Page 1

Pneumatic VAV Reset Volume Controllers

CSC-3000 Series*

Installation Guide

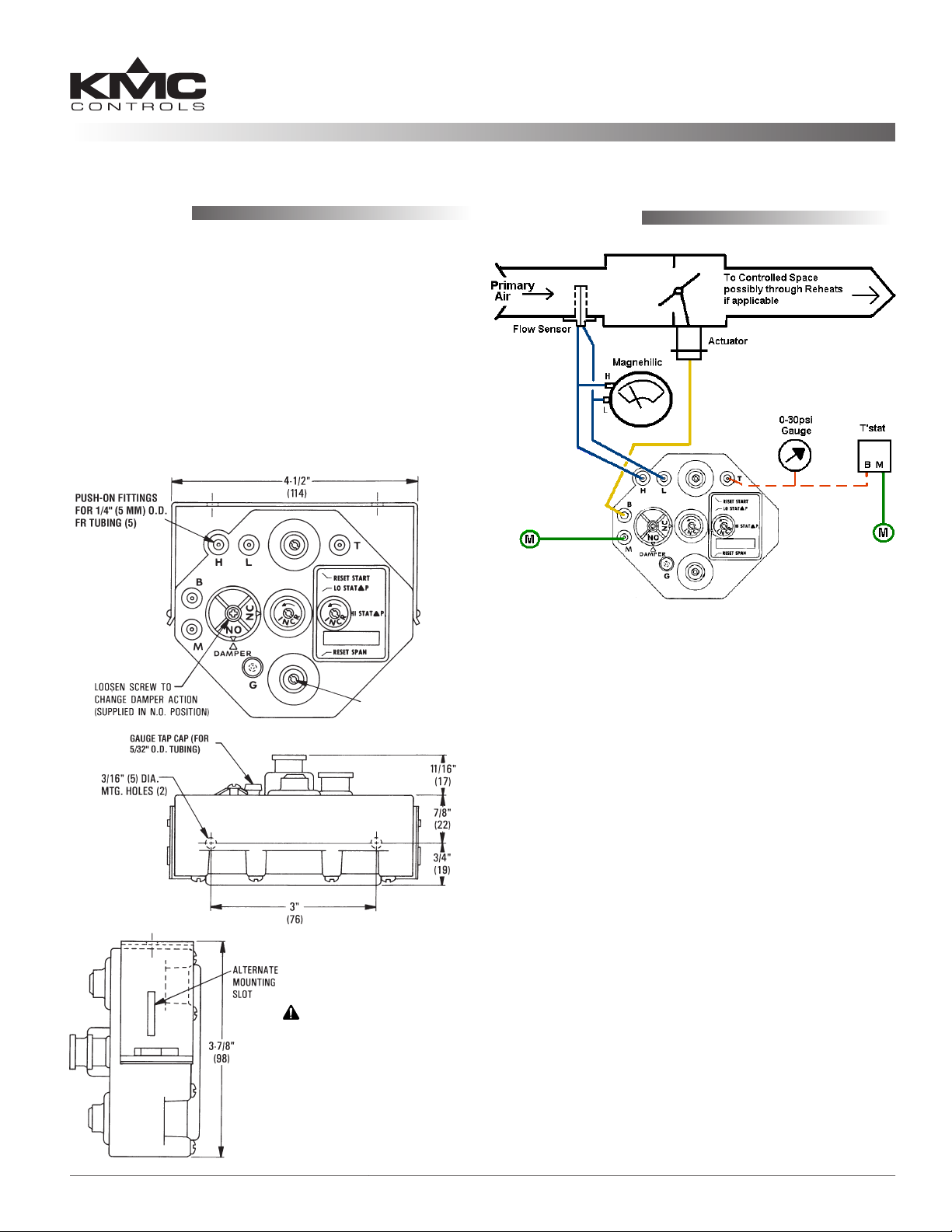

Mounting

CSC-3000 series controllers are position sensitive and must

be mounted and calibrated in either the horizontal or

vertical plane.

1. As near to the ow sensor pickup as is feasible,

connect the mounting bracket to the mounting surface

with two self-threading screws in the two 3/16" (5 mm)

mounting holes. Be sure to leave enough room to make

connections.

2. Insert the controller, face down, up, right or le. The

controller must be installed and adjusted in the same

plane or readjustment will be necessary.

All adjustments

are CCW to

increase

*(These instructions do not apply to the CSC-3014 or the

CSC-3501/3505; see their separate Installation Guides.)

Connections

Magnehelic gauge and 0–30 psi

gauge in illustration added for

checkout and calibration purposes

Typical CSC-3011 Application and Connections

For adjusting start

point and span (upper

and lower knobs) see

the Application Guide

All dimensions are in inches (mm)

CAUTION

Pneumatic devices

must be supplied with

clean, dry control air.

Any other medium

(e.g., oil or moisture

contamination) will

cause the device to fail.

For all models of the CSC-3000 series, use 1/4" (5 mm)

O.D. “FR” tubing on the following push-on ings:

1. Connect the clean, dry, oil-free main air supply to Port

“M” (15 to 30 psi).

2. Connect the damper actuator to Port “B”.

3. Connect the thermostat output to Port “T”.

4. Connect the high pressure tap on the air ow sensor to

Port “H”.

5. Connect the low pressure tap on the air ow sensor to

Port “L”.

6. Check for proper connections. Make sure all tubes

are snug on their ings. If loose, trim the end of the

tubing and reconnect it to ensure there are no leaks.

NOTE: Over time, the tube may stretch or develop

microcracks. Trim the end of tube back to

undamaged material and reconnect. Replace the

tubing if it is brile or discolored.

NOTE: You can easily test for leaks with a squeeze

bulb to ensure there are no leaks at the actuator

diaphragm or ings.

7. Use a ow hood or “tee” a Magnehelic® (or equivalent)

dierential pressure gauge between the controller and

the ∆P pick-up to determine ow rates.

CSC-3000 Series 1 Installation Guide

Page 2

Adjustments and Calibration

NOTE: Do NOT adjust start point and span (upper and

lower knobs) without thoroughly reviewing the

Application Guide. For information about direct

vs. reverse reset, see the Application Guide.

Damper Action

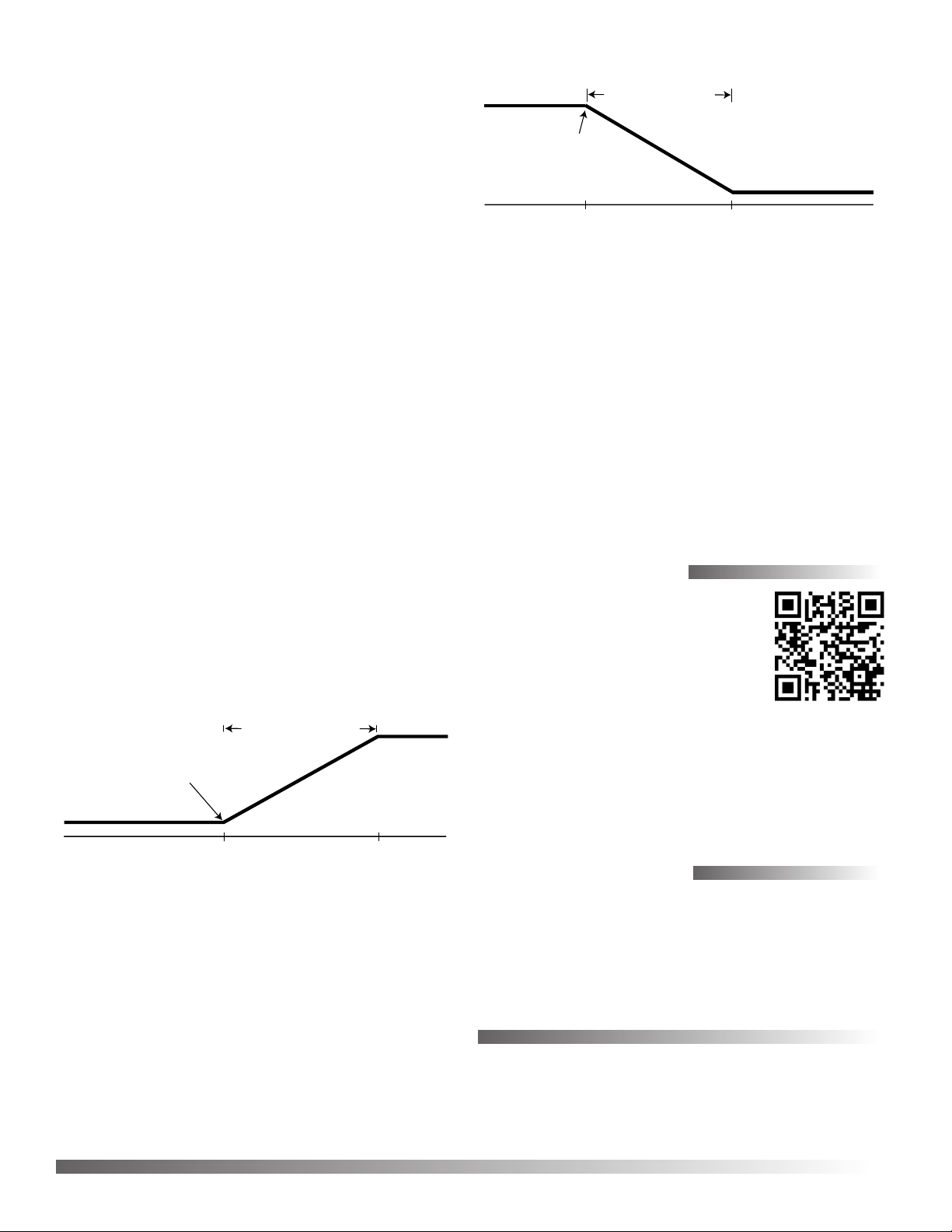

REVERSE Reset Minimum and Maximum

Max. Airflow

Reset Start Point

• 3 psig: CSC-3021/3026

• 8 psig: CSC-3011/3016/3017/3025

• 10 psig: CSC-3023

Reset Span (5 psig)

(Cooling w/ RA Thermstat or

Heating w/ DA Thermostat)

Min. Airflow

The damper action is factory-set at Normally Open (NO).

To change to Normally Closed (NC):

1. Loosen the damper selection screw.

2. Turn the selection dial clockwise until the “NC” arrow

aligns with the “DAMPER” arrow.

NOTE: Accuracy in the alignment of the arrows is

very important. Make this adjustment as exact

as possible.

3. Tighten the selection screw. Be sure the screw is tight

(2 to 4 in-lbs. of torque), but if overtightened, the

plastic will strip out.

Adjusting Minimums and Maximums

When adjusting the minimum and maximum ow

seings, the output responds slowly to changes in the

setpoint. Wait for the ow rate to stabilize aer making

an adjustment (usually 20 to 30 seconds) before making

further adjustments. Also, if the damper position is all

the way closed or open when starting this step, turn the

adjustment one full turn, and then wait 20 to 30 seconds

for a change in the ow reading of the Magnehelic gauge.

If no change occurs aer this time, repeat until the ow

rate changes. (See the Application Guide for more tips.)

DIRECT Reset Minimum and Maximum

Reset Start Point

• 3 psig: CSC-3021/3026

• 8 psig: CSC-3011/3016/3017/3025

• 10 psig: CSC-3023

Min. Airflow

NOTE: The direct reset illustration above assumes no

relays between the thermostat and “T” port.

For Direct Reset (DA thermostat for cooling or RA

thermostat for heating), perform the following steps:

1. Disconnect the “T” port. Temporarily plug the tubing.

(Do NOT plug the port.)

2. Adjust the LO STAT ∆P (center dial) to the desired

Minimum airow.

3. Reconnect the tubing at “T” port.

4. Adjust thermostat to call for full airow (15 psi or

more at “T” port).

5. Adjust the HI STAT ∆P (dial on right) to the desired

Maximum airow.

6. Repeat Steps 1 through 5 to verify the seings.

Reset Span (5 psig)

Max. Airflow

(Cooling w/ DA Thermstat or

Heating w/ RA Thermostat)

Thermostat Pressure

Thermostat Pressure

NOTE: The reverse reset illustration above assumes no

relays between the thermostat and “T” port.

For Reverse Reset (RA thermostat for cooling or DA

thermostat for heating), perform the following steps:

1. Disconnect the “T” port and leave it open. Temporarily

plug the open tubing.

2. Adjust the LO STAT ∆P (center dial) to the desired

Maximum airow.

3. Reconnect the tubing at port “T”.

4. Adjust the thermostat to call for minimum airow (15

psi or more at “T” port).

5. Adjust the HI STAT ∆P (dial on the right) to the

desired Minimum airow.

6. Repeat Steps 1 through 5 to verify the seings.

More Information

For specications, see the Data Sheet for

these controllers. For additional adjust-

ments, calibration, troubleshooting,

principles of operation, and sample applications, see the Application Guide for

these controllers. For support documents,

see the CSC-3000 series product page (bit.ly/y0G2sI) on

the KMC Controls web site (kmccontrols.com).

This Installation Guide does not apply to the CSC-3014

(designed to work with CTC-2100 Thermostats) or the

CSC-3501/3505 (Linear Volume Reset Controllers). See

their separate Data Sheets and Installation Guides.

Important Notices

The material in this document is for information purposes

only. The contents and the product it describes are subject to

change without notice. KMC Controls, Inc. makes no representations or warranties with respect to this document. In no event

shall KMC Controls, Inc. be liable for any damages, direct or

incidental, arising out of or related to the use of this document.

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com; info@kmccontrols.com

CSC-3000 Series 2 Installation Guide

© 2012 KMC Controls, Inc. 213-019-01M

Loading...

Loading...