klover STAR 14, DIVA PLUS, MAGNIFIKA, PELLET FIRE PLACE 18, BI-FIRE MID Technical Manual

...

IDRO FIRMWARE

with LED display

S

E

T

OK

Set

°C

1

2

3 4

6

5

TECHNICAL MANUAL

Updated on 02/07/13 – Rev. 2.5

Installed on:

STAR 14 – STAR 14 Sartoriale

DIVA

DIVA MID

DIVA PLUS

MAGNIFIKA

PELLET FIRE PLACE 18

BI-FIRE MID

BI-FIRE

2

3

TABLE OF CONTENTS

1. GENERAL DESCRIPTION ............................................................................................................................................ 4

1.1 Console ..................................................................................................................................................................... 4

1.2 What are the buttons for ............................................................................................................................................ 6

2. THE MENU - CHRONO-THERMOSTAT ....................................................................................................................... 7

3. OPERATIVE MODE ...................................................................................................................................................... 8

3.1 Stove ignition............................................................................................................................................................. 8

3.2 No stove ignition........................................................................................................................................................ 9

3.3 Stove working............................................................................................................................................................ 9

3.4 Modification of DHW and water temperature setting ................................................................................................. 9

4. TEMPERATURE PROBES ......................................................................................................................................... 10

4.1 Room/water temperature probe .............................................................................................................................. 10

4.2 Pellet flue gas temperature probe ........................................................................................................................... 11

4.3 Wood flue gas temperature probe (BI-FIRE MID – BI-FIRE wood side) ................................................................. 11

5. WHAT HAPPENS IF... ................................................................................................................................................. 12

6. ALARMS ...................................................................................................................................................................... 12

7. FUNCTIONING PRINCIPLE ........................................................................................................................................ 13

7.1 Ignition cycle ........................................................................................................................................................... 13

7.2 Work phase ............................................................................................................................................................. 15

7.3 DHW power work phase ......................................................................................................................................... 17

7.4 Work phase with open room thermostat contact ..................................................................................................... 19

7.5 BI-FIRE MID and BI-FIRE Functioning principle ..................................................................................................... 21

8. BOOTLOADER PROGRAMMER ................................................................................................................................ 22

8.1 Firmware loading in power board ............................................................................................................................ 22

9. DATABASE ................................................................................................................................................................. 23

9.1 DATABASE access keys ........................................................................................................................................ 23

10. POWER BOARD CALIBRATIONS .......................................................................................................................... 24

10.1 Calibrations access keys reserved to T.A.C. table .................................................................................................. 24

10.2 How to calibrate parameters ................................................................................................................................... 24

10.3 How to calibrate pellet flue gas probe ..................................................................................................................... 25

11. PARAMETERS TABLES ......................................................................................................................................... 26

12. PARAMETERS EXPLANATION ............................................................................................................................. 34

13. WIRING DIAGRAMS ............................................................................................................................................... 39

13.1 DIVA – STAR14 wiring diagram (Motherboard I023) ............................................................................................ 39

13.2 DIVA MID – DIVA PLUS wiring diagram (Motherboard I023) ................................................................................. 40

13.3 MAGNIFIKA wiring diagram (Motherboard I023).................................................................................................... 41

13.4 PELLET FIRE PLACE 18 wiring diagram (Motherboard I023) .............................................................................. 42

13.5 BI-FIRE MID – BI-FIRE wiring diagram (Motherboard I023) ................................................................................. 43

14. USEFUL ADVICE .................................................................................................................................................... 44

15. NOTES .................................................................................................................................................................... 45

4

1. GENERAL DESCRIPTION

1.1 Console

The equipment's functioning state is displayed by the console. Many types of displays and the

available settings based on the selected menu can be made by accessing the menu.

Figure 1 shows the display in equipment on conditions.

SET

OK

Set

°C

1

2 3 4 6

5

60°C

Po 5

Figure 2 shows the display in equipment on conditions (on products with ventilation).

SET

OK

Set

°C

1

2 3 4 6

5

60°C 2

P5 2

Figure 3 shows the display in equipment on conditions (on pellet/wood combined products).

SET

OK

Set

°C

1

2 3 4 6

5

60°C

P5 L

EFFECTIVE WORK POWER (modulation)

Fig. 2

BOILER WATER TEMPERATURE

WORK POWER

VENTILATION POWER (optional)

Fig. 3

BOILER WATER TEMPERATURE

WORK POWER

WOOD SIDE ON

Fig. 1

BOILER WATER TEMPERATURE

WORK POWER

5

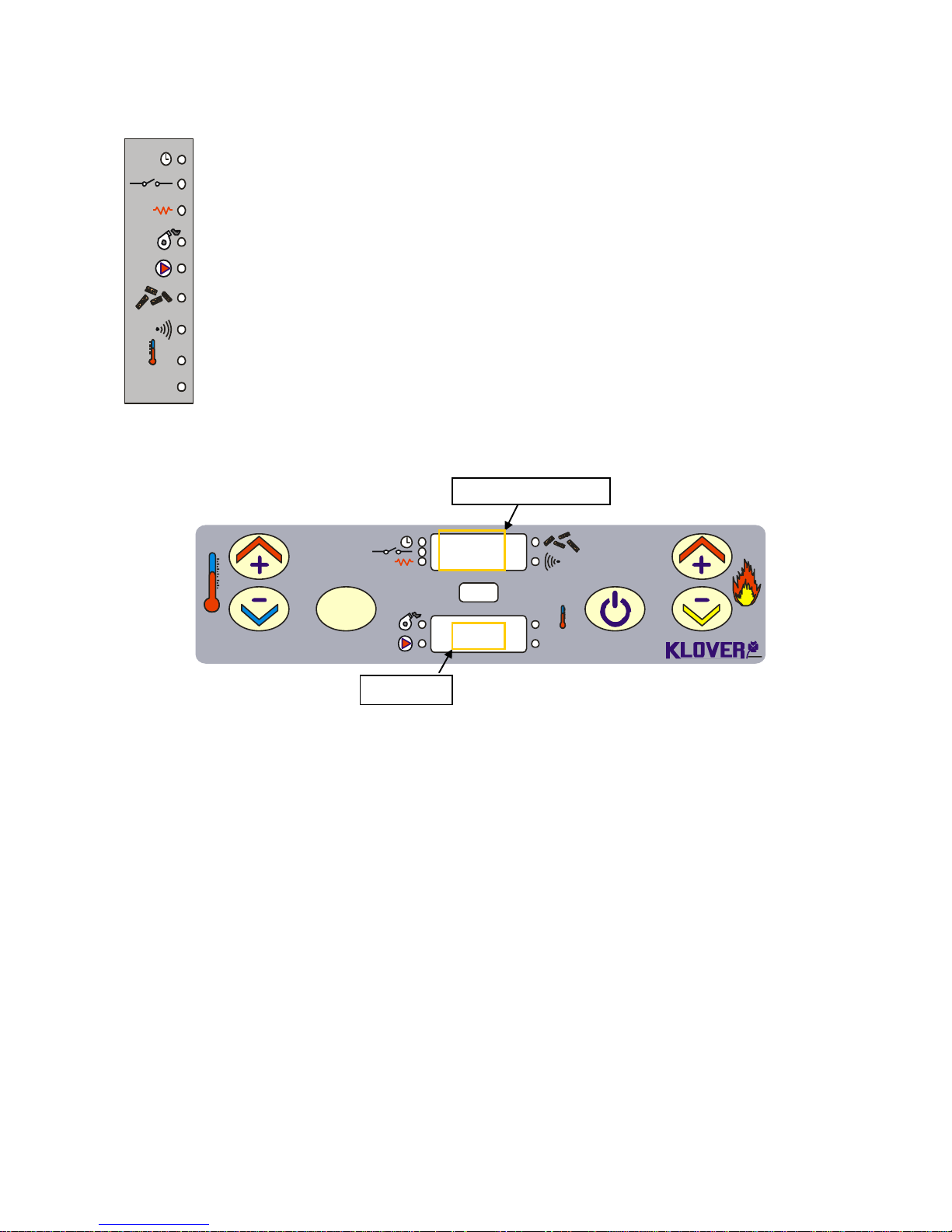

Figure 4 describes the meaning of the state LEDs on the display's console (1st LED SERIES).

°C

OK

SET

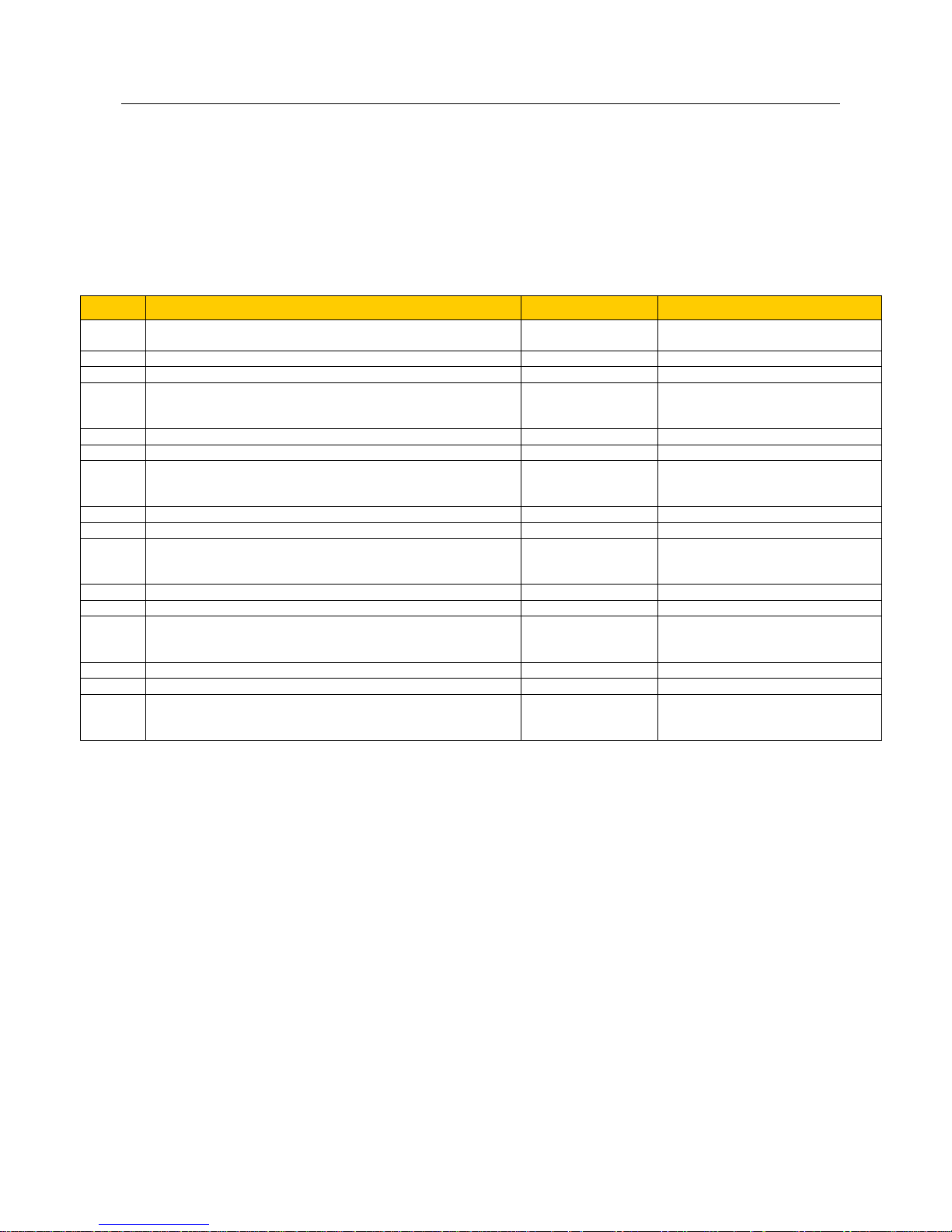

Figure 5 shows the display during operative parameters setting or programming.

SET

OK

Set

°C

1

2 3 4 6

5

Lun

Ut 01

The MENU LEVEL area shows the current parameter/menu level.

The INPUT area shows the entered programming values.

CHRONO-THERMOSTAT: the LED is on when at least one ignition and switch-off program is

active.

ROOM THERMOSTAT: the LED is on when room thermostat contact is open.

IGNITION RESISTANCE: the LED is on when ignition resistance is active.

FLUE GAS EXTRACTOR: the LED is on when the flue gas intake device is active.

PUMP: the LED is on when system circulation pump is active.

SCREW FEED: the LED is on when the pellet load motor reducer switches on.

REMOTE CONTROL RECEPTION: the LED is on when a button on the supplied remote control is

pressed and signal reaches the board.

TEMPERATURE OK: the LED is on when temperature set on SET H2O is reached.

SET: the LED is on when SET button on display is pressed.

Fig. 4

Fig. 5

INPUT

MENU LEVEL

6

1.2 What are the buttons for

BUTTON

DESCRIPTION

MODE

ACTION

1

Increases temperature (1)

In programming..

Modifies/increases the selected menu value.

Working/off (after having

pressed SET once).

Increases DHW/water thermostat

temperature value.

2

Decreases temperature (2)

In programming..

Modifies/decreases the selected menu

value.

Working/off (after having

pressed SET once).

Decreases DHW/water thermostat

temperature value.

3

Set

-

Pressed once accesses “SET H2O” or “SET

SANI”.

Consecutively pressed twice accesses the

user menu.

In menu..

Accesses the subsequent sub-menu level.

In parameters programming..

Sets parameter value and goes to

subsequent parameter.

4

ON/OFF

Outlet

Working..

Ignites and switches off stove when pressed

for 2 seconds.

In alarm block..

Releases alarm.

In menu/programming..

Goes to upper menu level memorising the

made modifications.

5

Increases power (3)

Working/off..

Increases stove's work power.

In menu..

Goes to previous menu entry.

In programming..

Goes back to previous sub-menu entry

memorising the made modifications.

6 Decreases power (4)

Working/off..

Decreases stove's work power.

In menu..

Goes to subsequent menu entry.

In programming..

Goes back to subsequent sub-menu entry

memorising the made modifications.

(1) The flue gas temperature is displayed on upper display and water in boiler temperature on lower

display when held down.

(2) Current time is displayed when held down.

(3) Keep pressed for two seconds go directly to work phase, skipping the entire ignition cycle (see “Useful

advice”).

(4) Keep pressed for a few seconds (during switch-off) to switch-off flue gas intake device and proceed

with new stove ignition without having to wait "Stand-by" time (see “Useful advice”).

7

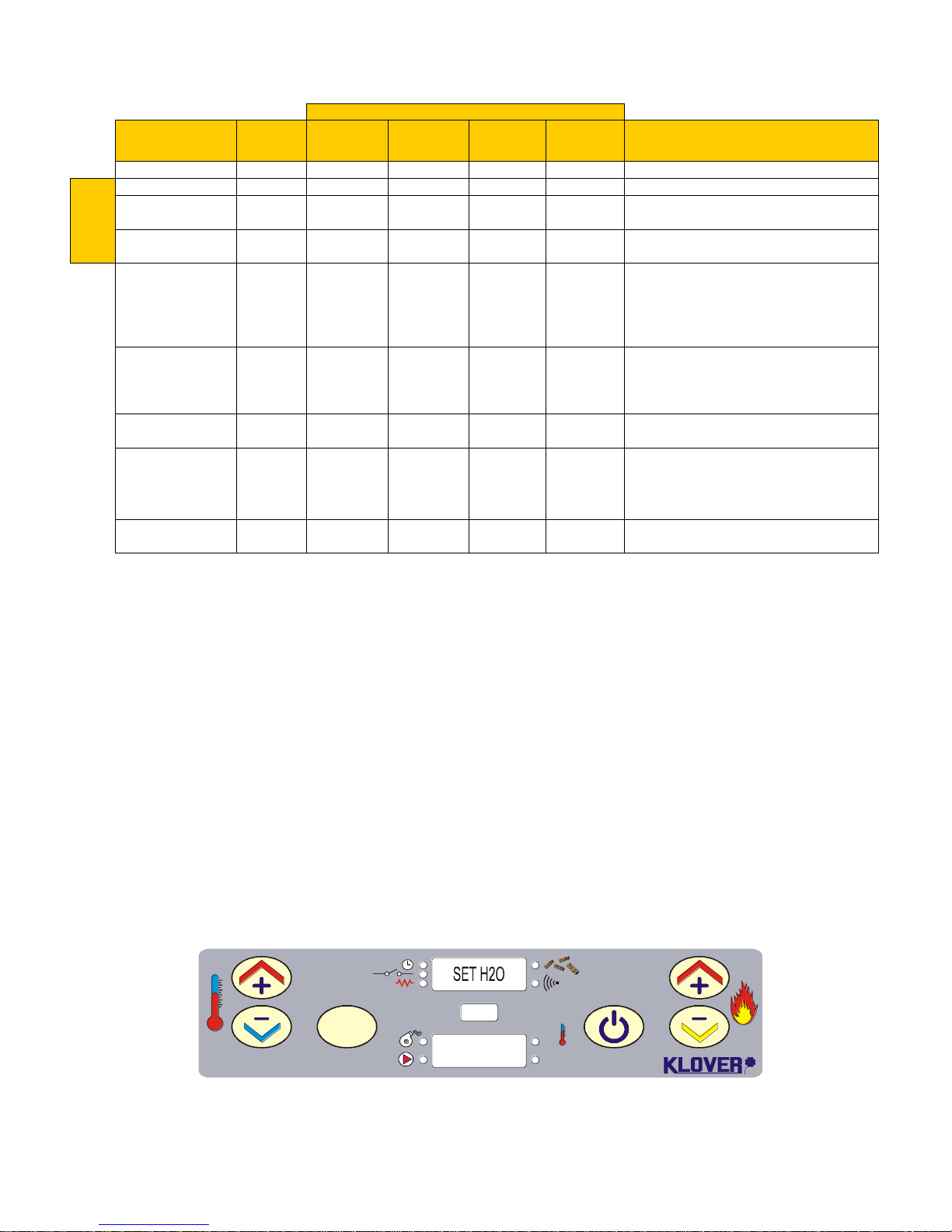

2. THE MENU - CHRONO-THERMOSTAT

The Menu is accessed by pressing key 3 (Set) twice.

This is divided into different levels (called UT...) to access the board's programming and settings.

The technical programming access menu entry (UT04) (parameters reserved to Technical Assistance Centre)

is protected by access key (see “Power board calibrations”).

The menu structure is summarised in the following table:

MENU

MEANING

VALUE

VALUE THAT CAN BE SET

UT01

Set current day or OFF (the chrono-thermostat is completely

deactivated by setting OFF).

Day or OFF

OFF, Mon, Tues, Wed,…..Sun

UT02

Set current time.

Hour

From 00 to 23

UT03

Set current minutes.

minutes

From 00 to 59

UT04

The various parameters tables reserved to Technical

Assistance Centre are accessed by setting one of the access

keys.

-

From 00 to P5

UT05

First program ignition time.

Time

From 00.00 to 23.50 with 10’ steps

UT06

First program switch-off time.

Time

From 00.00 to 23.50 with 10’ steps

UT07

Choice of days first program is to be considered

(program times will be considered by setting ON on day;

program times will not be considered by setting OFF on day).

Day/State

Mon on/off, Tues on/off, Wed

on/off, Thurs on/off, Fri on/off, Sat

on/off, Sun on/off

UT08

Second program ignition time.

Time

From 00.00 to 23.50 with 10’ steps

UT09

Second program switch-off time.

Time

From 00.00 to 23.50 with 10’ steps

UT10

Choice of days second program is to be considered (program

times will be considered by setting ON on day; program times

will not be considered by setting OFF on day).

Day/State

Mon on/off, Tues on/off, Wed

on/off, Thurs on/off, Fri on/off, Sat

on/off, Sun on/off

UT11

Third program ignition time.

Time

From 00.00 to 23.50 with 10’ steps

UT12

Third program switch-off time.

Time

From 00.00 to 23.50 with 10’ steps

UT13

Choice of days third program is to be considered

(program times will be considered by setting ON on day;

program times will not be considered by setting OFF on day).

Day/State

Mon on/off, Tues on/off, Wed

on/off, Thurs on/off, Fri on/off, Sat

on/off, Sun on/off

UT14

Fourth program ignition time.

Time

From 00.00 to 23.50 with 10’ steps

UT15

Fourth program switch-off time.

Time

From 00.00 to 23.50 with 10’ steps

UT16

Choice of days fourth program is to be considered

(program times will be considered by setting ON on day;

program times will not be considered by setting OFF on day).

Day/State

Mon on/off, Tues on/off, Wed

on/off, Thurs on/off, Fri on/off, Sat

on/off, Sun on/off

Set “OFF” in user menu Ut01 to deactivate chrono-thermostat.

8

3. OPERATIVE MODE

The stove's normal functioning principle with reference to the available functions for the user is

described below.

The display appears as in figure 6 before igniting the stove.

SET

OK

Set

°C

1

2 3 4 6

5

22:35

Off

3.1 Stove ignition

Press key 4 for a few seconds to ignite the stove. Ignition is shown on display as in figure 7.

SET

OK

Set

°C

1

2 3 4 6

5

Asp

Fun

The stove sequentially runs the start-up phases as defined by the parameters managing levels and

timing (see “Parameters tables”), after stove ignition.

The method according to which the stove reaches work condition is shown in the following

prospectus, if alarm or anomaly conditions do not arise.

The various functioning conditions, which cleaning, economy modulation, etc. are also described.

Fig. 6

CLOCK

STOVE STATE

Fig. 7

DIALOGUE

9

Devices

Country

Duration

Ignition

resistance

Flue gas

intake

device

Screw feed

Pump

When it occurs

OFF - OFF

OFF

OFF

OFF

ON/OFF

IGNITION

CYCLE

FUN ASP

8”

ON

ON

OFF

OFF

For the first 8" in ignition

LOAD PELL

Pr01

ON

ON

ON

OFF

For a time set on Pr01 or before reaching

temperature on Pr13 after “FUN ASP” state

FIRE ON

Pr02

OFF

ON

ON

OFF/ON

For a time set on Pr02 after “LOAD PELL”

state

“Work from Power 1

to Power 5”

-

OFF

ON

ON

ON

- H2O Temperature < “SET H2O”

- Closed room thermostat contact

- Flue gas temperature < Pr14

- No alarm detected

ECO T-OFF

-

OFF

ON

ON

OFF

- Open room thermostat contact with H2O

temperature < “SET H20” and “SET SANI”

ECO H2O

Pr12 or

Pr23

OFF

ON

ON

OFF/ON *

- Reached temperature set on “SET H2O”

- Reached temperature set on “SET SANI”

STOP FIRE

OFF

OFF

OFF

OFF/ON *

- Exceeded temperature set on Pr12 after

having reached temperature set on “SET

H2O”.

- Exceeded time set on Pr23 after having

reached temperature set on “SET H2O”

COOL FIRE

Pr24

OFF

ON

ON

OFF/ON *

- Lapsed time set on Pr03

* Pump switch-on depends on whether the room thermostat contact is open or closed in this condition. In both cases, the

pump switches on if water in boiler temperature exceeds temperature set on “SET H2O” by 5°C (safety to avoid overtemperature).

3.2 No stove ignition

If the flue gas temperature has not reached Pr13 minimum value admitted after Pr01 time has lapsed,

the stove places itself in “NO FIRE” alarm state.

3.3 Stove working

The stove goes to work phase, representing the normal functioning mode, after positive ignition (for

display conditions see “Console”).

The system pump switches on if water in boiler temperature is higher than Pr15.

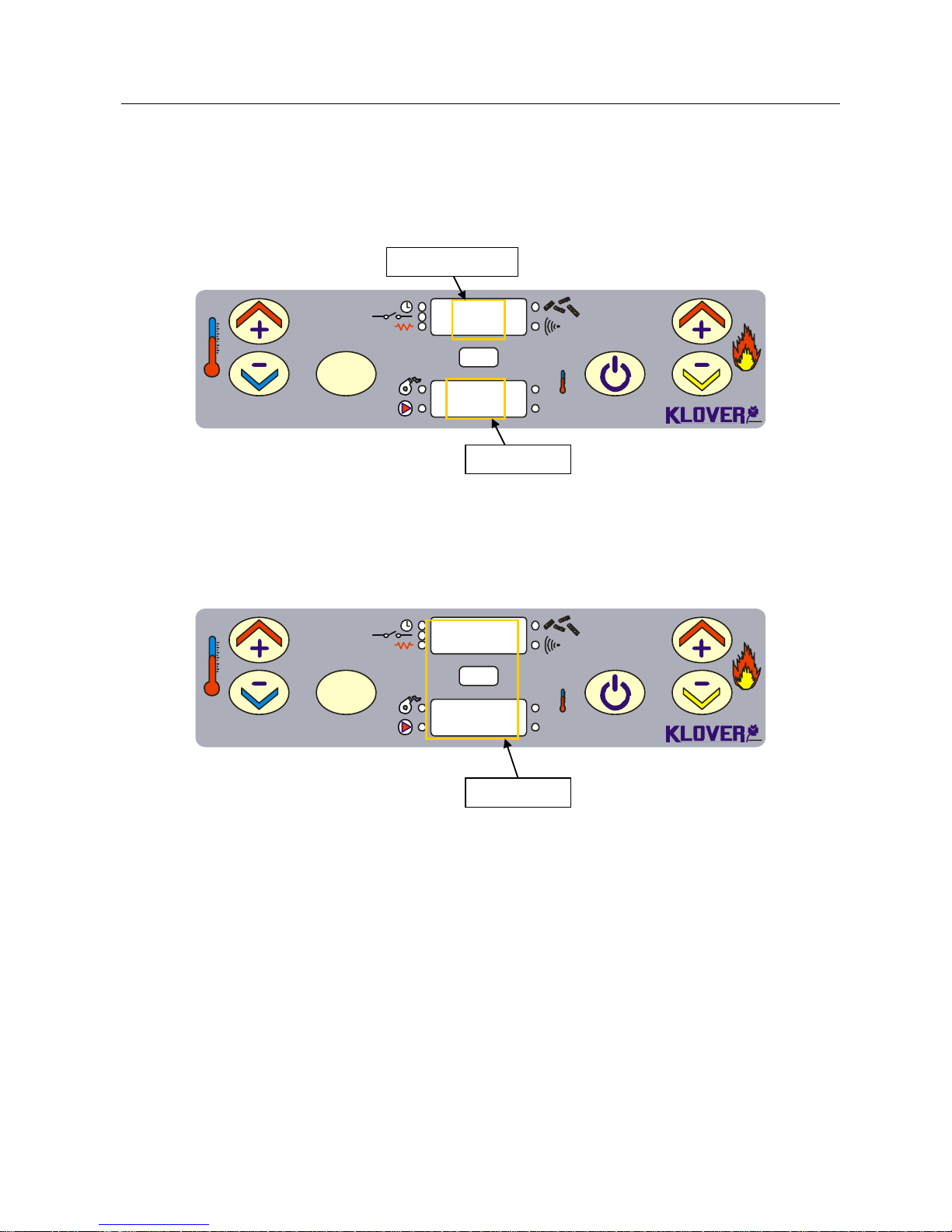

3.4 Modification of DHW and water temperature setting

- Water Temperature

Press key 3 to select “SET H2O” (with work power set from Power 1 to Power 5) to modify water

temperature. Press keys 1 and 2. The display appears as in figure 8 during this operation.

S.R.L.

SET

OK

Set

°C

1

2 3 4 6

5

60°C

Wait 5 seconds after setting wanted value.

Fig. 8

10

The stove enters functioning economy upon reaching said temperature.

The stove now automatically switches off if at least one of the following conditions exist:

If it remains in Functioning Economy “ECO-H2O” for a time set on Pr23 (120 minute default setting).

If it exceeds temperature differential set on Pr12 (10°C default setting) or H2O Temperature > (“SET

H2O” + Pr12)

- DHW Temperature (only on prepared models)

Press key 3 to select “SET SANI” (with work power set on DHW Power) to modify DHW temperature.

Press keys 1 and 2. The display appears as in figure 9 during this operation.

S.R.L.

SET

OK

Set

°C

1

2 3 4 6

5

65°C

Wait 5 seconds after setting wanted value.

4. TEMPERATURE PROBES

The used temperature probes' features are given below.

4.1 Room/water temperature probe

The room/water probe used to measure water or room (in case of air stoves) temperature has the

following features:

IP67, NTC Thermoplastic probe: like NTC 10K ± 1% = 3435

Measuring field: -50/+120°C

Obtain a tester to check if probe is faulty, set it in ohm and measure the two probe pins (wire ends):

The probe measures about 10kohm at 25°C if it works correctly

If the probe is faulty: - resistance greater than 1Mohm (open)

- resistance to 0 ohm (in short)

The tester can also be used to check if the probe connection to the power board contacts are in short;

if 0 ohm resistance is measured by connecting the tester to the contacts, these are in short.

The lower display shows water (or room) temperature at 02°C if the room/water probe is not

connected to the power board. The display appears as in figure 10.

S.R.L.

SET

OK

Set

°C

1

2 3 4 6

5

Fig. 9

Fig. 10

02°

C

11

4.2 Pellet flue gas temperature probe

The flue gas probe used to measure the pellet's flue gas temperature has the following features:

Thermocouple probe: J type

Measuring field: 0/+350°C

Obtain a tester to check if probe is faulty, set it in ohm and measure the two probe pins (wire ends);

however, this only verifies if the probe is interrupted (no change compared to value shown on

unconnected tester).

The tester can also be used to check if the probe connection to the power board contacts are in short;

if 0 ohm resistance is measured by connecting the tester to the contacts, these are in short.

The upper display shows the pellet flue gas temperature (by pressing key 1) at 284°C if the pellet flue

gas probe is not connected to the power board. The display appears as in figure 11.

S.R.L.

SET

OK

Set

°C

1

2 3 4 6

5

Pay attention to wires polarity when connecting the pellet flue gas probe to the power board. A

fixed temperature of 30°C appears on upper display that does not change with the increase of

flue gas temperature if the wires' polarity is inverted.

4.3 Wood flue gas temperature probe (BI-FIRE MID – BI-FIRE wood side)

The flue gas probe used to measure the wood's flue gas temperature has the following features:

2 Wires PT1000 probe: PT 1000 class B

Measuring field: 0/+500°C

Obtain a tester to check if probe is faulty, set it in ohm and measure the two probe pins (wire ends):

The probe measures about 1k 1.1kohm at 25/30°C if it works correctly

If the probe is faulty: - resistance greater than 1Mohm (open)

- resistance to 0 ohm (in short)

The tester can also be used to check if the probe connection to the power board contacts are in short;

if 0 ohm resistance is measured by connecting the tester to the contacts, these are in short.

The lower display shows the wood flue gas temperature (by pressing key 2) at h86°C if the wood flue

gas probe is not connected to the power board. The display appears as in figure 12.

S.R.L.

SET

OK

Set

°C

1

2 3 4 6

5

Fig. 11

284

Fig. 12

LEGn

h86

C

12

5. WHAT HAPPENS IF...

...the stove does not ignite

In case of no ignition, the “NO FIRE” alarm is displayed.

Hold button 4 (switch on/off) for a few seconds to restore the stove to standard conditions (remove the alarm).

...lack of power for a few seconds

Once the power is restored, the stove immediately restarts from the status it had before the power outage

(recovering the set work power).

... lack of power

As soon as the power is restored after a power outage, the stove sets on “STOP FIRE” mode and carries out

the entire switch off cycle until its cooling. Once this phase is completed, the stove can be normally switched

on to proceed working at the set power.

…the fire door is open or closed improperly

In case the door is open or closed improperly, the motor reducer cannot be powered electrically, not allowing

the stove to switch on. If the fire door is opened during the normal operation, the stove burns all the pellet in

the brazier, activating the “ALAR NO FIRE” alarm (sudden switch off). The flue is dirty, blocked or not

manufactured correctly.

In case the flue is dirty, blocked or not manufactured correctly, the motor reducer cannot be powered

electrically not allowing the stove to switch on. If the flue blocks during the normal operation, the stove burns

all the pellet in the brazier, activating the “ALAR NO FIRE” alarm (sudden switch off).

...the stove is overheated

In case of water over-temperature in the boiler, the message

“ALAR HOT H2O” is displayed first, followed by an acoustic alarm. At this point the motor reducer is not

electrically powered, because the rearm safety thermostat is activated. Therefore the thermostat must be

rearmed before switching on the stove.

...pellet insert unhooked or hooked improperly

In case the pellet insert is unhooked or hooked improperly, the motor reducer cannot be powered electrically,

not allowing the insert to switch on. If it is unhooked during the normal operation, the insert burns all the pellet

in the brazier, activating the “ALAR NO FIRE” alarm (sudden switch off).

6. ALARMS

The board intervenes and signals the occurred irregularity in case of functioning anomaly, operating in

different mode depending on type of alarm. The following alarms are foreseen in the board.

DISPLAY

ORIGIN OF ALARM

ALAR SOND H2O

Faulty or disconnected water temperature probe

ALAR HOT H2O

Water over-temperature. When water temperature exceeds 92°C

ALAR SOND FUMI

Faulty or disconnected flue gas temperature probe.

ALAR HOT TEMP

Flue gas over-temperature. When flue gas temperature exceeds 280°C

ALAR NO FIRE

No ignition. When flue gas minimum temperature (Pr13) is not reached within

maximum ignition cycle time (Pr01).

ALAR NO FIRE

Sudden switch-off during work phase. When, during work, the flue gas

temperature drops below minimum threshold (Pr13).

NO H2O

No water level. When water in boiler does not reach minimum level (only on

Sicuro Top BI-FIRE and BI-FIRE MID system)

Every alarm causes the equipment to immediately switch-off.

After time set on Pr11 (alarms delay) alarm state is reached; press key 4 to reset it.

13

7. FUNCTIONING PRINCIPLE

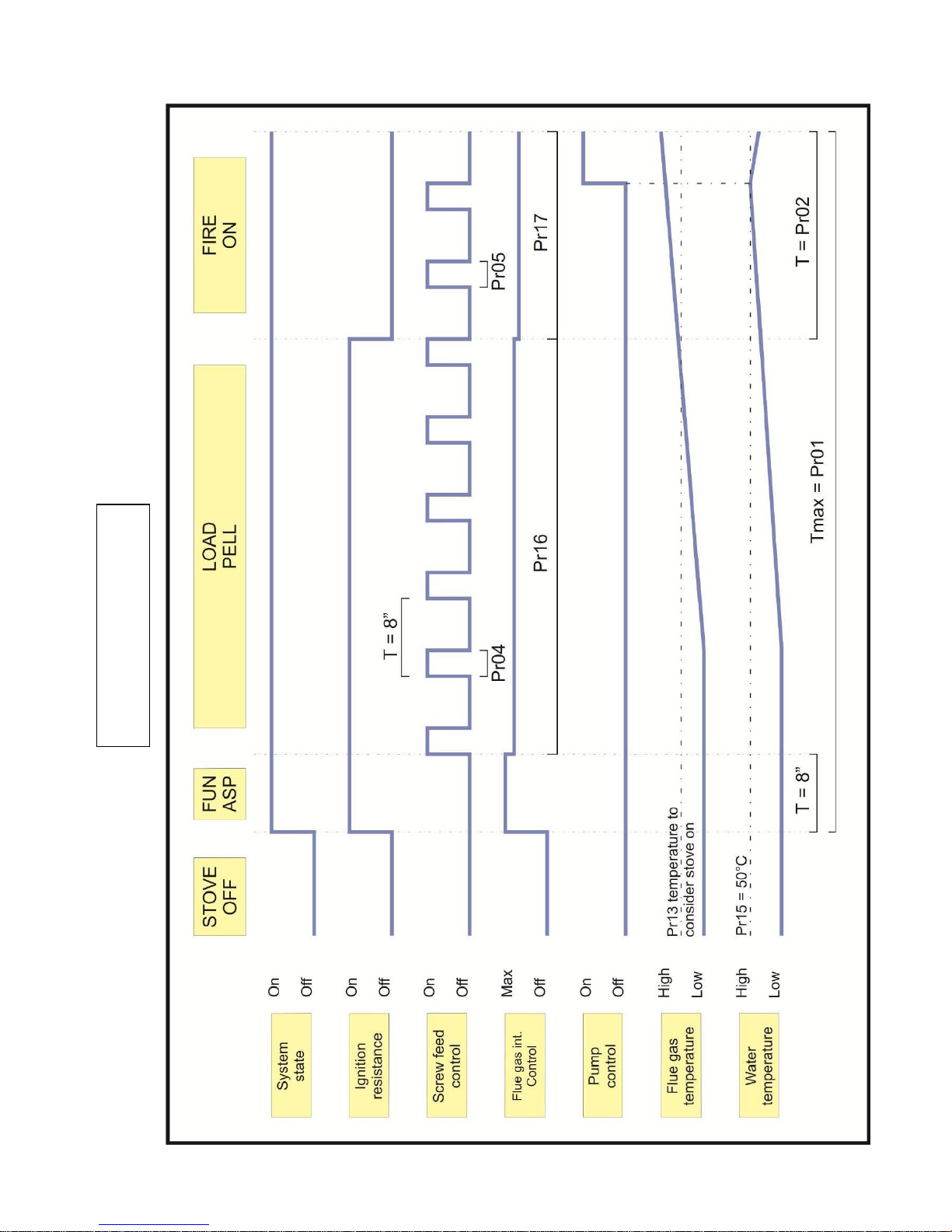

7.1 Ignition cycle

The ignition cycle can last max 18 minutes and is divided into three phases:

1 - FUN ASP : Intake device function

duration 8 seconds

2 - LOAD PELL : Pellet loading and resistance ignition

Pr01 = “LOAD PELL” duration

A pre-load phase may be present in “LOAD PELL” phase with specifications according to parameters Pr45,

Pr46 and Pr47.

3 - FIRE ON : Resistance switch-off and flame stabilising

Pr02 = “FIRE ON” duration

The stove goes to work phase at power set in ignition using buttons 1 and 2 after ignition cycle.

14

IGNITION PHASE

15

7.2 Work phase

The set work power or 1, 2, 3, 4, 5, SANI (optional) is shown on upper display during the stove's normal

functioning.

A “SET H20” (maximum temperature) can be set by working from Power 1 to Power 5. The stove enters

Functioning Economy “ECO-H2O” upon reaching of such set.

Before reaching temperature set on “SET H20”, the stove starts modulating power by decreasing pellet intake

and reducing flue gas intake device speed.

Example: “SET H2O” set at 75 °C

Work power set at 5

- The work power automatically changes to 4 upon reaching 71°C.

- The work power automatically changes to 3 upon reaching 72°C.

- The work power automatically changes to 2 upon reaching 73°C.

- The work power automatically changes to 1 upon reaching 74°C.

- The work power automatically changes to Functioning economy “ECO H2O” upon reaching 75°C.

The stove now automatically switches off if at least one of the following conditions exist:

If it remains in Functioning Economy “ECO-H2O” for a time set on Pr23 (120 minute default setting).

If it exceeds temperature differential set on Pr12 (10°C default setting) or H2O Temperature > (“SET

H2O” + Pr12)

With the following condition the stove automatically ignites:

If it drops below temperature differential set on Pr12 (10°C default setting) or H2O temperature < (“SET

H2O” – Pr12)

If the above-mentioned condition occurs when the stove is still carrying out the switch off cycle, it is required to

wait until it ends.

Loading...

Loading...