KMC Controls BAC-9300 Series, BAC-9301 HPU, BAC-9301 FCU 2-Pipe, BAC-9311 HPU, BAC-9301 RTU Installation Manual

...Page 1

BAC-9300 Series Controller

Installation Guide

CONTENTS

Introduction .............................................. 1

Mount Controller ........................................ 1

Connect Sensors and Equipment .................. 2

Connect (Opt.) Pressure Flow Sensor ............ 3

Connect (Opt.) Ethernet Network .................. 3

Connect (Optional) MS/TP Network............... 4

Connect Power .......................................... 4

Power and Communication Status ................. 4

MS/TP Network Isolation Bulbs .................... 5

Congure/Program the Controller ................. 6

Sample (BAC-9311) Wiring .......................... 7

Input/Output Objects/Connections ................ 8

Replacement Parts ....................................10

Important Notices .....................................10

INTRODUCTION

Complete the following steps to install a KMC

Conquest™ BAC-9300 Series Unitary Controller.

For controller specications, see the data sheet at

kmccontrols.com. For additional information, see

the KMC Conquest Controller Application Guide.

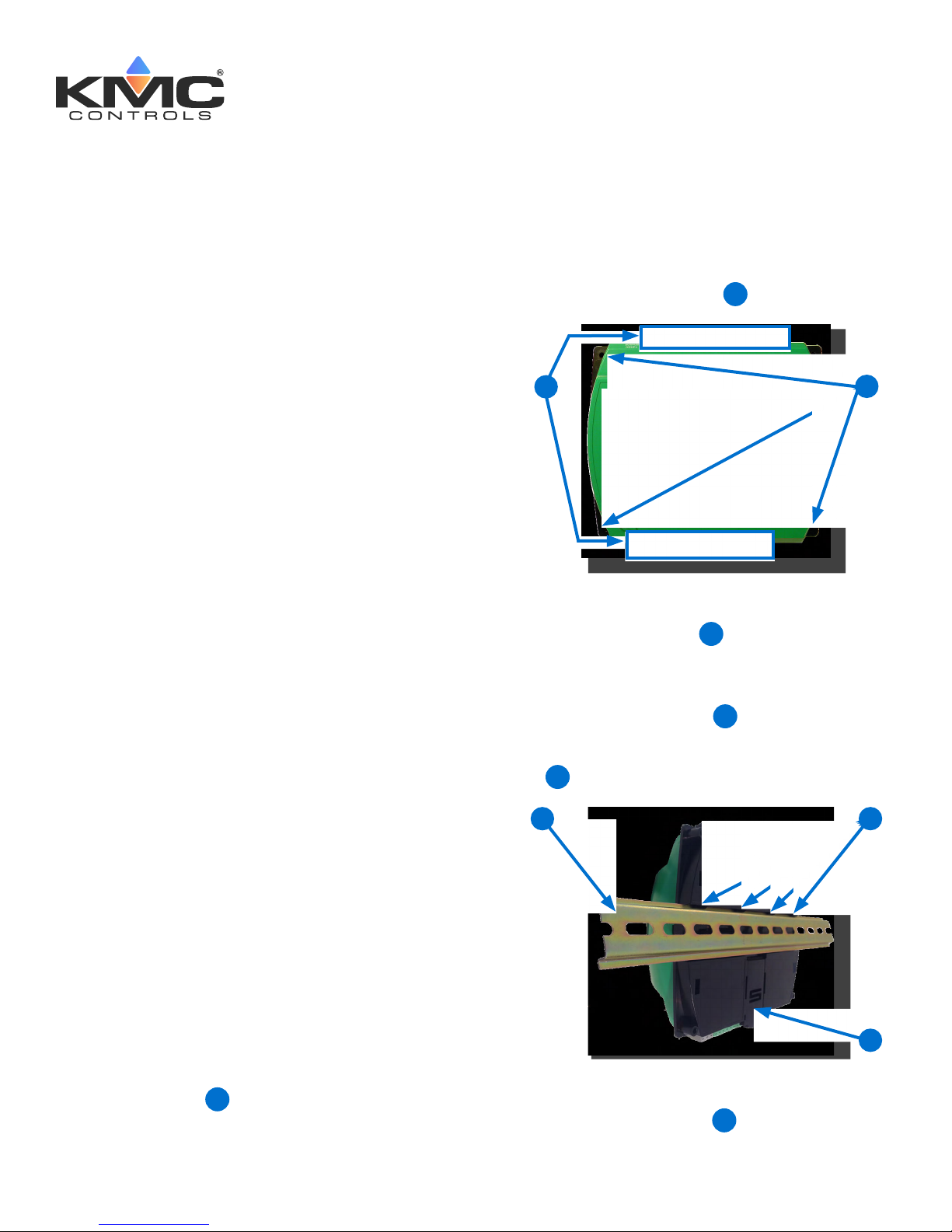

NOTE: The black terminals are for power. The

green terminals are for inputs and

outputs. The gray terminals are for

communication.

2. Screw a #6 sheet metal screw through each

corner of the controller

1

On a DIN Rail

1. Position the DIN rail

controller is installed the color-coded terminal

blocks are easy to access for wiring.

.

2

so that when the

3

2

MOUNT CONTROLLER

NOTE: Mount the controller inside a metal

enclosure for RF shielding and physical

protection.

NOTE: To mount the controller with screws on

a flat surface, complete the steps in On

a Flat Surface on page 1. Or to mount

the controller on a 35 mm DIN rail

(such as integrated in an HCO-1103

enclosure), complete the steps in On a

DIN Rail on page 1.

On a Flat Surface

1. Position the controller so the color-coded

terminal blocks

wiring.

are easy to access for

1

2. Pull out the DIN Latch

3. Position the controller so that the top four tabs

of the back channel rest on the DIN rail.

5

3

4. Lower the controller against the DIN rail.

5. Push in the DIN Latch

rail.

until it clicks once.

4

to engage the DIN

6

5

4

KMC Controls, 19476 Industrial Drive, New Paris, IN 46553 / 877.444.5622 / Fax: 574.831.5252 / www.kmccontrols.com

Page 2

NOTE: To remove the controller, pull the DIN

Latch until it clicks once and lift the

controller off the DIN rail.

CONNECT SENSORS AND EQUIPMENT

NOTE: See Sample (BAC-9311) Wiring on

page 7 and Input/Output Objects/

Connections on page 8 for more

information. See also the YouTube

video KMC Conquest Wiring: BAC-

9300 Series Unitary Controllers.

NOTE: A digital STE-9000 Series NetSensor

can be used for conguring the

controller (see Congure/Program

the Controller on page 6). After the

controller has been congured, an

STE-6010, STE-6014, or STE-6017

analog sensor can be connected to the

controller in place of the NetSensor.

See the relevant installation guide for

additional details.

sensor into the (yellow) ROOM SENSOR port

of the controller.

8

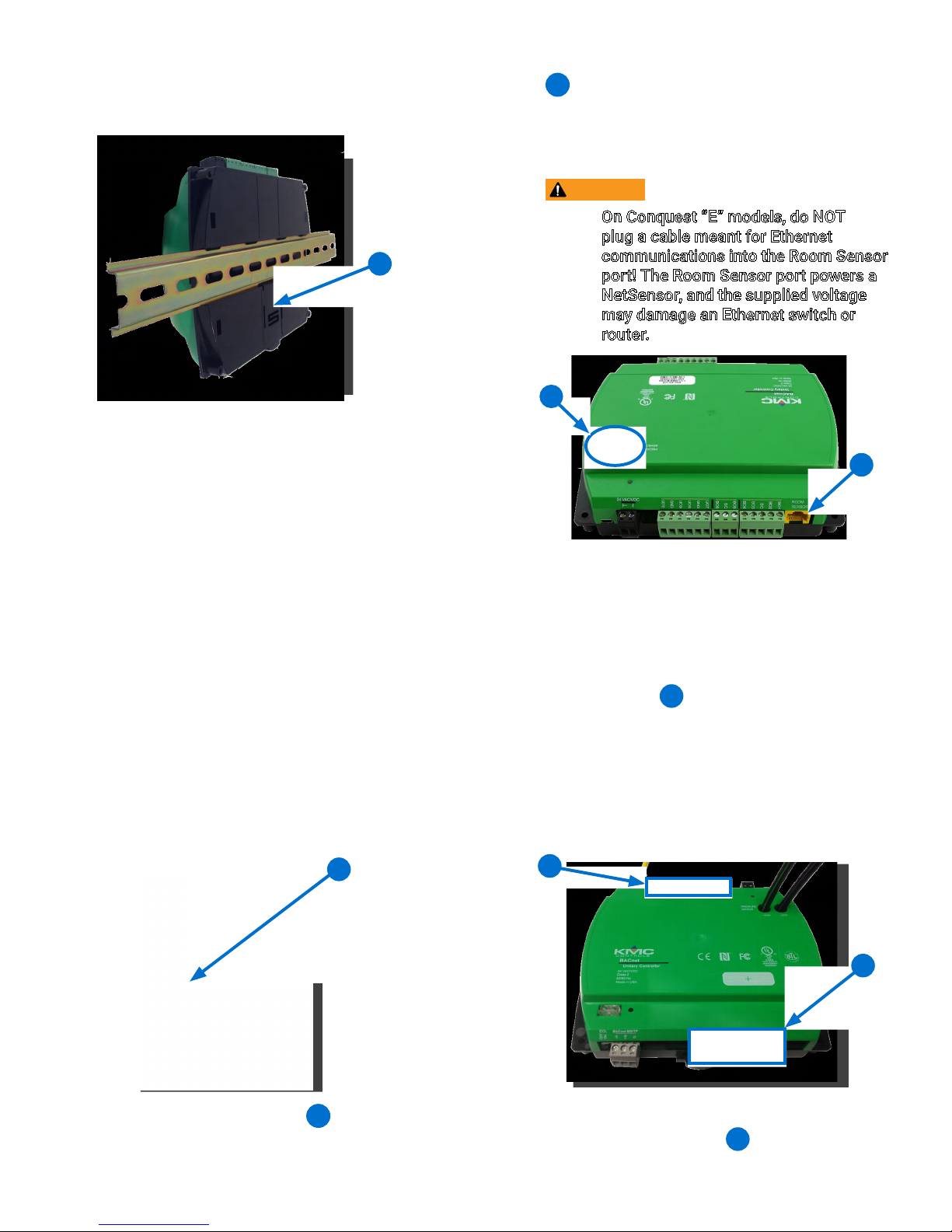

NOTE: The Ethernet patch cable should be a

maximum of 150 feet (45 meters).

CAUTION

On Conquest “E” models, do NOT

plug a cable meant for Ethernet

6

communications into the Room Sensor

port! The Room Sensor port powers a

NetSensor, and the supplied voltage

may damage an Ethernet switch or

router.

9

8

NOTE: Auxiliary VAV equipment such as fans,

heaters, reheat valves, and discharge

air temperature sensors can be

connected to the controller.

2. Wire additional sensors to the green (input)

10

terminal block

NOTE: Wire sizes 12–24 AWG can be clamped

in each terminal.

NOTE: No more than two 16 AWG wires can

be joined at a common point.

.

1. Plug an Ethernet patch cable 7 connected to

an STE-9000 Series or STE-6010/6014/6017

BAC-9300 Series Controller Installation Guide 2 925-019-02G

7

11

10

3. Wire additional equipment to the green

11

(output) terminal block

.

Page 3

CAUTION

Do NOT connect 24 VAC to the analog

outputs (UO7–UO10 and GNDs)!

NOTE: Use 24 VAC (only) with triac outputs

(BO1–BO6 with SCs).

CONNECT (OPT.) PRESSURE FLOW SENSOR

NOTE: Complete the steps in this section to

connect an air flow sensor to the BAC9311/9311C/9311CE controller.

NOTE: BAC-9301/9301C/9301CE controllers

do not have PRESSURE SENSOR ports.

NOTE: Use 1/4 inch (6.35 mm) FR tubing.

Tubing should not be longer than 6 feet

(20 meters).

1. Remove the black shipping plugs

PRESSURE SENSOR ports.

2. Connect the high pressure tube from the

pressure flow sensor to the HIGH

the controller.

3. Connect the low pressure tube from the

pressure flow sensor to the LOW

the controller.

12

from the

9

12

port on

13

port on

13

CONNECT (OPT.) ETHERNET NETWORK

1. For BAC-93x1CE models (only), connect

14

an Ethernet patch cable

to the 10/100

ETHERNET port (“E” models only).

CAUTION

On Conquest “E” models, do NOT

plug a cable meant for Ethernet

communications into the Room Sensor

port! The Room Sensor port powers a

NetSensor, and the supplied voltage

may damage an Ethernet switch or

router.

NOTE: The Ethernet patch cable should be

T568B Category 5 or better and a

maximum of 328 feet (100 meters)

between devices.

NOTE: Before May 2016, BAC-xxxxCE models

had a single Ethernet port. They now

have dual Ethernet ports, enabling

daisy-chaining of controllers

the Daisy-Chaining Conquest Ethernet

Controllers Technical Bulletin on

the KMC Partner web site for more

information.

NOTE: On newer models, the Room Sensor

8

port is yellow

instead of black to

help differentiate it from the black

Ethernet ports.

14

. See

BAC-9300 Series Controller Installation Guide 3 925-019-02G

NOTE: For more information, see Sample

(BAC-9311) Wiring on page 7 and the

YouTube video KMC Conquest Wiring:

BAC-9300 Series Unitary Controllers.

14

Page 4

CONNECT (OPTIONAL) MS/TP NETWORK

CONNECT POWER

1. For BAC-93x1/93x1C models (only), connect

the BACnet network to the gray BACnet MS/

15

TP terminal block

15

.

NOTE: Use 18 gauge AWG shielded twisted

pair cable with maximum capacitance

of 51 picofarads per foot (0.3 meters)

for all network wiring (Belden cable

#82760 or equivalent).

A. Connect the –A terminals in parallel with

all other –A terminals on the network.

B. Connect the +B terminals in parallel with all

other +B terminals on the network.

NOTE: Follow all local regulations and wiring

codes.

1. Connect a 24 VAC, Class-2 transformer to the

black power terminal block of the controller.

A. Connect the neutral side of the transformer

17

to the controllers common terminal

⊥

B. Connect the AC phase side of the

transformer to the controllers phase

18

∼

terminal

17

.

18

.

C. Connect the shields of the cable together

at each device using a wire nut or the S

terminal in KMC BACnet controllers.

2. Connect the cable shield to a good earth

ground at one end only.

NOTE: For principles and good practices

when connecting an MS/TP network,

see Planning BACnet Networks

(Application Note AN0404A).

NOTE: The EOL switch is shipped from the

factory in the OFF position.

3. If the controller is at either end of a BACnet

MS/TP network (only one wire under the

16

terminals), turn the EOL switch

to ON.

NOTE: For more information, see Sample

(BAC-9311) Wiring on page 7 and the

YouTube video KMC Conquest Wiring:

BAC-9300 Series Unitary Controllers.

16

NOTE: Connect only one controller to each

transformer with 12—24 AWG copper

wire.

NOTE: Use either shielded connecting cables

or enclose all cables in conduit to

maintain RF emissions specications.

NOTE: For more information, see Sample

(BAC-9311) Wiring on page 7 and the

YouTube video KMC Conquest Wiring:

BAC-9300 Series Unitary Controllers.

POWER AND COMMUNICATION STATUS

The status LEDs indicate power connection and

network communication. The descriptions below

describe their activity during normal operation (at

least 5 to 20 seconds after power-up/initialization

or restart).

NOTE: If both the green READY LED and the

amber COMM LED remain OFF, check

the power and cable connections to the

controller.

BAC-9300 Series Controller Installation Guide 4 925-019-02G

Page 5

Green READY LED

19

After controller power-up or restart is complete,

the READY LED flashes steadily about once per

second, indicating normal operation.

19

21

22

Amber (BACnet MS/TP) COMM LED

During normal operation, the COMM LED

20

flickers as the controller receives and passes

the token over the BACnet MS/TP network.

When the network is not connected or

communicating properly, the COMM LED

flashes more slowly (about once a second).

20

Amber ETHERNET LED

The amber Ethernet LED flashes when the

22

controller is communicating with a 100BaseT

Ethernet network.

The amber Ethernet LED remains OFF when

the (powered) controller is communicating

with the network at only 10 Mbps (instead of

100 Mbps).

NOTE: If both the green and amber Ethernet

LEDs remain OFF, check the power and

network cable connections.

MS/TP NETWORK ISOLATION BULBS

The two network isolation bulbs 23 serve three

functions:

Removing the (HPO-0055) bulb assembly

opens the MS/TP circuit and isolates the

controller from the network.

Green ETHERNET LED

21

NOTE: The Ethernet status LEDs

indicate network connection and

communication speed.

The green Ethernet LED stays ON when the

controller is communicating with the network.

The green Ethernet LED is OFF when the

(powered) controller is not communicating

with the network.

If one or both bulbs are ON, the network is

improperly phased. This means the ground

potential of the controller is not the same

as other controllers on the network. If

this happens, x the wiring. See Connect

(Optional) MS/TP Network on page 4.

If the voltage or current on the network

exceeds safe levels, the bulbs blow, opening

the circuit. If this happens, x the problem and

replace the bulb assembly.

23

BAC-9300 Series Controller Installation Guide 5 925-019-02G

Page 6

CONFIGURE/PROGRAM THE CONTROLLER

See the table for the most relevant KMC Controls

tool for conguring, programming, and/or creating

graphics for the controller. See the documents or

Help systems for the respective KMC tool for more

information.

See the table (on the next page) for the most

relevant KMC Controls tools for conguring,

programming, and/or creating graphics for the

controller. See the tools’ documents or Help

systems for more information.

NOTE: After the controller has been

congured, an STE-6010/6014/6017

series analog sensor can be connected

to the controller in place of an STE9000 series digital NetSensor.

SETUP PROCESS

Cong-

uration

Programming

(Control Basic)

Web Page

Graphics*

**** ****

KMC

CONTROLS

TOOL

Conquest

NetSensor

Internal con-

guration web

pages in Conquest Ethernet

“E” models**

KMC Connect

Lite™ (NFC)

app***

KMC Connect™ software

TotalControl™

software

NOTE: A BAC-9301CE can be congured by

connecting an HTML5-compatible

web browser to the controller’s default

IP address (192.168.1.251). See

the Conquest Ethernet Controller

Conguration Web Pages Application

Guide for more information about the

built-in conguration web pages.

NOTE: To congure a VAV controller, enter

the correct K factor for the VAV

box. Typically, this is supplied by

the manufacturer of the VAV unit. If

this information is unavailable, use

an approximate K factor from the

chart in the Appendix: K Factors for

VAV section in the KMC Conquest

Controller Application Guide.

For instructions on VAV balancing:

With an STE-9000 series NetSensor, see

the VAV Airflow Balancing with an STE-9xx1

section of the KMC Conquest Controller

Application Guide.

KMC Con-

*Custom graphical user-interface web pages can be

hosted on a remote web server, but not in the

controller.

**Conquest Ethernet-enabled “E” models with the

latest rmware can be congured with an HTML5

compatible web browser from pages served from

within the controller. For information, see the Con

quest Ethernet Controller Conguration Web

Pages Application Guide.

***Near Field Communication via enabled smart

phone or tablet running the KMC Connect Lite app.

****Full conguration and programming of KMC

Conquest controllers is supported starting with

TotalControl ver. 4.0.

verge™ module

for Niagara

WorkBench

KMC Converge GFX

module for

Niagara WorkBench

With a BAC-5051E Router, see its application

and installation guide.

With KMC Connect or TotalControl, see the

Help system for the software.

BAC-9300 Series Controller Installation Guide 6 925-019-02G

Page 7

SAMPLE (BAC-9311) WIRING

(Single Duct VAV, Series Fan Powered with Modulating Reheat and Vent Control)

NOTE: Connect the STE-9xxx (or

STE-6010/6014/6017 with

no ventilation control) sensor

to the Room Sensor port

using a max. of 150 feet

of Ethernet patch cable.

NOTE: See the KMC Conquest Controller

Application Guide for information

about switched commons (SC),

using VDC power, and other issues.

NOTE: Use 24 VAC (only) on triac

outputs (BO1–BO6 with SCs)!

CAUTION: Do NOT connect 24 VAC

to the analog outputs

(UO7–UO10 and GNDs)!

CONNECTIONS (SAMPLE)

INPUTS

UI3 = DAT SENSOR

UI8 = PRI POSITION

ROOM SENSOR

OUTPUTS (Binary/Triac)

BO1 = FAN ENABLE

BO5 = PRI DAMPER CW

BO6 = PRI DAMPER CCW

OUTPUTS (Universal/Analog)

UO7 = MOD REHEAT

UO8 = FAN SPEED

NETWORK

MS/TP OR ETHERNET

POWER

STE-9521

STE-6010-10

BAC-9311 Controller

SENSOR

ROOM

Fan

Start

~

BO1

COM

BO2

MEP-4001/

CW P1

SC

BO5

BO3

BO4

Damper

Primary

Actuator

SC

BO6

MEP-4013

P2CCW COM

UO7

UO8

GND

UO9

GND

PRESSURE

SENSOR

Mod

Reheat

+

UO10

–

–

–

~

24 VAC/VDC

HIGH LOW

H

to flow sensor

Fan

Voltage

Speed

+

–

–

24 VAC

L

1/4" (6.35) FR tubing

Line

HN

~

PhaseNeutral

NOTE: For MS/TP models, turn the End Of

Line switch ON at both physical ends

of the MS/TP network. Connect the

cable shield to earth ground at only

one point.

NOTE: For Ethernet models, connect the

controller to the network with a

standard Ethernet patch cord.

NOTE: For more wiring examples, see the

wiring diagrams that are part of the

application library in KMC Connect,

Converge, or TotalControl. Early

models shown in the drawings had

different terminal locations. Follow

the terminal labels (not location).

BAC-9300 Series Controller Installation Guide 7 925-019-02G

RED

BLK

From

Previous

Controller

SHLD

EOL

ON

OFF

SHLD

RED

BLK

To

Next

Controller

MS/TP

-A

10/100

ETHERNET

S

+B

UI3

GND

UI4

UI5

GND

UI6

UI7

GND

UI8

(From Optional MEP-4x13 10K

Ohm Feedback Potentiometer)

NOTE: Analog inputs accept 1K or 10K

sensors, 0–12 VDC, or 4–20 mA.

(Optional)

STE-1405

To

Ethernet

DISCHARGE AIR TEMP

10KΩ, TYPE 3 Thermistor

Page 8

INPUT/OUTPUT OBJECTS/CONNECTIONS

BAC-9301 FCU (2-PIPE) BAC-9301 FCU (4-PIPE)

Inputs Inputs

AI1 Space Sensor (on Room Sensor port) AI1 Space Sensor (on Room Sensor port)

AI2 Space Setpoint Offset (on port) AI2 Space Setpoint Offset (on port)

AI3/UI3 Discharge Air Temperature AI3/UI3 Discharge Air Temperature

AI4/UI4 Outdoor Air Temp AI4/UI4 Outdoor Air Temp

AI5/UI5 Space Humidity AI5/UI5 Space Humidity

AI6/UI6 Supply Water Temperature AI7/UI7 Analog Input #7

AI8/UI8 Analog Input #8 AI8/UI8 Analog Input #8

BI7/UI7 Fan BI6/UI6 Fan

Outputs Outputs

AO7/UO7 Analog Heat/Cool Valve (Proportional)* AO7/UO7 Analog Cooling Valve (Proportional)*

AO8/UO8 Auxiliary Heat (Proportional)** AO8/UO8 Analog Heating Valve (Proportional)**

AO9/UO9 Analog Output #9 AO9/UO9 Analog Output #9

AO10/UO10 Fan Speed Control AO10/UO10 Fan Speed Control

BO1 Fan Low Speed BO1 Fan Low Speed

BO2 Fan Medium Speed BO2 Fan Medium Speed

BO3 Fan High Speed BO3 Fan High Speed

BO4 Binary Heat/Cool Valve (On/Off)* BO4 Binary Cooling Valve (On/Off)*

BO5 Auxiliary Heat (On/Off)** BO5 Binary Heating Valve (On/Off)**

BO6 Binary Output #6 BO6 Binary Output #6

*AO7 and BO4 are controlled simultaneously.

**AO8 and BO5 are controlled simultaneously.

*AO7 and BO4 are controlled simultaneously.

**AO8 and BO5 are controlled simultaneously.

BAC-9301 HPU BAC-9311 HPU

Inputs Inputs

AI1 Space Sensor (on Room Sensor port) AI1 Space Sensor (on Room Sensor port)

AI2 Space Setpoint Offset (on port) AI2 Space Setpoint Offset (on port)

AI3/UI3 Discharge Air Temperature AI3/UI3 Discharge Air Temperature

AI4/UI4 Outdoor Air Temp AI4/UI4 Outdoor Air Temp

AI5/UI5 Space Humidity AI5/UI5 Space Humidity

AI7/UI7 Analog Input #7 AI7/UI7 Analog Input #7

AI8/UI8 Analog Input #8 AI8/UI8 Analog Input #8

BI6/UI6 Fan AI9 Duct Pressure (internal sensor)

BI6/UI6 Fan

Outputs Outputs

AO7/UO7 Analog Output #7 AO7/UO7 Analog Output #7

AO8/UO8 Analog Output #8 AO8/UO8 Analog Output #8

AO9/UO9 Economizer Output AO9/UO9 Economizer Output

AO10/UO10 Analog Output #10 AO10/UO10 Analog Output #10

BO1 Fan Start - Stop BO1 Fan Start - Stop

BO2 Stage 1 Compressor BO2 Stage 1 Compressor

BO3 Stage 2 Compressor BO3 Stage 2 Compressor

BO4 Reversing Valve BO4 Reversing Valve

BO5 Auxiliary Heat BO5 Auxiliary Heat

BO6 Binary Output #6 BO6 Binary Output #6

BAC-9300 Series Controller Installation Guide 8 925-019-02G

Page 9

BAC-9301 RTU BAC-9311 RTU

Inputs Inputs

AI1 Space Sensor (on Room Sensor port) AI1 Space Sensor (on Room Sensor port)

AI2 Space Setpoint Offset (on port) AI2 Space Setpoint Offset (on port)

AI3/UI3 Discharge Air Temperature AI3/UI3 Discharge Air Temperature

AI4/UI4 Outdoor Air Temp AI4/UI4 Outdoor Air Temp

AI5/UI5 Space Humidity AI5/UI5 Space Humidity

AI7/UI7 Analog Input #7 AI7/UI7 Economizer Feedback

AI8/UI8 Analog Input #8 AI8/UI8 Analog Input #8

BI6/UI6 Fan AI9 Duct Pressure (internal sensor)

BI6/UI6 Fan

Outputs Outputs

AO7/UO7 Analog Cooling Output AO7/UO7 Analog Cooling Output

AO8/UO8 Analog Heating Output AO8/UO8 Analog Heating Output

AO9/UO9 Economizer Output AO9/UO9 Economizer Output

AO10/UO10 Analog Output #10 AO10/UO10 Analog Output #10

BO1 Fan Start - Stop BO1 Fan Start - Stop

BO2 Cool Stage 1 BO2 Cool Stage 1

BO3 Cool Stage 2 BO3 Cool Stage 2

BO4 Binary Output #4 BO4 Binary Output #4

BO5 Heating Stage 1 BO5 Heating Stage 1

BO6 Heating Stage 2 BO6 Heating Stage 2

BAC-9311 VAV

Inputs

AI1 Space Sensor (on Room Sensor port)

AI2 Space Setpoint Offset (on port)

AI3/UI3 Discharge Air Temperature

AI4/UI4 Analog Input #4

AI5/UI5 Analog Input #5

AI6/UI6 Analog Input #6

AI7/UI7 Analog Input #7

AI8/UI8 Primary Damper Position

AI9 Primary Duct Pressure (internal sensor)

Outputs

AO7/UO7 Analog Heat

AO8/UO8 Fan Speed

AO9/UO9 Analog Output #9

AO10/UO10 Analog Output #10

BO1 Fan

BO2 Heating Stage 1

BO3 Heating Stage 2

BO4 Heating Stage3

BO5 Primary Damper CW

BO6 Primary Damper CCW

NOTE: See Sample (BAC-9311) Wiring on

page 7 for more information.

NOTE: Universal Input (UIx) terminal = Analog

Input (AIx) object or Binary Input (BIx).

Universal Output (UOx) terminal =

Analog Output (AOx) object.

NOTE: Universal (analog) inputs and outputs

can be congured to emulate binary

(on/off or voltage/no-voltage) objects.

They are used with GND terminals.

NOTE: Binary Output (BOx) terminals are

triacs and are used with SC terminals

instead of GND terminals.

BAC-9300 Series Controller Installation Guide 9 925-019-02G

Page 10

REPLACEMENT PARTS

IMPORTANT NOTICES

HPO-0055 Replacement Network

Bulb Module for Conquest

Controllers, Pack of 5

HPO-9901 Conquest Hardware

Replacement Parts Kit

NOTE: HPO-9901 includes the following:

Terminal Blocks DIN Clips

(1) Black 2 Position (2) Small

(2) Grey 3 Position (1) Large

(2) Green 3 Position

(4) Green 4 Position

(2) Green 5 Position

(2) Green 6 Position

NOTE: See the Conquest Selection Guide for

more information about replacement

parts and accessories.

The material in this document is for information

purposes only. The contents and the product it

describes are subject to change without notice.

KMC Controls, Inc. makes no representations or

warranties with respect to this document. In no

event shall KMC Controls, Inc. be liable for any

damages, direct, or incidental, arising out of or

related to the use of this document.

The KMC logo is a registered trademark of KMC

Controls, Inc. All rights reserved.

TEL: 574.831.5250

FAX: 574.831.5252

EMAIL: info@kmccontrols.com

© 2019 KMC Controls, Inc. Specifications and design subject to change without notice 925-019-02G

BAC-9300 Series Controller Installation Guide 10 925-019-02G

Loading...

Loading...