Page 1

Dual Input Receiver Controllers

Installation Guide

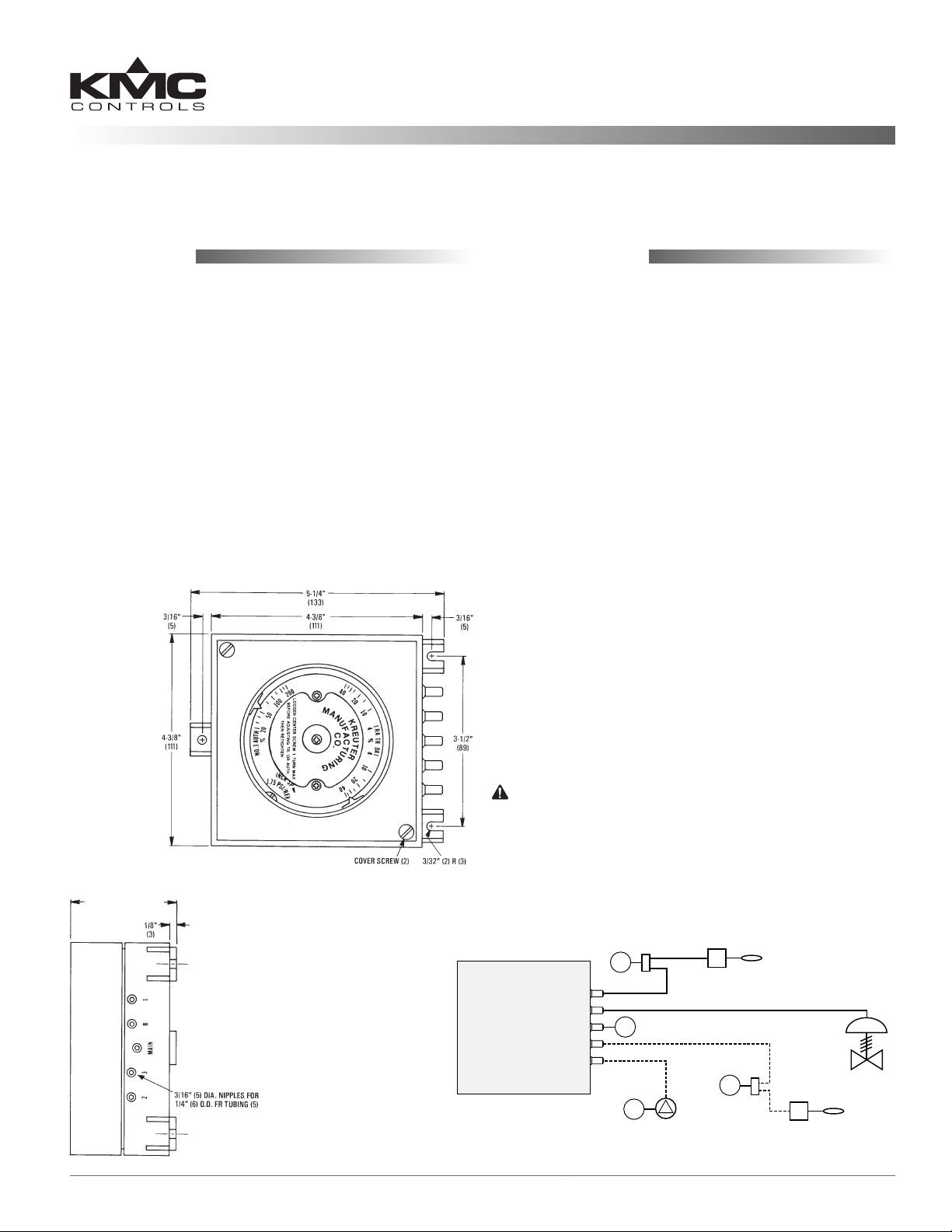

ConnectionsMounting

CCC-1001/1002

The CCC-1001 and CCC-1002 are not position sensitive, but they must be calibrated and mounted in the

same orientation.

1. Locate the three mounting ears (anges) on the

unit.

2. Place the controller on the mounting surface and

mark the locations of the two top ears.

3. Partially install two mounting screws (#8 or #10)

on the marks. These should be 3-1/2" (89 mm)

apart.

4. Slide the top ears under the screws.

5. Install the third mounting screw in the boom ear

and tighten all three screws.

The units are supplied as Direct Acting (DA). If

Reverse Acting (RA) is required:

1. Locate the tubing connections on the back of the

controller.

2. Cut the branch tubing at the DA connection

(lower right corner).

3. Remove tubing from the two-prong guides.

4. Connect branch tubing to the RA connection

(upper right corner) using brass ings

(provided).

5. Secure extra tubing in the two-prong guides.

A CCC-1001/1002 controller has ve 3/16" (5 mm)

ports to accept 1/4" (6 mm) O.D. polyethylene tubing.

Connect the controller to other units as follows:

1. Main control air to Port M. This should be 20 psig

(137 kPa), 30 psig (207 kPa) max.

2. Primary input, 3–15 psig, to Port 1.

3. Remote setpoint adjustment, 3–15 psig with a +/–

10% oset, to Port 2.

4. Secondary input to Port 3.

CAUTION

Pneumatic devices must be supplied with clean, dry

control air. Any other medium (e.g., oil or moisture

CCC-1001 =

2-3/16" (56 mm);

CCC-1002 =

2-5/16" (59 mm)

CCC-1001/1002 (Dual Input Receiver Controllers) 1 Installation Guide

CCC-1001 Shown

Secondary Input: 3

Remote Setpoint: 2

contamination) will cause the device to fail.

M

Primary Input: 1

Output Signal: B

Main Air: MAIN

Optional Remote

Restrictor

M

Regulator

M

Setpoint Adjust

(sensed medium, e.g., hot water)

Restrictor

M

Optional Secondary Transmitter

(sensed medium, e.g., outside air)

Primary Transmitter

Controlled

Device

Page 2

Adjustments and Calibration

CCC-1001 Controller

NOTE: Throling range is the percent change of

the primary input (Port 1) that causes a

100% change in the branch output (Port B).

Authority is the change in the secondary

input (Port 3) in relation to the change in

the primary input that will cause the same

change in the output and is expressed as a

percentage (see the Authority Calibration

section).

1. Remove cover before making any adjustments.

2. Set the desired throling range:

A. Loosen large center screw (1 turn

maximum).

B. Remove main control air from Port M.

C. Move the setpoint indicator to the desired

% throling range (4 to 40%) on the DA

or RA scale. See the Throling Range

Adjustment section on page 3.

D. Connect main air to “M.”

3. Set the desired authority:

A. Calculate the required authority. See the

Authority Calibration section.

B. Set the authority indicator to the desired

value.

C. Tighten center screw.

4. Adjust the setpoint output by turning the setpoint

screw (located at the lower right of the unit). See

the Setpoint Calibration section on page 3.

5. Reinstall the cover.

CCC-1002 Controller

NOTE: Follow the steps 1 through 4 for adjusting

the CCC-1001, and then continue with steps

5 through 8.

Throttling Range Adjustment

Throling range % can be calculated by the following formula:

Port 1 Units Desired to Make

100% Change in Port B (Output)

Port 1 Primary Input Span

(Same Units as Above)

x

Span of Controlled

12

x 100

Device (psi)

Example: Port 1 is connected to a temperature

transmier with a range of 40 to 240° F

(200° F span). Branch output is controlling

a 3 to 8 psi (5 psi span) device. Desired

throling range is 20° F. Then throling

range % = (20° F)/(200° F) x (12 psi)/(5 psi) x

100 = 24%.

Authority Calibration

This adjustment determines the eect of a secondary

transmier (Port 3) on the setpoint of the receivercontroller.

Example: Reset the HWS (Hot Water Supply)

temperature setpoint based on OAT

(Outside Air Temperature). The HWS

transmier has a range of 40 to 240° F for 3

to 15 psi (0.06 psi/° F), and it is connected

to the Port 1 primary input. The OAT

transmier has a range of –40 to 160° F for 3

to 15 psi (0.06 psi/° F), and it is connected to

the Port 3 secondary input.

NOTE: This example does not compensate for TR

(throling range) across the reset schedule

but assumes a constant branch pressure.

The reset schedule shows the temperatures and pressures at the extreme ends of the operating schedule.

5. Turn the face dial until the desired input signal

(Port 1) pressure value lines up with the clear

arrow indicator.

6. Carefully slide the cover straight down, so that

the cover gear teeth and the setpoint adjustment

sha mesh.

7. Tighten the cover.

8. Apply the adhesive dial face if required.

CCC-1001/1002 (Dual Input Receiver Controllers) 2 Installation Guide

OAT Port #3

Pressure

5.4 psi 0° F 180° F 11.4 psi

7.5 psi 35° F 140° F 9.0 psi

9.6 psi 70° F 100° F 6.6 psi

Authority % =

D P @ Port 1

D P @ Port 3

(D P = Change in Pressure)

Reset Schedule

Outside Air

Temperature

x 100%

Hot Water

Temperature

11.4 – 6.6

=

9.6 – 5.4

HWS Port #1

Pressure

x 100%

(In the Example Above)

= 114%

Page 3

Setpoint Calibration

Initial setpoint calibration is done aer the spring

tube on the back of the controller has been properly

connected and secured and the throling range and

authority adjustments have been set and locked.

1. Make the following connections:

A. Main air supply (20 psi) to MAIN.

B. Branch (output) gauge to Port B.

C. For SINGLE input operation, connect

pressure to Port 1 equal to the desired

setpoint, OR for DUAL input operation,

connect pressures to Ports 1 and 3 that

correspond to the reset schedule at

approximately midrange.

D. If the remote setpoint adjustment is to

be used, connect pressure to Port 2 that

corresponds to zero oset.

E. Unused inputs are le unconnected.

2. Turn the setpoint adjustment screw to obtain an

output equal to the midrange pressure of the

controlled device.

A. If in the DA mode and branch pressure

is high, turn the setpoint screw CW; if

branch pressure is low, turn the setpoint

screw CCW.

B. If in the RA mode and branch pressure

is high, turn the setpoint screw CCW; if

branch pressure is low, turn the setpoint

screw CW.

Aer the system is live, minor adjustments to the

setpoint calibration can easily be done if the setpoint

oset is known. Each complete clockwise rotation, of

the screw, is equivalent to a 1.75 psi increase in Port

1 pressure. To increase the setpoint, turn the adjustment screw CW; to decrease the setpoint, turn the

adjusment screw CCW. The number of turns equals:

Setpoint Offset (° F)

Port 1 Primary Input Span

(° F)

Port 1 Primary Input Span (psi)

x

1.75

Remote Setpoint Adjustment

An input pressure change of 3 to 15 psi to Port 2 will

change the setpoint 20% of the span of the primary

transmier. The eect of the change is direct in

nature. An increase in Port 2 pressure from 9 to 15

psi increases the setpoint 10% and a decrease in Port

2 pressure from 9 to 3 psi decreases the setpoint 10%.

Example: If the Port 1 transmier has a range of 40

to 240° F (200° F span), then the remote

setpoint adjustment pressure on Port 2 can

change the setpoint +/– 20° F or a total of

40° F or 20% of the Port 1 primary input

span.

Accessories

External restrictor HFO-0022 (Restrictor T, 28.8 scim)

might be required if replacing a receiver/controller

using internal restrictors. All transmiers used with

the CCC-1001/1002 require an external restrictor.

For other pneumatic accessories, such as connectors,

tubing, ings, lters, and gauges, see the Compressed Air Accessories section in the Electronic and

Pneumatic Controls Condensed Catalog (SP-071).

Maintenance

No routine maintenance is required. Each component is designed and manufactured for reliability

and performance. Careful installation will ensure

long term dependability.

Example: Port 1 is connected to a temperature

transmier with a range of 40 to 240° F

(200° F span) and an output of 3 to 15 psi

(12 psi span). The desired control point is

7° F higher than the actual control point.

Then, the number of turns = (7°)/(200°)

x (12 psi)/1.75 = 0.24. Thus, the set point

adjustment screw should be turned 1/4 of a

turn CW.

CCC-1001/1002 (Dual Input Receiver Controllers) 3 Installation Guide

Page 4

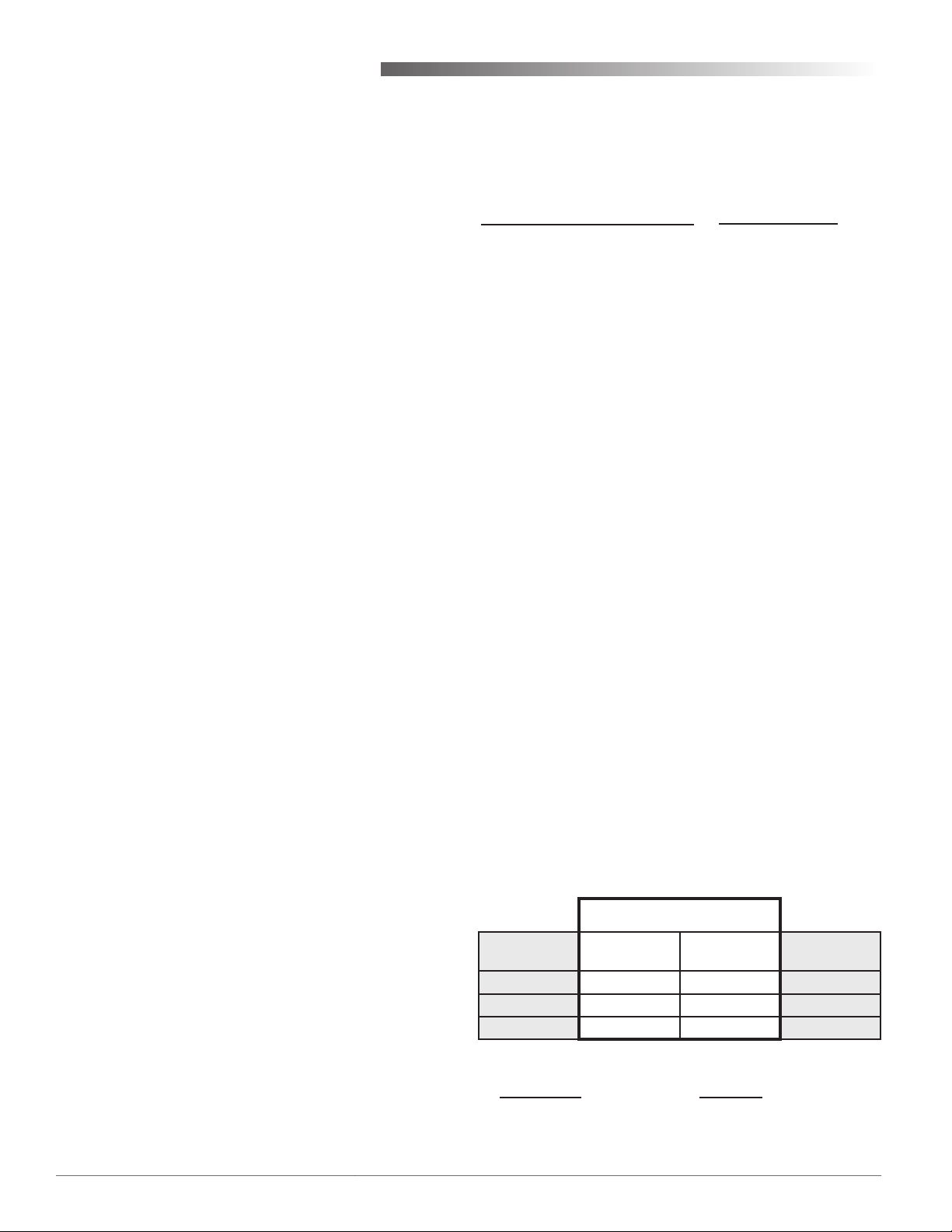

Competitor Cross-Reference

The CCC-1002 can replace many competitor single/

dual-input receiver/controllers such as:

• Barber-Colman (Schneider Electric) RKS1001/2001/3002/4002

• Honeywell RP908A/RP908B/RP920A/RP920B

• Johnson T-9000 and T-5801/5802

• Robertshaw (Schneider Electric) P341 and 2341

• Siemens 185 and 195 series

A cross-reference of corresponding piping for some

of these controllers is shown in the chart below.

NOTE: External restrictor HFO-0022 might be

required if replacing a receiver/controller

using internal restrictors.

Primary Input: 1

Output Signal: B

Main Air: MAIN

Secondary Input: 3

Remote Setpoint: 2

Optional Remote

M

Restrictor

M

Regulator

M

Setpoint Adjust

Primary Transmitter

(sensed medium, e.g., hot water)

Controlled

Device

Restrictor

M

Optional Secondary Transmitter

(sensed medium, e.g., outside air)

KMC

Ports

CCC-1002 RKS RP908 RP920 T-5800 P341 P541 195

Main Air MAIN M M 1 S M M S

Output Signal B B-c B 2 O B B C

Primary Input 1 1 1 3 CV 1 S 1 or 2

Secondary Input 3 2 2 5 M 3 R 1 or 2

Remote Setpoint 2 RSPA CPA 9 SP 2 C 3

Barber-

Colman

Honeywell Johnson Robertshaw Siemens

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com; info@kmccontrols.com

CCC-1001/1002 (Dual Input Receiver Controllers) 4 Installation Guide

© 2009 KMC Controls, Inc. 218-019-01E

Loading...

Loading...