Page 1

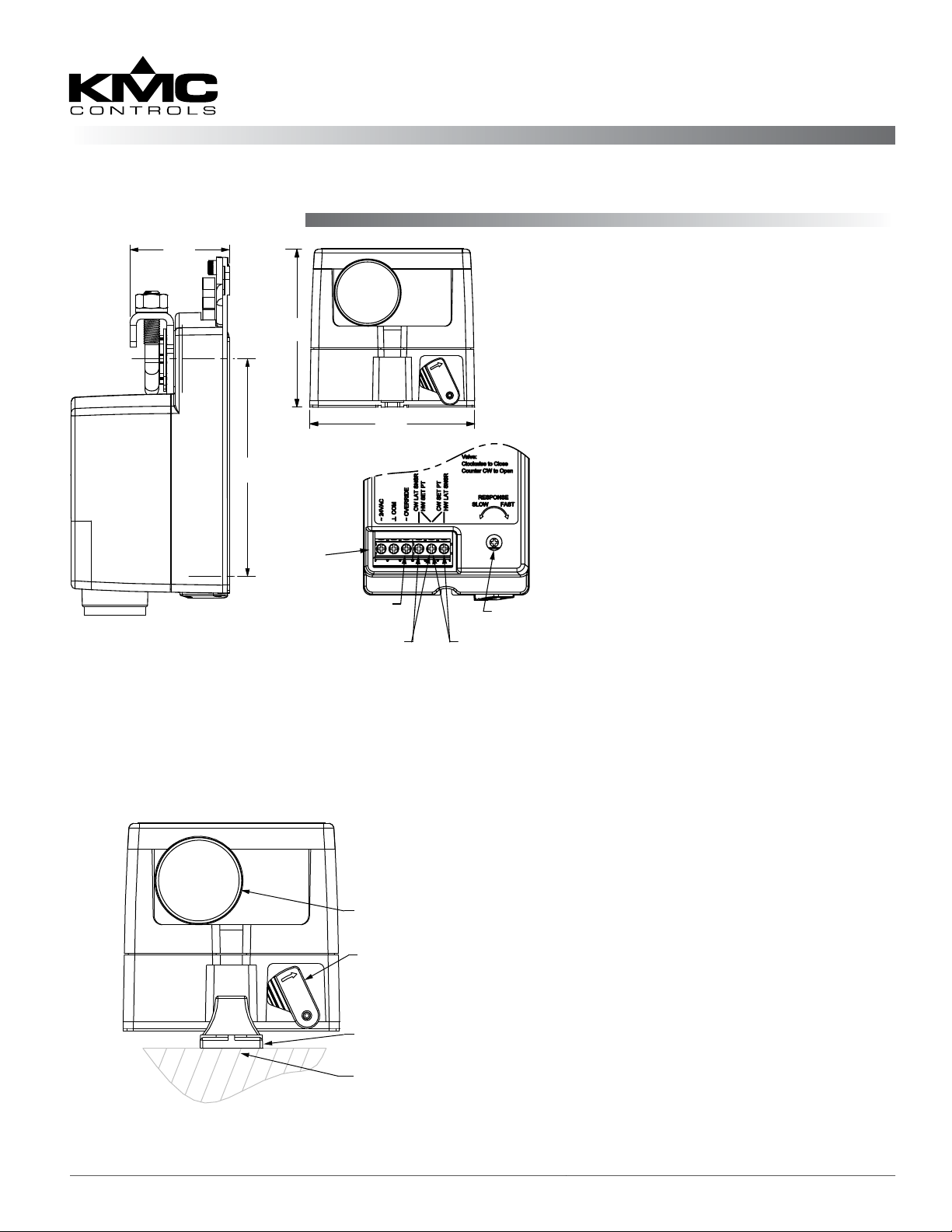

CEP-4703 Mounting

Analog Electronic DAT Controller-Actuator

CEP-4703/4703V

Installation Guide

1.568 [40]

2.5

[63.5]

3.437

[87.3]

CEP-4703

Terminals

(under cover)

Override input (remembers

position and closes valve on

no call

2.6

[66]

for heat or cool)

Cold water LAT sensor or

hot water setpoint resistor

Sensitivity

adjustment

Cold water setpoint

resistor or hot water

LAT sensor

NOTE: Thismountingsectionisspecic

to the CEP-4703. For mounting a

CEP-4703V, see CEP-4703V Valve

Mounting on page 2.

1. Ensure the damper or valve shaft can

move freely through its entire range

of motion, and x any binding before

installing the actuator. Turn the damper

blade to its fully closed position.

2. Press (to the right) and hold the gear

disengagement lever, rotate the actuator

to the fully closed position, and release

the lever.

NOTE: Depending on the damper-seal

design, backing the actuator o

its stop approximately 5° may

provide tight damper shut-o.

3. Align the actuator and slide it onto the

shaft.

4. Leaving a gap between the actuator

and mounting surface to prevent any

binding, nger-tighten the nuts on the

V-bolt.

5. Insert the non-rotation bracket (HMO4002 supplied or HMO-4001 “T” bracket

available separately) into the slot at the

base of the actuator (as shown in the

illustration).

6. Secure the non-rotation bracket with

two (2) #8 or #10 self-tapping screws.

Removeable conduit fitting

with 1/2" NPS threaded hole

7. Evenly tighten the V-bolt nuts 30 to 35

in-lb.

Gear disengagement lever

8. If desired, use a 7/64-inch hex key

wrench to loosen and position the endstop screw.

Non-rotation bracket

(HMO-4002)

Mounting surface

NOTE: The two holes at the top of the

actuator are NOT for use in

direct-coupled applications.

They are for remote mounting,

such as with the optional HLO4001 Crank Arm Kit (see the Data

Sheet).

CEP-4703/4703V 1 Installation Guide

Page 2

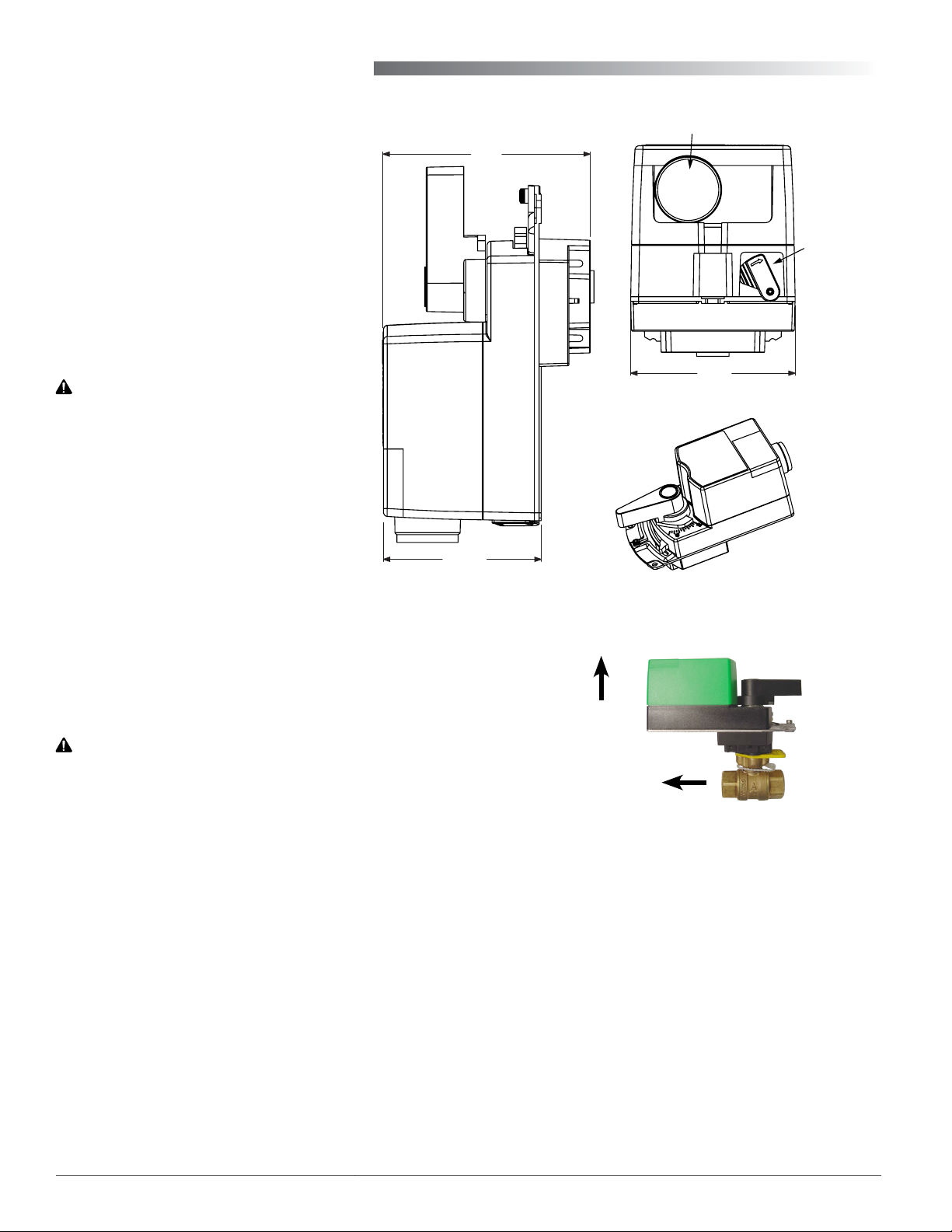

CEP-4703V Valve Mounting

3.437

[87.3]

1.568 [40]

2.6

[66]

[63.5]

2.5

CEP-4703

Override input (remembers

position and closes valve on

no call

for heat or cool)

Cold water LAT sensor or

hot water setpoint resistor

Cold water setpoint

resistor or hot water

LAT sensor

Sensitivity

adjustment

Terminals

(under cover)

NOTE: To assemble a quick-mount

“V” actuator on a valve

body, see the HPO-5074

Installation Guide on the

KMC web site.

1. Clean the lines upstream from the

valve. Remove any debris larger

than 0.06" (0.015 mm).

2. Align the valve’s ow indicator

with the system ow.

3. Mount the valve so the actuator is

positioned over the valve body.

CAUTION

To prevent condensation from dripping

onto the actuator housing, mount the

valve with the actuator in the upright

position or, at most, at a 45° angle.

4. Seal valves with approved pipe

sealant.

5. Using two wrenches, secure the

valve to the pipe. Torque should

not exceed 75 ft-lb. (102 N

•m).

2.5

[63.3]

3.28

[83.2]

CEP-4703V

Removable conduit fitting

with 1/2" NPS threaded hole

2.6

[66]

Gear

disengagement

lever

6. Eliminate air from the system to

keep the valves full of uid during operation.

NOTE: If the system experiences large amounts of

debris, steps should be taken to keep the

system clean.

CAUTION

Using mineral oil lubricants or other incompatible

substances in system fluids may damage EPDM

rubber seals in valves. Before using any lubricant or

additive in a water or ethylene glycol base, consult

the substance manufacturer for compatibility with

EPDM (Ethylene Propylene Diene Monomer).

CEP-4703V Actuator

UP

SYSTEM FLOW

VFB-43 Series Valve Body

ACTION:

Full CW = Valve Closed (System Off)

Full CCW = Valve Open (System On)

CEP-4703/4703V 2 Installation Guide

Page 3

Wiring Connections

1. Loosen the screw on the conduit ing and lift up

to remove the ing.

2. Using a utility knife or drill, cut the red plug

to accept wiring or replace the plug with an

application-specic ing.

NOTE: The red plug (or similar ing) protects

internal components from debris, helping to

ensure long actuator life.

3. Thread wires through the plugged opening and

connect to the terminal block as shown.

4. Reinstall the conduit ing and tighten the screw.

Setpoint Resistor*

°F Ohms °F Ohms

Chilled Water Hot Water

54 16.9K 94 6.98K

56 16.2K 96 6.65K

58 15.4K 98 6.34K

60 14.7K 100 6.04K

62 14.0K 102 5.90K

*1/4 Watt, 1%

Configured for Cooling

24 VAC

Contact

STE-1401

Setpoint Resistor

Configured for Heating

24 VAC

Contact

Setpoint Resistor

STE-1401

Contact Closed = System On; Open = System Off

CW to Close; CCW to Open

Operation

After the mechanical and electrical installations have

been completed, cycle the actuator to verify the direction of rotation for normal operation.

When the CEP-4703/4703V is connected to power:

1. The actuator drives to the fully closed position

(for two minutes). If the Override signal is present (contact closed across two terminals), indicating system On, the actuator waits one more minute and then starts controlling. If the Override

Control Sequence

100

100

% On Time

% On Time

0

0

CLOSE 1F SP 1F OPEN

signal is absent (contact open), indicating system

O, the actuator waits in the closed position.

2. Whenever the system goes O, the actuator

stores its current position and then drives to the

fully closed position.

3. Whenever the system goes On, the actuator re-

turns to its previous (stored) position, waits one

minute, and resumes controlling.

When controlling, the CEP-4703/4703V control sequence is as shown in the diagram.

% On-Time Slope Adjustable Via Sensitivity Adjustment

Maximum = 30% per °F (faster response but less stable)

Minimum = 3% per °F (slower response but more stable)

% On-Time Period = 1 Minute

CEP-4703/4703V 3 Installation Guide

Page 4

Troubleshooting

No Rotation or Wrong Stroke Range

More Information

NOTE: Pausing for up to two minutes is part of

normal operation. See Operation on page

3.

• Check that the shaft moves freely. (Press and

hold the gear disengagement lever and manually

rotate the shaft.)

• Check wiring. (See Wiring Issues section below.)

• Check for a tripped circuit breaker to the

transformer, for proper supply voltage from the

transformer (or power supply), and for enough

capacity (VA) for all connected devices. See their

respective data sheets and Tips for Connecting

24-Volt Power Application Note (AN0604D)

available on the KMC Controls web site.

• Check the adjustable stop position.

Wiring Issues

• Check for correct wiring at the each device.

• Use a voltmeter and ohmmeter to check the

terminals for expected values.

• See Tips for Connecting 24-Volt Power Applica-

tion Note (AN0604D).

For specicationsand

other information, see

the CEP-4703/4703V

Data Sheet on the KMC

web site.

For information on

assembling a quickmount CEP-4703V

actuator on a valve

body, see the HPO-5074

Installation Guide.

NOTE: Wiring must be adequate to avoid

excessive voltage drop on long runs! Allow

plenty of “cushion” in measurements. A

meter may be too slow to register transient

dips or peaks during startup.

Maintenance

No routine maintenance is required. Careful

installation will also ensure long term reliability and

performance.

Accessories

HCO-1151 Weather shield kit

HLO-4001 Crank arm kit

HMO-4001 Non-rotation “T” bracket

HMO-4002 Replacement non-rotation

bracket

STE-1401 Duct temperature sensor (Type

III, 10K)

Important Notices

The material in this document is for information

purposes only. The contents and the product it

describes are subject to change without notice. KMC

makes no representations or warranties with respect

to this document. In no event shall KMC be liable for

any damages, direct or incidental, arising out of or

related to the use of this document.

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com

info@kmccontrols.com

CEP-4703/4703V 4 Installation Guide

© 2014 KMC Controls, Inc. 036-019-05A

Loading...

Loading...