Page 1

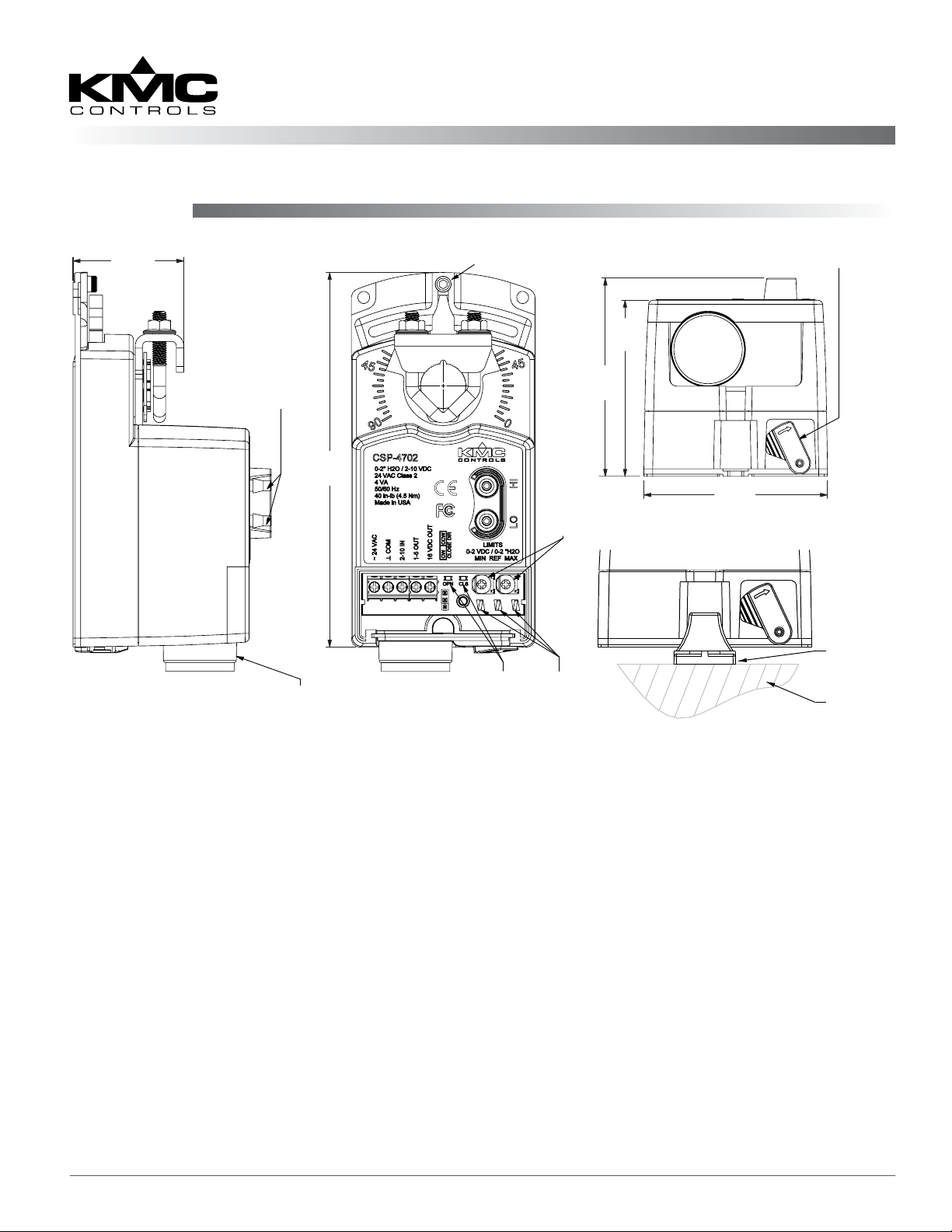

Mounting

1.563

(39.7)

Analog Differential-Pressure VAV Controller/Actuator

CSP-4702

Installation Guide

Gear

Adjustable Stop

Disengagement Lever

2.812

(71.4)

2.50

(63.5)

2.60

(66.0)

HMO-4002

Non-Rotation

Bracket

Mounting

Surface

∆

P Ports

Barbed

Connections

for 1/4" FR

Tubing

5.312

(134.9)

Removeable Conduit Fitting

with 1/2" NPS Threaded Hole

Open &

Close

LEDs

Min/Max

Flow

Setting

Pots

Min/Max

Flow Limit

Meter Taps

Illustration 1—Overview (Direct-Coupled Mounting)

NOTE: For VAV applications with the analog

CTE-5202 thermostat, see the CTE-5202

Applications Guide. For static pressure

3. Align the actuator and slide it onto the shaft.

approximately 5° may provide tight

damper shut-o.

controller applications, see the CSP-

4702 Static Pressure (Bypass) Control

Application Guide.

4. Leaving a small gap between the actuator and

mounting surface to prevent any binding, ngertighten the nuts on the V-bolt.

The CSP-4702 mounts directly to 1/4- to 5/8-inch (6 to

16 mm) round shafts or 1/4- to 7/16-inch (6 to 11 mm)

square shafts.

5. Insert the provided (HMO-4002) non-rotation

bracket into the slot at the base of the actuator

and secure the non-rotation bracket with two #8

1. Ensure the damper can move freely through its

or #10 self-tapping screws.

entire range of motion, and x any binding before

installing the actuator. Turn the damper blade to

its fully closed position.

2. Press (to the right) and hold the gear disengage-

ment lever (see Illustration 1), rotate the actuator

to the fully closed position, and release the lever.

NOTE: Depending on the damper-seal design,

backing the actuator o its stop

6. Evenly tighten the V-bolt nuts (30–35 in-lb.).

7. If desired, use a 7/64-inch hex key wrench to

loosen and position the end-stop screw.

NOTE: The two holes at the top of the actuator

are NOT for use in direct-coupled

applications. (They are for remote

mounting, such as with the optional HLO4001 Crank Arm Kit.)

CSP-4702 1 Installation Guide

Page 2

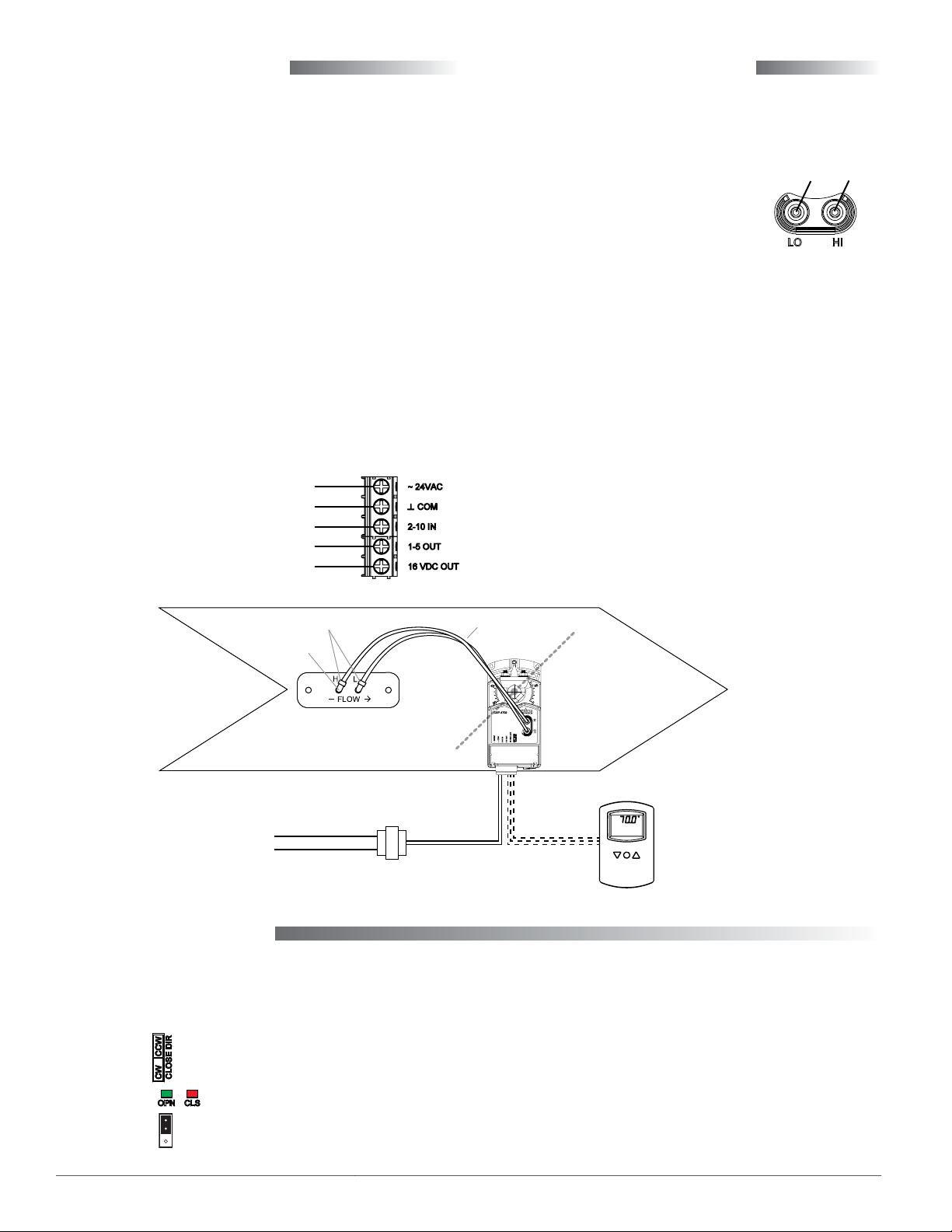

Wiring Connections

Air Pressure Connection

1. Loosen the screw on the conduit ing and lift up

to remove the ing.

2. Using a utility knife or drill, cut the red plug

to accept wiring or replace the plug with an

application-specic ing.

NOTE: The red plug (or similar ing) protects

internal components from debris, helping to

ensure long actuator life.

3. Thread wires through the plugged opening and

connect to the terminal block as shown.

4. Make the air pressure connections (see Air

Pressure Connection on page 2), set MIN/

MAX ow (see Min. and Max. Flow Limits on

page 3), and change the rotation direction (see

Rotation Direction on page 2) as needed.

5. Reinstall the conduit ing and tighten the screw.

~24 VAC (Class 2 Only) Power

Common (Power, Input, Outputs)

2–10 VDC Thermostat Signal (Input)

1–5 VDC Air Pressure Signal (Output)

16 VDC Power to Thermostat (Output)

Connect the CSP-4702 to a dierential pressure ow

sensor with 1/4-inch OD x 0.040-inch wall FR instrument and control tubing:

1. Connect the “HI” port to the

To

“ L”

To

“H”

(high side) “H” of the sensor.

2. Connect the “LO” port to the

(low side) “L” of the sensor.

NOTE: For use as a static pressure controller, see

the CSP-4702 Static Pressure (Bypass)

Control Application Guide.

NOTE: For VAV applications, the SSS-1000 series

dierential pressure ow sensor must be

mounted with the arrow pointing in the

direction of the air ow. To connect to 1/4inch tubing from the CSP-4702, an SSS-100x

dierential pressure ow sensor requires

a 3/8" to 1/4" barb union adapter and 1"

of 3/8" OD x 0.062 “FR” tubing for both

connections (as shown in the illustration).

An SSS-101x sensor does not require the

3/8" tubing or adapter.

NOTE: All tubing should be free of kinks and

restrictions.

3/8" to 1/4" Union Adapters

3/8" Tubing

SSS-100x Sensor

Illustration 2—Connections

1/4-Inch Tubing

CSP-4702

Damper

24 VAC CTE-5202

(Used in VAV

applications but

not in static

SET

POINT

pressure bypass

applications)

Rotation Direction

The CSP-4702 is factory-set for counterclockwise to

close. To reverse the direction (with the conduit cover

removed), move the jumper to the CW position.

CCW = Jumper on Upper 2 Pins

Illustration 3—Rotation Indicators and Jumper

CSP-4702 2 Installation Guide

NOTE: For about 15 seconds after power is applied,

no rotation occurs and one or both of the

LEDs will ash. The Close LED illuminates

(solid red) when the actuator is closing. The

Open LED illuminates (solid green) when

opening. When the actuator reaches the end

of rotation or the mechanical stop, the LED

may stay illuminated a brief time if the

called for condition remains unsatised.

Page 3

Min. and Max. Flow Limits

NOTE: If desired, the min. and max. limits can be

set within the thermostat or the CSP-4702,

but

do not try to set the limits at BOTH

the controller and the thermostat (or

else the limits will not reect either the

controller’s or the thermostat’s limits).

Limits Set at the CSP-4702

To set the minimum and maximum ow limits at the

CSP-4702 (with thermostat supplying 2–10 VDC):

1. Ensure the thermostat output is 2–10 VDC. For

the CTE-5202 thermostat, see the CTE-5202

Applications Guide.

2. Loosen the screw on the conduit ing and lift up

to remove the ing.

3. Connect a voltmeter to the meter taps. The

middle pin (REF) is the common for the outer

(MIN and MAX) pins.

4. Adjust the MIN potentiometer for the desired

minimum voltage. The factory default is 0 VDC =

0" wc.

NOTE: 1 VDC = 1" wc. If, for example, the desired

minimum is 0.5" wc, set the voltage for 0.5

VDC.

5. Adjust the MA X potentiometer to the desired

maximum voltage. The factory default is 2 VDC =

2" wc.

NOTE: If, for example, the desired maximum is 1.5"

wc, set the voltage for 1.5 VDC.

6. Reinstall the conduit ing and tighten the screw.

Limits Set at the Thermostat

To set the ow limits at the thermostat (with CSP4702 potentiometers set at their defaults):

1. Return the CSP-4702 potentiometers to the factory

defaults if necessary (see above).

2. Set the thermostat output limits according to its

instructions. For the CTE-5202 thermostat, see the

CTE-5202 Applications Guide.

NOTE: Voltage from the thermostat = desired ΔP

x (voltage span = 8 VDC)/(pressure span =

2" wc) + 2 VDC. For example, if a minimum

of 0.1" is desired instead of the default 0",

then 0.1 x 4 + 2 (= 0.4 + 2) = 2.4 VDC for the

minimum limit. If a maximum of 1.9" is

desired instead of the default 2", then 1.9 x

4 + 2 (= 7.6 + 2) = 9.6 VDC for the maximum

limit.

LIMITS

0-2 VDC / 0-2"H2O

MIN REF MAX

Illustration 4—CSP-4702 Limits Adjustment

Operation Test

To test the CSP-4702 operation:

1. Temporarily disconnect the thermostat signal

wire leading to the “2–10 IN” terminal.

2. Jumper the “2–10 IN” terminal to the “16 VDC

OUT” terminal. The green Open LED should

illuminate, and the shaft drive hub should start

rotating the damper open. The damper should

go to full open unless the maximum limit was

set at the CSP-4702, and then the damper will

only go to the maximum seing. If the damper is

rotating closed, change the direction jumper. (See

Rotation Direction on page 2.)

3. Remove any jumper to the “2–10 IN” terminal.

If there is a normal amount of airow in the

duct at the time (creating a dierential pressure

exceeding the minimum limit), the red Close LED

should illuminate, and the shaft drive hub should

be rotating the damper closed. The damper

should go to full closed unless the minimum limit

was set at the CSP-4702, and then the damper will

only go to the minimum seing. If the damper

is rotating open, change the rotation direction

jumper. (See Rotation Direction on page 2.)

4. Reconnect the thermostat signal wire to the “2–10

IN” terminal.

5. Adjust the thermostat’s setpoint all the way up

(simulating a drop in temperature and a need for

less cooling or more heating) and then all the way

down (simulating a rise in temperature and a

need for more cooling or less heating) and check

that the damper position reacts accordingly.

Maintenance

No routine maintenance is required. The motors

are permanently lubricated and all internal geartrain components are oil-impregnated. Careful

installation will also ensure long term reliability and

performance.

CSP-4702 3 Installation Guide

Page 4

Troubleshooting

Static Pressure Control

No Rotation

NOTE: For about 15 seconds after power is applied,

no rotation occurs and one or both of the

LEDs will ash.

• Check that the shaft moves freely. (Press and

hold the gear disengagement lever and manually

rotate the shaft.)

• Check wiring. (See Wiring Issues section below.)

• Check for a tripped circuit breaker to the

transformer, for proper supply voltage from the

transformer (or power supply), and for enough

capacity (VA) for all connected devices. See their

respective data sheets and Tips for Connecting

24-Volt Power Application Note (AN0604D)

available on the KMC Controls web site.

• Check that the direction jumper is in the proper

position. See Rotation Direction on page 2.

• Check the polarity and level of the input signal

from the thermostat.

Wrong Rotation Direction or Stroke Range

• Check the position of the direction jumper. See

Rotation Direction on page 2.

• Check the ow limits (on the controller and the

thermostat). See Min. and Max. Flow Limits on

page 3.

Besides VAV applications, the CSP-4702 can also act

as a static pressure controller in such applications as

AHU or RTU bypass control. It is not then connected

to a thermostat. For information, see the CSP-4702

Static Pressure (Bypass) Control Application

Guide.

More Information

For specications, see

the CSP-4702 Data Sheet

on the KMC web site.

For applications (with

the CTE-5202 thermostat) and other information, see the CTE-5202

Applications Guide.

• Check the adjustable stop position.

No Pressure Output Signal

• Check the wiring. (See Wiring Issues section

below.)

• Check air ow and sensor. Tubing should be free

of kinks and restrictions. Sensor must be oriented

in the correct airow direction.

Wiring Issues

• Check for correct wiring at the each device.

• Use a voltmeter and ohmmeter to check the

terminals for expected values.

• See Tips for Connecting 24-Volt Power Applica-

tion Note (AN0604D).

NOTE: Wiring must be adequate to avoid

excessive voltage drop on long runs! Allow

plenty of “cushion” in measurements. A

meter may be too slow to register transient

dips or peaks during startup.

For information about

using the CSP-4702 as

static pressure controller

in AHU/RTU bypass

applications, see the

CSP-4702 Static Pressure

(Bypass) Control Application Guide.

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com; info@kmccontrols.com

CSP-4702 4 Installation Guide

© 2014 KMC Controls, Inc. 036-019-04E

Loading...

Loading...