Page 1

Installation Guide

CSC-2000 Series Overview

Reset Volume Controllers

CSC-2000 Series

The CSC-2000s are dierential-pressure (∆P), submaster controllers with adjustable minimum and

maximum airow seings. A master controller,

typically a room thermostat, resets the CSC velocity

setpoint.

CSC-2000s are available as direct acting for normally

open VAV terminal units, and reverse acting for normal closed VAV terminal units. Each unit is equipped

with separate adjustment knobs for minimum and

maximum airow seings. CSC-2001/2002s are

equipped with 0–10 reference dials, while all others

have blind adjustments. Calibrate all models using

standard airow measuring equipment.

The spring range of the actuator does not maer

to the controller. However, sucient main air is

required to provide the actuator with enough force

to operate the damper/linkage.

Any sequencing with other controllers, valves, or

pneumatic-electric relays must be sequenced with

the controller’s reset range, not the actuator’s spring

range.

These controllers are typically used on single-duct

applications but may be found in dual-duct applications. When working on dual-duct applications

it may be necessary to work on one duct at a time

while closing o the other.

The CSC-2000 series controllers are position sensitive. See the Mounting section on the next page for

the proper vertical/horizontal orientation for the different models.

CAUTION

Pneumatic devices must be supplied with clean,

dry control air. Any other medium (e.g., oil or

moisture contamination) will cause the device

to fail.

Connections Adjustments

CSC-2000 Series Reset Volume Controllers 1 Installation Guide

Page 2

Specifications

Mounting

Output Sensitivity 0 to 1" range unit,

5 psig/0.02" wg (35 kPa/5 Pa)

0 to 2" range units,

5 psig/0.04"wg (35 kPa/10 Pa)

Main Air Pressure 15 to 30 psig (103 to 207 kPa)

Max. Signal Pressure 6" wg (1493 Pa) applied to

either port (X or Y)

Material Flame retardant plastic (beige

or gray)

Output Capability 0 to supply pressure

Weight 7.5 oz. (213 grams)

Temperature Limits

Operating 40° to 120° F (4° to 49° C)

Shipping –40° to 140° F (–40° to 60° C)

Direct Acting BEIGE units (CSC-2001/2003/2007/

2009/2017) are designed for normally open dampers

with direct-acting thermostats for cooling and reverse-acting thermostats for heating.

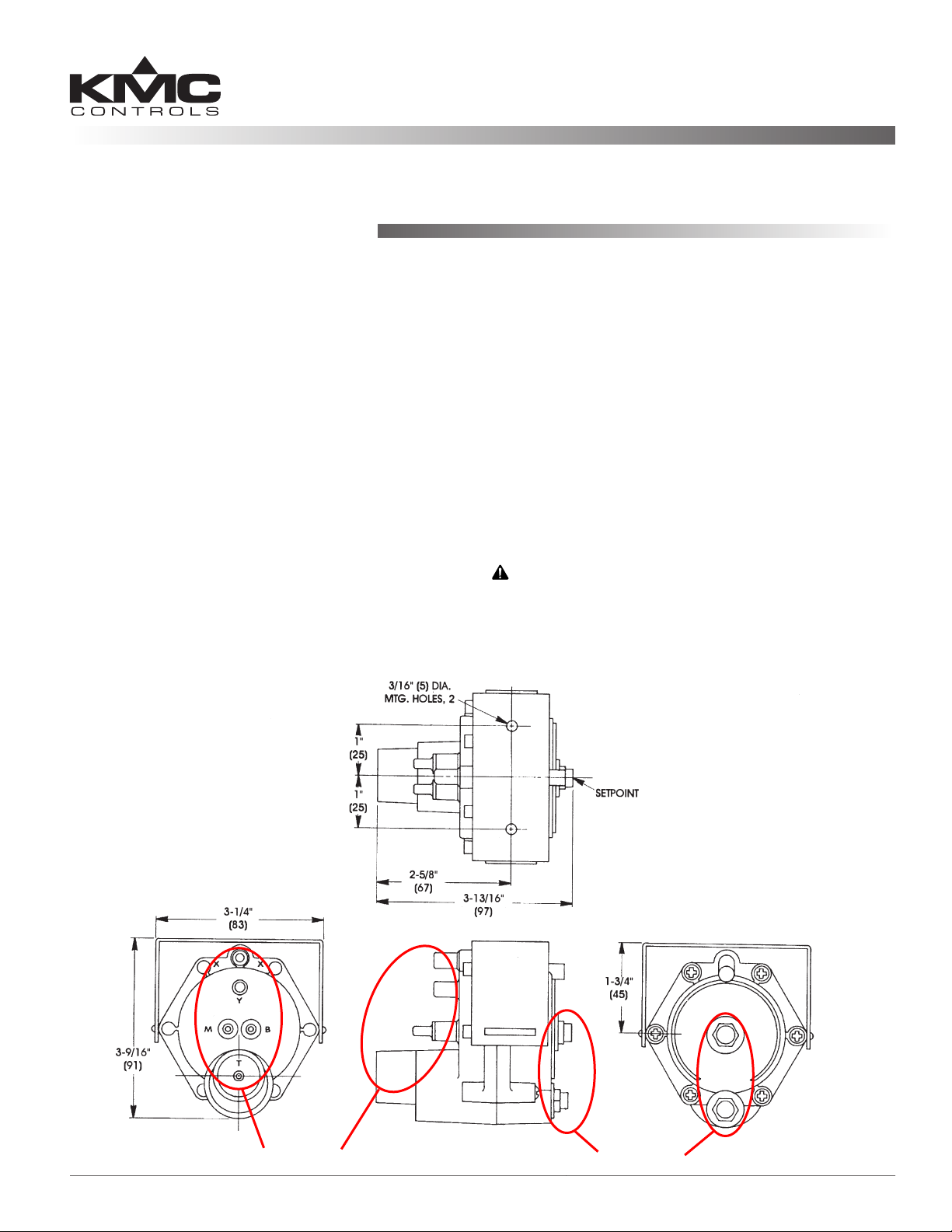

As close to the ow sensor pickup as is feasible,

fasten the mounting bracket to the mounting surface

with two self-threading screws in the two 3/16 in.

(5 mm) holes. (Make sure to leave enough room to

make connections.)

The CSC-2000 series are position sensitive:

• The minimum and maximum ow limits must

be set (calibrated) in the same position the

controller will be mounted.

• The CSC-2001/2002 (with 0–10 molded plastic

dials) must be mounted horizontally with dial

adjustment knobs facing up.

• The CSC-2003 through CSC-2018 (no molded

dials) may be mounted horizontally (preferred),

with the adjustment knobs up or down, or

mounted vertically (the diaphragm inside must

be in a horizontal or vertical plane).

NOTE: If replacing a CSC-2001-22 or CSC-2002-22

(designed for vertical mount and now

obsolete), use the CSC-2001 or CSC-2002 as

appropriate and mount dials face up or use

the CSC-2003 or CSC-2004 as appropriate

and mount vertically or horizontally.

Reverse Acting GRAY units (CSC-2002/2004/2008/

2010/2018) are designed for normally closed damp-

ers with reverse-acting thermostats for cooling and

direct-acting thermostats for heating.

For additional specications of particular models,

see the CSC-2000 Data Sheet.

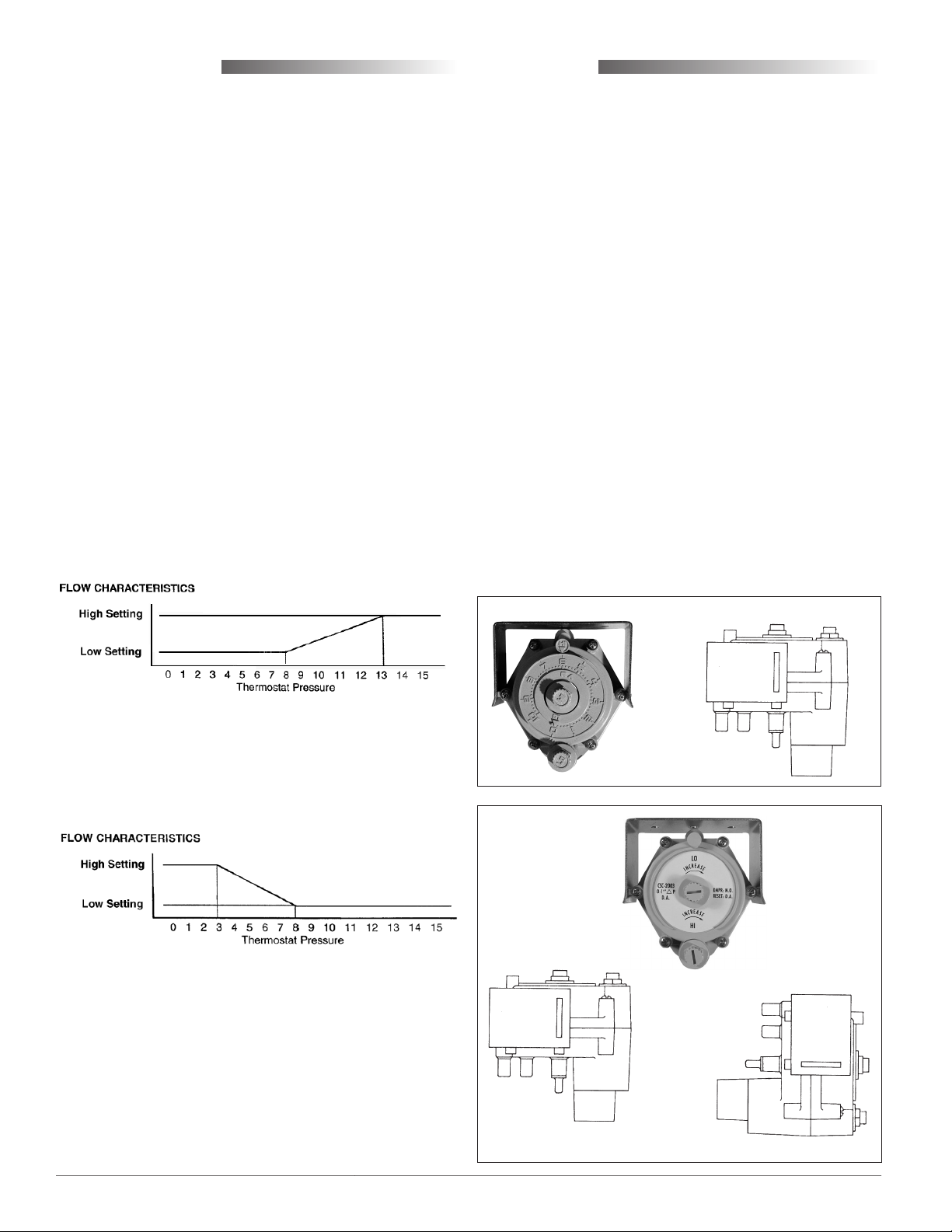

Horizontal Mount, Knobs Up Only

With 0–10 Molded Plastic Dial

(CSC-2001/2002)

Without

Molded Dial

(CSC-2003

through CSC-

2018)

Horizontal Mount

(Preferred, Knobs Up or Down)

CSC-2000 Series Reset Volume Controllers 2 Installation Guide

Or Vertical Mount

Page 3

Connections

Adjustments and Calibration

All Units

For all models of the CSC-2000 Series use 1/4 in. (6

mm) O.D. “FR” tubing for the following connections:

1. Connect the main air supply to port “M”.

2. Connect the actuator to port “B”.

3. Connect the thermostat to port “T”.

Beige Units

Use 3/8 in. O.D. “FR” tubing with a maximum

length of 24 in. to connect:

1. High pressure to port “X”.

2. Low pressure to port “Y”.

Gray Units

Use 3/8 in. O.D. “FR” tubing with a maximum

length of 24 in. to connect:

1. Low pressure to port “X”.

2. High pressure to port “Y”.

CAUTION

Pneumatic devices must be supplied with clean,

dry control air. Any other medium (e.g., oil or

moisture contamination) will cause the device

to fail.

Troubleshooting

The CSC-2000 series are position sensitive. Be sure

to mount the controller with the correct orientation.

See the Mounting section.

NOTE: If the controller is calibrated in a position

other than the nal mounting position, the

calibration (minimum and maximum ow

limits) will be o.

To minimize issues related to pressure, always use

3/8 in. tubing for the “X” and “Y” ports and keep

the tubing lengths as short as possible. If the sensor has 1/4 in. ings, use 3/8 in. tubing and adapters at the sensor.

Some older style ow sensors may have restrictive

openings for the low pressure pickup. Replacement

of the ow sensor pickup may be necessary.

For additional troubleshooting information, see the

CSC-2000 Applications Guide.

GRAY Controllers (Reverse Acting)

1. Check that there is 0 psi at the “T” Port.

®

2. Use a ow hood or “tee” a Magnehelic

equivalent) dierential pressure gauge between

the controller and the ∆P pick-up.

3. The “HI” ow seing limit (center knob) must

be set rst. Temporarily adjust the thermostat

for a branch pressure lower than the 3 psig reset

start point (maximum cooling); typically 1 psig or

less is best. Removing the thermostat branch line

would be another acceptable method. Adjust the

“HI” knob (center knob) counterclockwise to increase or clockwise to decrease ∆P limit. Normally

one-half turn will cause a 0.1 ∆P change. Allow

for reaction time. Depending on actuator size and

position, timing will vary. To position an actuator/damper from closed to open may take several

minutes.

4. The “LO” ow seing limit must be set aer the

“HI”. Temporarily adjust the thermostat for a

branch pressure higher than the 8 psig reset stop

point (minimum cooling); typically 12 psig or

greater is best. Removing the thermostat branch

line and teeing-in to the main air line would be

another acceptable method. Adjust the “LO” knob

(outside knob) counterclockwise to increase or

clockwise to decrease ∆P limit. Normally one-half

turn will cause a 0.1 ∆P change. Allow for reaction

time.

5. Recheck the “HI” and the “LO” seings at least

twice, verify seings, and ne tune each time if

necessary. This procedure will remove internal

component tensions and conrm seings.

6. Reconnect the thermostat branch line if necessary,

and adjust the thermostat to the desired room

temperature setpoint.

NOTE

NOTE

NOTE: For principles of operation and sample

: The “LO” adjustment limits the travel of

the reset mechanism. Therefore, the reset

span will be less than 5 psig, the upper limit

being less than 8 psig.

: Always make adjustments in the same

plane/orientation as the one in which the

unit will operate.

applications, see the CSC-2000 Applications

Guide.

(or

CSC-2000 Series Reset Volume Controllers 3 Installation Guide

Page 4

BEIGE Controllers (Direct Acting)

1. Check that there is 0 psi at the “T” Port.

2. Use a ow hood or “tee” a Magnehelic® (or equivalent) dierential pressure gauge between the

controller and the ∆P pick-up.

3. The “LO” ow seing limit (center knob) must

be set rst. Temporarily adjust the thermostat

for a branch pressure lower than the 8 psig reset

start point (minimum cooling); typically 6 psig or

less is best. Removing the thermostat branch line

would be another acceptable method. Adjust the

“LO” knob (center knob) clockwise to increase or

counterclockwise to decrease ∆P limit. Normally

one-half turn will cause a 0.1 ∆P change. Allow

for reaction time. Depending on actuator size and

position, timing will vary. To position an actuator/damper from closed to open may take several

minutes.

NOTE: If the “LO” ow seing limit must be set at

“0” (zero minimum), do not turn the “LO”

knob fully counterclockwise. The knob will

adjust three to four full turns aer a zero

minimum is reached. Turning the “LO”

knob fully counterclockwise will result in

a negative reset condition. This means that

when the controller is beginning to reset

at 8 psig from the thermostat, it must rst

overcome the negative adjustment and will

not begin to reset until a higher thermostat

reset pressure is reached. This negative

reset will also reduce the eective range

of the controller by reducing the high end

and narrowing the reset span. If a zero

minimum is required, adjust the “LO” knob

until the controller just begins to crack the

damper open, then back-o one-fourth turn

and verify zero airow.

4. The “HI” ow seing limit (outer knob) must be

set aer the “LO”. Temporarily adjust the thermostat for a branch pressure higher than the 13

psig reset stop point (maximum cooling); typically

17 psig or greater is best. Removing the thermostat branch line and teeing-in to the main air line

would be another acceptable method. Adjust the

“HI” knob (outer knob) clockwise to increase or

counterclockwise to decrease ∆P limit. Nominally

one-half turn will cause a 0.1 ∆P change. Allow for

reaction time.

5. Recheck the “LO” and the “HI” seings at least

twice, verify seings, and ne tune each time if

necessary. This procedure will remove internal

component tensions and conrm seings.

6. Reconnect the thermostat branch line if necessary,

and adjust the thermostat to the desired room temperature setpoint.

NOTE

NOTE

: The “HI” adjustment limits the travel of

the reset mechanism. Therefore, the reset

span will be less than 5 psig, the upper limit

being less than 13 psig.

: Always make adjustments in the same

plane/orientation as the one in which the

unit will operate.

Maintenance

No routine maintenance is required. Each component is designed and manufactured for reliability

and performance. Careful installation and use will

ensure long-term dependability.

CAUTION

Pneumatic devices must be supplied with clean,

dry control air. Any other medium (e.g., oil

or moisture contamination) will result in the

device’s eventual failure.

More Information

For additional specications of particular models,

see the CSC-2000 Data Sheet (hp://bit.ly/PWVwol).

For principles of operation, troubleshooting, and

sample applications, see the CSC-2000 Applications

Guide (hp://bit.ly/RAWIzn).

(Scan QR code

to download

Applications

Guide.)

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com; info@kmccontrols.com

CSC-2000 Series Reset Volume Controllers 4 Installation Guide© 2012 KMC Controls, Inc. 205-019-01R

Loading...

Loading...