Page 1

Installation, Operation, and Application Guide

for

AppStat™

BAC-4000 series controllers for

Fan Coil Units, Roof Top Units, and Heat Pump Units.

Revision G

Page 2

Installation, Operation, and Application Guide for AppStat

©2014, KMC Controls, Inc.

NetSensor, WinControl, and the KMC logo are registered trademarks of KMC

Controls, Inc.

AppStat, BACstage, FlexStat, FullBAC, TotalControl, SimplyVAV, and the

SimplyVAV logo are trademarks of KMC Controls, Inc.

All rights reserved. No part of this publication may be reproduced,

transmitted, transcribed, stored in a retrieval system, or translated into any

language in any form by any means without the written permission of KMC

Controls, Inc.

Printed in U.S.A.

The material in this manual is for information purposes only. The contents

and the product it describes are subject to change without notice. KMC

Controls, Inc. makes no representations or warranties with respect to this

manual. In no event shall KMC Controls, Inc. be liable for any damages, direct

or incidental, arising out of or related to the use of this manual.

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

U.S.A.

TEL: 1.574.831.5250

FAX: 1.574.831.5252

E-mail: info@kmccontrols.com

2 Revision G

Page 3

Installation, Operation, and Application Guide for AppStat Contents

C o n t e n t s

Contents 3

Section 1: Introduction to the AppStat 7

Specifications 8

Installation accessories 12

AppStat model numbers 13

Safety considerations 16

Section 2: Installing the AppStat 17

Planning for motion sensing 17

Mounting the AppStat 18

Rough-in preparation 19

Installing the AppStat 19

Connecting inputs 20

Remote space temperature sensor (optional) 20

Discharge air temperature sensor 21

Fan status switch (optional) 21

Water temperature sensor 22

Outside air temperature 23

Connecting outputs 24

Connecting to a three-speed fan 24

Connecting to a modulating fan 25

Connecting on/off valves 26

Connecting to modulating valves 27

Connecting an economizer 28

Connecting power 28

Maintenance 29

Section 3: User functions 31

Operating the AppStat 31

Entering a user password 34

Changing the active setpoints 35

Setting the operating modes 36

Section 4: Commissioning functions 39

Enter the commissioning mode 40

Setting the commissioning setpoints 41

Set up communications 43

Set the time and date 45

Setting the occupancy schedule 47

Set fan coil unit system options 50

Set roof top unit system options 53

Set heat pump unit system options 56

Revision G 3

Page 4

Contents KMC Controls, Inc.

Advanced options 60

Section 5: Sequences of operation 65

Room temperature setpoints 66

Types of setpoints 66

Setpoint limits 67

Occupancy, motion sensing, and standby 67

Automatic cooling and heating changeover 68

Scheduling occupancy 68

Dehumidification sequence 68

Fan status 68

Display blanking and backlight 69

Temperature sensing inputs 69

Space temperature sensing 69

Outside air temperature sensing 69

Water temperature sensor 69

Discharge air temperature sensor 70

PID control loops 70

Valve operation for fan coil units 70

On/Off valves 70

Modulating valves 71

Two-pipe water supply temperature evaluation 71

Electric heat for fan coil units 72

Fan operation for fan coil units 72

One, two, and three speed fans 72

Modulating fans 72

Automatic fan control 73

Modulating cooling and heating for Roof Top Units 73

Cooling 73

Heating 73

Valve action 73

Staged heating and cooling for for roof top and heat pump units 74

Staged cooling 74

Staged heating 74

Fan control for roof top and heat pump units 74

Economizer cooling for roof top and heat pump units 75

Heat pump unit specific functions 75

Reversing valve action 75

Auxiliary or emergency heat action 75

Section 6: Application drawings 77

Fan Coil Unit applications 78

Fan Coil Unit—Four-pipe with three-speed fan and on/off valves 78

Fan Coil Unit—Four-pipe with three-speed fan and modulating valves 80

Fan Coil Unit—Four-pipe with modulating fan and on/off valves 82

Fan Coil Unit—Four-pipe with modulating fan and modulating valves 84

4 Revision G

Page 5

Installation, Operation, and Application Guide for AppStat Contents

Fan Coil Unit—Two-pipe with three-speed fan and on/off valves 86

Fan Coil Unit—Two-pipe with three-speed fan and modulating valve 88

Fan Coil Unit—Two-pipe with modulating fan and on/off valve 90

Fan Coil Unit—Two-pipe with modulating fan and modulating valve 92

Fan Coil Unit—Two-pipe with three-speed fan, modulating valve, and electric heat 94

Fan Coil Unit—Two-pipe with modulating speed fan, modulating valve, and electric heat 96

Roof Top Unit applications 98

Roof Top Unit—Two-stage gas heat and two-stage DX cooling 98

Roof Top Unit—Two-stage gas heat and two-stage DX cooling with economizer 100

Roof top unit—Cooling and heating with modulating valves and economizer 102

Roof Top Unit—Two-stage gas heat, chilled water cooling with modulating valve and

economizer 104

Roof Top Unit—Two-stage DX cooling, hot water heating with economizer 106

Heat Pump Unit applications 108

Heat pump unit—Three heat, two cool 108

Heat Pump Unit—Three heat, two cool and economizer 110

Section 7: System integration 113

BACnet objects 114

Input objects 114

Output objects 115

Value objects 117

Schedule object 119

Loop objects 119

Connecting to an MS/TP network 121

Index 125

Revision G 5

Page 6

Contents KMC Controls, Inc.

6 Revision G

Page 7

Installation, Operation, and Application Guide for AppStat

Sec tion 1: Introductio n to t h e A ppSt at

This section provides a description of the BAC-4000 series of controllers

KMC Controls, Inc.. It also introduces safety information. Review this

material before installing or operating the controllers.

The BAC-4000 series of controllers are space mounted devices that combine a

BACnet controller with temperature, humidity and motion sensors. The

controllers include programs for the following applications.

Roof top units, both single or multi-stage, or similar split or unitary

packaged systems

Heat pumps

Two and four pipe fan coil units

The AppStat controllers are native BACnet, Application Specific Controllers.

BACnet communication parameters, device instance, MAC address, baud rate,

room occupant adjustments, and application configuration values are set from

password protected front panel controls.

All models feature an integrated BACnet schedule and hardware real-time

clock with 72-hour capacitor backup for standalone operation or network

time synchronization.

A two-piece mechanical design, featuring a removable backplate, facilitates

easy wiring and installation.

Revision G 7

Page 8

Section 1: Introduction to the AppStat KMC Controls, Inc.

Specifications

AppStat specifications are subject to change without notice.

User Interface

The user interface is a color display and with five push buttons. Through the

menu driven display, an operator can do the following.

Add or change user passwords

Change setpoints

Set BACnet addressing

Set up and commission the installation

Configure any available options

Security

Separate passwords for users and controls technicians.

Display type

128 × 128 pixels

Active color LCD with LED back lighting

1.00 x 1.04 inches (25 x 26 mm)

Inputs and outputs

All inputs and outputs are preprogrammed and application specific. No field

configuration is required for most installations. For details on input and

output connections see the section Application drawings on page 77.

Analog inputs

Analog inputs represent BACnet analog input objects and are configured

for discharge air temperature, remote temperature sensor, water

temperature sensor, and fan status. Not all input sensors are applicable or

required for all models.

Sensors are automatically detected.

Inputs accept industry-standard 10,000 Ω, Type II or Type III thermistors

sensors.

Input overvoltage protection up to 24 volts AC, continuous.

12-bit analog-to-digital conversion

Analog outputs

Analog outputs are configured to represent BACnet analog objects. The

outputs control modulating valves, variable speed fans, damper positions

or other equipment that requires a proportional input signal.

8 Revision G

Page 9

Installation, Operation, and Application Guide for AppStat Section 1: Introduction to the AppStat

Short-circuit protected

Loads up to 10 mA at 0–12 volts DC

8-bit PWM digital-to-analog conversion

Relay outputs

Relay outputs are configured to represent BACnet binary objects. The

outputs control on/off valves, speeds for three-speed fans, fan start circuits,

or other equipment that requires an on or off input signal.

All relay outputs are normally open, SPST, Form “A” relays

1 Ampere maximum per relay at 24 volts AC or DC for each output.

Maximum for all relay outputs is 3 amperes (72VA).

Connectors

Screw terminal block mounted to backplate

Wire size 14-22 AWG

Communications—BACnet MS/TP

Integral peer-to-peer BACnet MS/TP network communications.

Network speeds from 9600 to 76,800 baud.

Front panel configurable device instance, MAC address, and baud.

Automatic baud detection.

Screw terminal block mounted to backplate. Wire size 14–22 AWG

Meets or exceeds ANSI/ASHRAE BACnet Standard 135-2008 for

Application Specific Controllers

Accuracy–temperature only models

Type Thermistor

Accuracy ±0.36° F (±0.2° C)

Resistance 10,000 Ω at 77° F (25° C)

Operating range 48 to 96° F (8.8 to 35.5° C)

Accuracy–temperature and humidity models

Temperature Sensor

Type CMOS

Accuracy ±0.9° F offset (±0.5° C) from 40° to 104° F

(4.4 to 40° C)

Resolution ±0.1°F (±0.1° C)

Operating range 36 to 120° F (2.2 to 48.8° C)

Response time 5 to 30 seconds

Revision G 9

Page 10

Section 1: Introduction to the AppStat KMC Controls, Inc.

Humidity Sensor

Type CMOS

Humidity 0 to 100% RH

Accuracy at 25° C ± 2% RH from 10 to 90% RH

Response time 4 seconds or less

Regulatory

UL 916 Energy Management Equipment

FCC Class A, Part 15, Subpart B and complies with Canadian ICES-003

Class B

BACnet Testing Laboratory listed as an application specific controller

SASO PCP Registration KSA R-103263

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference,

and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Environmental limits

Operating 32 to 120° F (0 to 49° C)

Shipping –40 to 140° F (–40 to 60° C)

Humidity 0–95% relative humidity

(non-condensing)

Installation

Supply voltage 24 volts AC (–15%, +20%), 50-60 Hz, 12 VA, Class 2

only, non-supervised.

All circuits, including supply voltage, are power

limited circuits.

Weight Approximately 6 ounces (170 grams)

Case material Flame retardant plastic

10 Revision G

Page 11

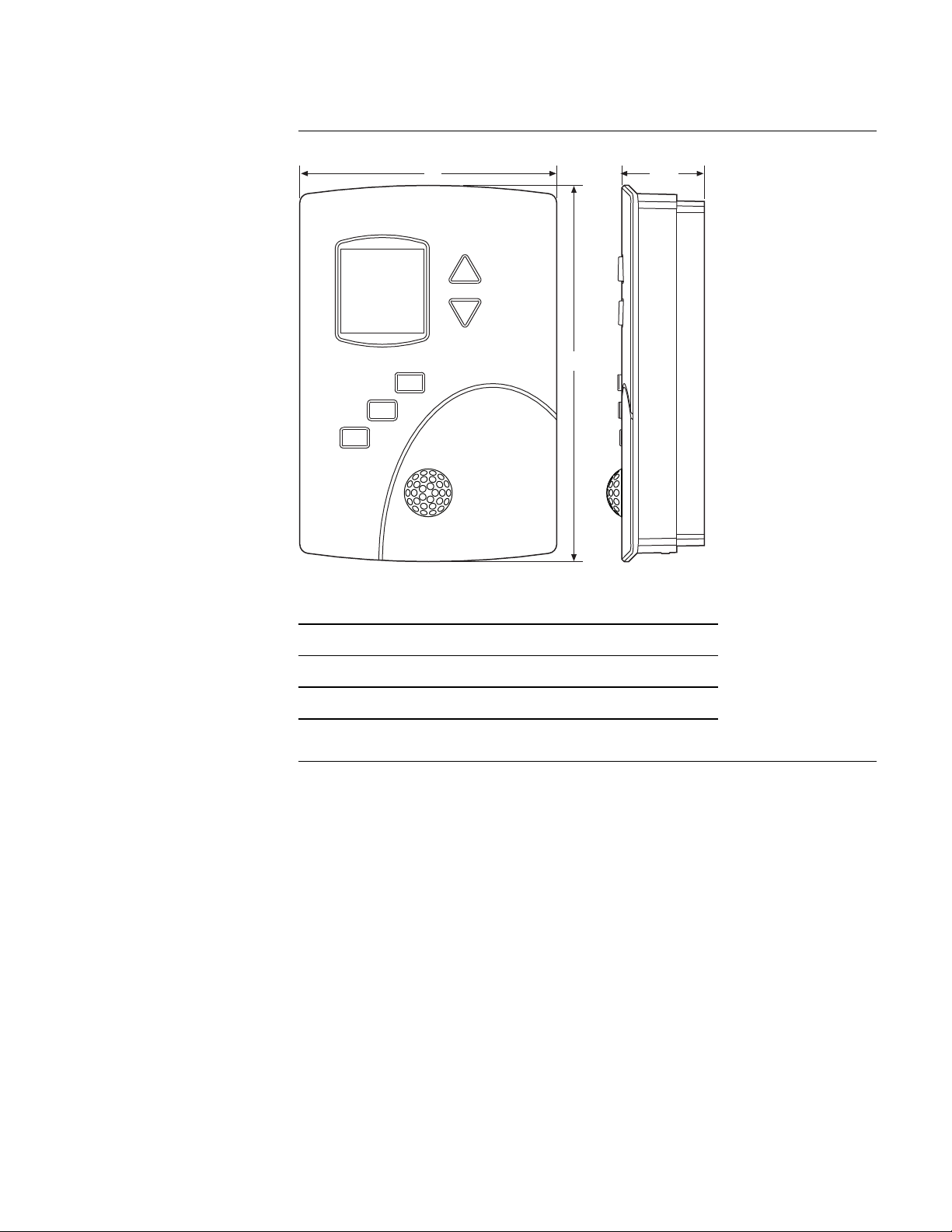

A

B

C

Installation, Operation, and Application Guide for AppStat Section 1: Introduction to the AppStat

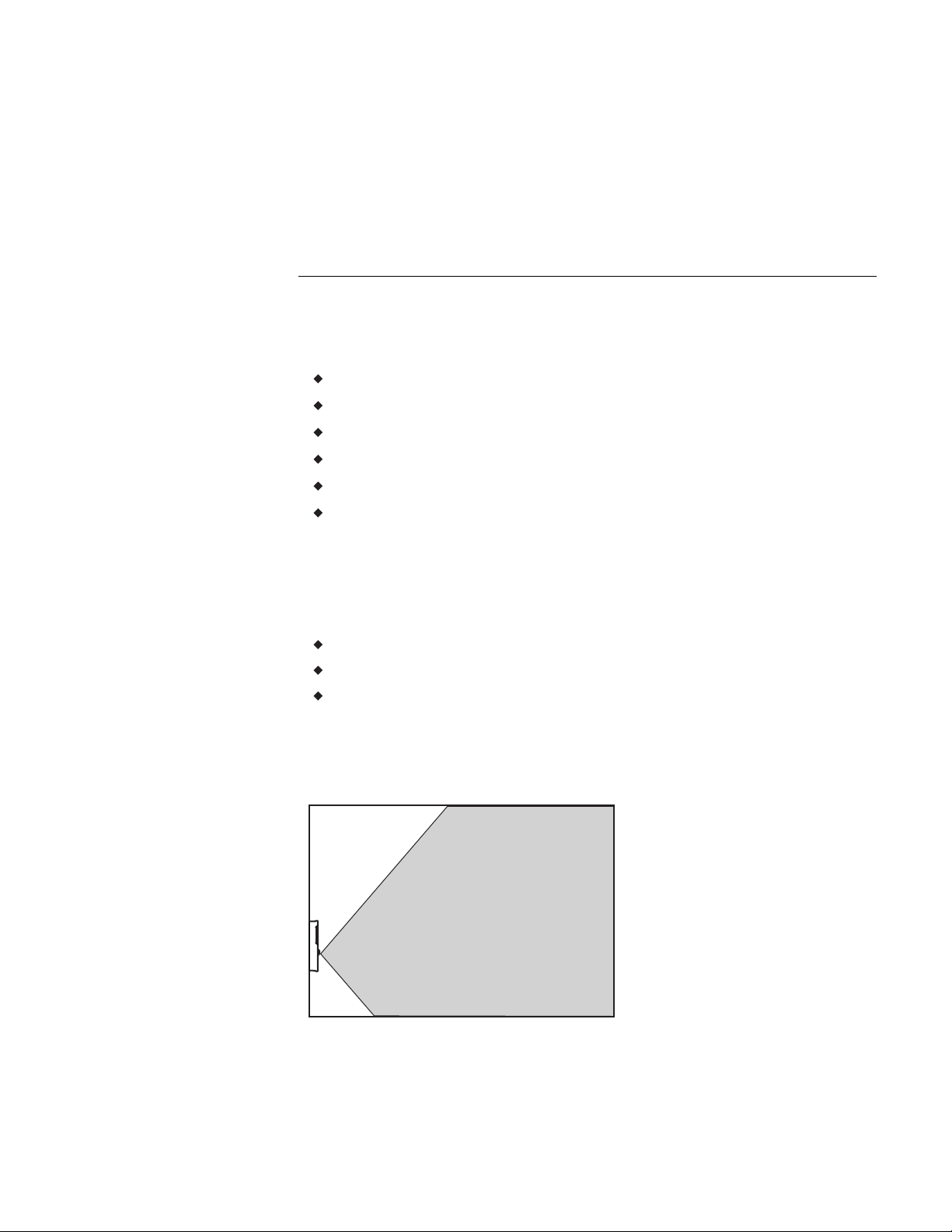

Dimensions

Table 1–1 AppStat Dimensions

A B C

3.50 in. 5.12 in. 1.12 in.

89 mm 130 mm 29 mm

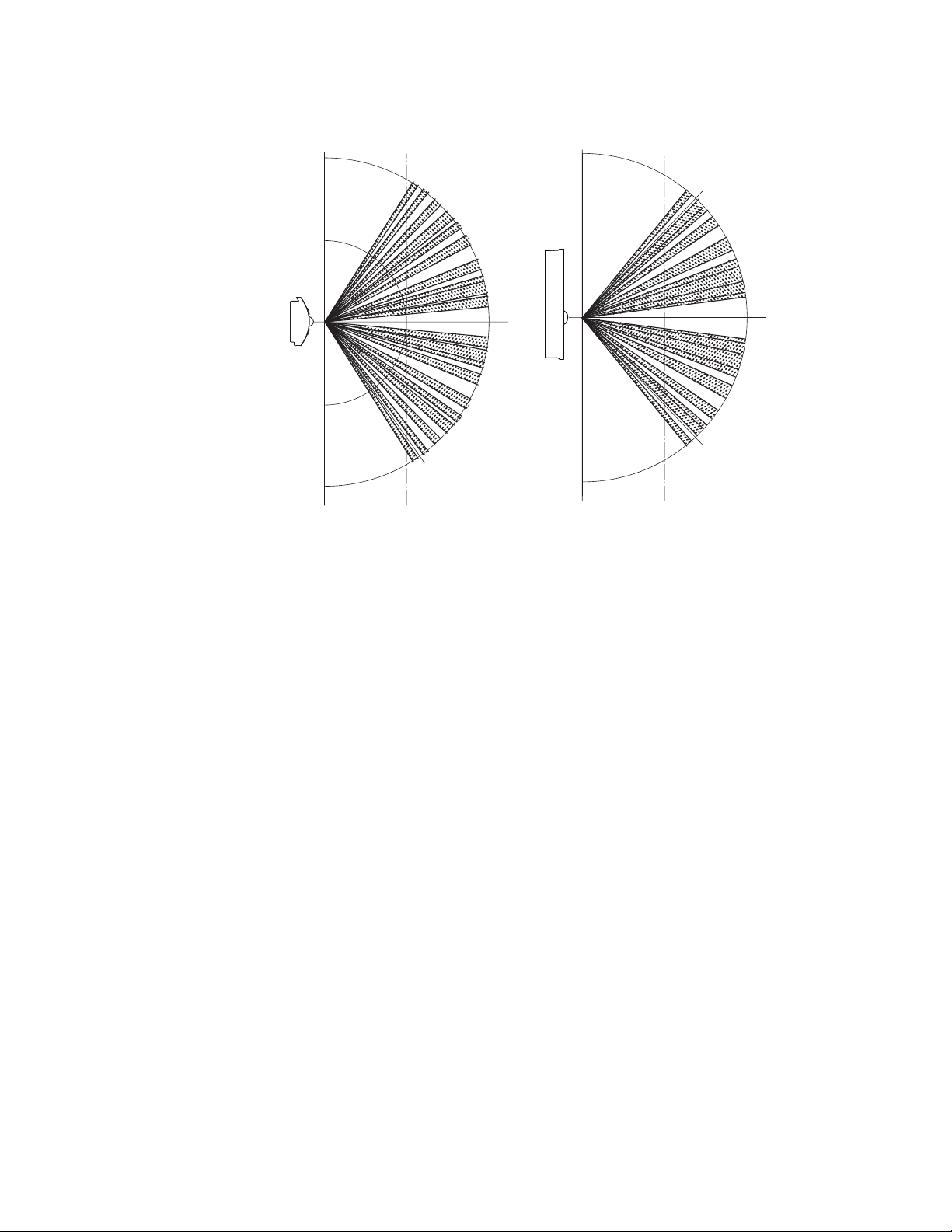

Motion sensor

Motion sensors are options available only on select models.

Detector type Passive infrared

Range 33 feet (10 meters). See the following

diagrams.

Revision G 11

Page 12

10 m

32.8 ft

10 m

32.8 ft

0°

46.5

°

Y

55

°

10 m

32.8 ft

10 m

32.8 ft

X

0°

Side viewTop view

Section 1: Introduction to the AppStat KMC Controls, Inc.

Installation accessories

The following accessories are available from KMC Controls, Inc.

XEE-6111-040 Single-hub 120 volt power transformer

XEE-6112-040 Dual-hub 120 volt power transformer

XEE-6311-075 120/240/277/480VAC, 24 VAC, 75 VA transformer

HMO-10000W White mounting plate kit for retrofit on horizontal

boxes or 4 x 4 handy boxes

12 Revision G

Page 13

BAC-4 _ _ _ CW0001

1 3-speed fan, On/off valves

2 3-speed fan, Modulating valves

3 3-speed or modulating fan,

modulating or On/Off valves

7 Modulating fan, On/Off valves

8 Modulating fan, Modulating Valves

0 Without humidity

2 With humidity

0 Without motion

2 With motion

Installation, Operation, and Application Guide for AppStat Section 1: Introduction to the AppStat

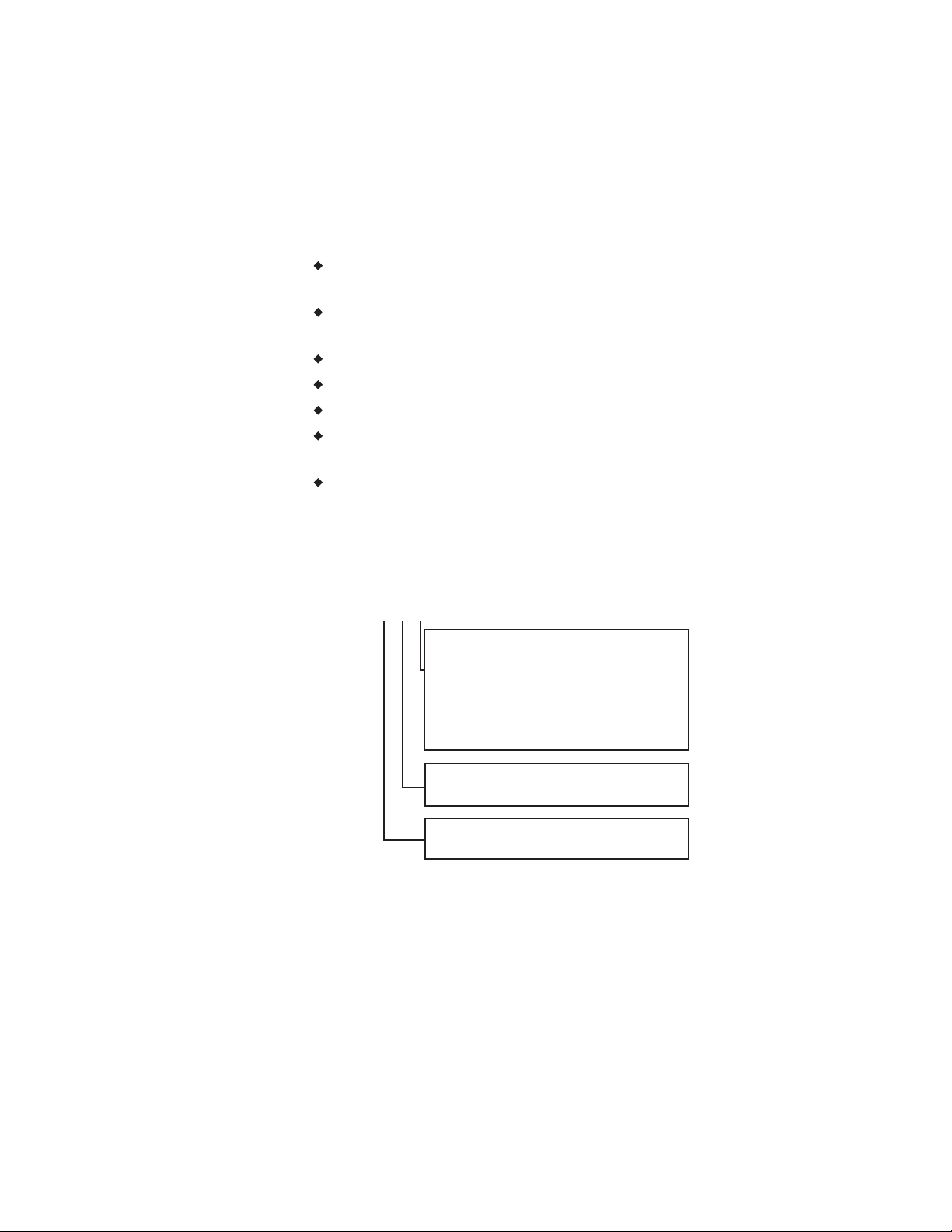

AppStat model numbers

Use the following charts to identify features in a specific AppStat model.

Fan coil units—The model numbers for these controllers end with "0001".

The inputs, outputs, and sequences of operation are configured and

programmed for the following functions.

Two-pipe heating and cooling with on/off valves, modulating valves or

both

Four-pipe heating and cooling with on/off valves, modulating valves or

both

Three-speed or modulating fan control

Automatic or manual fan control

Remote space temperature sensor

Local temperature setback mode based on optional built-in motion

sensor

Dehumidification on models with humidity sensor

See the following chart for the specific features included with each model.

Illustration 1–1 Model numbers for fan coil units

Revision G 13

Page 14

BAC-4 _ _ _ CW0002

1

2H/2C On/off valves or stages

3 2H/2C On/off or modulating valves

and economizer

0 Without humidity

2 With humidity

0 Without motion

2 With motion

Section 1: Introduction to the AppStat KMC Controls, Inc.

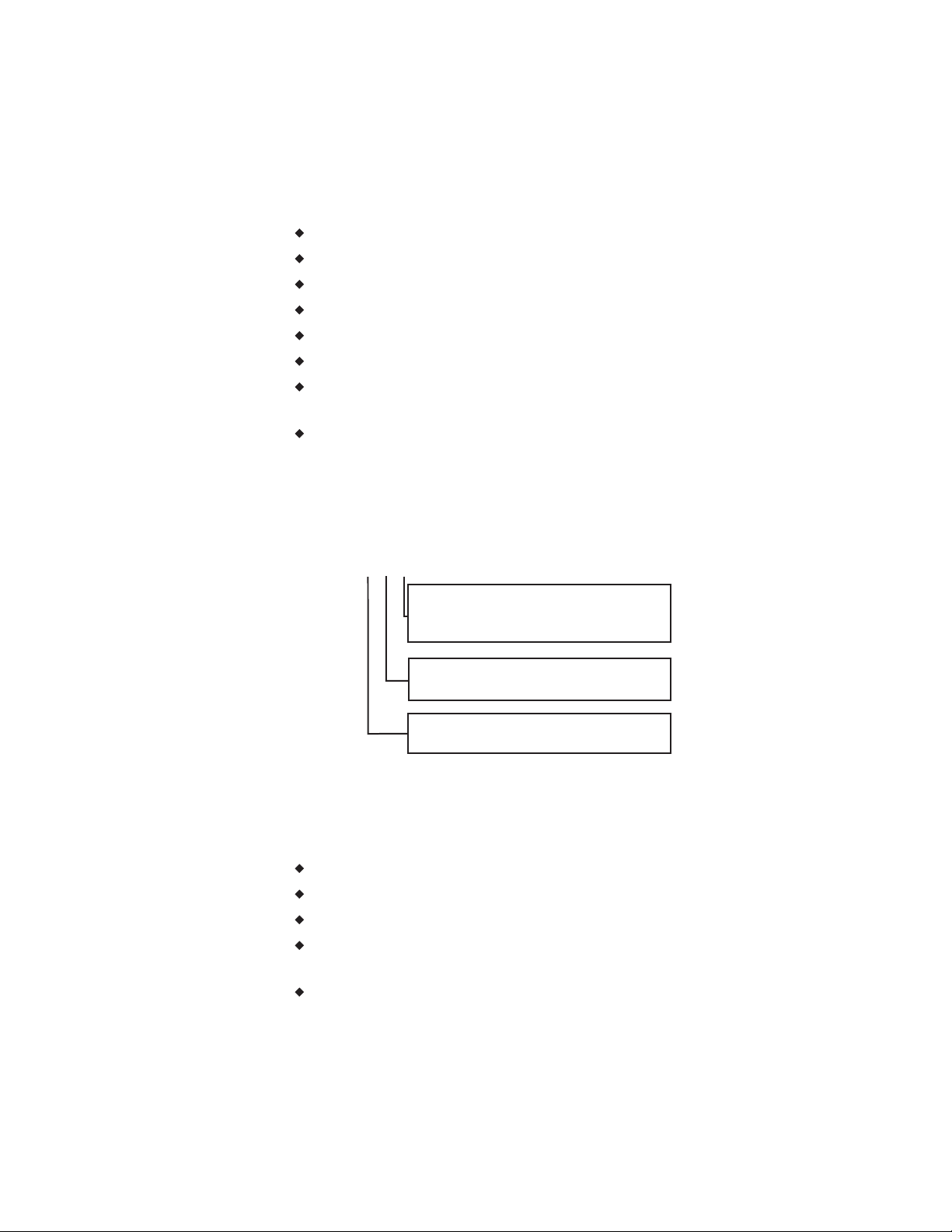

Roof top units—The model numbers for these controllers end with "0002".

These models control roof top or similar packaged or split unitary units. The

inputs, outputs, and sequences of operation are configured and programmed

for the following functions.

Automatic or manual fan control

Modulating valves or on/off heating and cooling valves.

One or two stage heating

One or two stage cooling

Optional economizer

Remote space temperature sensor

Local temperature setback mode based on optional built-in motion

sensor

Dehumidification on models with humidity sensor

See the following chart for the specific features included with each model.

Illustration 1–2 Model numbers for roof top units

14 Revision G

Heat pump units—The model numbers for these controllers end with "0003".

The inputs, outputs, and sequences of operation are configured and

programmed for the following functions.

Two stages of heat and two stages of cooling plus auxiliary heat

Optional economizer

Dehumidification-in models with auxiliary heat and a humidity sensor

Local temperature setback mode based on optional built-in motion

sensor

Automatic or manual fan control

Page 15

BAC-4 _ _ _ CW0003

1

3H/2C

3 3H/2C and economizer

0 Without humidity

2 With humidity

0 Without motion

2 With motion

Installation, Operation, and Application Guide for AppStat Section 1: Introduction to the AppStat

See the following chart for the specific features included with each model.

Illustration 1–3 Model numbers for heat pump units

Revision G 15

Page 16

Danger

Warning

Caution

Section 1: Introduction to the AppStat KMC Controls, Inc.

Safety considerations

KMC Controls, Inc. assumes the responsibility for providing you a safe

product and safety guidelines during its use. Safety means protection to all

individuals who install, operate, and service the equipment as well as

protection of the equipment itself. To promote safety, we use hazard alert

labeling in this manual. Follow the associated guidelines to avoid hazards.

Danger represents the most severe hazard alert. Bodily

harm or death will occur if danger guidelines are not

followed.

Warning represents hazards that could result in severe

injury or death.

Caution indicates potential personal injury, equipment

damage, or property damage if instructions are not followed.

Note: Notes provide additional information that is important.

Tip: Provides programing tips and shortcuts that may save time.

16 Revision G

Page 17

Installation, Operation, and Application Guide for AppStat

Sec tion 2: Installing the AppS tat

This section provides important instructions and guidelines for installing

the AppStat. Carefully review this information before installation begins.

Installing the sensors includes the following topics that are covered in this

section.

Planning for motion sensing on page 17

Mounting the AppStat on page 18

Connecting inputs on page 20

Connecting outputs on page 24

Connecting power on page 28

Maintenance on page 29

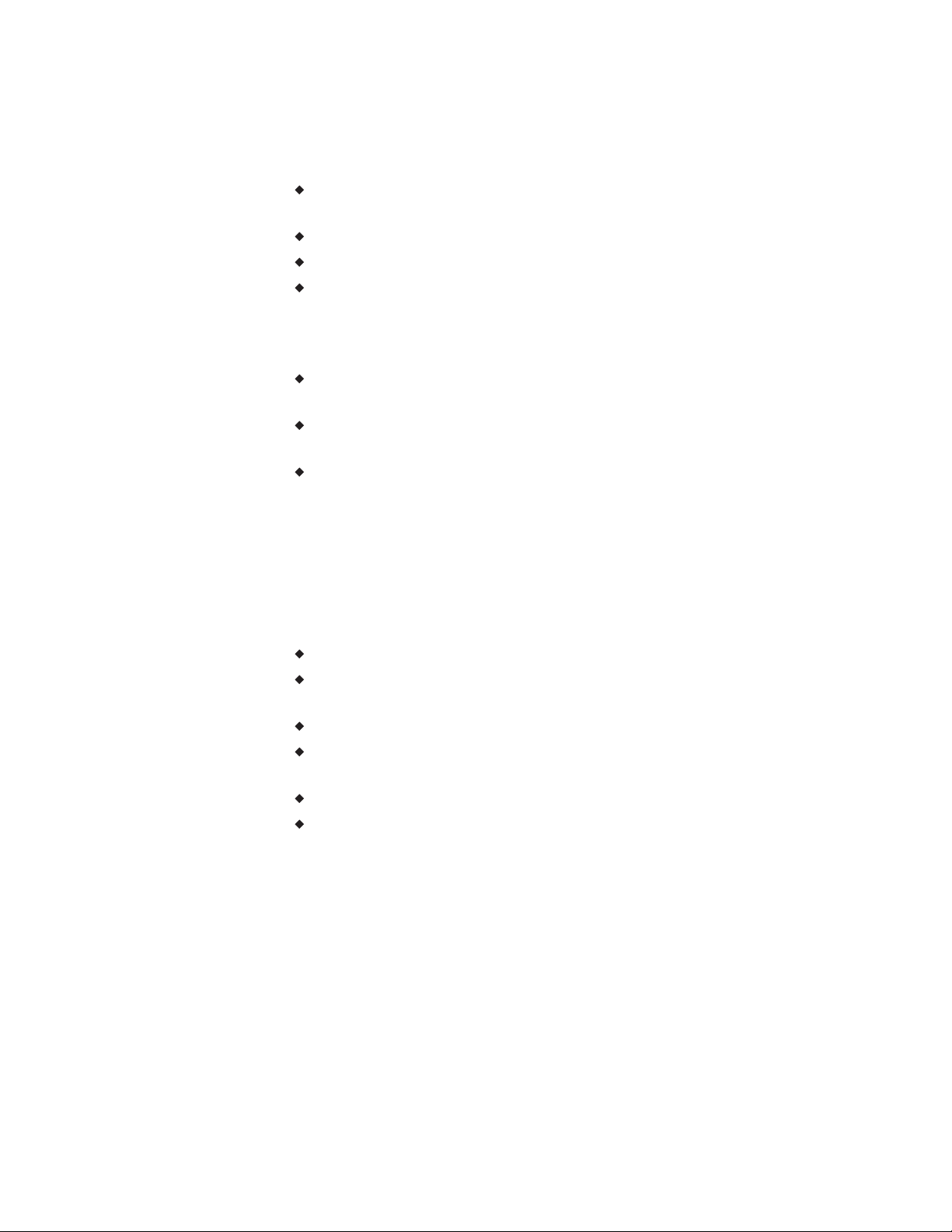

Planning for motion sensing

For models with a motion sensor mount the AppStat on a wall that will have

an unobstructed view of the typical traffic in the coverage area. When

choosing a location, do not install the sensor in the following areas.

Behind curtains or other obstructions

In locations that will expose it to sunlight or heat sources

Near a heating or cooling inlet or outlet.

For details on the coverage pattern, see Specifications on page 8.

Illustration 2–1 Typical motion sensing coverage area

Revision G 17

Page 18

Section 2: Installing the AppStat KMC Controls, Inc.

The effective detection range is approximately 10 meters or 33 feet. Factors

that may reduce the range include:

The difference between the surface temperature of the object and the

background temperature of the room is too small.

Object movement in a direct line toward the sensor.

Very slow or very fast object movement.

Obstructions as shown in the illustration Typical motion sensing coverage

area on page 17.

False detections may be triggered by:

The temperature inside the detection range suddenly changes because of

the entry of cold or warm air from an air-conditioning or heating unit.

The sensor being directly exposed to sunlight, an incandescent light, or

other source of far-infrared rays.

Small animal movement.

Mounting the AppStat

For the most accurate performance, install the AppStat on an inside wall

where it can sense the average room temperature. Avoid locations with direct

sunlight, heat sources, windows, air vents, and air circulation or obstructions

such as curtains, furniture, etc.

The AppStat must not be:

Mounted on an exterior wall.

Mounted on or near an object with large a thermal mass such as a

concrete block wall.

Blocked from normal air circulation by obstructions.

Exposed to heat sources such as lights, computers, copiers, or coffee

makers, or to direct sunlight at any time of the day.

Exposed to drafts from windows, diffusers, or returns.

Exposed to air flow through connecting conduits or empty spaces behind

walls.

For models with motion sensing, see the topic, Planning for motion sensing.

18 Revision G

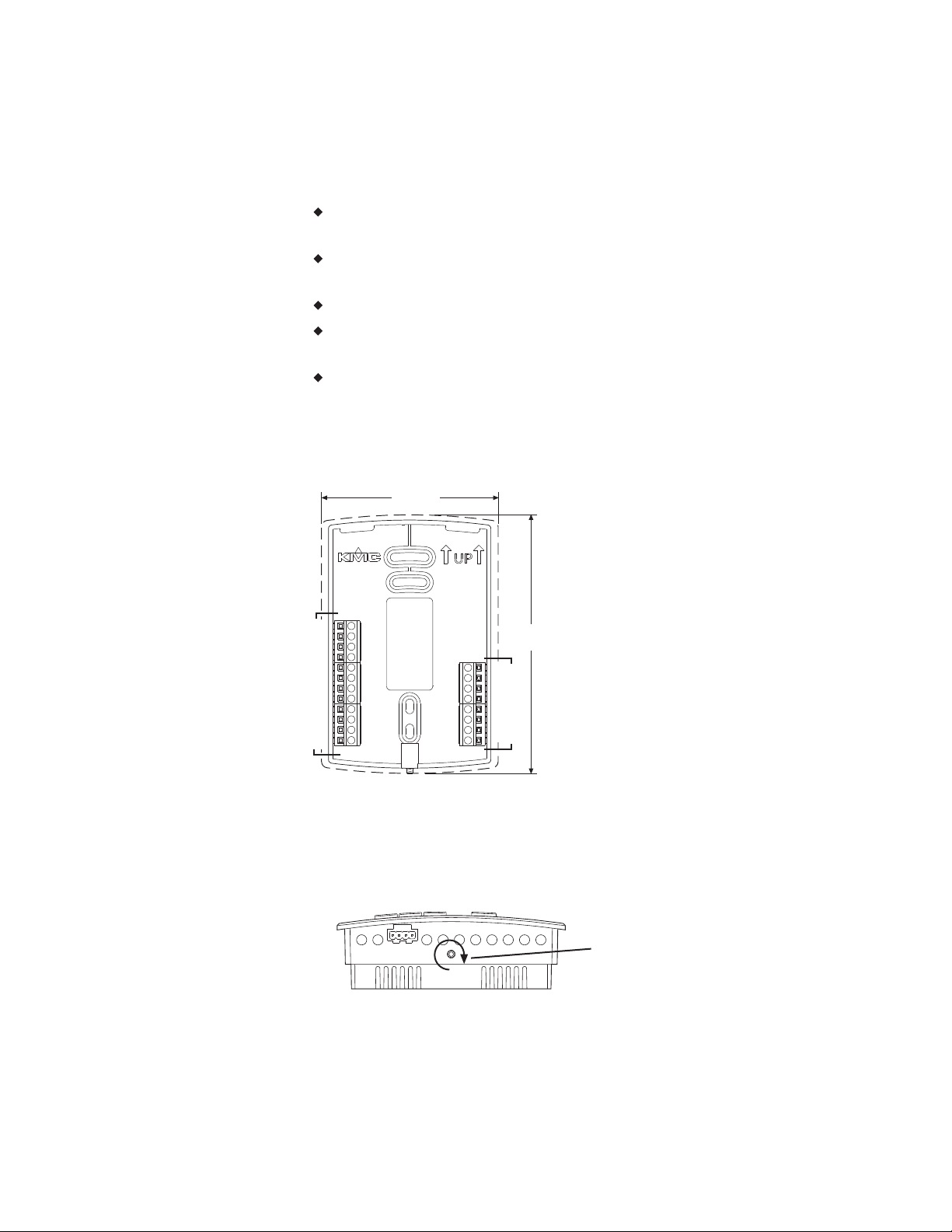

Page 19

A

5.12 in.

130 mm

3.50 in.

89 mm

Inputs and

network

Power and outputs

Turn clockwise to remove

from base.

Installation, Operation, and Application Guide for AppStat Section 2: Installing the AppStat

Rough-in preparation

Complete rough-in wiring at each location before mounting an AppStat. This

includes the following steps.

Install the supplied mounting base directly to a wall, a vertical electrical

box, or a box with a wall plate kit.

Routing the connecting cable or cables from the AppStat to the

equipment it is controlling.

If required, install an appropriate wall plate kit.

Block leaks and airflow from conduits with plumber’s putty or similar

material.

If replacing an existing thermostat, label existing wires for reference

when removing the existing thermostat.

Illustration 2–2 AppStat mounting base details

Installing the AppStat

To install the controller on a mounting base, do the following:

1. Turn the Allen screw in the base of the sensor clockwise until it clears

the case.

2. Swing the AppStat away from the mounting base to remove it.

3. Route wiring for the AppStat through the mounting base.

Revision G 19

Page 20

Turn counterclockwise

until the screw engages

the base.

Caution

Section 2: Installing the AppStat KMC Controls, Inc.

4. Position the base with the embossed UP toward the ceiling and fasten it

directly to a vertical 2x4 inch electrical box. For horizontal boxes or

4x4 applications, use a wall plate kit. See Installation accessories on page

12 for part numbers.

5. Connect the wires for the AppStat to the terminals in the mounting base.

6. Place the top of the sensor over the top of the mounting base and swing

it down over the Allen screw bracket. Be careful not to pinch any wiring.

7. Turn the Allen screw counterclockwise until it backs out of the mounting

base and engages the case.

To prevent mounting screw heads from touching the circuit

board in the controller, use only the mounting screws

supplied with the controller. Using screws other than the

type supplied may damage the AppStat.

Connecting inputs

The inputs for the AppStat are configured for specific functions and do not

require set up in the field. Not all inputs are required for every model or

application. See the topic BACnet objects on page 114 for the configuration

properties of the input objects.

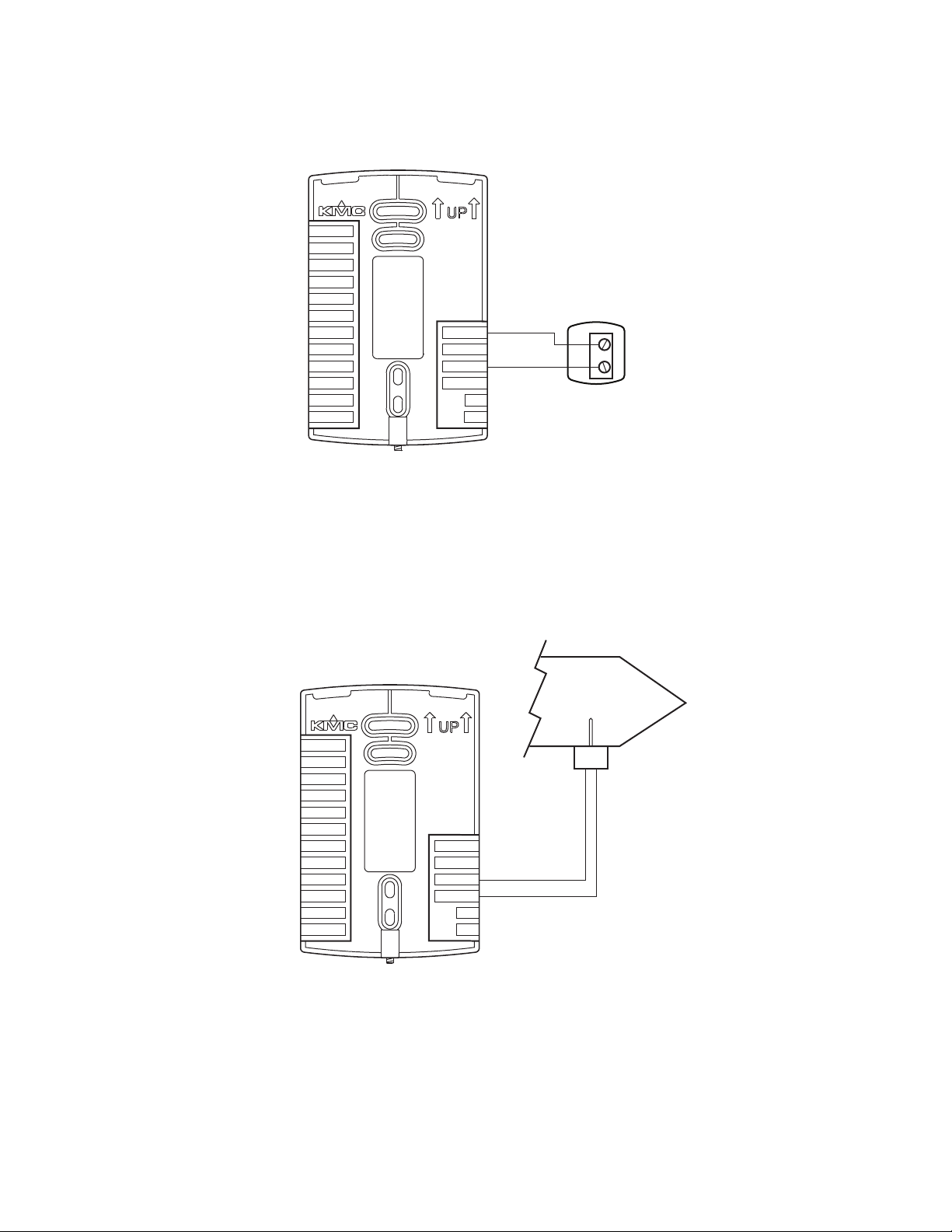

Remote space temperature sensor (optional)

Connect a 10kΩ, TypeII thermistor temperature sensor to the remote space

temperature (RS) input and ground (GND) terminals. The input includes the

internal pull-up resistor. An STE-6011W10 sensor is suitable for this

application. Follow the instructions supplied with the sensor for installation.

When a remote space temperature input is connected to the AppStat, the

remote temperature is used instead of the internal temperature sensor.

20 Revision G

Page 21

STE-6011W10

or equivalent

MS/TP

+B

A

RS

WST

GND

DAT

COM

FAN-L

FAN-M

FAN-H

R

BO4

BO5

GND

AO6

AO8

AO7

24VAC

STE-1405 or

equivalent

DAT

MS/TP

+B

A

RS

WST

GND

DAT

COM

FAN-L

FAN-M

FAN-H

R

BO4

BO5

GND

AO6

AO8

AO7

24VAC

Installation, Operation, and Application Guide for AppStat Section 2: Installing the AppStat

Illustration 2–3 Wiring for remote space temperature sensor

Discharge air temperature sensor

Connect a 10kΩ, Type III thermistor temperature probe to the discharge air

temperature (DAT) input. The input includes the internal pull-up resistor. An

STE-1405 sensor is suitable for this application. Follow the instructions

supplied with the sensor for installation.

Illustration 2–4 Wiring for Discharge Air Temperature Sensor

Fan status switch (optional)

Connect a Normally Closed Fan Status switch to the Discharge Air

Revision G 21

Temperature (DAT) input and ground (GND) terminals. The input includes

the internal pull-up resistor. A CSE-1102 differential pressure switch is

Page 22

FST

N.C Fan Status

CSE-1102

FAN

MS/TP

+B

A

RS

WST

GND

DAT

COM

FAN-L

FAN-M

FAN-H

R

BO4

BO5

GND

AO6

AO8

AO7

24VAC

Section 2: Installing the AppStat KMC Controls, Inc.

suitable for this application. Follow the instructions supplied with the switch

for installation.

Illustration 2–5 Wiring for a fan status switch

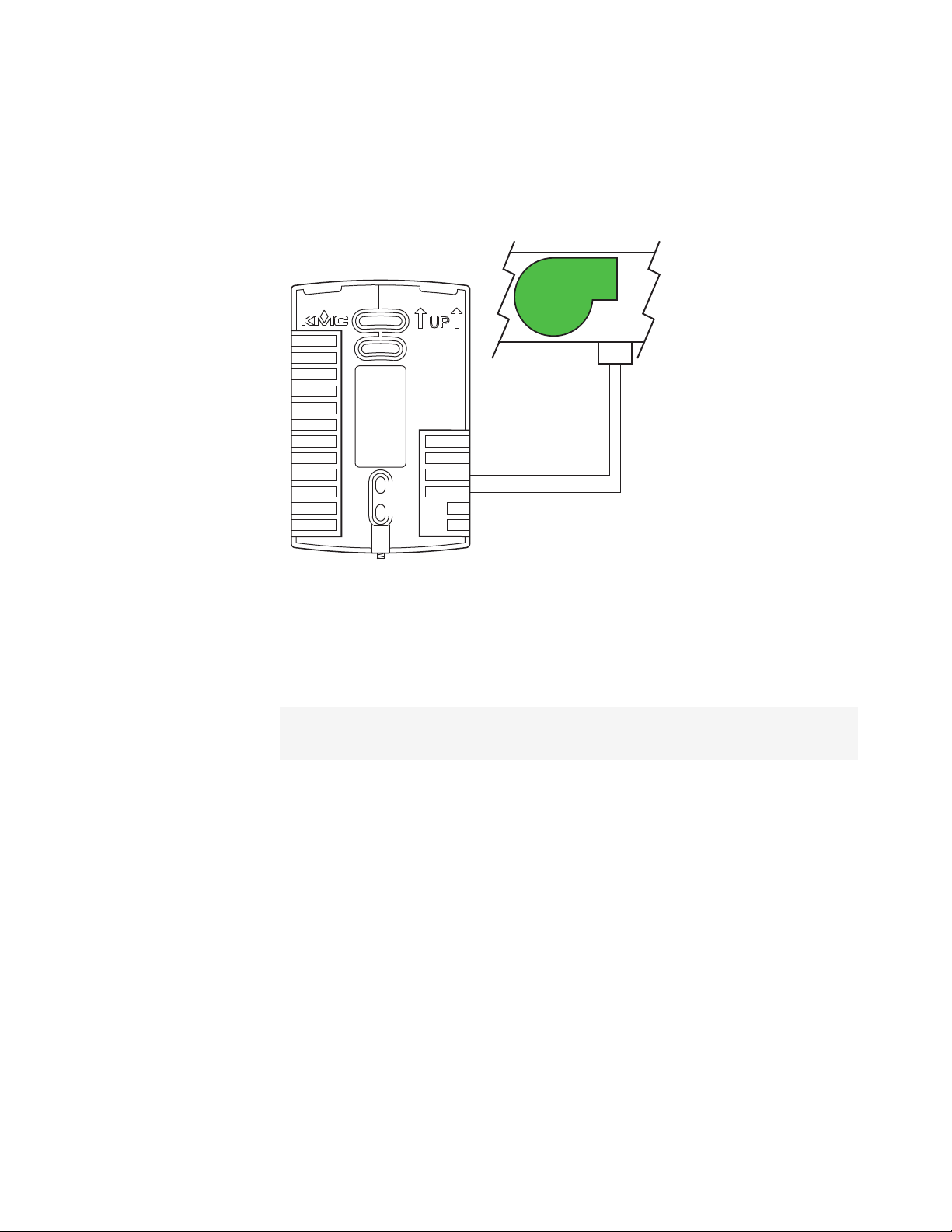

Water temperature sensor

Connect a 10kΩ, Type III thermistor temperature probe to the water

temperature (WST) input. The input includes the internal pull-up resistor. An

STE-1455 sensor is suitable for this application. Follow the instructions

supplied with the sensor for installation.

Note: The water temperature sensor is a required input sensor for 2-pipe fancoil

units.

22 Revision G

Page 23

STE-1455 or

equivalent

WST

MS/TP

+B

A

RS

WST

GND

DAT

COM

FAN-L

FAN-M

FAN-H

R

BO4

BO5

GND

AO6

AO8

AO7

24VAC

STE-1451 or

equivalent

MS/TP

+B

A

RS

OAT

GND

DAT

ECON

G

Y1

Y2

RC

W1

W2

RH

AO6

AO7

COM

24VAC

OAT

Installation, Operation, and Application Guide for AppStat Section 2: Installing the AppStat

Illustration 2–6 Wiring for a water temperature sensor

Outside air temperature

Connect a 10kΩ, Type III thermistor temperature probe to the outside air

temperature (OAT) input. The input includes the internal pull-up resistor. An

STE-1451 sensor is suitable for this application. Follow the instructions

supplied with the sensor for installation.

Illustration 2–7 Wiring for an outside air temperature sensor

Revision G 23

Page 24

Caution

Section 2: Installing the AppStat KMC Controls, Inc.

Connecting outputs

The AppStat outputs are model dependent and are configured for specific

applications.

No field programming or set up is required or possible.

Depending on model and application, the AppStat outputs are designed

for either 24 voltAC or 0-10 voltDC loads.

The outputs may represent analog or digital signals.

See the topic BACnet objects on page 114 for the configuration properties

of the output objects.

Improperly connecting loads or equipment to output

terminals may damage the equipment. Connect only as

shown in the following diagrams or application drawings.

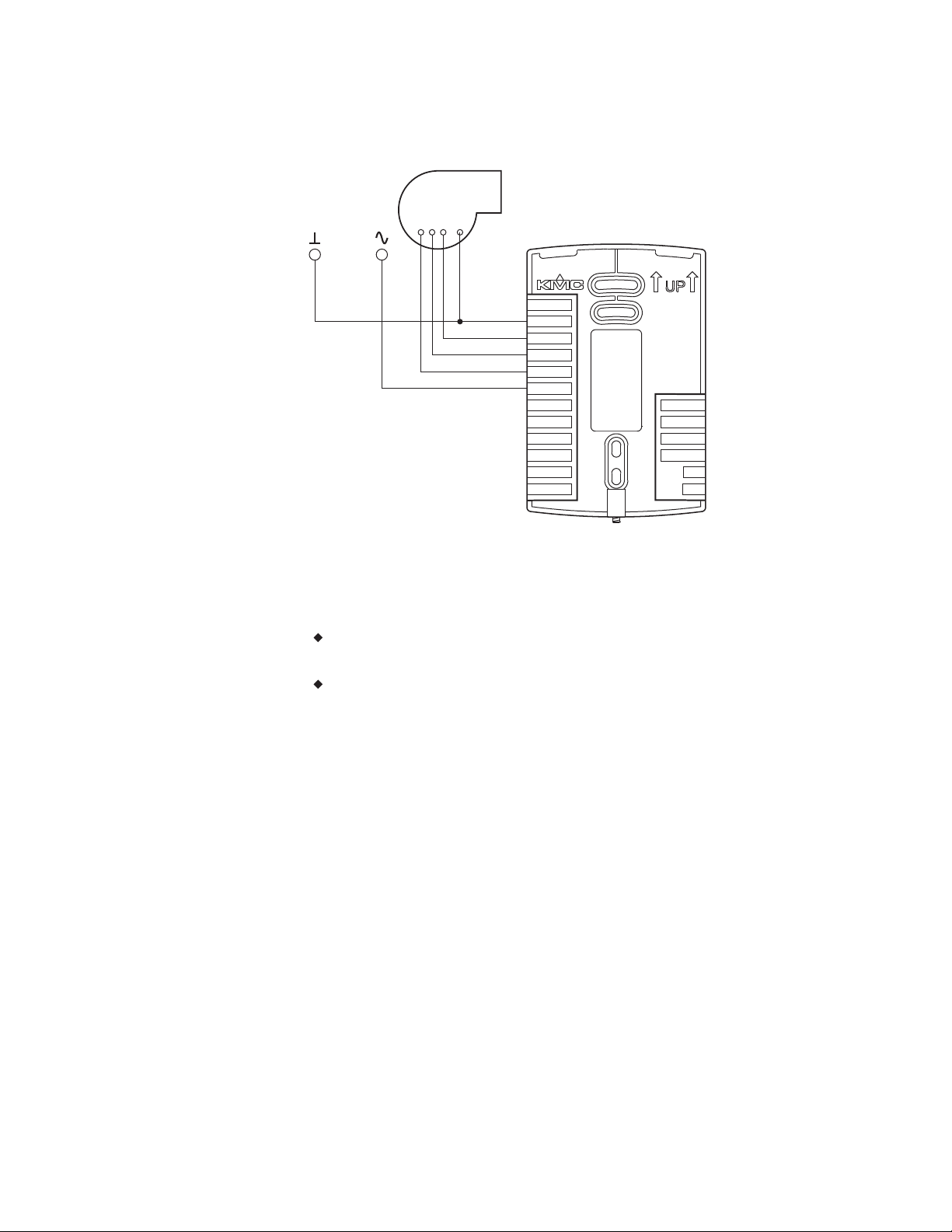

Connecting to a three-speed fan

The following diagram shows the connections for a three-speed fan. The fan

circuits must be a 24-volt AC pilot duty only.

For a single-speed fan, use only the FAN-L connection.

For a two-speed fan, use the FAN-L and FAN-H connections.

For a three-speed, use FAN-L, FAN-M, and FAN-H

24 Revision G

Page 25

High

Med

LoW

Com

24 VAC

MS/TP

+B

A

RS

WST

GND

DAT

COM

FAN-L

FAN-M

FAN-H

R

BO4

BO5

GND

AO6

AO8

AO7

24VAC

Installation, Operation, and Application Guide for AppStat Section 2: Installing the AppStat

Illustration 2–8 Connections to a three-speed fan

Connecting to a modulating fan

The following diagram shows the connections for a modulating speed fan.

The fan start circuit must be a 24-volt AC circuit. Connect it to the

FAN-L output.

The speed control is a 0-10 volt DC analog output.

Revision G 25

Page 26

Speed

Start

Com

24 VAC

MS/TP

+B

A

RS

WST

GND

DAT

COM

FAN-L

FAN-M

FAN-H

R

BO4

BO5

GND

AO6

AO8

AO7

24VAC

Cooling Heating

24 VAC

MS/TP

+B

A

RS

WST

GND

DAT

COM

FAN-L

FAN-M

FAN-H

R

BO4

BO5

GND

AO6

AO8

AO7

24VAC

Section 2: Installing the AppStat KMC Controls, Inc.

Illustration 2–9 Connections for a modulating fan

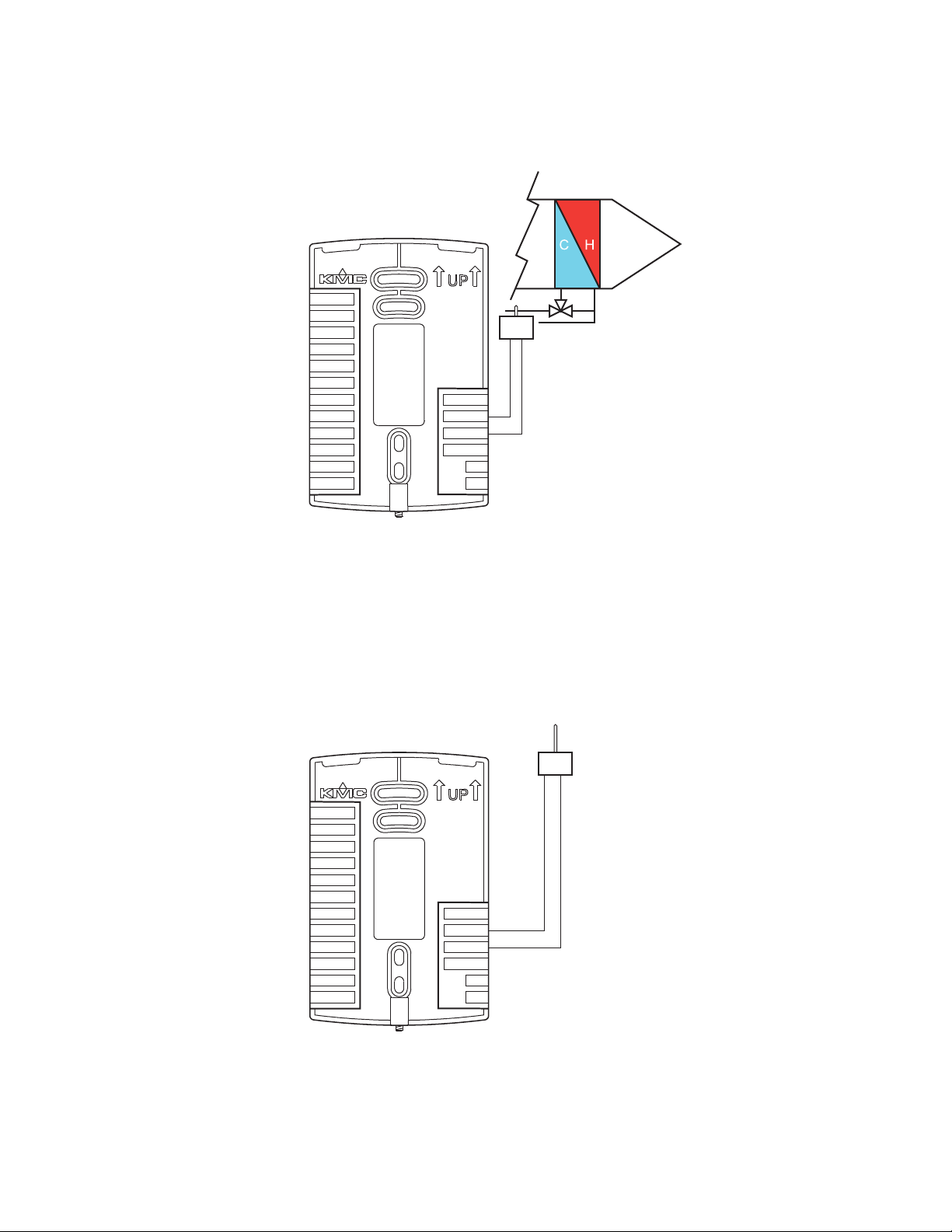

Connecting on/off valves

The following diagram shows the connections on/off valves.

The valves are activated by 24-volts AC.

The outputs are 24-volt relays.

Illustration 2–10 Connections to on/off valves

26 Revision G

Page 27

0-10

VDC

0-10

VDC

Cooling Heating

24 VAC

MS/TP

+B

A

RS

WST

GND

DAT

COM

FAN-L

FAN-M

FAN-H

R

BO4

BO5

GND

AO6

AO8

AO7

24VAC

Installation, Operation, and Application Guide for AppStat Section 2: Installing the AppStat

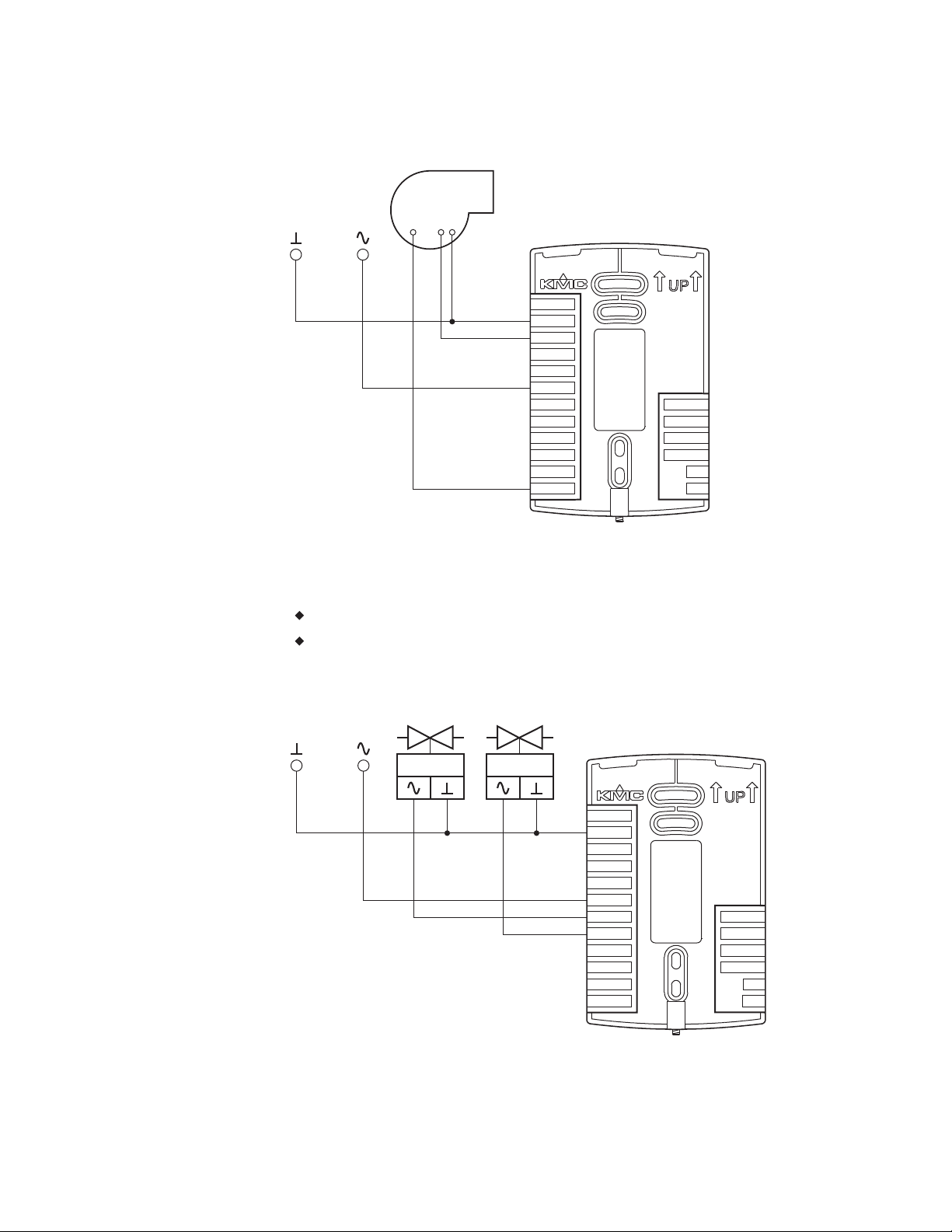

Connecting to modulating valves

The following diagram shows the connections for a modulating mixing

valves. The valve control signal is a 0-10 volt analog output.

Illustration 2–11 Modulating heating and cooling valves

Revision G 27

Page 28

0-10

VDC

24 VAC

MS/TP

+B

A

RS

OAT

GND

DAT

ECON

G

Y1

Y2

RC

W1

W2

RH

AO6

AO7

COM

24VAC

Section 2: Installing the AppStat KMC Controls, Inc.

Connecting an economizer

The following diagram shows the connections for an economizer. The damper

control signal is a 0-10 volt analog output.

Illustration 2–12 Wiring for an economizer

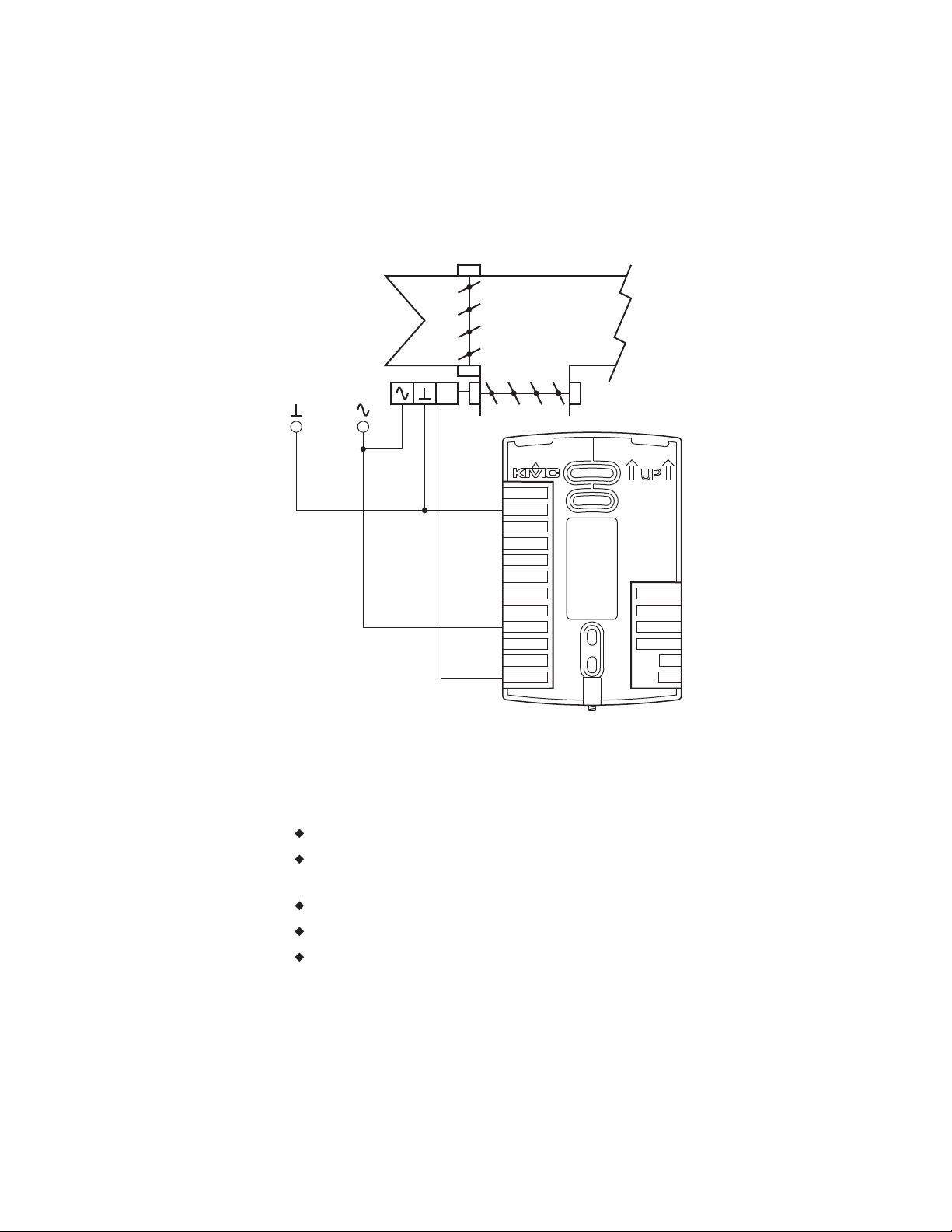

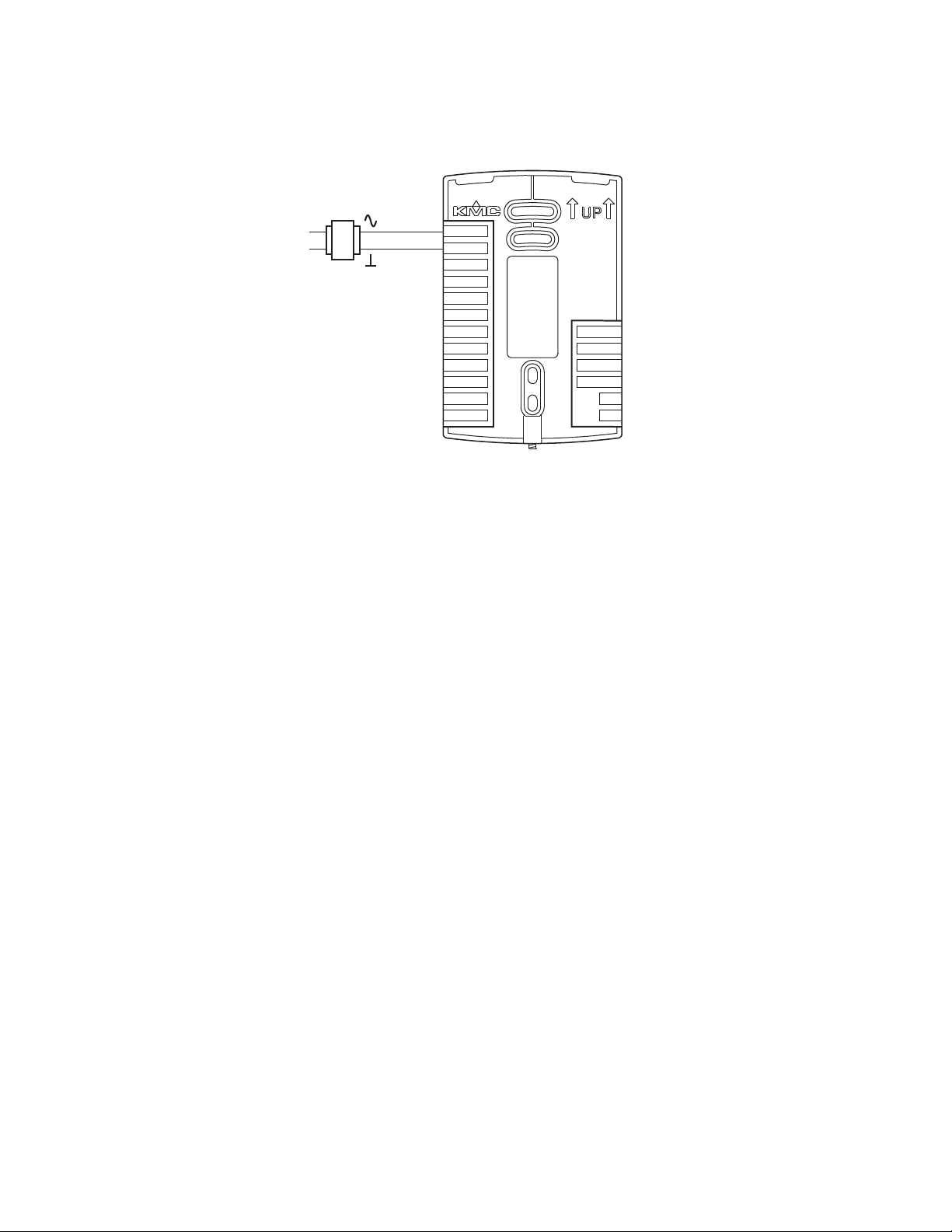

Connecting power

The AppStat requires an external, 24 volt, AC power source. Use the

following guidelines when choosing and wiring transformers.

Use only a Class-2 transformer of the appropriate size to supply power.

KMC Controls recommends powering the AppStat from a dedicated

controls transformer.

Connect the transformer’s neutral lead to the COM terminal.

Connect the AC phase lead to the 24VAC terminal.

Power is applied to the controller when the transformer is powered.

See Installation accessories on page 12 for a list of transformers available from

28 Revision G

KMC Controls, Inc.

Page 29

24 VAC

Class-2

Controls

transformer

MS/TP

+B

A

RS

WST

GND

DAT

COM

FAN-L

FAN-M

FAN-H

R

BO4

BO5

GND

AO6

AO8

AO7

24VAC

Installation, Operation, and Application Guide for AppStat Section 2: Installing the AppStat

Illustration 2–13 Wiring for AppStat power

Maintenance

Remove dust as necessary from the holes in the top and bottom. Clean the

display with soft, damp cloth and mild soap.

Revision G 29

Page 30

Section 2: Installing the AppStat KMC Controls, Inc.

30 Revision G

Page 31

COOLING SETPT

Up and down

buttons

Soft key

buttons

Soft key

bar

Optional

motion sensor

72

F

°

AUTO AUTO

DoneEnterCncl

Installation, Operation, and Application Guide for AppStat

Sec tion 3: Use r f u n c tio ns

This section covers topics for the end user in a facility.

AppStat user functions are limited to changing the following functions.

Active temperature setpoints

Fan operation

Changing between heating and cooling

Override scheduled occupancy or occupancy based on the schedule in

the AppStat.

Change the display between Fahrenheit and Celsius

Operating the AppStat

AppStat functions are accessible through a user interface consisting of simple,

context sensitive menus. The menus are opened and options are selected by

using the buttons and a color display on the front of the AppStat.

Pressing either the up button or down button changes a selection,

setting, or value.

Pressing the Enter button saves the selected setting or value. Typically

the Enter button is the middle of the three buttons below the display.

Saving a selection also advances to the next display.

Illustration 3–1 AppStat display and buttons

Revision G 31

Page 32

Section 3: User functions KMC Controls, Inc.

The three buttons below the display are defined by labels in the soft key bar.

Typically the buttons are designated for the following functions.

Back—Returns to the previous menu.

Cncl—Cancels current changes.

Done—Push this button at any point while entering a value. For example,

if you have entered the first two digits of a password and the remaining

two digits are correct, pushing Done completes the entry of the

password.

Enter—Pushing this button enters the selection and advances to the next

step.

Exit—Returns to temperature display.

The operating modes of the AppStat are represented by the display icons.

Table 3–1 Operating mode icons

Icon Description Mode

The fan icon rotates when the system

fan is operational. In systems with

multispeed fans the icon rotation is

the same regardless of speed. When

fan operation is set to automatic, the

word "Auto" is placed under the

icon.

Occupied—Occupancy is set to

occupied by the schedule maintained

in the controller.

Unoccupied—Occupancy is set to

unoccupied by the schedule

maintained in the controller.

Standby—The space is temporarily

unoccupied because of lack of

detected motion in the room.

Override—A user has entered

temperature setpoints that override

the unoccupied setpoints.

Fan

Occupancy

Occupancy

Occupancy

Occupancy

Cooling—The system will cool the

space until the cooling setpoint is

reach. The icon is in motion when

cooling is taking place.

32 Revision G

Heating/Cooling

Page 33

Installation, Operation, and Application Guide for AppStat Section 3: User functions

Operating mode icons (continued)

Icon Description Mode

Heating—The system will heat the

space until the heating setpoint is

reached. The icon is in motion when

heating is taking place.

Off System is off Heating/Cooling

Dehumidification—During

dehumidification the system will

heat and cool at the same time to

remove humidity and maintain the

active temperature setpoint. The icon

is in motion while dehumidification

is taking place.

Heating/Cooling

Heating/Cooling

Revision G 33

Page 34

F

°

70

AUTO AUTO

SECURITY

ADMIN LEVEL

0 0 0 0

Section 3: User functions KMC Controls, Inc.

Entering a user password

User functions may require a password consisting of four numbers. Once a

user password is entered it will remain active for 60-seconds after the last

button is pushed.

Enter a user password

Procedure Steps Display

1 Starting display

2 Enter the Level 1

password.

Start at the temperature display.

1.

Press any button on the AppStat. The display

changes to the Security User Level display.

2.

Press either the or button to change the

first digit of the password.

3.

Press the Enter button to select the next

digit. Repeat for all four digits.

4.

If the password is correct, the display will

advance to the first menu.

34 Revision G

Page 35

F

°

70

AUTO AUTO

F

°

68

HEATING SETPT

Done

Enter

Cncl

F

°

72

COOLING SETPT

Done

Enter

Cncl

Installation, Operation, and Application Guide for AppStat Section 3: User functions

Changing the active setpoints

To enter or change the active temperature setpoints you may need user

password. To enter the password, see Entering a user password on page 34.

Note: In the following procedure the current active setpoint–either cooling or

heating–is the first setpoint to change. Once that setpoint is entered, the

display advances to the next setpoint.

To change the operation of the fan, occupancy, or heating/cooling, see the

topic Setting the operating modes on page 36.

Change the active temperature setpoints

Procedure Steps Display

1 Starting display

2 Change the active

setpoints

Start at the temperature display.

Note:

The next step may require a user

password. See

34

.

1.

Press either the or button to change the

active temperature setpoint.

Entering a user password on page

Note: A user password may be required

after pushing the first button.

2.

Press the Enter button to save the value. The

display will advance to the next setpoint

3.

Press either the or button to change the

next setpoint.

4.

Press the Enter button to save the value. The

display will return to the temperature

display.

Revision G 35

Page 36

F

°

70

AUTO AUTO

Enter

Cncl

MODE: HEAT

COOL

AUTO

OFF

Enter

Cncl

MODE: EMERGENCY

HEAT

COOL

AUTO

OFF

Section 3: User functions KMC Controls, Inc.

Setting the operating modes

The operating modes set the following functions.

Fan operation

Changing between heating and cooling

Override scheduled occupancy or occupancy that has been set by a

schedule.

Change the display units from Fahrenheit to Celsius.

To change the occupied temperature setpoints, see the topic Changing the

active setpoints on page 35.

Set the operating modes

Procedure Steps Display

1 Starting display

2 Change the heating

or cooling mode.

Start at the temperature display.

Note:

The following procedures may require a

user password. See

page 34

1.

.

Push the button under the heating/cooling

Entering a user password on

icon.

Note: If a user password has previously been

entered or if the AppStat has not been set up

with a user password, entering a password is

not required.

2.

Press either the or button to select the

heating/cooling mode. The mode may be one

of the following.

Emergency—(Option) Turns on the auxiliary

heating in a heat pump unit.

Heat—The system will only heat the space.

Cool—The system will only cool the space.

Auto—The system will switch between

heating and cooling.

Heating/cooling icons

Off—The system is turned off.

3.

Press the Enter button to save the setting.

The display returns to the temperature

display.

36 Revision G

Page 37

Enter

Cncl

FAN: ON

AUTO

Enter

Cncl

FAN: HIGH

MED

LOW

AUTO

Installation, Operation, and Application Guide for AppStat Section 3: User functions

Set the operating modes (continued)

Procedure Steps Display

1.

3 Set the fan mode.

Push the button under the fan icon.

Note: If a user password has previously been

entered or if the AppStat has not been set up

Fan icon

with a user password, entering a password is

not required.

2.

Press the Enter button to select the next

digit. Repeat for all four digits.

3.

Press either the or button to select the

fan mode from the following options.

Auto—Sets the fan to run only when

1-speed fan option

there is a call for heat or cooling. The

word AUTO will be placed under the fan

icon.

On—Sets a single speed fan will run

continuously.

Low, Med, High—Sets the speed at which

3-speed or modulating fans will run

Multi-speed fan option

continuously.

4.

Press the Enter button to save the setting.

The display returns to the temperature

display.

Revision G 37

Page 38

F

°

65

AUTO AUTO

Enter

Cncl

LOCAL OVRD: ON

OFF

F

°

70

AUTO AUTO

°

21

c

.0

AUTO AUTO

Section 3: User functions KMC Controls, Inc.

Set the operating modes (continued)

Procedure Steps Display

4 Change the override

setpoint

Entering an override setpoint can only take

place if the AppStat is in the unoccupied mode.

1.

Push the button under the unoccupied icon

.

Note: If a user password has previously been

entered or if the AppStat has not been set up

with a user password, entering a password is

not required.

2.

Press either the or button to change the

first digit of the password.

3.

Press the Enter button to select the next

digit. Repeat for all four digits.

4.

Press either the or button to turn the

override on or off.

Override Off—The controller uses the

unoccupied setpoint as the active setpoint.

Override On—the controller changes to the

occupied setpoint which can then be

temporarily changed.

5.

Press the Enter button to save the setting.

5 Change the display

38 Revision G

units

Note: When the system is in the unoccupied

mode, changing the active setpoint will

automatically place the system in the

override mode.

To temporarily change the display units to

either Celsius or Fahrenheit, press and hold the

middle button under the display until the units

change.

Page 39

Installation, Operation, and Application Guide for AppStat

Sec tion 4: Co m m i s s io n ing f u n c t ions

This topics in this section are advanced topics for control technicians and

engineers. These topic cover procedures for the initial AppStat setup.

The AppStat commissioning functions are values and settings that are entered

during the installation and commissioning of a controller and the equipment

it is controlling. Typically these functions do not change after the installation

and commissioning process.

To set up the commissioning functions, you will need the following

information.

Information about the equipment

The sequence of operation for the equipment

The building automation system plans for controllers that are part of a

network.

Users may change the occupied heating and cooling setpoints without

accessing the commissioning functions. This procedure is covered in the topic

User functions on page 31.

Note: The instructions for the AppStat commissioning functions cover all of the

functions that can be set in the controller. Not all functions are available on

every model of controller. Consult the installation and operation manual

supplied with the controller to verify the application programming in the

AppStat.

Revision G 39

Page 40

F

°

70

AUTO AUTO

Push together for

commissioning

AUTO AUTO

70

F

°

SECURITY

ADMIN LEVEL

0 0 0 0

Enter

Cncl

MAIN

SETPOINT

SCHEDULE

SYSTEM

COMM

ADVANCED

Section 4: Commissioning functions KMC Controls, Inc.

Enter the commissioning mode

For access to the commissioning functions you will need to know Password 2.

If the controller has not been previously set up, no password is required.

A new Password 2 can be entered in the advanced commissioning

functions. See the topic Advanced options on page 60.

Enter the commissioning mode

Procedure Steps Display

1 Starting display

2 Enter the

commissioning

password

Start from the temperature display.

1.

Press the left and right buttons below the

display at the same time and hold them until

the display changes to the SECURITY USER

LEVEL display.

Note: If Password 2 has not previously been

entered, the display will change to the

MAINmenu.

2.

Press either the or button to change the

first digit of Password 2.

3.

Press the Enter button to select the next

digit. Repeat for all four digits. The Enter

button is the middle of the three buttons

below the display.

3 Select a

40 Revision G

commissioning

function

Access to the commissioning functions always

starts at the MAIN menu display.

Page 41

F

°

70

AUTO AUTO

SECURITY

ADMIN LEVEL

0 0 0 0

Enter

Cncl

MAIN

SETPOINT

SCHEDULE

SYSTEM

COMM

ADVANCED

Installation, Operation, and Application Guide for AppStat Section 4: Commissioning functions

Setting the commissioning setpoints

The commissioning setpoints set the operational setpoints and limits for the

AppStat. The functions of the setpoints and how they are used are describe in

the topic Room temperature setpoints on page 66. Setting commissioning

setpoints requires entering Password2 which is described in the topic Enter

the commissioning mode on page 40.

Note: Not all setpoints in the following procedure are applicable to all models of

AppStat. Those setpoints are marked as (optional).

Procedure to set the commissioning setpoints

Procedure Steps Display

1.

1 Starting display

Start at the temperature display.

2.

Enter Password 2. The display changes to the

MAIN menu display.

2 Choose and set the

setpoints.

1.

From the MAIN menu , press either the or

button to select SETPOINTS.

2.

Press Enter. The SETPOINT menu opens

3.

Choose and set each of the following

setpoints.

Revision G 41

Page 42

Back

Enter

Cncl

SETPOINT

OCC COOL

OCC HEAT

UNOCC COOL

UNOCC HEAT

MIN COOLING

MAX HEATING

DIFFERENTIAL

Section 4: Commissioning functions KMC Controls, Inc.

Procedure to set the commissioning setpoints (continued)

Procedure Steps Display

OCC COOL—The cooling setpoint that is

used as the active setpoint when the system

is occupied.

OCC HEAT—The heating setpoint that is

used as the active setpoint when the system

is occupied.

UNOCC COOL—The cooling setpoint that is

used as the active setpoint when the system

is unoccupied.

UNOCC HEAT—The heating setpoint that is

used as the active setpoint when the system

is unoccupied.

MIN COOLING—The minimum cooling

setpoint that a user can select as the active

setpoint.

MAX HEATING—The maximum heating

setpoint that a user can select as the active

setpoint.

DIFFERENTIAL—The minimum value

between the cooling or heating setpoints.

The AppStat will always maintain this

difference between setpoints.

STBY OFFSET—(optional) A value used to

calculate the standby setpoint. The standby

setpoint is calculated by adding or

subtracting the offset value to or from the

value of the occupied setpoint.

DEHUM SETPOINT—(optional) Sets the

setpoint for dehumidification.

Dehumidification starts when the relative

humidity is above the dehumidification

setpoint.

DEHUM DEADBAND—(optional) The

system will remain in dehumidification until

the relative humidity falls below a value of

dehumidficaion setpoint minus the

dehumidification deadband value.

42 Revision G

Page 43

F

°

70

AUTO AUTO

SECURITY

ADMIN LEVEL

0 0 0 0

MAIN

SETPOINT

SCHEDULE

SYSTEM

COMM

ADVANCED

BackEnterExit

COMM

DEVICE ID

MAC

BAUD

BackEnterExit

D ID: 0000001

DoneEnterEnter

Installation, Operation, and Application Guide for AppStat Section 4: Commissioning functions

Set up communications

Setting BACnet communications properties is required only if the AppStat is

integrated into a network with other BACnet controllers. Entering the

communications properties requires entering Password 2 which is described

in the topic Enter the commissioning mode on page 40.

See the topic Connecting to an MS/TP network on page 121 for network

wiring details.

Set BACnet communication properties

Procedure Steps Display

1.

1 Starting display

Start at the temperature display.

2.

Enter Password 2. The display changes to the

MAIN menu display.

2 Change the network

communication

properties.

1.

From the MAIN menu , press either the or

button to select COMM.

2.

Press Enter. The COMMmenu opens.

3.

Choose and set the following properties.

l DEVICE ID—This is the BACnet device

instance. The device instance must be

within the range of 1 to 4,194,302.

l MAC—The MAC address must be in the

range of 1-127.

l BAUD—Set to match other devices on

the BACnet MS/TP network. The choices

are Auto, 9600, 19,200, 38,400, or 76,800.

Note: After changing a communication

property the AppStat will reset.

Revision G 43

Page 44

MAC: 1

DoneEnterEnter

BAUD: 76800

38400

19200

9600

Auto

DoneEnterCncl

Section 4: Commissioning functions KMC Controls, Inc.

Set BACnet communication properties (continued)

Procedure Steps Display

44 Revision G

Page 45

F

°

70

AUTO AUTO

SECURITY

ADMIN LEVEL

0 0 0 0

MAIN

SETPOINT

SCHEDULE

SYSTEM

COMM

ADVANCED

BackEnterExit

SCHEDULE

SET CLOCK

SETPOINT HOLD

ENTIRE WEEK

WEEKDAYS

WEEKEND

INDV DAYS

HOLIDAYS

DelEnterExit

Installation, Operation, and Application Guide for AppStat Section 4: Commissioning functions

Set the time and date

Setting the time and date requires entering Password 2 which is described in

the topic Enter the commissioning mode on page 40.

Note: If the AppStat is connected to a BACnet network that includes a time service

master, the time and date are automatically set to the network time and

date.

To change the schedule, see the procedure Setting the occupancy schedule on

page 47.

Set the time and date

Procedure Steps Display

1.

1 Starting display

Start at the temperature display.

2.

Enter Password 2. The display changes to the

MAIN menu display.

1.

2 Select the

SCHEDULE menu.

From the MAIN menu , press either the or

button to select SCHEDULE.

2.

Press Enter. The SCHEDULE menu opens.

3.

Choose SET CLOCK and then press Enter.

The SET Clock menu opens.

Revision G 45

Page 46

SET CLOCK

DATE

TIME

UTC OFFSET

DST ENABLE

DST AUTO

DST START

DST END

BackEnterExit

Section 4: Commissioning functions KMC Controls, Inc.

Set the time and date (continued)

Procedure Steps Display

3 Choose a clock

function to set.

Choose one of the features in the SET CLOCK

menu to change the date, time, or Daylight

Saving Time (DST) setting.

DATE—The current calendar date.

TIME—Time is set according to a 12-hour

clock.

UTC OFFSET—Enter the time offset—in

minutes—between local standard time and

Universal Time Coordinated. The value of

the property ranges from -780 to +780

seconds. The time zones to the west of the

zero degree meridian are positive values;

those to the east are negative values. The

value of the UTC Offset property is

subtracted from the UTC received in a UTC

Time Synchronization service request to

calculate the correct local standard time.

DST ENABLE—Set to TRUE to enable

Daylight Saving Time and FALSE to use

standard time year around.

DST AUTO—When set to TRUE, the AppStat

automatically calculates the start and end

dates from relative dates. For example, set

DST START to the first Sunday in March

instead of a calendar date.

DST START and DST END—Enter the dates

and time to begin observing DST. If DST

AUTO is set to TRUE the dates are relative;

if set to FALSE the date is a calendar date.

46 Revision G

Page 47

F

°

70

AUTO AUTO

SECURITY

ADMIN LEVEL

0 0 0 0

MAIN

SETPOINT

SCHEDULE

SYSTEM

COMM

ADVANCED

BackEnterExit

Installation, Operation, and Application Guide for AppStat Section 4: Commissioning functions

Setting the occupancy schedule

The schedule in the AppStat controls the occupancy mode. If the schedule is

set to ON, the AppStat uses the occupied setpoint as the active setpoint. If the

schedule is OFF, the unoccupied setpoint is used.

Note: The schedule in the AppStat is a BACnet schedule object. If the AppStat is

connected to a BACnet network the schedule can be set up with a BACnet

operator workstation.

Setting the occupancy schedule requires entering Password2 which is

described in the topic Enter the commissioning mode on page 40.

To change the time and date, see the procedure Set the time and date on page

45.

Set up schedules

Procedure Steps Display

1.

1 Starting display

Start at the temperature display.

2.

Enter Password 2. The display changes to the

MAIN menu display.

1.

2 Select the

SCHEDULE menu.

Revision G 47

From the MAIN menu , press either the or

button to select SCHEDULE.

2.

Press Enter. The SCHEDULE menu opens.

Page 48

SCHEDULE

SET CLOCK

SETPOINT HOLD

ENTIRE WEEK

WEEKDAYS

WEEKEND

INDV DAYS

HOLIDAYS

BackEnterExit

ENTIRE WEEK

1: 12:00:00 AM ON

2:

--:--:---- ----

3:

--:--:---- ----

4:

--:--:---- ----

5:

--:--:---- ----

6:

--:--:---- ----

DelEnterExit

Section 4: Commissioning functions KMC Controls, Inc.

Set up schedules (continued)

Procedure Steps Display

1.

3 Choose and set a

weekly schedule.

From the SCHEDULE menu, choose one of

the following schedule entry methods to

enter a weekly schedule.

l ENTIRE WEEK—Sets the schedule for

all seven days of the week at one time.

l WEEKDAYS—Sets the schedule for

Monday to Friday. Saturday and Sunday

are not changed

l WEEKEND—Sets the schedule for

Saturday and Sunday. Monday to Friday

remain unchanged.

l INDIVIDUAL DAYS—Sets the schedule

for just the selected day of the week.

2.

Change the daily times and values in the

schedule to set the occupancy mode to either

ON or OFF.

l When finished with each pair push Enter

or Done.

l When finished with the schedule push

Exit to return to the SCHEDULE menu.

48 Revision G

Page 49

HOLIDAYS

HOL1

HOL2

HOL3

HOL4

HOL5

HOL6

HOL7

DelEnterExit

HOL2

DATE

DEC 12 2013

TYPE: DATE

DelEnterExit

HOL3

START DATE:

NOV 27 2013

END DATE:

DEC 12 2013

TYPE: DATE RANGE

DelEnterExit

HOL5

MON WK DAY:

OCT 31 THU

TYPE: WEEK N DAY

DelEnterExit

Installation, Operation, and Application Guide for AppStat Section 4: Commissioning functions

Set up schedules (continued)

Procedure Steps Display

4 Choose and set a

holiday schedule

Use a holiday schedule to override the values in

the weekly schedule. Months and years can be

entered as follows:

To choose ANY as the year, select the year

and push the down arrow past the current

year

For month the choices are any of the twelve

months of the year, ANY, EVEN, and ODD.

1.

From the SCHEDULE menu, choose

HOLIDAYS.

2.

From the HOLIDAYS list, choose a holiday

to edit.

3.

From the menu for the holiday, choose

l DATE—Snter a single date on which the

holiday schedule will override the values

of the weekly schedule.

l DATE RANGE—Enter a range of dates

on which the values and times listed in

the holiday schedule will override the

values of the weekly schedule.

l WEEK N DAY—A day of the week and

month on which the values and times

listed in the holiday schedule will

override the values of the weekly

schedule.

Revision G 49

Page 50

F

°

70

AUTO AUTO

SECURITY

ADMIN LEVEL

0 0 0 0

MAIN

SETPOINT

SCHEDULE

SYSTEM

COMM

ADVANCED

BackEnterExit

SYSTEM

LOCAL OVRD TIME

FAN OFF DELAY

OCCUPIED FAN

CL VALVE ACTION

HT VLV ACTION

FAN MAXIMUM

FAN MINIMUM

BackEnterExit

SYSTEM

LOCAL OVRD TIME

FAN OFF DELAY

OCCUPIED FAN

VLV ACTION

FAN MAXIMUM

FAN MINIMUM

AUX HEAT

BackEnterExit

BackEnterCncl

LOCAL OVRD TIME

2 60 mins

Section 4: Commissioning functions KMC Controls, Inc.

Set fan coil unit system options

The items in the system menu control application specific functions for fan coil

units. Entering the system options requires entering Password 2 which is

described in the topic Enter the commissioning mode on page 40.

Set up fan coil unit system options

Procedure Steps Display

1.

1 Starting display.

Start at the temperature display.

2.

Enter Password 2. The display changes to the

MAIN menu display.

1.

2 Choose and set the

fan coil system

options.

From the MAIN menu , press either the or

button to select SYSTEM.

2.

Press Enter. The SYSTEM menu opens.

3 Set the local override

time.

3.

Choose any of the following items.

LOCAL OVRD TIME

FAN OFF DELAY

OCCUPIED FAN

CL VALVE ACTION (Four-pipe only)

HT VLV ACTION (Four-pipe only)

VLV ACTION (Two-pipe only)

FAN MAXIMUM (Modulating fans only)

FAN MINIMUM (Modulating fans only)

FAN SPEEDS (Three speed fans only)

AUX HEAT (Two-pipe only)

From the SYSTEM menu choose LOCAL OVRD

TIME to set the time the AppStat will hold an

override temperature setpoint as the active

setpoint. At the end of the period, the AppStat

will use either an occupied or unoccupied

setpoint as the active setpoint.

50 Revision G

Page 51

BackEnterCncl

FAN OFF DELAY

2 2 mins

BackEnterCncl

OCCUPIED FAN:

ON

OFF

CL VLV ACTION:

NORMAL OPEN

NORMAL CLOSED

DelEnterCncl

HT VLV ACTION:

NORMAL OPEN

NORMAL CLOSED

DelEnterCncl

VLV ACTION:

NORMAL OPEN

NORMAL CLOSED

DelEnterCncl

Installation, Operation, and Application Guide for AppStat Section 4: Commissioning functions

Set up fan coil unit system options (continued)

Procedure Steps Display

4 Set the fan delay.

5 Set the occupied fan

control.

6 Set the valve action.

From the SYSTEM menu choose FAN DELAY

OFF to set the time the system fan will continue

to run after the last heating or cooling stage is

turned off.

From the SYSTEM menu choose OCCUPIED

FANto choose the following:

When ON, the fan will run continuously

when the schedule is occupied (On).

When the schedule is unoccupied (Off) the

fan will run only when there is a call for

heating or cooling.

Select one of the valve actions from the

SYSTEMmenu. Not all choices apply to every

application.

CL VALVE ACTION—(Four-pipe only)

HT VLV ACTION—(Four-pipe only)

VLV ACTION—(Two-pipe only)

Valve action selections are the same for all three

types of valves.

NORMAL OPEN—The valve changes from

fully open to fully closed as the AppStat

varies the valve output from 0 to 10 volts.

NORMAL CLOSED—The valve changes

from fully closed to fully open as the

AppStat varies the valve output from 0 to 10

volts.

Revision G 51

Page 52

BackEnterCncl

FAN MINIMUM:

35 %utoz

BackEnterCncl

FAN MAXIMUM:

100 %utoz

BackEnterCncl

FAN SPEEDS:

THREE SPEEDS

TWO SPEEDS

SINGLE SPEED

AUX HEAT:

Enable

Disable

DelEnterCncl

Section 4: Commissioning functions KMC Controls, Inc.

Set up fan coil unit system options (continued)

Procedure Steps Display

7 Set fan speeds for

modulating speed

fans.

8 Set fan speeds for

three-speed fans.

9 Enable auxiliary heat

Select FAN MINIMUM or FAN MAXIMUM

from the SYSTEM menu to set fan speed for

modulation fans.

FAN MINIMUM—Sets the slowest speed at

which the fan will run when a user sets the

fan speed to LOW.

FAN MAXIMUM—Sets the fastest speed at

which the fan will run when a user sets the

fan speed to HIGH.

The MED speed is automatically set halfway

between the LOW and HIGH settings.

Select FAN SPEEDS from the SYSTEM menu to

designate the number of speeds at which the

installed fan will run.

Choose AUX HEAT from the SYSTEM menu to

enable auxiliary heat in two-pipe applications.

52 Revision G

Page 53

F

°

70

AUTO AUTO

SECURITY

ADMIN LEVEL

0 0 0 0

MAIN

SETPOINT

SCHEDULE

SYSTEM

COMM

ADVANCED

BackEnterExit

BackEnterExit

SYSTEM

LOCAL OVRD TIME

FAN OFF DELAY

OCCUPIED FAN

MIN OFF TIME

STAGE DELAY

ECON ENABLE

MIN ECON DAMPER

SYSTEM

STAGE DELAY

ECON ENABLE

MIN ECON DAMPER

ECON ENABLE TEM

MIN DAT

DEHUM ENABLE

HEATING FAN

BackEnterExit

BackEnterCncl

LOCAL OVRD TIME

2 60 mins

Installation, Operation, and Application Guide for AppStat Section 4: Commissioning functions

Set roof top unit system options

The items in the system menu control application specific functions for roof

top units. Entering the system options requires entering Password 2 which is

described in the topic Enter the commissioning mode on page 40.

Set up roof top unit system options

Procedure Steps Display

1.

1 Starting display.

Start at the temperature display.

2.

Enter Password 2. The display changes to the

MAIN menu display.

1.

2 Choose and set the

roof top system

options.

From the MAIN menu , press either the or

button to select SYSTEM.

2.

Press Enter. The SYSTEM menu opens.

3 Set the local override

time.

3.

Choose any of the following items.

LOCAL OVRD TIME

FAN OFF DELAY

OCCUPIED FAN

MIN OFF TIME

STAGE DELAY

ECON ENABLE

MIN ECON DAMPER

ECON ENABLE TEM

MIN DAT

HEATING FAN

From the SYSTEM menu choose LOCAL OVRD

TIME to set the time the AppStat will hold an

override temperature setpoint as the active

setpoint. At the end of the period, the AppStat

will use either an occupied or unoccupied

setpoint as the active setpoint.

Revision G 53

Page 54

BackEnterCncl

FAN OFF DELAY

2 2 mins

BackEnterCncl

OCCUPIED FAN:

ON

OFF

BackEnterCncl

MINOFF TIME:

5 mins

BackEnterCncl

STAGE DELAY:

10 mins

Section 4: Commissioning functions KMC Controls, Inc.

Set up roof top unit system options (continued)

Procedure Steps Display

4 Set the fan delay.

5 Set the occupied fan

control.

6 Set up staged cooling

and heating.

From the SYSTEM menu choose FAN OFF

DELAY to set the time the system fan will

continue to run after the last heating or cooling

stage is turned off.

From the SYSTEM menu choose OCCUPIED

FANto choose the following:

When ON, the fan will run continuously

when the AppStat schedule is ON (occupied).

When the AppStat schedule is OFF

(Unoccupied) the fan will run only when

there is a call for heating or cooling.

To set up staged cooling and heating do the

following:

1.

From the SYSTEM menu choose MIN OFF

TIME to enter the time a stage must remain

turned off before it can be turned on again.

2.

From the SYSTEM menu choose STAGE

DELAY to enter the time the first stage must

remain turned on before the second stage

can be turned on.

54 Revision G

Page 55

BackEnterCncl

ECON ENABLE:

ENABLED

DISABLED

BackEnterCncl

MIN ECON DAMPER:

10%

BackEnterCncl

ECON ENABLE TEM:

60 °F

BackEnterCncl

MIN DAT:

55 °F

BackEnterCncl

DEHUM ENABLE:

ENABLE

DISABLE

BackEnterCncl

HEATING FAN:

AUTO

OFF

Installation, Operation, and Application Guide for AppStat Section 4: Commissioning functions

Set up roof top unit system options (continued)

Procedure Steps Display

7 Enable the

economizer.

(Optional feature)

The economizer feature is an option and not

available on all models.

To set up the economizer do the following:

1.

From the SYSTEM menu choose ECON

ENABLE to enable the economizer

application.

2.

From the SYSTEM menu choose MIN ECON

DAMPER to set the minimum position for

the economizer damper.

3.

From the SYSTEM menu choose ECON

ENABLE TEM. Enter the value that the

outside air temperature must fall below

before the economizer damper can open.

4.

From the SYSTEM menu choose MIN DAT.

Enter the minimum discharge air

temperature that will be allowed during

cooling when the economizer is enabled.

8 Enable

9 Set heating fan

Revision G 55

dehumidification.

(Optional feature)

control.

From the SYSTEM menu choose DEHUM

ENABLE to enable or disable dehumidification.

Dehumidification is only available on models

with a humidity sensor.

From the SYSTEM menu choose HEATING

FAN and then choose one for the following.

AUTO—The fan runs only on a call for heat.

OFF—The AppStat will not command the fan

to run. Typically this setting used for

systems with baseboard heat or some similar

split system configuration.

Page 56

F

°

70

AUTO AUTO

SECURITY

ADMIN LEVEL

0 0 0 0

MAIN

SETPOINT

SCHEDULE

SYSTEM

COMM

ADVANCED

BackEnterExit

BackEnterExit

SYSTEM

LOCAL OVRD TIME

FAN OFF DELAY

OCCUPIED FAN

MIN OFF TIME

STAGE DELAY

ECON ENABLE

MIN ECON DAMPER

SYSTEM

ECON ENABLE TEM

MIN DAT

REV VLV PLRTY

AUX HEAT

AUX HT LOCKOUT

COMP LOCK TEMP

DEHUM ENABLE

BackEnterExit

Section 4: Commissioning functions KMC Controls, Inc.

Set heat pump unit system options

The items in the system menu control application specific functions for heat

pump units. Entering the system options requires entering Password 2 which

is described in the topic Enter the commissioning mode on page 40.

Set up heat pump unit system options

Procedure Steps Display

1.

1 Starting display.

Start at the temperature display.

2.

Enter Password 2. The display changes to the

MAIN menu display.

1.

2 Choose and set the

heat pump system

options.

From the MAIN menu , press either the or

button to select SYSTEM.

2.

Press Enter. The SYSTEM menu opens.

3.

Choose any of the following items.

LOCAL OVRD TIME

FAN OFF DELAY

OCCUPIED FAN

MIN OFF TIME

STAGE DELAY

ECON ENABLE (optional)

MIN ECON DAMPER (optional)

ECON ENABLE TEM (optional)

MIN DAT (optional)

REV VLV PLRTY

AUX HEAT (optional)

AUX HT LOCKOUT (optional)

COMP LOCK TEMP

DEHUM ENABLE (optional)

56 Revision G

Page 57

BackEnterCncl

LOCAL OVRD TIME

2 60 mins

BackEnterCncl

FAN OFF DELAY

2 2 mins

BackEnterCncl

OCCUPIED FAN:

ON

OFF

BackEnterCncl

MINOFF TIME:

5 mins

BackEnterCncl

STAGE DELAY:

10 mins

Installation, Operation, and Application Guide for AppStat Section 4: Commissioning functions

Set up heat pump unit system options (continued)

Procedure Steps Display

3 Set the local override

time.

4 Set the fan delay.

5 Set the occupied fan

control.

6 Set up staged cooling

and heating.

From the SYSTEM menu choose LOCAL OVRD

TIME to set the time the AppStat will hold an

override temperature setpoint as the active

setpoint. At the end of the period, the AppStat

will use either an occupied or unoccupied

setpoint as the active setpoint.

From the SYSTEM menu choose FAN DELAY

OFF to set the time the system fan will continue

to run after the last heating or cooling stage is

turned off.

From the SYSTEM menu choose OCCUPIED

FANto choose the following:

When ON, the fan will run continuously

when the AppStat schedule is ON (occupied).

When the AppStat schedule is OFF

(Unoccupied) the fan will run only when

there is a call for heating or cooling.

To set up staged cooling and heating do the

following:

1.

From the SYSTEM menu choose MIN OFF

TIME to enter the time a stage must remain

turned off before it can be turned on again.

2.

From the SYSTEM menu choose STAGE

DELAY to enter the time the first stage must

remain turned on before the second stage

can be turned on.

Revision G 57

Page 58

BackEnterCncl

ECON ENABLE:

ENABLED

DISABLED

BackEnterCncl

MIN ECON DAMPER:

10%

BackEnterCncl

ECON ENABLE TEM:

60 °F

BackEnterCncl

MIN DAT:

55 °F

DelEnterCncl

RV VLV PLRTY:

ACTIVE HEATING

ACTIVE COOLING

DelEnterCncl

AUX HEAT:

Comp Lockout

3rd Stage

None

Section 4: Commissioning functions KMC Controls, Inc.

Set up heat pump unit system options (continued)

Procedure Steps Display

7 Enable the

economizer.

(Optional feature)

The economizer feature is an option and not

available on all models.

To set up the economizer do the following:

1.

From the SYSTEM menu choose ECON

ENABLE to enable the economizer

application.

2.

From the SYSTEM menu choose MIN ECON

DAMPER to set the minimum position for

the economizer damper.

3.

From the SYSTEM menu choose ECON

ENABLE TEM. Enter the value that the

outside air temperature must fall below

before the economizer damper can open.

4.

From the SYSTEM menu choose MIN DAT.

Enter the minimum discharge air

temperature that will be allowed during

cooling when the economizer is enabled.

8 Set the reversing

9 Set up auxiliary heat.

58 Revision G

valve polarity.

(Optional feature)

From the SYSTEM menu choose REV VLV

PLRTY. Select one of the polarity settings.

Active Heating—The O/B output terminal is

active on a call for heating.

Active Cooling—The O/B output terminal is

active on a call for cooling.

From the SYSTEM menu choose AUX HEAT.

Comp Lockout—The AppStat will enable

auxiliary heat only when the compressors are

locked out because of low outside air

temperature.

3rd Stage—The AppStat uses the auxiliary

heat as a third stage of heating.

None—No auxiliary heat is enabled.

Page 59

DelEnterCncl

AUX HT LOCKOUT:

60 °F

DelEnterCncl

COMP LOCK TEMP:

25 °F

BackEnterCncl

DEHUM ENABLE:

ENABLE

DISABLE

Installation, Operation, and Application Guide for AppStat Section 4: Commissioning functions

Set up heat pump unit system options (continued)

Procedure Steps Display

10 Set the lockout

temperature for

auxiliary heat.

11 Set the compressor

low temperature

lockout.

12 Enable

dehumidification.

(Optional feature)

From the SYSTEM menu choose AUX HT

LOCKOUT to set the minimum outside air

temperature for auxiliary heat lockout. Auxiliary

heat will not operate above this temperature.

From the SYSTEM menu choose COMP LOCK

TEMP to set the minimum outside air

temperature for compressor operation.

Compressors will not operate below this

temperature.

From the SYSTEM menu choose DEHUM

ENABLE to enable or disable dehumidification.

Dehumidification is only available on models

with a humidity sensor and auxiliary heat is

enabled.

Revision G 59

Page 60

F

°

70

AUTO AUTO

MAIN

SETPOINT

SCHEDULE

SYSTEM

COMM

ADVANCED

BackEnterExit

ADVANCED

RESTORE APP

LOOPS

PASSWORDS

CALIBRATION

DISPLAY

KEY LOCKOUT

BackEnterExit

Section 4: Commissioning functions KMC Controls, Inc.

Advanced options

Use the advanced options to set up the following items.

Choosing an application and units of measure.

Adjusting the PID loops

Changing passwords

Calibrating inputs

Setting the display blanking

Modifying access to users with Password 1.

Setting the advance options requires entering Password 2 which is described

in the topic Enter the commissioning mode on page 40.

Choosing advance options

Procedure Steps Display

1.

13 Starting display.

Start at the temperature display.

2.

Enter Password 2. The display changes to the

MAIN menu display.

14 Choose the

ADVANCED

menu.

1.

From the MAIN menu , press either the or

button to select ADVANCED.

2.

Press Enter. The ADVANCED menu opens.

3.

Choose any of the following functions.

RESTORE APP

LOOPS

PASSWORDS

CALIBRATION

DISPLAY

KEY LOCKOUT

60 Revision G

Page 61

RESTORE APP

2P FCU-METRIC

4P FCU-METRIC

2P FCU-ENGLISH

4P FCU-ENGLISH

BackEnterCncl

RESTORE APP

RTU-METRIC

RTU-ENGLISH

BackEnterCncl

RESTORE APP

HPU-METRIC

HPU-ENGLISH

BackEnterCncl

LOOPS

COOL PROP

COOL INTG

HEAT PROP

HEAT INTG

BackEnterExit

Installation, Operation, and Application Guide for AppStat Section 4: Commissioning functions

Choosing advance options (continued)

Procedure Steps Display

15 Reset the

application and

choose units of

measure.

16 Adjust the PID

loops.

Choose RESTORE APP from the ADVANCED

menu to reset the AppStat to the original