Kmart 01639069-2 Owner’s Manual

Operator's Manual

I:Rl FI'SlVl N

208cc Engine

Front Tine Tiller

Model No. 247.29934

* SAFETY

* ASSEMBLY

* OPERATION

CAUTION: Before using

this product, read this

manual and follow all

* MAINTENANCE

* PARTS LIST

* ESPANOL

safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, iL 60179, U.S.A.

Visit our web site: www.craftsman.com

FORM1/0.769-05511A

12/02/2009

WarrantyStatement..................................Pac

SafeOperationPractices..........................Pac

SafetyLabels............................................Pac

Assembly..................................................Pac

Operation..................................................Pac

ServiceandMaintenance.........................Pac

Off-SeasonStorage..................................Pac

Whenoperatedand maintainedaccordingtoallsuppliedinstructions,ifthis Craftsmanproductfailsduetoa defectin materialorworkmanship

withintwoyearsfromthedate orpurchase,takeittoanySearsor otherauthorizedCraftsmanlocationin theUnitedStatesforfreerepair.Call

1-800-4-MY-HOME®for thenearestauthorizedlocation.

Thiswarrantyappliesfor only90 daysfromthedateof purchaseifthisproductis everusedforcommercialor rentalpurposes.

ThiswarrantycoversONLYdefectsinmaterialandworkmanship.SearswillNOTpayfor:

• Expendableitemsthatbecomewornduringnormaluse,includingbutnotlimitedto blades,tines,orbelts.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationor maintenance.

• Repairsnecessarybecauseofoperatorabuse,includingbutnotlimitedto damagecausedbyimpactingobjectsthat bendthe frameor

motorcrankshaft.

• Repairsnecessarybecauseofoperatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,orfailuretomaintaintheequipmentaccordingtothe instructionscontainedintheoperator'smanual.

• Repairsnecessaryduetoimproperfuelmixture,contaminatedor stalefuel.

• Normaldeteriorationandwearofthe exteriorfinishes,or productlabelreplacement.

e2

es3-6

e7

es8-10

es11-17

es18-22

TroubleShooting.......................................Page24

PartsList...................................................Page26-29

LabelMap.................................................Page34

RepairProtectionAgreement...................Page37

Espa_ol.....................................................Page38

ServiceNumbers......................................BackCover

e23

CRAFTSMAN FULLWARRANTY

Thiswarrantyappliesonlywhilethisproductiswithinthe UnitedStates.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstateto state.

Sears, Roebuckand Co.,Hoffman Estates,IL60179

EngineSeries: 208cc

EngineOilType: 10w30

EngineOilCapacity: 20ounces

Fuel: UnleadedGasoline

SparkPlug: TorchF6RTC

SparkPlugGap: .030"

Model Number.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

©SearsBrands,LLC 2

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthe personalsafetyand/orpropertyof

yourselfandothers. Readandfollowallinstructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothesafeopera-

tionpracticesinthismanual.Aswithanytypeof powerequipment,

carelessnessorerroronthepart of theoperatorcan resultin

seriousinjury.Thismachineis capableofamputatingfingers,hands,

toesandfeetandthrowingdebris.Failureto observethe following

safetyinstructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknownto Stateof California

tocausecancerandbirthdefectsorotherreproductiveharm.Bat-

tery posts,terminals,andrelatedaccessoriescontainleadand lead

compounds,chemicalsknowntotheStateof Californiatocause

cancerandreproductiveharm.Washhandsafterhandling.

TRAINING

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualinasafeplacefor futureand regularreference

andfororderingreplacementparts.

• ReadtheOperator'sManualand followallwarningsand safety

instructions.Failuretodosocan resultin seriousinjurytothe

operatorand/orbystanders.Forquestions,call 1-800-4MY-HOME.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsof agetooperatethis

machine.Children14andover shouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultstooperatethis machinewithoutproper

instruction.

• Keepbystanders,pets,andchildrenatleast75feetfromthe

machinewhileit isin operation.Stopmachineifanyoneenters

thearea.

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

Your Responsibility=Restrict theuseofthis powermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandonthemachine.

SAVETHESEINSTRUCTIONS!

PREPARATION

• Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall rocks,bottles,cans,or otherforeignobjectswhich

couldbepickedupor thrownandcausepersonalinjuryor

damageto themachine.

• Alwayswearsafetyglassesor safetygogglesduringoperation

andwhileperformingan adjustmentorrepair,to protectyour

eyes.Thrownobjectswhichricochetcancauseseriousinjuryto

theeyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesorjewelrycan becaughtin movable

parts.Neveroperatethismachineinbarefeetorsandals.

• Beforestarting,checkallboltsandscrewsforpropertightnessto

besurethe machineisinsafeworkingcondition.Also,visually

inspectmachineforany damageatfrequentintervals.

• Disengageclutchleversandshift(if provided)intoneutral("N")

beforestartingtheengine.

• Neverleavethismachineunattendedwiththeenginerunning.

• Neverattempttomakeanyadjustmentswhiletheengineis

running,exceptwherespecificallyrecommendedintheoperator's

manual.

• Maintainor replacesafetyandinstructionslabels,asnecessary.

3

SafeHandling of Gasoline:

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineis spilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Neverfill containersinsideavehicleor ona truckor trailerbed

witha plasticliner.Alwaysplacecontainersonthegroundaway

fromyourvehiclebeforefilling.

• Whenpractical,removegas-poweredequipmentfromthetruck

ortrailerand refuelitontheground.Ifthisis notpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

• Keepthe nozzleincontactwiththerimof the fueltankor

containeropeningatalltimes untilfuelingiscomplete.Donot use

a nozzlelock-opendevice.

• Extinguishallcigarettes,cigars,pipesandother sourcesof

ignition.

• Neverfuel machineindoors.

• Neverremovegascapor addfuelwhiletheengineishotor run-

ning.Allowenginetocool atleasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Fill tankto nomorethan1/2inchbelow

bottomoffillerneckto allowspaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipe itofftheengineandequipment.Move

unitto anotherarea.Wait5 minutesbeforestartingtheengine.

• To reducefirehazards,keepmachinefreeofgrass,leaves,or

otherdebrisbuild-up.Cleanupoil orfuelspillageandremoveany

fuelsoakeddebris.

• Neverstorethe machineorfuelcontainerinsidewherethereis an

openflame,sparkor pilotlightason awaterheater,spaceheater,

furnace,clothesdryer orothergasappliances.

OPERATION

• Do notputhandsorfeetnear rotatingparts.Contactwiththe

rotatingpartscanamputatehandsandfeet.

• Do notoperatemachinewhileundertheinfluenceof alcoholor

drugs.

• Neveroperatethismachinewithoutgoodvisibilityor light.Always

be sureofyourfootingandkeepa firmholdonthe handles.

• Keepbystandersawayfromthe machinewhileitisinoperation.

Stopthe machineif anyoneentersthearea.

• Becarefulwhentillinginhardground.Thetines maycatchinthe

groundandpropelthetillerforward.Ifthis occurs,letgoofthe

handlebarsanddo notrestrainthemachine.

• Exerciseextremecautionwhenoperatingonor crossinggravel

surfaces.Stayalertforhiddenhazardsortraffic. Donotcarry

passengers.

• Neveroperatethemachineat hightransportspeedson hardor

slipperysurfaces.

• Exercisecautiontoavoidslippingorfalling.

• Lookdownand behindandusecarewheninreverseor pulling

machinetowardsyou.

• Startthe engineaccordingtothe instructionsfoundinthis manual

and keepfeetwellawayfromthetinesatall times.

• Afterstrikingaforeignobjector ifyourmachineshouldstart mak-

inganunusualnoiseor vibration,immediatelyshuttheengineoff.

Disconnectthesparkplugwire,grounditagainsttheengineand

performthefollowingsteps:

a. Inspectfor damage.

b. Repairorreplaceanydamagedparts.

c. Checkforanyloosepartsandtightento assurecontinued

safeoperation.

• Disengageall clutchlevers(iffitted)and stopenginebeforeyou

leavethe operatingposition(behindthe handles).Waituntil

thetinescometo a completestopbeforeuncloggingthetines,

makinganyadjustments,or inspections.

• Neverrunanengineindoorsorinapoorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,an odorlessanddeadlygas.

• Mufflerandenginebecomehot andcancauseaburn.Do not

touch.

• Usecautionwhentillingnearfences,buildingsandunderground

utilities.Rotatingtinescancausepropertydamageor personal

injury.

• Donotoverloadmachinecapacityby attemptingtotillsoil too

deepattoo fastofa rate.

• Ifthemachineshouldstartmakinganunusualnoiseor vibration,

stoptheengine,disconnectthe sparkplugwire andgroundit

againsttheengine.Inspectthoroughlyfordamage.Repairany

damagebeforestartingandoperating.

• Keepallshields,guards,and safetydevicesinplaceandoperat-

ing properly.

• Neverpick uporcarrymachinewhiletheengineis running.

• Useonlyattachmentsandaccessoriesapprovedbythemanu-

factureras listedin the PartsListpagesofthisoperator'smanual.

Failuretodosocan resultin personalinjury.

• Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgement.ContactCustomerSupportat 1-800-4MY-

HOMEforassistanceandthenameof thenearestservicedealer

MAINTENANCE & STORAGE

• Keepthemachine,attachmentsandaccessoriesin safeworking

order.

• Allowthemachinetocoolat leastfiveminutesbeforestoring.

Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.

• Checkboltsandscrewsforpropertightnessatfrequentintervals

to keepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

• Beforecleaning,repairing,or inspecting,stopthe engineand

makecertainthetinesandall movingpartshavestopped.

Disconnectthe sparkplugwireandgrounditagainsttheengineto

preventunintendedstarting.

4

• Do notchangetheenginegovernorsettingsor over-speedthe

engine.Thegovernorcontrolsthemaximumsafeoperatingspeed

ofengine.

Maintainor replacesafetyandinstructionlabels,asnecessary.

Followthis manualfor safeloading,unloading,transporting,and

storageof thismachine.

Alwaysreferto theoperator'smanualforimportantdetailsifthe

machineisto bestoredforan extendedperiod.

If thefueltankhastobe drained,do thisoutdoors.

Observeproperdisposallawsandregulationsforgas,oil,etc.to

protecttheenvironment.

Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or130hoursof

operation.Attheendof theAverageUsefulLifehavethemachine

inspectedannuallybyanauthorizedservicedealertoensurethat

allmechanicalandsafetysystemsareworkingproperlyandnot

wornexcessively.Failuretodo socanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modifyengineinanyway.

Tamperingwiththegovernorsettingcanleadto a runawayengineand

causeitto operateatunsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(CO),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbe usedonornearanyunimprovedforest-covered,

brushcoveredor grass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestermeetingapplicablelocalor

statelaws(if any)

Ifa sparkarresterisused,itshouldbemaintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442oftheCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterforthemufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowall instructionson themachine

beforeattemptingtoassembleandoperate.

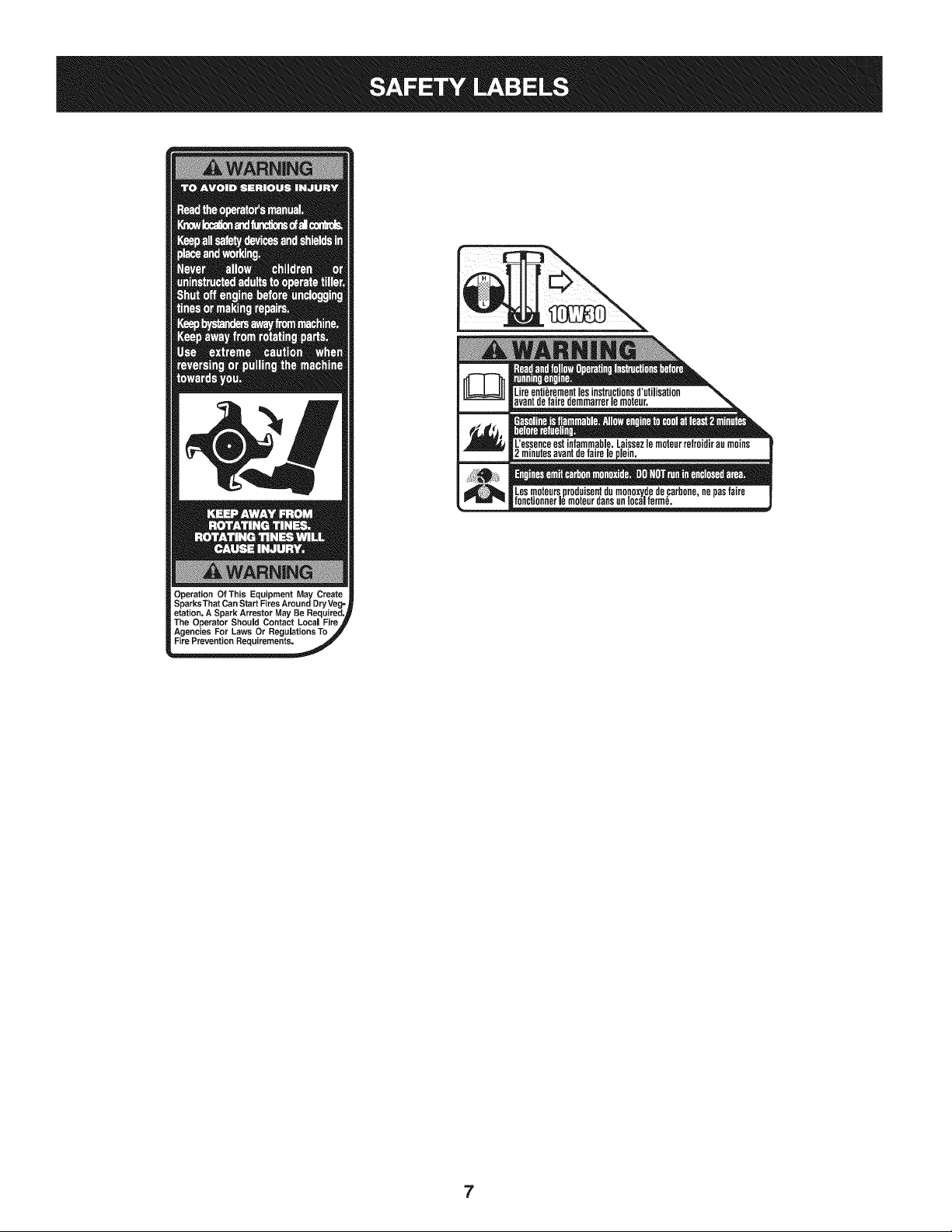

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING-- ROTATING TINES

Do not put hands or feet near rotating parts. Contact with the rotating parts can amputate

hands and feet.

WARNING--GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine

and muffler to cool before touching.

WARNING: YourResponsibility--Restrictthe useofthispowermachinetopersonswhoread,understandandfollowthe

warningsand instructionsinthis manualandonthemachine.

SAVETHESEINSTRUCTIONS!

6

u_ avantdetairedemmarrerlemoteur.

Lireenti_rementlesinstructionsd'utiiisation

Fire Prevention Requirements,

J_ L'essenceestintammabie.Laissezlemoteurretroidiraumoins

2minutesavantdefairelepiein=

Lesmeteursproduisen!domnpoxydedesarbone,nepasfaire

_onctionnerlemoteuroansuniocaJTerme.

7

IMPORTANT:Thisunit isshippedwithoutgasolineoroil inthe engine.

Becertaintoserviceenginewithgasolineandoilas instructedinthe

Operationsectionof this manualbeforeoperatingyourmachine.

NOTE:Referenceto rightandlefthandsideof the Tillerisobserved

fromtheoperatingposition.

OPENING CARTON

1. Cuteachcornerofthe cartonverticallyfromtop to bottom.

2. Removeall looseparts.

3. Removeloosepackingmaterial.

REMOVING UNIT FROM CARTON

1. Usethehandlebartoliftand pullthe tillerbackwardstoa flat

area.Checkthecartonthoroughlyforlooseparts.

2. Besurenotto kinktheforwardclutchcable.

LOOSE PARTS IN CARTON

• HandlebarAssembly

• Tiller

• EngineOil

• Operator'sManual

• DepthGageAssembly

f

J

Figure2

f

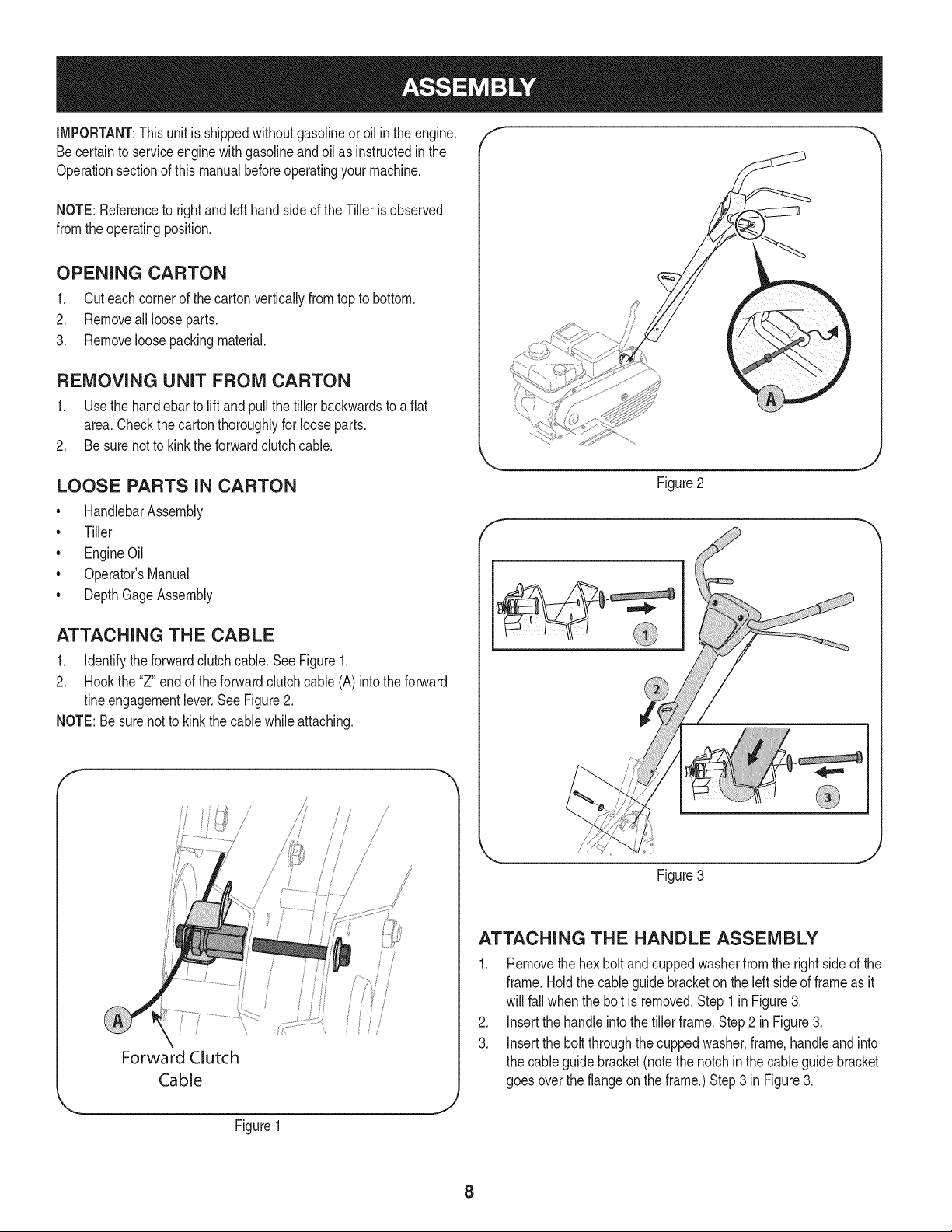

ATTACHING THE CABLE

1. Identifytheforwardclutchcable.SeeFigure1.

2. Hookthe"Z"endofthe forwardclutchcable(A) intotheforward

fineengagementlever.SeeFigure2.

NOTE:Besure nottokinkthecablewhileattaching.

/

/

/

Forward Clutch

Cable

J

Figure1

Figure3

ATTACHING THE HANDLE ASSEMBLY

1. Removethehexbolt andcuppedwasherfromthe rightsideof the

frame.Holdthecableguidebracketonthe left sideofframeas it

willfall whentheboltis removed.Step1in Figure3.

2. Insertthehandleintothe tillerframe.Step2in Figure3.

3. Inserttheboltthroughthecuppedwasher,frame,handleandinto

thecableguidebracket(notethenotchinthe cableguidebracket

goesovertheflangeon theframe.)Step3in Figure3.

8

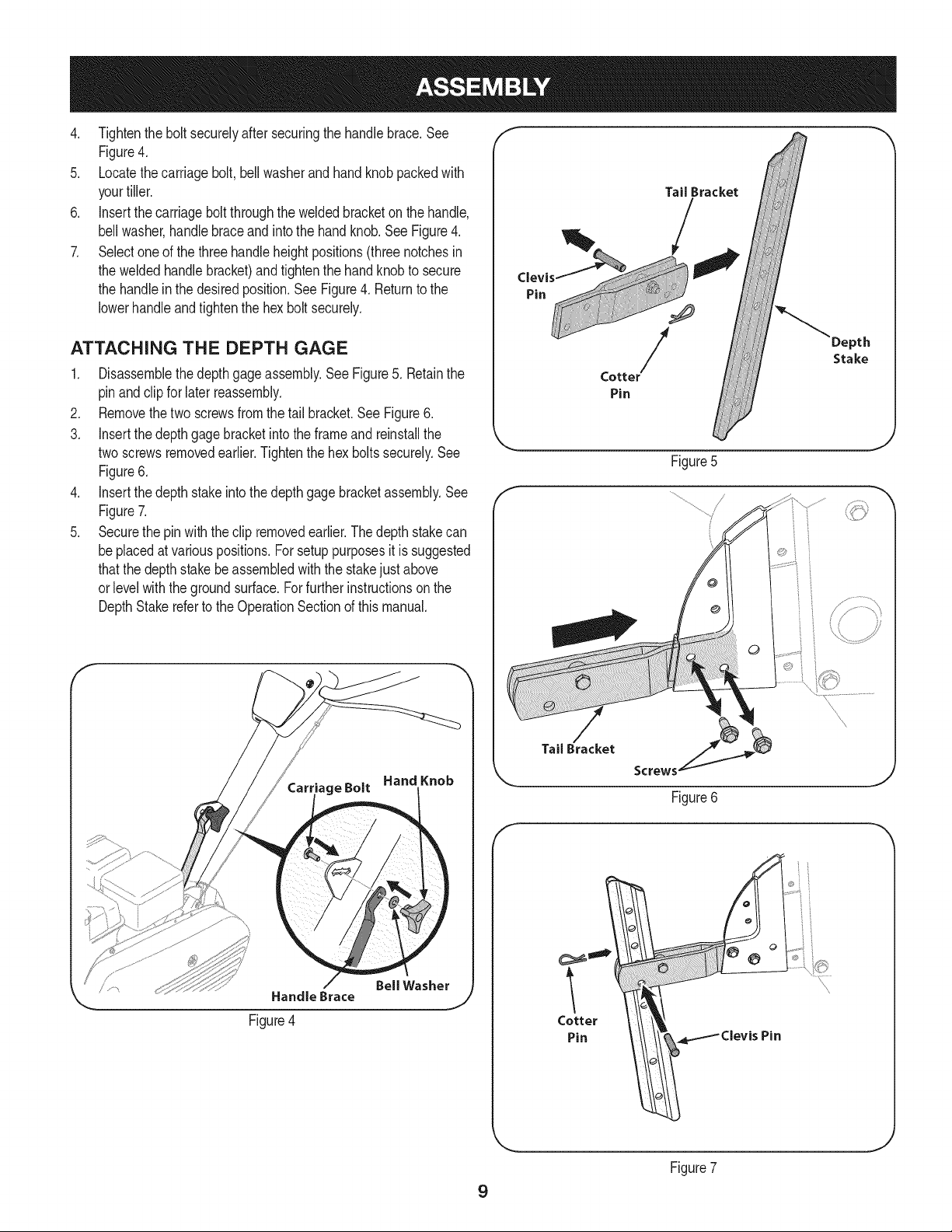

4. Tightentheboltsecurelyaftersecuringthe handlebrace.See

Figure4.

5. Locatethecarriagebolt,bellwasherandhandknobpackedwith

yourtiller.

6. Insertthe carriageboltthroughtheweldedbracketonthehandle,

bellwasher,handlebraceandintothe handknob.SeeFigure4.

7. Selectoneofthe threehandleheightpositions(threenotchesin

theweldedhandlebracket)andtightenthe handknobtosecure

thehandleinthe desiredposition.SeeFigure4. Returntothe

lowerhandleandtightenthe hexboltsecurely.

Tail Bracket

ATTACHING THE DEPTH GAGE

1. Disassemblethedepthgageassembly.See Figure5.Retainthe

pinandclipfor laterreassembly.

2. Removethetwo screwsfromthe tailbracket.See Figure6.

3. Insertthe depthgagebracketintotheframeand reinstallthe

twoscrewsremovedearlier.Tightenthehexboltssecurely.See

Figure6.

4. Insertthe depthstakeintothedepthgagebracketassembly.See

Figure7.

5. Securethepinwiththeclip removedearlier.Thedepthstakecan

beplacedat variouspositions.Forsetuppurposesitissuggested

thatthedepthstakebeassembledwiththe stakejust above

orlevelwiththe groundsurface.Forfurtherinstructionsonthe

DepthStakerefertotheOperationSectionofthis manual.

Hand Knob

Depth

Stake

Pin

Figure5

.................. /,

.....................

Tail Bracket

Figure6

f

(:otter

Pin

9

_Clevis Pin

J

Figure7

ADJUSTMENTS

Priortooperatingyour tiller,carefullyreadand followall instructions

below.Performall adjustmentsto verifyyourtillerisoperatingsafely

_andpropery.

Checktheadjustmentof the wheels:

Thetiller isshippedwiththewheelsadjustedsothatthe machinesits

level.Thewheelsneedto beadjustedto meetyourtillingneedsbefore

operation.Thisadjustmentismadeby removingtheclevispinfromthe

wheelyokeand raisingthewheelsto thedesiredheight.SeeFigure8.

Checktheadjustmentof the forwardclutchcableasfollows:

1. Disconnectandgroundthesparkplugwireagainsttheengine.

2. Adjustthecablebylooseningthe hexnut.SeeFigure9.

3. Turnthecablecollar sectiononeor twoturnsto increaseor

decreasetensionon thecable.SeeFigure10.

4. Retightenthelocknutagainstthe cablecollar.SeeFigure11.

5. Withtheforwardfine engagementhandlein the neutral(released)

position,pullthe starterropeseveraltimes.Thetinesshouldnot

turn.

6. Iftheyturnforwardor inreverse,adjusttheclutchcableto

decreaseor increasetensionusingthepreviousstepslisted.

7. Checkagainfor correcttensionon theclutchcable.

f

J

Figure9

f

WheelYoke

Pin

\

Figure10

f

Depth

Stake

J

Figure8

Nut

10

J

Figure11

f

Fuel Ca

Oil Fill Cap

& Dipstick

Tiller Tines

Muffler

Forward Tine

Engagement Lever

-- Handle Height

Adjustment

_th Stake

.J

Figure12

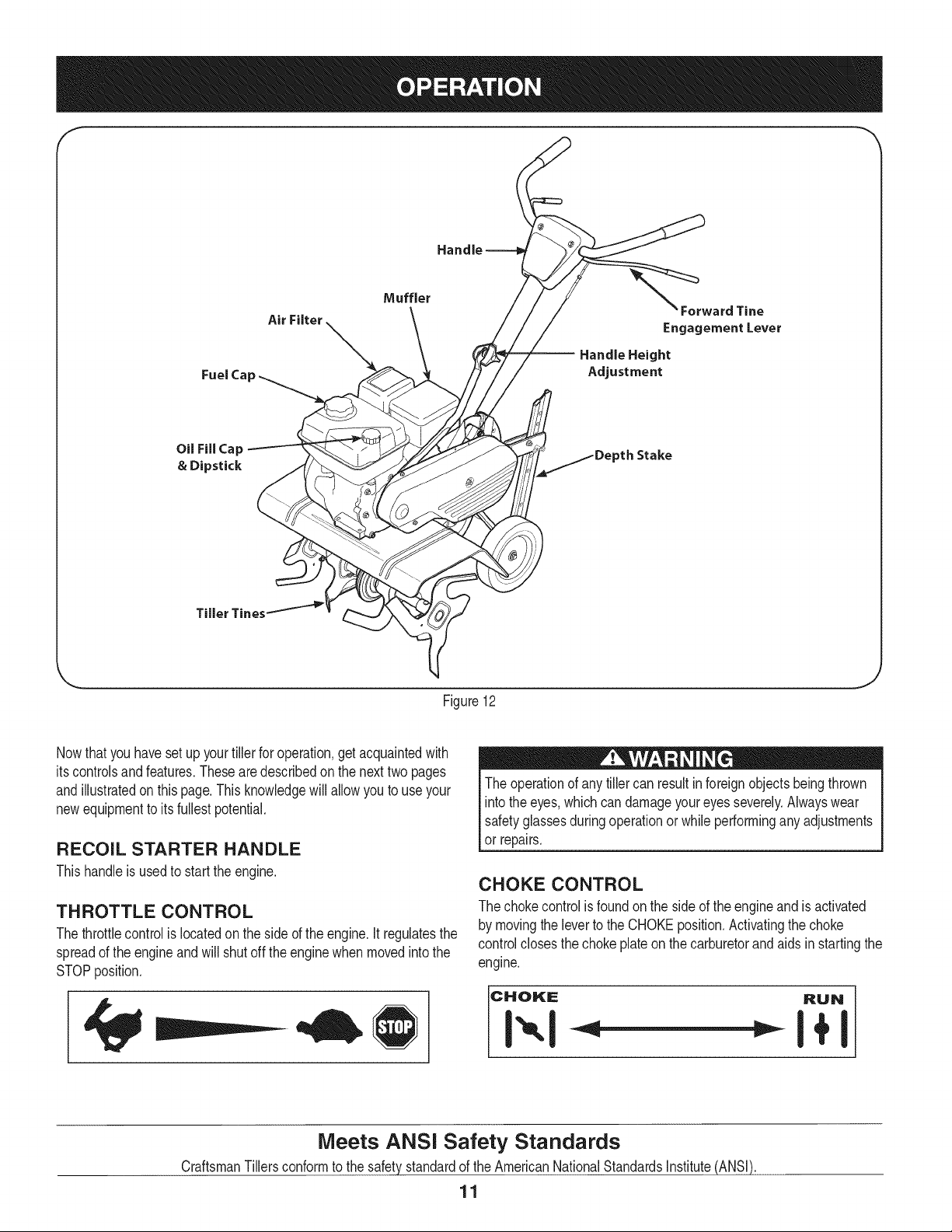

Nowthat youhavesetup yourtillerfor operation,getacquaintedwith

itscontrolsandfeatures.Thesearedescribedonthe nexttwopages

andillustratedon thispage.Thisknowledgewillallowyou to useyour

newequipmenttoits fullestpotential.

RECOIL STARTER HANDLE

Thishandleisusedto starttheengine.

THROTTLE CONTROL

Thethrottlecontrolis locatedon thesideof theengine.Itregulatesthe

spreadoftheengineandwill shutoff theenginewhenmovedintothe

STOPposition.

Meets ANSi Safety Standards

CraftsmanTillersconformtothe safetystandardoftheAmericanNationalStandardsInstitute(ANSI).

Theoperationofanytillercan resultinforeignobjectsbeingthrown

intothe eyes,whichcandamageyoureyesseverely.Alwayswear

safetyglassesduringoperationor whileperforminganyadjustments

or repairs.

CHOKE CONTROL

Thechokecontrolis foundonthesideofthe engineandisactivated

bymovingthe levertotheCHOKEposition.Activatingthechoke

controlclosesthe chokeplateonthecarburetorandaidsin startingthe

engine.

CHOKE RUN

11

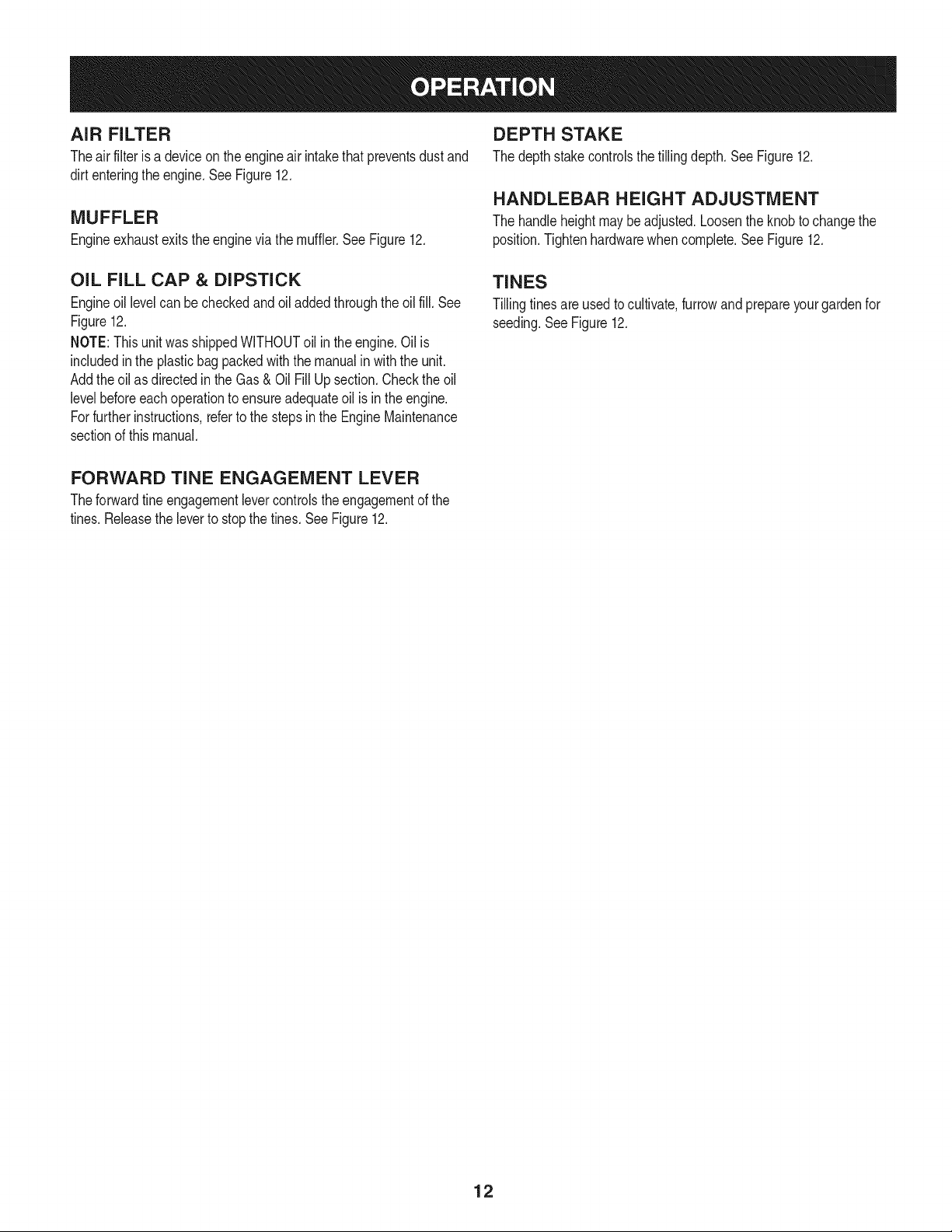

AiR FILTER

Theair filterisa deviceonthe engineair intakethatpreventsdustand

dirtenteringtheengine.SeeFigure12.

MUFFLER

Engineexhaustexitstheenginevia themuffler.SeeFigure12.

DEPTH STAKE

Thedepthstakecontrolsthetillingdepth.SeeFigure12.

HANDLEBAR HEIGHT ADJUSTMENT

Thehandleheightmaybeadjusted.Loosenthe knobtochangethe

position.Tightenhardwarewhencomplete.SeeFigure12.

OIL FILL CAP & DIPSTICK

Engineoil levelcanbecheckedandoiladdedthroughtheoil fill. See

Figure12.

NOTE:ThisunitwasshippedWITHOUToil inthe engine.Oilis

includedintheplasticbag packedwiththemanualinwiththe unit.

Addtheoil asdirectedin theGas& OilFillUpsection.Checktheoil

levelbeforeeachoperationtoensureadequateoil is intheengine.

Forfurtherinstructions,refertothestepsintheEngineMaintenance

sectionof thismanual.

FORWARD TINE ENGAGEMENT LEVER

Theforwardtine engagementlevercontrolstheengagementof the

tines.Releasetheleverto stopthetines.SeeFigure12.

TINES

Tillingtinesareusedtocultivate,furrowandprepareyourgardenfor

seeding.SeeFigure12.

12

GAS AND OIL FILL-UP

Oil (one bottle shipped with unit)

FirstTimeUse

1. Removeoilfilldipstick.

2. Withthetilleron levelground,usea funneltoemptyentire

contentsofoil bottleprovidedintothe engine.

3. Replaceoilfilldipstickandtighten.

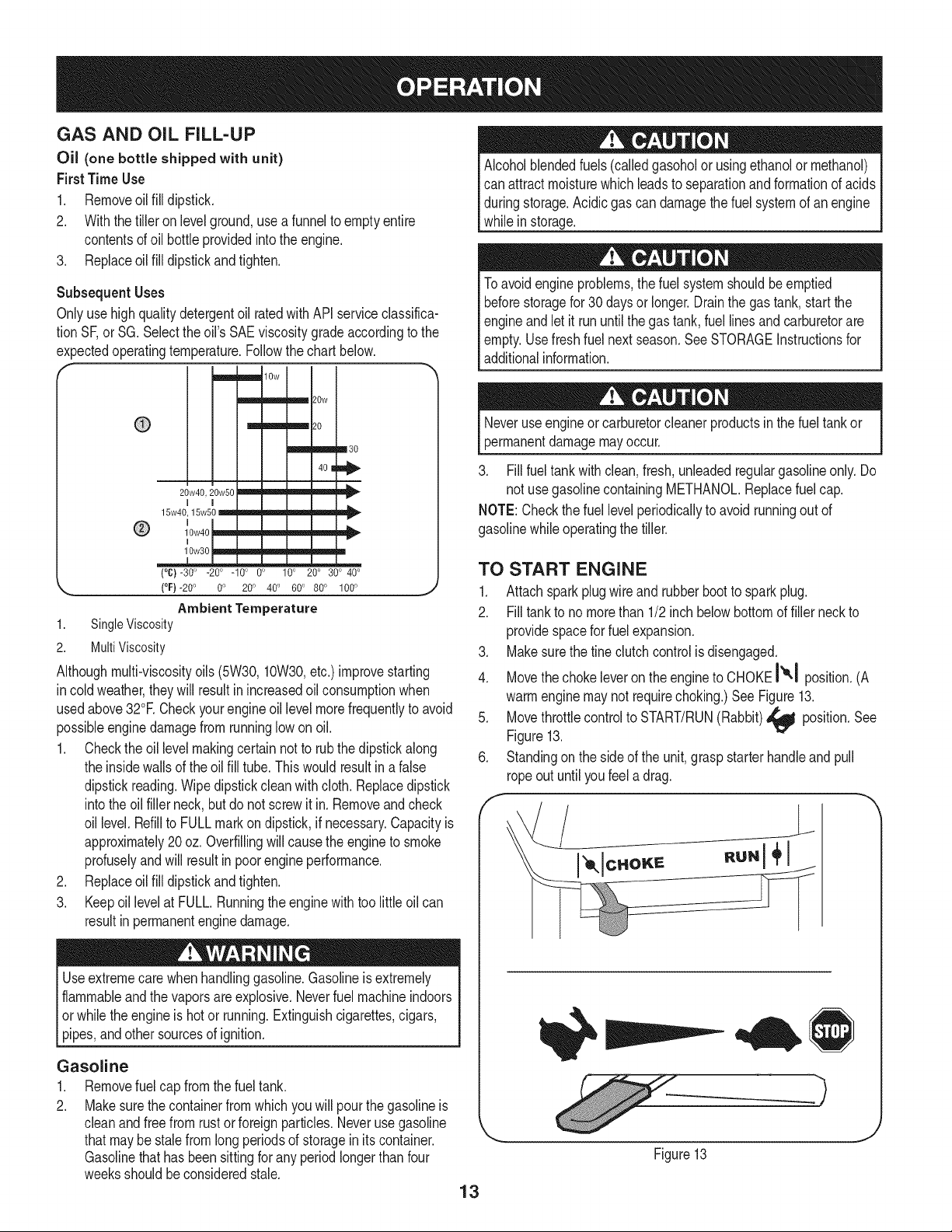

Subsequent Uses

Onlyusehighqualitydetergentoil ratedwithAPIserviceclassifica-

tionSF,or SG.Selecttheoil'sSAEviscositygradeaccordingto the

expectedoperatingtemperature.Followthechartbelow.

Imml mira 10w

_ _ )0W

mm m?0

mmm mmm B30

40 I_

20w40.20w50 _ _ _ _

I I

15w40, 15w50 ml .,i,_ m_,R, ram= .,,,,=._,,,,,,,,,l_

®

10w40

[ P"

10w30 iw,_mm_ _m

(°C)-300 -200 -100 0'_ 100 200 300400

(°F)-20 o 0o 200 400 60o 800 1000

Ambient Temperature

1. SingleViscosity

2. MultiViscosity

Althoughmulti-viscosityoils (5W30,10W30,etc.)improvestarting

in coldweather,theywillresultinincreasedoil consumptionwhen

usedabove32°F.Checkyourengineoil levelmorefrequentlytoavoid

possibleenginedamagefromrunninglowon oil.

1. Checktheoillevelmakingcertainnotto rubthedipstickalong

theinsidewallsofthe oil fill tube.Thiswould resultina false

dipstickreading.Wipedipstickcleanwithcloth. Replacedipstick

intotheoil fillerneck,butdonotscrewit in.Removeandcheck

oil level.Refillto FULLmarkon dipstick,ifnecessary.Capacityis

approximately20oz.Overfillingwillcausetheengineto smoke

profuselyandwill resultin poorengineperformance.

2. Replaceoilfilldipstickandtighten.

3. Keepoil levelatFULL.Runningtheenginewithtoolittleoilcan

resultinpermanentenginedamage.

v

m..-

Alcoholblendedfuels(calledgasoholorusingethanolormethanol)

canattractmoisturewhichleadsto separationandformationofacids

duringstorage.Acidicgascandamagethefuel systemofanengine

whileinstorage.

Toavoidengineproblems,thefuel systemshouldbeemptied

beforestoragefor30daysor longer.Drainthegastank,startthe

engineandletit rununtilthegastank,fuellinesand carburetorare

empty.Usefreshfuelnextseason.SeeSTORAGEInstructionsfor

additionalinformation.

Neveruseengineor carburetorcleanerproductsinthefueltankor

permanentdamagemayoccur.

3. Fillfuel tankwithclean,fresh,unleadedregulargasolineonly.Do

notusegasolinecontainingMETHANOL.Replacefuelcap.

NOTE:Checkthefuellevelperiodicallytoavoidrunningoutof

gasolinewhileoperatingthetiller.

TO START ENGINE

1. Attachsparkplugwireandrubberbootto sparkplug.

2. Filltankto no morethan 1/2inchbelowbottomoffiller neckto

providespacefor fuelexpansion.

3. Makesurethe tineclutchcontrolisdisengaged.

4. Movethechokeleveron theenginetoCHOKEI'_1 position.(A

warmenginemaynotrequirechoking.)SeeFigure13.

5. Movethrottlecontrolto START/RUN(Rabbit)_1_ position.See

Figure13.

6. Standingonthe sideofthe unit,graspstarterhandleandpull

ropeoutuntilyoufeela drag.

f

Useextremecarewhenhandlinggasoline.Gasolineis extremely

flammableandthevaporsareexplosive.Neverfuelmachineindoors

orwhilethe engineis hotor running.Extinguishcigarettes,cigars,

pipes,andothersourcesof ignition.

Gasoline

1. Removefuelcap fromthefueltank.

2. Makesurethecontainerfromwhichyouwill pourthe gasolineis

cleanandfreefrom rustorforeignparticles.Neveruse gasoline

thatmaybestalefromlongperiodsofstorageinitscontainer.

Gasolinethathas beensittingforanyperiodlongerthanfour

weeksshouldbeconsideredstale.

\

Figure13

13

7. Pulltheropewitha rapid,continuous,fullarm stroke.Keepafirm

griponthe starterhandle.Lettheroperewindslowly.

8. Repeat,if necessary,untilenginestarts.Whenenginestarts,

movechokecontrolgraduallytowardtheRUNI_'I position..

9. Ifenginefalters,movechokecontrolbacktowardtheCHOKE

I'_1 positionand repeatsteps5 though8.

10. ALWAYSkeepthethrottlecontrolintheSTART/RUN(Rabbit)

positionwhenoperatingthetiller.

TO STOP ENGINE

1. Tostopthewheelsandtines,releasethe ForwardClutchBail.

2. Movethrottlecontrolleverto slow(turtle)_ position.

Wheneverpossible,graduallyreduceenginespeedbefore

stoppingengine.

3. Movethrottlecontrolleverto STOP_ orOFFposition.

4. Disconnectsparkplugwireandgrounditagainsttheengineto

preventaccidentalstartingwhilethe equipmentisunattended.

TO ENGAGE DRIVE & TINES

1. Forforwardmotionof thewheelsand powertothetinespullthe

ForwardClutchBailupagainstthe handlebar.

2. Whentilling,relaxandletthewheelspullthemachinewhilethe

tinesdig.Walkslowlybehindthetiller allowingitto moveatits

ownpacewhilekeepinga securegriponthehandlebarwithyour

elbowsflexed.

3. Releasethe bailto stoptheforwardmotionofwheelsandtines.

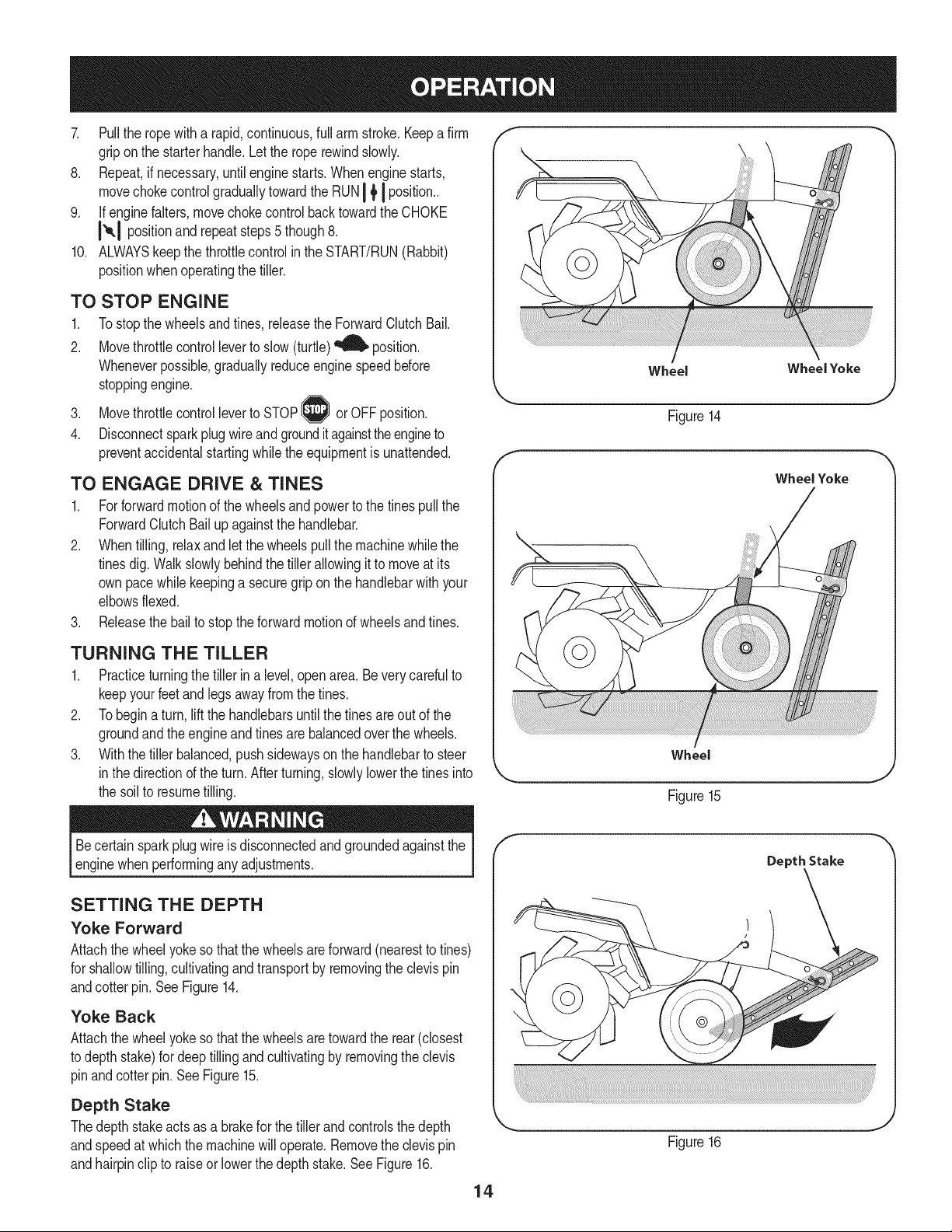

Wheel

Figure14

Wheel Yoke

J

Wheel Yoke

TURNING THE TILLER

1. Practiceturningthetillerinalevel,openarea.Beverycarefulto

keepyourfeetandlegsawayfromthetines.

2. Tobeginaturn, liftthehandlebarsuntil thetinesareoutofthe

groundandtheengineandtinesarebalancedoverthewheels.

3. Withthetillerbalanced,pushsidewayson the handlebartosteer

in thedirectionoftheturn.Afterturning,slowlylowerthetinesinto

thesoilto resumetilling.

Becertainsparkplugwireisdisconnectedandgroundedagainstthe

enginewhenperforminganyadjustments.

SETTING THE DEPTH

Yoke Forward

Attachthe wheelyokesothatthewheelsareforward(nearesttotines)

forshallowtilling,cultivatingandtransportbyremovingtheclevispin

andcotterpin. SeeFigure14.

Yoke Back

Attachthe wheelyokesothatthewheelsaretowardtherear(closest

todepthstake)for deeptillingandcultivatingbyremovingtheclevis

pinandcotterpin.SeeFigure15.

Wheel

.J

Figure15

f

Depth Stake

Depth Stake

Thedepth stakeactsasa brakeforthe tillerandcontrolsthedepth

andspeedat whichthemachinewilloperate.Removetheclevispin

andhairpinclipto raiseorlowerthedepthstake.SeeFigure16.

Figure16

14

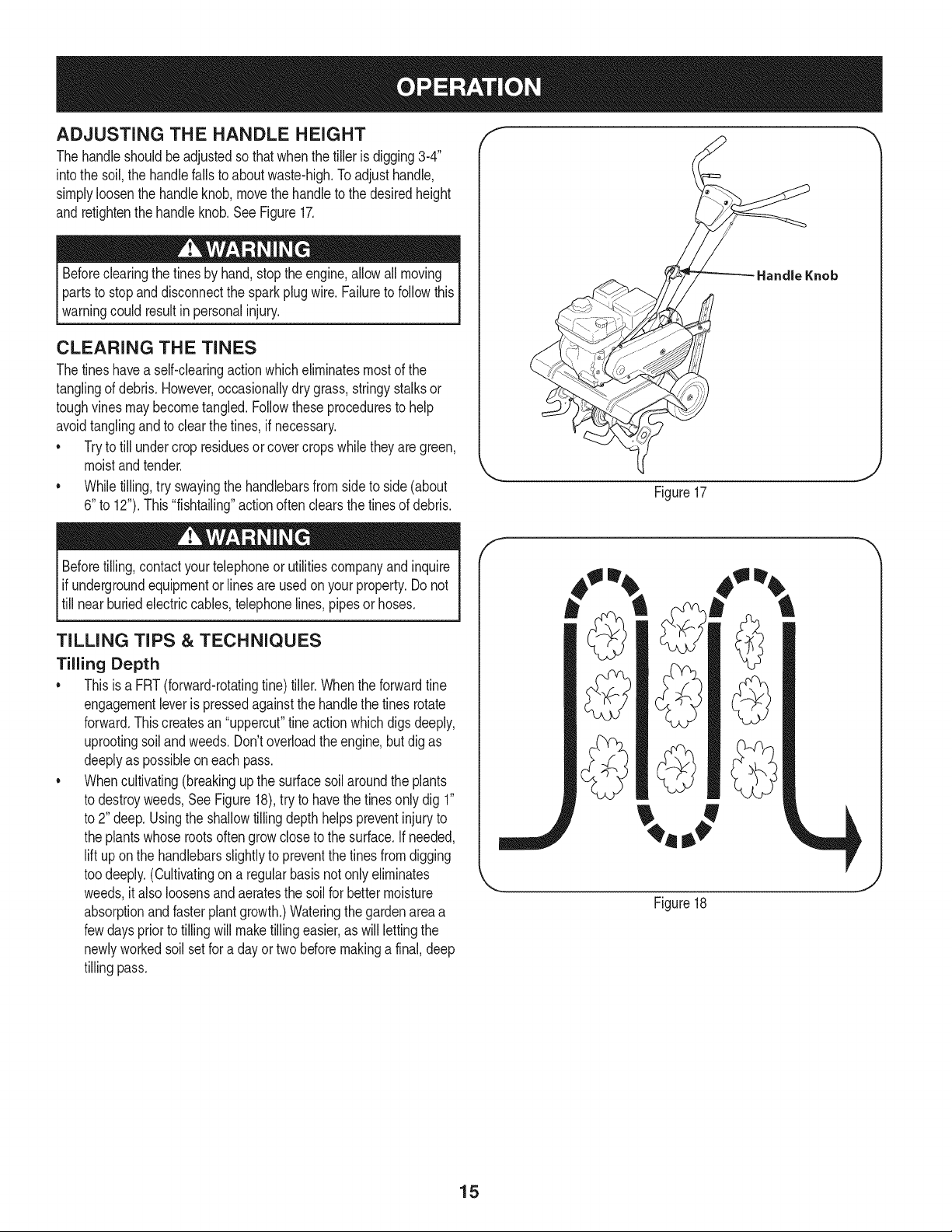

ADJUSTING THE HANDLE HEIGHT

Thehandleshouldbe adjustedsothatwhenthe tillerisdigging3-4"

intothe soil,thehandlefallstoaboutwaste-high.To adjusthandle,

simplyloosenthehandleknob,movethe handletothedesiredheight

andretightenthe handleknob.SeeFigure17.

Beforeclearingthe tinesby hand,stoptheengine,allowall moving

partsto stopanddisconnectthe sparkplugwire.Failureto followthis

warningcouldresultin personalinjury.

CLEARING THE TINES

Thetineshavea self-clearingactionwhicheliminatesmostofthe

tanglingofdebris.However,occasionallydry grass,stringystalksor

toughvinesmaybecometangled.Followtheseprocedurestohelp

avoidtanglingandtoclearthetines,if necessary.

• Tryto tillundercropresiduesorcovercropswhile theyare green,

moistandtender.

• Whiletilling,try swayingthehandlebarsfromsidetoside (about

6"to12").This"fishtailing"actionoftenclearsthetinesof debris.

Beforetilling,contactyourtelephoneor utilitiescompanyandinquire

l ifundergroundequipmentorlinesareusedonyour property.Donot

|till nearburiedelectriccables,telephonelines,pipesor hoses.

[

TILLING TIPS & TECHNIQUES

Tilling Depth

• Thisisa FRT(forward-rotatingfine)tiller.Whentheforwardtine

engagementleverispressedagainstthehandlethetinesrotate

forward.Thiscreatesan"uppercut"tineactionwhichdigsdeeply,

uprootingsoilandweeds.Don'toverloadtheengine,butdigas

deeplyas possibleon eachpass.

• Whencultivating(breakingupthe surfacesoilaroundtheplants

todestroyweeds,SeeFigure18),tryto havethetinesonlydig 1"

to2" deep.Usingtheshallowtillingdepthhelpspreventinjuryto

theplantswhoserootsoftengrow closetothesurface.If needed,

lift uponthe handlebarsslightlytopreventthetinesfromdigging

toodeeply.(Cultivatingona regularbasisnotonlyeliminates

weeds,it alsoloosensandaeratesthe soilfor bettermoisture

absorptionandfasterplantgrowth.)Wateringthegardenareaa

fewdayspriortotillingwillmaketillingeasier,aswill lettingthe

newlyworkedsoilsetfora dayortwo beforemakinga final,deep

tillingpass.

Figure17

f

J

Figure18

15

Choosing the Correct Tine Speed

Withexperience,you willfindthe tillingdepthandtilling speed

combinationthatisbestfor yourgarden.Settheenginethrottleleverat

a speedtogivetheengineadequatepowerandyetallowittooperate

atthe slowestpossiblespeeduntilyouhaveachievedthemaximum

tillingdepthyoudesire.Fasterenginespeedsmaybedesirable

whenmakingfinalpassesthroughtheseedbedorwhencultivating.

Selectionofthe correctenginespeed,inrelationtothe tillingdepth,

willensurea sufficientpowerleveltodothejobwithoutcausingthe

enginetolabor.

Suggested Tilling Patterns

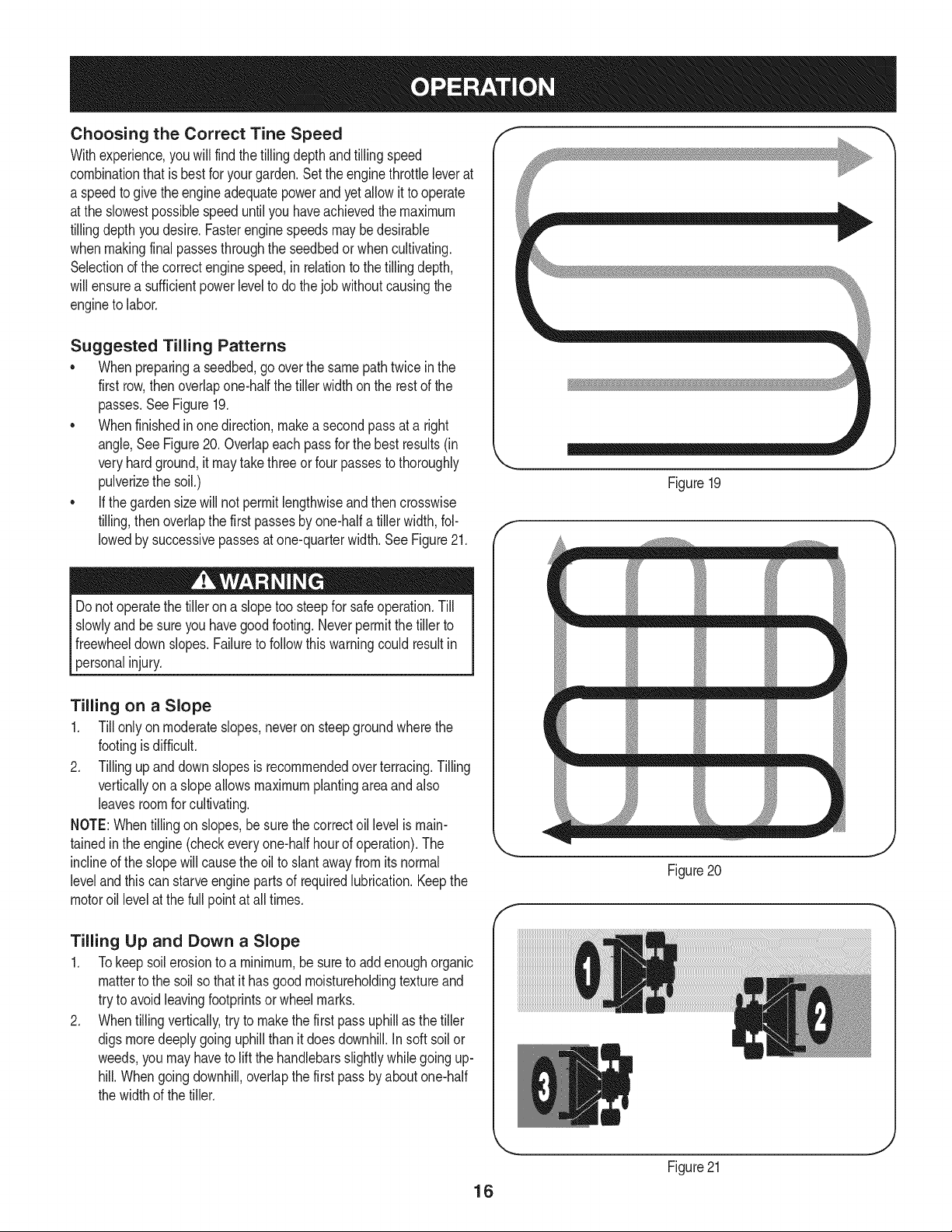

• Whenpreparinga seedbed,go overthesamepathtwiceinthe

firstrow,thenoverlapone-halfthetillerwidthontherestof the

passes.SeeFigure19.

• Whenfinishedinonedirection,makeasecondpassat a right

angle,SeeFigure20.Overlapeachpassfor thebestresults(in

veryhardground,itmaytakethreeorfour passestothoroughly

pulverizethesoil.)

• If thegardensizewillnotpermitlengthwiseandthencrosswise

tilling,thenoverlapthefirstpassesby one-halfatillerwidth,fol-

lowedby successivepassesatone-quarterwidth.SeeFigure21.

Figure19

Donot operatethetillerona slopetoosteepforsafeoperation.Till

slowlyandbe sureyouhavegoodfooting.Neverpermitthetillerto

freewheeldownslopes.Failuretofollowthiswarningcouldresultin

personalinjury.

Tilling on a Slope

1. Till onlyonmoderateslopes,neveronsteepgroundwherethe

footingisdifficult.

2. Tillingupanddownslopesisrecommendedoverterracing.Tilling

verticallyon a slopeallowsmaximumplantingareaandalso

leavesroomforcultivating.

NOTE:Whentillingonslopes,besurethe correctoillevelismain-

tainedinthe engine(checkeveryone-halfhourofoperation).The

inclineof theslopewillcausetheoilto slantawayfromitsnormal

levelandthiscan starveenginepartsofrequiredlubrication.Keepthe

motoroil levelatthefullpointatall times.

Tilling Up and Down a Slope

1. Tokeepsoil erosiontoa minimum,besuretoaddenoughorganic

mattertothe soilsothatit hasgoodmoistureholdingtextureand

tryto avoidleavingfootprintsor wheelmarks.

2. Whentillingvertically,try tomakethefirst passuphillasthetiller

digsmoredeeplygoinguphillthan itdoesdownhill.In softsoilor

weeds,youmayhavetolift thehandlebarsslightlywhilegoingup-

hill.Whengoingdownhill,overlapthefirst passbyaboutone-half

thewidthof thetiller.

[

m_m_

t j

Figure20

16

Figure21

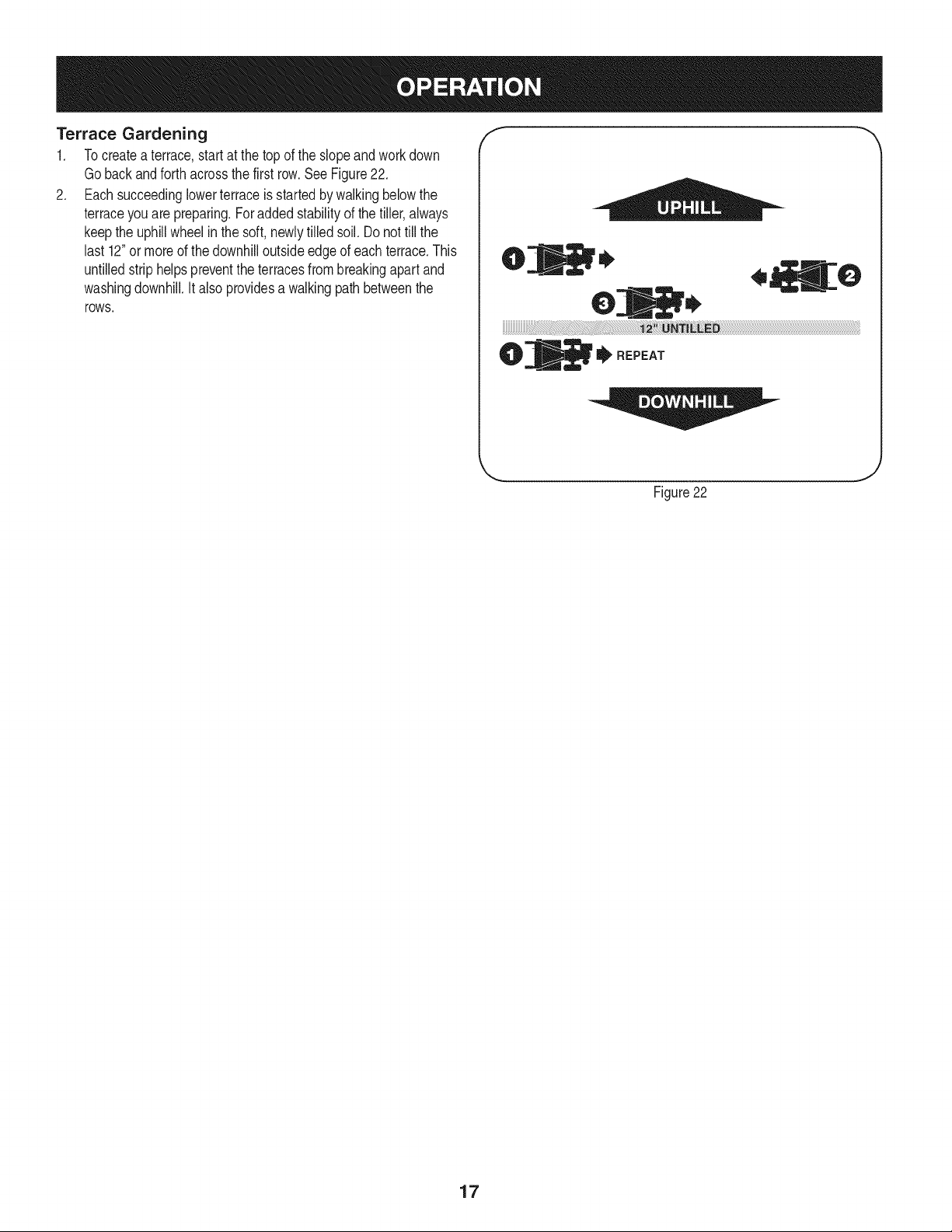

Terrace Gardening

1. Tocreateaterrace,startat thetopoftheslopeandworkdown

Gobackandforthacrossthefirstrow.SeeFigure22.

2. Eachsucceedinglowerterraceisstartedby walkingbelowthe

terraceyouare preparing.Foraddedstabilityofthe tiller,always

keepthe uphillwheelinthesoft,newlytilledsoil. Donottillthe

last 12"or moreofthedownhilloutsideedgeofeachterrace.This

untilledstriphelpspreventtheterracesfrombreakingapartand

washingdownhill.Italsoprovidesawalkingpathbetweenthe

rows,

f

,O

' REPEA'

J

Figure22

17

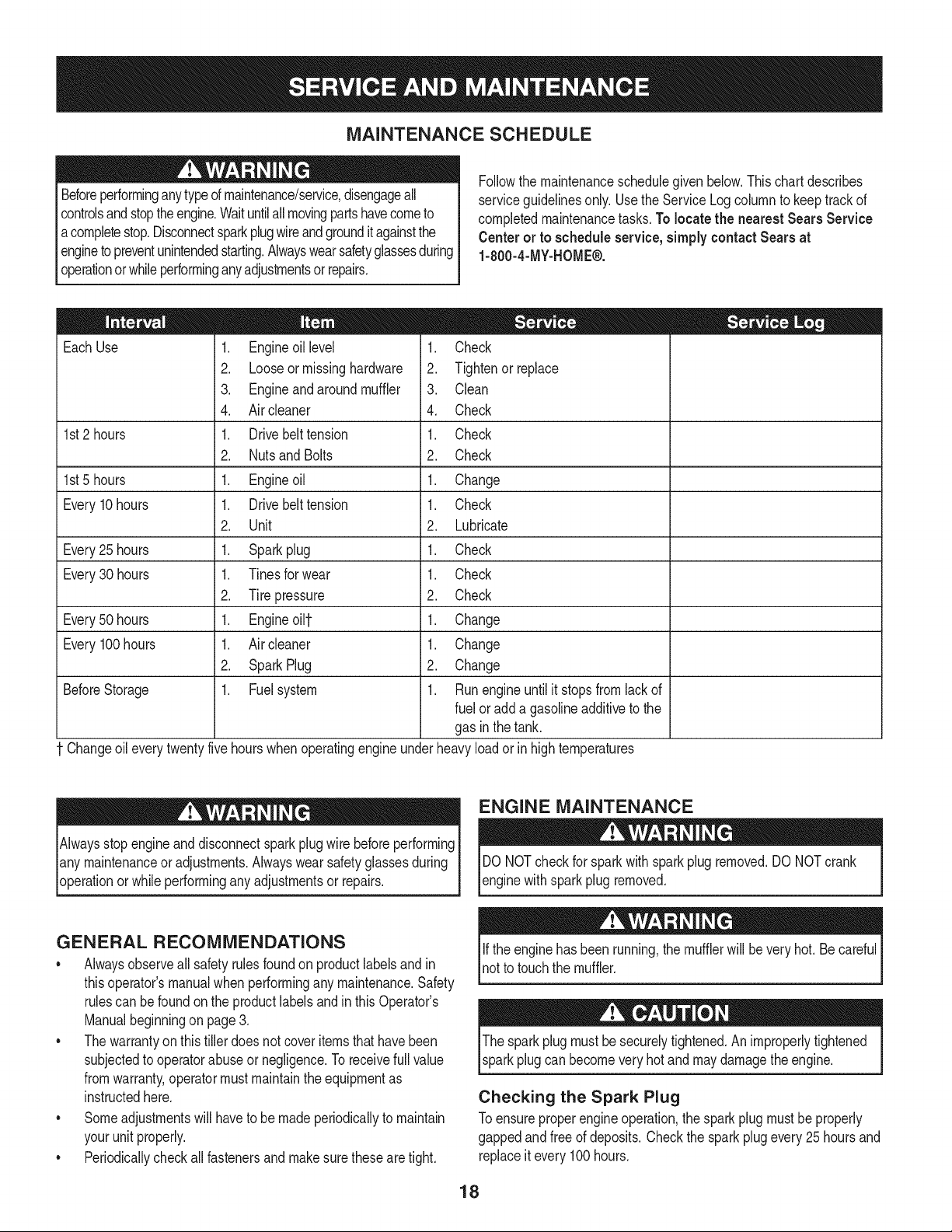

MAINTENANCE SCHEDULE

Beforeperforminganytypeof maintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.To locate the nearest Sears Service

Centeror toscheduleservice,simplycontactSears at

1-800-4-MY-HOME®.

operationor whileperforminganyadjustmentsor repairs.

Followthemaintenanceschedulegivenbelow.Thischartdescribes

= =

EachUse

1st2 hours

1st5 hours

Every10hours

Every25 hours

Every30 hours

Every50 hours

Every100hours

BeforeStorage

.

Engineoillevel

2.

Looseormissinghardware

3.

Engineandaroundmuffler

4.

Aircleaner

1.

Drivebelttension

2.

Nutsand Bolts

1.

Engineoil

1.

Drivebelttension

2.

Unit

1.

Sparkplug

1.

Tinesforwear

2.

Tirepressure

1.

Engineoill-

1.

Aircleaner

2.

SparkPlug

1.

Fuelsystem

1. Check

2. Tightenor_place

3. Clean

4. Check

1. Check

2. Check

1. Change

1. Check

2. Lubricate

1. Check

1. Check

2. Check

1. Change

1. Change

2. Change

1. Runengineuntilit stopsfromlackof

fueloradda gasolineadditivetothe

gasin thetank.

Changeoileverytwentyfivehourswhenoperatingengineunderheavyloadorinhightemperatures

Alwaysstopengineanddisconnectsparkplugwirebeforeperforming

lanymaintenanceor adjustments.Alwayswearsafetyglassesduring

[operationorwhile performinganyadjustmentsor repairs.

GENERAL RECOMMENDATIONS

• Alwaysobserveallsafetyrulesfoundonproductlabelsandin

thisoperator'smanualwhenperforminganymaintenance.Safety

rulescan befoundonthe productlabelsandin thisOperator's

Manualbeginningon page3.

• Thewarrantyonthistillerdoesnotcoveritemsthathavebeen

subjectedto operatorabuseor negligence.Toreceivefull value

fromwarranty,operatormustmaintainthe equipmentas

instructedhere.

• Someadjustmentswillhavetobe madeperiodicallyto maintain

yourunit properly.

• Periodicallycheckallfastenersand makesurethesearetight.

ENGINE MAINTENANCE

DONOTcheckforsparkwithsparkplugremoved.DO NOTcrank

enginewithsparkplug removed.

Iftheenginehas beenrunning,themufflerwillbeveryhot. Becareful

notto touchthemuffler.

Thesparkplugmustbesecurelytightened.Animproperlytightened

sparkplugcanbecomeveryhot andmaydamagetheengine.

Checking the Spark Plug

Toensureproperengineoperation,the sparkplugmustbeproperly

gappedandfreeof deposits.Checkthesparkplugevery25hoursand

replaceitevery100hours.

18

1. Removethesparkplugbootandusea sparkplugwrenchto

removetheplug.See Figure23.

2. Visuallyinspectthesparkplug.Discardthesparkplugif thereis

apparentwear,orif the insulatoriscrackedor chipped.Cleanthe

sparkplugwitha wirebrushifitis to be reused.

3. Measurethepluggapwitha feelergauge.Correctas necessary

bybendingsideelectrode.SeeFigure24.The gapshouldbeset

to0.030in.

4. Checkthatthe sparkplugwasherisingoodconditionandthread

thesparkplugin byhandtopreventcrossthreading.

5. Afterthesparkplugis seated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2turnafterthe

sparkplugseatsto compressthewasher.Whenreinstallinga used

sparkplug,tighten1/8-1/4turnafterthe sparkplugseatsto compress

thewasher.

Neverusegasolineorlowflashpointsolventsfor cleaningtheair

ceanereement. A f re orexpos oncoud resut.

Servicing the Air Cleaner

Theair cleanerpreventsdamagingdirt, dust,etc.,fromenteringthe

carburetorand beingforcedintotheengineandis importantto engine

lifeandperformance.Neverruntheenginewithoutan aircleaner

completelyassembled.Checktheaircleanerbeforeeachuse.

Paperfilterscannotbecleanedandmustbe replacedonce a year

orevery 100operatinghours;moreoftenifusedin extremelydusty

conditions.

1. Pressthe tabontheairfiltercover,lift the coverandremovethe

airfilter.SeeFigure25.

2. Discardoldairfilter.

3. Installnewairfilter.

4. Closethecover.

NOTE:Ifthe filteristornordamagedin anyway,replaceit.

Donot sprayenginewithwatertocleanbecausewatercould

contaminatefuel. Usingagardenhoseorpressurewashingequip-

mentcanalso forcewaterintothemuffleropening.Waterthat passes

throughthemufflercanenterthe cylinder,causingdamage.

,Electrode

0.02-0.03 in.

===_1_====0.60-0.80 rnrn

Air Filter

Cover

Filter

Figure23

J

Figure24

Accumulationofdebrisaroundmufflercouldcausea fire.Inspectand

cleanbeforeeveryuse.

Cleaning the Engine

If theenginehasbeenrunning,allowitto coolforatleasthalfan hour

beforecleaning.Periodicallyremovedirtbuild-upfromtheengine.

Cleanaroundthe muffler.Cleanwithabrushorcompressedair.

J

Figure25

19

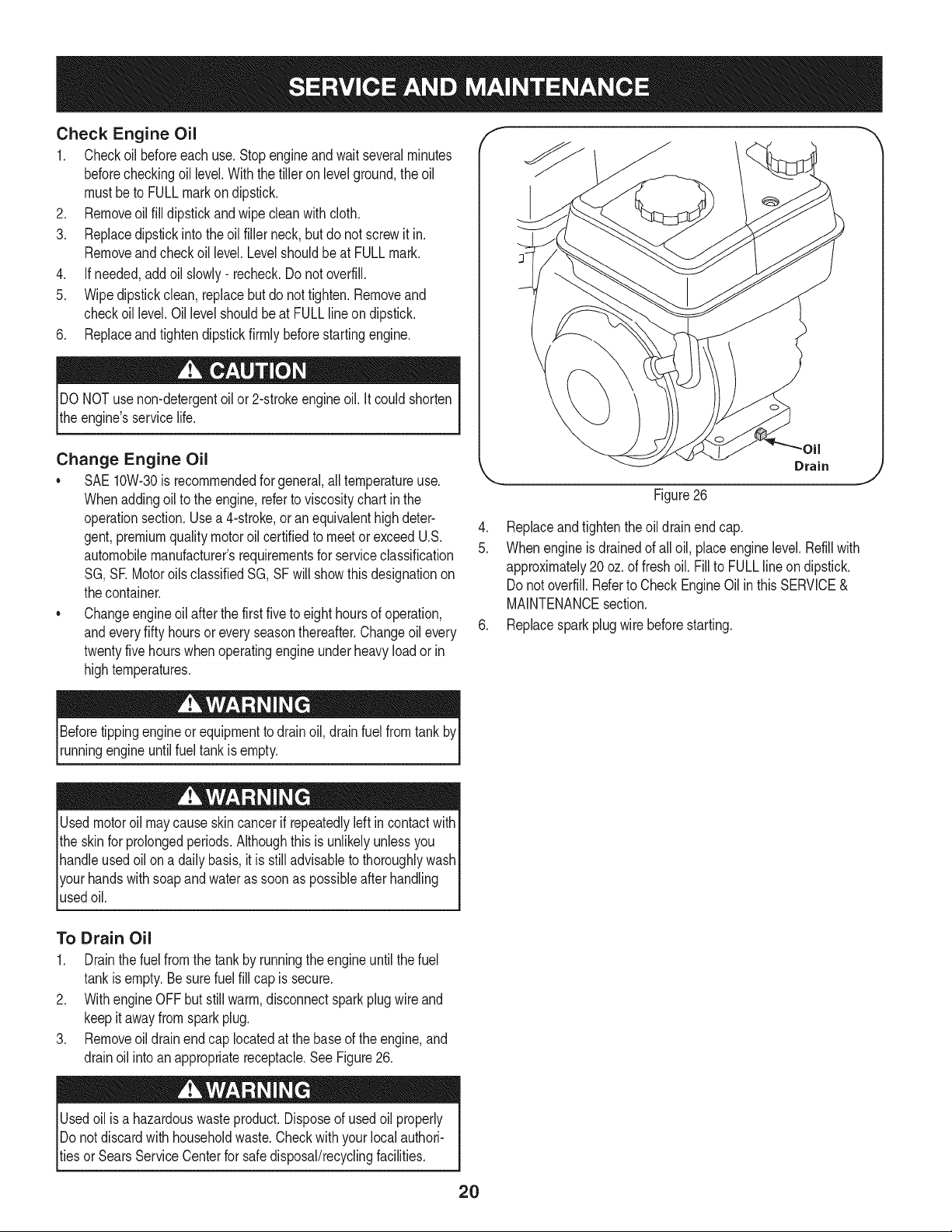

Check Engine Oil

1. Checkoilbeforeeachuse.Stopengineandwaitseveralminutes

beforecheckingoil level.Withthetilleronlevelground,theoil

mustbeto FULLmarkon dipstick.

2. Removeoil filldipstickandwipecleanwithcloth.

3. Replacedipstickintothe oilfiller neck,butdonotscrewitin.

Removeandcheckoil level.Levelshouldbeat FULLmark.

4. If needed,addoil slowly- recheck.Donot overfill.

5. Wipedipstickclean,replacebutdonot tighten.Removeand

checkoil level.Oillevelshouldbeat FULLlineondipstick.

6. Replaceandtightendipstickfirmlybeforestartingengine.

DONOTuse non-detergentoilor 2-strokeengineoil.Itcouldshorten

theengine'sservicelife.

Change Engine Oil

• SAE10W-30is recommendedforgeneral,all temperatureuse.

Whenaddingoilto theengine,referto viscositychart inthe

operationsection.Usea4-stroke,oranequivalenthighdeter-

gent,premiumqualitymotoroil certifiedtomeetor exceedU.S.

automobilemanufacturer'srequirementsfor serviceclassification

SG,SR MotoroilsclassifiedSG,SFwillshowthisdesignationon

thecontainer.

• Changeengineoil afterthefirstfivetoeighthoursofoperation,

andeveryfifty hoursoreveryseasonthereafter.Changeoilevery

twentyfivehourswhenoperatingengineunderheavyloadorin

hightemperatures.

Beforetippingengineor equipmenttodrainoil,drainfuel fromtank by

runningengineuntilfuel tankisempty.

Usedmotoroil maycauseskincancerifrepeatedlyleftincontactwith

theskinfor prolongedperiods.Althoughthis isunlikelyunlessyou

handleusedoil onadailybasis,itis stilladvisabletothoroughlywash

yourhandswithsoapandwateras soonas possibleafterhandling

usedoil.

oil

Drain

Figure 26

4. Replaceandtightenthe oildrainendcap.

5. Whenengineisdrainedofall oil,placeenginelevel.Refillwith

approximately20oz.offreshoil.Fillto FULLlineondipstick.

Donot overfill.Referto CheckEngineOil inthisSERVICE&

MAINTENANCEsection.

6. Replacesparkplugwire beforestarting.

To Drain Oil

1. Drainthefuelfromthe tankby runningtheengineuntilthefuel

tankisempty.Besurefuelfill capissecure.

2. WithengineOFFbutstillwarm,disconnectsparkplugwireand

keepitawayfromsparkplug.

3. Removeoil drainendcap locatedatthebaseoftheengine,and

drainoil intoanappropriatereceptacle.SeeFigure26.

Usedoilisa hazardouswasteproduct.Disposeofusedoilproperly

IDonotdiscardwithhouseholdwaste.Checkwithyourlocalauthori-

_tiesor SearsServiceCenterforsafedisposal/recyclingfacilities.

2O

Loading...

Loading...