Page 1

Low Limit Controllers, DPDT

Installation Guide

CTE-3016/3017/3026/3027

Mounting

The controller can be mounted in any position,

but avoid locations subject to excessive vibration.

For manual reset models, position the controller to

permit convenient access to the reset buon.

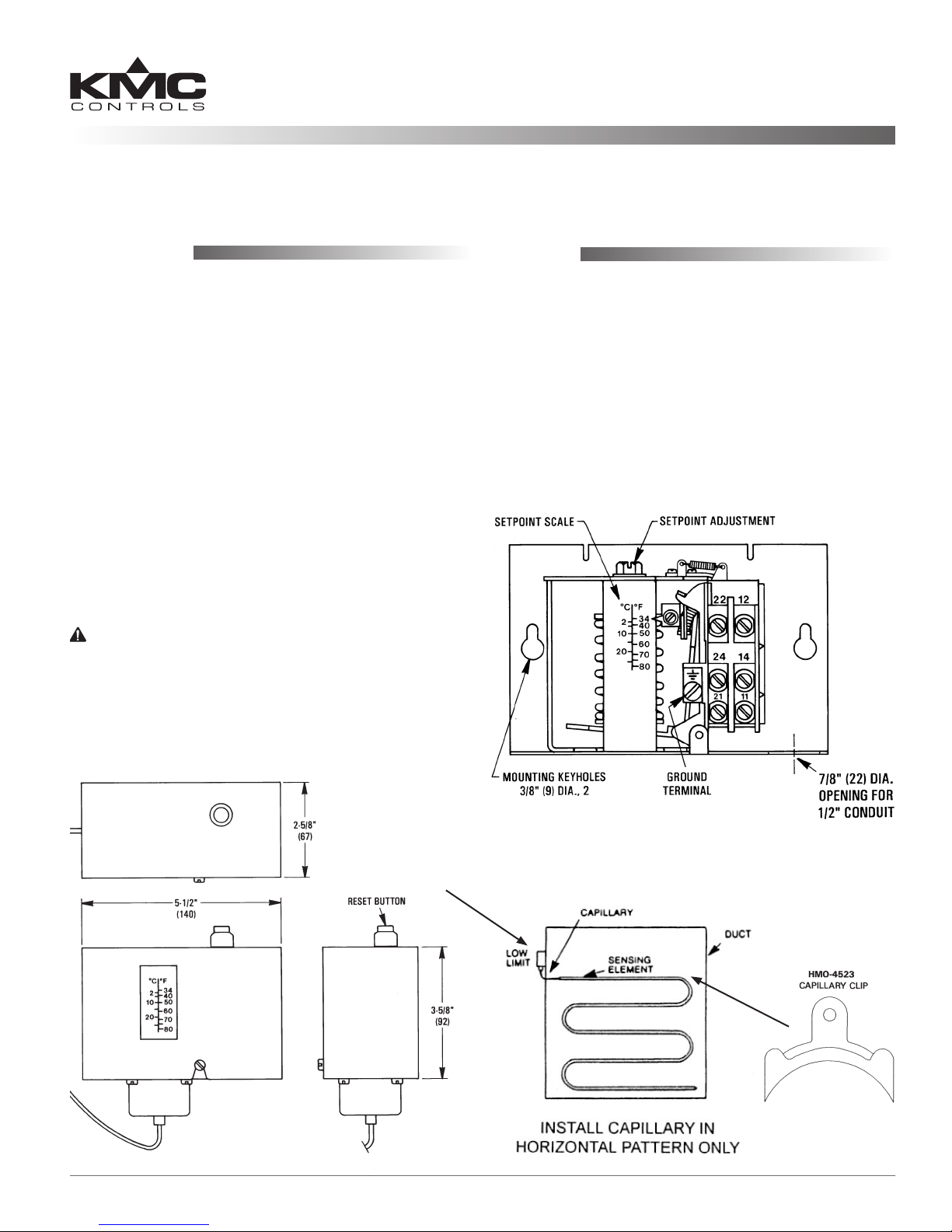

1. Loosen the front screw and remove the cover.

2. Using the two 3/8" mounting keyholes, mount

the case ush against the duct work or any at

surface.

3. Install the sensing capillary in a horizontal

serpentine fashion across the downstream side of

a water coil.

4. Using the included HMO-4523 capillary clips,

support the sensing capillary at sucient points

to prevent damage from vibration and/or air

movement.

CAUTION

Do not kink or apply excessive force to the capillary

element.

5. Make the appropriate connections to the terminal

blocks. (See the Wiring section.)

Wiring

An opening for installing a connector for 1/2" conduit

is provided in the boom of the case.

All wiring should comply with national and local

electrical codes. Using 14 AWG solid copper wire is

recommended.

Strip wire ends 3/8", insert the wire ends under

the cup washers on the switch block, and securely

retighten terminal screws. Wire terminals according

to the Actuation and Reset section on the next page.

CTE-3016/3017/3026/3027 1 Installation Guide

CTE-3017 Shown

Page 2

Actuation and Reset

Specifications

Terminals 11 and 21 are “common” terminals, 14

and 24 are Normally Closed (above setpoint), and

12 and 22 are Normally Open (see the diagram

below). When the sensed temperature falls below

setpoint, connections “11–14” and “21–24” open and

connections “11–12” and “21–22” close. The switch

latches in this position until the sensed temperature

rises 5° F (3° C) above setpoint and the controller is

reset either (depending on the model) automatically

or manually by depressing the reset buon located in

the top of the controller case.

The controller cannot be manually reset until the

sensed temperature is at least 5° F (3° C) above the

setpoint.

22 (NO)

24 (NC)

21

(Common)

(Connections Shown in Above-Setpoint, NC, Unactuated Position)

11

(Common)

12 (NO, Closes

on Low Temp.)

14 (NC, Opens

on Low Temp.)

Setpoint Adjustment

The setpoint is the temperature at which contacts

“11–14” and “21–24” open as the unit senses a fall in

temperature. To adjust the setpoint:

• Turn the range adjustment screw CW to decrease

the setpoint.

• Turn the range adjustment screw CCW to

increase the setpoint.

Range 34° to 70° F (1.1° to 21° C)

Dierential 4.5° F xed (2.5° C)

Switch Action DPDT

Element

Electrical Ratings

Inductive 14 FLA (Full Load Amperes)

84 LRA (Locked Rotor

3/4 HP @ 120 VAC, 2 HP @ 240

Pilot Duty 720 VA max. @ 120 to 600 VAC,

Approvals CUL US Listed, CE Compliant,

Weight 1.2 lbs. (0.54 kg)

Materials Plated steel case, plastic cover

Mounting Surface mount with capillary

Temperature Limits

Operating –60 to 160° F (–51 to 71° C)

Shipping –60 to 160° F (–51 to 71° C)

NOTE: See the CTE-3016/3017/3026/3027 Data

3/32" (2.4 mm) diameter, 6-foot

(183 cm) or 20-foot (607 cm)

length, vapor-lled, tin-plated

copper capillary, maximum

temperature 300° F (149° C)

@ 120 VAC, 12 FLA @ 240 VAC

Amperes) @ 120 VAC, 72 LRA

@ 240 VAC

VAC

144 VA max. @ 24 VAC

RoHs compliant

installed in horizontal serpentine paern

Sheet (717-035-21) for more information.

Testing

A manual test lever located under the cover (below

and to the le of the controller spring) allows the

unit to be manually actuated during system tests.

Accessories

HMO-4523 Capillary Clip (3 or 5 provided,

depending on length)

Maintenance

No routine maintenance is required. Each component is designed for dependable, long-term reliability, and performance. Careful installation will also

ensure long-term reliability and performance.

© 2010 KMC Controls, Inc. 717-019-21B

CTE-3016/3017/3026/3027 2 Installation Guide

Important Notices

The material in this document is for information

purposes only. The contents and the product it

describes are subject to change without notice. KMC

Controls, Inc. makes no representations or warranties with respect to this document. In no event shall

KMC Controls, Inc. be liable for any damages, direct

or incidental, arising out of or related to the use of

this document.

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com; info@kmccontrols.com

Loading...

Loading...