Kmart 21AB40M1099, 01739328-1 Owner’s Manual

Operator's Manual

I:Rl FI'SlVl N

208cc Engine

Rear Tine Tiller

Model No. 247.29930

* SAFETY

* ASSEMBLY

* OPERATION

CAUTION: Before using

this product, read this

manual and follow aJl

* MAINTENANCE

* PARTS LIST

* ESPANOL

safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, iL 60179, U.S.A.

Visit our web site: www.craftsman.com

FORM1/0.769-05423D

1/2/2012

WarrantyStatement..................................Pac

Safetyinstructions....................................Pac

Assembly..................................................Pac

Operation..................................................Pac

ServiceandMaintenance.........................Pac

Off-SeasonStorage..................................Pac

TroubleShooting.......................................Pac

CRAFTSMAN TWO YEAR FULL WARRANTY

FORTWOYEARSfromthe dateof purchase,this productis warrantedagainstanydefectsin materialorworkmanship,A defectiveproductwill

receivefreerepairorreplacementif repairis unavailable,

Forwarranty coverage details to obtain free repairor replacement,visit the web site: www.craftsman.com

This warranty covers ONLYdefects in material andworkmanship. Warrantycoverage does NOTinclude:

• Expendableitemsthatcan wearoutfromnormalusewithinthewarrantyperiod,suchas theblades,tines,orbelts.

• Productdamageresultingfromuserattemptsat productmodificationor repairorcausedby productaccessories.

• Repairsnecessarybecauseof accidentorfailuretooperateor maintaintheproductaccordingtoall suppliedinstructions.

• Preventivemaintenance,or repairsnecessarydueto improperfuelmixture,contaminatedor stalefuel.

e2

es3-6

es7-10

es11-16

es17-22

e23

e24

PartsList...................................................Page26-39

Labels.......................................................Page40

RepairProtectionAgreement...................Page43

Espa_ol.....................................................Page44

ServiceNumbers......................................BackCover

Thiswarrantyisvoidif thisproductiseverusedwhile providingcommercialservicesorif rentedtoanotherperson.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstatetostate.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

EngineSeries: 208cc

EngineOilType: 10w30

EngineOilCapacity: 20ounces

Fuel: UnleadedGasoline

SparkPlug: F6RTC

SparkPlugGap: .030"

ModelNumber.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

©KCDIP,LLC 2

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingto thesafeopera-

tionpracticesinthismanual.Aswithanytypeof powerequipment,

carelessnessorerroronthe partof theoperatorcan resultin

seriousinjury.Thismachineiscapableofamputatingfingers,hands,

toesandfeetandthrowingdebris.Failureto observethefollowing

safetyinstructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateof California

tocausecancerandbirthdefectsorotherreproductiveharm.Bat-

tery posts,terminals,andrelatedaccessoriescontainleadand lead

compounds,chemicalsknowntothe Stateof Californiatocause

cancerandreproductiveharm.Washhandsafterhandling.

TRAINING

• Read,understand,andfollowall instructionson the machineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualina safeplaceforfutureand regularreference

andfororderingreplacementparts.

• ReadtheOperator'sManualand followallwarningsand safety

instructions.Failuretodosocan resultin seriousinjuryto the

operatorand/or bystanders.Forquestions,call1-800-4MY-HOME.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsof agetooperatethis

machine.Children14andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultstooperatethis machinewithoutproper

instruction.

• Keepbystanders,pets,andchildrenatleast75feetfromthe

machinewhileit isin operation.Stopmachineifanyoneenters

thearea.

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

Your Responsibility--Restrictthe useof thispowermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon the machine.

SAVETHESEINSTRUCTIONS!

PREPARATION

• Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall rocks,bottles,cans,or otherforeignobjectswhich

couldbepickedupor thrownandcausepersonalinjuryor

damageto themachine.

• Alwayswearsafetyglassesor safetygogglesduringoperation

andwhileperformingan adjustmentorrepair,to protectyour

eyes.Thrownobjectswhichricochetcancauseseriousinjuryto

theeyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesorjewelrycan becaughtin movable

parts.Neveroperatethismachineinbarefeetorsandals.

• Beforestarting,checkallboltsandscrewsfor propertightnessto

besurethe machineisinsafeworkingcondition.Also,visually

inspectmachinefor anydamageatfrequentintervals.

• Disengageclutchleversandshift(if provided)into neutral("N")

beforestartingtheengine.

• Neverleavethismachineunattendedwiththeenginerunning.

• Neverattempttomakeanyadjustmentswhilethe engineis

running,exceptwherespecificallyrecommendedinthe operator's

manual.

• Maintainorreplacesafetyandinstructionslabels,asnecessary.

3

SafeHandling of Gasoline:

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycan occurwhengasolineisspilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Neverfill containersinsidea vehicleor ona truckor trailerbed

witha plasticliner.Alwaysplacecontainersonthe groundaway

fromyourvehiclebeforefilling.

• Whenpractical,removegas-poweredequipmentfromthetruck

ortrailerand refuelitonthe ground.Ifthisis notpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

• Keepthe nozzleincontactwiththerimofthe fueltankor

containeropeningatalltimes untilfuelingiscomplete.Donotuse

a nozzlelock-opendevice.

• Extinguishallcigarettes,cigars,pipesandother sourcesof

ignition.

• Neverfuel machineindoors.

• Neverremovegascapor addfuel whilethe engineishot or run-

ning.Allowenginetocool atleasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Fill tankto nomorethan1/2inchbelow

bottomoffillerneckto allowspacefor fuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipe itoff theengineandequipment.Move

unitto anotherarea.Wait5 minutesbeforestartingtheengine.

• To reducefirehazards,keepmachinefreeof grass,leaves,or

otherdebrisbuild-up.Cleanupoil orfuelspillageand removeany

fuelsoakeddebris.

• Neverstorethe machineorfuelcontainerinsidewherethereis an

openflame,sparkor pilotlightas on awaterheater,spaceheater,

furnace,clothesdryerorothergasappliances.

OPERATION

• Do notputhandsorfeetnear rotatingparts.Contactwiththe

rotatingpartscanamputatehandsandfeet.

• Do notoperatemachinewhileunderthe influenceofalcoholor

drugs.

• Neveroperatethismachinewithoutgoodvisibilityor light.Always

be sureof yourfootingandkeepa firmholdonthehandles.

• Keepbystandersawayfromthe machinewhileit isinoperation.

Stopthe machineif anyoneentersthearea.

• Becarefulwhentillinginhardground.Thetines maycatchinthe

groundandpropelthetillerforward.Ifthis occurs,let goofthe

handlebarsanddo not restrainthemachine.

• Exerciseextremecautionwhenoperatingonor crossinggravel

surfaces.Stayalertforhiddenhazardsortraffic. Donotcarry

passengers.

• Neveroperatethemachineat hightransportspeedsonhardor

slipperysurfaces.

• Exercisecautiontoavoidslippingorfalling.

• Lookdownand behindandusecarewhenin reverseor pulling

machinetowardsyou.

• Startthe engineaccordingtothe instructionsfoundinthis manual

and keepfeetwell awayfromthetinesat all times.

• Afterstrikingaforeignobjector ifyourmachineshouldstartmak-

inganunusualnoiseor vibration,immediatelyshutthe engineoff.

Disconnectthe sparkplugwire,grounditagainstthe engineand

performthefollowingsteps:

a. Inspectfordamage.

b. Repairorreplaceanydamagedparts.

c. Checkforanyloosepartsandtightento assurecontinued

safeoperation.

• Disengageall clutchlevers(iffitted)and stopenginebeforeyou

leavethe operatingposition(behindthe handles).Waituntil

thetinescometo a completestopbeforeuncloggingthe tines,

makinganyadjustments,or inspections.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,an odorlessanddeadlygas.

• Mufflerandenginebecomehotandcancausea burn.Do not

touch.

• Usecautionwhentillingnearfences,buildingsandunderground

utilities.Rotatingtinescan causepropertydamageorpersonal

injury.

• Donotoverloadmachinecapacitybyattemptingtotillsoil too

deepattoo fastof a rate.

• Ifthe machineshouldstartmakinganunusualnoiseor vibration,

stoptheengine,disconnectthesparkplugwire andgroundit

againsttheengine.Inspectthoroughlyfordamage.Repairany

damagebeforestartingandoperating.

• Keepallshields,guards,and safetydevicesinplaceandoperat-

ing properly.

• Neverpickuporcarrymachinewhiletheengineis running.

• Useonly attachmentsandaccessoriesapprovedbythe manu-

factureras listedin thePartsListpagesofthisoperator'smanual.

Failuretodosocan resultin personalinjury.

• Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgement.ContactCustomerSupportat 1-800-4MY-

HOMEforassistanceandthenameof thenearestservicedealer

MAINTENANCE & STORAGE

• Keepthemachine,attachmentsandaccessoriesin safeworking

order.

• Allowthemachinetocoolat leastfiveminutesbeforestoring.

Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.

• Checkboltsandscrewsforpropertightnessat frequentintervals

to keepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

• Beforecleaning,repairing,or inspecting,stopthe engineand

makecertainthetinesandall movingpartshavestopped.

Disconnectthe sparkplugwireandgrounditagainsttheengineto

preventunintendedstarting.

4

• Do notchangetheenginegovernorsettingsor over-speedthe

engine.Thegovernorcontrolsthemaximumsafeoperatingspeed

ofengine.

Maintainor replacesafetyandinstructionlabels,as necessary.

Followthis manualfor safeloading,unloading,transporting,and

storageof thismachine.

Alwaysreferto theoperator'smanualforimportantdetailsifthe

machineisto bestoredforan extendedperiod.

If thefuel tankhasto be drained,do thisoutdoors.

Observeproperdisposallawsandregulationsforgas,oil, etc.to

protecttheenvironment.

Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or 130hoursof

operation.Atthe endof theAverageUsefulLifehavethemachine

inspectedannuallybyanauthorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failureto do socan resultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modifyenginein anyway.

Tamperingwiththegovernorsettingcan leadto a runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOff RoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(CO),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brushcoveredor grass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any)

Ifa sparkarrestorisused,it shouldbe maintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442ofthe CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarrestorforthe muffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

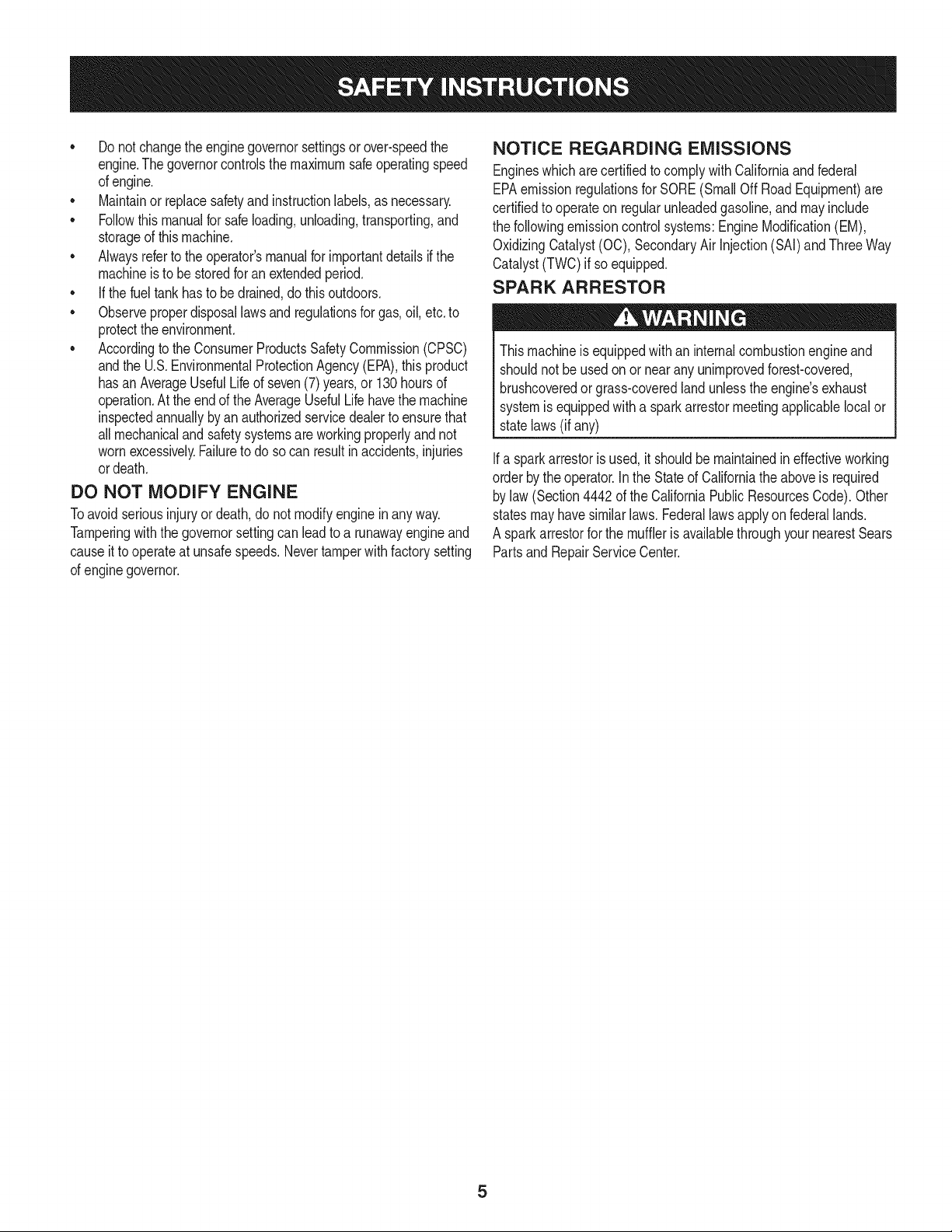

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowallinstructionson themachine

beforeattemptingto assembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine

and muffler to cool before touching.

WARNING: YourResponsibility--Restricttheuseofthispowermachineto personswhoread,understandandfollowthe

warningsand instructionsinthis manualandonthemachine.

SAVETHESEINSTRUCTIONS!

6

NOTE:Thisunitis shippedwithoutgasolineor oil intheengine.Be

certaintoserviceenginewithgasolineandoil as instructedin the

Operationsectionofthis manualbeforeoperatingyourmachine.

NOTE:Referenceto rightand lefthandsideof theTillerisobserved

fromtheoperatingposition.

OPENING CARTON

1. Removeallstaplesfromaroundthebottomofthe perimeter.

2. Removethecartonfromtheskid.

3. Removealllooseparts.

4. Removeloosepackingmaterial.

REMOVING UNIT FROM SKID

1. Thetiller isheavy,do notattemptto removeitfromtheskiduntil

instructedtodo so intheseassemblysteps.

2. Checkcartonthoroughlyforanyotherlooseparts.

LOOSE PARTS IN CARTON

• HandlebarAssembly

• Tiller

• EngineOil

• Operator'sManual

ATTACHING THE HANDLE ASSEMBLY

1. Installthe handleontothetillerusingthehardwarepre-installed

onthehandlemountingbrackets.Thisconsistsofa 5/16-18x

3.00"hexbolt,a handlecrankassembly,retainerbracketandtwo

5/16-18flangelocknuts.Removethishardwarefromthehandle

mountingbracketson thetiller.Referto Figure1inset.

f -_,

3. Installthehandle-crankadjustmentrod intothe topholeof the

mountingbracketfromtheleft handsideof thehandleassembly,

securewiththeotherflangelocknut previouslyremoved.Fit

thehexend ofthe retainerbracketoverthe flangelocknut.See

Figure1.

4. Tightenthehexboltinstalledin Step2 atthis time.Becarefulnot

toovertightenthishardware.

5. Withthehandlein the desiredposition,tightenthehandlecrank

adjustmentrodatthistime.

ATTACHING THE CABLES

1. Routethetwocablesalongthe handleassemblyon therighthand

side.

2. Connectthe reversecable(Red)tothe reversecablecontrolby

feedingthez-hookthroughthe holeon thereversecablecontrol

fromtheinsidetowardstheoutside.SeeFigure2.

f ---

/

Figure1

2. Insertthe handleintothe handlemountingbrackets,liningupthe

pre-drilledholes.Insertthe5/16-18x3.00"hexboltinthebottom

holefromtheleft handside throughtotheotherside.Placethe

roundholeendofthe hexretainerbracketoverthehexboltand

securelooselywitha bellwasherand5/16-18flangelocknut

removedearlier.Referto Figure1inset.

NOTE:Thebellwashershouldbepositionedwiththetopd thebellshape

towardsthehexnutwhichwillcreatetensionandfurthersecuretheflange

locknutoncetightened.Donottightenthishardwareatthistime. 7

Figure2

3. Connecttheforwarddrivecable(Black)tothe clutchbailby

feedingthez-hookthroughthe holeon theclutchbailfromthe

outsidetowardstheinside.SeeFigure2.

NOTE:Testthefunctionofthe reverseclutchby pullingthe reverse

handleand releasingit.The handleshouldreturntoits neutral

position.If it doesn't,contactCustomerSupportforassistanceorthe

nearestdealer.

Totest thefunctionoftheforwarddrivebail,lift thebailto thehandle

andreleaseit.The bailshouldreturntoits neutralposition.Ifit doesn't,

contactCustomerSupportforassistanceorthe nearestdealer.

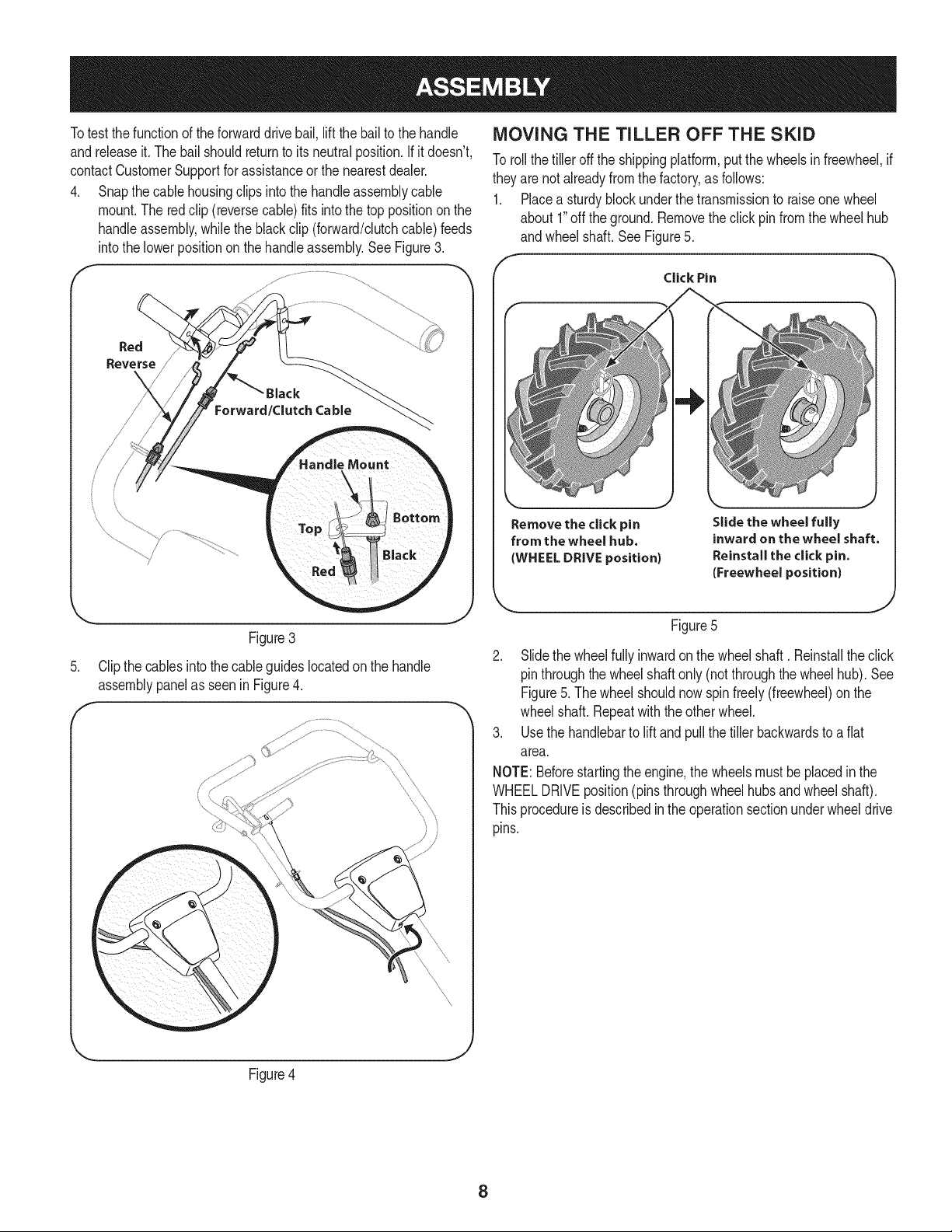

4. Snapthecablehousingclipsintothehandleassemblycable

mount.Theredclip(reversecable)fitsinto thetop positiononthe

handleassembly,whiletheblackclip (forward/clutchcable)feeds

intothe lowerpositiononthe handleassembly.See Figure3.

Red

Reverse

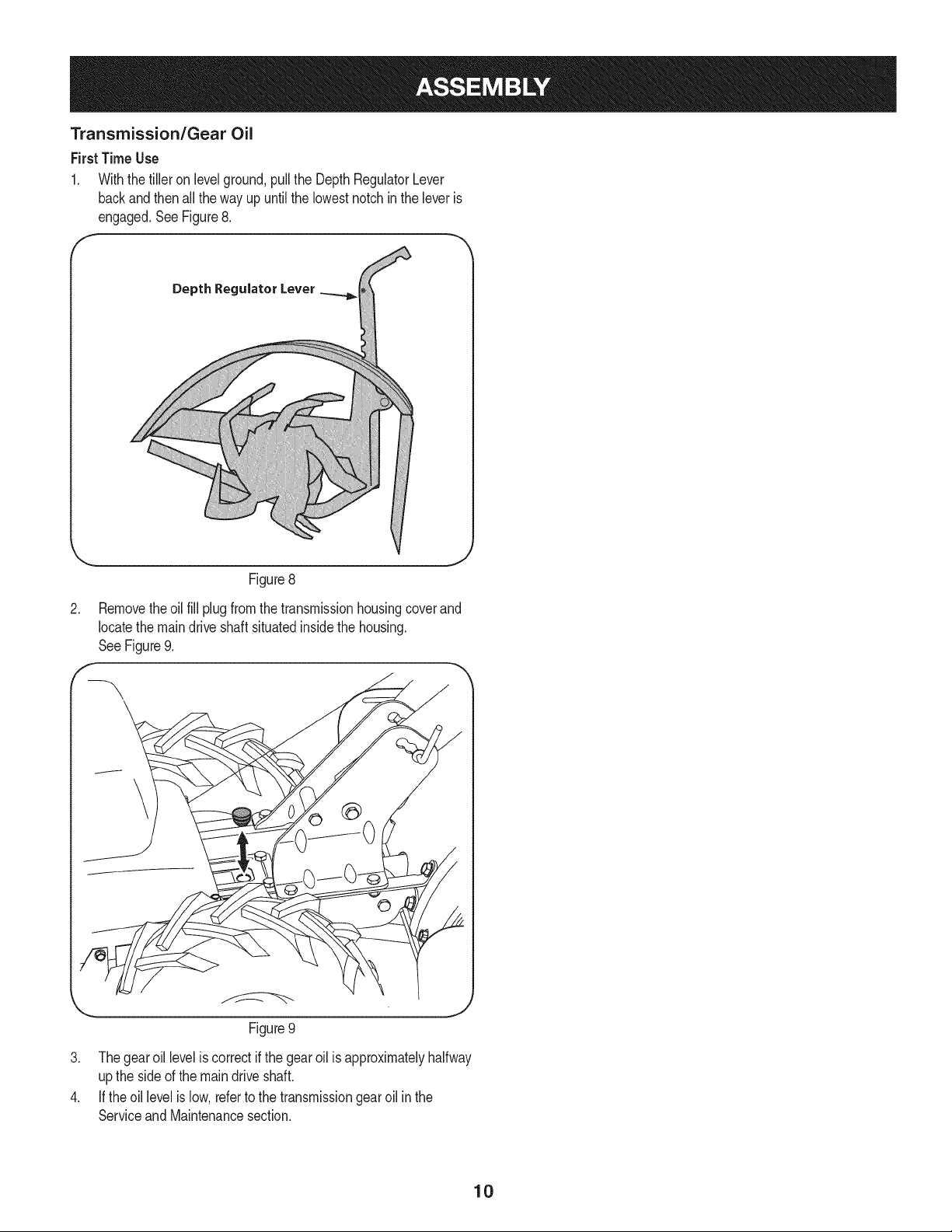

MOVING THE TILLER OFF THE SKID

Torollthetilleroff the shippingplatform,put thewheelsinfreewheel,if

theyarenotalreadyfromthefactory,asfollows:

1. Placeasturdyblockunderthetransmissiontoraiseonewheel

about1"off theground.Removetheclickpinfromthewheelhub

andwheelshaft.SeeFigure5.

f

Click Pin

Figure3

Clipthe cablesintothe cableguideslocatedon thehandle

assemblypanelas seenin Figure4.

Remove the click pin

from the wheel hub.

(WHEEL DRIVE position)

Slide the wheel fully

inward on the wheel shaft.

Reinstall the click pin.

(Freewheel position)

Figure5

2. Slidethewheelfullyinwardonthe wheelshaft. Reinstalltheclick

pinthroughthewheelshaftonly(notthroughthewheelhub).See

Figure5.Thewheel shouldnowspinfreely(freewheel)onthe

wheelshaft.Repeatwiththeotherwheel.

3. Usethehandlebartolift andpullthetillerbackwardstoa flat

area.

NOTE:Beforestartingtheengine,thewheelsmustbe placedinthe

WHEELDRIVEposition(pinsthroughwheelhubsandwheel shaft).

Thisprocedureisdescribedintheoperationsectionunderwheeldrive

pins.

Figure4

J

8

SET-UP

Checking and Adding Oil

Theengineis shippedwithoutoil intheengine.Youmustfill the

enginewithoil beforeoperating.Runningtheenginewithinsufficient

_o cancauseserous engnedamageandvod the productwarranty.

Initial Use

1. Removetheoil filldipstick.

2. Placethetilleron levelground,usea funnelto emptyentire

contentsofthe oil bottleprovidedwiththe unitintotheengine.

3. Replacetheoil fill dipstickandtighten.

Checkingand adding oil

1. Placethetillerona flat, levelsurface.

2. Removetheoil fillercap/dipstickandwipethedipstickclean.See

Figure6.

Fuel Recommendations

Useautomotivegasoline(unleadedorlowleadedtominimizecombus-

tionchamberdeposits)witha minimumof 87 octane.Gasolinewith

up to 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neverusean oil/gasolinemixtureordirty gasoline.Avoidgetting

dirt, dust,or waterinthe fueltank.DONOTuse E85gasoline.

• Refuelina well-ventilatedareawiththe enginestopped.Donot

smokeorallowflamesor sparksin theareawheretheengineis

refueledor wheregasolineisstored.

• Donotoverfillthe fueltank.After refueling,makesurethe tank

capis closedproperlyandsecurely.

• Becarefulnotto spillfuelwhenrefueling.Spilledfuelorfuel vapor

mayignite.Ifany fuelis spilled,makesurethe areaisdry before

startingthe engine.

• Avoidrepeatedor prolongedcontactwithskinorbreathingofvapor.

Adding Fuel

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsareexplosive.Neverfuelthe machine

indoorsorwhilethe engineishotor running.Extinguishcigarettes,

cigars,pipesandothersourcesof ignition.

1. Besureengineisoutdoorsandina well-ventilatedarea.

2. Cleanareaaroundthefuelfill capandremovethefuelfill cap.

3. UsinganapprovedredGASOLINEcontainer,addfuelslowly,being

carefultoavoidspilling.

4. Fillthetankuntilthefuelreachesthe "fuelfull"indicatormark.See

Figure7.

Figure6

3. Insertthe cap/dipstickintothe oilfillerneck,butdo not screwitin.

4. Removetheoil fillercap/dipstick.Ifthelevelislow,slowlyaddoil

untiloil levelregistersbetweenhigh(H) and low(L), Figure6.

NOTE:Donotoverfill.Overfillingwithoil maycausesmoking,hard

starting,or sparkplugfouling.

5. Replaceandtightencap/dipstickfirmlybeforestartingengine.

NOTE:DONOTallowoil leveltofall belowthe"L"markon the

dipstick.Doingsomayresultinequipmentmalfunctionsordamage.

NOTE:Tochangethe oilon yourengine,seethe Maintenance

Sectionofthismanual.

Fuel Level Indicator

TopView

Figure7

.

Replacethefuelcapandtightensecurely.Wipeupspilledfuel

beforestartingengine.IffuelisspilledDONOTstartengine.Move

machineawayfromareaofspillage.Avoidcreatinganysourceof

ignitionuntilfuelvaporsaregone.

9

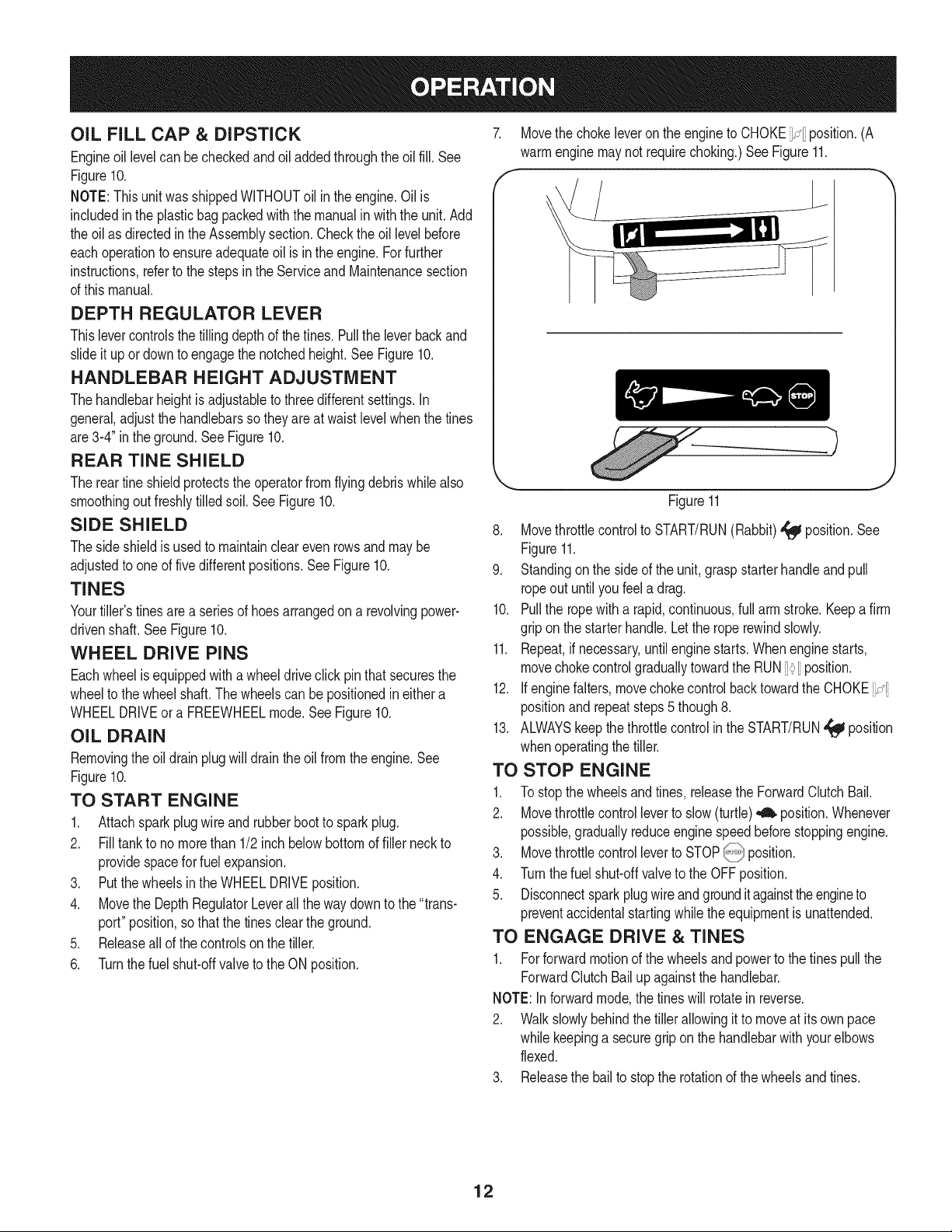

Transmission/Gear Oil

First Time Use

1. Withthetilleron levelground,pullthe DepthRegulatorLever

backandthenallthe wayup untilthe lowestnotchinthe leveris

engaged.SeeFigure8.

F

Depth Regulator Lever

Figure8

,

Removetheoil fillplugfromthetransmissionhousingcoverand

locatethemaindriveshaft situatedinsidethe housing.

SeeFigure9.

\

\

Figure9

3. Thegearoil leveliscorrectifthe gearoilisapproximatelyhalfway

uptheside ofthe maindriveshaft.

4. If theoillevelislow,refertothetransmissiongearoilinthe

ServiceandMaintenancesection.

10

f

Forward Clutch Bail

Fuel Cap & Tine Engagement

Muffler

Air Filter

Choke

Throttle

Pull Starter Handle

OUFill Cap

& Dipstick

Oil Drain

Nowthat youhavesetup yourtillerforoperation,getacquaintedwith

itscontrolsandfeatures.Thesearedescribedon thenexttwopages

andillustratedonthispage.Thisknowledgewillallowyouto useyour

newequipmenttoitsfullestpotential.

ulator

Handle Height

Adjustment

Rear Tine Shield

Side Shield

Tines

Wheel Drive Pin

,J

Figure10

CHOKE CONTROL

Theoperationofanytillercanresultinforeignobjectsbeingthrowninto

theeyes,whichcandamageyoureyesseverely.Alwayswearsafety

[gassesdurngoperatonorwh eperformnganyadjustmentsorrepars.

RECOIL STARTER HANDLE

Thishandleisusedto starttheengine.See Figure10.

THROTTLE CONTROL

Thethrottlecontrolislocatedonthefrontof theengine.It regulatesthe

spreadoftheengineandwill shutoff theenginewhen movedintothe

STOPposition.SeeFigure10.

Meets ANSi Safety Standards

CraftsmanTillersconformtothe safetystandardofthe AmericanNationalStandardsInstitute(ANSI).

Thechokecontrolisactivatedbymovingtheleverto theCHOKE

position.Activatingthe chokecontrolclosesthechokeplateonthe

carburetorandaidsinstartingtheengine.

AIR FILTER

Theairfilteris a deviceon theengineairintakethatpreventsdustand

dirtenteringtheengine.SeeFigure10.

MUFFLER

Engineexhaustexitstheenginevia themuffler.SeeFigure10.

REVERSE HANDLE

TheReverseHandlecontrolsthe reversedriveofthe wheelsandthe

tines.SeeFigure10.

FORWARD CLUTCH BAiL & TINE ENGAGEMENT

Theforwardclutchbailcontrolstheengagementofthe forwarddriveof

thewheelsandtines.See Figure10.

11

OiL FiLL CAP & DIPSTICK

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill. See

Figure10.

NOTE:Thisunitwasshipped%THOUToil inthe engine.Oilis

includedintheplasticbag packedwiththemanualinwiththeunit.Add

theoilas directedintheAssemblysection.Checktheoil levelbefore

eachoperationtoensureadequateoilisintheengine.Forfurther

instructions,referto thestepsinthe ServiceandMaintenancesection

ofthismanual.

DEPTH REGULATOR LEVER

Thislevercontrolsthetillingdepthof thetines.Pulltheleverbackand

slideit upor downto engagethenotchedheight.SeeFigure10.

HANDLEBAR HEIGHT ADJUSTMENT

Thehandlebarheightisadjustableto threedifferentsettings.In

general,adjustthehandlebarsso theyareatwaistlevelwhenthetines

are3-4"intheground.SeeFigure10.

REAR TIME SHIELD

Thereartine shieldprotectstheoperatorfromflyingdebriswhilealso

smoothingout freshlytilledsoil.SeeFigure10.

SiDE SHIELD

Theside shieldisusedto maintainclearevenrowsandmaybe

adjustedtooneof fivedifferentpositions.SeeFigure10.

TINES

Yourtiller'stinesarea seriesof hoesarrangedona revolvingpower-

drivenshaft.See Figure10.

WHEEL DRIVE PiNS

Eachwheelisequippedwitha wheeldriveclick pinthatsecuresthe

wheelto thewheel shaft.Thewheelscanbe positionedineithera

WHEELDRIVEor a FREEWHEELmode.SeeFigure10.

OiL DRAIN

Removingthe oildrainplugwilldrainthe oil fromtheengine.See

Figure10.

TO START ENGINE

1. Attachsparkplugwireand rubberboottosparkplug.

2. Filltankto nomorethan1/2inchbelowbottomof fillerneckto

providespaceforfuelexpansion.

3. Putthe wheelsintheWHEELDRIVEposition.

4. MovetheDepthRegulatorLeverallthewaydownto the"trans-

port"position,sothatthetinescleartheground.

5. Releaseall ofthecontrolsonthe tiller.

6. Turnthefuelshut-offvalveto theON position.

7. Movethechokeleveron theengineto CHOKE_÷ position.(A

warmenginemaynotrequirechoking.)SeeFigure11.

f -,

_.. .J

Figure11

8. Movethrottlecontrolto START/RUN(Rabbit)_ position.See

Figure11.

9. Standingon the sideof theunit,graspstarterhandleandpull

ropeoutuntilyoufeela drag.

10. Pullthe ropewitha rapid,continuous,fullarm stroke.Keepafirm

gripon thestarterhandle.Letthe roperewindslowly.

11. Repeat,ifnecessary,untilenginestarts.Whenenginestarts,

movechokecontrolgraduallytowardthe RUN_[ position.

12. Ifenginefalters,movechokecontrolbacktowardtheCHOKEi:_

positionand repeatsteps5 though8.

13. ALWAYSkeepthethrottlecontrolintheSTART/RUN,_ position

whenoperatingthetiller.

TO STOP ENGINE

1. To stopthewheelsandtines, releasetheForwardClutchBail.

2. Movethrottlecontrolleverto slow(turtle)_ position.Whenever

possible,graduallyreduceenginespeedbeforestoppingengine.

3. Movethrottlecontrolleverto STOP_ii_ position.

4. Turnthefuelshut-offvalveto theOFFposition.

5. Disconnectsparkplugwireandgrounditagainsttheengineto

preventaccidentalstartingwhilethe equipmentisunattended.

TO ENGAGE DRIVE & TINES

1. Forforwardmotionofthewheelsandpowertothe tinespullthe

ForwardClutchBailupagainstthe handlebar.

NOTE:Inforwardmode,thetineswill rotatein reverse.

2. Walkslowlybehindthetillerallowingitto moveat itsown pace

whilekeepinga securegrip onthehandlebarwithyourelbows

flexed.

3. Releasethebailto stoptherotationofthewheelsandtines.

12

To move tiller in reverse: (Do not till in reverse)

a. ReleasetheForwardClutchBail.

b. Liftthe handlebaruntilthetinesare offthe ground.

c. Slowlypull backonthe ReverseLever,andcarefullywalk

backwardswiththe machine.

NOTE:In reversemode,thetineswill rotateforward.

d. If longerdistancesneedtobe coveredinreverse,shutoff the

engine,thenplacethe twowheelsinFREEWHEEL.

TURNING THE TILLER

1. Practiceturningthetillerin a level,openarea.Beverycarefulto

keepyourfeetandlegsawayfromthe tines.

2. Tobeginaturn,liftthe handlebarsuntilthetinesareout ofthe

groundandtheengineandtinesarebalancedoverthewheels.

3. Withthetillerbalanced,pushsidewayson the handlebartosteer

inthedirectionoftheturn.Afterturning,slowlylowerthe tinesinto

thesoil toresumetilling.

SETTING THE DEPTH

Toadjustthesideshields,removethewingnuts.Movethesideshieldto the

desiredpositionandreplacethewingnuts.Tightensecurely.SeeFigure13.

f ---

\

Becertainsparkplugwireisdisconnectedandgroundedagainstthe

enginewhenperforminganyadjustments.

Tillingdepthiscontrolledbythedepthstakewhichcanbeadjustedtofive

differentsettings.Adjustthesideshieldsasyouadjustthedepthstake.

• Whenusingthe tillerfor thefirsttime,usethesecondadjustment

holefromthetop (1"oftillingdepth).

• Whenbreakingupsodandforshallowcultivation,usethe setting

whichgives1"oftillingdepth(secondholefromthetop).Place

thesideshieldsintheirlowestposition.

• Forfurtherdepth,raisethedepthstakeandsideshieldsandalso

makeoneor twomorepassesoverthearea.

• Whentillingloosesoil,thedepthstakemayberaisedtoits

highestposition(usebottomadjustmenthole)to givethedeepest

tillingdepth.Raisethe sideshieldsto theirhighestposition.

• Totransporttiller,lowerthedepthstake(usetopadjustmenthole).

Toadjustthedepthstake,pull backon thedepthadjustmentbracket

(A)and pushupor down(B) untilthe bracketreachesthe desired

position,thenreleasethebracket(C).SeeFigure12.

\ j

Figure13

ADJUSTING THE HANDLE HEIGHT

Thehandleshouldbeadjustedsothat whenthetiller isdigging3-4"

intothesoil,thehandlefallsto aboutwaste-high.Toadjusthandle,

simplyloosenthehandleadjustmentcrank,movethehandleto the

desiredheightand retightentheadjustmentcrank.See Figure14.

J

Figure12 13

Figure14

CLEARING THE TINES

Beforeclearingthetinesby hand,stoptheengine,allowall moving

partstostopanddisconnectthesparkplugwire.Failuretofollowthis

warningcouldresultinpersonalinjury.

* Thetineshavea self-clearingactionwhicheliminatesmostof the

tanglingofdebris.However,occasionallydrygrass,stringystalks

ortoughvinesmaybecometangled.Followtheseproceduresto

helpavoidtanglingandtoclearthetines, ifnecessary.

* Toreducetangling,setthedepth regulatordeepenoughto get

maximum"chopping"actionasthe tineschopthe materialagainst

theground.Also,trytotill undercropresiduesorcovercrops

whiletheyaregreen,moistandtender.

* Whiletilling,tryswayingthehandlebarsfromsideto side(about

6"to 12").This"fishtailing"actionoftenclearsthetinesof debris.

TILLING TiPS & TECHNIQUES

Beforetilling,contactyourtelephoneor utilitiescompanyandinquire

l ifundergroundequipmentorlinesareusedon yourproperty.Donot

[till nearburiedelectriccables,telephonelines,pipesor hoses.

Tilling Depth

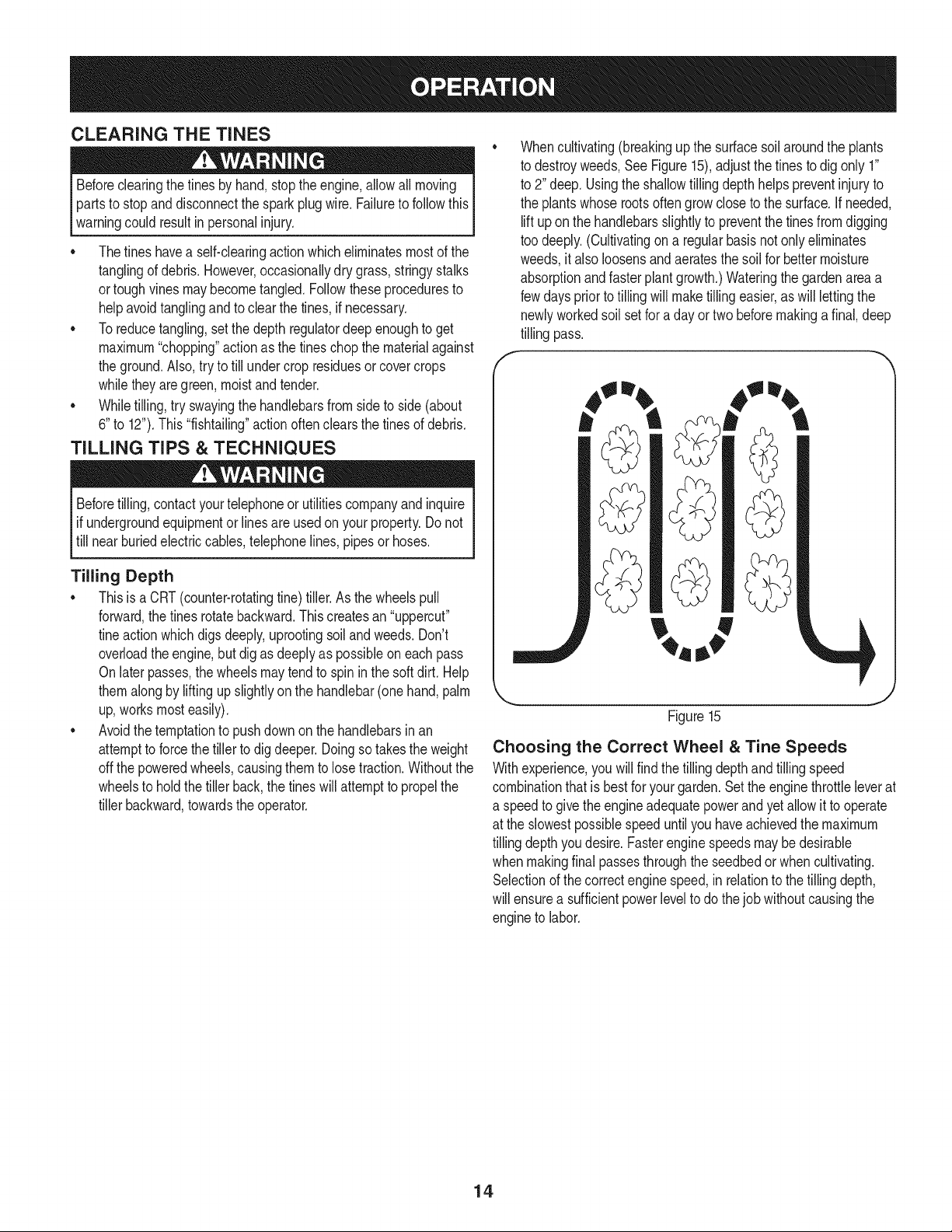

* ThisisaCRT(counter-rotatingtine)tiller.Asthewheelspull

forward,thetinesrotatebackward.Thiscreatesan"uppercut"

tineactionwhichdigsdeeply,uprootingsoilandweeds.Don't

overloadtheengine,but digasdeeplyas possibleoneachpass

On laterpasses,thewheelsmaytendto spininthe softdirt. Help

themalongbyliftingupslightlyonthe handlebar(onehand,palm

up,worksmosteasily).

* Avoidthetemptationto pushdownonthe handlebarsinan

attempttoforcethetillerto digdeeper.Doingsotakestheweight

off thepoweredwheels,causingthemto losetraction.Withoutthe

wheelstoholdthe tillerback,thetineswill attempttopropelthe

tillerbackward,towardstheoperator.

Whencultivating(breakingupthe surfacesoilaroundthe plants

todestroyweeds,SeeFigure15),adjustthe tinestodigonly 1"

to2" deep.Usingtheshallowtillingdepthhelpspreventinjuryto

theplantswhoserootsoftengrowclosetothe surface.Ifneeded,

liftupon thehandlebarsslightlyto preventthetinesfromdigging

toodeeply.(Cultivatingon a regularbasisnot onlyeliminates

weeds,it alsoloosensandaeratesthe soilfor bettermoisture

absorptionandfasterplantgrowth.)Wateringthegardenareaa

fewdayspriortotilling willmaketillingeasier,aswill lettingthe

newlyworkedsoilsetfor a dayor twobeforemakingafinal,deep

tillingpass.

Figure15

Choosing the Correct Wheel & Tine Speeds

Withexperience,you willfind thetilling depthandtillingspeed

combinationthatis bestforyourgarden.Settheenginethrottleleverat

a speedto givethe engineadequatepowerandyet allowit tooperate

atthe slowestpossiblespeeduntilyouhaveachievedthemaximum

tillingdepthyoudesire.Fasterenginespeedsmaybe desirable

whenmakingfinal passesthroughtheseedbedor whencultivating.

Selectionofthe correctenginespeed,inrelationtothetillingdepth,

willensurea sufficientpowerlevelto do thejobwithoutcausingthe

engineto labor.

14

Suggested Tilling Patterns

• Whenpreparinga seedbed,gooverthe samepathtwice inthe

firstrow,thenoverlapone-halfthetiller widthontherestof the

passes.SeeFigure16.

Ifthegardensizewill notpermitlengthwiseandthencrosswise

tilling,thenoverlapthefirst passesbyone-halfatiller width,fol-

lowedby successivepassesatone-quarterwidth.SeeFigure18.

f

Figure18

Figure16

Whenfinishedinonedirection,makea secondpassata right

angle,SeeFigure17.Overlapeachpassfor thebestresults(in

veryhardground,it maytakethreeorfour passestothoroughly

pulverizethesoil.)

f

m m m m

r

t_ m _ m

Figure17

Tilling on a Slope

Donotoperatethetillerona slopetoosteepfor safeoperation.Till

slowlyandbesureyouhavegoodfooting.Neverpermitthetillerto

freewheeldownslopes.Failuretofollowthiswarningcouldresultin

personalinjury.

1. Till onlyon moderateslopes,neveronsteepgroundwherethe

footingisdifficult.

2. Tillingupand downslopesis recommendedoverterracing.Tilling

verticallyon aslopeallowsmaximumplantingareaandalso

leavesroomforcultivating.

NOTE:Whentillingon slopes,be surethe correctoillevelismain-

tainedin theengine(checkeveryone-halfhourofoperation).The

inclineof theslopewillcausethe oilto slantawayfromits normal

levelandthis canstarveenginepartsof requiredlubrication.Keepthe

motoroil levelat thefull pointat all times.

Tilling Up and Down a Slope

1. To keepsoilerosionto a minimum,besureto addenoughorganic

matterto thesoil sothat it hasgoodmoisture-holdingtextureand

try toavoidleavingfootprintsor wheelmarks.

2. Whentillingvertically,tryto makethefirst passuphillasthetiller

J

digsmoredeeplygoinguphillthanit doesdownhill.Insoft soilor

weeds,youmayhaveto liftthehandlebarsslightlywhilegoingup-

hill.Whengoingdownhill,overlapthefirstpassby aboutone-half

thewidthof thetiller.

15

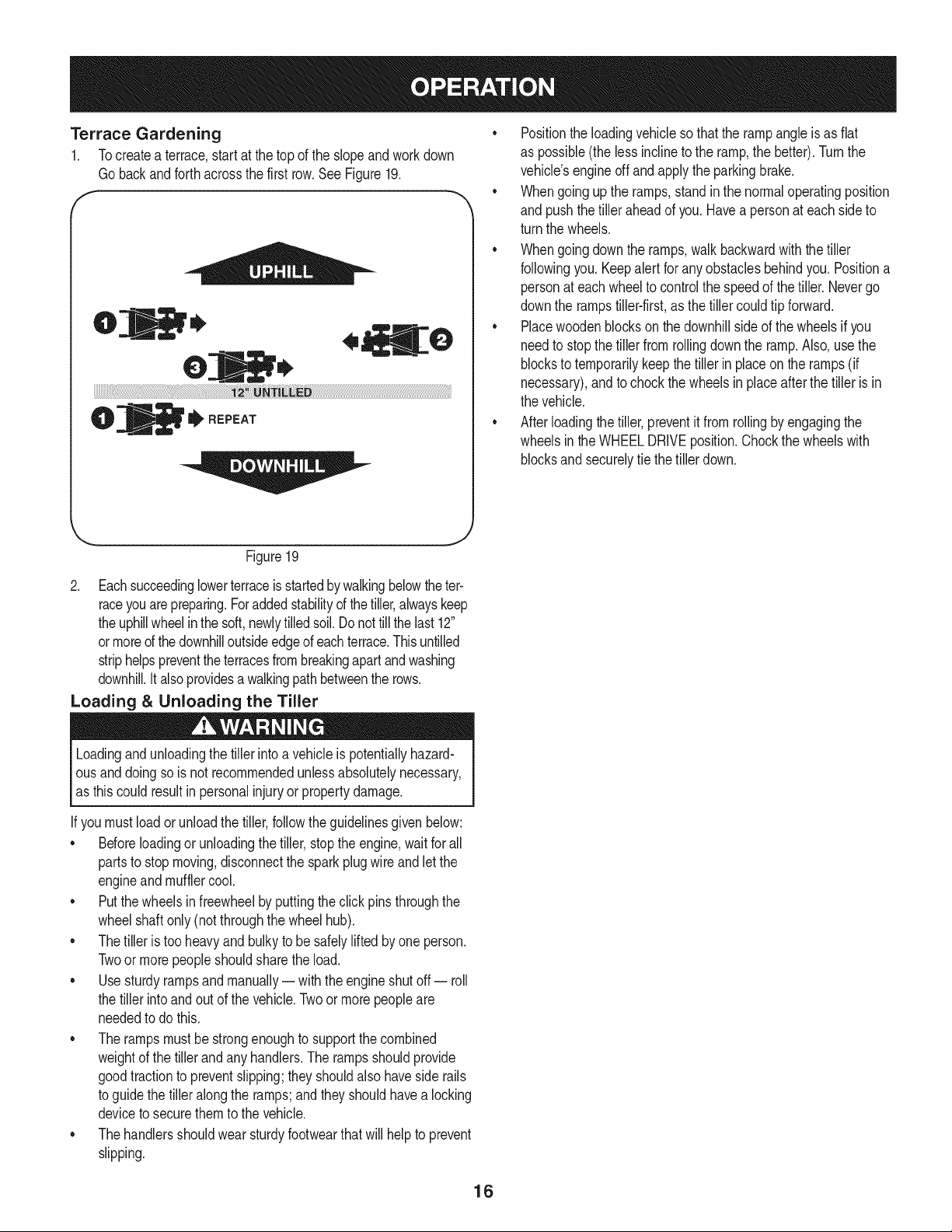

Terrace Gardening

1. Tocreatea terrace,startatthetopof theslopeandworkdown

Gobackandforthacrossthefirstrow.See Figure19.

f

Figure19

• Positiontheloadingvehiclesothatthe rampangleis asflat

as possible(thelessinclineto theramp,the better).Turnthe

vehicle'sengineoffandapplytheparkingbrake.

• Whengoinguptheramps,standin thenormaloperatingposition

and pushthetilleraheadof you.Havea personateachsideto

turnthe wheels.

• Whengoingdownthe ramps,walkbackwardwiththetiller

followingyou.Keepalertfor anyobstaclesbehindyou.Positiona

personateachwheeltocontrolthe speedof thetiller.Nevergo

downthe rampstiller-first,asthetillercouldtip forward.

• Placewoodenblockson thedownhillsideof thewheelsif you

needtostopthe tillerfromrollingdowntheramp.Also,usethe

blockstotemporarilykeepthetiller in placeonthe ramps(if

necessary),andto chockthe wheelsin placeafterthe tilleris in

thevehicle.

• Afterloadingthe tiller,preventitfromrollingby engagingthe

wheelsintheWHEELDRIVEposition.Chockthewheelswith

blocksandsecurelytiethe tillerdown.

J

2. Eachsucceedinglowerterraceisstartedbywalkingbelowtheter-

raceyouarepreparing.Foraddedstabilityofthetiller,alwayskeep

theuphillwheelin thesoft,newlytilledsoil.Donottillthelast 12"

ormored the downhilloutsideedgeofeachterrace.Thisuntilled

striphelpspreventthe terracesfrombreakingapartandwashing

downhill.It alsoprovidesa walkingpathbetweentherows.

Loading & Unloading the Tiller

Loadingandunloadingthetiller intoa vehicleis potentiallyhazard-

ousanddoingso isnot recommendedunlessabsolutelynecessary,

as thiscouldresultinpersonalinjuryor propertydamage.

If youmustloador unloadthetiller,followthe guidelinesgiven below:

• Beforeloadingor unloadingthetiller,stopthe engine,waitforall

partstostopmoving,disconnectthesparkplugwireandletthe

engineandmufflercool.

• Putthewheelsin freewheelbyputtingtheclickpinsthroughthe

wheelshaftonly(notthroughthewheelhub).

• Thetilleris tooheavyandbulkyto be safelyliftedby oneperson.

Twoor morepeopleshouldsharethe load.

• Usesturdyrampsandmanually-- withtheengineshutoff -- roll

thetillerintoand outofthe vehicle.Twoormorepeopleare

neededtodothis.

• The rampsmustbestrongenoughto supportthecombined

weightofthe tillerandany handlers.Therampsshouldprovide

goodtractiontopreventslipping;theyshouldalsohavesiderails

toguidethe tilleralongthe ramps;andtheyshouldhavealocking

devicetosecurethemto thevehicle.

• Thehandlersshouldwearsturdyfootwearthatwill helpto prevent

slipping.

16

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.To locate the nearest Sears Service

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

operationor whileperforminganyadjustmentsor repairs.

Followthemaintenanceschedulegivenbelow.Thischartdescribes

= =

EachUse

1st2 hours

1st5 hours

Every10hours

Every25 hours

Every30 hours

Every50 hours

Every100hours

BeforeStorage

1. Engineoillevel

2. Looseormissinghardware

3. Engineandaroundmuffler

4. Aircleaner

1. Drivebelttension

2. Nutsand Bolts

1. Engineoil

1. Drivebelttension

2. Unit

1. Sparkplug

1. Transmissionoillevel

2. Tinesforwear

3. Tirepressure

1. Engineoi11-

1. Aircleaner

2. SparkPlug

1. Fuelsystem

1. Check

2. Tightenor_place

3. Clean

4. Check

1. Check

2. Check

1. Change

1. Check

2. Lubricate

1. Check

1. Check

2. Check

3. Check

1. Change

1. Change

2. Change

1. Runengineuntilit stopsfromlackof

fueloradda gasolineadditivetothe

gasin thetank.

Changeoileverytwentyfivehourswhenoperatingengineunderheavyloadorinhightemperatures

ENGINE MAINTENANCE

Beforeperforminganytypeofmaintenanceon themachine,waitfor

allpartsto stopmovinganddisconnectthe sparkplugwire.Failureto

followthis instructioncouldresultinpersonalinjuryorpropertydamage.

GENERAL RECOMMENDATIONS

• Alwaysobserveallsafetyrulesfoundonproductlabelsandin

thisoperator'smanualwhenperforminganymaintenance.Safety

rulescan befoundonthe productlabelsandin thisOperator's

Manualbeginningon page3.

• Thewarrantyonthistillerdoesnotcoveritemsthathavebeen

subjectedtooperatorabuseornegligence.Toreceivefullvaluefrom

warranty,operatormustmaintaintheequipmentasinstructedhere.

• Someadjustmentswillhaveto be madeperiodicallytomaintain

yourunit properly.

• Periodicallycheckall fastenersand makesurethesearetight.

DONOTcheckforsparkwithsparkplugremoved.DONOTcrank

enginewithsparkplug removed.

Iftheenginehas beenrunning,themufflerwillbeveryhot. Becareful

notto touchthemuffler.

Thesparkplugmustbesecurelytightened.Animproperlytightened

sparkplugcanbecomeveryhot andmaydamagetheengine.

Checking the Spark Plug

Toensureproperengineoperation,thesparkplugmustbeproperly

gappedandfreeof deposits.Checkthe sparkplugevery25hoursand

replaceitevery100hours.

17

Removethesparkplugbootanduse a sparkplugwrenchto

removetheplug.See Figure20.

Figure20

2. Visuallyinspectthesparkplug.Discardthesparkplugif thereis

apparentwear,orif the insulatoriscrackedorchipped.Cleanthe

sparkplugwitha wirebrush ifit isto be reused.

3. Measurethepluggapwitha feelergauge.Correctas necessary

bybendingsideelectrode.SeeFigure21.The gapshouldbeset

to0.030in.

Servicing the Air Cleaner

Neverusegasolineor lowflashpoint solventsforcleaningtheair

cleanerelement.A fireor explosioncouldresult.

Theaircleanerpreventsdamagingdirt,dust,etc.,fromenteringthe

carburetorandbeingforcedintothe engineandis importanttoengine

lifeandperformance.Neverruntheenginewithoutanair cleaner

completelyassembled.Checktheair cleanerbeforeeachuse.

Paperfilterscannotbecleanedand mustbereplacedoncea year

or every100operatinghours;moreoftenif usedinextremelydusty

conditions.

1. Pressthetab ontheair filtercover,liftthecoverand removethe

air filter.SeeFigure22.

_Foam .....................

Element ............

Air Filter

Cover

Filter

Electrode

0.02-0.03 in.

===_ 4=======0.60-0.80 mm

Figure21

4. Checkthatthe sparkplugwasherisingoodconditionandthread

thesparkplugin by handtopreventcross-threading.

5. Afterthesparkplugis seated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2turnafterthe

sparkplugseatsto compressthewasher.Whenreinstallinga used

sparkplug,tighten1/8-1/4turnafterthesparkplugseatsto compress

thewasher.

Figure22

2. Discardoldair filter.

3. installnewair filter.

4. Closethecover.

NOTE:Ifthe filteristornor damagedinany way,replaceit.

Donotsprayenginewithwatertocleanbecausewatercould

contaminatefuel.Usinga gardenhoseor pressurewashingequip-

mentcanalsoforcewaterintothe muffleropening.Waterthatpasses

throughthe mufflercanenterthe cylinder,causingdamage.

Cleaning the Engine

Accumulationofdebrisaroundmufflercouldcausea fire. inspectand

cleanbeforeeveryuse.

Iftheenginehas beenrunning,allow itto coolfor at leasthalf anhour

beforecleaning.Periodicallyremovedirt build-upfromtheengine.

Cleanaroundthemuffler.Cleanwitha brushor compressedair.

18

Check Engine Oil

1. Checkoilbeforeeachuse.Stopengineandwaitseveralminutes

beforecheckingoil level.Withthetilleron levelground,theoil

mustbeto FULLmarkon dipstick.

2. Removeoilfill dipstickandwipecleanwithcloth.

3. Replacedipstickintothe oilfillerneck,butdonot screwitin.

Removeandcheckoil level.Levelshouldbeat FULLmark.

4. If needed,addoil slowly- recheck.Donot overfill.

5. Wipedipstickclean,replacebutdonot tighten.Removeand

checkoil level.Oillevelshouldbeat FULLlineondipstick.

6. Replaceandtightendipstickfirmlybeforestartingengine.

Change Engine Oil

DONOTuse non-detergentoilor 2-strokeengineoil.Itcould shorten

theengine'sservicelife.

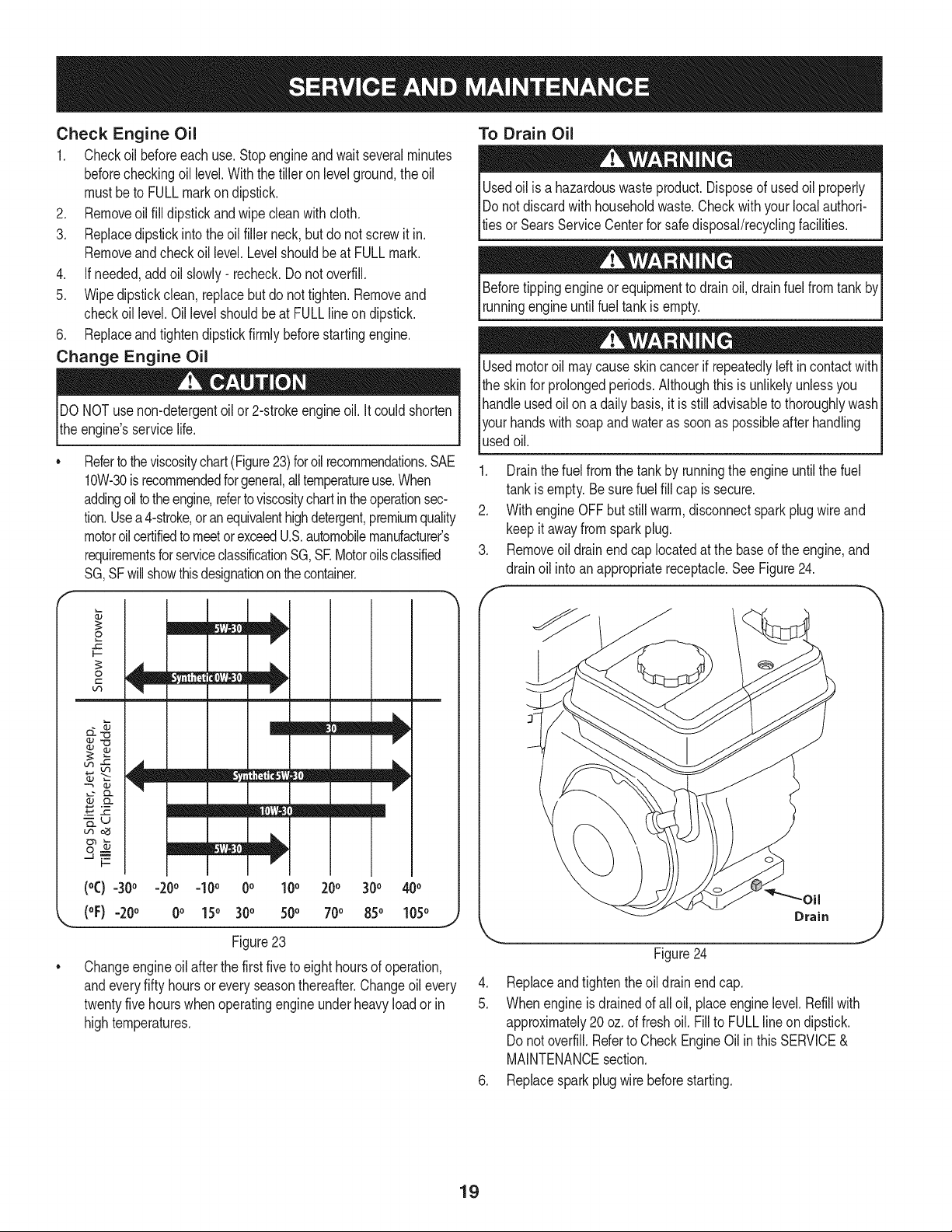

Refertotheviscositychart(Figure23)foroil recommendations.SAE

10W-30is recommendedforgeneral,alltemperatureuse.When

addingoiltotheengine,refertoviscositychartintheoperationsec-

tion.Usea4-stroke,oranequivalenthighdetergent,premiumquality

motoroilcertifiedto meetorexceedU.S.automobilemanufacturer's

requirementsforserviceclassificationSG,SE Motoroilsclassified

SG,SFwillshowthisdesignationonthecontainer.

To Drain Oil

Usedoil isa hazardouswasteproduct.Disposeofusedoil properly

IDo notdiscardwithhouseholdwaste.Checkwithyour localauthori-

lties or SearsServiceCenterforsafedisposal/recyclingfacilities.

Beforetippingengineorequipmentto drainoil, drainfuelfrom

runningengineuntilfuel tankisempty.

Usedmotoroil maycauseskincancerifrepeatedlyleft incontactwith

theskinfor prolongedperiods.Althoughthisisunlikelyunlessyou

handleusedoilon a dailybasis,it isstilladvisabletothoroughlywash

yourhandswithsoapandwateras soonas possibleafterhandling

usedoil.

1. Drainthefuelfromthe tankbyrunningthe engineuntilthe fuel

tankisempty.Besurefuelfill capis secure.

2. WithengineOFFbutstillwarm,disconnectsparkplugwireand

keepitawayfromsparkplug.

3. Removeoil drainendcap locatedatthe baseof theengine,and

drainoil intoanappropriatereceptacle.See Figure24.

f -,,,

2

I.-

0

m

m

_J _j

_u

uqo_

m

I--

!

m

(°C) -30° -20° -10° 0° 10° 200 300 400

(oF)-20 o 0o 150 300 500 700 850 1050

Figure23

Changeengineoilafterthefirstfiveto eighthoursofoperation,

andeveryfifty hoursoreveryseasonthereafter.Changeoil every

twentyfivehourswhenoperatingengineunderheavyloadorin

hightemperatures.

Drain

Figure24

.

Replaceandtightentheoildrainendcap.

5.

Whenengineisdrainedofall oil, placeenginelevel.Refillwith

approximately20oz.offreshoil. Fillto FULLlineondipstick.

Donot overfill.Referto CheckEngineOilinthis SERVICE&

MAINTENANCEsection.

6. Replacesparkplugwirebeforestarting.

J

19

Check Transmission Gear Oil

Checkthetransmissiongearoilafterevery30 hoursofoperation

orwheneveryounoticeanyoil leak.Operatingthe tillerwhenthe

transmissionis lowon oilcan resultin severedamage.

ToChecktheTransmissionGearOil Level:

1. Checkthegearoil levelwhenthetransmissionis cool.Gearoil

willexpandinwarmoperatingtemperaturesandthis expansion

willprovidean incorrectoil levelreading.

2. Withthetiller on levelground,pulltheDepthRegulatorLeverall

thewayup

3. Removetheoil fillplugfromthetransmissionhousingand look

insidethe oilfillholeto locatethemaindriveshaftsituatedbelow

thehole.SeeFigure25.

LUBRICATION

Afterevery10operatinghours,oilor greasethelubricationpoints.Use

cleanlubricatingoil (#30weightmotoroilis suitable)andcleangeneral

purposegrease(greasecontaininga metallubricantis preferred,if

available).SeeFigure26.

Handlebar

Hardware Depth Reg_

\

J

Figure25

4. Thegearoil leveliscorrectifthe gearoilisapproximatelyhalfway

uptheside ofthe maindriveshaft.

5. If thegearoil levelislow,addgearoilasdescribednext.Ifthe

gearoillevelis okay,securelyreplacetheoil fillplug.

6. If addingonlya fewouncesof gearoil,useAPIratedGb4 or

Gb5 gearoil havingaviscosityof SAE 140,SAE85%140or SAE

80W-90.ifrefillinganemptytransmission,useonlyGb4 gearoil

havingaviscosityof SAE85W-140or SAE140.

7. Whilecheckingfrequentlytoavoidoverfilling,slowlyaddgearoilinto

theoilfill holeuntilitreachesthehalfwaypointonthedriveshaft.

8. Securelyreplacetheoil fillplug.

Change Transmission Gear Oil

Thetransmissiongearoildoesnot needtobe changedunlessithas

beencontaminatedwithdirt, sandor metalparticles.Seeanautho-

rizedSearsServiceCentertohavethetransmissiongearoil changed

orto scheduleservice,simplycontactSearsat 1-800-4-MY-HOME®.

Tine Shaft

Wheel Shaft

Figure26

• Removethewheels,cleanthe wheelshaftandapplya thin

coatingofgrease.

• Greasetheback,frontandsidesofthe depthregulatorlever.

• Removethetinesandcleanthefine shaft.Usea fileor sandpa-

perto gentlyremoveanyrust,burrsor roughspots(especially

aroundtheholesin theshaft).Applygreaseto theendsofthe

shaftbeforeinstallingthetines.

• Oilthethreadson thehandlebarheightadjustmentscrewsand

thehandlebarattachingscrews.

TIRE PRESSURE

Checktheairpressureinbothtires.Theair pressureshouldbe

between15-20PSI.Keepbothtiresequallyinflatedto helpprevent

machinefrompullingtooneside.

HARDWARE

Checkforlooseor missinghardwareafterevery10operatinghours

andtightenor replace= as needed= beforereusingthetiller.Be

sureto checkthe screwsunderneaththe tillerhoodthat securethe

transmissioncoverandthe DepthRegulatorLevertothetransmission.

2O

BELT REPLACEMENT

Ifthedrive beltor reversebeltneedsto be replaced,itis bestto

replacebothbeltsatthe sametime.Useonlya factoryauthorized

beltas an "over-the-counter"beltmaynotperformsatisfactorily.

Theprocedurerequiresaveragemechanicalabilityandcommonly

availabletools.

Toreplacethe DriveandReversebelts,followthesesteps:

1. Makesurethe tillerisona flat surface,withtheengineturned

offandthe sparkplugwireunpluggedandgroundedto prevent

unintendedfiringofthe engine.

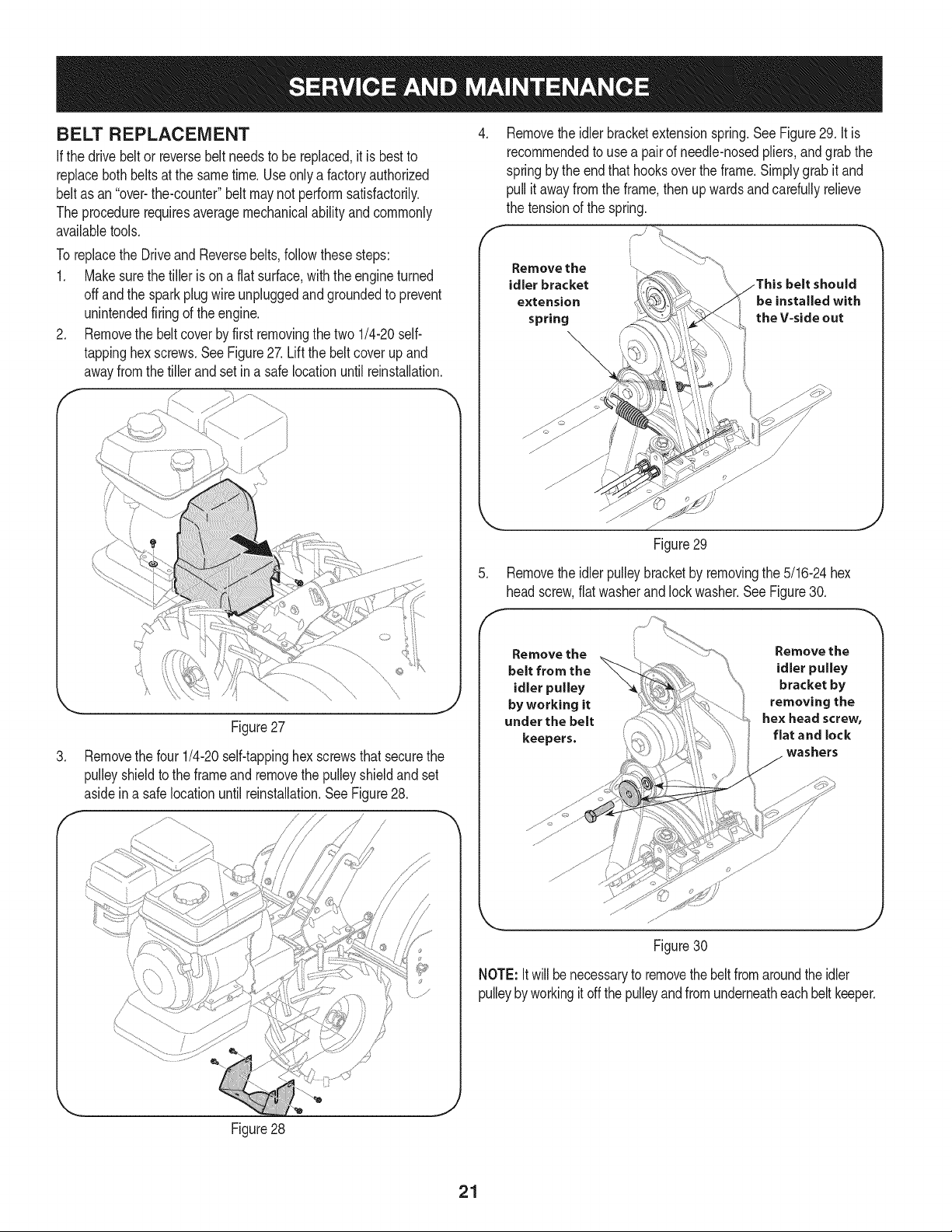

2. Removethe beltcoverby firstremovingthetwo1/4-20self-

tappinghexscrews.SeeFigure27.Liftthe beltcoverupand

awayfromthetiller andsetin a safelocationuntilreinstallation.

f

.

Removethe idlerbracketextensionspring.SeeFigure29.It is

recommendedto usea pairof needle-nosedpliers,andgrabthe

springby theendthathooksovertheframe.Simplygrabitand

pull itawayfromthe frame,thenup wardsandcarefullyrelieve

thetensionof thespring.

Remove the

idler bracket

extension

spring

Figure29

5. Removethe idlerpulleybracketbyremovingthe5/16-24hex

headscrew,flatwasherandlockwasher.SeeFigure30.

Figure27

.

Removethe four1/4-20self-tappinghexscrewsthatsecurethe

pulleyshieldtothe frameandremovethepulleyshieldandset

asideina safelocationuntil reinstallation.SeeFigure28.

/

Remove the

belt from the

idler pulley

by working it

under the belt

keepers.

Remove the

idler pulley

bracket by

removing the

hex head screw,

flat and lock

washers

Figure30

NOTE:Itwillbenecessaryto removethebeltfromaroundtheidler

pulleybyworkingitoffthe pulleyandfromunderneatheachbelt keeper.

Figure28

J

21

6. Removethehexboltssecuringthetransmissiondrivepulley,then

removethepulleyalongwiththetwobelts. SeeFigure31.

F V-side out

Remove he× bolt with belts

,

Figure31

7. Replacetheold beltswiththe newbeltsin the sameorderthey

wereremoved.Thelongerbelt (1916658)belongscloserto the

engine(V-sideout),withthe shorterbelt(1916657)positioned

closertothe tines.

8. Reinstallthetransmissiondrive pulleywiththenewbelts.

9. Reassemblethetillerinthereverseorderinwhichitwasdisas-

sembled.

NOTE:Whenreinstallingthebeltcover,besuretoengagethebail

andholditso thatthedrivebeltis tightbeforeattemptingto reinstall

thebeltcover.Thiswill enablethebeltto fall underthebeltkeeping

mechanismbuiltintothebelt cover.Failuretodo socoulddamagethe

beltand/or beltcover.

Remove pulley

TINES

Thetineswill wearwithuseand shouldbeinspectedatthe beginning

ofeachtillingseasonandafterevery30 operatinghours.Thetines

canbereplaced.Refertothe PartsListsectionofthismanualforpart

numbers.

Tine Inspection

Withuse,thetineswill becomeshorter,narrowerandpointed.Badly

worntineswill resultin a lossoftilling depth,and reducedeffective-

nesswhenchoppingupandturningunderorganicmatter.

Removing/Installing a Tine Assembly

1. Removethetineshieldendcoversandside shieldsbyremoving

thethreewingnutson eachsidethatsecurethem.

2. A fineassemblyconsistsofalefthandtineanda righthandfine.

NOTE:Thetineassemblymovesinacounter-rotatingmotionwith

thesharpedgesof thetinespositionedtoenterthe soilfirst when

counter-rotating.Notethispositionof thetinesfor reinstallationof the

newfineassemblies.

Toremoveafineassembly,simplyremovethecotterpinsecuring

theclevispin.SeeFigure32.

_' Clevis Pin

Cotter Pin

Figure32

4. Removethe clevispinandslidetheassemblyto theoutsideof

theunit andoffofthe fineshaft.

5. Beforereinstallingthe tineassembly,inspectthefineshaftfor

rust,roughspotsor burrs.Lightlyfileor sand,as needed.Applya

thincoatof greasetotheshaft.

6. Installeachfineassemblysothatthecutting(sharp)edgeof the

tineswillenterthesoilfirstwhenthetillermovesforward.Keep

inmindthatthesetinesare counter-rotating,sosecurethefine

assemblytothefineshaft usingtheclevispinandcotter pin.

22

Loading...

Loading...