switch to the

left and lower switch to the right. (See Illustration 8.)

NOTE: IN2mustalsobeconguredinthemenufor

DAT. See Conguration and Operation on

page 7.

For an active voltage device (optional 1–5 VDC static

pressure reading from a CSP-4702 on IN9), set the

switches to the 0–12 VDC position, with the upper

switch to the right and lower switch to the left.

NOTE: Unlike the EOL switch pairs, the INPUT

switch pairs must NOT have both switches

set to the same direction—if one of the

pair’s switches is set to the left, for example,

the other must be set to the right (or vice

versa). ALL the input pull-up resistor

switch pairs must be fully latched in either

10K Ohm or 0–12 VDC position even if

a switch pair has no input connected! A

single incorrect switch position may cause

errors in multiple inputs.

Power Connection

Connect a KMC Controls 24 volt, Class-2 transformer

to the power terminals on the FlexStat’s backplate:

1. Connect the transformer’s neutral lead to the 24

VAC Common/–/C terminal. (See Illustration 5.)

2. Connect the AC phase lead to the 24 VAC

Phase/

~/R terminal.

Power is applied to the FlexStat when the transformer is powered.

KMC Controls recommends powering only one controller/thermostat from each transformer. If installing

a FlexStat in a system with other controllers/thermostats powered from a single transformer, however,

phasing must be correct and the total power drawn

from the transformer must not exceed its rating.

Network Wiring

For an MS/TP network, use a three-conductor cable

(Belden cable #82760 or equivalent):

1. Connect the –A terminals in parallel with all

other –A terminals on the network. (See Illustrations 2 through 5.)

2. Connect the +B terminals in parallel with all

other +B terminals.

3. Connect the shields of the cable together at each

device. Use a wire nut at the FlexStat or the S

terminal in KMC BACnet controllers. Connect

the cable shield to a good earth ground at one

end only.

NOTE: The S terminal in KMC controllers is

provided as a connecting point for the

shield. The terminal is not connected to the

ground of the controller. When connecting

to controllers from other manufacturers,

verify the shield connection is not

connected to the controller’s ground.

NOTE: For more information on principles and

good practices when connecting an MS/TP

network, see Planning BACnet Networks

(Application Note AN0404A).

BAC-120063CW-ZEC FlexStat 6 Installation and Configuration Guide, Rev. G

Page 7

Network EOL (End-Of-Line) Termination

The controllers/thermostats on the physical ends of

an EIA-485 wiring segment must have end-of-line

termination installed for proper network operation.

(See Illustrations 7 and 8.) If a FlexStat is at the physical end of the MS/TP network line, set both the EOL

termination switches to On (to the right) on the back

of the circuit board. If not on the end, ensure that

both switches are O (to the left).

Configuration and Operation

WED 7/30 5:33 PM

DAT

Zone Information (# of

Zones, # of Zones Calling

for Cooling, and # of Zones

Calling for Heating)

COOL:

OCC:

FAN:

COOL CALLS 5

Up

Illustration 7—MS/TP Network End-Of-Line Termination

Input Pull-Up Switches

10K Ω

0-12 V

IN9

EOL Switches

OFF

ON

IN8

Switch

Pushed

Left

Switch

Pushed

Right

IN7

IN4

IN3

IN2

NOTE: EOL = End

Of Line of BACnet

MS/TP network.

NOTE: 10K Ω inputs

are configurable for

Type II or Type III

thermistors in

FlexStat’s menu.

Illustration 8—EOL/Pull-Up Switch Positions

Left

(Override)

Down

Right

(Menu)

Illustration 9—FlexStat Display and Button Functions

NOTE: For additional information, see the relevant

partsoftheCongurationsectioninthe

FlexStat Operation Guide (but not all

things apply to this model).

NOTE: Seings and adjustments may require a

password.

Configure the Application and Address

Toaccessthemenus,presstherightbuon.Navigate

themenusandchangeseingsbypressingacombinationofbuons. Press the:

• Enter buon to select and/or exit value editing.

• Up/Down buon to move among entries (up/

down lines).

• Left/Right buon to move among valueelds

(left/right spaces).

• Left buon to return to the Home screen.

Congure the application through the menu system.

From the Main Menu, select ADVANCED (enter

password if needed) and then APPLICATION.

APPLICATION

DEGREES SCALE: °F

APP:

ROOF TOP

OPT: 2H/2C

ADDITIONAL SETUP

ZONE DEV INS RANGE

BAC-120063CW-ZEC FlexStat 7 Installation and Configuration Guide, Rev. G

ADDITIONAL SETUP

DAMPER

FAN

SENSORS

ZONE HYSTERESIS: 2

VALVE HT OR CL: HEAT

DEVICE TYPE: 0-10V

STAGING

Page 8

NOTE: The BAC-120063CW-ZEC FlexStat comes

preconguredfora2H/2CRTUandzone

device number range of 1000000 through

1000016.

Select:

1. APP: ROOF TOP or HEAT PUMP.

2. OPT: Match stages of heating and cooling to the

RTU or HPU.

3. Under ADDITIONAL SETUP > SENSORS,

change IN2 from NONE to DAT.

SENSORS

IN2:

DAT

NOTE: The default Type III (10K ohm) thermistor

seing for DAT can be changed to Type II

(if needed) in ADVANCED > INPUTS > 2:

DISCH AIR TEMP > SENSOR: >.

INPUT #2

DISCH AIR TEMP

VALUE: 55.0°F

CAL. OFFSET: 0.0

OUT-OF-SERVICE: FALSE

FILTER WEIGHT: 6

SENSOR:

>

10K TYPE III

4. Under ADDITIONAL SETUP, change other

defaults if needed.

5. Under ZONE DEV INS RANGE, the default base

zone device numbers (with up to 16 zones of SimplyVAV controllers) start at 1000001 as a default.

To change the default base numbers to 2000001,

3000001, or 4000001, select the desired range.

ZONE DEVICE INSTANCE

RANGE:

1M = 1000001–1000016

2M = 2000001–2000016

3M = 3000001–3000016

4M = 4000001–4000016

1M

To set the FlexStat’s BACnet Device Instance (and

optionally name and location):

1. Select ADVANCED (enter password if needed)

and then DEVICE.

2. Change (or conrm) INSTANCE to 1000000.

DEVICE

INSTANCE:

NAME: ZEC_FlexStat_1

LOCATION: KMC Controls

1000000

To congure the MAC address, from the Main Menu,

select ADVANCED (enter password if needed) and

then COMMUNICATIONS.

COMMUNICATIONS

ACTIVE:

STATUS: ACTIVE

ETHERNET SETTINGS

IP SETTINGS

FOREIGN DEV SETTINGS

MS/TP SETTINGS

CONFIGURE

COMMUNICATIONS

ACTIVE:

STATUS: ACTIVE

MAC ADDRESS: 20

BAUD: 38400

AUTO-BAUD: OFF

MAX MASTER: 20

MS/TP

To set protocol and parameters for BACnet communications:

1. Select ACTIVE: CONFIGURE.

2. Select MS/TP SETTINGS.

3. Change MAC ADDRESS to 20 (if needed).

4. Change MAX MASTER to 20 (or other relevant

number depending on network).*

5. Select ACTIVE: MS/TP and restart the FlexStat.

*NOTE: For a network of 16 SimplyVAV controllers,

seing the Max Master to 20 will make

the network more ecient and perform

faster. For network connections to larger

networks with other equipment, the MAC

address should be the same as the largest

MAC address in the network for maximum

performance.

NOTE: If the Zone Device Instance range is

changed from the default, change the

FlexStat’s Device Instance to correspond

with the range (e.g., 3000000 for a range of

NOTE: ACTIVE: CONFIGURE must FIRST BE

SELECTED before any of the values can be

changed! Otherwise values are read only.

Setpoints

3000001—3000016).

If the controllers are going to be networked, congure the system address as needed and make note of

the FlexStat MAC and Device Instance. If the system

is stand-alone, address the FlexStat for MAC 20,

The home screen displays the DAT in large numbers

(instead of room temperature that FlexStats normally

display). To change the heating and cooling DAT

setpoints, under the Main Menu, select SETPOINTS.

Device Instance 1000000. (See Illustration 2.)

BAC-120063CW-ZEC FlexStat 8 Installation and Configuration Guide, Rev. G

Page 9

SETPOINTS

COOL DAT SETPOINT:

HEAT DAT SETPOINT: 130° F

DUCT ST STPT: 0.5 in H2O

55° F

that one day in the Individual Days menu

may be easier (two entries) than entering

schedules for each day separately in the

Individual Days menu (ve entries).

The optional duct static pressure setpoint is also in

this menu.

NOTE: The airow minimum limit in each

SimplyVAV controller needs to be at least

10 cfm (and 25 cfm is recommended).

Otherwise, the controller will not properly

sense the local duct DAT during minimum

ow. See BAC-8000 series for more

information about the controller-actuators.

Heat/Cool, Fan, Occupancy, and Override

When the fan is commanded to run, the animated

“FAN” icon on the display rotates. When the fan

command stops, the fan icon is motionless.

The “OCC” icon shows a sun when in Occupied

mode and a quarter moon when in Unoccupied

mode.

HEAT or COOL will show (and be animated when

there is an active command to move the temperature

toward the setpoint via mechanical heating/cooling

or an economizer), depending on the current mode.

This can also be turned OFF.

To override these modes from the Home (temperature display) screen, press the Left arrow buon.

Press Up or Down to get to the desired line and then

Enter (twice) to edit the mode seing. Press Left to

exit to Home.

Schedules

SCHEDULE

ENTIRE WEEK [MON–SUN]

WEEKDAYS [MON–FRI]

WEEKEND [SAT–SUN]

INDIVIDUAL DAYS

HOLIDAYS

ENTIRE WEEK

1:

7:30:00 AM ON

2: 5:15:00 PM OFF

3:

4:

5:

6:

[—>] DELETES ENTRY

NOTE: The last overlapping entry overrides

any other. For example, suppose the

WEEKDAYS menu is used to set all

weekdays for 7:00 AM ON and 5:00 PM

OFF, and then the INDIVIDUAL DAYS

menu is used to add some additional

evening meeting ON times for Tuesday

and Wednesday. If the WEEKDAYS menu

is later used to change the ON time from

7:00 to 7:15, schedules for all the individual

week days will be reset to conform to

what appears in the WEEKDAYS menu

and any special times for individual days

will be erased. (Special day schedules will

then need to be added again through the

INDIVIDUAL DAYS menu).

The Holiday entries will override the normal occupied weekly schedule entries and keep those days’

seings at their setback values. (Setback values are

entered in the Setpoints section of the Main Menu.)

HOLIDAYS

HOL1:

JAN 1 2017

HOL2: APR 14 2017

HOL3: MAY 29 2017

HOL4: JULY 4 2017

HOL5: SEPT 4 2017

HOL6: NOV 23 2017

HOL7: NOV 24 2017

NOTE: See the FlexStat Operation Guide for more

information on generic FlexStat operation.

Trends

The BAC-120063CW-ZEC Flexstat is precongured

for the following trend logs:

1. DAT (AI2 sampled at 30 second intervals).

2. DAT (at 1 minute intervals).

3. DAT (at 5 minute intervals).

4. Number of zones (AV22 at 1 minute intervals) of

SimplyVAVs.

The factory default schedule is always occupied

(ON). To modify the schedule for mixed occupied

(ON) and unoccupied (OFF) times, select Schedules

in the Main Menu.

NOTE: If a day of a week (e.g., Friday) has a

dierent schedule than the rest, using the

Weekdays menu rst and then modifying

BAC-120063CW-ZEC FlexStat 9 Installation and Configuration Guide, Rev. G

5. Number of calls for cooling (AV24 at 1 minute

intervals) from SimplyVAVs.

6. Number of calls for heating (AV25 at 1 minute

intervals) from SimplyVAVs.

7. Duct static pressure (AV103 at 1 minute intervals)

from an optional CSP-4702.

8. Duct static pressure setpoint (AV104 at 1 minute

Page 10

intervals) to an optional CSP-4702.

The Trend Viewer is available in the Main Menu to

view the (last 256 samples of) data in tabular format.

Software, such as KMC Connect or TotalControl, can

view the trend objects as graphs as well as change

the interval as desired.

The dierent sampling rates allow a “longer” or

“ner resolution” view of the trends. The default

sampling intervals can be changed by the user in

ADVANCED > DEVICE.

NOTE: The faster the sampling rate, the faster the

256 samples are lled and the values start

over.

NOTE: The FlexStat menu allows seing of

intervals only in multiples of 1 minute (not

seconds). If you change a default “seconds”

interval in the menu, you will not be able to

set it back to the original without a factory

reset or BAS software.

Zone Hysteresis (Changeover)

In the Additional Setup menu, the Zone Hysteresis

value (AV102) is the number of controllers (above

50% of the total) required for “majority rule” in

changing heating/cooling modes for the RTU or

HPU. The default is 1. For an explanation of this

changeover seing option, see Sequence of Operation

on page 10.

NOTE: Firmware earlier than R2.0.0.4 did not have

this option.

Zone Status

In the lower right of the home screen, smaller leers

show, in rotation:

• The detected number of connected zones of

SimplyVAVs.

• The number of zones calling for cooling.

• The number of zones calling for heating.

NOTE: After power-up or restarting of the FlexStat

and/or SimplyVAVs, the zone numbers

require several minutes to show correct

values.

For more detailed information, under the Main

Menu, select ZONE STATUS to view the status of all

connected zones. Options for each zone’s values are:

• Call for Cooling

• Call for Heating

• No Call for Either

• No Communication with a Zone (either there is a

communication problem with a zone or no zone

is connected)

The Zone Status screen also shows the Duct Status

pressure.

Sequence of Operation

NOTE: The HPU and RTU sections of the FlexStat

Application Guide have some basic

generic information about HPU and RTU

operation.

The BAC-120063CW-ZEC FlexStat determines RTU/

HPU heating or cooling mode by “majority rule”

of the number of heating and cooling calls from the

SimplyVAV controllers. If the number of heating and

cooling calls is equal, the previous mode is maintained.

The number of controllers above 50% of the total re-

quired for changeover to the other mode is controlled

by Zone Hysteresis (in the Additional Setup menu).

For the default seing of 1, a majority by one control-

ler will cause the mode to switch. For example, 8

controllers calling for heating versus 7 controllers

calling for cooling will change the RTU/HPU mode

from cooling to heating.

NOTE: If Zone Hysteresis is changed to 2, then

heating/cooling mode maintains the

previous mode until there are two more

zones needing the opposite mode than

those needing the current mode. Increasing

the number can be helpful if the system

seems to be switching modes back and

forth too quickly. The maximum hysteresis

value is 16.

NOTE: See Zone Hysteresis (Changeover) on page

10 and Congure the Application and

Address on page 7.

In RTU/HPU heating mode, the heating setpoint and

the cooling setpoint are both set to 110°. In RTU/

HPU cooling mode, the heating setpoint and the

cooling setpoint are both set to 55°. If there is no call

for heating or cooling (all VAV boxes are satised),

the cooling setpoint is set to 110° and the heating

setpoint is set to 55°.

During a scheduled O time, the RTU/HPU fan does

not run unless there is a call for heating or cooling.

BAC-120063CW-ZEC FlexStat 10 Installation and Configuration Guide, Rev. G

Page 11

Troubleshooting

Customization

• For optimal temperature control, all spaces

within a particular zone should be exposed to

similar environmental factors (e.g., all border a

perimeter wall or all be within insulated interior

spaces). Otherwise, for example, depending on

the weather, perimeter spaces may consistently

need heating when interior spaces consistently

need cooling.

• The DAT sensor must be properly connected and

congured. See Input Connections on page 6

and Congure the Application and Address on

page 7.

• The Device Instance of the FlexStat should

correspond with the Device Instance range of the

SimplyVAVs. See Congure the Application and

Address on page 7.

• Check the wiring. See Wiring Considerations on

page 5, Output Connections on page 5,

Input Connections on page 6, Power Connec-

tion on page 6, and Network Wiring on page

6.

Additional customization can be done using KMC

Connect, KMC Converge, or TotalControl. For example, a fan status switch (such as a KMC CSE-110x

or a CSE-120x) could be connected to IN3 (with the

appropriate pull-up switch seing) and the following

code could be run in Program 9 or 10.

REM FAN STATUS

REM A Normally Open dry contact

switch is connected to AI3 (with

pull-up switch set to 10K ohms)

REM BV16 shows Active when switch is

closed (fan running) and Inactive

when switch is open (not running)

IF AI3 < 0.5 THEN BV16 = 1 ELSE BV16

= 0

NOTE: Set the program to Run on Cold Start, save

it, and restart the FlexStat.

The value of BV16 (active or inactive) could then be

displayed on a card in the KMC Commander interface or a TotalControl graphics page.

• Check EOL switches. See Network EOL (End-Of-

Line) Termination on page 7.

• See also Zone Status on page 10.

• See also Setpoints on page 8.

• See also Schedules on page 9.

• See also Zone Hysteresis (Changeover) on page

10.

• See also Sequence of Operation on page 10.

• See the relevant parts of the Troubleshooting

section in the FlexStat Operation Guide.

Maintenance

Remove dust as necessary from the holes in the top

and boom. Clean the display with a soft, damp

cloth and mild soap.

Remote (BAC-5051E) Interface

The BAC-5051E BACnet router provides a means of

remotely monitoring and changing the conguration

of the zoning system with a web browser. For more

information, see the BAC-5051E Router Application

and Installation Guide.

BAC-120063CW-ZEC FlexStat 11 Installation and Configuration Guide, Rev. G

Page 12

IoT (KMC Commander) Interface

Additional Resources

KMC Commander provides an easy setup and

interface of zoning (via web page or phone app) with

remote monitoring and control, scheduling, trends,

alarms, and integration with other IoT (Internet of

Things) devices. For information, see VAV and IoT

RetrotsforVVTApplicationGuide.

See additional information about this model FlexStat

on the BAC-120063CW-ZEC web page.

For general operation, conguration, troubleshooting, and other information, see the (generic) FlexStat

Operation Guide and FlexStat Application Guide.

See also the BAC-8000 series for information about

the VAV controller-actuators.

See also the CSP-4702 page for information about the

dierential pressure controller/actuator.

For remotely monitoring and changing the

conguration, see the BAC-5051E Router

Application and Installation Guide.

For IoT use with KMC Commander, see VAV and

IoTRetrotsforVVTApplicationGuide.

Important Notices

The material in this document is for information

purposes only. The contents and the product it

describes are subject to change without notice.

KMC Controls, Inc. makes no representations or

warranties with respect to this document. In no event

shall KMC Controls, Inc. be liable for any damages,

direct or incidental, arising out of or related to the

use of this document.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference,

and (2) this device must accept any interference

received, including interference that may cause

undesired operation. A BAC-12xxxx Class B digital

apparatus complies with Canadian ICES-003.

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com

info@kmccontrols.com

BAC-120063CW-ZEC FlexStat 12 Installation and Configuration Guide, Rev. G

© 2019 KMC Controls, Inc. 913-019-30G

Loading...

Loading...