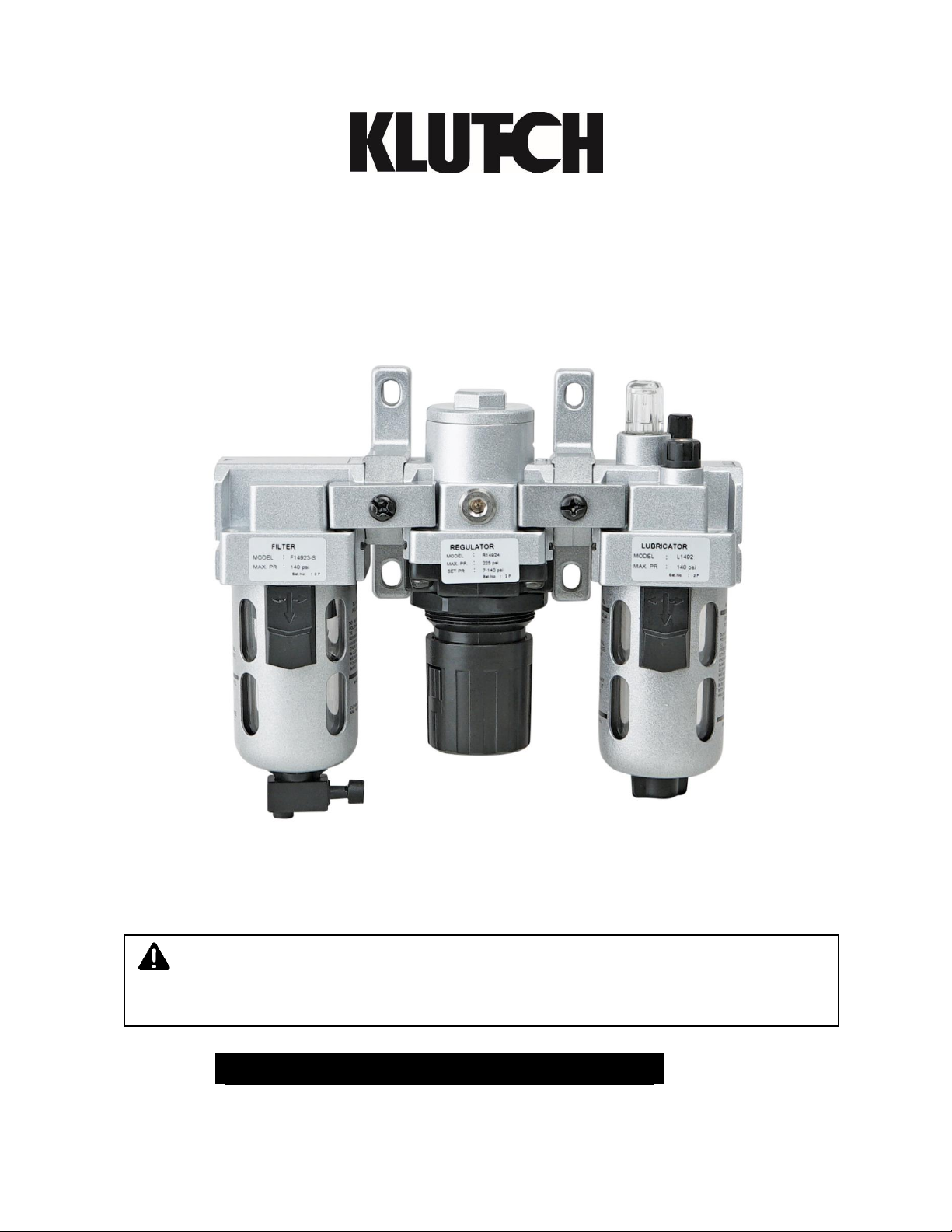

Klutch 48577, 48576, 48575 Owner's Manual

Filter Regulator and Lubricator

Owner’s Manual

Items #48577, #48576, #48575

,

WARNING: Read carefully and understand all ASSEMBLY AND OPERATION

INSTRUCTIONS before operating. Failure to follow the safety rules and other basic safety

precautions may result in serious personal injury.

2

Thank you very much for choosing a Klutch® product!

For future reference, please complete the owner’s record below:

Serial Number/Lot Date Code: ________________________________

Purchase Date: ____________________________________________

Save the receipt, warranty, and this manual. It is important that you read

the entire manual to become familiar with this product before you begin

using it.

This filter regulator and lubricator is designed for certain applications

only. Northern Tool & Equipment is not responsible for issues arising

from modification or improper use of this product such as an application

for which it was not designed. We strongly recommend that this product

not be modified and/or used for any application other than that for which

it was designed.

For technical questions, please call 1-800-222-5381.

3

Table of Contents

Intended Use .......................................................................................................................................... 4

Technical Specifications ...................................................................................................................... 5

Important Safety Information ............................................................................................................... 6

Safety Labels ......................................................................................................................................... 7

Main Parts of Product ........................................................................................................................... 8

Assembly Instructions ........................................................................................................................ 13

Before Each Use .................................................................................................................................. 14

Operating Instructions ........................................................................................................................ 14

Troubleshooting .................................................................................................................................. 15

Maintenance Instructions ................................................................................................................... 17

Limited Warranty ................................................................................................................................. 19

4

Intended Use

•

The Klutch Filter Regulator and Lubricator is one of the most popular air preparation units. The

regulator and lubricator are assembled together to form a single unit.

•

The air filter is used to separate dust, dirt, moisture, and other contaminants from compressed air.

•

The filter has a die-cast aluminum body, polycarbonate bowl with a steel bowl guard, and a high

performance sintered bronze filtering element.

•

Filter is designed with a Separator and Shield for efficient moisture separation. It is combined with

a Regulator which maintains a steady outlet pressure, unaffected by variations/fluctuations in the

inlet pressure.

•

The Filter Regulator and Lubricator has a non-raising, press-to-lock adjusting knob for locking at

any set pressure. The Filter Regulator and Lubricator works on a diaphragm-operated, relieving

mechanism with pressure compensated by a balanced poppet.

•

Air lubricators are used to feed lubricants to pneumatic equipment. These maintain a constant oil-

to-air density over a wide range of flow.

•

The lubricator has fog/micro misting abilities, up to 50-foot pipe runs.

•

The head is fitted with an oil drop indicator, an oil drop controller, and an oil filling plug.

•

A 1/8” mechanical air pressure gauge is included.

WHY USE A FILTER?

•

The air being supplied to the equipment may contain moisture, dust, dirt, or other foreign particles

which can damage the equipment. To prevent damage, install a filter before the equipment.

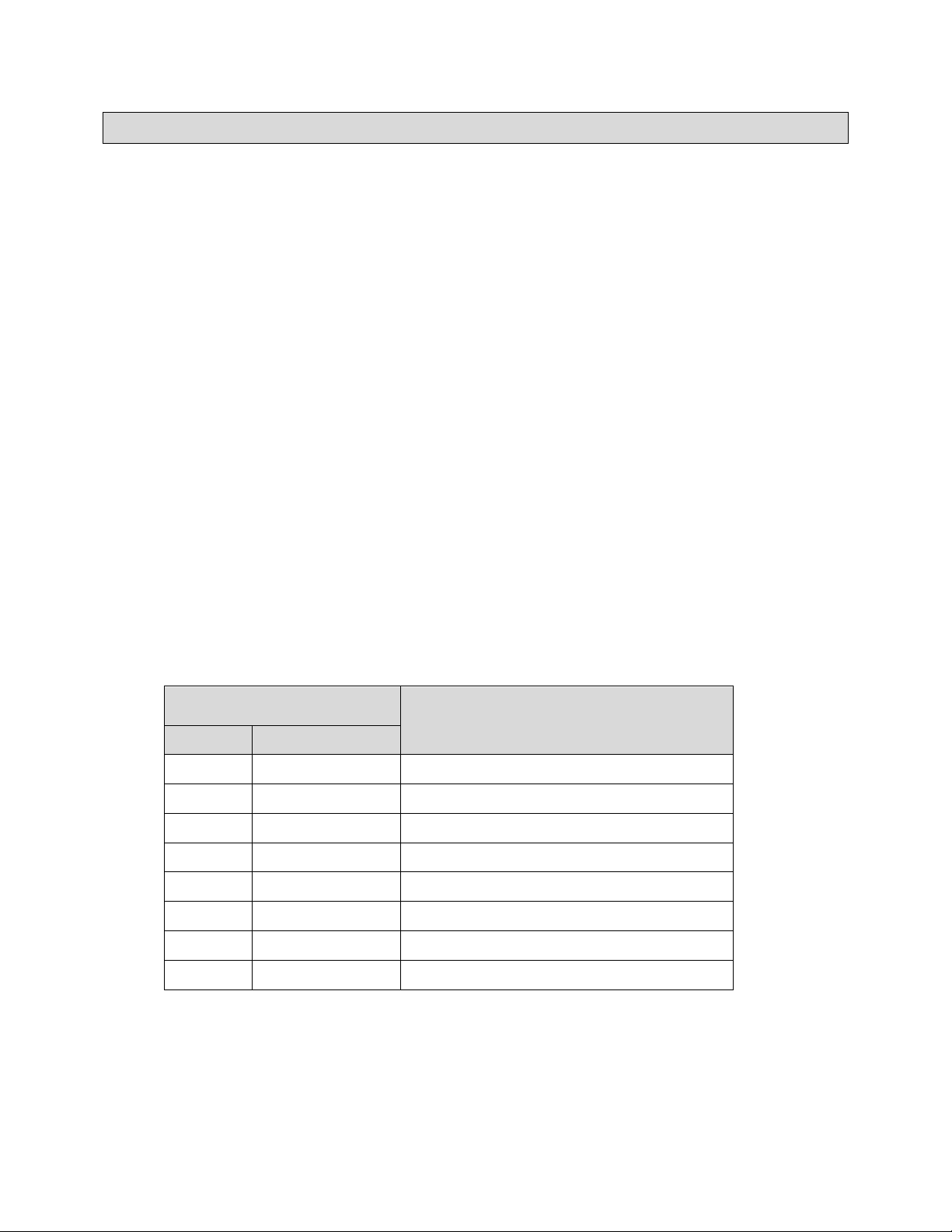

GENERAL SELECTION GUIDE FOR CHOOSING THE CORRECT FILTER BASED ON COMPRESSOR

SIZE

Compressor

Filters

HP

CFM

1HP

Up to 4 CFM

Miniature 1/4”

2 HP

Up to 9 CFM

Miniature 1/4”

3 HP

Up to 13 CFM

Miniature 1/4”

5 HP

Up to 22 CFM

Miniature 1/4”

10 HP

Up to 45 CFM

Intermediate 3/8”

15 HP

Up to 67 CFM

Intermediate 3/8”, Standard 1/2”

20 HP

Up to 90 CFM

Standard 1/2”

25 HP

Up to 112 CFM

Standard 1/2”

STANDARD CONFIGURATION

•

40-micron filtering element.

•

Press Manual Drain with Night Time Drain feature which automatically drains off the bowl once

the compressed air supply to the filter is switched off.

5

WHY USE A REGULATOR?

Air regulators are used to provide a controlled and consistent air supply as required by different

pneumatic equipment. The knob can be used to adjust the air supply thus resulting in increasing or

decreasing the air pressure.

STANDARD CONFIGURATION

•

Pressure adjustment range of 7 - 145 PSI (0.5 - 10 BAR)

OPTIONAL CONFIGURATION

Custom built include the following Pressure Adjustment ranges:

•

3 - 28 PSI (0.2 - 2 BAR)

•

3 - 58 PSI (0.2 - 4 BAR)

•

8 - 100 PSI (0.5 - 7 BAR)

WHY USE A LUBRICATOR?

Air lubricators are used with air supply lines where the compressed air is required to be lubricated before

being supplied to the tool /equipment

.

WETTED COMPONENTS

Aluminum, Bronze, Steel, Acetal, Polycarbonate, Stainless Steel & Nitrile, Brass

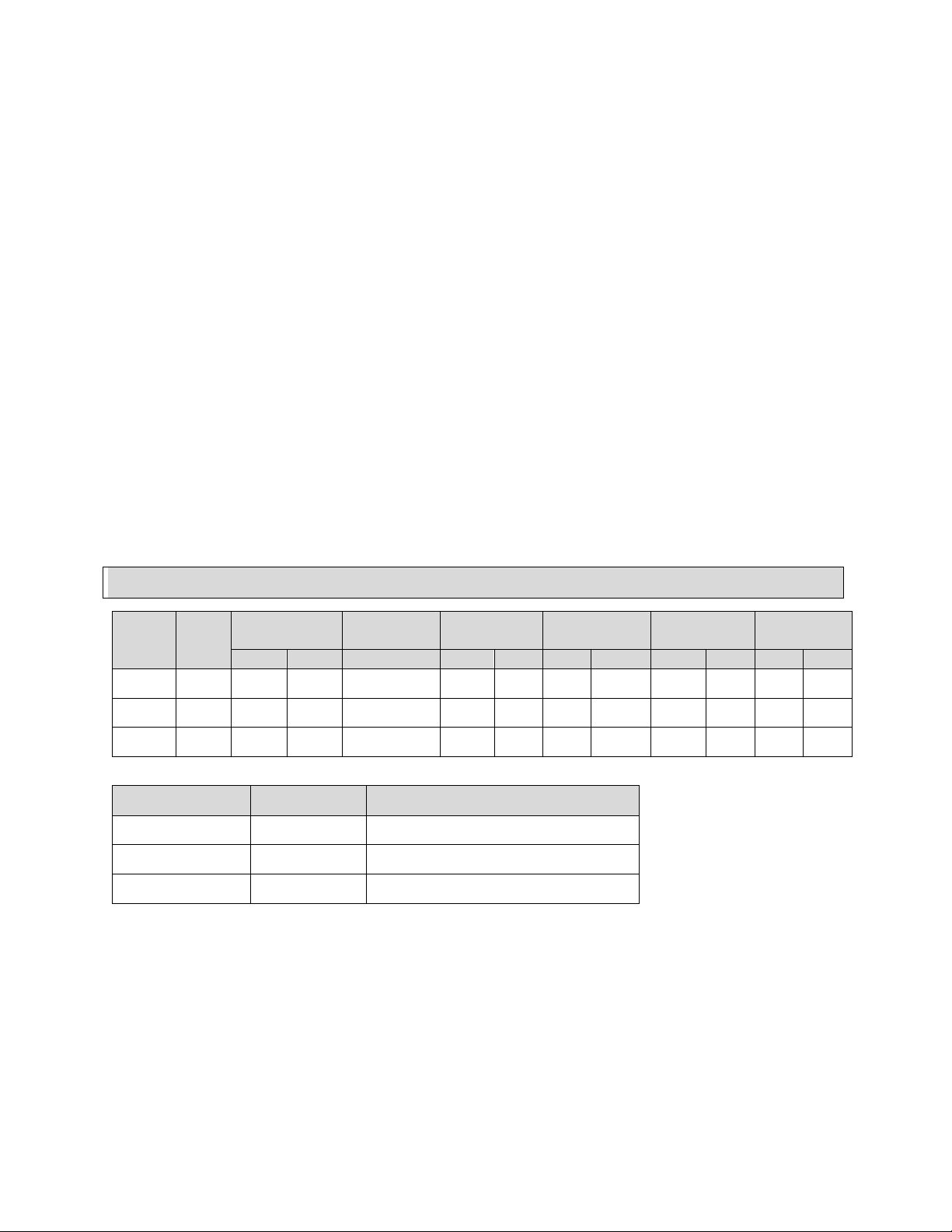

Technical Specifications

Part

No.

Port

Size

Flow Rate

(Max)**

Pressure

Gauge

Bowl

Size (Filter)

Bowl Size

(Lubricator)

Height

Width

CFM

LMP

Port Size

oz.

ml

oz.

ml

Inch

mm

In

mm

48577

1/4"

18

500

1/8"

0.3

9

0.68

20

6.69

170

7.87

200

48575

3/8"

71

2000

1/8"

1.08

32

1.93

57

8.66

220

9.84

250

48576

1/2"

106

3000

1/8"

1.5

44

5.17

152

11.0

280

12

305

Part Number

Port Size

Mechanical Pressure Gauge

48577

1/4"

✓

48575

3/8”

✓

48576

1/2”

✓

6

Important Safety Information

⚠WARNING

• Read and understand all instructions. Failure to follow all instructions may result in serious injury

or property damage.

• The warnings, cautions, and instructions in this manual cannot cover all possible conditions or

situations that could occur. Exercise common sense and caution when using this tool. Always be

aware of the environment and ensure that the tool is used in a safe and responsible manner.

• Do not allow persons to operate or assemble the product until they have read this manual and

have developed a thorough understanding of how it works.

• Do not modify this product in any way. Unauthorized modification may impair the function and/or

safety and could affect the life of the product. There are specific applications for which the

product was designed.

• Use the right tool for the job. DO NOT attempt to force small equipment to do the work of larger

industrial equipment. There are certain applications for which this equipment was designed. It will

be a safer experience and do the job better at the capacity for which it was intended. DO NOT

use this equipment for a purpose for which it was not intended.

• Industrial or commercial applications must follow OSHA requirements.

⚠WARNING

WORK AREA SAFETY

• Inspect the work area before each use. Keep work area clean, dry, free of clutter, and well-lit.

Cluttered, wet, or dark work areas can result in injury. Using the product in confined work areas

may put you dangerously close to other cutting tools and rotating parts.

• Do not use the product where there is a risk of causing a fire or an explosion; e.g., in the

presence of flammable liquids, gases, or dust. The product can create sparks, which may ignite

the flammable liquids, gases, or dust.

• Do not allow the product to come into contact with an electrical source. The tool is not insulated

and contact will cause electrical shock.

• Keep children and bystanders away from the work area while operating the tool. Do not allow

children to handle the product.

• Be aware of all power lines, electrical circuits, water pipes, and other mechanical hazards in your

work area. Some of these hazards may be hidden from your view and may cause personal injury

and/or property damage if contacted.

Loading...

Loading...