Page 1

FlexStat™ BACnet Programmable Thermostats

Operation Guide

BAC-10000 Series

Contents

Overview ................................................................2

Applications and Installation

Operation (Basic)

Home, Main Menu, and Override Screens

Navigation

Main Menu and Settings

Room Temp. Setpoint Adjustment

H/C, Fan, Occupancy, and Override

Configuration (Initial Setup)

Main Menu Overview

About the FlexStat

Advanced Menu

(Advanced) Application Options

(Advanced) CB (Control Basic) Programs

(Advanced) BACnet Communications

(Advanced) Date/Time

(Advanced) BACnet Device Properties

(Advanced) Inputs

(Advanced) Temp. Setpoint Limits

(Advanced) Motion Sensor

(Advanced) Security Levels and Passwords

(Advanced) Trend Logs

(Advanced) Test

Alarms

Date/Time

Schedules

Setpoints

System Setup

Trend Viewer

Resetting the FlexStat

Types of Reset

Warm and Cold Starts

Restore Factory

Network Connection

BAC-10000 Series 1 Operation Guide, Rev. J

............................................................... 11

BACnet MS/TP Network Communication

PC Data Port Connection

....................................................3

..........................................................3

............................................... 4

..................................................5

..............................................10

......................................................... 11

.......................................................... 12

...........................................................13

.....................................................13

.....................................................13

............................................14

....................................................14

.................................................15

............................................. 16

...................................2

..........3

...................................... 3

.......................3

................... 3

...................................4

.........................................4

...................... 5

.........6

..............7

..................................... 7

.............8

............................................8

.................... 8

...............................8

....... 9

................................... 10

....................................... 14

......16

...............................16

Specifications, design, and operation are subject to change without notice.

Troubleshooting ....................................................17

Alarm Issues

Alarm, (False) Fan Fail

Alarm, (False) Low Limit (Freeze Stat)

Alarm, (False) Space Temp. or Humidity

Communication Issues

Firmware Upgrade Fails

KMD-5576 Communication Faulty

MS/TP Network Communication Faulty

Cover and Display Issues

Cover Binds on Backplate

Display Is Blank or Erratic

Display Freezes (Buttons Have No Effect)

Custom Programming and Web Issues

Control Basic Programs Do Not Work

Custom Web Graphics Do Not Work

Input, Sensor, and Value Issues

Input Values Are Outside the Expected Range

Motion/Occupancy Sensor Does Not Work

Temperature Reading Is Incorrect

Temperature Setpoint Is Not Maintained

Output, Fan, and Relay Issues

Analog Output Does Not Work

Fan Does Not Run

Relay (Internal) Does Not Work

Relay (External) Does Not Work

Wiring Issues

Maintenance

Firmware Upgrade

Programming (Custom)

Accessories

Support

Important Notices

Reference

Index

.................................................................23

Acronyms and Abbreviations

Definitions of Terms

.....................................................................26

......................................................17

.................................... 17

............ 17

........17

......................................17

.................................17

................17

......... 17

................................... 18

..............................18

.............................. 18

...... 18

............... 18

............18

.............18

.......................... 19

19

...19

.................. 19

.......19

...........................20

...................... 20

..........................................20

.....................20

....................21

..................................................... 21

.........................................................22

................................................22

.........................................22

...........................................................22

................................................. 23

..............................................................24

............................. 24

..........................................25

Page 2

Overview

Applications and Installation

The KMC FlexStat series of intelligent temperature/

humidity/occupancy-sensing, wall-mounted, thermostat/controllers are native BACnet Advanced

Application Controllers (B-AAC) for use in a BACnet system. The FlexStat simplies networked zone

control for common packaged HVAC equipment,

such as packaged rooop units, fan coil units, heat

pumps, and other similar applications. In addition, applications such as pressure dependent VAV,

terminal reheat, and medium-sized central station air

handling equipment applications may also be addressed through the on-board libraries of programs

built into the devices.

The on-board library of programs permits rapid

conguration of a wide range of HVAC control applications.

The FlexStat series also provides the capability to

customize the standard library of sequences using

KMC’s BACstage programming tool. This enables a

local authorized KMC installing contractor to adapt

the standard library to the unique site needs and application specic requirements of a particular project.

Dimensions in

inches (mm)

1.125

(28.6)

4.192 (106)

5.551

(141)

Terminal Blocks

on Removable

Backplate for

Easy Wiring

Communication with

Other BACnet Devices

Optional

Temperature

Sensing

3 Analog

Inputs

for Other

Sensors or

Contacts

24 Volts AC

Power

Humidity

and

Motion

Sensing

Up to 9

Outputs

(Analog

and/or

Relays)

Quick (Temporary) Network/

Programming Access

Applications

• AHU

• FCU

• HPU

• RTU

1. Wire the FlexStat’s backplate to the desired

equipment and set the FlexStat’s end-of-line and

input pull-up resistor switches.

2. Select the relevant application and options from

the (Advanced) Application submenu of the

Advanced Menu and other appropriate menus.

3. Congure the FlexStat for the BACnet network.

(See Network Connection on page 16.)

For general mounting and connection details,

including network wiring, EOL termination, power

connections, input/output connections, pull-up

resistor switch seings, see the relevant model’s

Installation Guide. For extended information about

wiring and sequences for specic applications, see

the BAC-10000 Series Application Guide.

EIA-485 Data Port for

Quick Network Access

BAC-10000 Series 2 Operation Guide, Rev. J

Page 3

Operation (Basic)

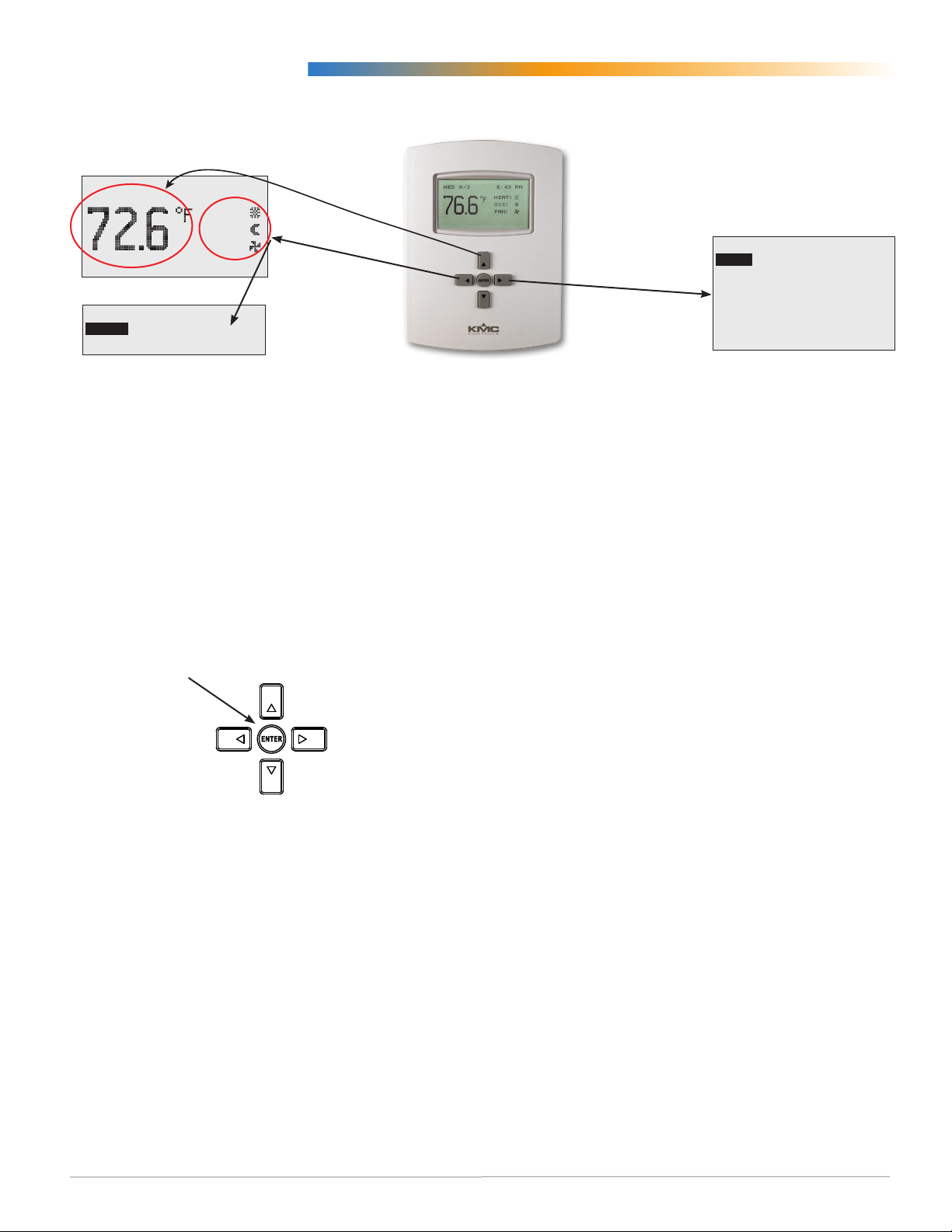

Home, Main Menu, and Override Screens

Home Screen

WED 11/19 3:20 PM

Setpoint

COOL:

OCC:

FAN:

HUM: 36% RH

Override Screens

FAN MODES

UNOCC:

OCC: AUTO

AUTO

Override

Navigation

Navigate the menus and change seings by pressing a combination of various arrow buons and the

Enter buon. Push the:

• Enter buon to select and/or exit value editing.

• Up or Down buon to move among entries.

• Right or Le buon to move among value elds.

• Le buon to return to the Home screen.

Up/Setpoint Button

Enter Button

Left/Override

Button

Right/Menu

Button

Configuration Screens

MAIN MENU

ABOUT

Menu

ADVANCED

ALARM

DATE/TIME

SCHEDULE

SETPOINTS

SYSTEM

Room Temp. Setpoint Adjustment

From the Home (temperature display) screen, press

the Up or Down arrow buon once to view the existing setpoint.

To temporarily change the setpoint, press the Up

or Down arrow buon repeatedly until the desired

seing is displayed and press Enter. (If Enter is not

pressed, the display will return to the Home screen

aer about ve seconds and the new setpoint value

will still be saved.) The new setpoint will hold until

the next schedule change.

To permanently change the setpoint for occupied

mode, go to the Setpoints section under the Main

Menu. (In the Setpoints menu, heating/cooling setpoints/setbacks and deadband can be changed with,

if required, the correct password access. See Set-

points on page 13.)

Down/Setpoint Button

H/C, Fan, Occupancy, and Override

When the fan is commanded to run, the animated

Main Menu and Settings

“FAN” icon rotates (if programmed to). When the

fan command stops, the fan icon is motionless.

From the Home (temperature display) screen, press

the Right arrow buon to enter the Main Menu. You

may need to enter a password to change any seings.

The “OCC” icon shows a sun when in Occupied

mode and a quarter moon when in Unoccupied

mode.

HEAT or COOL will show (and be animated when

NOTE: Access to the Main Menu, setpoint adjust,

and System/Occupancy/Fan override may

require a password.

there is an active command), depending on the current mode. This can also be turned OFF.

To override these modes from the Home (tempera-

ture display) screen, press the Le arrow buon.

Press Up or Down to get to the desired line and then

Enter (twice) to edit the mode seing. Press

Leto

exit to Home.

BAC-10000 Series 3 Operation Guide, Rev. J

Page 4

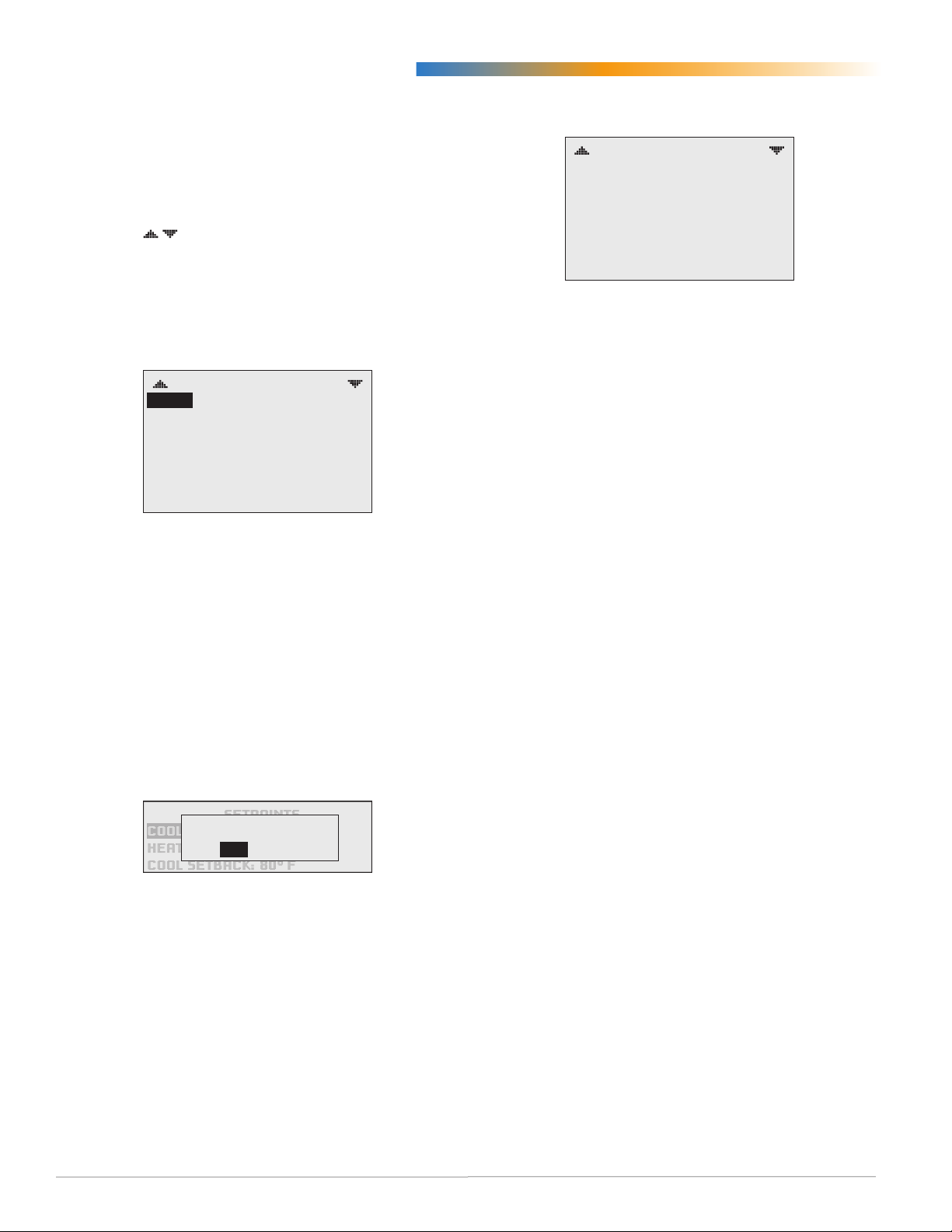

Configuration (Initial Setup)

NOTE: Menus shown in this document reect

rmware version R1.3.0.4 or later. Actual

context-sensitive screens are dependent

on rmware version, FlexStat model, and

options selected.

NOTE: If appear at the top of the screen

(such as in the Main Menu), scroll up or

down to see the rest of the menu’s oscreen choices.

Main Menu Overview

MAIN MENU

ABOUT

ADVANCED

ALARM

DATE/TIME

SCHEDULE

SETPOINTS

SYSTEM

Navigate the menus and change seings by pressing

a combination of buons. Press the:

• Enter buon to select and/or exit value editing.

• Up/Down buon to move among entries (up/

down lines).

• Le/Right buon to move among value elds

(le/right spaces).

About the FlexStat

ABOUT FLEXSTAT

FW: R1.3.0.0

BUILT: DEC 11 2009 @13:55:07

ASV: BAC_1xx63 R1.3.0.0 +6

MODEL: BAC–11163C

APP: AIR HANDLER

OPT: MOD H / MOD C

INSTANCE: 1

This display-only screen shows (scroll to see all):

• Firmware version (FW)

• Build date

• Application soware version (ASV)

• Model number

• Application conguration and options (set in the

Application menu)

• Device instance (set in the Device menu)

• MAC address (set in the Communications menu)

• Serial number

• Board revision

NOTE: ASV will show CUSTOM if any built-in

Control Basic program (1–5) is not running

or has auto-run disabled.

• Le buon to return to the Home screen.

NOTE: A log-in may be required to access menu

items.

SETPOINTS

SAVE CHANGE?

COOL SETPT:

HEAT SETPT: 67° F

COOL SETBACK: 80° F

YES

NO

When prompted about a change (on any menu),

press Right/Le to select the desired choice and

then Enter.

BAC-10000 Series 4 Operation Guide, Rev. J

Page 5

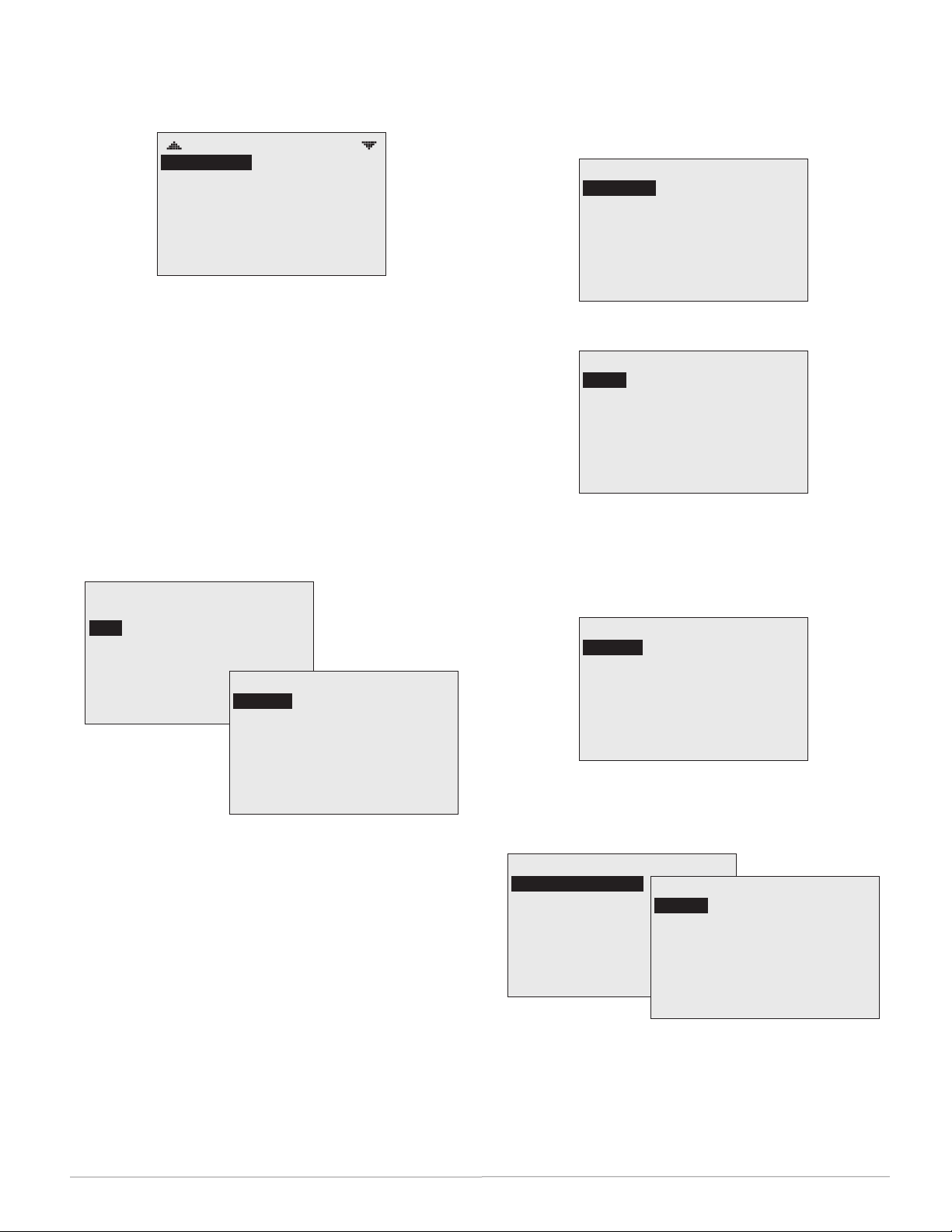

Advanced Menu

ADVANCED

APPLICATION

CB PROGRAMS

COMMUNICATION

DATE/TIME

DEVICE

INPUTS

LIMITS

The Advanced Menu displays various submenus.

Not all submenus can be seen on the screen at one

time. Scroll up or down to see additional submenus.

To select the desired submenu, press:

1. Up/Down to move.

2. Enter to select.

NOTE: The Advanced Menu has more submenus

than can appear on the screen at once. Keep

scrolling up or down to see all the options.

(Advanced) Application Options

APPLICATION

DEGREES SCALE: °F

APP:

FAN COIL

OPT: 4-PIPE

ADDITIONAL SETUP

ADDITIONAL SETUP

DAMPER

FAN

HUMIDITY

SENSORS

VALVE

Auxiliary Heat (Heat Pump Only)

AUX HEAT SETUP

AUX HEAT:

DELAY (MINS): 60

COMP LOCKOUT

Damper Setup

DAMPER SETUP

ECON:

MIN POSITION (%): 10

CNTRL (0–100%): 2–10 V

ECON ENBLE TEMP: 55° F

LOW LIMIT ALARM: 45° F

MODULATING

NOTE: If the Economizer option is selected when

there is no mixed air temperature sensor

connected, a Low Limit Alarm will result.

See Alarms on page 11.

Fan Setup

FAN SETUP

SPEEDS:

OFF DELAY (SECS): 180

UNOCC: AUTO

OCC: AUTO

CONSTANT SPEED

NOTE: For a Fan Fail Alarm, see Sensor Setup on

page 6 and Alarms on page 11.

To change ° F or C, preprogrammed application type,

and options, press:

1. Up/Down to move among entries.

2. Enter to select.

3. Right/Le to move among value elds.

Humidity Setup

HUMIDITY SETUP

DEHUMIDIFICATION

HUMIDIFICATION

DEHUMIDIFICATION

DEHUM:

ALLOW HTG DEHUM: NO

DEHUM SETPT: 60%RH

DEHUM DEADBAND: 5%RH

ENABLE

4. Up/Down to increment/decrement value.

The type of application (as well as the model of

FlexStat) aects the context-sensitive options under

Additional Setup.

NOTE: If a dehumidication option is enabled, the

Space Humidity Alarm will also be enabled.

See Alarms on page 11.

BAC-10000 Series 5 Operation Guide, Rev. J

Page 6

Sensor Setup

(Advanced) CB (Control Basic) Programs

SENSOR SETUP

IN 2:

DISCH AIR TEMP

The Input 2 sensor (AI2) can be congured for

discharge air temperature (Type III thermistor is the

default), fan status (dry contact), or unused.

• If set for discharge air temperature, the sensor

can be calibrated and changed from the default

Type III thermistor to a Type II. See (Advanced)

Inputs on page 8.

• If set for discharge air temperature, Trend Log

#2 is automatically created and monitors the

discharge air temperature, but it has no eect on

operation.

• If set for fan status and no closed contact is

detected when there is a call for fan operation, a

Fan Fail Alarm is created. See Alarms on page 11.

• If set for unused, built-in applications will not

use AI2, but the input would be available to

custom programming.

Staging Setup

STAGING

STG DELAY (MINS):

3

Valve Setup

VALVE SETUP

TYPE:

ACTION: NRM OPEN

2–POSITION

CB PROGRAMS

PROG1:

PROG2: RUNNING

PROG3: RUNNING

PROG4: RUNNING

PROG5: RUNNING

PROG6: HALTED

PROG7: IDLE

RUNNING

PROGRAM #1

SETPOINTS & MODES

AUTO-RUN: TRUE

CHANGE: READY

STATE: RUNNING

HALT REASON: NORMAL

HALT DESC:

OUT OF SERVICE: FALSE

To halt or load/run the built-in (1–5) and custom

(6–10) Control Basic programs, press:

1. Up/Down to move among entries.

2. Enter to select.

3. Right/Le to move among value elds.

4. Up/Down to increment/decrement value.

NOTE: If custom Control Basic programs are

installed and a restore to factory seings

is performed, all factory programs are

restarted but all custom Control Basic

programs are halted. Change the state

of each program by loading/running the

program from the CB Programs menu (or

BACstage).

NOTE: If custom Control Basic programs are

installed and set to autorun, whenever the

rmware is updated, ALL (factory and

custom) programs are halted.

If custom Control Basic programs are

installed but NOT set to autorun,

whenever the rmware is updated, factory

programs are restarted but any (manual)

running custom programs are halted at

restart.

Change the state of each custom program

by using the Update Manager or loading/

running each program from the CB

Programs menu (or BACstage).

UPDATE MANAGER

PROGRAM CONFIG ERROR

ENABLE FACTORY:

ENABLE CUSTOM: NO

EDIT CB PROGRAMS

DONE

NO

NOTE: Customized programs are the responsibility

of the user. KMC Controls does not provide

support for such programs.

BAC-10000 Series 6 Operation Guide, Rev. J

Page 7

(Advanced) BACnet Communications

Sample Time Zones Oset to Equal UTC

COMMUNICATIONS

MAC ADDRESS:

BAUD RATE: 38400

MAX MASTER: 127

1

To set parameters for BACnet MS/TP EIA-485

communications, press:

1. Up/Down to move among entries.

2. Enter to select.

NOTE: The Max Master is the highest MAC

address a device will aempt to locate

when polling for master devices on

the local network. To avoid possible

communication issues with the network

or a computer connected through a KMD5576 USB Communicator, the Max Master

number should be the lowest number

needed for that network.

(Advanced) Date/Time

DATE/TIME

DATE:

TIME: 1:43:59 PM

UTC OFFSET: 300

DST ENABLE: TRUE

DST AUTO: TRUE

DST START:

>2ND SUN MAR 2:00 AM

APRIL 11 2009

Alaska 9 hours = 540 minutes

USA/Canada Pacic

8 hours = 480 minutes

Standard Time

USA/Canada Mountain

7 hours = 420 minutes

Standard Time

USA/Canada Central

6 hours = 360 minutes

Standard Time

USA/Canada Eastern

5 hours = 300 minutes

Standard Time

Bolivia, Chile 4 hours = 240 minutes

Argentina, Uruguay 3 hours = 180 minutes

United Kingdom,

0 hours = 0 minutes

Portugal

Europe (most countries) –1 hours = –60 minutes

Egypt, Israel, Turkey –2 hours = –120 minutes

Kuwait, Saudi Arabia –3 hours = –180 minutes

United Arab Emirates –4 hours = –240 minutes

India, Sri Lanka –5.5 hours = –330 minutes

China, Mongolia –8 hours = –480 minutes

Korea, Japan –9 hours = –540 minutes

New Zealand –12 hours = –720 minutes

NOTE: The BACnet standard for this oset value

is: “The time zones to the west of the zero

degree meridian shall be positive values,

and those to the east shall be negative

values.” The value is in minutes, not hours.

To enter date and time information, press:

1. Up/Down to move among entries.

2. Enter to select.

3. Right/Le to move among value elds.

4. Up/Down to increment/decrement value.

For areas that observe Daylight Saving Time, select

True/On for DST ENABLE.

If the FlexStat is used in a BACnet network with UTC

(Coordinated Universal Time) synchronization (via

broadcasting or addressing a single thermostat) set

the UTC Oset value. The UTC Oset value is in

minutes and corresponds to the distance of the local

time zone to the zero degree meridian. In stand-alone

operation or networks that do not have UTC broadcasts, seing this value is not necessary.

BAC-10000 Series 7 Operation Guide, Rev. J

Page 8

(Advanced) BACnet Device Properties

(Advanced) Temp. Setpoint Limits

DEVICE

INSTANCE:

NAME: FlexStat_101

LOCATION: KMC Controls

RESTART: NO

RESTORE FACTORY: NO

1

To set the BACnet device instance, name, and

location, press:

1. Up/Down to move among entries.

2. Enter to select.

The FlexStat can also be restarted or restored to

factory defaults from this menu. See Reseing the

FlexStat on page 14 for more information about that

function.

(Advanced) Inputs

INPUTS

1: SPACE TEMP

2:

DISCH AIR TEMP

3: MIXED AIR TEMP

4: OUTSIDE AIR TEMP

4: SPACE HUMIDITY

Inputs vary according to model, selected application,

and selected application options. See (Advanced) Ap-

plication Options on page 5.

To change sensor type and calibration oset, press:

1. Up/Down to move among entries.

2. Enter to select.

INPUT #2

DISCH AIR TEMP

VALUE: 60.0° F

CAL. OFFSET: 0.0

OUT-OF-SERVICE: FALSE

SENSOR:

10K TYPE III

LIMITS

OCC MIN CLG:

OCC MAX HTG: 76° F

UNOCC MIN CLG: 77° F

UNOCC MAX HTG: 65° F

71° F

To set the minimum and maximum allowed user/

operator setpoint values, press:

1. Up/Down to move among entries.

2. Enter to select.

3. Right/Le to move among value elds.

4. Up/Down to increment/decrement value.

(Advanced) Motion Sensor

MOTION SENSOR

MOTION OCC:

STATE: OCCUPIED

In BAC-11xxx models, a motion/occupancy sensor

may be enabled to trigger occupancy override.

During scheduled “o” times, the motion sensor will

start occupancy override (for 1 hour as a default)

when it detects motion. Occupancy override will end

(with the default seing) 1 hour aer motion was

last detected. The length of occupancy override is

congurable in the System menu. See System Setup

on page 13.

To enable/disable or monitor the motion/occupancy

sensor (if installed), press:

ENABLE

3. Right/Le to move among value elds.

4. Up/Down to increment/decrement value.

Value will show a temperature reading or a voltage

(0.0 to 3.0), depending on the sensor. Analog sensors

can be calibrated using the Calibration Oset option.

1. Enter to select.

2. Right/Le to move among value elds.

3. Up/Down to increment/decrement value.

The State eld monitors whether motion has been

detected during the last scan of the motion sensor

input (BI6). Detected motion will show an “occupied” state. This can be used during troubleshooting

to determine if motion is being detected.

BAC-10000 Series 8 Operation Guide, Rev. J

Page 9

(Advanced) Security Levels and Passwords

SECURITY

ACCESS LEVELS

PASSWORDS

ACCESS LEVELS

SETPOINT ADJ:

MAIN MENU: ADMIN

SYSTEM MODE: OPER

OCC OVERRIDE: USER

FAN OCC/UNOCC: OPER

NONE

Access to the Main Menu, Setpoint Adjust, and

System/Occupancy/Fan seings have a default

password level of User. This level can be changed for

each function to None, Operator, or Administrator

through the Access Levels menu. Passwords are set

in the Passwords menu.

Any person can view the display but might not be

able to change any seings without logging in with

one of the three levels of passwords:

• None (Level “0”): No password is required

(everyone has access).

• User (Level 1): See the Menu Items Access Levels

chart.

• Operator (Level 2): See the Menu Items Access

Levels chart.

• Administrator (Level 3): Can access all menus

and change all editable values. DO NOT

FORGET THIS PASSWORD!

NOTE: Seing a password to (the default) 0000

eliminates the password prompt and

allows full access for that level. If no

password is set for ADMIN, no password

prompt will occur. If any password is set

for ADMIN, the menu items accessible

at the various levels are shown in the

following chart.

NOTE: Changes in security levels and/or

passwords take eect when the current

Administrator log-in has timed out. Log-

ins last until 60 seconds (default) aer

the last buon press. Desired length of

inactivity time-out can be changed in the

Systems submenu.

NOTE: When seing a password, the Up buon

increases the alphanumeric value (0

through 9 and then A through Z). The

Down buon decreases the value. DO NOT

FORGET THE ADMIN PASSWORD!

PASSWORDS

USER:

OPERATOR:

ADMIN:

1 0 0 0

1 2 3 4

5 6 7 8

To enter an alphanumeric password at the prompt:

1. Up/Down to move.

2. Enter to select.

3. Up/Down to increment/decrement value.

The required password level is specied in the

prompt.

For additional security and protection from

vandalism, install the FlexStat inside a third-party

locking thermostat guard/cover (but proper airow

must be maintained).

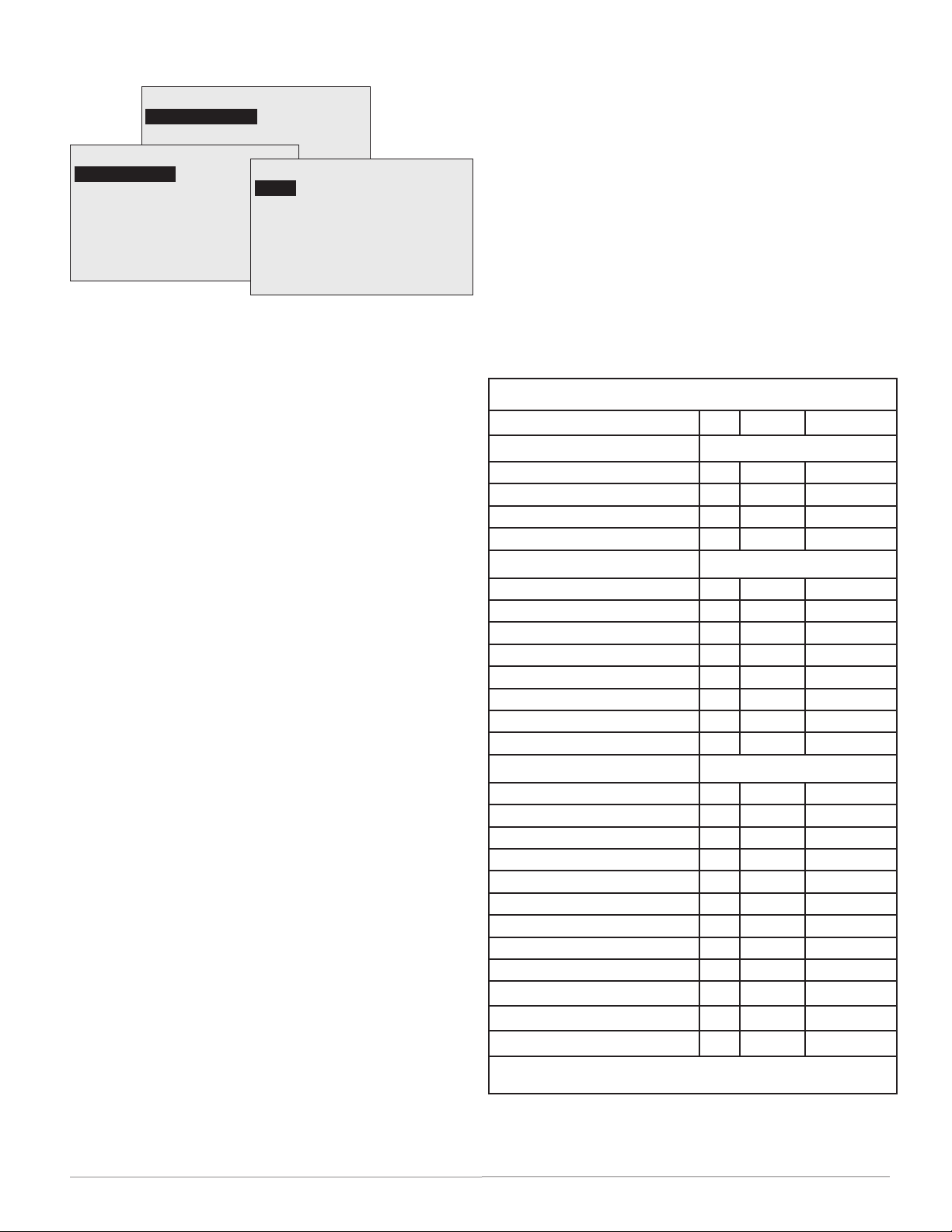

Menu Items Access Levels

Menus User Operator Administrator

Home Screen * = Selectable, Default is User

Setpoint Adjust (Up/Down) x* x* x*

System Mode (Auto/Heat/Cool/Off) x* x* x*

Occupancy Override (On/Off) x* x* x*

Fan Modes (Auto/On/Off) x* x* x*

Main Menu* (Default is User)

About x x x

Advanced x x

Alarm x x

Date/Time x x

Schedule x x

Setpoints x x

System x x

Trend Viewer x x x

Advanced Menu

Application x

Additional Setup x

Control Basic Programs x x

Communication x

Date/Time x x

Device x

Inputs x x

Limits x x

Motion Sensor x x

Security x

Trend Logs x x

Test x x

This chart shows conditions in which an administrator password is set

(is not 0000) and default password levels are used.

BAC-10000 Series 9 Operation Guide, Rev. J

Page 10

(Advanced) Trend Logs

(Advanced) Test

TREND LOGS

TREND 1:

TREND 2: TRUE

TREND 3: FALSE

TREND 4: FALSE

TREND 5: FALSE

TREND 6: FALSE

TREND 7: FALSE

TRUE

TREND #1

SPACE TEMPERATURE LOG

OBJECT REF: AI1

LOG ENABLE: TRUE

INTERVAL (MINS): 10

STOP W/FULL: FALSE

RESET COUNT: NO

COUNT: 256

TOTAL CNT: 613

VIEW LOG BUFFER

TL #1–SPACE TEMP

APR17 1:27PM, 71.4

APR17 2:27PM, 71.5

APR17 3:27PM, 71.6

APR17 4:27PM, 71.8

APR17 5:27PM, 76.3

APR17 6:27PM, 81.2

APR17 7:27PM, 82.3

NOTE: Space temperature (AI1) is the default trend

log #1. If AI2 is congured for discharge air

temperature, that will become the default

trend log #2. See Sensor Setup on page 6.

To set the desired object to track, press:

1. Up/Down to move among entries.

TEST

LCD/KEY TEST

The test menu merely tests the display’s pixels and

key functions.

1. Up/Down to move among entries.

2. Enter to select and exit.

2. Enter to select.

The trend log buer may be viewed by scrolling

down and selecting View Log Buer. The buer may

also be viewed from the Main Menu by scrolling

down to the Trend Viewer (see page 13).

NOTE: The BACnet standard for log intervals

is hundredths of seconds. The simplied

display on the FlexStat converts the value

to minutes. However, BACstage™ and

TotalControl® do display hundredths of

seconds but in dierent ways. For a “10”

(minute) interval on a FlexStat display,

TotalControl would show “00:10:00.00”

(hours:minutes:seconds.hundredths of

seconds) and BACstage would show

“60000” (hundredths of seconds) instead.

NOTE: If applicable to the model, the humidity

sensor is AI5 and the motion sensor is

BI6, which can also be congured for trend

logs. See the BAC-10000 Series Application

Guide (P/N 913-019-03) or relevant BAC10000 Series Installation Guide for other

desired input and output objects in an

application.

BAC-10000 Series 10 Operation Guide, Rev. J

Page 11

Alarms

Date/Time

SAT 4/11 3:20 PM

COOL:

OCC:

FAN:

SERVICE HUM: 20%RH

ALARMS

* SPACE TEMP ALARM 04/11

04/11/09 08:37:56

<AI1> SPACETEMP

PRESENT VALUE = 90.1

EXCEEDS HIGH_LIMIT

<EE1>

SPACETEMPALARM

DELETE ALARM?

YES

NO

A ashing “SERVICE” on the Home screen indicates

an alarm. To view and delete alarms, press:

1. Right to move among elds.

2. Enter to select. (Enter on Alarm Details screen to

delete the alarm.)

3. Le to go back one page.

Built-in alarms are triggered under these conditions:

• Space Temp Alarm—temperature outside the

range of 56 to 86° F for over 300 seconds.

DATE/TIME

DATE:

TIME: 1:43:59 PM

APR 11 2009

To enter date and time information (only), press:

1. Up/Down to move among entries.

2. Enter to select.

3. Right/Le to move among value elds.

4. Up/Down to increment/decrement value.

More options (such as UTC oset and daylight saving time options) are available in the (Advanced)

Date/Time menu (see page 7).

• Space Humidity Alarm—humidity above 65%

for over 300 seconds. This is available only in

FlexStat models with a humidity sensor and a

dehumidication option selected in the Humidity setup). See Humidity Setup on page 5.

• Fan Fail Alarm—no fan status signal within ve

seconds of call for fan (and Input 2 is congured

for the fan status sensor option). See Sensor Setup

on page 6.

• Low Limit Alarm (freeze stat)—space

temperature is below the adjustable (under

Damper Setup) low limit alarm temp for one

second (when congured for the economizer

option). Aer a low limit alarm is generated,

the fan will not run until aer the FlexStat

is restarted. See Restart under Reseing the

FlexStat on page 14. See also Damper Setup on

page 5.

(Up to six additional alarms may be added with

custom programming.)

NOTE: Time delays and limits can be modied in

the corresponding Event Enrollment objects

using TotalControl.

BAC-10000 Series 11 Operation Guide, Rev. J

Page 12

Schedules

SCHEDULE

WEEKDAYS [MON–FRI]

WEEKEND [SAT–SUN]

ENTIRE WEEK [MON–SUN]

INDIVIDUAL DAYS

HOLIDAYS

To select the desired schedule, press:

1. Up/Down to move among entries.

2. Enter to select.

3. Le to go back one page.

WEEKDAYS

1:

7:30:00 AM ON

2: 5:15:00 PM OFF

3:

4:

5:

6:

[—>] DELETES ENTRY

To enter weekly schedules for occupied (ON) and

unoccupied (OFF) times, press:

HOLIDAYS

HOL1:

JAN 1 2009

HOL2: MAR 21 2009

HOL3: MAY 26 2009

HOL4: JULY 4 2009

HOL5: SEPT 1 2009

HOL6: NOV 27 2009

HOL7: NOV 28 2009

The Holiday entries will override the normal

occupied weekly schedule entries and keep those

days’ seings at their setback values. Setback

values are entered in the Setpoints section of the

Main Menu. (See also the maximum and minimum

setpoint values in the Limits section of the Advanced

Menu.)

To enter upcoming holidays, press:

1. Up/Down to move among entries.

2. Enter to select.

3. Right/Le to move among value elds.

4. Up/Down to increment/decrement value.

1. Right/Le to move among days and Enter to

select.

2. Up/Down to move among entries and Enter to

select and edit.

3. Right/Le to move among value elds.

4. Up/Down to increment/decrement value.

5. Enter to exit value editing.

6. Le to move back to days or back one page.

BAC-10000 Series 12 Operation Guide, Rev. J

Page 13

Setpoints

SETPOINTS

COOL SETPT:

HEAT SETPT: 67° F

COOL SETBACK: 80° F

HEAT SETBACK: 64° F

MIN SETPT DIFF: 2° F

DEADBAND: 2° F

DEHUM SETPT: 60 % RH

In the Setpoints menu, deadband, setbacks, and

setpoints for various values are set. (The room

temperature setpoint can also be manually changed

from the Home menu.)

To adjust the setpoints, press:

1. Up/Down to move among entries.

74° F

When Display Blanking is enabled (Y), the display

turns o at the same time the backlight goes o

(aer reset, initial power-up, or time-out). When any

buon is pressed, the display will reappear until the

time-out is reached again.

The menu/display/backlight time-out (seconds

since the last buon is pushed) is set in Inactivity.

Access to the Main Menu, setpoint adjust, and

System/Occupancy/Fan override have a default

password level of User. This level can be changed for

each function to None, Operator, or Administrator

through this screen. Passwords are set in the (Advanced) Passwords menu. See (Advanced) Security

Levels and Passwords on page 9.

2. Enter to select.

3. Up/Down to increment/decrement value.

System Setup

SYSTEM

SYSTEM ENABLE:

OCC OVRIDE (HRS): 1.0

INACTIVITY (SECS): 60

DISPLAY BLANKING: NO

To adjust the system conguration values, such as

system enable (auto, o, heat, or cool), occupancy

override time, and display inactivity time-out:

1. Up/Down to move among entries.

2. Enter to select.

3. Up/Down to increment/decrement value.

AUTO

Trend Viewer

TREND VIEWER

1:

SPACE TEMP 34

2: SPACE HUMIDITY 27

3: FAN 19

4: COOL 1 18

5: COOL 2 21

6:

7:

To view trend log buers, press:

1. Up/Down to move among entries.

2. Enter to select.

Trend logs are set up in the (Advanced) Trend Logs

menus (see page 10).

TL #1 SPACE TEMP

APR11 1:27PM, 70.3

APR11 2:27PM, 71.3

APR11 3:27PM, 71.6

APR11 4:27PM, 71.8

APR11 5:27PM, 76.3

APR11 6:27PM, 81.2

APR11 7:27PM, 82.3

Occupancy Override on this menu is the amount of

time (in hours) a manual change in the setpoint (via

the Up and Down buons) will be allowed to override the scheduled setpoint. When the time is set to

0, the override state will last until the next schedule

change.

BAC-10000 Series 13 Operation Guide, Rev. J

Page 14

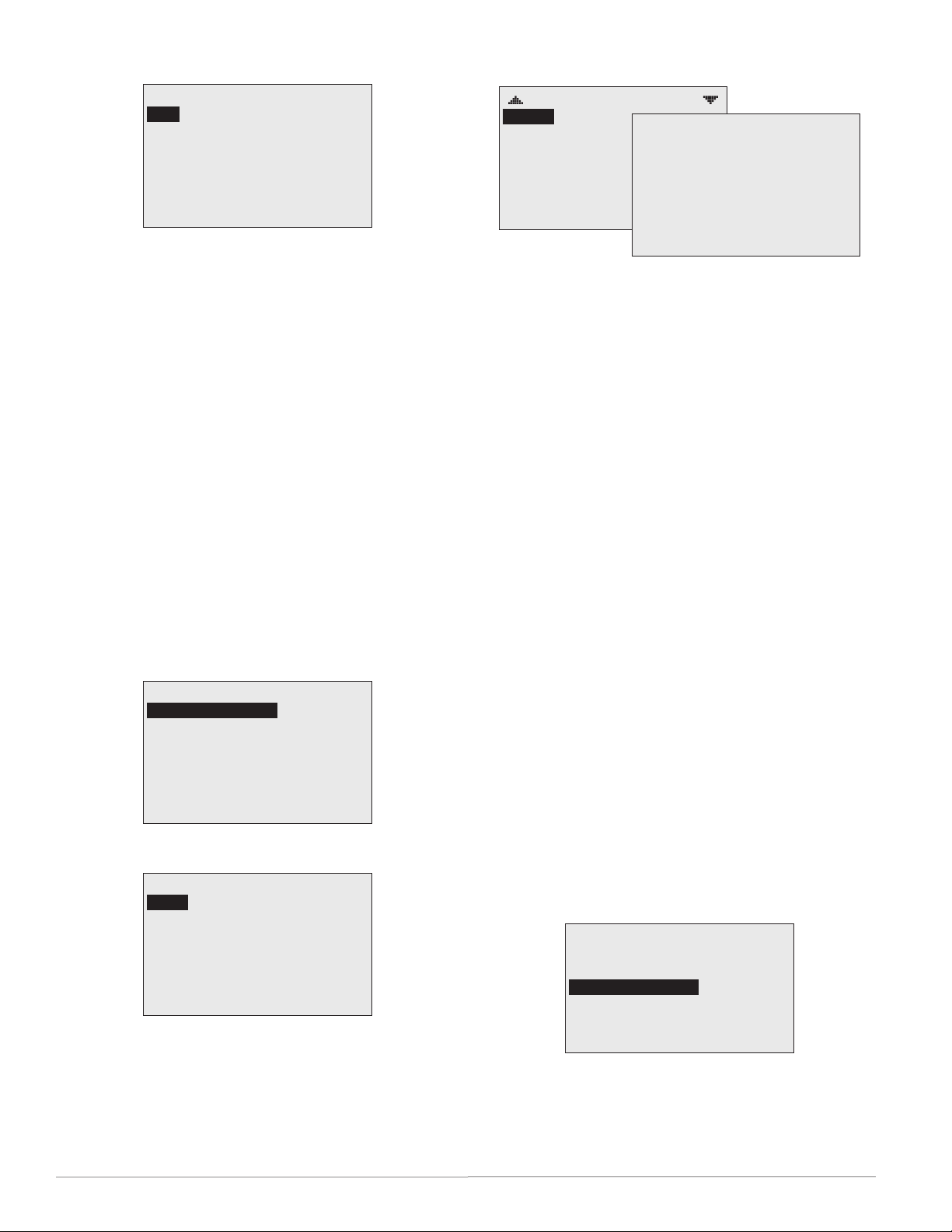

Resetting the FlexStat

Types of Reset

If the FlexStat is not operating correctly or if a low

limit alarm has occurred, the FlexStat should be

reset (reinitialized). Any reset interrupts normal operation, and three types of reset exist:

• A warm start is generally the least disruptive op-

tion (restarting normal operation the quickest).

• If problems still persist, try a cold start. (This

should also be used aer a new Control Basic

program is loaded and compiled.)

• If problems still persist (or major changes in a

rmware update have taken place) restoring fac-

tory defaults (and reconguring and reprogramming the FlexStat) may be required.

Warm and Cold Starts

CAUTION

During a restart, the analog outputs go to zero,

and relays go to their normally open state. A restart is a process that lasts around ten seconds,

and it may result in several changes of state

for an output, turning equipment off and on

abruptly. Before resetting the FlexStat, manually

override equipment as needed. If a large fan

is controlled by the FlexStat, for example, set

a minimum off time. See Fan Setup on page 5

(built-in, selectable applications with compressors have a default programmed minimum off

time of 300 seconds).

A warm start does the following in the FlexStat:

• Restarts the controller’s Control Basic programs.

• Leaves conguration and programming intact.

NOTE: Menu changes may take up to about two

minutes to write to nonvolatile Flash

memory. If power to the FlexStat is lost

during this time, changes may be lost.

Restarting the FlexStat from its menu,

TotalControl, or BACstage are the

recommended methods.

NOTE: When power is restored aer an outage,

the FlexStat will aempt to do a warm

start as long as the values in RAM are

retained (up to about four hours). If

the the RAM checksum test fails, a cold

start will be done instead. (In custom

Control Basic programming, using the

POWERLOSS command may be desirable

to determine start-up conditions and to take

appropriate actions—see the Help system

in TotalControl or BACstage for more

information.)

ADVANCED

APPLICATION

CB PROGRAMS

COMMUNICATION

DATE/TIME

DEVICE

LIMITS

SECURITY

DEVICE

INSTANCE: 1

NAME: FlexStat_101

LOCATION: KMC Controls

RESTART:

RESTORE FACTORY: NO

WARM START

To perform a WARM start, do one of the following:

• (Aer zeroing out objects during the restart

process) restores present values of objects to

• From the FlexStat menu, select Advanced > Device > Restart > Warm Start.

their last values before the restart (until they are

updated by the FlexStat’s programs).

• From TotalControl or BACstage, select Reinitialize Device > Warm Start.

• Restarts the controller’s Control Basic programs.

• Momentarily remove power to the FlexStat.

• Leaves conguration and programming intact.

To perform a COLD start, do one of the following:

CAUTION

If the checksum test in RAM fails during a warm

• From the FlexStat menu, select Advanced > Device > Restart > Cold Start.

start, a cold start is performed instead.

A cold start does the following in the FlexStat:

• From TotalControl or BACstage, select Reinitialize Device > Cold Start.

• (Aer zeroing out objects during the restart

process) returns all object values to their relinquished defaults (until they are updated by the

FlexStat’s programs).

BAC-10000 Series 14 Operation Guide, Rev. J

Page 15

Restore Factory

Restore Factory (restoring the FlexStat to the factory

seings) does the following:

• Clears present values.

• Restores the object database/conguration to the

defaults.

• Restarts the controller’s (factory installed) Control Basic programs.

NOTE: The MAC address and device instance are

not restored to their original defaults, and

custom Control Basic programs are not

deleted. If custom Control Basic programs are

installed, all factory programs are restarted

but all custom Control Basic programs are

halted. Custom programs may be restarted by

loading/running the programs from the CB

Programs menu. See (Advanced) CB (Control

Basic) Programs on page 6.

CAUTION

When returned to factory defaults, analog outputs will go to zero and relays will go to their

normally open state. Before restarting the thermostat, manually override equipment as needed.

CAUTION

After a return to factory defaults, applications are

unconfigured. You must select the desired application and appropriate settings before connected

equipment will operate properly. (See (Advanced)

Application Options on page 5.)

To restore the FlexStat to factory seings:

1. Select Restore Factory from the Advanced > Device menu.

2. When prompted for the required restart, press

Enter. (To Cancel, press the right buon and then

Enter or just let the display time-out).

3. Aer the FlexStat has restarted, review the settings and recongure as needed.

ADVANCED

APPLICATION

CB PROGRAMS

COMMUNICATION

DATE/TIME

DEVICE

LIMITS

SECURITY

DEVICE

INSTANCE: 1

NAME: FlexStat_101

LOCATION: KMC Controls

RESTART: NO

RESTORE FACTORY:

RESTART REQUIRED!

YES

CANCELRESTART

BAC-10000 Series 15 Operation Guide, Rev. J

Page 16

Network Connection

BACnet MS/TP Network Communication

Connect the network wiring and set the EOL switches accordingly. (See the Installation Guide for wiring

and end-of-line switch information.)

From the FlexStat menus, adjust the device instance

number, the MAC address, and baud rate from the

defaults as necessary. Set the Max Master to the

minimum necessary for the network. See (Advanced)

BACnet Device Properties on page 8 and (Advanced)

BACnet Communications on page 7.)

NOTE: The current FlexStat MAC address and

device instance numbers can be viewed in

the About menu. Each BACnet device on a

network must have a unique MAC address

and device instance.

PC Data Port Connection

The FlexStat is equipped with a PC data port located

at the boom of the thermostat housing. This port

provides a temporary EIA-485 (formerly RS-485)

connection to the digital network for network setup

or troubleshooting.

To connect a computer to the port, a means of

converting the EIA-485 signal to a USB or EIA-232

(formerly RS-232) signal will be needed. For USB,

use a KMC KMD-5576 USB Communicator. For

EIA-232, use a third-party interface. (See the instructions included with those devices and soware.) To

connect to the PC data port:

1. Connect the keyed, at end of the KMD-5624

interface cable (included with the KMD-5576) to

the port on the boom of the FlexStat.

2. Connect the modular plug of the cable to the

interface device that converts the EIA-485 signal

from the FlexStat into a USB or EIA-232 signal.

3. Connect the suitable cable from the interface

device to the computer’s serial or USB port.

Install any required soware and congure the

port as necessary.

NOTE: To avoid faulty communication with the

KMD-5576 USB Communicator, the Max

Master number may need to be reduced

to the minimum required for the network

and the driver and latency seings on

the computer may need to be checked or

updated. See Troubleshooting on page 17.

KMD-5576

KMD-5624

Cable

BAC-10000 Series 16 Operation Guide, Rev. J

Page 17

Troubleshooting

Alarm Issues

Alarm, (False) Fan Fail

• Check conguration. Be sure the Fan Status

option is not selected when there is no sensor/

switch for it.

• Check that the IN2 (fan status) input pull-up

resistor switches are fully latched in the correct

positions. Any passive, dry contact should use

the 10K Ohm seing. (See the Connections and

Wiring section of the relevant BAC-10000 Series

Installation Guide.)

• Check IN2 (fan status) input wiring.

• Check the connected fan status sensor/switch.

• Using BACstage or TotalControl, check that AI2

(fan status) is not congured as “Out Of Service.”

Alarm, (False) Low Limit (Freeze Stat)

• Check the Low Limit Alarm seing—see Damper

Setup on page 5.

• Check conguration. Be sure the Economizer

option is not selected when there is no mixed air

temperature sensor.

• Check that the IN3 (mixed air temp.) input

pull-up resistor switches are fully latched in the

correct positions (see the Connections and Wiring

section of the relevant BAC-10000 Series Installation Guide).

• Check IN3 (mixed air temperature) input wiring.

• Check the connected mixed air temperature sensor.

• Using BACstage or TotalControl, check that AI3

(mixed air temp.) is not congured as “Out Of

Service.”

NOTE: Aer a low limit alarm is generated, the

fan will not run until aer the FlexStat

is restarted. See Reseing the FlexStat on

page 14.)

Alarm, (False) Space Temp. or Humidity

• See Alarms on page 11.

• See Temperature Reading Is Incorrect on page 19.

• See Temperature Setpoint Is Not Maintained on

page 19.

• Using TotalControl, adjust the limits or time

delay.

Communication Issues

Firmware Upgrade Fails

• Ensure the WD (watch dog) jumper is temporarily removed during the upgrade process (see the

KMD-5699 Installation Guide, P/N 913-019-04).

Reinstall the pin on the le and center pins aer

the upgrade process is complete.

• Check connections.

• Ensure rmware for the correct model is selected

in the Firmware Upgrade Tool.

NOTE: If rmware for a wrong model is acciden-

tally installed, the outputs will not match the

applications/conguration on the display.

NOTE: Backing up the existing seings and

rmware image before or during the

upgrade process is good practice.

NOTE: Restoring to the factory defaults and

reconguring might be needed if how the

FlexStat operates changes. Read all notes

accompanying the rmware update!

KMD-5576 Communication Faulty

• Upgrade to the latest version of BACstage (ver.

2.4.0.25 or later required).

• Check the seings for the USB port on the

computer (Device Manager > Ports) and the

MS/TP port in BACstage (Access > Connection

Parameters).

• Reduce the Max Master number down to the

minimum needed for that network—see (Ad-

vanced) BACnet Communications on page 7.

• Install latest driver and check latency seings.

See Latency Seings for KMD-5576 Service Bulletin (SB0308A) on the KMC web site.

• See also MS/TP Network Communication Faulty

below.

MS/TP Network Communication Faulty

• Reduce the Max Master number down to the

minimum needed for that network—see (Ad-

vanced) BACnet Communications on page 7.

• Check that EOL switches are fully latched in the

correct positions (see the relevant BAC-10000

Series Installation Guide).

• Check MAC address and device instance numbers.

• Check baud rate.

BAC-10000 Series 17 Operation Guide, Rev. J

Page 18

Cover and Display Issues

Custom Programming and Web Issues

Cover Binds on Backplate

• Carefully remove the FlexStat cover from the

backplate and inspect for bent pins and/or terminal socket connectors. If cover pins are bent, use

a needle-nose pliers to straighten them. If socket

connectors are bent, use a pointed object (such

as a thumbtack or straightened paperclip) to

straighten them. (Pushing the pointed object into

the socket from the back side can be helpful.)

• Replace the backplate.

NOTE: When installing the cover on the

backplate, be sure to not pinch or dislodge

any wiring. Do not use excessive force.

If there is any binding, pull out cover

and examine pins and terminal socket

connectors.

Display Is Blank or Erratic

• Check that Display Blanking is not unintention-

ally enabled. (See System Setup on page 13.)

• Check for a tripped circuit breaker to the transformer.

• Check for proper supply voltage from transformer and that the transformer has enough

capacity (VA) for all connected devices (see their

respective data sheets).

• Carefully remove the FlexStat cover from the

backplate, check pins and connectors, and reinsert. (See Cover Binds on Backplate on page 18.)

• Check connections.

• Put another FlexStat on the installed backplate,

and if the second FlexStat functions properly,

replace the rst FlexStat.

Display Freezes (Buttons Have No Effect)

• Carefully remove the FlexStat cover from the

backplate and ensure the WD (watch dog)

jumper (near the boom of the board) is installed

on the le and center pins. The jumper is temporarily removed during a rmware update and

should be reinstalled when the process is completed. (See the KMD-5699 Installation Guide,

P/N 913-019-04, for more information.) Reinstalling the cover on the backplate will restart the

FlexStat.

Control Basic Programs Do Not Work

NOTE: The FlexStat has a library of built-

in applications and options that are

congured through the FlexStat’s display.

Beyond these standard congurations,

custom changes can be added to a FlexStat

using KMC’s BACstage (ver. 2.4.0.26 or

later) or TotalControl (ver. 2.0.5 or later).

NOTE: Control Basic (read-only) programs 1

through 5 are used for built-in applications

and can not be modied directly. Programs

6 through 10 are empty and can be used for

additional programming. Using BACstage

or TotalControl, a program (1 through 5)

can be copied, pasted into a new program

code object (6 through 10), edited, and

run in place of the original. (Although

programs 1–5 cannot be edited, they can be

halted and set to not autorun aer restart.)

NOTE: Customized programs are the responsibility

of the user. KMC Controls does not provide

support for such programs.

• In the BAC-10000 Series Application Guide (P/N

913-019-03), carefully REVIEW ALL the infor-

mation in the Custom Programming section!

• Set programs to autorun and/or check if they

have halted. Review (Advanced) CB (Control

Basic) Programs on page 6.

• Ensure objects are wrien to correct priority

levels. See the Custom Web Graphics section in

the BAC-10000 Series Application Guide (P/N

913-019-03).

• Custom programming requires BACstage (ver.

2.4.0.26 or later) or TotalControl (ver. 2.0.5 or

later). Upgrade to the latest version for the most

complete functionality.

• For assistance with Control Basic commands, see

the Help system in TotalControl or BACstage.

Custom Web Graphics Do Not Work

• In the BAC-10000 Series Application Guide (P/N

913-019-03), review the Custom Web Graphics

section.

• See also Control Basic Programs Do Not Work

above.

BAC-10000 Series 18 Operation Guide, Rev. J

Page 19

Input, Sensor, and Value Issues

Input Values Are Outside the Expected Range

• Check that ALL the input pull-up resistor

switches are fully latched in the correct positions.

See the Connections and Wiring section of the

relevant BAC-10000 Series Installation Guide. A

single incorrect switch position may aect multiple inputs. All input switches must be latched

in either 10K Ohm or 0–12 VDC positions even

if no input is connected! Input switch pairs (3-4,

5-6, and 7-8) must never have both switches set

to the le or both to the right—if switch 3 is set

to the le, for example, 4 must be set to the right

(or vice versa).

• Check that the correct input type is selected on

the Inputs screen. A Type III thermistor is the

default on IN2 through IN4. See (Advanced)

Inputs on page 8.

• Check input wiring. See Wiring Issues on page 21.

• Check connected sensors.

• Using BACstage or TotalControl, check that the

input is not congured as “Out Of Service.”

• Restore the FlexStat to factory seings (see Reset-

ting the FlexStat on page 14) and recongure.

Motion/Occupancy Sensor Does Not Work

• The initial rmware (R.1.0.0.0 and earlier) did not

support this sensor within the built-in selectable

programs. Custom programming was required—

see the BAC-10000 Series Application Guide, P/N

913-019-03. Upgrade to the latest rmware for

built-in support.

• Aer an initial power-up or restart, the motion/

occupancy sensor requires about 30 seconds

before it will begin responding to motion.

• The motion/occupancy sensor initiates override

only during “o” times in the schedule. See

Schedules on page 12.

• Check that the motion sensor is enabled and

detects motion. See (Advanced) Motion Sensor on

page 8.

• Using BACstage or TotalControl, check that BI6

(occ status) is not congured as “Out Of Service.”

• The FlexStat must be installed where there is a

clear view of typical trac area (reliable range is

out to about 33 feet). Remove or move obstacles.

Reinstall the FlexStat in a more optimal location

if necessary.

• Connect remote motion sensors to an input

(requires custom programming).

• For more information on detection performance,

paerns, conguration, programming, and other

issues, see the Motion/Occupancy Sensor section

in the BAC-10000 Series Application Guide.

Temperature Reading Is Incorrect

• Aer applying power for the rst time (or aer

an outage), allow the FlexStat to self-calibrate a

few minutes before verifying temperature reading.

• If the discrepancy is small, adjust the calibration

oset—see (Advanced) Inputs on page 8.

• Check that the thermistor is centered in its hole at

the boom of the case and has an air gap around

it. Also check that its leads are not pinched,

shorted, or broken and that the tape holding

down the leads is not loose. (Some early models

with humidity sensors did not have the additional thermistor—temperature was derived from

the same chip that measured humidity.)

• Using BACstage or TotalControl, check that

AI1 (space temp.) is not congured as “Out Of

Service.”

• Check that the FlexStat is not mounted on an

outside wall, is not exposed to heat sources or

sunlight, is not exposed to dras from windows

or air vents, or is not blocked from normal air

circulation.

• See also Input Values Are Outside the Expected

Range on page 19.

Temperature Setpoint Is Not Maintained

• Select Occupied mode from the Home Menu—

see H/C, Fan, Occupancy, and Override on page 3.

• Override the fan to On from the Home Menu—

see H/C, Fan, Occupancy, and Override on page 3.

• Check that the appropriate application is selected—see (Advanced) Application Options on

page 5.

• Check that room temperature is being sensed

correctly—see Temperature Reading Is Incorrect

on page 19.

BAC-10000 Series 19 Operation Guide, Rev. J

Page 20

Output, Fan, and Relay Issues

Analog Output Does Not Work

CAUTION

Do not mistakenly connect 24 VAC to an analog

output ground. This is not the same as a relay’s

switched common. See the backplate’s terminal

label for the correct terminal.

NOTE: The maximum current of an analog output

is 20 mA @ 12 VDC. Excessive loads will

be clamped at the maximum. Relays may

chaer or fail to latch if they need more

current than the maximum allowed. KMC

REE-3111/3112 relays, for example, could be

connected to the analog outputs, but REE3211/3221/3213 relays would not operate

reliably with analog outputs because their

required power exceeds the FlexStat’s

capacity. (REE-3211/3221/3213 relays could,

however, be used with the FlexStat relays

and a separate power source.)

• Check current draw of load—it must be 20 mA or

less. Substitute an output device that draws less

current.

• Check that the output is on.

• See Wiring Issues on page 21.

• See also Fan Does Not Run on page 20.

• If Restore Factory has just been performed, see

the Note and Cautions in Restore Factory on

page 15.

• If the rmware has just been upgraded, rmware for the wrong model type may have been

installed (e.g., BAC-1xx63 rmware accidentally

installed in a model BAC-1xx36). In the About

menu, ASV may simply read “CUSTOM” instead

of something like “BAC_1xx36 R1.1.0.5” as it

normally would have done. If so, repeat the rmware upgrade and ensure that the correct type of

rmware is selected for the connected model.

NOTE: ASV in the About menu will also show

CUSTOM if any built-in Control Basic

program (1–5) is not running or has autorun disabled.

Fan Does Not Run

NOTE: The animated fan icon is coupled with

BV18 in the packaged programming (not

the actual fan output terminal).

• Select Occupied mode from the Home Menu—

see H/C, Fan, Occupancy, and Override on page 3.

• Override the fan to On from the Home Menu—

see H/C, Fan, Occupancy, and Override on page 3.

• See Wiring Issues on page 21.

• Check that the appropriate application is se-

lected—see (Advanced) Application Options on

page 5.

• Check the fan conguration—see Fan Setup on

page 5.

• Restart the FlexStat. Aer a low limit alarm is

generated, the fan will not run until aer the

FlexStat is restarted. (See Reseing the FlexStat

on page 14.)

Relay (Internal) Does Not Work

CAUTION

Relays are for Class-2 voltages (24 VAC) only.

Do not connect line voltage to the relays!

NOTE: Max. output current is 1 A for individual

relays @ 24 VAC/VDC or a total of 1.5 A

per bank of 3 relays (relays 1–3, 4–6, and

7–9). Do not aach a device that draws

current that exceeds the corresponding

value. Relays are NO, SPST (Form “A”).

• Check current draw of load. Substitute an output

device that draws less current.

• Check that the output is on.

• See Wiring Issues on page 21.

• Restart the FlexStat.

• If Restore Factory has just been performed, see

the Note and Cautions in Restore Factory on

page 15.

BAC-10000 Series 20 Operation Guide, Rev. J

Page 21

Wiring Issues

• If the rmware has just been upgraded, rmware for the wrong model type may have been

installed (e.g., BAC-1xx63 rmware accidentally

installed in a model BAC-1xx36). In the About

menu, ASV may simply read “CUSTOM” instead

of something like “BAC_1xx36 R1.1.0.5” as it

normally would have done. If so, repeat the rmware upgrade and ensure that the correct type of

rmware is selected for the connected model.

NOTE: ASV in the About menu will also show

CUSTOM if any built-in Control Basic

program (1–5) is not running or has autorun disabled.

Relay (External) Does Not Work

• See Analog Output Does Not Work on page 20.

• See Relay (Internal) Does Not Work on page 20

CAUTION

Do not mistakenly connect 24 VAC to an analog

output ground. This is not the same as a relay’s

switched common. See the backplate’s terminal

label for the correct terminal.

CAUTION

Relays are for Class-2 voltages (24 VAC) only.

Do not connect line voltage to the relays!

• Remove the FlexStat from the backplate and

inspect the terminals for loose or shorted wires.

• Use a voltmeter and ohmmeter to check the

terminals for expected values. See the illustration

below and the the Connections and Wiring section of the relevant BAC-10000 Series Installation

Guide.

NOTE: Voltage on the BACnet MS/TP terminals

changes according to the signals (passing

of the token) between controllers on the

network. No voltage indicates a bad

connection or simply no active network.

NOTE: Values Shown Are Approximate!

NOTE: BAC-1xxx63 Backplate Terminals Shown

NOTE: SC = Switched (Relay) Common, Should

BACnet

MS/TP

Network

Inputs

24 VAC

with FlexStat Removed; Outputs and Inputs

Vary According to Application

Have the Phase Side of 24 VAC Connected

(Wiring Inputs

and Outputs

Dependent on

Application)

+B

–A

IN4

IN3

GND

IN2

Common/– / C

Phase/ /R

0.1–0.2 VDC (If Network

}

Token Passing is Present)

10K Ohms (Thermistor)

or

}

O Ohms (Closed Contact)

24 VAC

}

• Check the wiring at the connected devices.

Outputs

Analog 9

Resistance

Dependent

on Device

24 VAC

(Jumper to

Turn Device

On Manually)

GND 7–9

Analog 8

Analog 7

Relay 6

SC 4–6

Relay 5

Relay 4

Relay 3

SC 1–3

Relay 2

Relay 1

Terminal Voltages and Resistances with FlexStat REMOVED from Backplate

BAC-10000 Series 21 Operation Guide, Rev. J

Page 22

Maintenance

Accessories

Remove dust as necessary from the holes in the top

and boom. Clean the display with so, damp cloth

and mild soap.

To maintain maximum sensitivity of optional built-in

motion sensors, occasionally wipe dust or dirt o the

lens—but do not use any uid on the sensor.

Firmware Upgrade

The existing version of rmware can be viewed from

the About the FlexStat screen. (See About the Flex-

Stat on page 4).

Firmware in the FlexStat can be upgraded using

a PC and a KMD-5699 rmware ash upgrade kit

available from KMC Controls. (For full upgrade

instructions, see the KMD-5699 Installation Guide,

P/N 913-019-04.)

HMO-10000 Horizontal or 4 x

4 handy box wall

mounting plate,

light almond

HMO-10000W HMO-10000 in

white

HPO-0044 Replacement cover

hex screw

KMD-5567 Network surge

suppressor

KMD-5575 Network repeater/

isolator

KMD-5576 EIA-485 to USB

Communicator

Programming (Custom)

The FlexStat has a library of built-in applications and

options that are congured through the FlexStat’s

display. Beyond these standard congurations, custom changes can be added to a FlexStat using KMC’s

BACstage (ver. 2.4.0.26 or later) or TotalControl (ver.

2.0.5 or later). See the BAC-10000 Series Application

Guide (P/N 913-019-03) for more information.

NOTE: Customized programs are the responsibility

of the user. KMC Controls does not provide

support for such programs.

KMD-5624 PC data port

(EIA-485) cable

(FlexStat to USB

Communicator)—

included with the

KMD-5576 (buy for

third-party EIA232 interfaces)

KMD-5699 FlexStat rmware

ash upgrade kit

SP-001 Flat blade and hex

end screwdriver

(with KMC logo)

for cover hex

screws

XEE-6111-040 Transformer, 120-

to-24 VAC, 40 VA,

single-hub

XEE-6112-040 Transformer, 120-

to-24 VAC, 40 VA,

dual-hub

BAC-10000 Series 22 Operation Guide, Rev. J

Page 23

Support

Important Notices

FlexStats come with a printed

Installation Guide. Additional

resources for conguration,

application, operation,

programming, upgrading

and much more is available on the award-winning

KMC Controls web site

(www.kmccontrols.com).

The collection of FlexStat

documents won a prestigous

publications award for technical marketing support from

the Chicago chapter of the

Society for Technical Communication in March 2010.

The KMC logo and TotalControl are registered

trademarks and BACstage is a trademark of KMC

Controls, Inc. All rights reserved. No part of this

publication may be reproduced, transmied, transcribed, stored in a retrieval system, or translated

into any language in any form by any means without

the wrien permission of KMC Controls, Inc.

The material in this document is for information

purposes only. The contents and the product it

describes are subject to change without notice.

KMC Controls, Inc. makes no representations or

warranties with respect to this document. In no event

shall KMC Controls, Inc. be liable for any damages,

direct or incidental, arising out of or related to the

use of this document.

BAC-10000 Series 23 Operation Guide, Rev. J

Page 24

Reference

Acronyms and Abbreviations

Common acronyms and abbreviations in FlexStat

and related documents include:

amp = amperes

A = amperes

AAC = Advanced Application Controller

A/C = air conditioning

AC = alternating current

AHU = air handling unit

avg. = average

AWG = American Wire Gauge

BACnet = Building Automation Control network

BTL = BACnet Testing Laboratories

C = Celsius

c = cubic feet per hour

cfm = cubic feet per minute

cm = centimeters

DA = direct acting

DC = direct current

DPDT = double pole double throw

DPST = double pole single throw

EIA = Electronic Industries Alliance

EOL = end of line

F = Fahrenheit

FCU = fan coil unit

FIU = fan induction unit

-lbs. = foot pounds

g = grams

LCD = liquid crystal display

mA = milliamperes

MAC = media access control

max. = maximum

min. = minimum

mm = millimeters

MS/TP = master-slave/token-passing

NC = normally closed

NO = normally open

pF = picofarad

RA = reverse acting

RH = relative humidity

RS = Recommended Standard

RTC = real time clock

RTU = roof top unit

SPDT = single pole double throw

SPST = single pole single throw

UL = Underwriters Laboratories

USB = universal serial bus

UTC = Coordinated Universal Time

V = volts

VA = volt-ampere

VAC = volts alternating current

VAV = variable air volume

VDC = volts direct current

W = was

HPU = heat pump unit

HVAC = heating ventilating and air conditioning

Hz = hertz

IP = Internet protocol

BAC-10000 Series 24 Operation Guide, Rev. J

NOTE: See also the Green Building and Controls

Glossary (SB-046) for denitions of various

terms in this catalog.

Page 25

Definitions of Terms

For denitions of various terms in this

document, refer to the award-winning

pocket-sized Green Building and Con-

trols Glossary (SB-046). A hyperlinked

online version can be downloaded from

the Brochures section of KMC Controls

web site, www.kmccontrols.com. Some

of the more important glossary terms

for this document are included on this page:

Air Handling Unit (AHU)—An HVAC system compo-

nent that conditions and delivers air through the

system. It typically contains one or more supply

and return fans, heating/cooling coils, and lters

to condition the air.

®

BACnet

(Building Automation Control Network)—

An interoperable, nonproprietary, communication protocol standard conceived by a consortium of building managers, system users, and

manufacturers. BACnet denes how information

is packaged for transportation between building

automation system vendors.

EIA-485—A serial communications standard in

which the voltage dierence between two wires

conveys the data. It is commonly used to network

controllers via twisted-pair wiring. It was formerly known as RS-485.

Fan Coil Unit (FCU)—A fan terminal unit that condi-

tions the air in a single room or zone. FCUs generally contain heating and cooling coils and have

the ability to supply outside air to a space.

Heat Pump Unit (HPU)—A unit that uses direct

expansion to remove or add heat to a space. On

a call for heat, the heat pump pulls heat from a

source such as outside air or the ground and puts

it into a space. On a call for cooling, the process is

reversed.

Max Master—The highest MAC address a device will

aempt to locate when polling for master devices

on the local network.

MS/TP (Master Slave/Token Passing)—A protocol

(using the EIA-485 signaling standard) in which

master devices can initiate requests for data but

slave devices cannot (since slaves can only reply

to messages from other devices). KMC advanced

application controllers are all MS/TP master

devices.

Native BACnet Device—A device that is fully BACnet

compatible and uses BACnet as its primary, if not

exclusive, method of communication.

PID (Proportional Integral Derivative) Control—A

control algorithm that enhances the PI control

algorithm by adding a component that is proportional to the rate of change (derivative) of the

deviation of the controlled variable. This compensates for system dynamics and allows faster

control response.

PID Loop Controller—A controller with an algorithm

that calculates an output value that is based on

the sensed value and the required setpoint. PID

loop controllers provide more accurate and stable

control than simpler controllers.

Proportional Control—A type of control in which a

controlled device may operate at any position between fully closed to fully open. Within a specic

range, the output response maintains a constant

ratio to the input signal.

Protocol—A denition or set of communication rules

by which information is exchanged between devices on a network.

Real Time Clock (RTC)—A device that keeps track of

the current time in a controller even if power is

interrupted for a period of time.

Relative Humidity (RH)—The ratio of the amount of

water vapor in air to the maximum amount of

water vapor that could be in the air if the vapor

were at its saturation conditions.

Roof Top Unit (RTU)—An HVAC unit that is supplied

as a package and installed outside of a building.

Router—A device that connects two or more networks

and chooses the best path for data packets.

USB (Universal Serial Bus)—A popular, plug-and-

play, high-speed, serial computer interface.

UTC (Coordinated Universal Time)—An international

standard for determining time zones.

Variable Air Volume (VAV)—A method of tempera-

ture control in which the volume of constant temperature supply air exiting a duct is modulated

(via dampers) to maintain a temperature setpoint

in an individual space.

BAC-10000 Series 25 Operation Guide, Rev. J

Page 26

Index

Symbols

4 x 4 Handy Box Mounting Plate: 22

A

Abbreviations: 24

About the FlexStat: 4

Access Levels, Password: 9

Accessories: 22

Acronyms: 24

Adjustment. See Configuration; Override; Setpoint

Administrator Password: 9

Advanced Menu: 5

Alarms: 5, 6, 11, 17

Analog Outputs: 14, 20

Application Options: 2, 5, 15

Application Software Version (ASV): 4

ASV (Application Software Version): 4

Auto, Off, Heat, or Cool (System Enable): 13

Auxiliary Heat, Heat Pump: 5

B

Backlight: 13

Backplate: 2, 18

BACnet: 2, 7, 16, 17

Baud Rate: 16

Binding, Cover on Backplate: 18

Blanking, Display: 13

Board Revision: 4

Build Date: 4

Buttons: 3

C

Calibration Offset: 8

Cold Start: 14

Communication

Settings: 7

Troubleshooting: 7, 17

Configuration: 4

Control Basic Programs: 6, 15, 18

Cool, Heat, Auto, Off (System Enable): 13

Coordinated Universal Time (UTC): 7

C or F, Selecting Temp. Scale: 5

Cover: 18

Custom

Programs: 6, 18, 22

Web Graphics: 18

CUSTOM in ASV: 4, 20

D

Damper Set-Up: 5

Data Port: 16

Date: 7, 11

Deadband: 13

Definitions of Terms: 25

Degrees F or C: 5

Delay, Fan: 5, 14

Detector. See Motion Sensor

Device Instance: 4, 8, 15, 16

Device Properties: 8

Discharge Air Temperature: 6

Display

Blanking: 13

Overview: 3

Time-Out: 13

Troubleshooting: 18

E

Economizer (Damper): 5

EIA-485: 16

EOL (End Of Line) Switches: 17

F

Factory Defaults: 8, 14

Fan

Delay: 5, 14

Fail Alarm: 6, 11, 17

(Manual) Override: 3

Set-Up: 5

Status: 6

Troubleshooting: 19

Firmware

Troubleshooting: 17, 19

Upgrading: 6, 22

Viewing Current: 4

F or C, Selecting Temp. Scale: 5

Freeze Stat.

FW. See Firmware

See Low Limit Alarm

BAC-10000 Series 26 Operation Guide, Rev. J

Page 27

G

Glossary, Green Buildings Controls: 25

H

Heat, Cool, Auto, Off (System Enable): 13

HMO-10000 Mounting Plate: 22

Home (Temperature Display) Screen: 3

Horizontal Handy Box Mounting Plate: 22

HPO-0044 Cover Screw: 22

Humidity

Alarm: 11

Dehumidification Setpoint: 13

Setup: 5

Trend Log: 10

I

IN2: 6

Inactivity Time-Out: 13

Initial Set-Up: 4

Inputs: 8

Installation: 2

J

Jumper, WD: 18

K

KMC Controls: 23

KMD-5567 Surge Suppressor: 22

KMD-5575 Repeater/Isolator: 22

KMD-5576 USB Communicator: 16, 17, 22

KMD-5624 PC Data Port Cable: 22

KMD-5699 Firmware Upgrade Kit: 22

L

Limits: 8, 11

Low Limit Alarm: 5, 11, 17

M

MAC Address: 4, 7, 15, 16

Main Menu: 3, 4

Maintenance: 22

Max Master: 7, 16, 17

Menu

Advanced: 5

Main: 4

Model Number: 4

Motion Detector. See Motion Sensor

Motion Sensor: 8, 19

MS/TP: 7, 16, 17

N

Navigation: 3

Network: 7, 16, 17, 22

Notices: 23

O

Occupancy

Mode: 3

Override: 3, 13

Sensor. See Motion Sensor

Off, Auto, Heat, or Cool (System Enable): 13

Offset, Calibration: 8

Operation

Basic: 3

Configuring (Set-Up): 4

Operator Password: 9

Outage, Power: 14

Outputs: 14, 20

Override: 3, 13

P

Passwords: 9, 13

PC Data Port: 16

Power Outage/Removal: 14

Programming, Custom: 6, 18, 22

Pull-Up Resistor Switches: 17, 19

R

Reference: 24

Reinitialize: 8, 14

Relays: 21

Reset: 8, 14

Restart: 8, 14

Restore: 8, 15

RS-485.

See EIA-485

S

Schedules: 12

Security: 9

Sensor

Calibration: 8

Setup: 6

Troubleshooting: 19

Type: 8

Value: 8

Serial Number: 4

Setbacks: 13

BAC-10000 Series 27 Operation Guide, Rev. J

Page 28

Setpoints

Adjustment: 3, 13

All: 13

Temperature (Only): 3

Troubleshooting: 19

Setup and Configuration: 4

SP-001 Screwdriver: 22

Space

Humidity Alarm: 11

Temp Alarm: 11

Staging: 6

Start (Reset), Cold or Warm: 14

Support, Technical: 23

Switches

EOL (End of Line): 17

Pull-Up Resistors: 19

System

Enable: 13

Setup: 13

T

Temperature

Alarm: 11

Limits: 8

Scale, Selecting: 5

Setpoint: 3, 8, 13

Trend Log: 10

Troubleshooting: 19

Terminals: 2, 18

Terms: 25

Test Menu: 10

Time: 7, 10, 11

Time-Out (Inactivity): 13

Transformer: 22

Trend Logs

Inputs: 6, 10

Intervals: 10

Setup: 10

Viewer: 13

Troubleshooting: 17

U

Universal Time, Coordinated (UTC): 7

Update Manager: 6

Upgrading Firmware: 17, 22

USB Communicator: 16

User Password: 9

UTC (Coordinated Universal Time): 7

V

Value, Sensor: 8

Valve Set-Up: 6

Viewer

Alarms: 11

Trends: 13

W

Warm Start: 14

WD (Watch Dog) Jumper: 18

Web Site, KMC Controls: 23

Wiring: 2, 21

X

XEE-6000 Series Transformers: 22

KMC Controls, Inc.

19476 Industrial Drive, New Paris, IN 46553

574.831.5250

www.kmccontrols.com

info@kmccontrols.com

BAC-10000 Series 28 Operation Guide, Rev. J

© 2010 KMC Controls, Inc. 913-019-02J

Loading...

Loading...