Page 1

Installation, Operation,

and

Applications Guide

for

BAC-7000 Series VAV controllers

For applications version 2.2

AN0311ARevision C

Page 2

KMC Controls

Important notices ©2014, KMC Controls, Inc.

WinControl, NetSensor, and the KMC logo are registered trademarks of KMC

Controls, Inc.

TotalControl, BACstage, and FullBAC are trademarks of KMC Controls, Inc.

All rights reserved. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language in any form

by any means without the written permission of KMC Controls, Inc.

Printed in U.S.A.

Disclaimer The material in this manual is for information purposes only. The contents and the

product it describes are subject to change without notice. KMC Controls, Inc. makes

no representations or warranties with respect to this manual. In no event shall KMC

Controls, Inc. be liable for any damages, direct or incidental, arising out of or related

to the use of this manual.

KMC Controls

19476 Industrial Drive

New Paris, IN 46553

U.S.A.

TEL: 1.574.831.5250

FAX: 1.574.831.5252

E-mail: info@kmccontrols.com

Revision C2

Page 3

BAC-7000 VAV Installation, applications, and operation guide

Contents

Section 1:

Specifications .....................................................................................................................................................6

Accessories and replacement parts ..............................................................................................................10

Safety considerations .....................................................................................................................................11

Section 2:

Set the rotation limits .....................................................................................................................................14

Mounting on a VAV terminal unit ...............................................................................................................16

Wiring compartment ......................................................................................................................................17

Connecting inputs ..........................................................................................................................................18

Connecting outputs ........................................................................................................................................19

Connecting to a NetSensor ............................................................................................................................20

Connecting to an MS/TP network ...............................................................................................................21

Connecting an airflow sensor .......................................................................................................................23

Connecting power ..........................................................................................................................................23

Section 3:

Operation .........................................................................................................................................................25

Controls and Indicators .................................................................................................................................25

Restoring factory settings ..............................................................................................................................28

Maintenance ....................................................................................................................................................30

About the controllers 5

Installing the controllers 13

Operation 25

Section 4:

Assigning network addresses .......................................................................................................................31

Configuring for pressure independent VAV ..............................................................................................32

Configuring for pressure dependent VAV .................................................................................................33

Section 5:

Balancing overview ........................................................................................................................................35

The balancing procedure ...............................................................................................................................36

Section 6:

Input sources ...................................................................................................................................................39

Space setpoints ................................................................................................................................................40

Occupancy and standby ................................................................................................................................40

PID control loops ............................................................................................................................................41

Pressure independent airflow sequence .....................................................................................................41

Pressure dependent temperature control ....................................................................................................41

Changeover ......................................................................................................................................................41

Damper operation ...........................................................................................................................................42

Fan operation ..................................................................................................................................................42

Reheat sequence ..............................................................................................................................................42

Balancing sequence ........................................................................................................................................43

Configuration and set up 31

Balancing with a NetSensor 35

Sequences of operation 39

Section 7:

Pressure independent applications ..............................................................................................................46

Pressure dependent applications ................................................................................................................54

Revision C 3

Applications for BAC-7000 series VAV controllers 45

Page 4

KMC Controls

Section 8:

Input objects ....................................................................................................................................................61

Output objects .................................................................................................................................................62

Value objects ....................................................................................................................................................62

Loop objects .....................................................................................................................................................63

Control Basic programs .................................................................................................................................64

Reference to objects and programs 61

Revision C4

Page 5

BAC-7000 VAV Installation, applications, and operation guide

SECTION 1

About the controllers

This section is a description of the KMC Controls BAC-7000 series

VAV controllers. It also introduces safety information. Review this

material before installing or operating the controller.

The

BAC-7000 series VAV controllers

designed for VAV terminal units. An integrated actuator and the supplied programs

make these ideal controllers for single duct pressure independent or pressure

dependent VAV terminal units. The

following features.

are native BACnet, direct digital controllers

BAC-7000 VAV controllers

include the

◆ BACnet MS/TP compliant

◆ Automatically assigns the MAC address and the device instance

◆ On-board airflow sensor for use with a single or multi-point differential

pressure measuring station or pitot tube

◆ Use to control single duct VAV, parallel fan, and reheat

◆ An internal, easy-to-use air balancing program for air balancing

technicians.

◆ No programming required

◆ Configurable with any BACnet operator workstation

The embedded standard applications provide a wide range of single duct VAV

terminal applications for both pressure independent and pressure dependent

(bypass) terminal unit applications.

Pressure independent KMC Controls supplies the BAC-7000 series VAV controllers

for the following pressure independent configurations.

◆ Single duct cooling

◆ Single duct cooling with parallel fan and on/off or modulating reheat

◆ Airflow balancing

Pressure dependent The BAC-7000 series VAV controllers can be set up for the

following pressure dependent (bypass VAV) configurations.

◆ Single duct cooling

◆ Single duct with modulating or On/Off reheat

Revision C 5

Page 6

About the controllers

Specifications

KMC Controls

Specifications

BAC-7000 specifications are subject to change without notice.

Inputs and outputs

BAC-7000 series VAV controllers are supplied with three universal inputs and three

output connections. The type of output is model dependent. All inputs and outputs

are configured to support the standard application Control Basic programs.

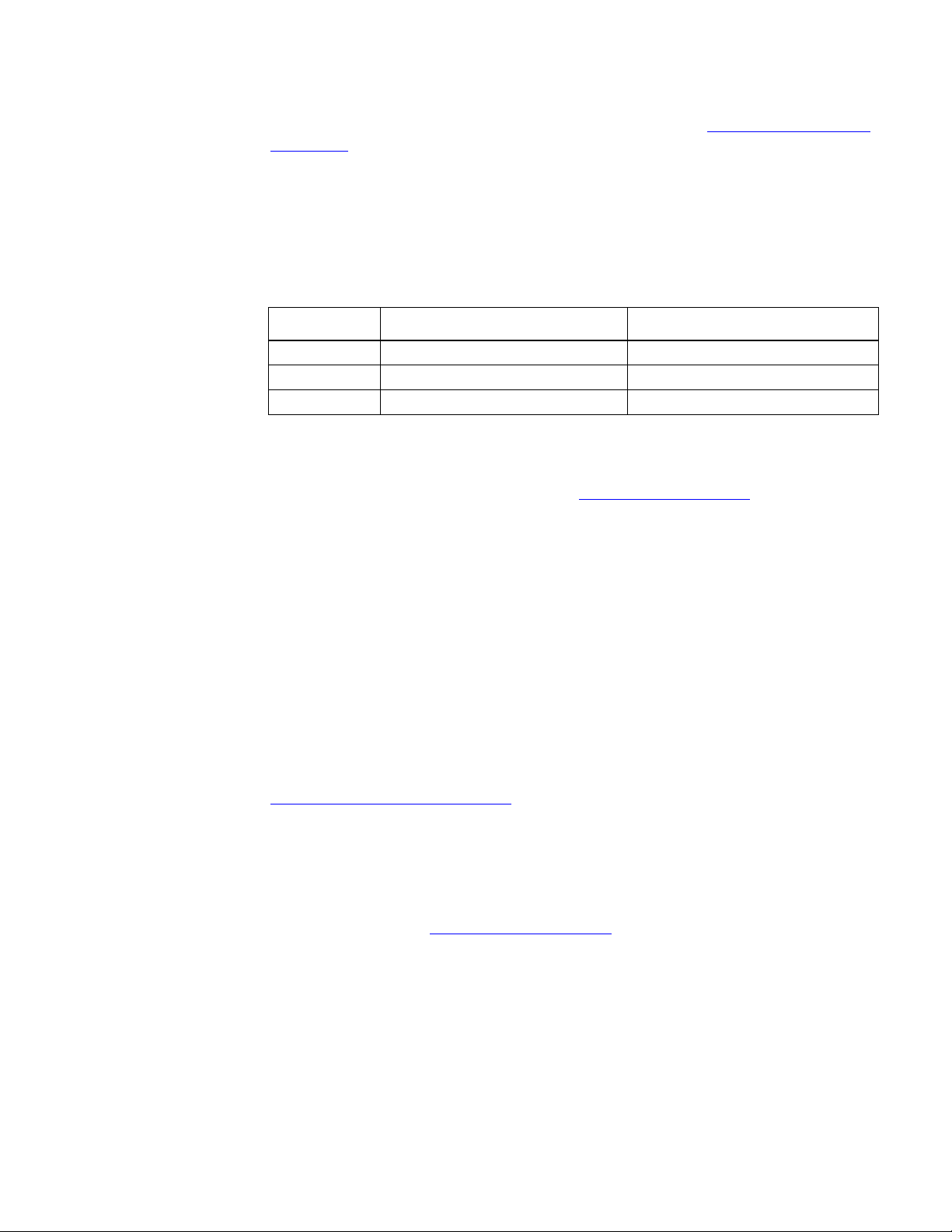

Table 1-1 BAC-7000 series inputs and outputs

Universal

Model

BAC-7001 3 3

BAC-7003 3 1 1 1

BAC-7051 3 3

BAC-7053 3 1 1 1

inputs

Universal

outputs

Triac

outputs

Relay

outputs

Inputs All universal inputs are configured to support

supplied Control Basic programs. They are

configurable as analog, binary, or accumulator

objects to support custom programs.

Key features Standard units of measure.

Overvoltage input protection

Pull–up resistors Switch selectable for none or 10 kΩ.

Connector Removable screw terminal block, wire size

AWG

14–22

Conversion 10–bit analog–to–digital conversion

Pulse Counting Up to 16 Hz

Input range 0–5 volts DC

Outputs, Universal All universal outputs are configured to support

supplied Control Basic programs. They are

configurable as analog or binary objects to support

custom programs.

Key features Output short protection

Standard units of measure

Connector Removable screw terminal block

Wire size 14–22 AWG

Output voltage 0–10 volts DC analog

0–12 volts DC binary

Output current 100 mA per output

Outputs, Relay Relay outputs are configured as binary outputs to

support the supplied Control Basic programs.

Switching Maximum switching 30 volts AC at 2 ampere

Connector Removable screw terminal block

Wire size 14–22 AWG

6

Revision C

Page 7

BAC-7000 VAV Installation, applications, and operation

guide

Outputs, triac Triac outputs are configured as binary outputs to

Switching Optically isolated triac output; maximum switching

Connector Removable screw terminal block

Communications

BACnet MS/TP EIA–485 operating at rates up to 76.8 kilobaud

NetSensor Standard applications compatible with model

About the controllers

Specifications

support the supplied Control Basic programs.

30 volts AC at 1 ampere

Wire size 14-22 AWG

Automatic baud detection

Automatically assigns MAC addresses and device

instance numbers

Removable screw terminal block

Wire size 14–22 AWG

KMD-1161. Custom programming required for other

models.

Connects through RJ–12 connector

Programmable features

Program objects 10 program objects, 4 for standard Control Basic

programs, 6 available for custom programs

PID loop objects 4

Value objects 40 analog and 40 binary

Supported objects See PIC statement for supported BACnet objects

Schedule objects 8 schedule objects

3 calendar objects

Trend objects 8 each of which holds 256 samples

Alarms and events

Intrinsic reporting Supported for input, output, value, accumulator,

trend and loop objects

Notification class objects 8

Memory Programs and program parameters are stored in

nonvolatile memory

Auto restart on power failure

Applications programs KMC Controls supplies the controllers with

programming sequences for single-duct VAV

applications:

◆ Pressure independent cooling with or without

parallel fan or reheat

◆ Pressure dependent single duct cooling with or

without reheat

◆ Airflow balancing

Revision C

7

Page 8

About the controllers

Specifications

KMC Controls

Airflow sensor The sensor is flow through sensor with dual

platinum film RTD sensors on a ceramic base. The

sensor output is converted to a voltage that

represents 0 to 3000 FPM (15.24 m/s) using 24-inch,

1/4 inch FR tubing and SSS-1000 series flow pickups.

Airflow through the sensor is approximately 1.12

SCFH (32 liters/hour) at 0.25 inches of WC (62.5 Pa)

pressure drop.

The airflow sensor is available as a standard BACnet

analog input object.

Actuator specifications

Torque, minimum 50 in-lb. (5.7 N•m)

Torque, maximum 70 in-lb. (7.9 N•m)

Angular rotation 0 to 95°

Adjustable end stops at 45/60/90° rotation

Motor timing: BAC-7001, 18°/minute at 60 Hz

BAC-7003 15°/minute at 50 Hz

Motor timing: BAC-7051, 60°/minute at 60 Hz

BAC-7053 50°/minute at 50 Hz

Shaft size Fits 0.5 inch (13 mm) round shafts

See Shaft adaptors on page 10 for 0.38 inch shafts.

Regulatory UL 916 Energy Management Equipment

FCC Class B, Part 15, Subpart B

BACnet Testing Laboratory listed

CE compliant

SASO PCP Registration KSA R-103263

Installation

Supply voltage 24 volts AC (–15%, +20%), 50-60 Hz, 8 VA minimum,

15 VA maximum load, Class 2 only, non-supervised

All circuits, including supply voltage, are power

limited circuits.

Weight 2.4 lb. (1.1 kg)

Case material Flame retardant green plastic

Environmental limits

Operating 32 to 120° F (0 to 49° C)

Shipping –40 to 140° F (–40 to 60° C)

Humidity 0–95% relative humidity (non-condensing)

Models

BAC-7001 BACnet AAC for VAV, 18°/minute at 60 Hz

BAC-7051 BACnet AAC for VAV, 60°/minute at 60 Hz

BAC-7003 BACnet AAC for VAV FIU, 18°/minute at 60 Hz

BAC-7053 BACnet AAC for VAV FIU, 60°/minute at 60 Hz

8

Revision C

Page 9

BAC-7000 VAV Installation, applications, and operation

A

C

B

D

guide

Dimensions

About the controllers

Specifications

Table 1-2 Controller dimensions

ABCD

8.23 in. 4.22 in. 2.25 in. 0.510 in.

209 mm 107 mm 57 mm 13 mm

Revision C

9

Page 10

About the controllers

Accessories and replacement parts

KMC Controls

Accessories and

replacement parts

Replacement parts

HMO-4531 Non Rotation Bracket- KMD-7001

HPO-0054 Bulbs

HPO-0063 2-PIN KMD jumper (5/Pkg)

Shaft adaptors

HFO-0011 3/8 inch (9.5 mm) shaft adaptor

Airflow sensors Order one of the following for installation on VAV

units without airflow sensor pickup tubes.

SSS-1012 3-5/32 in. length (80 mm) for 1/4 inch O.D. tubing

SSS-1013 5-13/32 in. length (137 mm) for 1/4 inch O.D. tubing

SSS-1014 7-21-32 in. length (195 mm) for 1/4 inch O.D. tubing

SSS-1015 9-29/32 in. length (252 mm) for 1/4 inch O.D. tubing

Power transformer

XEE-6111-40 Single-hub 120 volt transformer

XEE-6112-40 Dual-hub 120 volt transformer

10

Revision C

Page 11

BAC-7000 VAV Installation, applications, and operation

Danger

Warning

Caution

Note

Detail

guide

About the controllers

Safety considerations

Safety

considerations

KMC Controls assumes the responsibility for providing you a safe product and

safety guidelines during its use. Safety means protection to all individuals who

install, operate, and service the equipment as well as protection of the equipment

itself. To promote safety, we use hazard alert labeling in this manual. Follow the

associated guidelines to avoid hazards.

Danger represents the most severe hazard alert. Bodily harm or death will

occur if danger guidelines are not followed.

Warning represents hazards that could result in severe injury or death.

Caution indicates potential personal injury or equipment or property damage

if instructions are not followed.

Notes provide additional information that is important.

Provides programing tips and shortcuts that may save time.

Revision C

11

Page 12

About the controllers

Safety considerations

KMC Controls

12

Revision C

Page 13

BAC-7000 VAV Installation, applications, and operation guide

SECTION 2

Installing the controllers

This section provides important instructions and guidelines for

installing BAC-7000 series VAV controllers. Carefully review this

information prior to installation.

Installing the BAC-7000 series VAV controllers includes the following topics that are

included in this section.

◆ Set the rotation limits on page 14

◆ Mounting on a VAV terminal unit on page 16

◆ Connecting inputs on page 18

◆ Connecting outputs on page 19

◆ Connecting to a NetSensor on page 20

◆ Connecting to an MS/TP network on page 21

◆ Connecting an airflow sensor on page 23

◆ Connecting power on page 23

Revision C 13

Page 14

Installing the controllers

Caution

Caution

Stop Pins

(1 of 2)

Stop

Selections

Clockwise

(CW)

Pins

Counterclockwise

(CCW)

Pins

Set the rotation limits

KMC Controls

Set the rotation

limits

Before mounting the controller, set the rotational limits with the two supplied stop

pins. These settings limit the shaft rotation in the clockwise (CW) and

counterclockwise (CCW) directions. (See

The maximum amount of shaft rotation is 90°. Placing a stop pin in both 90° slots

allows the actuator the full 90° of travel. Placing a stop pin in any other slot restricts

actuator rotation in the either the CW or CCW direction. Refer to

pin placement and travel. The first number represents the CCW pin and the second

the CW pin.

Illustration 2-1.)

Illustration 2-2 for

To prevent damage to the actuator, always install both stop pins.

Before setting the rotation limits on the controller, refer to the damper position

specifications in the VAV control box to which the controller will be attached.

Setting rotation limits that do not match the VAV damper may result in

improper operation or equipment damage.

14

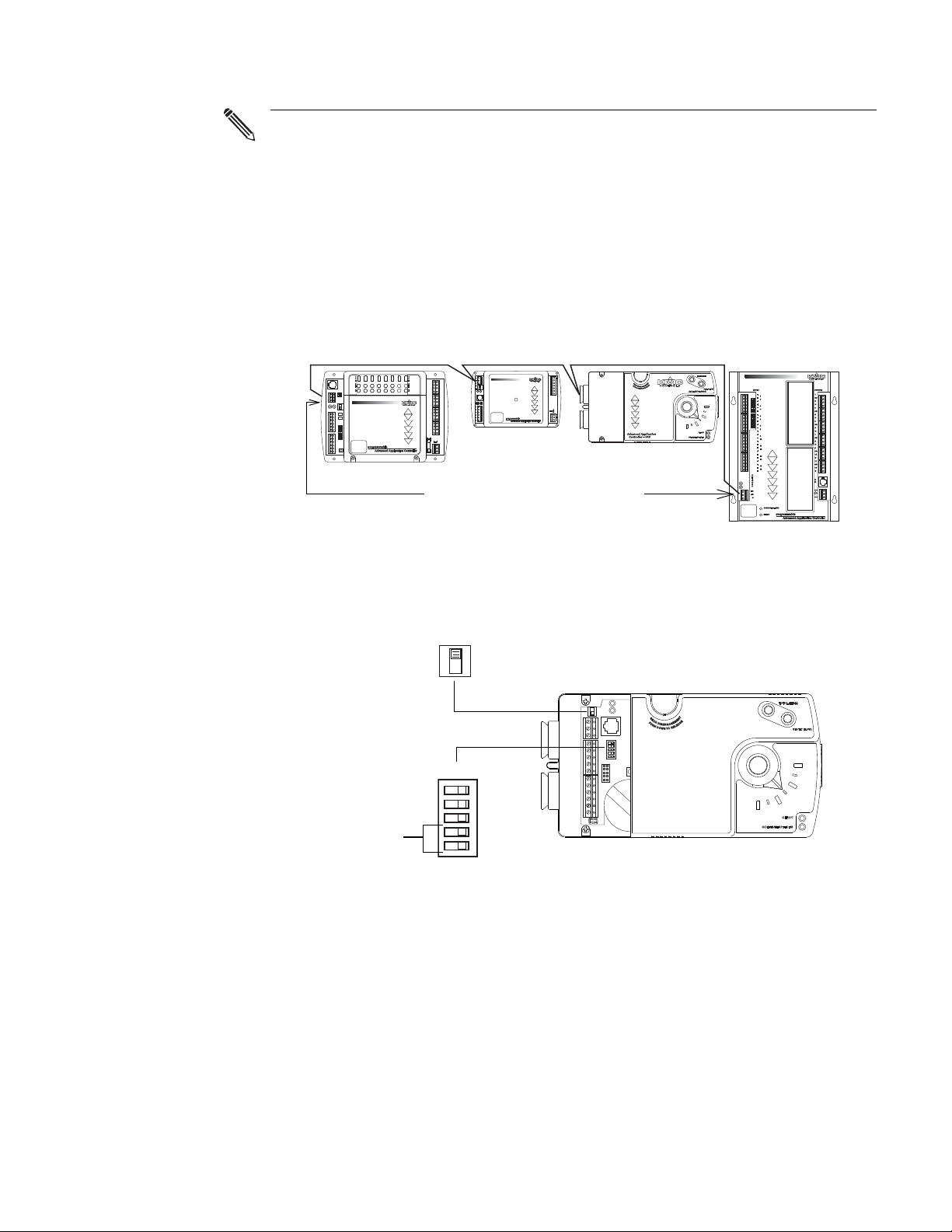

Illustration 2-1 Controller stop selections

To set the rotational limits, do the following:

1. Turn the controller over so you have access to the back.

2. Locate the two stop pins installed in the back of the unit. (You will find one pin

in a CCW setting and one in a CW setting.)

3. If the stop pins are positioned as required, leave them in place.

4. Identify the limits for the VAV terminal unit damper.

5. Remove one or both pins and place them in the correct slot.

Revision C

Page 15

BAC-7000 VAV Installation, applications, and operation

guide

Installing the controllers

Set the rotation limits

Illustration 2-2 Controller travel and stop selections

Revision C

15

Page 16

Installing the controllers

Note

Note

Anti-rotation

bracket

Gear clutch button

Air sensor

inputs

Conduit

plugs

Lock tab

Removable

conduit plate

Access cover Drive hub Status LEDs

Mounting on a VAV terminal unit

KMC Controls

Mounting on a

VAV terminal unit

Mount the controller inside of a metal enclosure. To maintain RF emissions

specifications, use either shielded connecting cables or enclose all cables in conduit.

Mount the controller directly over the damper shaft. A minimum shaft length of 1.75

inch (45 mm) is required. The base of the controller must contact the mounting

surface to allow installation of a bracket to prevent the controller from rotating.

KMC Controls designed the controller for use with either 1/2 inch round or

3/8 inch square damper shafts. For installations with a 3/8 inch round shaft,

use an HFO–0011 shaft adaptor.

Mount the controller close enough to the pitot tubes to keep the tubing length

to be less than 24 inches between the controller’s inputs and the tubes.

16

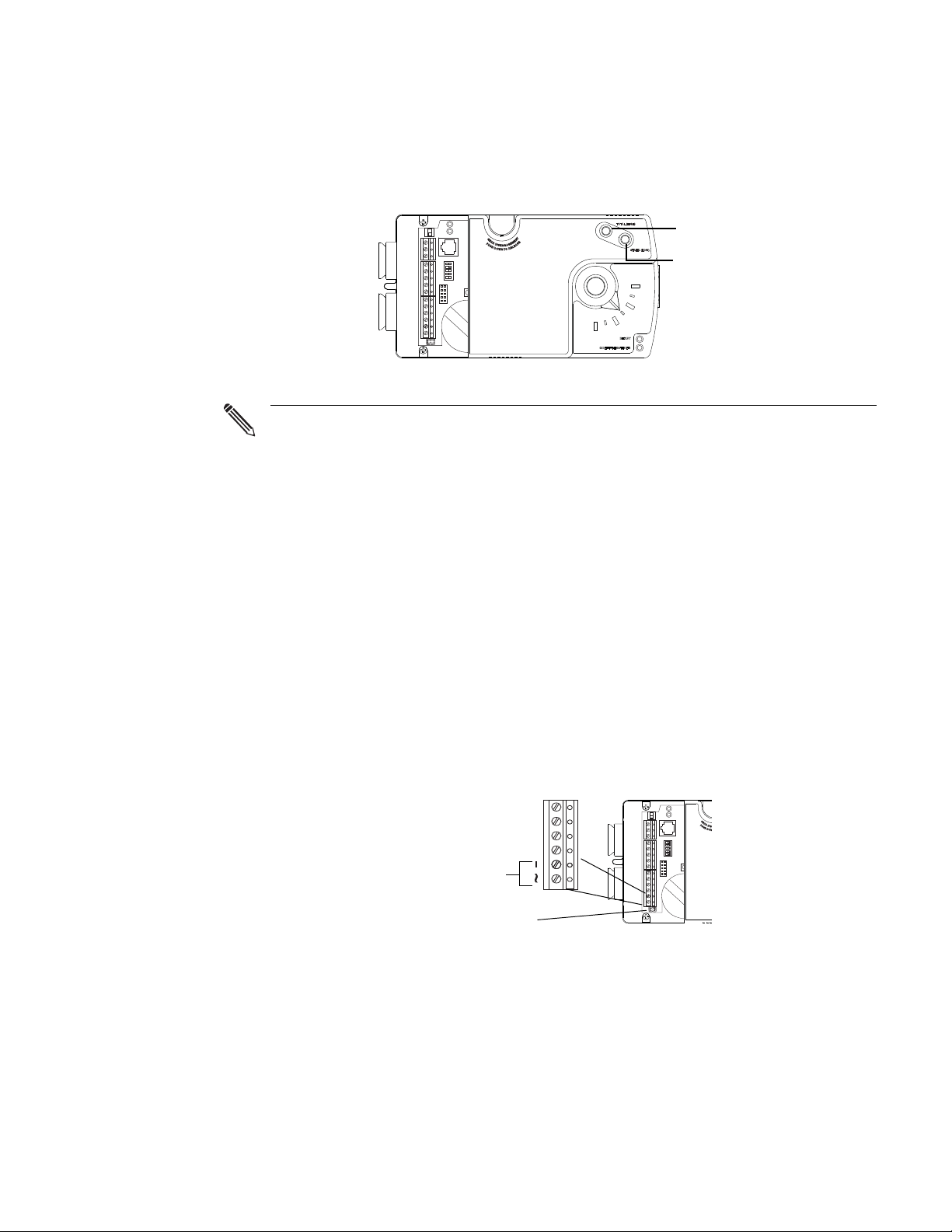

Illustration 2-3 BAC-7000 VAV series controls and indicators

Mount the controller as follows:

1. Back the set screws out of the drive hub until the shaft can fit through the collar.

2. Place the controller on the damper shaft in the approximate final position.

3. Position the anti-rotation bracket and secure it using #8 or #10 self-tapping

screws. Verify the notch in the bracket securely engages the lock tab on the

controller. (Refer to Illustration 2-3.)

4. Manually position the VAV damper in the fully open position.

5. Press the gear clutch button and rotate the drive hub in the same direction that

opened the damper. Turn the hub until it reaches a rotation limit.

6. Tighten the two set screws in the drive hub to approximately 50–inch pounds

(5.65 N

•m) to lock the hub to the shaft.

Revision C

Page 17

BAC-7000 VAV Installation, applications, and operation

MS/TP

network

Input

Output

Power

Isolation lamps

Power jumper

RJ–12

Input pull-up

resistors

MS/TP end-of-line

termination

Restart button

guide

Installing the controllers

Wiring compartment

Wiring

compartment

All input, output, power and network connection points are located beneath the

access cover. Remove the two screws that secure this cover to remove the cover.

The controller comes with a removable conduit plate. The plate provides two

inch threaded conduit couplings. If conduit connections are used, note the

0.5

following:

◆ The conduit plate may be removed by removing the two screws that secure the

access cover and removing the cover. Connect the required conduit and replace

the plate in the controller housing.

◆ The plugs may also be sliced to allow wiring to enter the controller with a

minimum of outside contaminates.

Revision C

Illustration 2-4 Connection points inside wiring compartment

17

Page 18

Installing the controllers

Note

Pull-up

resistors

Off On

Input

terminals

Connecting inputs

KMC Controls

Connecting inputs

The BAC-7000 VAV controllers have three universal inputs. Each input is configured

to support the standard application programs in the controller. By using the pull-up

resistors, either passive or active devices may be connected to the inputs.

KMC supplied Control Basic programs assigns inputs to the following functions.

◆ Connect Input 1 to the space temperature sensor input such as the 10 kΩ.

thermistor in an STE-6000 series sensor.

◆ Connect Input 2 as a setpoint input such as a 0-10 kΩ. dial on an STE-6000

series sensor.

◆ Input 3 is for a 10 kΩ. discharge air temperature sensor.

If a NetSensor is connected to the controller, the standard application

programming will use the temperature and setpoint from the NetSensor and

not from devices connected to Input 1 and Input 2.

Setting the pull–up resistors For passive input signals, such as thermistors or

switch contacts, set the pull-up switch to the On position. See

Illustration 2-5 for the

pull-up switch location.

18

Illustration 2-5 Input terminals and pull-up resistors

Ground terminals Use the GND terminal located next to the input terminals for the

input ground connection. Up to two wires, size 14–22 AWG, can be inserted into the

ground terminal. If more than two wires must be joined at a common point, use an

external terminal strip for the additional wires.

Revision C

Page 19

BAC-7000 VAV Installation, applications, and operation

Caution

Output

terminals

Output

terminals

guide

Installing the controllers

Connecting outputs

Connecting

outputs

The output terminal configuration for a BAC-7001 and BAC-7051 controllers is

different than the configuration for BAC-7003 and BAC-7053 controllers.

For a listing of the configuration of the controller output objects, see the section

Output objects on page 62.

BAC-7001 and BAC-7051 output connections

BAC-7001 and BAC-7051 controllers provide three universal outputs. These output

are rated for 0-10 volt DC loads. Returns are connected to the GND terminal next to

output O3 as shown in the illustration

BAC-7001 output terminals on page 19.

O1 O2 O3

GND

Illustration 2-6 BAC-7001 output terminals

BAC-7003 and BAC-7053 output connections

The BAC-7003 and BAC-7053 include one single-stage triac, one relay and one

universal output.

O1 T2 RTN2 R3 RTN3

Illustration 2-7 Output terminals

When connecting loads to the triac or relay output, use only the terminal

marked RTN associated with the triac or relay for the 24-volt circuit.

Output O1 This output is a universal output that can be programmed as either an

analog object for modulating reheat. The universal output is rated for 0-10 volt DC

loads. Use the GND terminal on the input connector block for the ground.

Output T2 This is a triac output programmed to switch 24-volt reheat circuits. The

output is rated for 24 volt, 1 ampere loads, and switches on zero crossing. Use the

RTN2 terminal for the T2 load.

Output R3 This is a normally open relay contact programmed to control a 24-volt

fan starting circuit. The relay contacts are rated for 24-volts at 2 amperes. Use RTN3

for the R3 load.

Output 4 Output 4 is internally connected to the actuator motor.

Revision C

19

Page 20

Installing the controllers

Note

75 feet Max.

Connecting to a NetSensor

KMC Controls

Connecting to a

NetSensor

The Network RJ-12 connector provides a connection port to a NetSensor model

KMD-1161. Link the controller to a NetSensor with a KMC Controls approved cable

up to 75 feet long. See the installation guide supplied with the NetSensor for

complete NetSensor installation instructions.

If a NetSensor is connected to the controller, the standard application

programming will use the temperature and setpoint from the NetSensor and

not from devices connected to Input 1 and Input 2.

-A S

+B

1

GND

Illustration 2-8 Connecting to a NetSensor

20

Revision C

Page 21

BAC-7000 VAV Installation, applications, and operation

S

+B

-A

S

+B

-A

S

+B

-A

guide

Installing the controllers

Connecting to an MS/TP network

Connecting to an

MS/TP network

BAC-7000 series VAV controllers BACnet MS/TP compliant controllers. For

monitoring and control by building automation system, connect them only to a

BACnet MS/TP network.

Connections and wiring

Use the following principles when connecting a controller to an MS/TP network:

◆ Connect no more than 128 addressable BACnet devices to one MS/TP network.

The devices can be any mix of controllers or routers.

◆ To prevent network traffic bottlenecks, limit the MS/TP network size to 60

controllers.

◆ Use 18 gauge, twisted pair, shielded cable with capacitance of no more than

50 picofarads per foot for all network wiring. Belden cable model #82760 meets

the cable requirements.

◆ Connect the -A terminal in parallel with all other - terminals.

◆ Connect the +B terminal in parallel with all other + terminals.

◆ Connect the shields of the cable together at each controller. For KMC BACnet

controllers use the S terminal.

◆ Connect the shield to an earth ground at one end only.

◆ Connect a KMD–5575 BACnet MS/TP repeater between every 32 MS/TP

devices or if the cable length will exceed 4000 feet (1220 meters). Use no more

than four repeaters per MS/TP network.

◆ Place a KMD–5567 surge surpressor in the cable where it exits from a building.

See Application Note AN0404A, Planning BACnet Networks for additional

information about installing controllers.

Illustration 2-9 MS/TP network wiring

Revision C

21

Page 22

Installing the controllers

Note

Set end-of-line termination to

On in these controllers only.

EOL switch

Network

disconnect

switch

Off On

Connected

Disconnected

Connecting to an MS/TP network

The BAC-7000 terminals are labeled -A, +B and S. The S terminal is provided

as a connecting point for the shield. The terminal is not connected to the

ground of the controller. When connecting to controllers from other

manufacturers, verify the shield connection is not connected to ground.

End of line termination switches

The controllers on the physical ends of the EIA-485 wiring segment must have endof-line termination installed for proper network operation. Set the end-of-line

termination to On using the EOL switches.

KMC Controls

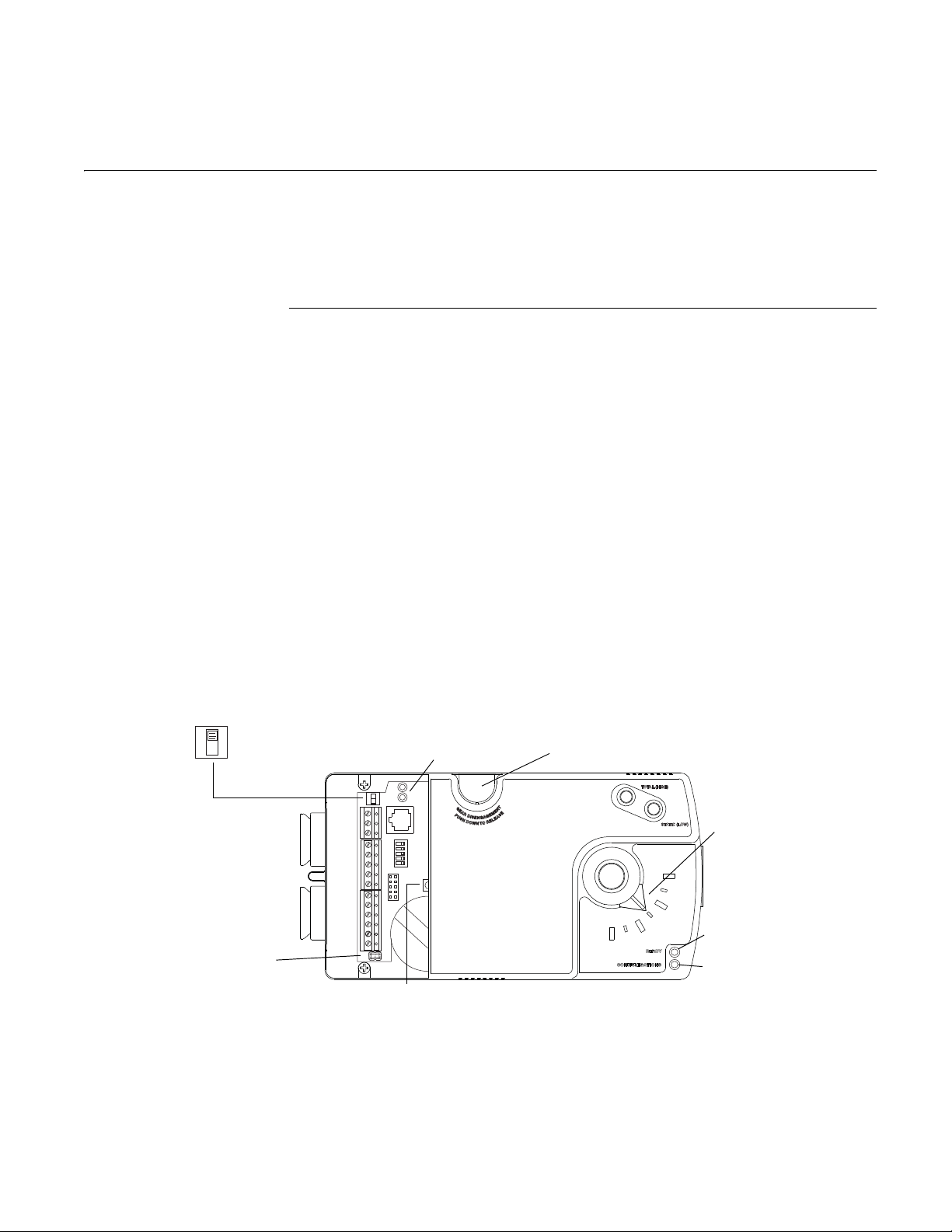

Illustration 2-10 Location for end-of-line termination

Illustration 2-5 shows the position of the controllers End-of-Line switches

associated with the MS/TP connection points.

Illustration 2-11 Location of EOL switch

22

Revision C

Page 23

BAC-7000 VAV Installation, applications, and operation

Note

Total (High)

Static (Low)

Power

terminals

Power

jumper

guide

Installing the controllers

Connecting an airflow sensor

Connecting an

airflow sensor

Connecting power

An airflow sensor is incorporated as one of the inputs to the controller. Remove the

plugs and connect the tubing from the pitot assembly to the airflow sensor inputs

above the drive hub. (See

Illustration 2-12.). The airflow sensor is programmed as

input 4.

Illustration 2-12 Airflow sensor inputs

Mount the controller close enough to the pitot tubes to keep the tubing length

to be less than 24 inches between the controller’s inputs and the tubes.

The controllers require an external, 24 volt, AC power source. Use the following

guidelines

when choosing and wiring transformers.

◆ Use a KMC Controls Class–2 transformer of the appropriate size to supply

power to the controllers.

◆ KMC Controls recommends powering only one controller from each

transformer.

◆ Do not run 24 volt, AC power from within an enclosure to external controllers.

Connect the 24 volt AC power supply to the power terminal block on the lower right

side of the controller near the power jumper. Connect the ground side of the

transformer to the – terminal and the AC phase to the ~

(phase) terminal. Power is

applied to the controller when the transformer powered and the power jumper is in

place.

Illustration 2-13 Power terminals and jumper

Revision C

23

Page 24

Installing the controllers

Connecting power

KMC Controls

24

Revision C

Page 25

BAC-7000 VAV Installation, applications, and operation guide

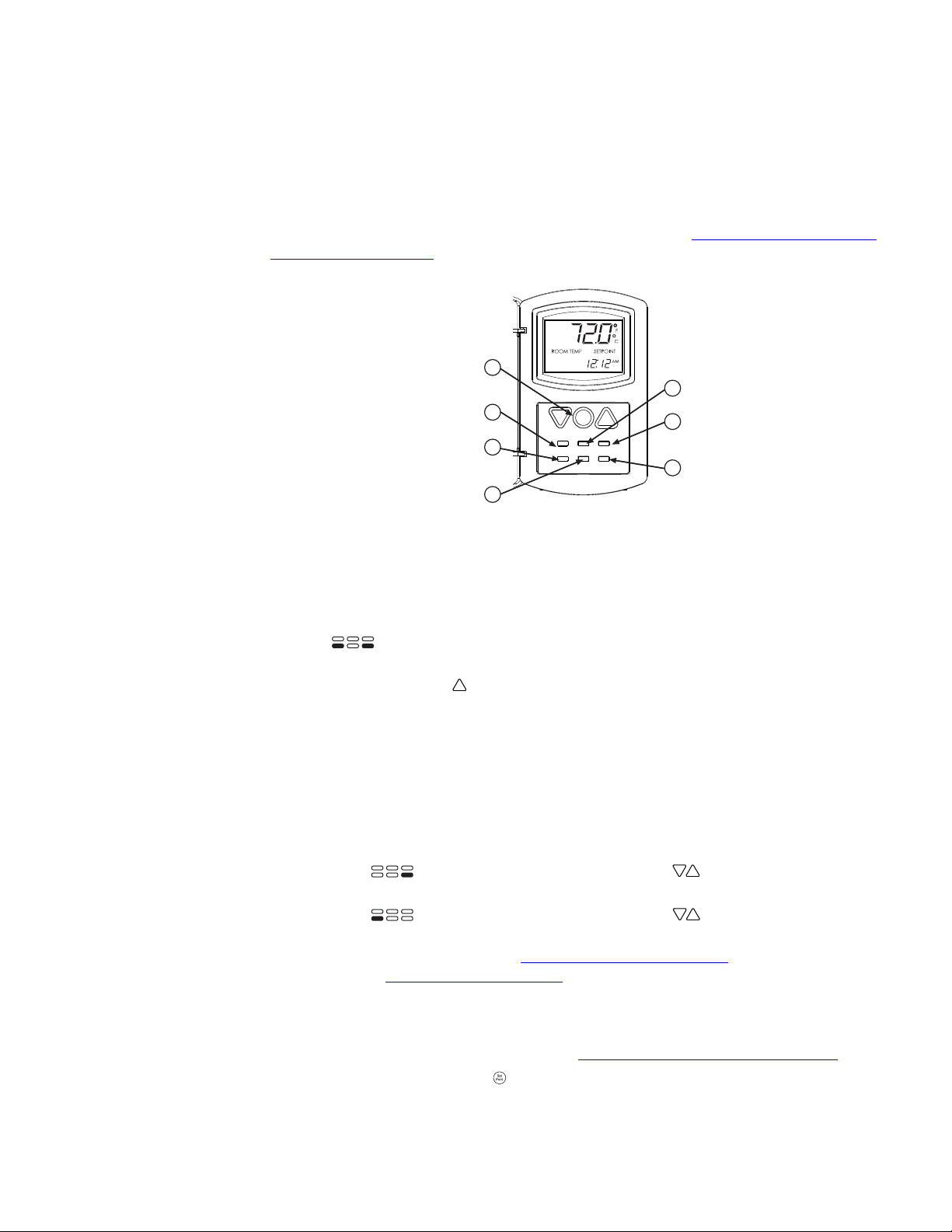

Network

disconnect

switch

Connected

Disconnected

Ready LED

Communication LED

Gear clutch button

Damper

position

indicator

Network

isolation

bulbs

Restart button

Power jumper

SECTION 3

Operation

This section provides a brief overview of the BAC-7000 series VAV

controllers. Review this material before installing the controllers.

Operation

Controls and Indicators

Once configured, programmed and powered, the controller requires very little user

intervention.

The following topics describe the controls and indicators found on the controller.

Additional information for automatic addressing functions are described in the

guide MS/TP Automatic MAC Addressing Installation Instructions that is available

from the KMC Controls web site.

Network disconnect switch

The network disconnect switch is located near the RJ-12 connector. Use this switch to

enable or disable the MS/TP network connection. When the switch is ON the

controller can communicate on the network; when it is OFF, the controller is isolated

from the network.

Alternately, you may remove the isolation bulbs to isolate the controller from the

network.

Ready LED

The green Ready LED indicates the state of the controller. This includes automatic

addressing functions that are fully described in the guide MS/TP Addressing For

BACnet Controllers.

Revision C 25

Illustration 3-1 Controls and indicators

Page 26

Operation

Controls and Indicators

KMC Controls

Power up During controller initialization, the Ready LED is continuously

illuminated for 5 to 20 seconds. Once initialization is complete, the Ready LED

begins flashing to indicate normal operation.

Normal operation During normal operation, the Ready LED flashes a repeating

pattern of one second on and then one second off.

Restart button acknowledge The restart button includes several functions for

automatic addressing that are acknowledged with the Ready LED. When the restart

button is pressed, the Ready LED illuminates continuously until either of the

following take place:

• The restart button is released.

• The restart button time-out period is reached and a restart operation is

complete. Restart button operations are listed in the following table.

Table 3-1 Ready LED patterns for restart button operations

Controller state LED pattern

The controller is set as an automatic

addressing anchor. The MAC in the

controller is set to 3

The controller has sent the automatic

addressing lock command to the network

No restart operation Ready LED remains unlit until the restart

A rapid repeating pattern of a short flash

followed by a short pause.

Two short flashes followed by a long

pause. The pattern repeats until the restart

button is released.

button is released.

Communications (Com) LED

The yellow Communications LED indicates how the controller is communicating

with other controllers on the network.

Sole master Repeating pattern of a long flash and a short pause that repeats once a

second. It indicates that the controller has either generated the token or is a sole MS/

TP master and has yet to establish communications with other MS/TP devices.

Token passing A short flash each time the token is passed. The frequency of the

flash is an indication of how often the device receives the token.

Nomad patterns There are three Com LED patterns that indicate that the controller

is an automatic addressing nomad controller that is receiving valid MS/TP traffic.

Table 3-2 Automatic addressing nomad patterns

26

Controller state LED pattern

Lost nomad A long flash

Wandering nomad A long flash followed by three short

flashes

Assigned nomad Three short flashes followed by a long

pause.

Revision C

Page 27

BAC-7000 VAV Installation, applications, and operation

guide

Error conditions for the LEDs

Error conditions are indicated with a combination of the Ready and Com LEDs.

◆ If the Ready LED and Com LED are both unlit, check the fuse, power, and

connections to the controller.

◆ If the Ready LED alternates with the Com LED at a one-half-second rate, there

is an error in the controller’s memory. Restoring the controller to factory

default settings will typically resolve the problem.

Isolation bulbs

The two network isolation bulbs, located next to the network switch, serve three

functions:

◆ Removing the bulbs opens the EIA-485 circuit and isolates the controller from

the network.

◆ If one or both bulbs are lit, it indicates the network is improperly phased. This

means that the ground potential of the controller is not the same as other

controllers on the network.

◆ If the voltage or current on the network exceeds safe levels, the bulbs operate as

fuses and may protect the controller from damage.

Operation

Controls and Indicators

Gear clutch button

To manually position the damper, press the gear clutch button and rotate the drive

hub.

Revision C

27

Page 28

Operation

Caution

Note

Caution

Restoring factory settings

KMC Controls

Restoring factory

settings

If the controller appears to be operating incorrectly, or is not responding to

commands, you may need to reset the controller. Remove the cover and locate the

red restart button.

To perform a reset or restart, locate the red restart push-button and then—in

order—use one of the following procedures.

1. A warm start is the option least disruptive to the network and should be tried

first.

2. If problems persist, then try a cold start.

3. If the problems continues, restoring the controller to factory settings may be

required.

Read all of the information in this section before proceeding!

Momentarily pushing the red reset button while the controller remains

powered will have no effect on the controller.

Performing a warm start

A warm start changes the controller as follows:

◆ Restarts the controller’s Control Basic programs.

◆ Leaves object values, configuration, and programming intact.

In the unlikely event that the checksum test in RAM fails during the warm

start, the controller will automatically perform a cold start. During a cold start,

controller outputs may abruptly turn connected equipment on and off. To

prevent equipment damage, turn connected equipment off or temporarily

remove the output terminal blocks from the controller before performing a

warm start.

Do either of the following to perform a warm start:

◆ Reinitialize the controller with either BACstage or TotalControl Design Studio.

◆ Remove the power jumper for a few seconds and then replace it.

Performing a cold start

Performing a cold start changes the controller as follows:

◆ Restarts the controller programs.

◆ Returns all object states to their initial factory settings until the controller

programs update them.

◆ Leaves configuration and programming intact.

28

Revision C

Page 29

BAC-7000 VAV Installation, applications, and operation

Caution

Note

Caution

guide

Returning object values to their relinquished defaults during a cold start may

abruptly turn connected equipment on or off. To prevent equipment damage,

turn connected equipment off or temporarily remove the output terminal

blocks from the controller before performing a warm start.

To perform a cold start:

1. While the controller is powered, press and hold the restart button.

2. Remove the power jumper.

3. Release the red button before replacing the power jumper.

A cold start performed by this method is the same as performing a cold start

with BACstage or from TotalControl Design Studio.

Restoring to factory settings

Restoring a controller to factory settings changes the controller as follows:

Operation

Restoring factory settings

◆ Removes all programming.

◆ Removes all configuration settings.

◆ Restores the controller to factory default settings.

Resetting the controller erases all configuration and programming. After

resetting to factory settings, you must configure and program the controller to

establish normal communications and operation.

To reset the controller to factory settings.

1. If possible, use BACstage or TotalControl Design Studio to backup the

controller.

2. Remove the power jumper.

3. Press and hold the red restart button.

4. Replace the power jumper while continuing to hold the restart button.

5. Restore configuration and programming with BACstage or TotalControl

Design Studio.

Revision C

29

Page 30

Operation

Maintenance

KMC Controls

Maintenance

BAC-7000 series VAV controllers require no routine maintenance. If necessary, clean

with a damp cloth and mild soap.

30

Revision C

Page 31

BAC-7000 VAV Installation, applications, and operation guide

SECTION 4

Configuration and set up

The topics in this section are advanced topics for control technicians

and engineers. Carefully review this information before installing or

operating a controller.

Configuration of a BAC-7000 series VAV controller sets all of the values and settings

required to control a VAV terminal unit. Typically, these settings do not change after

the installation and commissioning process.

To set up the configuration functions, you will need the following items and

information.

Assigning network addresses

◆ Details about the VAV terminal unit including the configuration for fans and

reheat.

◆ A BACnet operator workstation such as BACstage or TotalControl.

◆ The building automation system plans for controllers connected to a network.

Every controller on a BACnet MS/TP network must have a unique device instance

and MAC address. Assigning the MAC address and device instance to a controller

can be done by using either the automatic or manual method.

Automatic addressing

If the controller is part of a KMC Controls network that uses automatic addressing,

follow the directions in the guide MS/TP Automatic MAC Addressing Installation

Instructions that is available from the KMC Controls web site.

Manual addressing

To manually address a new controller it must first be changed to an anchor

controller by doing the following:

1. Set the network switch to Off (disconnected).

2. Press and hold the restart button for 10 seconds. The Ready LED will start

flashing rapidly. The Com LED will remain dark.

3. Release the restart button.

4. Turn off controller power.

5. Set the anchor network switch to On (connected).

6. Turn on controller power. The Ready LED will blink slowly and the Com LED

will flash rapidly. This controller is now an anchor with a MAC address of 3.

Revision C 31

Page 32

Configuration and set up

Note

Configuring for pressure independent VAV

Once a controller is converted to an anchor controller, connect it to a BACnet

operator workstation and set the following properties.

◆ MAC address

◆ Device instance number

◆ Baud rate

KMC Controls

Configuring for

pressure

independent VAV

The BAC-7000 VAV controllers are supplied with programming and object

configuration for single-duct VAV cooling. The following value objects must be set

or verified with a BACnet operator workstation such as BACstage or TotalControl

for correct operation.

When changing any of the value objects in this procedure, make the changes to

the Relinquish Default property. If the change is added to the Priority Array

property at any other level, the change will be deleted when the controller

restarts.

Configure the damper direction to close

The CW_CLOSE value object sets the direction the controller will rotate the damper

to the closed position.

◆ Set this property to Yes (Active or 1) to set the controller to close the damper in

the clockwise direction.

◆ Set the property to No (Inactive or 0) to set the controller to close the damper in

the counter clockwise direction.

Change this value in the Relinquish Default property of Binary Value object 4.

Enter the volume correction factor

The volume correction factor is used to calculate airflow based on the primary air

inlet size of the VAV terminal unit. For round ducts, choose the correction factor

from the following table. Enter the factor in the Relinquish Default property of

Analog Value object 22, VOLFACTR.

32

Table 4-1 Volume factor for round ducts (inches)

Diameter Circumference Volume factor

4 12 5/8 0.087

5 15 3/4 0.136

6 18 7/8 0.196

7 22 0.267

8 25 1/8 0.349

9 28 1/4 0.442

10 31 3/8 0.545

12 37 3/8 0.785

14 44 1.068

16 50 1/4 1.396

Revision C

Page 33

BAC-7000 VAV Installation, applications, and operation

Volume factor =

0.785 x Diameter

144

2

guide

For other sizes of round ducts, use the following formula. Diameter is in inches.

For rectangular ducts, use the following formula. Width and Height are in inches.

Configuration and set up

Configuring for pressure dependent VAV

Volume factor =

Width x Height

144

Enable or disable reheat

The BAC-7000 VAV controllers are supplied with reheat enabled. To disable reheat,

set the Relinquish Default property of REHEAT, Binary Value object 5, to

Inactive

(0).

Configure auxiliary airflow (optional)

Auxiliary airflow sets the airflow when reheat is active and is not used if reheat is

disabled. Enter the value for the auxiliary airflow in the Relinquish Default property

of Analog Value object 28, AUX_FLOW.

Set the airflow limits

VAV airflow limits can be set with either a KMD-1161 NetSensor or with a BACnet

operator workstation. Enter the values in the Relinquish Default properties of

Analog Value objects 20 and 21, MIN_FLOW, and MAX_FLOW.

To set the values with a NetSensor, follow the procedures in the section Balancing

with a NetSensor on page 35.

Set the temperature setpoint limits

The temperature setpoint limits place limits on the highest heating setpoint and the

lowest cooling setpoint a user can enter. Enter the values in the Relinquish Default

properties of Analog Value objects 11 and 12, STPT_MIN and STPT_MAX.

Configuring for

pressure

dependent VAV

Revision C

To operate a BAC-7000 series VAV controller as a pressure dependent controller, use

a BACnet operator workstation to make the following changes.

◆ Halt Program object 1 and enable Program object 2 to run. If available, set the

program object to automatically run on a coldstart.

◆ Configure the damper direction to close on page 32

◆ Enable or disable reheat on page 33

◆ Set the temperature setpoint limits on page 33

33

Page 34

Configuration and set up

Configuring for pressure dependent VAV

KMC Controls

34

Revision C

Page 35

BAC-7000 VAV Installation, applications, and operation guide

Note

SECTION 5

Balancing with a NetSensor

Topics in this section are for control technicians or engineers who

will be balancing the airflow in the controllers.

The airflow balancing procedure described in this section requires the following

items.

◆ An airflow hood or other accurate method to measure airflow.

◆ An KMD-1161 NetSensor. If the system does not include one of these sensors,

temporarily disconnect the installed sensor and connect a KMD-1161 as a

service tool.

◆ The engineering design specifications for the minimum and maximum airflow

setpoints.

Balancing overview

The procedures in this section are for pressure independent systems only.

The airflow setpoints can be entered either in the balancing routines or they can be

entered through the use of a BACnet operator workstation. This is described in the

section

entered, they must be entered before balancing.

Balancing airflow is the process of calibrating the internal airflow sensor to a known

standard. In the field, airflow is measured with an airflow hood or other measuring

instrument and then compared to the airflow measurements from the sensor in the

controller. The balancing process uses a KMD-1161 NetSensor as the technicians

service tool for initiating the balancing sequence and entering actual flow

measurements.

When the balancing sequence starts, all other functions of the controller are locked

out.

Configuration and set up on page 31. Regardless of how these setpoints are

Revision C 35

Page 36

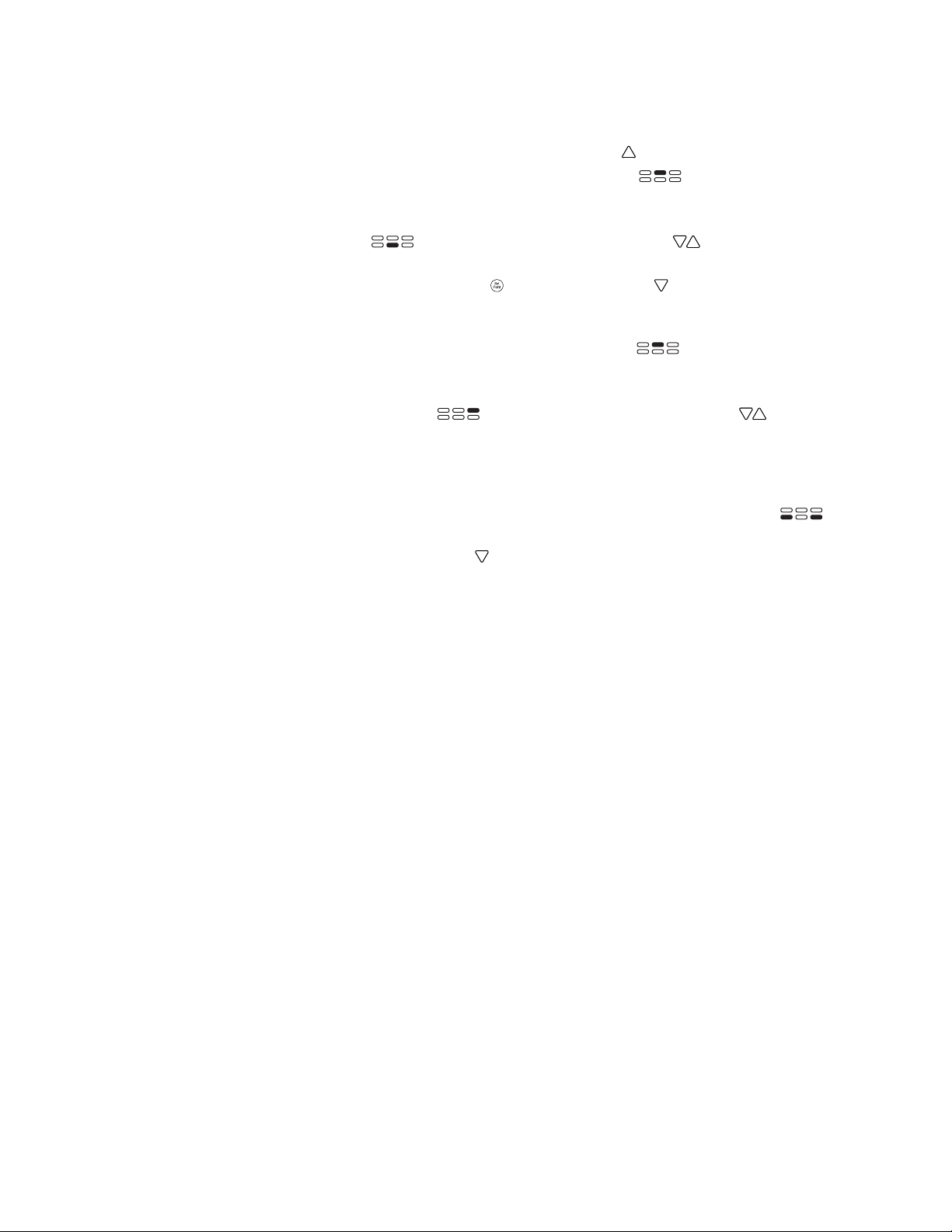

Balancing with a NetSensor

SET

POINT

TEMP O.A.T. OVERRIDE

B5 B6 B7

2

1

5

6

Choose airflow

1-Max 0-Min

Space temperature

Minimum airflow

setpoint

Actual airflow at

maximum

3

4

7

Airflow (CFM)

Actual airflow at

minimum

Maximum airflow

setpoint

The balancing procedure

KMC Controls

The balancing

procedure

This balancing procedure requires a KMD-1161 NetSensor as a service tool. If other

sensors are permanently installed, temporarily connect a KMD-1161 to the

controller, perform airflow balancing, and then return the original sensors to the

installation.

In the following procedures, the NetSensor buttons are referenced as they are

labeled on a standard KMD-1161. If the NetSensor has custom labeling, refer to the

button diagram included with each step or the illustration

Standard NetSensor button

assignments on page 36.

Illustration 5-1 Standard NetSensor button assignments

Start the balancing routine To start balancing or to set the airflow setpoints, do the

following.

1. Start the balancing routine by pushing together and then releasing B5 and

B7

. The display changes to AUX and then to OFF when the buttons are

released.

2. Push the Up button . The display changes to ON. The controller is now in the

balancing mode.

3. Wait approximately 15 seconds.

4. Continue with the procedure Enter airflow setpoints or Balance the airflow.

Enter airflow setpoints If required, enter the airflow setpoints from the NetSensor.

This is not necessary if these setpoints are entered from a BACnet operator

workstation during controller configuration.

1. Start balancing as described in the previous procedure.

2. Push B7 and use the Up and Down buttons to enter the maximum

airflow setpoint.

3. Push B5 and use the Up and Down buttons to enter the minimum

airflow setpoint.

4. Continue with the procedure Balance the airflow on page 36 or follow the

procedure End balancing on page 37.

Balance the airflow The following procedure balances airflow at the minimum and

maximum airflow setpoints.

36

1. If not in balancing, see the procedure Start the balancing routine on page 36.

2. Press the Setpoint button . The NetSensor should display “01”. This is the

indication that the controller is rotating the damper to the maximum airflow

setpoint.

Revision C

Page 37

BAC-7000 VAV Installation, applications, and operation

guide

• If the NetSensor is still displaying the temperature setpoint, wait

approximately 15 seconds.

• If the value is “00” press the Up button to change the display to”01”.

3. Monitor the actual airflow by pushing O.A.T. .

4. Once the actual airflow stabilizes, measure the airflow at the VAV outlet and

note the measurement.

5. Push B6 and use the Up and Down buttons to enter the measured

maximum airflow.

6. Press the Setpoint button and press the Down button. The display changes

to “00”. This is the indication that the controller is driving the damper to the

minimum airflow setpoint.

7. Monitor the actual airflow by pushing O.A.T .

8. Once the actual airflow stabilizes, measure the airflow at the VAV outlet and

note the measurement.

9. Push OVERRIDE and use the Up and Down buttons to enter the

measured minimum airflow.

End balancing End balancing by performing the following procedure. Balancing

will automatically end after two hours from the time the last button is pushed.

Balancing with a NetSensor

The balancing procedure

1. End balancing by pushing together and then releasing B5 and B7 . The

display changes to AUX and then to ON when the buttons are released.

2. Push the Down button . The display changes to OFF. The controller is now in

the normal operating mode.

Revision C

37

Page 38

Balancing with a NetSensor

The balancing procedure

KMC Controls

38

Revision C

Page 39

BAC-7000 VAV Installation, applications, and operation

guide

SECTION 6

Sequences of operation

Topics in the section cover the sequences of operation for the

BAC-7000 series VAV controllers. These are advanced topics for

control technicians and engineers.

These sequences of operation are descriptions of each major components of the

BAC-7000 VAV programming. They are provided as an aid to understanding on how

the controllers operate.

This section covers the following sequences of operation.

◆ Input sources on page 39

◆ Space setpoints on page 40

◆ Occupancy and standby on page 40

◆ PID control loops on page 41

◆ Changeover on page 41

◆ Pressure independent airflow sequence on page 41

◆ Pressure dependent temperature control on page 41

◆ Damper operation on page 42

◆ Fan operation on page 42

◆ Reheat sequence on page 42

◆ Balancing sequence on page 43

Sequences of operation

Input sources

Input sources

Revision C

The BAC-7000 series VAV controllers require specific sensors for room temperature,

room setpoint, and airflow through the VAV terminal unit.

The controllers are set up for KMD-1161 NetSensors. When a NetSensor is connected

to a controller, the programming automatically detects the sensor and updates

Analog Value objects AV1, SPACESTP, and AV2, SPACESSTPT, from the values

passed from the NetSensor.

If a NetSensor is not detected, the values from Analog Inputs objects AI1 and AI2,

ROOMTEMP and STESETPOINT, are passed to Analog Value objects AV1 and AV2.

Input AI1 is configured for a Type-II, 10 kΩ. thermistor and input AI2 is configured

for a 10 kΩ. potentiometer.

A third input is configured as Analog Input object AI3 for a Type-III, 10 kΩ.,

discharge air temperature sensor. This input is not required for any of the

programming sequences but may be installed for monitoring by a BACnet operator

workstation or another controller on the building management system network.

The airflow sensor is an internal, flow-through sensor that is connected to airflow

pickup tubes on the VAV terminal unit inlet. The input is represented by Analog

Input object AI4 and is configured to represent airflow in feet-per-minute.

39

Page 40

Sequences of operation

Space setpoints

KMC Controls

Space setpoints

The BAC-7000 VAV controllers use the following setpoints based on the user-entered

setpoint or the state of occupancy and standby. See the topic

on page 40 for a description of these modes.

Active setpoint—The active setpoint is the current setpoint the controller uses to

maintain temperature in the space. It is the Controlled Input property for Loop 1.

Controller programming sets this value to either the Cooling Setpoint or Heating

setpoint based on the state of Heating/Cooling value object. The active setpoint is

stored in Analog Value object AV26,

ACTIVESP.

Occupancy and standby

Table 6-1 Active setpoint calculations

Cooling setpoint Heating setpoint

Occupied Space setpoint + 1/2 deadband Space setpoint – 1/2 deadband

Standby Space setpoint + offset Space setpoint – offset

Unoccupied Unoccupied cooling setpoint Unoccupied heating setpoint

Space setpoint—This is the setpoint entered or selected by the user and is stored in

Analog Value object AV2, SPACESSTPT. The value is either the value set from the

NetSensor or Analog Input object

calculated from this setpoint. See the topic

Setpoint limits—The setpoint limits are entered by the controls technician during

controller setup and system commissioning. Analog Value object

limits the lowest cooling setpoint and Analog Value object

the highest heating setpoint allowed regardless of the setting or entry of the user

space setpoint.

AI1. The Active and Standby setpoints are

Input sources on page 39.

AV11, STPT_MIN,

AV12, STPT_MAX, limits

Occupancy and

standby

Unoccupied setpoints—These setpoints are entered by the controls technician

during controller setup and system commissioning. Analog Value objects AV39 and

AV40, UNOCC_HTG_SP and UNOCC_CLG_SP, are the setpoints used when the

system is unoccupied.

Standby setpoint—Standby setpoints are used when the controller is in the standby

state. It is a value calculated from the current active setpoint and the value of Analog

Value object AV3, OFFSET. The standby offset value is entered by the controls

technician during controller setup and system commissioning. See the topic

Occupancy and standby on page 40.

The BAC-7000 VAV controllers have no internal programming to enable a change to

the occupancy or standby modes.

Occupancy—Binary Value object BV2, UNOCC, sets the state controller occupancy.

When the controller is in the occupied state, the active setpoint is calculated as

described in the topic

unoccupied state, either the cooling or heating unoccupied setpoint is used as the

active setpoint. The state of this object can be controlled by a schedule object, custom

Control Basic programming, or from another device on the building management

network.

Standby—The Binary Value object BV1, STANDBY, sets the state of standby or

occupied. When the controller is in the occupied standby state, the standby setpoint

is used as the active setpoint. The state of this object can be controlled by a schedule

object, custom Control Basic programming, or from another device on the building

management network.

Space setpoints on page 40. When the controller is in the

40

Revision C

Page 41

BAC-7000 VAV Installation, applications, and operation

guide

Sequences of operation

PID control loops

PID control loops

A PID control loop calculates an error value from the difference between a measured

input value and a setpoint value. The error value is expressed as a percentage and is

typically used in a BAS controller to control the state of an output. When the

difference between the setpoint and measured input is large, the error is large. As

the system reduces the difference between the setpoint and measured input, the

error becomes smaller.

The BAC-7000 series VAV controllers use three PID loops.

◆ The active setpoint loop, Loop object 1—This is a direct-acting loop. It

compares the room temperature to the active setpoint to determine the VAV

flow requirement. The output of the loop is a percentage passed to Analog

Value object AV16, LP1.

◆ The flow request loop, Loop object 2—This is a direct-acting loop. It compares

actual airflow in Analog Value object AV27, VOLUME1 to the requested flow in

Analog Value object AV25, RQSTFLOW. The output of the loop is passed to

Analog Value object AV17, LP2, and is used to calculate the movement of the

damper to control airflow.

◆ The heating loop, Loop object 3—This reverse acting loop compares room

temperature to Analog Value object AV29, HEAT_SP. The output of the loop is

passed to Analog Value object AV18, LP3, to calculate the call for reheat. See the

Reheat sequence on page 42 for a description of the reheat sequence.

topic

The PID loops in the controllers are standard BACnet objects and are listed in the

Loop objects on page 63.

topic

Pressure independent airflow sequence

Pressure dependent temperature control

Changeover

For pressure independent VAV installations, the airflow through the VAV terminal

unit is determined by Loop 1 and Loop 2 both of which are direct acting loops.

Loop object 1, a direct acting loop, compares the room temperature to the active

setpoint to determine a required change in temperature which is passed to Analog

Value object AV16, LP1. The value of LP1 is inverted if in heating mode and not

inverted for cooling and then passed to Analog Value object 25, RQSTFLOW, as the

setpoint reference property for Loop object 2. This is compared to the actual airflow.

The result is passed to Analog Value object AV17, LP2. LP2 is then used by the

damper routine to open or close the damper.

See also the topic, Damper operation on page 42.

For pressure dependent (bypass) control, only Loop object 1 is used to control

damper position.

Loop object 1, a direct acting loop, compares the room temperature to the active

setpoint to determine a required change in temperature. The temperature change is

stored in Analog Value object AV16, LP1. LP1 is then used by the damper routine to

open or close the damper.

The BAC-7000 VAV controllers are configured as cooling only controllers. The

controller can be commanded to heating from another controller connected to the

building management system network or by adding custom Control Basic

programming. Changeover from cooling to heating is controlled by the Binary Value

object BV3, HEATING.

Revision C

41

Page 42

Sequences of operation

Damper operation

KMC Controls

Damper operation

Fan operation

Reheat sequence

The damper position is calculated and then commanded to move through Analog

Output object AO4, MOTOR. When the output is commanded to 0 volts the motor

drives the damper counterclockwise, 10 volts drives the damper clockwise, and 5

volts stops the damper. Controller programming limits the motor run-time in either

direction to no longer than 6 minutes. See

page 41 or Pressure dependent temperature control on page 41 for a description of how

damper position is determined.

Damper position is indicated by Analog Value object 32, DMPR_POS. It is calculated

with programming by measuring the time the damper has been commanded open

or closed and comparing it to the time required for 90° rotation. It is not used as

feedback in the control sequence.

(Pressure Independent only) If the controller is configured for fan operation, the

controller will start the fan when there is a call for reheat. The fan starts when the

Reheat Setpoint loop is above 5% and stops 30 seconds after the reheat output is

turned off. See the topic

BAC-7000 VAV controllers simultaneously control modulating and On/Off reheat

outputs. All reheat is controlled by Loop object 3 which is described in the topic

control loops on page 41.

Binary Value object BV5, REHEAT, enables both modulating and On/Off reheat.

Reheat sequence on page 42.

Pressure independent airflow sequence on

PID

Modulating reheat The controller controls for modulating reheat with 0-10 volts

DC at Analog Output object AO1, ANALOG_HEAT. On a call for reheat, the reheat

output is modulated over the span of the Heating Setpoint loop. If the loop is less

than 5%, the reheat output remains at zero.

HTG %

100

Reheat loop%

5

0

Illustration 6-1 Modulating reheat operation

HTG SPAN

HTG SP

Room temp increase

42

Revision C

Page 43

BAC-7000 VAV Installation, applications, and operation

Off

On

Reheat

100%

50%

5%

HTG SP

HTG SPAN Room temp. increase

Heat loop increase

0%

guide

On/Off reheat When reheat is enabled, the controller turns on the Binary Output 2

when the output of Loop object 3 reaches 50%. The output will remain on until the

output of the loop falls below 5%.

Staged reheat options The BAC-7000 controllers do not directly support staged

reheat. Staged reheat can be added by connecting an external staging relay to the

modulating reheat analog output. See the section Applications for BAC-7000 series

VAV controllers on page 45 for adding the staging relay.

Sequences of operation

Balancing sequence

Illustration 6-2

Balancing

sequence

Balancing airflow is the process of calibrating the internal airflow sensor to a known

standard. In the field, airflow is measured with an airflow hood or other measuring

instrument and then compared to the airflow measurements from the sensor in the

controller. The balancing process uses a KMD-1161 NetSensor as the technicians

service tool for initiating the balancing sequence and entering actual flow

measurements.

When the balancing sequence starts, all other functions of the controller are locked

out.

At the start of the sequence, the technician uses the NetSensor to drive the damper

open until the airflow reaches the maximum airflow setpoint. An airflow

measurement is made with an airflow hood and the actual airflow value is entered

into the controller. Once the actual airflow is entered, the technician commands the

controller to drive the damper closed to the minimum airflow setpoint. Another

measurement is made with the flow hood and that measurement is entered into the

controller.

After both measurements are entered, the programming in the controller calculates

airflow correction factors which are used to adjust measurements from the internal

airflow sensor. Balancing is complete and the controller is returned to normal

operation.

Balancing automatically ends two hours after the last button is pushed.

For the procedure to use the balancing routine, see the section Balancing with a

NetSensor on page 35.

Revision C

43

Page 44

Sequences of operation

Balancing sequence

KMC Controls

44

Revision C

Page 45

BAC-7000 VAV Installation, applications, and operation guide

SECTION 7

Applications for BAC-7000 series VAV controllers

This section covers the drawings, materials, and instructions for

specific VAV applications.

Each BAC-7000 VAV model is designed for a specific set of applications. The

following topics are for control technicians and engineers that will design

installations and install the controllers

The application drawings in this section are supported by the programming

supplied in the BAC-7000 series VAV controllers. Both pressure independent and

pressure dependent (bypass) applications are supported.

◆ Pressure independent applications on page 46

◆ Pressure dependent applications on page 54

Revision C 45

Page 46

Applications for BAC-7000 series VAV controllers

Pressure independent applications

KMC Controls

Pressure

independent

applications

The following pressure independent applications and configurations are supported

by BAC-7000 series VAV controllers.

◆ BAC-7001 or BAC-7051 with reheat and parallel fan on page 46

◆ BAC-7001 or BAC-7051 with staged reheat and parallel fan on page 48

◆ BAC-7003 or BAC-7053 with reheat and parallel fan on page 50

◆ BAC-7003 or BAC-7053 staged reheat and parallel fan on page 52

For pressure dependent applications, see the topic Pressure dependent applications on

page 54.

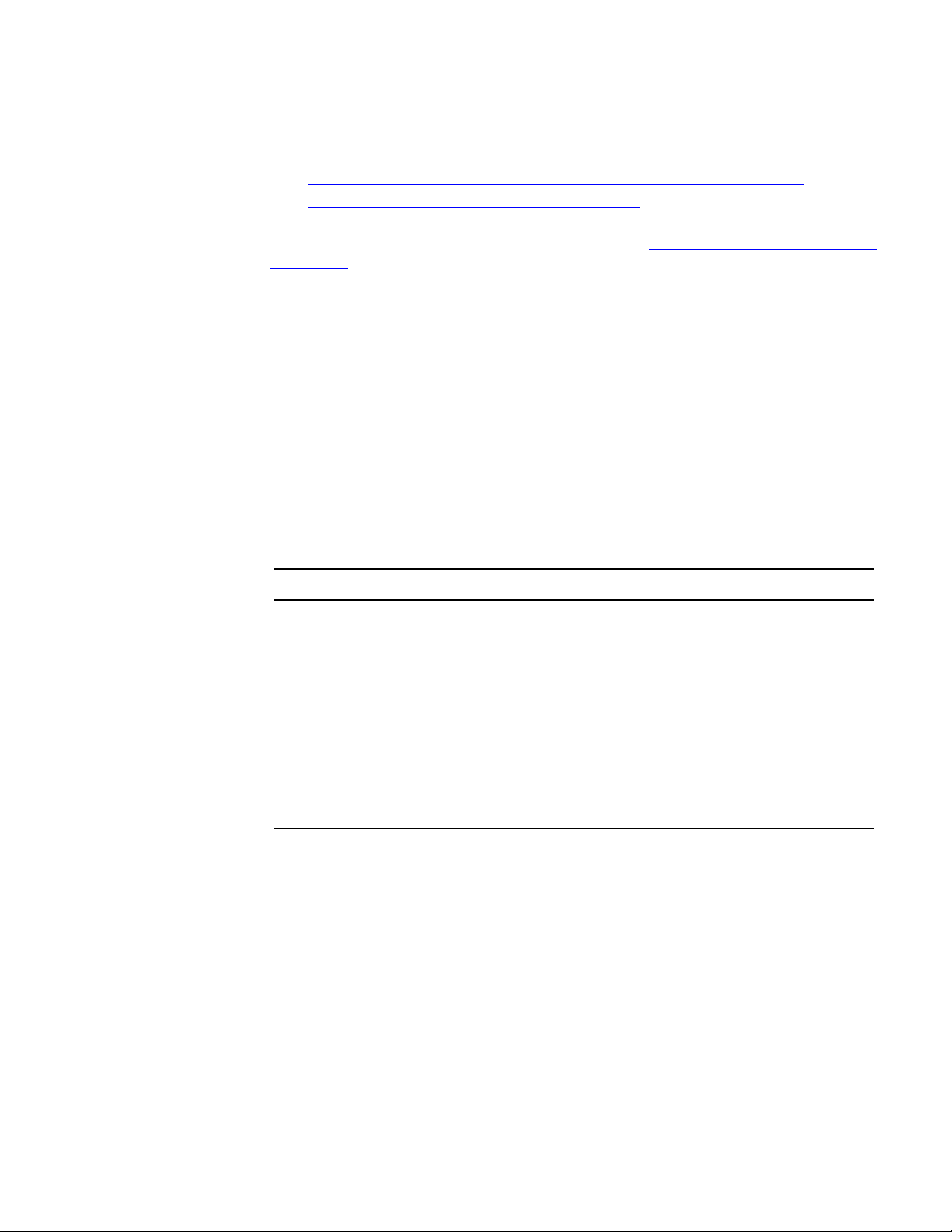

BAC-7001 or BAC-7051 with reheat and parallel fan

The standard programming in a BAC-7001 or BAC-7051 controller supports parallel

fan operation and On/Off reheat or modulating reheat. External relays are required

to switch the fan and On/Off reheat AC circuits.

◆ The fan output switches a relay for 24 volt AC pilot duty.

◆ The modulating option for reheat can control either an electric reheat unit with

an analog input or a modulating hot water valve. The analog reheat output at

output terminal AO1 varies between 0 and 10 volts DC.

◆ The On/Off reheat output switches a relay for 24 volt AC pilot duty.

For installation details, see the diagram Pressure independent BAC-7001 or BAC-7051

with reheat and parallel fan on page 47.

To configure the controller, see the topic Configuring for pressure independent VAV on

page 32.

Table 7-1 Bill of material for BAC-70x1 with reheat and parallel fan

REFERENCE PART # PART DESCRIPTION

DDC BAC-70X1 BACNET AAC FOR VAV, 3UI

AF SSS-100X AIRFLOW SENSOR, CHOOSE SIZE 'X' FROM DATA

SHEET

ST STE-60XX-10 CHOOSE 6011 OR 6014 SPACE TEMP SENSOR MODEL

ST-C KMD-569X TEMP SENSOR PLENUM CABLE W/CONN.

CHOOSE LENGTH

NS1 KMD-1161 NETSENSOR

FAN REE-3112 12VDC Control Relay

HT1 REE-3112 12VDC Control Relay

TX XEE-6311-50 Control Transformer, 120/240/277/480VAC-24VAC,

50VA

46

Revision C

Page 47

BAC-7000 VAV Installation, applications, and operation

guide

Applications for BAC-7000 series VAV controllers

Pressure independent applications

Illustration 7-1 Pressure independent BAC-7001 or BAC-7051 with reheat and parallel fan

Revision C

47

Page 48

Applications for BAC-7000 series VAV controllers

Pressure independent applications

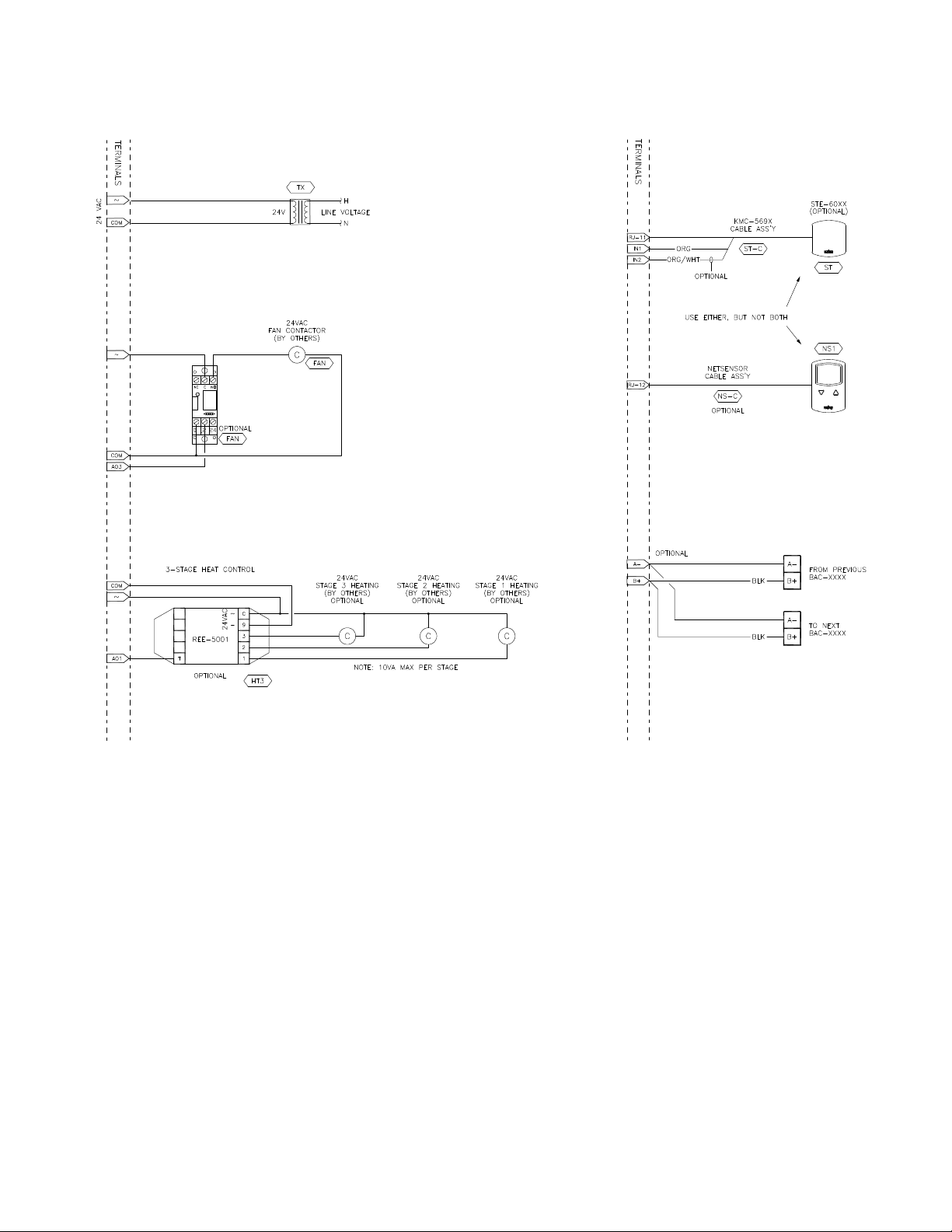

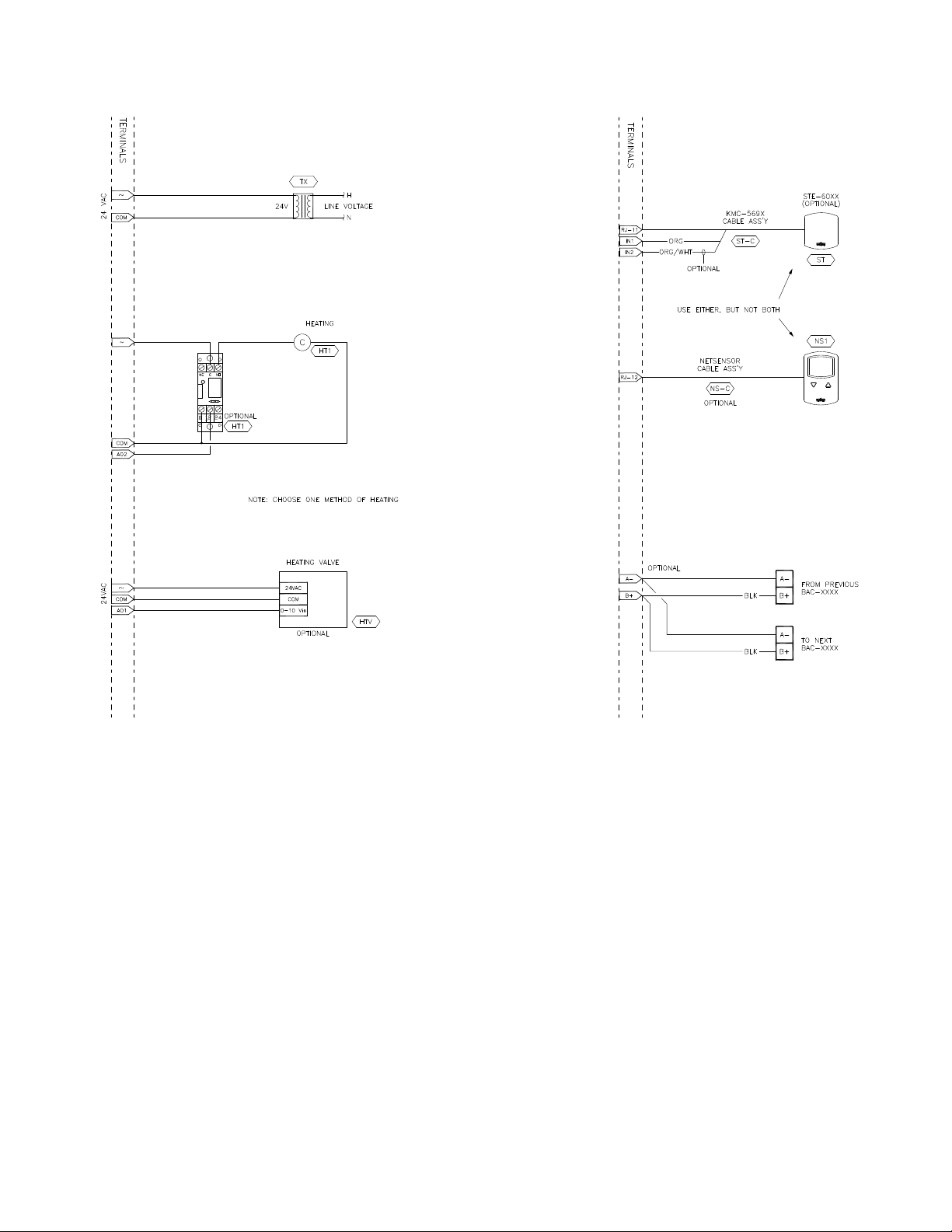

BAC-7001 or BAC-7051 with staged reheat and parallel fan

The standard programming in a BAC-7001 or BAC-7051 controller supports parallel

fan operation and staged reheat with the addition of a staging relay. An external

relay is also required for an AC fan circuit.

◆ The fan out relay switches a 24 volt AC pilot duty output.

◆ The analog reheat output at terminal AO1 varies between 0 and 10 volts DC to

control the staging relay.

For installation details, see the diagram Pressure independent BAC-7001 or BAC-7051

with staged reheat and parallel fan on page 49.

To configure the controller, see the topic Configuring for pressure independent VAV on

page 32.

Table 7-2 Bill of material for BAC-70x1 with staged reheat and parallel fan

REFERENCE PART # PART DESCRIPTION

DDC BAC-70X1 BACNET AAC FOR VAV, 3UI

ST STE-60XX-10 CHOOSE 6011 OR 6014 SPACE TEMP SENSOR MODEL

ST-C KMD-569X TEMP SENSOR PLENUM CABLE W/CONN.

AF SSS-100X AIRFLOW SENSOR, CHOOSE SIZE 'X' FROM DATA

NS1 KMD-1161 NETSENSOR

FAN REE-3112 12VDC Control Relay

HT3 REE-5001 3-STAGE RELAY CONTROLLER

TX XEE-6311-50 Control Transformer, 120/240/277/480VAC-24VAC,

KMC Controls

CHOOSE LENGTH

SHEET

50VA

48

Revision C

Page 49

BAC-7000 VAV Installation, applications, and operation

guide

Applications for BAC-7000 series VAV controllers

Pressure independent applications

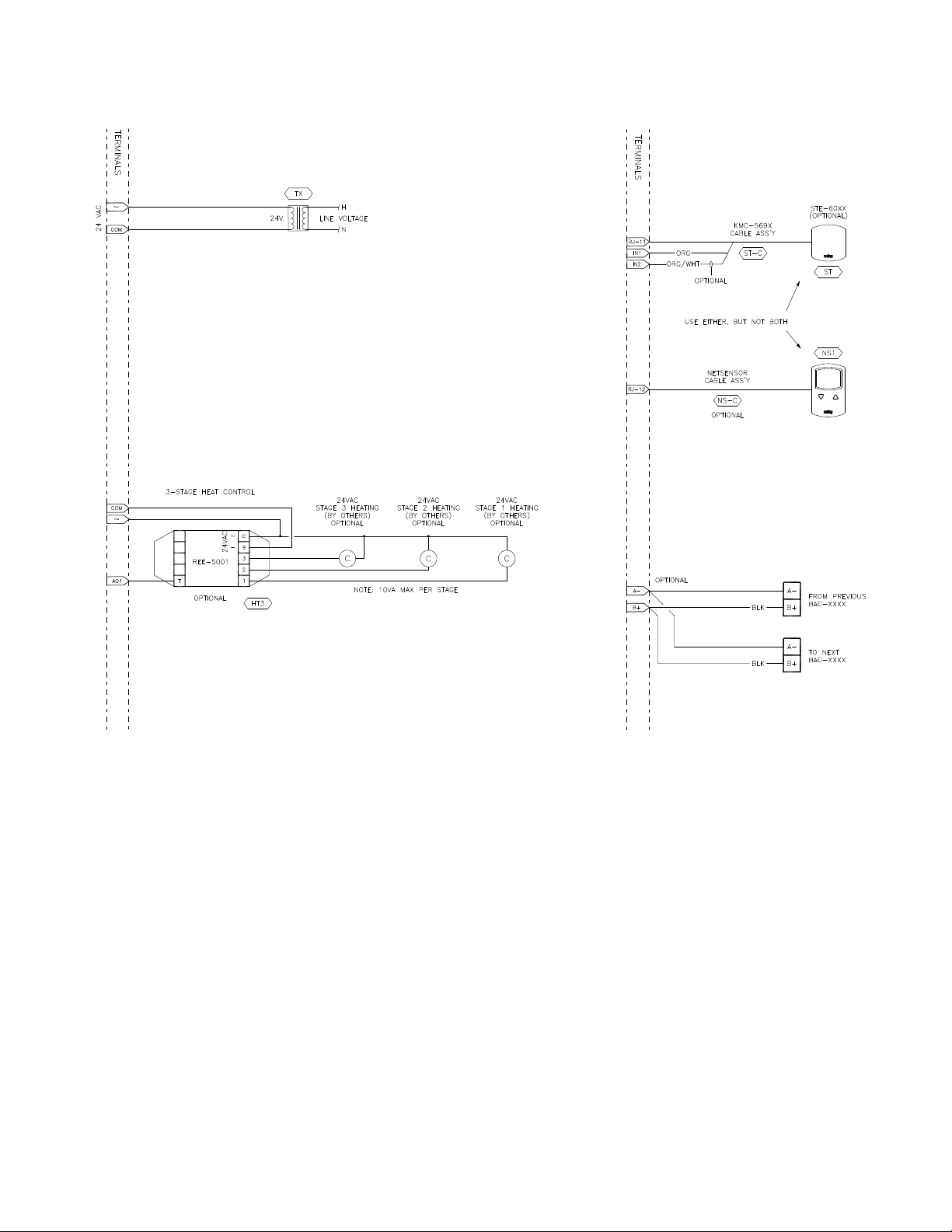

Illustration 7-2 Pressure independent BAC-7001 or BAC-7051 with staged reheat and parallel fan

Revision C

49

Page 50

Applications for BAC-7000 series VAV controllers

Pressure independent applications

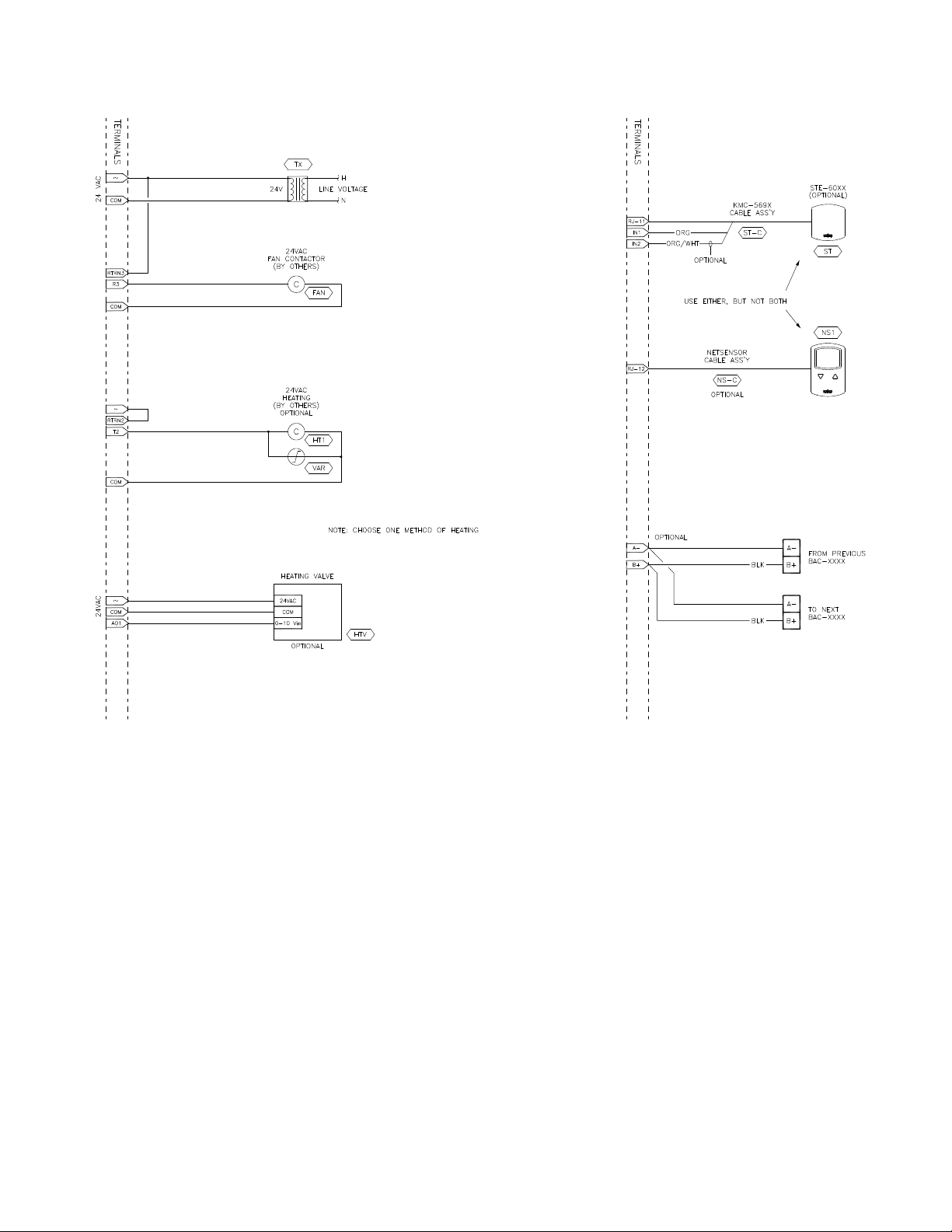

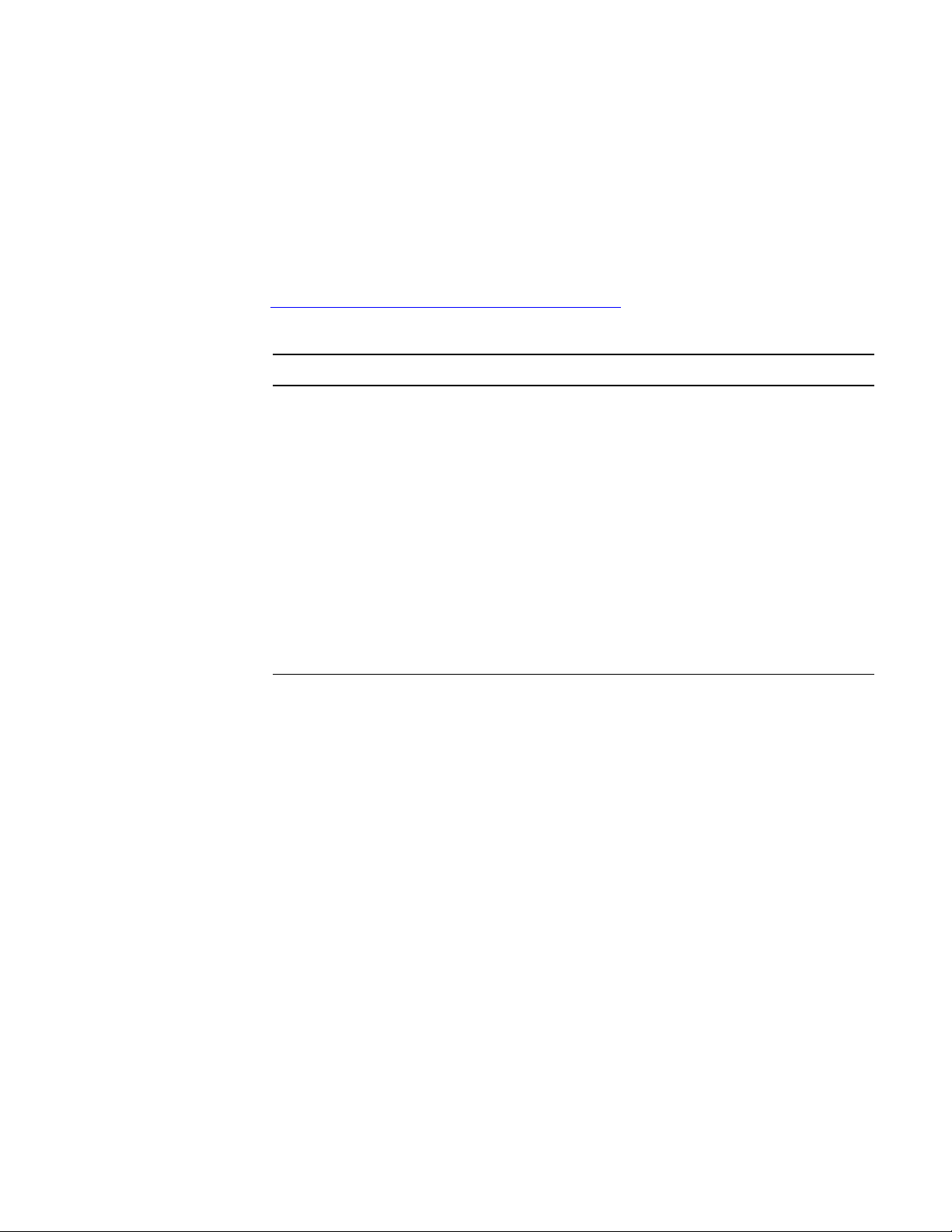

BAC-7003 or BAC-7053 with reheat and parallel fan

The standard programming in a BAC-7003 or BAC-7053 controller supports parallel

fan operation and On/Off reheat or modulating reheat. The BAC-7003 and

BAC-7053 controllers can directly control pilot duty switching for the fan and On/

Off reheat.

◆ The fan circuit is a 24 volt AC pilot duty output.

◆ The modulating option for reheat can control either an electric reheat unit with

an analog input or a modulating hot water valve. The analog reheat output at

output terminal AO1 varies between 0 and 10 volts DC.

◆ The On/Off reheat output is a 24-volt AC pilot duty output.

For connection details, see the diagram Pressure independent BAC-7003 or BAC-7053

with reheat and parallel fan on page 51.

To configure the controller, see the topic Configuring for pressure independent VAV on

page 32.

Table 7-3 Bill of materials for 70x3 with reheat and parallel fan

REFERENCE PART # PART DESCRIPTION

KMC Controls

DDC BAC-70X3 BACNET AAC FOR VAV, 1UI, 1 TRIAC, 1 N.O. RELAY

AF SSS-100X AIRFLOW SENSOR, CHOOSE SIZE 'X' FROM DATA

SHEET

ST STE-60XX-10 CHOOSE 6011 OR 6014 SPACE TEMP SENSOR MODEL

ST-C KMD-569X TEMP SENSOR PLENUM CABLE W/CONN.

CHOOSE LENGTH

AF SSS-100X AIRFLOW SENSOR, CHOOSE SIZE 'X' FROM DATA

SHEET

ST STE-60XX-10 CHOOSE 6011 OR 6014 SPACE TEMP SENSOR

MODEL

NS1 KMD-1161 NETSENSOR

TX XEE-6311-50 Control Transformer, 120/240/277/480VAC-24VAC,

50VA

50

Revision C

Page 51

BAC-7000 VAV Installation, applications, and operation

guide

Applications for BAC-7000 series VAV controllers

Pressure independent applications

Illustration 7-3 Pressure independent BAC-7003 or BAC-7053 with reheat and parallel fan

Revision C

51

Page 52

Applications for BAC-7000 series VAV controllers

Pressure independent applications

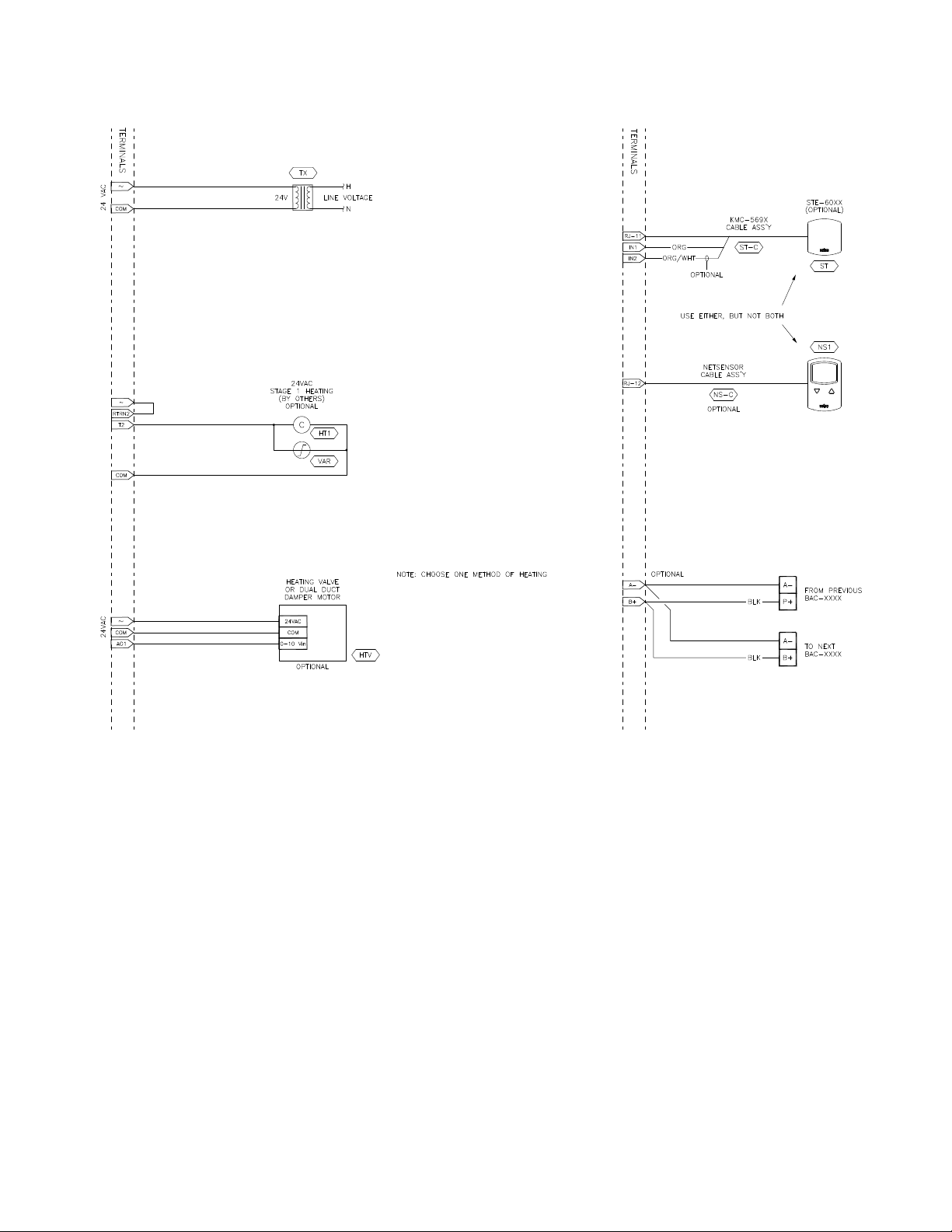

BAC-7003 or BAC-7053 staged reheat and parallel fan

The standard programming in a BAC-7003 or BAC-7053 controller supports parallel

fan operation and staged reheat with the addition of a staging relay. The BAC-7003

and BAC-7053 controllers can directly control pilot duty switching for the fan.

◆ The fan circuit is a 24 volt AC pilot duty output.

◆ The analog reheat output at terminal AO1 varies between 0 and 10 volts DC to

control the staging relay.

For connection details, see the diagram Pressure independent BAC-7003 or BAC-7053

with staged reheat and parallel fan on page 53.

To configure the controller, see the topic Configuring for pressure independent VAV on

page 32.

Table 7-4 Bill of material for BAC-70x1 with staged reheat and parallel fan

REFERENCE PART # PART DESCRIPTION

DDC BAC-70X3 BACNET AAC FOR VAV, 1UI, 1 TRIAC, 1 N.O. RELAY

ST STE-60XX-10 CHOOSE 6011 OR 6014 SPACE TEMP SENSOR MODEL

ST-C KMD-569X TEMP SENSOR PLENUM CABLE W/CONN.

AF SSS-100X AIRFLOW SENSOR, CHOOSE SIZE 'X' FROM DATA

NS1 KMD-1161 NETSENSOR

HT3 REE-5001 3-STAGE RELAY CONTROLLER

TX XEE-6311-50 Control Transformer, 120/240/277/480VAC-24VAC,

KMC Controls

CHOOSE LENGTH

SHEET

50VA

52

Revision C

Page 53

BAC-7000 VAV Installation, applications, and operation

guide

Applications for BAC-7000 series VAV controllers

Pressure independent applications

Illustration 7-4 Pressure independent BAC-7003 or BAC-7053 with staged reheat and parallel fan

Revision C

53

Page 54

Applications for BAC-7000 series VAV controllers

Pressure dependent applications

KMC Controls

Pressure

dependent

applications