klover ECOMPACT Series, ECOMPACT 150, ECOMPACT 250, ECOMPACT 290, ECOMPACT 190 Installation, Use, Maintenance And Helpful Tips

Page 1

ENGLISH

Pellet-burning

boiler ECOMPACT

150-190-250-290

INSTALLATION, USE, MAINTENANCE AND

HELPFUL TIPS

Main Revision 1.1

FPH_supplement: 001

Page 2

Page 3

DICHIARAZIONE DI

CONFORMITÀ

DECLARATION OF

CONFORMITY

Emesso da - Issued by

Indirizzo - Address

:

KLOVER s.r.l.

Via A. Volta, 8

37047 San Bonifacio (VR)

Tipo di apparecchio - Type of equipment

:

Heating boiler for solid fuel automatically stoked

Marchio commerciale -Trademark

:

KLOVER

Modello o tipo - Model or type

:

ECOMPACT 150

Uso - Use

:

Central heating in residential buildings

Costruttore - Manufacturer

:

KLOVER s.r.l.

L’oggetto della presente dichiarazione è conforme alle seguenti direttive UE:

The object of this declaration is comply with the following EU directives

2006/42/CE Direttiva macchine.

2006/42/CE Machinery Directive.

2014/35/UE del 26 Febbraio 2014 relativa l’armonizzazione delle legislazioni degli stati membri relative alla messa a disposizione sul mercato del

materiale elettrico destinato ad essere adoperato entro taluni limiti di tensione.

2014/35/UE 26 February 2014 on the harmonization of the laws of the Member States relating to the making available on the market of electrical

equipment designed for use within certain voltage limits.

2014/30/UE del 26 Febbraio 2014 relativa l’armonizzazione delle legislazioni degli stati membri relative alla compatibilità elettromagnetica.

2014/30/UE 26 February 2014 on the harmonization of the laws of the Member States relating to electromagnetic compatibility.

2011/65/UE del 21 Luglio 2016 relativa l’armonizzazione delle legislazioni degli stati membri relative alla restrizione all’uso di sostanze pericolose

nelle apparecchiature elettriche e elettroniche.

2016/65/UE 21 July 2016 on the harmonization of the laws of the Member States relating to the restriction in use of hazardous substances in

electrical and electronic equipment.

Riferimenti alle norme armonizzate:

References to the relevant harmonized standards:

EN 303-5

EN 55014-1 EN 55014-2

EN 61000-3-2 EN 61000-3-3

EN 62233

EN 60335-1

EN 60335-2-102

EN 50581

In qualità di costruttore e/o rappresentante autorizzato della società all’interno della CEE, si dichiara sotto la propria responsabilità che gli

apparecchi sono conformi alle esigenze essenziali previste dalle Direttive su menzionate.

As the manufacturer’s authorised representative within the EEC, we hereby declare under our sole responsibility that the equipment complies with

the provisions of the Directives stated above.

San Bonifacio (VR), 22/03/2018

Mario Muraro

Chairman of the Board

Page 4

DICHIARAZIONE DI

CONFORMITÀ

DECLARATION OF

CONFORMITY

Emesso da - Issued by

Indirizzo - Address

:

KLOVER s.r.l.

Via A. Volta, 8

37047 San Bonifacio (VR)

Tipo di apparecchio - Type of equipment

:

Heating boiler for solid fuel automatically stoked

Marchio commerciale -Trademark

:

KLOVER

Modello o tipo - Model or type

:

ECOMPACT 190

Uso - Use

:

Central heating in residential buildings

Costruttore - Manufacturer

:

KLOVER s.r.l.

L’oggetto della presente dichiarazione è conforme alle seguenti direttive UE:

The object of this declaration is comply with the following EU directives

2006/42/CE Direttiva macchine.

2006/42/CE Machinery Directive.

2014/35/UE del 26 Febbraio 2014 relativa l’armonizzazione delle legislazioni degli stati membri relative alla messa a disposizione sul mercato del

materiale elettrico destinato ad essere adoperato entro taluni limiti di tensione.

2014/35/UE 26 February 2014 on the harmonization of the laws of the Member States relating to the making available on the market of electrical

equipment designed for use within certain voltage limits.

2014/30/UE del 26 Febbraio 2014 relativa l’armonizzazione delle legislazioni degli stati membri relative alla compatibilità elettromagnetica.

2014/30/UE 26 February 2014 on the harmonization of the laws of the Member States relating to electromagnetic compatibility.

2011/65/UE del 21 Luglio 2016 relativa l’armonizzazione delle legislazioni degli stati membri relative alla restrizione all’uso di sostanze pericolose

nelle apparecchiature elettriche e elettroniche.

2016/65/UE 21 July 2016 on the harmonization of the laws of the Member States relating to the restriction in use of hazardous substances in

electrical and electronic equipment.

Riferimenti alle norme armonizzate:

References to the relevant harmonized standards:

EN 303-5

EN 55014-1 EN 55014-2

EN 61000-3-2 EN 61000-3-3

EN 62233

EN 60335-1

EN 60335-2-102

EN 50581

In qualità di costruttore e/o rappresentante autorizzato della società all’interno della CEE, si dichiara sotto la propria responsabilità che gli

apparecchi sono conformi alle esigenze essenziali previste dalle Direttive su menzionate.

As the manufacturer’s authorised representative within the EEC, we hereby declare under our sole responsibility that the equipment complies with

the provisions of the Directives stated above.

San Bonifacio (VR), 22/03/2018

Mario Muraro

Chairman of the Board

Page 5

DICHIARAZIONE DI

CONFORMITÀ

DECLARATION OF

CONFORMITY

Emesso da - Issued by

Indirizzo - Address

:

KLOVER s.r.l.

Via A. Volta, 8

37047 San Bonifacio (VR)

Tipo di apparecchio - Type of equipment

:

Heating boiler for solid fuel automatically stoked

Marchio commerciale -Trademark

:

KLOVER

Modello o tipo - Model or type

:

ECOMPACT 250

Uso - Use

:

Central heating in residential buildings

Costruttore - Manufacturer

:

KLOVER s.r.l.

L’oggetto della presente dichiarazione è conforme alle seguenti direttive UE:

The object of this declaration is comply with the following EU directives

2006/42/CE Direttiva macchine.

2006/42/CE Machinery Directive.

2014/35/UE del 26 Febbraio 2014 relativa l’armonizzazione delle legislazioni degli stati membri relative alla messa a disposizione sul mercato del

materiale elettrico destinato ad essere adoperato entro taluni limiti di tensione.

2014/35/UE 26 February 2014 on the harmonization of the laws of the Member States relating to the making available on the market of electrical

equipment designed for use within certain voltage limits.

2014/30/UE del 26 Febbraio 2014 relativa l’armonizzazione delle legislazioni degli stati membri relative alla compatibilità elettromagnetica.

2014/30/UE 26 February 2014 on the harmonization of the laws of the Member States relating to electromagnetic compatibility.

2011/65/UE del 21 Luglio 2016 relativa l’armonizzazione delle legislazioni degli stati membri relative alla restrizione all’uso di sostanze pericolose

nelle apparecchiature elettriche e elettroniche.

2016/65/UE 21 July 2016 on the harmonization of the laws of the Member States relating to the restriction in use of hazardous substances in

electrical and electronic equipment.

Riferimenti alle norme armonizzate:

References to the relevant harmonized standards:

EN 303-5

EN 55014-1 EN 55014-2

EN 61000-3-2 EN 61000-3-3

EN 62233

EN 60335-1

EN 60335-2-102

EN 50581

In qualità di costruttore e/o rappresentante autorizzato della società all’interno della CEE, si dichiara sotto la propria responsabilità che gli

apparecchi sono conformi alle esigenze essenziali previste dalle Direttive su menzionate.

As the manufacturer’s authorised representative within the EEC, we hereby declare under our sole responsibility that the equipment complies with

the provisions of the Directives stated above.

San Bonifacio (VR), 17/07/2017

Mario Muraro

Chairman of the Board

Page 6

DICHIARAZIONE DI

CONFORMITÀ

DECLARATION OF

CONFORMITY

Emesso da - Issued by

Indirizzo - Address

:

KLOVER s.r.l.

Via A. Volta, 8

37047 San Bonifacio (VR)

Tipo di apparecchio - Type of equipment

:

Heating boiler for solid fuel automatically stoked

Marchio commerciale -Trademark

:

KLOVER

Modello o tipo - Model or type

:

ECOMPACT 290

Uso - Use

:

Central heating in residential buildings

Costruttore - Manufacturer

:

KLOVER s.r.l.

L’oggetto della presente dichiarazione è conforme alle seguenti direttive UE:

The object of this declaration is comply with the following EU directives

2006/42/CE Direttiva macchine.

2006/42/CE Machinery Directive.

2014/35/UE del 26 Febbraio 2014 relativa l’armonizzazione delle legislazioni degli stati membri relative alla messa a disposizione sul mercato del

materiale elettrico destinato ad essere adoperato entro taluni limiti di tensione.

2014/35/UE 26 February 2014 on the harmonization of the laws of the Member States relating to the making available on the market of electrical

equipment designed for use within certain voltage limits.

2014/30/UE del 26 Febbraio 2014 relativa l’armonizzazione delle legislazioni degli stati membri relative alla compatibilità elettromagnetica.

2014/30/UE 26 February 2014 on the harmonization of the laws of the Member States relating to electromagnetic compatibility.

2011/65/UE del 21 Luglio 2016 relativa l’armonizzazione delle legislazioni degli stati membri relative alla restrizione all’uso di sostanze pericolose

nelle apparecchiature elettriche e elettroniche.

2016/65/UE 21 July 2016 on the harmonization of the laws of the Member States relating to the restriction in use of hazardous substances in

electrical and electronic equipment.

Riferimenti alle norme armonizzate:

References to the relevant harmonized standards:

EN 303-5

EN 55014-1 EN 55014-2

EN 61000-3-2 EN 61000-3-3

EN 62233

EN 60335-1

EN 60335-2-102

EN 50581

In qualità di costruttore e/o rappresentante autorizzato della società all’interno della CEE, si dichiara sotto la propria responsabilità che gli

apparecchi sono conformi alle esigenze essenziali previste dalle Direttive su menzionate.

As the manufacturer’s authorised representative within the EEC, we hereby declare under our sole responsibility that the equipment complies with

the provisions of the Directives stated above.

San Bonifacio (VR), 17/07/2017

Mario Muraro

Chairman of the Board

Page 7

CONTENTS

CONTENTS ........................................................................................................................................................................ 1

INTRODUCTION ................................................................................................................................................................. 3

IMPORTANT SAFETY INSTRUCTIONS ................................................................................................................................... 3

THE MACHINE AND THE PELLETS ................................................................................................................................. 4

COMPONENTS OF THE APPLIANCE ..................................................................................................................................... 4

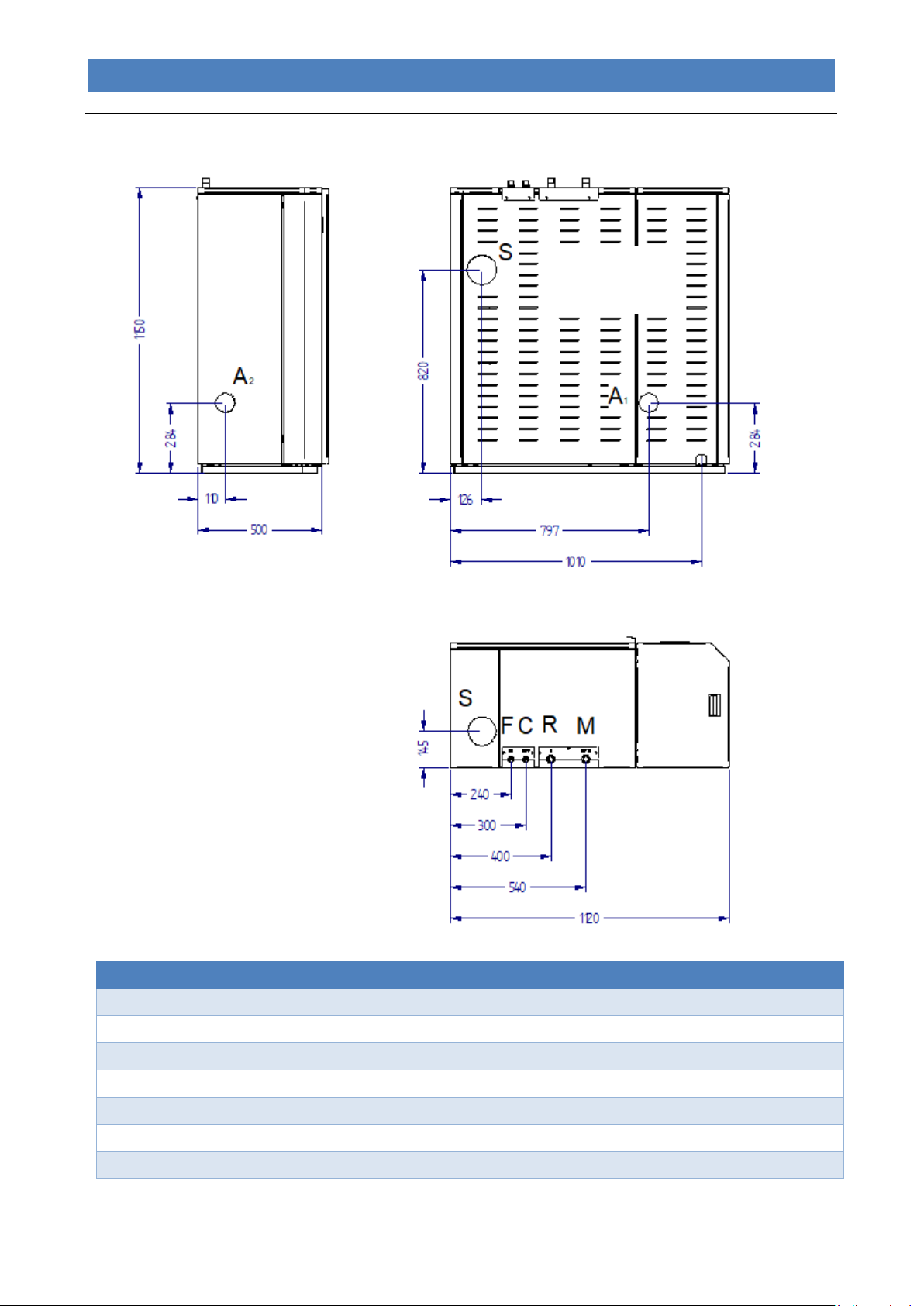

OVERALL DIMENSIONS ECOMPACT 150 - 190 ................................................................................................................. 6

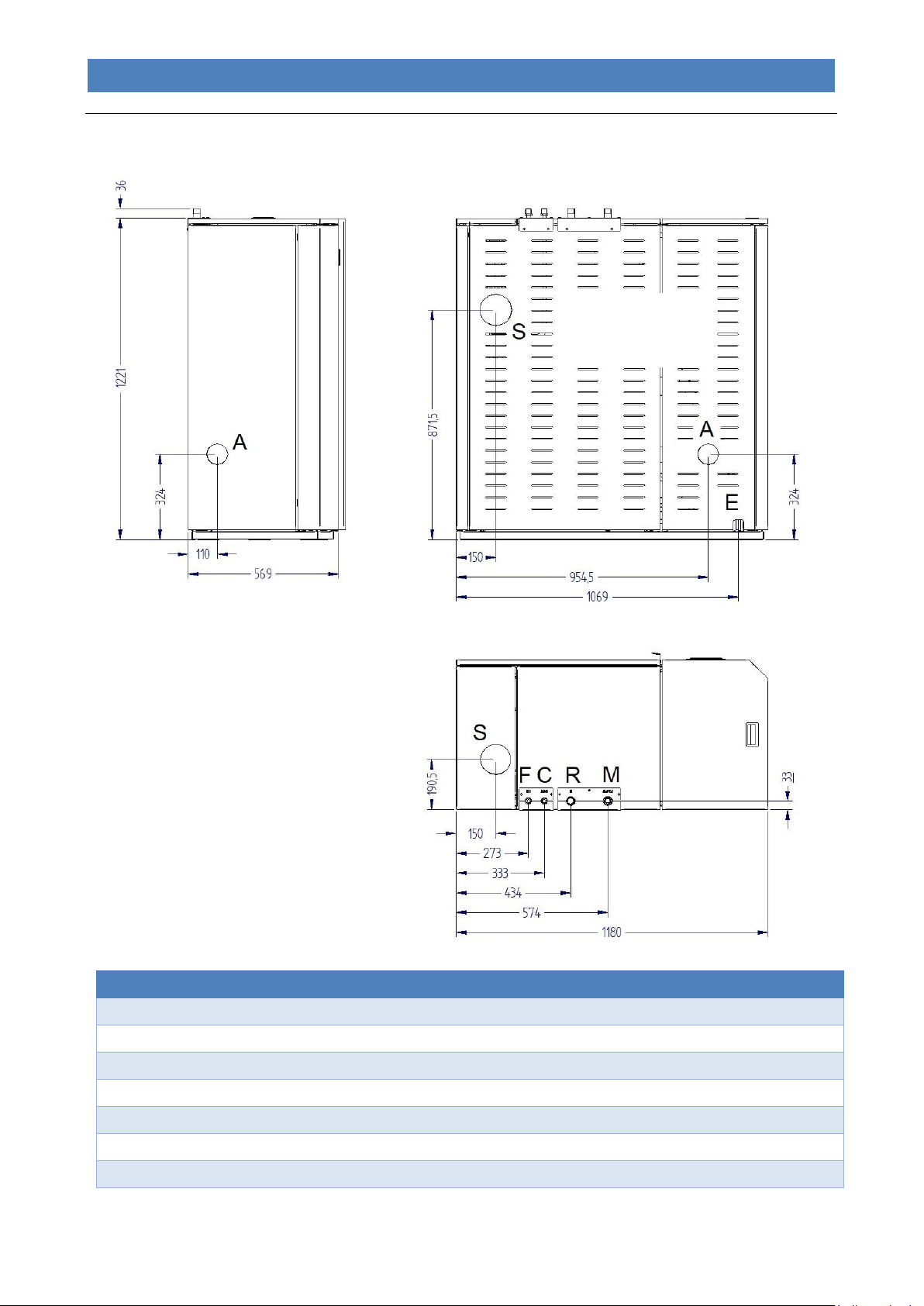

OVERALL DIMENSIONS ECOMPACT 250 - 290 ................................................................................................................. 7

CONNECTIONS DATA SHEET ECOMPACT 150 - 190 ......................................................................................................... 8

CONNECTIONS DATA SHEET ECOMPACT 250 - 290 ......................................................................................................... 9

TECHNICAL SPECIFICATIONS ECOMPACT 150 ............................................................................................................... 10

TECHNICAL SPECIFICATIONS ECOMPACT 190 ............................................................................................................... 11

TECHNICAL SPECIFICATIONS ECOMPACT 250 ............................................................................................................... 12

TECHNICAL SPECIFICATIONS ECOMPACT 290 ............................................................................................................... 13

AIRBORNE NOISE DATA ................................................................................................................................................... 14

PELLET PROPERTIES ...................................................................................................................................................... 14

REQUIREMENTS OF THE PLACE OF INSTALLATION ................................................................................................. 15

POSITIONING .................................................................................................................................................................. 15

SPACES AROUND AND ABOVE THE APPLIANCE .................................................................................................................. 15

EXTERNAL AIR INTAKE .................................................................................................................................................... 16

THE FLUE AND CONNECTION TO THE SAME ....................................................................................................................... 16

CHIMNEY ....................................................................................................................................................................... 18

ELECTRICAL CONNECTION .......................................................................................................................................... 19

CONTROL OF ANY COUPLED BOILER ................................................................................................................................ 19

CONTROL OF A POSSIBLE THREE-WAY MOTORIZED VALVE FOR DHW SYSTEM MANAGEMENT ............................................. 19

CONNECTION TO THE ROOM THERMOSTAT ....................................................................................................................... 20

HYDRAULIC CONNECTION ............................................................................................................................................ 20

THE DISPLAY .................................................................................................................................................................. 21

THE MENU ....................................................................................................................................................................... 23

INITIAL START-UP .......................................................................................................................................................... 26

SYSTEM CONFIGURATION ............................................................................................................................................... 26

FILLING THE SYSTEM FOR THE FIRST TIME........................................................................................................................ 28

PELLET LOADING AND CONNECTION TO THE MAINS POWER SUPPLY ................................................................................... 29

IGNITION CYCLE.............................................................................................................................................................. 29

SWITCH-OFF CYCLE ........................................................................................................................................................ 29

MODIFYING THE WORKING POWER .................................................................................................................................. 30

CHANGING THE WATER TEMPERATURE BOILER OR BUFFER ............................................................................................... 30

PROBLEMS, ALARMS, USEFUL ADVICES ................................................................................................................... 31

USEFUL INFO… .............................................................................................................................................................. 31

WHAT HAPPENS IF… ...................................................................................................................................................... 31

ALARM SIGNALS ............................................................................................................................................................. 32

CLEANING AND MAINTENANCE ................................................................................................................................... 33

PRECAUTIONS BEFORE CLEANING ................................................................................................................................... 33

ROUTINE CLEANING ........................................................................................................................................................ 33

NON-ROUTINE CLEANING ................................................................................................................................................ 35

CLEANING THE CERAMIC GLASS ...................................................................................................................................... 36

CLEANING THE FLUE ....................................................................................................................................................... 37

1

Page 8

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

MAINTENANCE ............................................................................................................................................................... 37

PCB PARAMETERS ........................................................................................................................................................ 38

PARAMETER TABLES ECOMPACT 150 ........................................................................................................................... 38

PARAMETER TABLES ECOMPACT 190 ........................................................................................................................... 40

PARAMETER TABLES ECOMPACT 250 ........................................................................................................................... 42

PARAMETER TABLES ECOMPACT 290 ........................................................................................................................... 44

WIRING DIAGRAM ........................................................................................................................................................... 46

STANDARD WARRANTY CONDITIONS ......................................................................................................................... 47

Dear client,

First of all we would like to thank you for choosing a “KLOVER” product and we hope you will be satisfied with this

product.

Read carefully the warranty certificate on the last page of this User guide.

We would like to thank you again for trusting KLOVER products, and we would also like inform you that these models

are the result of forty years of experience in the manufacture of solid fuel products using water as heat transfer fluid.

Every single detail of the product is manufactured by qualified staff, using the most advanced equipment.

The manual contains a detailed description of the appliance and its operation, instructions for proper installation, basic

maintenance and control points, which must be periodically performed; furthermore it contains practical advice which

helps to obtain maximum performance from the appliance with minimum fuel consumption.

Stay warm with KLOVER!

Copyright

All rights reserved. The reproduction of any part of this manual, in any form, without the explicit written permission of

KLOVER Srl. is forbidden. The content of this manual may be modified without notice. Although the documentation

contained in this manual has been carefully compiled and checked, KLOVER srl cannot be held liable for any damages

arising from the use of the same.

Copyright © 2018 KLOVER srl

2

Page 9

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

INTRODUCTION

Important safety instructions

Please read these instructions before installing and using the product.

- The installation and initial start-up of the appliance must be performed by skilled personnel trained in the relevant

safety standards. They will be responsible for the definitive installation of the appliance and its proper operation.

KLOVER srl shall not be held liable if these precautions are not observed.

- During the installation and use of the appliance, all local regulations - including those referring to national and

European Standards - must be observed.

- Connect the flue gas outlet to a flue with the specifications described in the “Flue and its connection” section of this

User guide.

- The appliance is not suitable for installation on a shared flue system.

- If the flue should catch fire, use appropriate fire extinguishing equipment or call the fire brigade.

- Connect the product to an earthed power socket. Avoid using sockets controlled by switches or automatic timers.

- Do not use the power supply cable if damaged or worn.

- If a multiple socket is used, make sure that the total voltage of the connected devices does not exceed the rated

voltage for the socket. Also make sure that the total voltage of all the devices connected to the socket does not

exceed the maximum permitted level.

- The plug on the appliance’s power cable should be connected only once the assembly and installation of the

appliance is complete. It should remain accessible after installation if the appliance is not fitted with a suitable and

accessible two-pole switch.

- Do not use flammable substances to clean the appliance or its parts.

- Do not leave flammable containers and substances in the place where the appliance is installed.

- The appliance works exclusively with wood pellets and only with the hearth door shut.

- NEVER open the door of the appliance during normal operation.

- The use of poor quality pellets or any other material can damage the appliance operation, voiding the warranty and

exempting the manufacturer from all liability.

- Do not use the appliance as an incinerator or for any use other than that for which it was designed.

- Do not use fuels other than those recommended.

- Do not use liquid fuels.

- The appliance, and its outer surfaces in particular, become very hot to the touch during operation; handle with

caution in order to avoid burns.

- Keep fuel and flammable materials at a safe distance.

- Only use original spare parts recommended by the manufacturer.

- Do not make any unauthorised modifications to the appliance.

- Do not touch the hot components of the product (ceramic glass, flue pipe) during normal operation.

- Never touch the appliance if you are barefoot and/or if you have wet or damp parts of the body.

- Use the appropriate button to switch off the electrical panel. Do not disconnect the power supply cable while the

appliance is operating.

- During the ignition phase and normal operation of the appliance, maintain the necessary safety distance and do not

remain standing in front of it.

- Keep children away from the appliance when it is running since they could get burned by touching its hot

components.

- Do not leave the packaging elements within reach of children or unassisted disabled persons.

- Children and inexperienced people must not be allowed to use the appliance.

- The appliance may be used by children no younger than 8 years of age and people with reduced physical, sensory or

mental capabilities, or those without experience of the appliance, as long as they are supervised or have received

instructions on how to use the appliance safely and understand the hazards inherent to the appliance.

- Children should not play with the appliance.

- User maintenance and cleaning operations should not be carried out by unsupervised children.

- Do not use the appliance in ways other than those indicated in this user guide.

- The appliance is designed for indoor use only.

- The appliance is designed for heating water and should therefore be connected to a plumbing system (radiators,

under-floor heaters, etc.). This system should be suitably designed and sized to distribute the power generated by

the appliance.

3

Page 10

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

Expansion tank

10 l

Safety valve

2.5 bar

Pressure gauge

0 – 4 bar

Automatic air vent valve

Yes

Heating system pump

Yes. Mod.25/70

Electrical setting for the connection of the domestic water flow switch

Yes

Electrical setting for boiler / buffer sensor

Yes

Electrical setting for the control of the optional automatic pellet loader

Yes

Remote control

Optional

- This user guide constitutes an integral part of the appliance. If the product is sold to another user, this manual must

be passed on to the new owner.

- The Klover ECOMPACT boilers are not suitable for use in UK smoke exempt areas.

KLOVER S.R.L. DECLINES ALL LIABILITY IN CASE OF ACCIDENTS DUE TO FAILURE TO COMPLY WITH THE

SPECIFICATIONS OF THIS MANUAL.

KLOVER S.R.L. DECLINES ALL LIABILITY DUE TO INCORRECT USE OF THE PRODUCT BY THE USER,

UNAUTHORISED MODIFICATION AND/OR REPAIRS, AND USE OF NON-ORIGINAL SPARE PARTS OR SPARE

PARTS NOT SPECIFICALLY DESIGNED FOR USE ON THIS PRODUCT MODEL.

KLOVER S.R.L. SHALL NOT BE HELD LIABLE FOR THE STOVE'S INSTALLATION. THE INSTALLER IS THE

SOLE PARTY RESPONSIBLE FOR THIS OPERATION AND IS ALSO ENTRUSTED WITH CHECKING THE FLUE,

EXTERNAL AIR VENT AND THE CORRECTNESS OF THE PROPOSED INSTALLATION SOLUTIONS. ALL THE

SAFETY REGULATIONS SET OUT IN THE SPECIFIC LAWS IN FORCE IN THE COUNTRY WHERE THE MACHINE

IS INSTALLED MUST BE OBSERVED.

NON-ROUTINE MAINTENANCE MUST ONLY BE PERFORMED BY AUTHORISED AND QUALIFIED STAFF.

To ensure the validity of the warranty, the user must comply with the instructions contained in this guide and, in

particular, must:

- Use the appliance within its operating limits;

- Regularly perform all maintenance activities;

- Authorise expert and competent people to use the appliance.

Failure to comply with the instructions contained in this guide shall automatically void the warranty.

THE MACHINE AND THE PELLETS

Components of the appliance

The table below shows the standard features of the appliance:

The appliance is delivered with the following equipment:

- No. 1 - user, installation and maintenance guide;

- No. 1 - power supply cable;

4

Page 11

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

Automatic air vent

valve

Main ON/OFF switch

Extractor flue gas pass

inspection

Safety thermostat

with manual reset

Pressure gauge

(indicates the

pressure of the

heating system)

High-efficiency

circulating pump for

heating system

Combustion chamber

door

Display

FRONT VIEW

LEFT FRONT TECHNICAL COMPARTMENT

Terminal for room

thermostat connection

Air intake pipe

Anti-interference filter

connection for power supply cable

with 2 built-in fuses (4A 250V).

Exapnsion vessel 10 lt with

pre-load 1 bar

Circulating pump speed

switch

5

Page 12

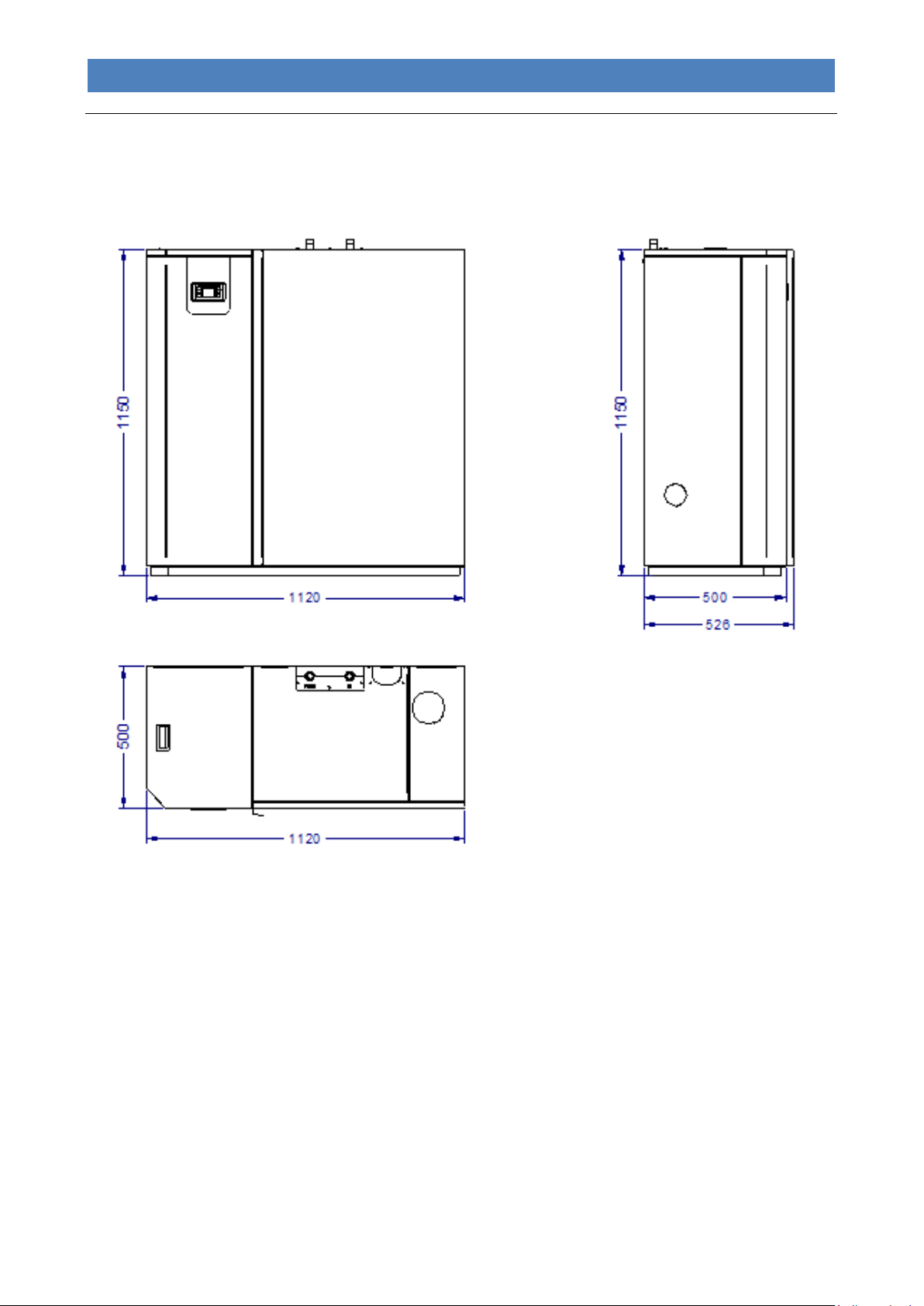

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

Overall dimensions ECOMPACT 150 - 190

EN - Rev 1.1

6

Page 13

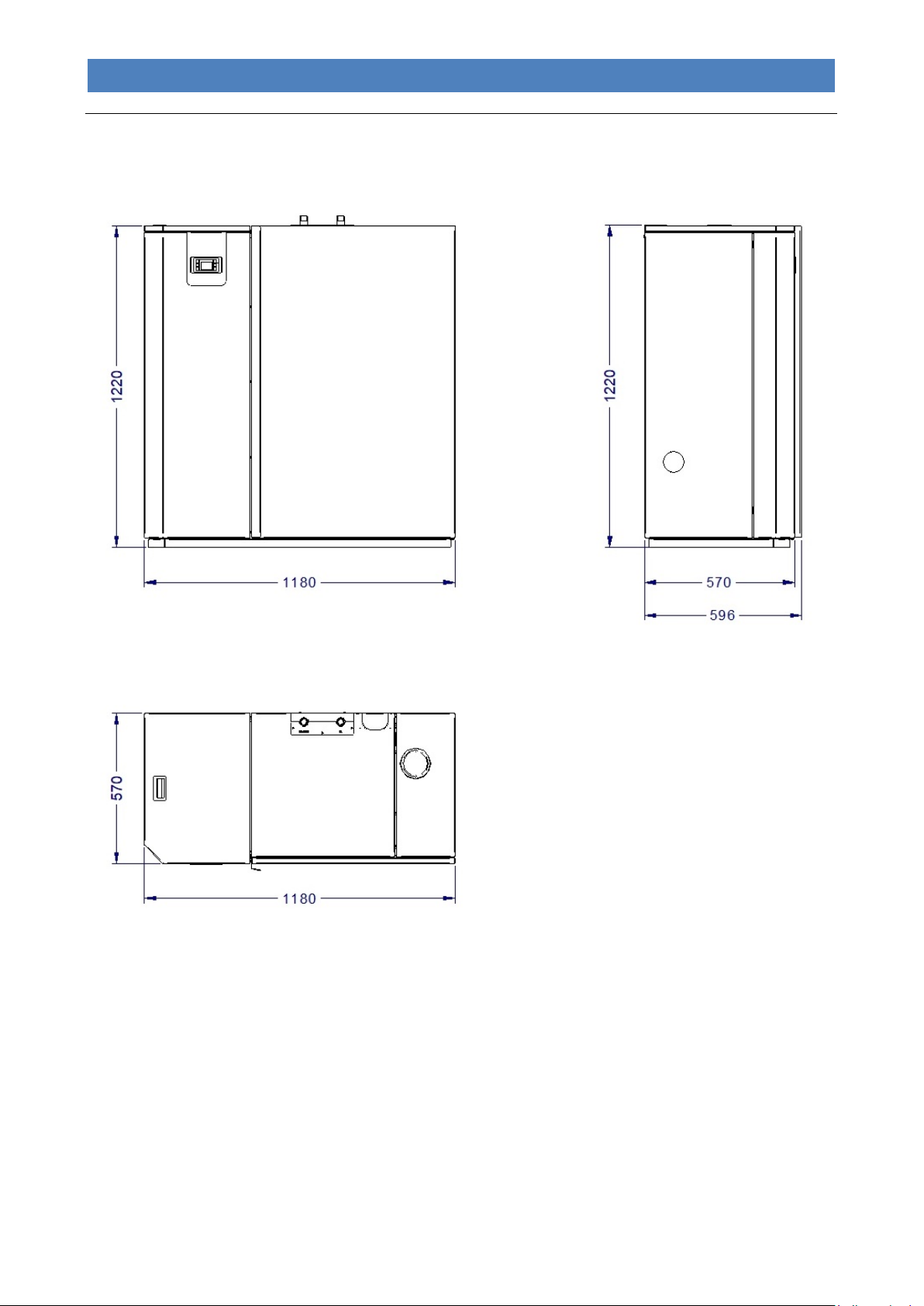

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

Overall dimensions ECOMPACT 250 - 290

EN - Rev 1.1

7

Page 14

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

Connections data sheet ECOMPACT 150 - 190

Description of connections

M = System Delivery

3/4" M

R = System Return

3/4" M

F = Domestic cold water inlet (on prepared models only)

1/2" M

C = Domestic hot water outlet (on prepared models only)

1/2" M

S = Upper or rear flue gas outlet

100 mm M

A = Rear or side fitting for connection of optional extraction pipe

40 mm

E = Electrical cable outlet

REAR VIEW

EN - Rev 1.1

8

Page 15

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

Connections data sheet ECOMPACT 250 - 290

Description of connections

M = System Delivery

3/4" M

R = System Return

3/4" M

F = Domestic cold water inlet (on prepared models only)

1/2" M

C = Domestic hot water outlet (on prepared models only)

1/2" M

S = Upper or rear flue gas outlet

100 mm M

A = Rear or side fitting for connection of optional extraction pipe

50 mm

E = Electrical cable outlet

REAR VIEW

EN - Rev 1.1

9

Page 16

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

Technical specifications ECOMPACT 150

Heat input (nominal setting)

kW (Kcal/h)

15.7 (13,500)

Heat input (reduced setting)

kW (Kcal/h)

4.5 (3,850)

Nominal thermal output

kW (Kcal/h)

14.6 (12,550)

Reduced thermal power

kW (Kcal/h)

4.2 (3,600)

Efficiency delivered to water at nominal thermal power

%

92.6

Efficiency delivered to water at reduced thermal power

%

93.3

CO at 10% oxygen at nominal thermal power

%

0.010

CO at 10% oxygen at reduced thermal power

%

0.033

Maximum power uptake

Watt

430*

Power uptake during operation at nominal thermal power

Watt

63

Power uptake during operation at reduced thermal power

Watt

35

Power uptake in stand-by

Watt

2

Nominal voltage

V

230

Nominal frequency

Hz

50

Expansion vessel litres/preloading bar

10 / 1

Maximum operating/recommended pressure

bar

2.5 / 1.5

Water side resistance at Δt= 20 K

mbar

135

Flue outlet diameter

mm

100

Air intake pipe diameter

mm

40

Minimum chimney draught at nominal thermal power

Pa

10.5

Minimum chimney draught at reduced power

Pa

6.7

Combustion gas mass at nominal thermal power

g/s

10.3

Combustion gas mass at reduced power

g/s

4.5

Pellet tank capacity

lt (kg)

92 (55)

Pellet tank filling opening dimensions

mm

330 x 260

Average exhaust flue gas temperature at nominal thermal power

°C

107.3

Average exhaust flue gas temperature at reduced power

°C

85.2

Boiler unit capacity

litres

42

Width

mm

1120

Height

mm

1150

Depth

mm

500

Minimum safety distance from flammable materials (side/rear)

mm

200 / 200

Weight

Kg

300

Boiler class as per EN303-5:2012

5

EN - Rev 1.1

* Power consumption only during the ignition cycle.

The appliance's heat output may vary depending on the type of pellets used.

10

Page 17

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

Technical specifications ECOMPACT 190

Heat input (nominal setting)

kW (Kcal/h)

19.7 (16,950)

Heat input (reduced setting)

kW (Kcal/h)

4.5 (3,850)

Nominal thermal output

kW (Kcal/h)

18.2 (15,650)

Reduced thermal power

kW (Kcal/h)

4.2 (3,600)

Efficiency delivered to water at nominal thermal power

%

92.3

Efficiency delivered to water at reduced thermal power

%

93.3

CO at 10% oxygen at nominal thermal power

%

0.010

CO at 10% oxygen at reduced thermal power

%

0.033

Maximum power uptake

Watt

430*

Power uptake during operation at nominal thermal power

Watt

63

Power uptake during operation at reduced thermal power

Watt

35

Power uptake in stand-by

Watt

2

Nominal voltage

V

230

Nominal frequency

Hz

50

Expansion vessel litres/preloading bar

10 / 1

Maximum operating/recommended pressure

bar

2.5 / 1.5

Water side resistance at Δt= 20 K

mbar

145

Flue outlet diameter

mm

100

Air intake pipe diameter

mm

40

Minimum chimney draught at nominal thermal power

Pa

10.0

Minimum chimney draught at reduced power

Pa

6.7

Combustion gas mass at nominal thermal power

g/s

12.3

Combustion gas mass at reduced power

g/s

4.5

Pellet tank capacity

lt (kg)

92 (55)

Pellet tank filling opening dimensions

mm

330 x 260

Average exhaust flue gas temperature at nominal thermal power

°C

114.0

Average exhaust flue gas temperature at reduced power

°C

85.2

Boiler unit capacity

litres

42

Width

mm

1120

Height

mm

1150

Depth

mm

500

Minimum safety distance from flammable materials (side/rear)

mm

200 / 200

Weight

Kg

300

Boiler class as per EN303-5:2012

5

EN - Rev 1.1

* Power consumption only during the ignition cycle.

The appliance's heat output may vary depending on the type of pellets used.

11

Page 18

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

Technical specifications ECOMPACT 250

Heat input (nominal setting)

kW (Kcal/h)

25.8 (22,100)

Heat input (reduced setting)

kW (Kcal/h)

7.5 (6,450)

Nominal thermal output

kW (Kcal/h)

23.3 (20,050)

Reduced thermal power

kW (Kcal/h)

6.5 (5,600)

Combustion efficiency at nominal thermal power

%

95.3

Efficiency delivered to water at nominal thermal power

%

90.3

Combustion efficiency at reduced thermal power

%

93.3

Efficiency delivered to water at reduced thermal power

%

87.9

CO at 10% oxygen at nominal thermal power

%

0.004

CO at 10% oxygen at reduced thermal power

%

0.022

Maximum power uptake

Watt

430*

Power uptake during operation at nominal thermal power

Watt

87

Power uptake during operation at reduced thermal power

Watt

54

Power uptake in stand-by

Watt

3.2

Nominal voltage

V

230

Nominal frequency

Hz

50

Expansion vessel litres/preloading bar

10 / 1

Maximum operating/recommended pressure

bar

2.5 / 1.5

Water side resistance at Δt= 20 K

mbar

184

Flue outlet diameter

mm

100

Air intake pipe diameter

mm

60

Minimum chimney draught at nominal thermal power

Pa

12.6

Minimum chimney draught at reduced power

Pa

10.6

Combustion gas mass at nominal thermal power

g/s

12.7

Combustion gas mass at reduced power

g/s

6.0

Pellet tank capacity

lt (kg)

120 (75)

Pellet tank filling opening dimensions

mm

400 x 290

Average exhaust flue gas temperature at nominal thermal power

°C

95.7

Average exhaust flue gas temperature at reduced power

°C

65.4

Boiler unit capacity

litres

52

Width

mm

1180

Height

mm

1220

Depth

mm

570

Minimum safety distance from flammable materials (side/rear)

mm

200 / 200

Weight

Kg

380

Boiler class as per EN303-5:2012

5

EN - Rev 1.1

* Power consumption only during the ignition cycle.

The appliance's heat output may vary depending on the type of pellets used.

12

Page 19

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

Technical specifications ECOMPACT 290

Heat input (nominal setting)

kW (Kcal/h)

29.7 (25,550)

Heat input (reduced setting)

kW (Kcal/h)

7.3 (6,300)

Nominal thermal output

kW (Kcal/h)

26.8 (23,050)

Reduced thermal power

kW (Kcal/h)

6.6 (5,700)

Combustion efficiency at nominal thermal power

%

95.1

Efficiency delivered to water at nominal thermal power

%

90.1

Combustion efficiency at reduced thermal power

%

94.3

Efficiency delivered to water at reduced thermal power

%

89.7

CO at 10% oxygen at nominal thermal power

%

0.002

CO at 10% oxygen at reduced thermal power

%

0.028

Maximum power uptake

Watt

430*

Power uptake during operation at nominal thermal power

Watt

87

Power uptake during operation at reduced thermal power

Watt

54

Power uptake in stand-by

Watt

3.2

Nominal voltage

V

230

Nominal frequency

Hz

50

Expansion vessel litres/preloading bar

10 / 1

Maximum operating/recommended pressure

bar

2.5 / 1.5

Water side resistance at Δt= 20 K

mbar

211

Flue outlet diameter

mm

100

Air intake pipe diameter

mm

60

Minimum chimney draught at nominal thermal power

Pa

11.7

Minimum chimney draught at reduced power

Pa

9.8

Combustion gas mass at nominal thermal power

g/s

15.8

Combustion gas mass at reduced power

g/s

5.5

Pellet tank capacity

lt (kg)

120 (75)

Pellet tank filling opening dimensions

mm

400 x 290

Average exhaust flue gas temperature at nominal thermal power

°C

112.3

Average exhaust flue gas temperature at reduced power

°C

65.3

Boiler unit capacity

litres

52

Width

mm

1180

Height

mm

1220

Depth

mm

570

Minimum safety distance from flammable materials (side/rear)

mm

200 / 200

Weight

Kg

380

Boiler class as per EN303-5:2012

5

EN - Rev 1.1

* Power consumption only during the ignition cycle.

The appliance's heat output may vary depending on the type of pellets used.

13

Page 20

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

UNIT

MEASUREMENT

UNIT IN CONTINUOUS OPERATION

Extract fan (Power level 1)

35

Extract fan (Power level 5)

43

Extract fan (Cleaning cycle)

49

UNITS IN NON-CONTINUOUS OPERATION

Auger screw motor

42

Turbulator cleaning motor

43

Circulating pump

38

Airborne noise data

The sound levels in the following table are basaed on the sound measurement of an Ecompact 250.

The sound level of the individual units was pltted at the distance of 1m from the sound source.

Ambient level measurement: 33 dB.

Please note that all of the measurements were taken in-house and do not come from a certified test centre.

This data should therefore be viewed as guidance only.

Pellet properties

The appliance has been tested with all types of pellets available on the market. The pellets must have the following

properties:

- Diameter 6 mm.

- Maximum length 35 mm.

- Maximum humidity content 8 – 9 %.

- 100% wood. Totally additive-free.

- Maximum ash residue 1.1 %.

To obtain good performance from the appliance, we recommend using good quality pellets. Pellets should be poured

into the tank using a shovel, and not directly from the bag.

Good quality pellets should have the following properties:

- Constant diameter cylinders with a smooth, shiny surface;

- There should not be a lot of sawdust inside the packaging;

- After grabbing a bunch of pellets and placing them into a container filled with water, good-quality pellets will sink and

poor-quality ones will tend to float;

- The quality certification data, in particular conformity to international standards such as EN14961-2, DIN 51731 and

O-NORM M7135, should be indicated on the packaging;

- The packages should be intact since pellets tend to absorb humidity. Humidity not only reduces the calorific value

and increases the amount of flue gases expelled, but also causes swelling of the product which may create problems

with the appliance.

The production of pellets must be compliant with some international standards (such as EN14961-2, DIN 51731 and ONORM M7135) which establish minimum values for quality checks on pellets. To facilitate the right choice of the

combustible material you can find below one of the most common certification marks identifying the quality of the pellets:

14

Page 21

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

Indication of the standard,

base reference for the quality

classes ENplus

Indication of the quality

class of the certified pellet

(preferably A1)

IT xxx

Code of the certified company

consisting of two elements:

- Symbol of the country of

production (example “IT”)

- Progressive number assigned at

the acquisition of the

certification (example "xxx")

The use of poor quality pellets or any other material can damage the appliance operation, voiding the warranty

and exempting the manufacturer from all liability.

In order to guarantee trouble-free combustion, the pellets must be stored in a dry place.

REQUIREMENTS OF THE PLACE OF INSTALLATION

Positioning

The initial phase for best installation of the appliance is to determine its optimum location; the following elements need to

be considered:

- The possibility of creating an external air vent;

- The possibility of creating a straight flue, preferably coaxial to the outlet of the appliance;

- Proximity to the main water drain and/or the boiler (if one already exists);

- Proximity or ease of connection to the water system;

- Ease of access for cleaning the appliance, the flue gas exhaust pipes and the flue.

The unit must be installed on a floor with a suitable load capacity. If the existing building does not fulfil this requirement

appropriate measures (e.g. load distribution plate) must be taken.

The minimum safety distance from flammable materials must be at least 200 mm from the sides and 100 mm

from the back of the appliance.

The installation must guarantee easy access for cleaning the appliance, the flue gas exhaust pipes and the flue, and any

subsequent maintenance operation by the Authorised technical assistance centre.

Once you have found the best location for the appliance, position it following the instructions given below.

The appliance must not be installed in small rooms, bedrooms, bathrooms or in areas with an explosive atmosphere.

Spaces around and above the appliance

The figure below shows the minimum distances from walls or other not-easily-removable furniture, that need to be taken

into consideration when positioning the appliance.

15

Page 22

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

30 cm

15 cm

Any shelves or false ceilings mounted above the appliance must be at least 50 cm away from the top part of it.

Furniture and movable objects made from flammable materials must be positioned at least 20 cm from the side surfaces

of the appliance; these objects must be moved when performing maintenance on the appliance.

Protect all structures that can catch fire against the radiated heat of the fire.

Any extra intervention by the Authorised technical assistance centre, which requires the appliance to be

disconnected from the system, will not be covered under warranty as described in the chapter “Standard

Warranty Conditions”.

External air intake

During operation, the appliance takes in air from the environment in which it is installed; It is therefore essential that this

air is replaced through an external air vent. The absence of the air vent may affect the flue draught and therefore the

combustion and the safety of the appliance.

Therefore it is mandatory to install an external air vent with a minimum completely free passage of at least 80 cm2

(round hole with minimum diameter of 15 cm protected with a special fixed large mesh grille).

If it not possible to put the external air vent in the same room as where the appliance is installed, this hole can be made

in an adjoining room as long as this room communicates permanently, by means of a transit hole (15 cm minimum

diameter).

The hole must be protected externally with a fixed grille. The protective grille must be checked periodically to ensure that

it is not obstructed, thereby impeding the passage of air. Therefore keep the air vents clear of obstructions.

The Standard FORBIDS the drawing of combustion air from garages, warehouses storing combustible materials, or from

business premises with a fire hazard.

If there are other heating or extraction devices inside the room, the air vents must guarantee a sufficient amount of air for

properly operating all the devices.

Only sealed appliances (e.g. C type gas appliances, according to the Standard) or appliances that do not cause a lower

pressure compared with the external environment can pre-exist or be installed in the place where the appliance is

installed.

Extractor fans can cause malfunctions to the appliance if used in the same room.

Chimney and Flue pipe

The chimney is essential to the efficient operation of a Klover appliance. The chimney should be constructed according

to these instructions, the relevant BS EN regulations and Building Regulations Approved Document J.

Shape and size of chimney: A round chimney of 125mm diameter is recommended. 125mm is also the minimum

diameter which should be used. If the appliance is DEFRA Exempt then it should be connected to a 125mm chimney as

standard (assuming that the outlet is not larger than 125mm). If it is not DEFRA Exempt then a calculation according to

BS EN 13384-1:2002 must be completed if it is to be connected to a 125mm diameter chimney.

The maximum recommended round chimney diameter is 150mm.

16

Page 23

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

Square or rectangular cross-sections must have rounded corners with radius not less than to 20 mm Rectangular crosssections must have a maximum ratio of 1.5 between the sides.

The chimney must have a constant, and unobstructed, internal cross section

Under no circumstances should the chimney be of a smaller diameter than the appliance outlet.

Connecting flue pipe: Short runs of single skin flue pipe to connect to the chimney may be run in a (minimum) diameter

of 100mm (as long as this is not smaller than the appliance outlet). An analysis port should be incorporated to enable,

flue gas analysis, draught measurement and commissioning.

Existing chimneys: Existing masonry chimneys should be lined with flexible stainless steel liner and the liner should be

insulated. All connections must be appropriately sealed.

Existing chimneys must be inspected, be clear of obstruction and have been swept clean immediately before installation

of the lining system.

No shared chimneys: Each appliance must connect to its own flue. No other appliance must connect to the same flue or

chimney. No other pipes or conduits must pass through the chimney or flue.

Sealed joins and connections: The appliance works with the combustion chamber in negative pressure and the flue pipe

under positive pressure; it is essential that all joints and flue and chimney connections are sealed. Single skin and twin

wall flue pipe should incorporate silicone seals at each joint. Other connections should be sealed with a suitable sealant

(for example high temperature silicone). All seals must be able to withstand 250ºC or more.

Suitable materials: Flue and chimney products used, including fixings and components, must be made of suitable, noncombustible materials conforming to the applicable regulations.

Aluminium and fibre cement pipes are forbidden.

Orientation and initial vertical rise: The flue system should run as vertically as possible as any deviations off the vertical

can adversely affect the draw. 45º is the maximum off-vertical angle than may be used. Non-vertical sections should

make up no more than ¼ of the effective height of the flue or chimney (measured from the appliance outlet to the top of

the chimney), and must not be longer than 2,000 mm.

There should be no more than 4 bends in the system, with a tee counting as 2 bends.

Securely fix and support the system to avoid vibration and movement.

90º bends should not be used. When using the rear outlet on the appliance a 90º tee should be used with sweeping

access and debris collection space.

When using the rear outlet any horizontal run should not exceed 150mm, including the arm of the tee.

An initial vertical run of 600mm from the appliance is recommended before any change in direction.

Cleaning Access: The system must provide access so that the entire system can be swept and cleaned.

Flue pipes must not pass through rooms in which the installation of combustion devices is prohibited.

IT IS STRICTLY FORBIDDEN TO INSTALL FLUE DAMPERS/BUTTERFLY VALVES.

Heat shielding: If combustible materials are present then minimum separation distances will need to be adhered or heat

shielding will be required. Please refer to Building Regulations Approved Document J, and also these installation

instructions.

Termination/Cowl: The cowl terminates the chimney and it is recommended that an effective anti-downdraft cowl should

always be used. It must have a usable outlet cross-section no less than double that of the flue onto which it is inserted.

In must prevent rainwater or snow entry. It must be ensure the discharge of combustion by-products even in the event of

winds from every direction and inclination.

17

Page 24

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

Height and draught: In order for the appliance to perform satisfactorily the chimney height must be sufficient to ensure a

draught of 12 Pa so as to clear the products of combustion and prevent smoke problems into the room.

A chimney height of not less than 4.5 m measured vertically from the outlet of the stove to the top of the chimney

should be satisfactory. Alternatively the calculation procedure given in BS EN 13384-1:2002 may be used as the basis

for deciding whether a particular chimney design will provide sufficient draught.

The outlet from the chimney should be above the roof of the building in accordance with the provisions of Building

Regulations Approved Document J diagram 17 or 18. Please see the diagram below.

18

Page 25

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

CN16

ELECTRICAL CONNECTION

The electric connection must only be performed by qualified staff, in compliance with all general and local safety

standards.

Check that the power supply voltage and frequency correspond to 230V – 50 Hz.

The appliance's safety is ensured when it is properly connected to an efficient earthing system.

In the electric connection to the mains power supply, include a 6 A – Id 30 mA differential trip-switch with suitable

breaking load. The electric connections, including the earth connection, must be made after shutting off the electrical

system.

When completing the system, bear in mind that the cables must be laid in an unmovable manner and far from parts

subject to high temperatures. During the final wiring of the circuit, only use components with a suitable electrical

protection rating. Do not pass electric cables in the immediate vicinity of the flue gas pipe, unless they are insulated with

suitable materials.

KLOVER srl declines all responsibility for injury to persons and animals or damage to objects due to failure to

connect the appliance to earth or to comply with IEC specifications.

Control of any coupled boiler

If the pellet appliance is to be coupled with a previously installed boiler in the system (e.g. wall-hung gas boiler), you

must ensure that the standard boiler stops when the pellet appliance takes over the heating of the system. The electrical

setting, which is accessible from the left-hand technical compartment, intervenes on the standard boiler when the

heating circulating pump of the pellet appliance starts up so as to avoid having two boilers operating simultaneously on

the same system. The coupled boiler is however always available for the production of domestic hot water.

The two wires fitted on the left-hand technical compartment of the appliance (blue and brown wires) will have an

output voltage of 230 V when the pellet appliance pump is working, and no voltage when the pump stops.

It is therefore necessary to connect the 2 wires to a relay that will control the Room Thermostat (R.T.) input of the

coupled boiler (see the following example).

Control of a possible three-way motorized valve for DHW system management

The pellet appliance is equipped as standard with a control for a possible 3-way motorised valve to be installed on the

domestic water circuit based on the selected system type (see “System configuration”). In the left-hand technical

compartment of the appliance there are four wires with fastons protected by a red seal, which can be used for controlling

the valve (see also “wiring diagram”). The four wires have different colours, and precisely:

- Blue wire = 3-WAY VALVE COMMON (Neutral 230 V)

- Black wire = SANITARY SIDE (Phase 230 V with DHW demand)

- Black wire = HEATING SIDE (Phase 230 V with no DHW demand)

- Yellow/green wire = GND

19

Page 26

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

Connection to the room thermostat

On the left-hand technical compartment of the appliance there is a bridged terminal which is used to connect the room

thermostat that will command the operation. The operation of the room thermostat is enabled with system types 1, 2 and

3 (see“System configuration”).

OPERATING PRINCIPLE

Open contact:

- The appliance switches directly to economy mode operation “T-AMB ECONOMY”

thus minimising its operating power.

- The heating circulating pump of the appliance switches off.

- The temperature in the boiler increases due to thermal inertia until it reaches the

temperature set with “SET H2O” and displays “T-H2O ECONOMY” on its monitor.

- The appliance now switches itself off automatically if at least one of the following

conditions occurs:

- If it remains in Economy mode Operation “T-H2O ECONOMY” for a time set

on Pr44 (20 minutes as default setting).

- If it exceeds the temperature differential set on Pr43 (set as default at 5°C),

in other words if Temperature H2O > (“SET H2O” + Pr43).

- The appliance will switch on again automatically if both of the following conditions

occur:

- The contact of the room thermostat closes.

- If it goes below the temperature differential of the “SET H2O”.

If the above condition occurs during the switch-off cycle, please wait until the cycle is complete.

N.B.: If the water temperature exceeds the set threshold of 80°C (safety temperature), the circulating pump of the

system is forcedly switched-on to ensure the disposal of excessive heat, thus avoiding high water temperatures in the

boiler. For this reason it is recommended that the heating system is not entirely closed.

In the configuration “System type 3”, the appliance switches to economy mode and then switches off only if the “SET

BOILER” temperature setting has been reached.

ATTENTION: In the event that the room sensor in the “Remote control” for the appliance is enabled, the appliance

switches to economy mode if the “SET ROOM” temperature setting has also been reached.

HYDRAULIC CONNECTION

The plumbing connections must be made in a rational way using the connections on the template of the appliance. To

facilitate connection of the pipes, all plumbing attachments have been fitted to the upper part of the appliance.

The appliance can be coupled with any other boiler already installed on the system. In this case it is essential to fit all the

necessary safety devices and shut-off valves based on the system and intended use. It is also necessary to consider all

laws and national, regional, provincial and municipal regulations of the country where the appliance is installed.

The appliance can be installed with the expansion vessel closed because it is equipped with a device for stopping fuel

loading, a safety manual reset thermostat and an audible alarm, which are activated if the temperature becomes too

high.

You can install the appliance in the same room as another boiler only if this has a sealed chamber; installation

must be performed in compliance with the current regulations.

When installing the appliance, it is advisable to fit an anti-condensation mixer valve between the delivery and

return pipes on the appliance’s heating system. The anti-condensation valve should be calibrated to 55°C with a

Kv value equal to or greater than 8 m3/h.

20

Page 27

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

Set

1

2

3

6

5

4

Set

1

2

3

6

5

4

DIALOGUE

REAL WORK POWER

(It is shown flashing only when it is different

from the one actually set)

17:19

t.H2O 60°C

WORK 3

2

CLOCK

TEMPERATURE REFERENCE

t.H2O = water temperature in boiler

t.BoL = boiler DHW storage tank

temperature

t.PUF = centralised buffer temperature

t.AMb = room temperature

TEMPERATURE

2nd LED SERIES

1st LED SERIES

When connecting the appliance to the system, you should provide a zone that is always open (such as

bathroom area) to enable the excess heat dissipation of the water in the body of the boiler.

The maximum mains water pressure should never exceed 2.5 bar; recommended operating pressure is 1.5 bar

(with the appliance in operation).

In the event of water with hardness exceeding 28 °f, an anti-limescale device must be installed. This must be

selected on the basis of the specific properties of the water.

TO AVOID COMPROMISING THE OPERATION AND LIFE OF THE HEAT PUMP, INSTALLATION OF A FILTER

AND A MAGNETIC DIRT SEPARATOR IS RECOMMENDED DOWNSTREAM OF THE RETURN PIPE ON THE

APPLIANCE.

The appliance must be mounted exclusively by qualified personnel. Scrupulously comply with the instructions given

in this guide.

The manufacturer declines any liability for damages caused due to incorrect assembly.

THE DISPLAY

The appliance's operating mode is displayed on the console. After turning on the menu, it is possible to choose from

many types of display and available settings according to the selected menu.

The figures below show the display when the appliance is in ON mode.

21

Page 28

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

!

Set

1

2

3

6

5

4

ROOM THERMOSTAT: the LED is on when the thermostat contact is open.

PROGRAMMABLE THERMOSTAT: the LED lights up when at least one start-up and switch-off program is active.

IGNITION PLUG: the LED is on when the ignition plug is active.

SCREW FEED: the LED lights up when the pellet loading gear motor is started.

FLUE GAS EXTRACTOR: the LED lights up when the flue gas extractor is active.

DHW DEMAND: the LED lights up when the DHW flow switch contact is closed (which means there is demand for

hot water) or the DHW storage boiler or buffer (where fitted) is in demand.

PUMP: the LED lights up when the system circulation pump is active.

ALARM: the LED lights up when the boiler is in a state of alarm.

1 2 3 4 5 6 7

On

M - 3 - 2 - 01

TIMER

DAY

DIALOGUE

MENU LEVEL

INPUT

The following figure describes the meanings of the status signals appearing on the left side of the display (1st LED

SERIES).

The meanings of the status signals appearing on the top right side of the display are described below (2nd LED

SERIES).

- LED 1: the LED lights up when the daily programme of the on off settings is active.

- LED 2: the LED lights up when the weekly programme of the on off settings is active.

- LED 3: the LED lights up when the weekend programme of the on off settings is active.

- LED 4: the LED lights up (flashing) when the operation parameters are being edited.

- LED 5: the LED lights up when the summer function is active.

- LED 6: the LED lights up when the winter function is active.

- LED 7: the LED is not currently used.

The following diagram shows the display when setting or programming operating parameters.

The INPUT area shows the entered programming values.

The MENU LEVEL area shows the current parameter/menu level.

The DIALOGUE area displays the meaning of the current parameter/menu.

22

Page 29

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

The table explains how the buttons on the display work.

KEY

DESCRIPTION

MODE

ACTION

1

Increase

temperature (1)

Programming mode..

Changes/increases the value of the selected menu item.

Working/off..

It increases the temperature of the room/water thermostat.

2

Decrease

temperature (2)

Programming mode..

Changes/decreases the value of the selected menu item.

Working/off..

It decreases the temperature of the room/water thermostat.

3

Set

-

Enters the menu in question.

Menu mode..

Accesses the next level of sub-menus.

4

ON/OFF

Outlet

Working..

Switches the appliance on and/or off when pressed for 2 seconds.

In alarm block..

Releases the alarm.

Menu/programming mode..

Moves you to the previous menu level, saving the changes made.

5

Decrease

power (3)

Working/off..

Decreases the working/fan power of the appliance.

Menu mode..

Moves you to the next menu item.

Programming mode..

Moves you to the next submenu item, storing the changes made.

6

Increase

power (3)

Working/off..

Increases the working/fan power of the appliance.

Menu mode..

Moves you to the previous menu item.

Programming mode..

Moves you to the previous submenu item, storing the changes made.

EN - Rev 1.1

(1) The first press selects “Set temperature for boiler water - SET H2O” or “Set DHW boiler temperature - SET BOILER”

or “Set centralised buffer temperature - SET BUFFER” based on the system configuration type.

(2) It selects “Set temperature for boiler water - SET H2O” when first pressed.

(3) It selects the operating power “SET POWER” when first pressed.

THE MENU

Access the Menu by pressing key 3 (Set).

The menu is divided into different items and levels, providing access to the programming and settings options of the

appliance.

Buttons 5 and 6 allow you to select the menus to be modified.

Buttons 1 and 2 allow you to change the set value in the selected menu.

Listed below are the menus present on the PCB, with the relevant explanations.

Menu 01 – Choose season

Allows you to set the season for appliance use (SUMMER / WINTER). Can only be used with plumbing system 3 (see

“System configuration”).

Menu 02 – Set clock

Allows for setting the current date and time.

23

Page 30

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

MENU LEVEL

SELECTION

MEANING

POSSIBLE VALUES

03 – 01 – 01

ACTIVATE TIMER

Enable/disable set programs

ON – OFF

MENU LEVEL

SELECTION

MEANING

POSSIBLE VALUES

03 – 02 – 01

DAILY TIMER

Enable/disable the daily programme

ON – OFF

03 – 02 – 02

START 1st DAY

Turn-on time of the first programme

Time – OFF

03 – 02 – 03

STOP 1st DAY

Turn-off time of the first programme

Time – OFF

03 – 02 – 04

START 2nd DAY

Turn-on time of the second programme

Time – OFF

03 – 02 – 05

STOP 2nd DAY

Turn-off time of the second programme

Time – OFF

MENU LEVEL

SELECTION

MEANING

POSSIBLE VALUES

03 – 03 – 01

WEEK TIMER

Enable/disable the weekly programme

ON – OFF

PROGRAMME 1

MENU LEVEL

SELECTION

MEANING

POSSIBLE VALUES

03 – 03 – 02

START PROG 1

Turn-on time of the first programme

Time – OFF

03 – 03 – 03

STOP PROG 1

Turn-off time of the first programme

Time – OFF

03 – 03 – 04

MONDAY PROG 1

Reference days of the first programme

On/off

03 – 03 – 05

TUESDAY PROG 1

On/off

03 – 03 – 06

WEDNESDAY PROG 1

On/off

03 – 03 – 07

THURSDAY PROG 1

On/off

03 – 03 – 08

FRIDAY PROG 1

On/off

03 – 03 – 09

SATURDAY PROG 1

On/off

03 – 03 – 10

SUNDAY PROG 1

On/off

PROGRAMME 2

MENU LEVEL

SELECTION

MEANING

POSSIBLE VALUES

03 – 03 – 11

START PROG 2

Turn-on time of the second programme

Time – OFF

03 – 03 – 12

STOP PROG 2

Turn-off time of the second programme

Time – OFF

03 – 03 – 13

MONDAY PROG 2

Reference days of the second programme

On/off

03 – 03 – 14

TUESDAY PROG 2

On/off

03 – 03 – 15

WEDNESDAY PROG 2

On/off

03 – 03 – 16

THURSDAY PROG 2

On/off

03 – 03 – 17

FRIDAY PROG 2

On/off

03 – 03 – 18

SATURDAY PROG 2

On/off

03 – 03 – 19

SUNDAY PROG 2

On/off

Menu 03 – Set timer

Sub-menu 03 – 01 – enable timer

Allows you to globally enable and disable all programmable thermostat functions. For the correct operation it is

recommended to enable it (“ON”) when at least one on/off programme (daily, weekly or weekend programme) is

activated.

Submenu 03 – 02 – daily program

Allows you to enable, disable and set the programmable thermostat daily programme functions.

Two operating time slots can be set according to the following table, where OFF signals the clock to ignore the

command:

Sub-menu 03 – 03 – weekly program

Allows you to enable, disable and set the programmable thermostat weekly program functions.

The weekly programmer has 4 independent on/off programmes; it is not essential to use all four simultaneously.

By setting OFF in the time field, the clock ignores the corresponding command.

24

Page 31

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

PROGRAMME 3

MENU LEVEL

SELECTION

MEANING

POSSIBLE VALUES

03 – 03 – 20

START PROG 3

Turn-on time of the third programme

Time – OFF

03 – 03 – 21

STOP PROG 3

Turn-off time of the third programme

Time – OFF

03 – 03 – 22

MONDAY PROG 3

Reference days of the third programme

On/off

03 – 03 – 23

TUESDAY PROG 3

On/off

03 – 03 – 24

WEDNESDAY PROG 3

On/off

03 – 03 – 25

THURSDAY PROG 3

On/off

03 – 03 – 26

FRIDAY PROG 3

On/off

03 – 03 – 27

SATURDAY PROG 3

On/off

03 – 03 – 28

SUNDAY PROG 3

On/off

PROGRAMME 4

MENU LEVEL

SELECTION

MEANING

POSSIBLE VALUES

03 – 03 – 29

START PROG 4

Turn-on time of the fourth programme

Time – OFF

03 – 03 – 30

STOP PROG 4

Turn-off time of the fourth programme

Time – OFF

03 – 03 – 31

MONDAY PROG 4

Reference days of the fourth programme

On/off

03 – 03 – 32

TUESDAY PROG 4

On/off

03 – 03 – 33

WEDNESDAY PROG 4

On/off

03 – 03 – 34

THURSDAY PROG 4

On/off

03 – 03 – 35

FRIDAY PROG 4

On/off

03 – 03 – 36

SATURDAY PROG 4

On/off

03 – 03 – 37

SUNDAY PROG 4

On/off

MENU LEVEL

SELECTION

MEANING

POSSIBLE VALUES

03 – 04 – 01

WEEKEND TIMER

Enable/disable the weekend programme

ON – OFF

03 – 04 – 02

START 1st WEEKEND

Turn-on time of the first programme

Time – OFF

03 – 04 – 03

STOP 1st WEEKEND

Turn-off time of the first programme

Time – OFF

03 – 04 – 04

START 2nd WEEKEND

Turn-on time of the second programme

Time – OFF

03 – 04 – 05

STOP 2nd WEEKEND

Turn-off time of the second programme

Time – OFF

TIP: in order to avoid confusion and any undesired switching on/off operations, only activate a single programme at a time (daily,

weekly or weekend programme).

Deactivate the daily program if you wish to use the weekly program instead. If you use the weekly program in programs 1, 2, 3

and 4, always keep the week-end program disabled.

Only enable week-end programming after disabling the weekly program.

Sub-menu 03 – 04 – week-end program

Enables/disables/sets the programmable timer's weekend functions (Saturday and Sunday).

Menu 04 – Choose language

Allows you to select the dialogue language from the available choices (Italian, English, French, German and Spanish).

Menu 05 – Acoustic alarm

Allows you to enable or disable the acoustic signal in the event of an alarm. The alarm signal is only available on the

appliance board, and not on the external “Remote control”.

Menu 06 – Initial load

Enables pellet pre-loading for 180” when the appliance is switched off and cooled down. Start the function with button 1

and stop with button 4. This may be useful if the appliance is switched on after the tank has been completely emptied, or

25

Page 32

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

T.A.

AB B

A

when it is filled for the first time. Warning: once the operation has been completed, before switching on the

appliance you should empty the accumulation of pellets deposited inside the brazier.

Menu 07 – Fireplace status

It allows for viewing the instantaneous state of the appliance, by showing the state of the various devices connected to it.

Several pages are displayed in succession. The data is reserved for Technical assistance Centre.

Menu 08 – Technical calibration

Allows you to access all data reserved for the Technical Assistance Centre. Access is protected by a password.

Unauthorised access can cause serious damage to the equipment, to things and the environment as well as personal

injuries.

Menu 09 – System type

Allows you to configure the appliance according to the type of system is has been connected to (see “System

configuration”).

INITIAL START-UP

System configuration

Before commissioning the appliance it is advisable to choose which type of system it has been connected to, by

accessing “Menu 06 – System type”.

The available configurations are given here below:

PLUMBING LAYOUT “1” – Boiler connected to a heating system and (potentially) an external plate heat exchanger for

the generation of DHW.

Plumbing layout 1 involves the connection of the boiler to a heating system (or centralised buffer) managed by one or

more room thermostats. These are connected to the terminal provided inside the left technical compartment on the

appliance. DHW generation, where required, will be achieved using a plate heat exchanger fitted externally to the boiler

and controlled by a flow-switch. This is also connected to a terminal provided on the boiler. This serves to bring the

appliance immediately to DHW output working mode and to switch a three-way motorised valve to give it priority.

26

Page 33

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

PLUMBING LAYOUT “2” – Boiler with built-in instant DHW, connected to a heating system with an additional DHW

generator.

Plumbing layout 2 involves the connection of the boiler with built-in instant DHW (prepared models only) to a heating

system managed by one or more room thermostats. These are connected to the terminal provided inside the left

technical compartment on the appliance. DHW generation is achieved via a mini storage tank built-into the appliance. It

is recommended to fit an alternative generator in order to guarantee constant DHW in this type of system. Control of this

combination is ensured by a three-way motorised valve connected to the pellet boiler. This allows the DHW generated by

the pellet boiler to be used only when it is operational and at a suitable temperature.

PLUMBING LAYOUT “3” – Boiler connected to a heating system and DHW storage boiler.

Plumbing layout 3 involves the connection of the boiler to a heating system managed by one or more room thermostats.

These are connected to the terminal provided inside the left technical compartment on the appliance. Any DHW

generation is achieved by a storage boiler fitted externally to the boiler. This is controlled by a temperature sensor

connected to the appliance.

27

Page 34

PELLET-BURNING BOILER ECOMPACT 150-190-250-290

EN - Rev 1.1

Centralised

buffer

The three-way motorised valve, controlled by the pellet boiler, manages the heating of the system or boiler, giving priority

to the latter.

Setting “Menu 01 – Select season” to SUMMER allows you to control the storage boiler only during the summer (with the

heating system off).

PLUMBING LAYOUT “4” – Boiler connected to a centralised buffer controlled by a H2O sensor connected to the boiler.

Plumbing layout 4 involves the connection of the boiler to a centralised buffer controlled by a temperature sensor

connected to the appliance. The boiler therefore operates only at the set temperature of the centralised buffer (“SET

BUFFER” can be set using keys 1 and 2). In this type of system there are no room thermostats or three-way valves

connected to the pellet boiler.

Filling the system for the first time

After the water connection of the appliance, fill the system as follows:

- Check the seal of all piping, the expansion vessel, and the circulation pump;

- Open the “automatic air release valve” on the appliance;

- Open the system load cock (mounted on the appliance) to load the system. Gradually allow the air to come out from

the appliance through the “automatic air release valve”; optimum working pressure is 1.5 bar (when the

appliance is operating);